Page 1

ABSOLUTE PRESSURE SENSOR

WSEN-PADS

USER MANUAL

2511020213301

VERSION 2.0

NOVEMBER 11, 2020

Page 2

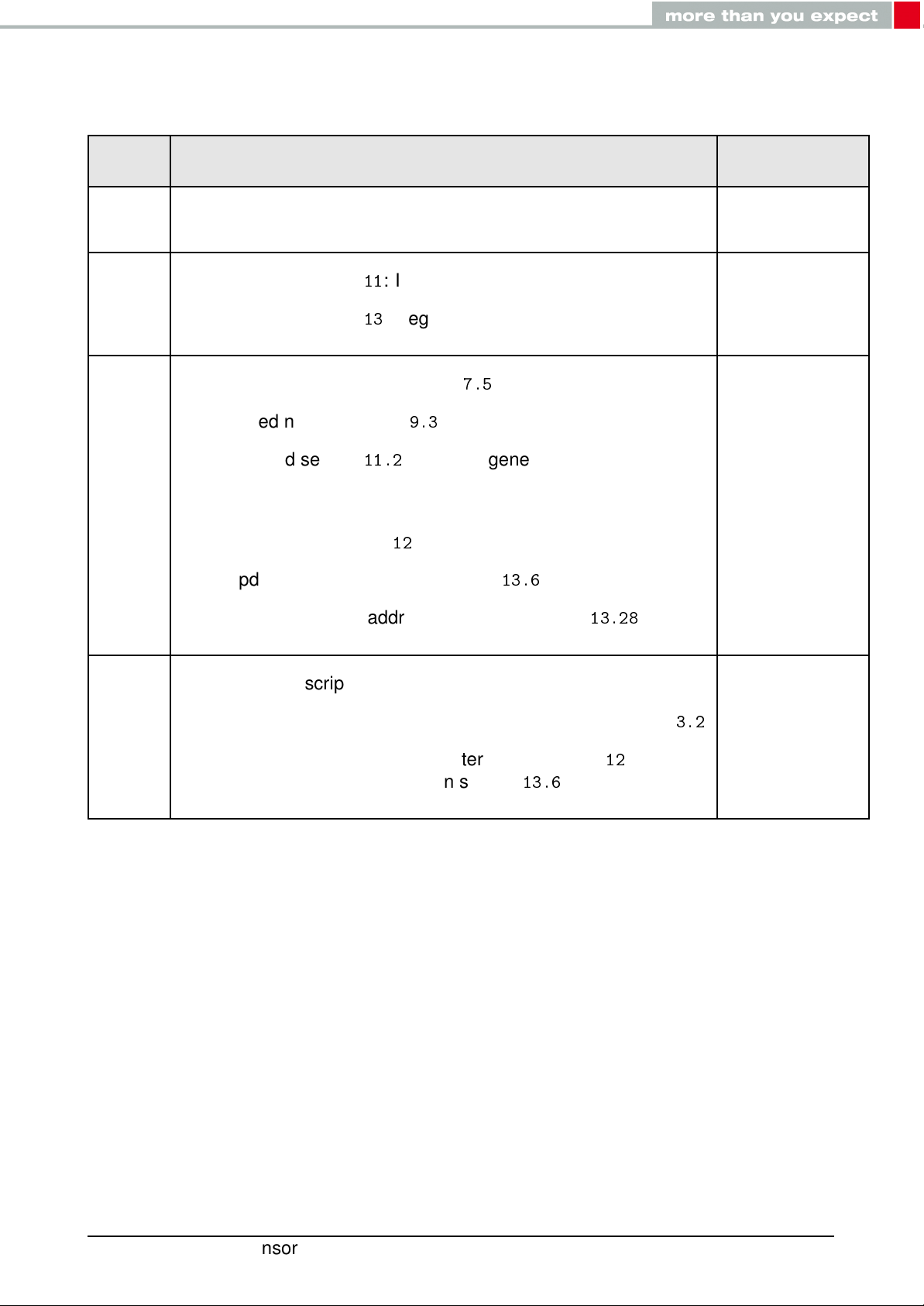

Revision history

Manual

version

0.1

1.0

1.1

Notes Date

• Initial release of the manual

• Updated section11: Interrupt functionality

• Updated section13: Register description

• Updated flowchart in section

• Added note to section

• Updated section

pressure threshold

• Updated address of reserved registers and register type of

REF_P_x in section12: Register Map

• Updated register name in section

9.3

11.2

: Interrupt generation based on

7.5

13.6

April 2019

June 2019

April 2020

2.0

• Updated register address to 0x7C in section

• Added description of the SPI interface.

• Updated pin description for the SPI interface in section

• Added ’SIM’ bit for the SPI interface in section12and

under register description in section

13.6

13.28

3.2

November 2020

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 1

Page 3

Abbreviations

Abbreviation Description

ASIC Application Specific Integrated Circuit

BDU Block Data Update

DRDY Data ready

ESD Electrostatic Discharge

FIFO First-In First-Out

HBM Human Body Model

I2C Inter Integrated Circuit

LGA Land Grid Array

LSB Least Significant Bit

MEMS Micro-Electro Mechanical System

MISO Master In Slabe Out

MOSI Master Out Slave In

MSB Most Significant Bit

NVM Non Volatile Memory

ODR Output Data Rate

PCB Printed Circuit Board

SPI Serial Peripheral Interface

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 2

Page 4

Contents

1 Introduction 7

1.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Key features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Operational functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.1 MEMS Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.2 ASIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.4 Digital filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.5 FIFO memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Filtering chain and data path . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Sensor specifications 10

2.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Pressure sensor specification . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Temperature sensor specification . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Pinning information 13

3.1 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Digital I2C interface 14

4.1 General characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 SDA and SCL logic levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Communication phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.1 Idle state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.2 START(S) and STOP(P) condition . . . . . . . . . . . . . . . . . . . 15

4.3.3 Data validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.4 Byte format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.5 Acknowledge(ACK) and No-Acknowledge(NACK) . . . . . . . . . . 16

4.3.6 Slave address for the sensor . . . . . . . . . . . . . . . . . . . . . . 17

4.3.7 Read/Write operation . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 I2C timing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Serial Peripheral Interface (SPI) 21

5.1 Data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Communcation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Sensor SPI Communcation . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3.1 SPI write operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.2 SPI read operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.3 SPI timing parameters . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Application circuit 26

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 3

Page 5

7 Quick start guide 28

7.1 Power-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 Communication with host controller . . . . . . . . . . . . . . . . . . . . . . . 29

7.3 Reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.4 Software reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.5 Sensor operation: single conversion mode . . . . . . . . . . . . . . . . . . . 31

7.6 Sensor operation: continuous mode . . . . . . . . . . . . . . . . . . . . . . 32

7.7 Power-off sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8 Modes of operation 34

8.1 Power-down mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Single conversion mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3 Continuous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.4 Additional configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.4.1 Low-power or low-noise configuration . . . . . . . . . . . . . . . . . 38

8.4.2 Enabling additional low-pass filter . . . . . . . . . . . . . . . . . . . 39

9 Reading output data 40

9.1 Reading pressure values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.2 Reading temperature values . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.3 Status register for reading the data . . . . . . . . . . . . . . . . . . . . . . . 42

10 FIFO buffer 43

10.1 Bypass mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.2 FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.3 Continuous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.4 Bypass-to-FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.5 Bypass-to-continuous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.6 Continuous-to-FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.7 FIFO status monitoring and control . . . . . . . . . . . . . . . . . . . . . . . 51

10.7.1 User-defined FIFO threshold . . . . . . . . . . . . . . . . . . . . . . 52

10.7.2 Reading data from FIFO buffer . . . . . . . . . . . . . . . . . . . . . 52

11 Interrupt functionality 53

11.1 Interrupt generation on pressure data-ready . . . . . . . . . . . . . . . . . . 53

11.2 Interrupt generation based on pressure threshold . . . . . . . . . . . . . . . 54

11.2.1 Interrupt latching . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.3 FIFO status based interrupt events . . . . . . . . . . . . . . . . . . . . . . . 58

11.4 Routing interrupt events to the INT pin . . . . . . . . . . . . . . . . . . . . . 58

12 Register map 60

13 Register description 61

13.1 INT_CFG (0x0B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

13.2 THR_P_L (0x0C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

13.3 THR_P_H (0x0D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

13.4 INTERFACE_CTRL (0x0E) . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

13.5 DEVICE_ID (0x0F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

13.6 CTRL_1 (0x10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

13.7 CTRL_2 (0x11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 4

Page 6

13.8 CTRL_3 (0x12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.9 FIFO_CTRL (0x13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

13.10 FIFO_WTM (0x14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

13.11 REF_P_L (0x15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

13.12 REF_P_H (0x16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

13.13 OPC_L (0x18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

13.14 OPC_H (0x19) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

13.15 INT_SOURCE (0x24) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

13.16 FIFO_STATUS_1 (0x25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

13.17 FIFO_STATUS_2 (0x26) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

13.18 STATUS (0x27) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

13.19 DATA_P_XL (0x28) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.20 DATA_P_L (0x29) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.21 DATA_P_H (0x2A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

13.22 DATA_T_L (0x2B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

13.23 DATA_T_H (0x2C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

13.24 FIFO_DATA_P_XL (0x78) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

13.25 FIFO_DATA_P_L (0x79) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

13.26 FIFO_DATA_P_H (0x7A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

13.27 FIFO_DATA_T_L (0x7B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

13.28 FIFO_DATA_T_H (0x7C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

14 Physical dimensions 77

14.1 Sensor drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14.2 Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

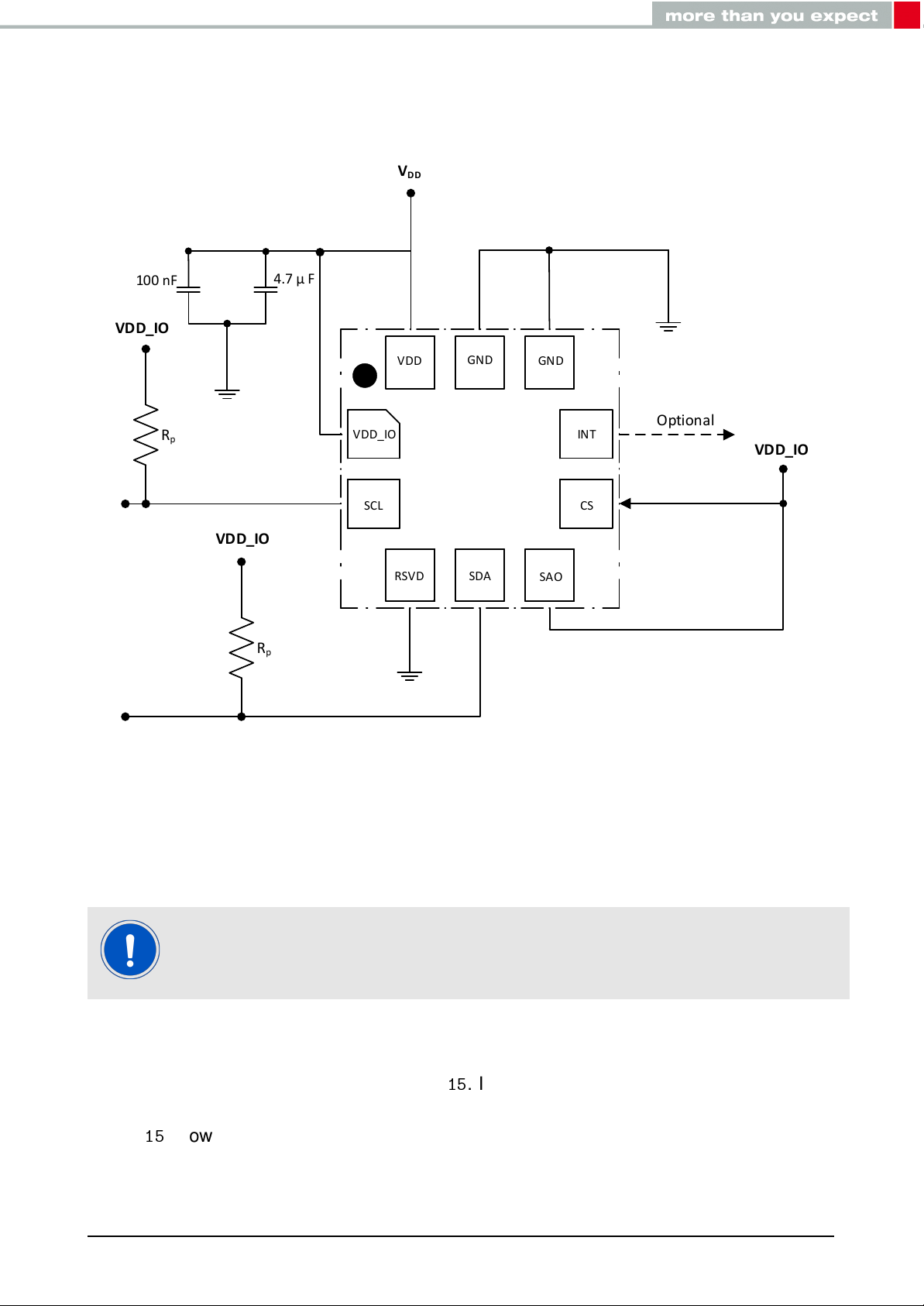

15 Manufacturing information 79

15.1 Moisture sensitivity level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

15.2 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

15.2.1 Reflow soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

15.2.2 Cleaning and washing . . . . . . . . . . . . . . . . . . . . . . . . . 81

15.2.3 Potting and coating . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

15.2.4 Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

15.2.5 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

16 Important notes 83

16.1 General customer responsibility . . . . . . . . . . . . . . . . . . . . . . . . . 83

16.2 Customer responsibility related to specific, in particular safety-relevant ap-

plications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

16.3 Best care and attention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

16.4 Customer support for product specifications . . . . . . . . . . . . . . . . . . 83

16.5 Product improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

16.6 Product life cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

16.7 Property rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

16.8 General terms and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 84

17 Legal notice 85

17.1 Exclusion of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

17.2 Suitability in customer applications . . . . . . . . . . . . . . . . . . . . . . . 85

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 5

Page 7

17.3 Usage restriction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

18 License terms for Würth Elektronik eiSos GmbH & Co. KG sensor product

software and source code 87

18.1 Limited license . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

18.2 Usage and obligations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

18.3 Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

18.4 Disclaimer of warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

18.5 Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

18.6 Applicable law and jurisdiction . . . . . . . . . . . . . . . . . . . . . . . . . . 88

18.7 Severability clause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

18.8 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 6

Page 8

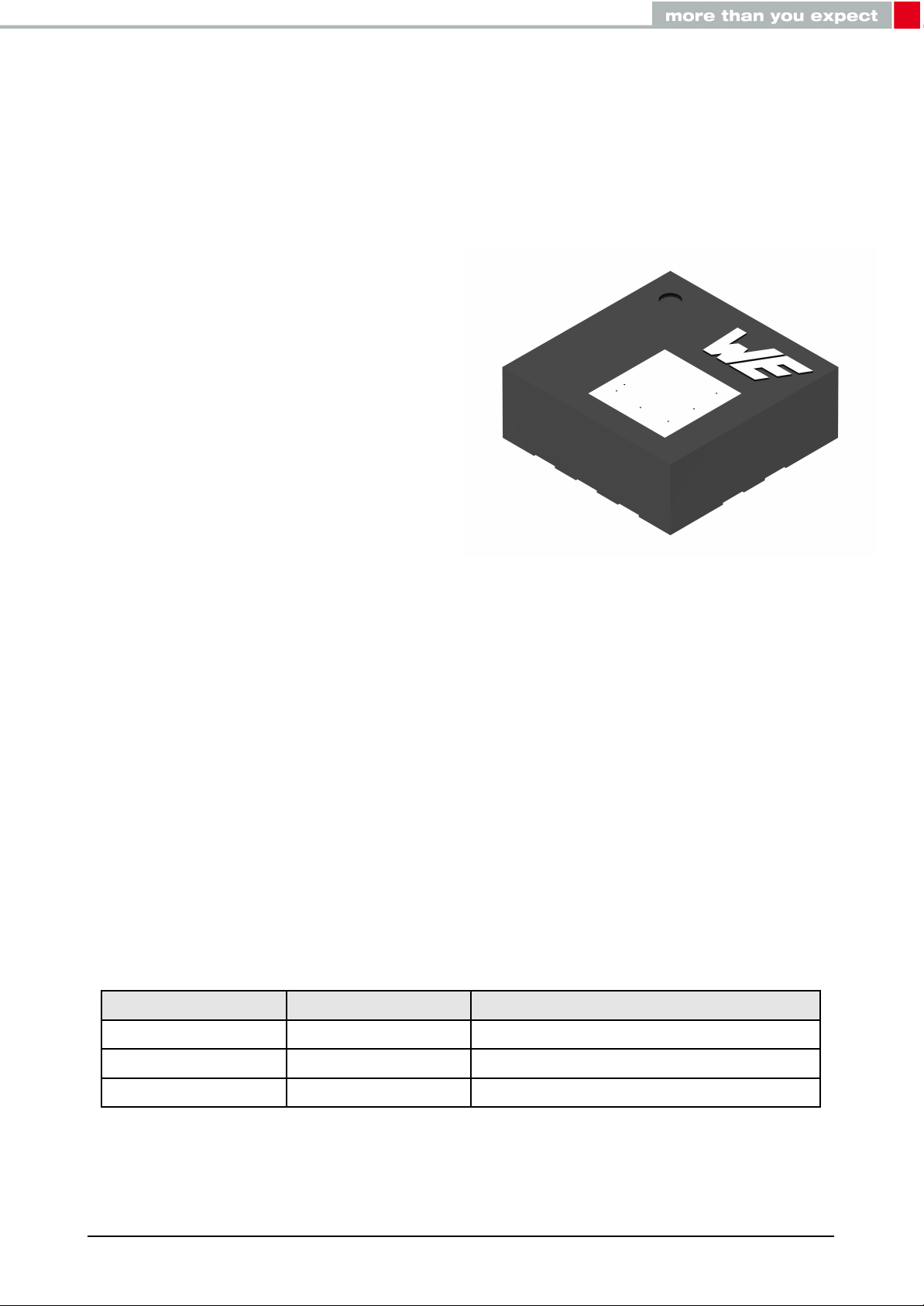

1 Introduction

This device is a MEMS based piezo-resistive absolute pressure sensor. The sensor comprises of a pressure sensing cell and an analog and digital signal processing unit. The

integrated ASIC with digital I2C interface provides a digital signal to the host controller. The

sensor has an embedded temperature sensor. A 128 level embedded FIFO buffer is available to store the pressure and temperature data. The sensor comes in fully molded holed

land grid array package (LGA) having a form factor of 2.0 x 2.0 x 0.8 mm.

1.1 Application

• Altimeters and barometers

• Weather stations

• GPS navigation enhancement

• Indoor navigation

• White goods

• Wearable devices

1.2 Key features

• Absolute pressure range: 26 to 126 kPa

• Output data rate: 1 Hz to 200 Hz

• Integrated temperature sensor

• Pressure data: 24-bits and temperature data: 16-bits

• Low current consumption: 4 µA

• Digital interface: I2C

• Embedded FIFO buffer: 128 levels

• Interrupt pin functionality: data-ready, pressure threshold

1.3 Ordering information

WE order code Dimensions Description

2511020213301 2.0 x 2.0 x 0.8 mm Tape & reel packaging

2511020213381 2.0 x 2.0 x 0.8 mm 5 pcs. cut tape packaging

2511223013301 33 x 20 mm Evaluation board

Table 1: Ordering information

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 7

Page 9

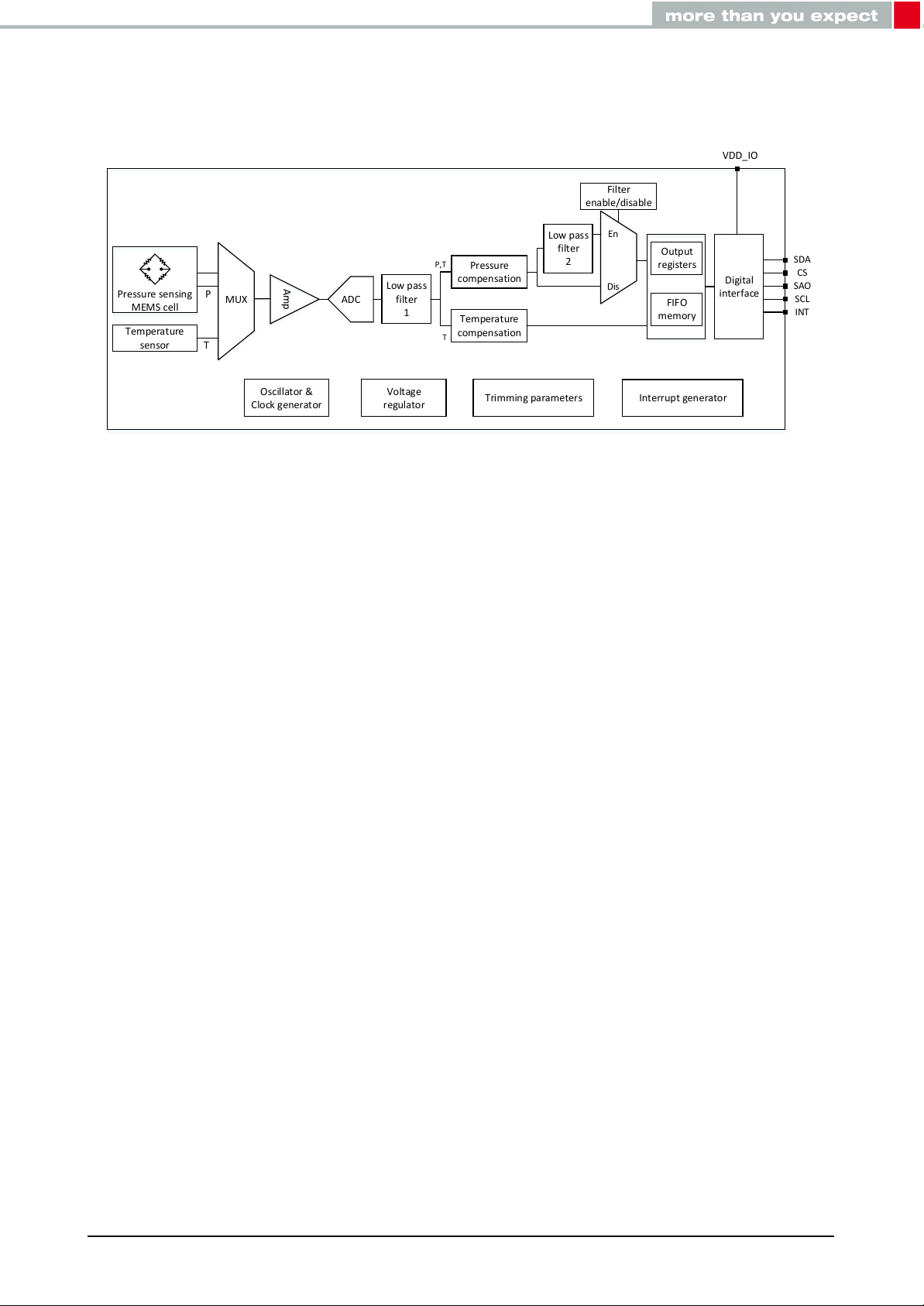

1.4 Block diagram

P,T

Amp

Temperature

sensor

ADC

Pressure

compensation

Temperature

compensation

Low pass

filter

2

Low pass

filter

1

MUX

Output

registers

FIFO

memory

Filter

enable/disable

Digital

interface

En

Dis

Pressure sensing

MEMS cell

SDA

CS

INT

SCL

Oscillator &

Clock generator

Voltage

regulator

Trimming parameters

VDD_IO

P

T

T

SAO

Interrupt generator

Figure 1: Block diagram

1.5 Operational functionality

1.5.1 MEMS Cell

The MEMS cell is the primary pressure sensing element. It contains piezo-resistors embedded on a suspended silicon membrane. The piezo-resistors are connected in a Wheatstone

bridge configuration. When pressure is applied, the membrane is deflected and the bridge

resistance changes. This change leads to a change of the Wheatstone output voltage proportional to the applied pressure. This analog signal is fed to the ASIC.

1.5.2 ASIC

The ASIC comprises of low-noise amplifier, analog-to-digital converter and other signal conditioning blocks that converts an uncompensated analog voltage equivalent to a 24-bit digital

pressure value.

The ASIC embeds a high-resolution temperature sensor which is used for internal compensation of the pressure signal. The temperature information can also be read as a 16-bit

digital value.

1.5.3 Calibration

The sensor is factory calibrated for both pressure and temperature measurements. The

trimming parameters are stored on-chip in the non volatile memory (NVM). Every-time the

sensor is powered on, these trimming parameters are copied from the NVM to the registers.

In normal use, no further calibration is required from the user.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 8

Page 10

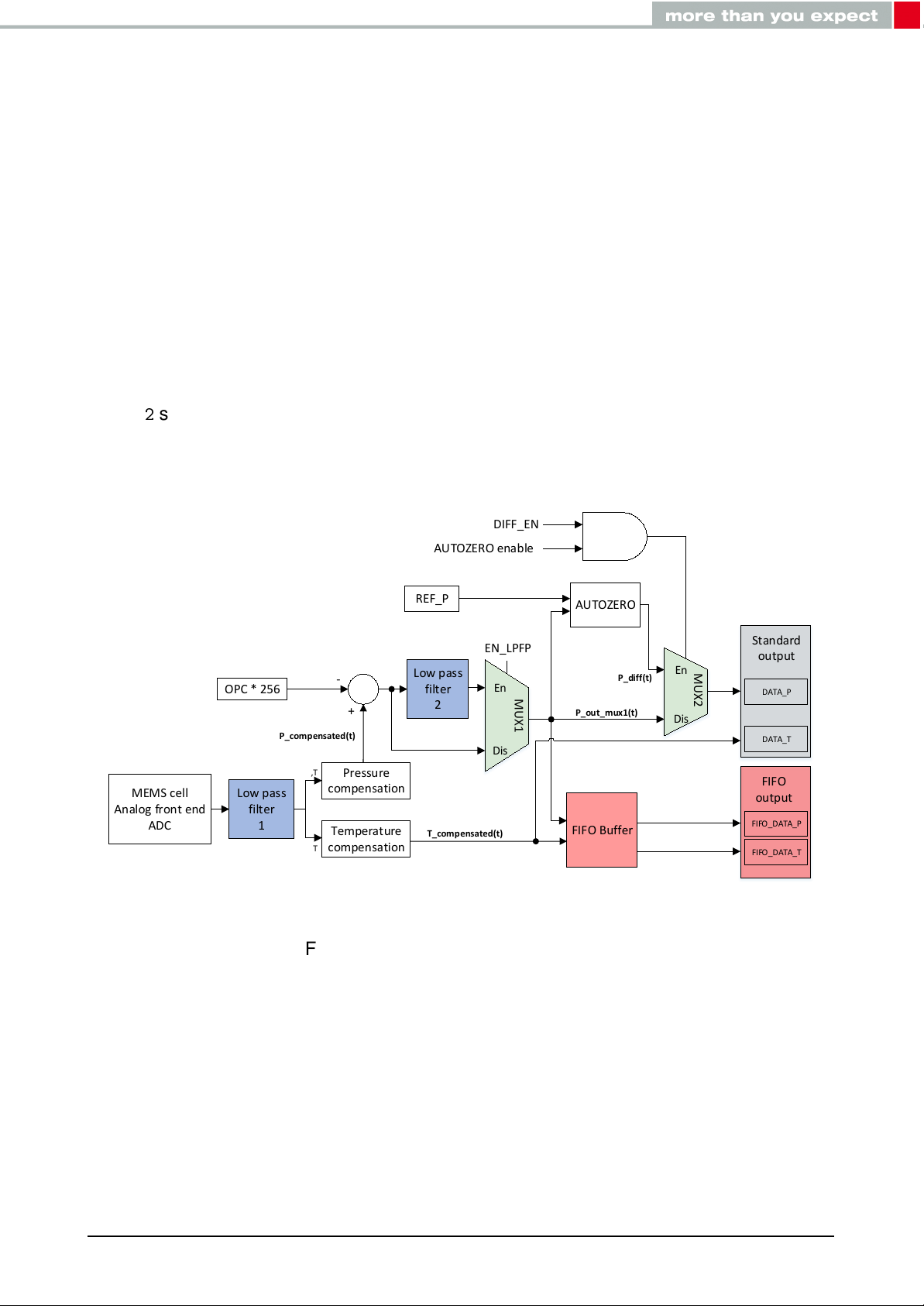

1.5.4 Digital filtering

P,T

Pressure

compensation

Temperature

compensation

Low pass

filter

2

Low pass

filter

1

DATA_P

DATA_T

EN_LPFP

En

Dis

T

MEMS cell

Analog front end

ADC

OPC * 256

-

+

En

Dis

AUTOZERO

REF_P

DIFF_EN

AUTOZERO enable

Standard

output

FIFO Buffer

FIFO_DATA_P

FIFO_DATA_T

FIFO

output

MUX

1

MUX

2

T_compensated(t)

P_compensated(t)

P_out_mux1(t)

P_diff(t)

The sensor has on-chip signal conditioning and embeds two digital low pass filters. The first

filter LPF1 is applied to both pressure and temperature data. The second filter LPF2 can be

optionally applied only to the pressure data. User can turn on or off this filter, depending on

his requirements.

1.5.5 FIFO memory

The sensor has embedded FIFO buffer that can store up to 128 levels of pressure and

temperature data. This can save host controller power, since the controller doesn’t have to

poll for data continuously.

1.6 Filtering chain and data path

Figure2shows detailed information about the functionality of the sensor. The sensor can be

operated in various operating modes and filter setting which determines the pressure and

temperature data path.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 9

Figure 2: Filtering chain and data path

Page 11

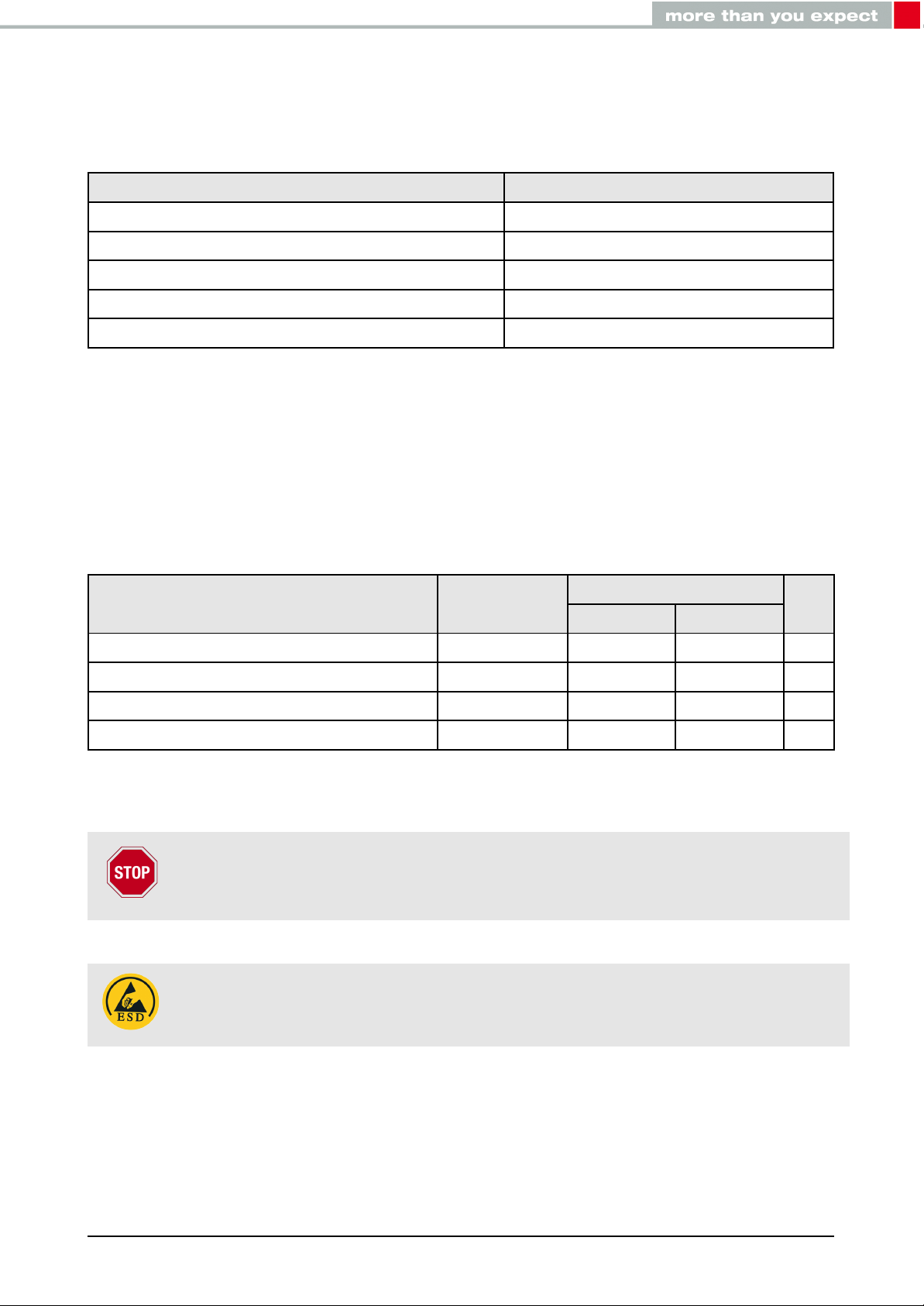

2 Sensor specifications

2.1 General information

Parameter Value

Operating temperature -40 up to +85°C

Storage conditions < 40 °C; < 90% RH

Communication interface I2C

Moisture sensitivity level (MSL) 3

Electrostatic discharge protection (HBM) 2.5 kV

Table 2: General information

2.2 Absolute maximum ratings

Absolute maximum ratings are the limits, the device can be exposed to without causing

permanent damage. Exposure to absolute maximum conditions for extended periods may

affect device reliability.

Parameter Symbol

Input voltage VDD pin V

Input voltage VDD_IO pin V

Input voltage SDA, SCL, CS & SAO pins V

Overpressure P

DD_MAX

DD_IO_MAX

IN_MAX

OVER

Table 3: Absolute maximum ratings

Supply voltage on any pin should never exceed 4.8 V.

The device is susceptible to be damaged by electrostatic discharge (ESD).

Always use proper ESD precautions when handling. Improper handling of the

device can cause performance degradation or permanent damage.

Value

Unit

Min Max

-0.3 4.8 V

-0.3 4.8 V

-0.3 VDD+0.3 V

2 Mpa

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 10

Page 12

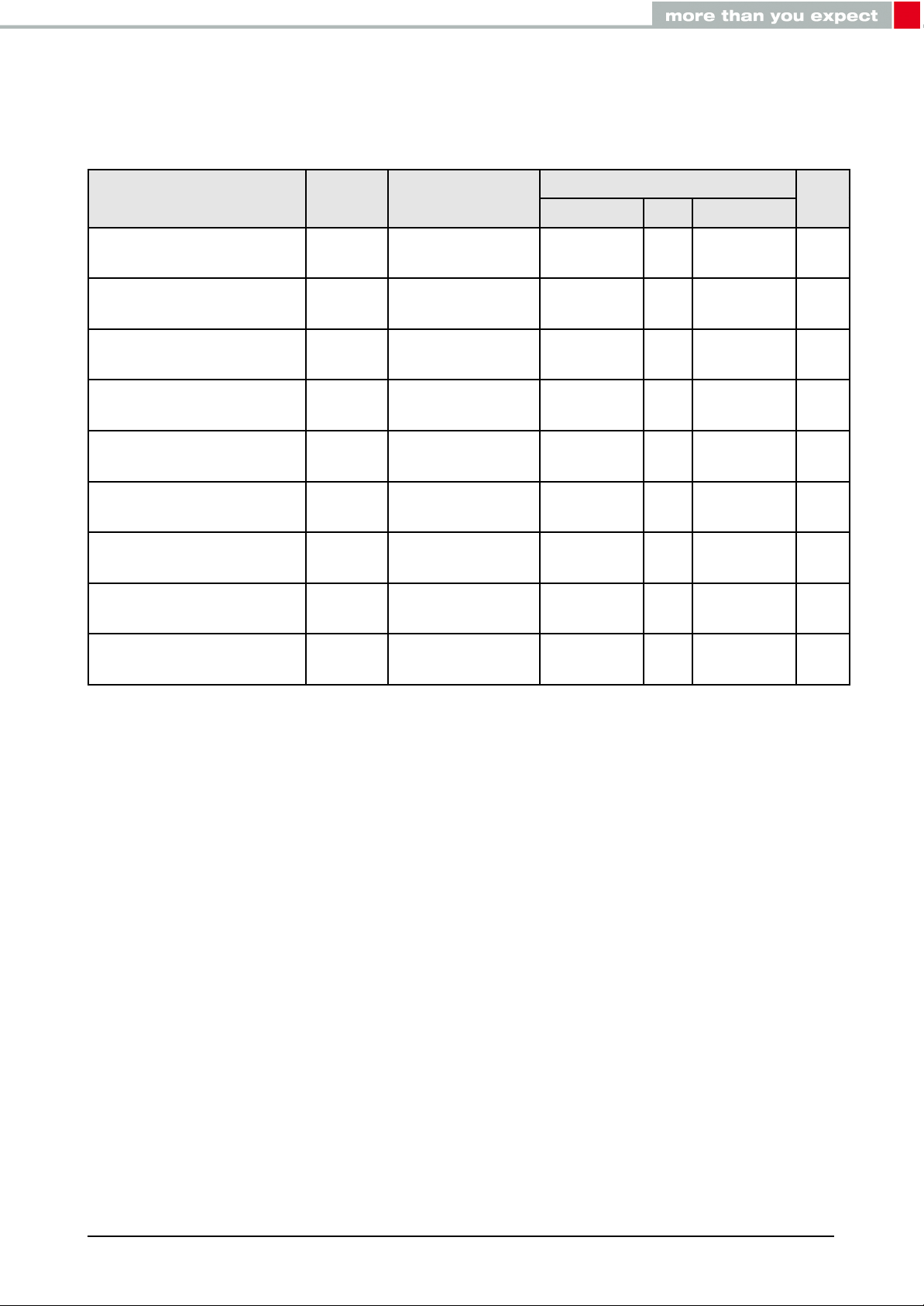

2.3 Pressure sensor specification

Unless otherwise stated, all the specified values were measured under the following conditions: T=25°C, VDD=3.3 V.

Parameter

Measurement

range

Absolute

accuracy

1

Relative

accuracy

2

Resolution

Sensitivity

Output data rate

Noise (RMS)

3

Offset change

over temperature

Long term drift

Symbol

Test conditions

Min Typ Max

P

RANGE

P

ACC_ABS

P

ACC_REL

RES

SEN

T= -20 to 80°C ±100 Pa

P= 80 to 110

kPa T= 25°C

P

P

ODR

P

NOISE

P

P

DRIFT

TCO

Low pass filter

enabled

P= 66 to 116 kPa

T= -20 to 65°C

Table 4: Pressure sensor specifications

Value

Unit

26 126 kPa

±2.5 Pa

24 bit

1/40960 kPa/digit

1 200 Hz

0.75

Pa

RMS

±65 Pa/°C

±33 Pa/Year

1. Absolute accuracy includes the soldering drift effects.

2. Typical value is defined based on characterization data with 2kPa interval.

3. Pressure noise RMS is measured in a controlled environment.

2.4 Temperature sensor specification

Parameter

Measurement range

Absolute accuracy

Resolution

Sensitivity

Symbol

Test conditions

Min Typ Max

T

RANGE

T

ACC_ABS

RES

SEN

T= 0 to 80°C ±1.5 °C

T

T

-40 +85 °C

Table 5: Temperature sensor specifications

Value

Unit

16 bit

0.01 °C/digit

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 11

Page 13

2.5 Electrical specifications

Unless otherwise stated, all the specified values were measured under the following conditions: T=25°C, VDD=3.3V.

Parameter

Operating supply

voltage

Supply voltage for I/O

pins

Current consumption in

low power mode

Current consumption in

low noise mode

Current consumption in

power down mode

Digital input voltage high-level

Digital input voltage low-level

Digital output voltage high-level

Symbol

V

DD

V

DD_IO

I

DD_LP

I

DD_LN

I

DD_PD

V

IH

V

IL

V

OH

Test conditions

ODR= 1Hz

ODR= 1Hz

Value

Min Typ Max

1.7 3.3 3.6

1.7 VDD+0.1

4

12

0.9

0.8*V

DD_IO

0.2*V

V

DD_IO

-0.2

DD_IO

Unit

V

V

µA

µA

µA

V

V

V

Digital output voltage low-level

V

IL

Table 6: Electrical specifications

0.2

V

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 12

Page 14

3 Pinning information

VDD_IO

SCL

RSVD

SDA

SAO

CS

INT

GND

GND

VDD

1

2

3

5

6

7

8

10

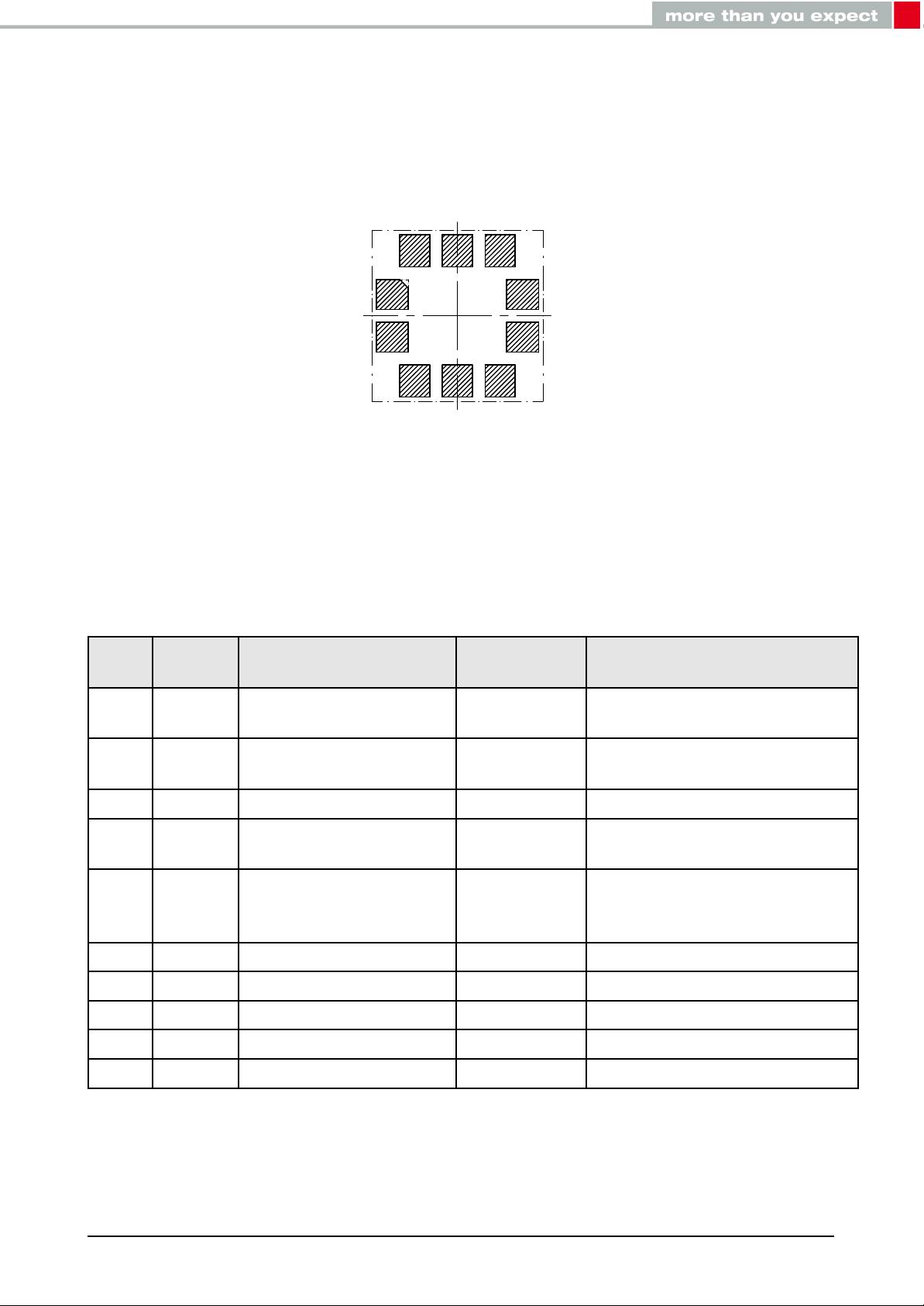

3.1 Pin configuration

Figure 3: Pin specifications (top view)

3.2 Pin description

Pin

No.

1 VDD_IO

2 SCL I2C/ SPI serial clock Input

3 RSVD Reserved Input Connect to ground

4 SDA

5 SAO

6 CS I2C enable/disable Input High: I2C enable

7 INT Interrupt Input/Output Do not connect if not used

8 GND Negative supply voltage Supply

Name Function I/O Comments

Positive supply voltage

for I/O pins

Supply

Internal pull-up disconnected

by default

I2C serial data; SPI

serial data input

I2C device address

selection; SPI chip

select pin

Input/Output

Input/Output

Internal pull-up disconnected

by default

High: device address LSB is 1

Low: device address LSB is 0

9 GND Negative supply voltage Supply

10 VDD Positive supply voltage Supply

Table 7: Pin description

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 13

Page 15

4 Digital I2C interface

Microcontroller

(Master)

R

p

R

p

Sensor

(Slave-1)

Sensor

(Slave-2)

+VDD

SCL

(serial clock)

SDA

(serial data)

Pull up resistors

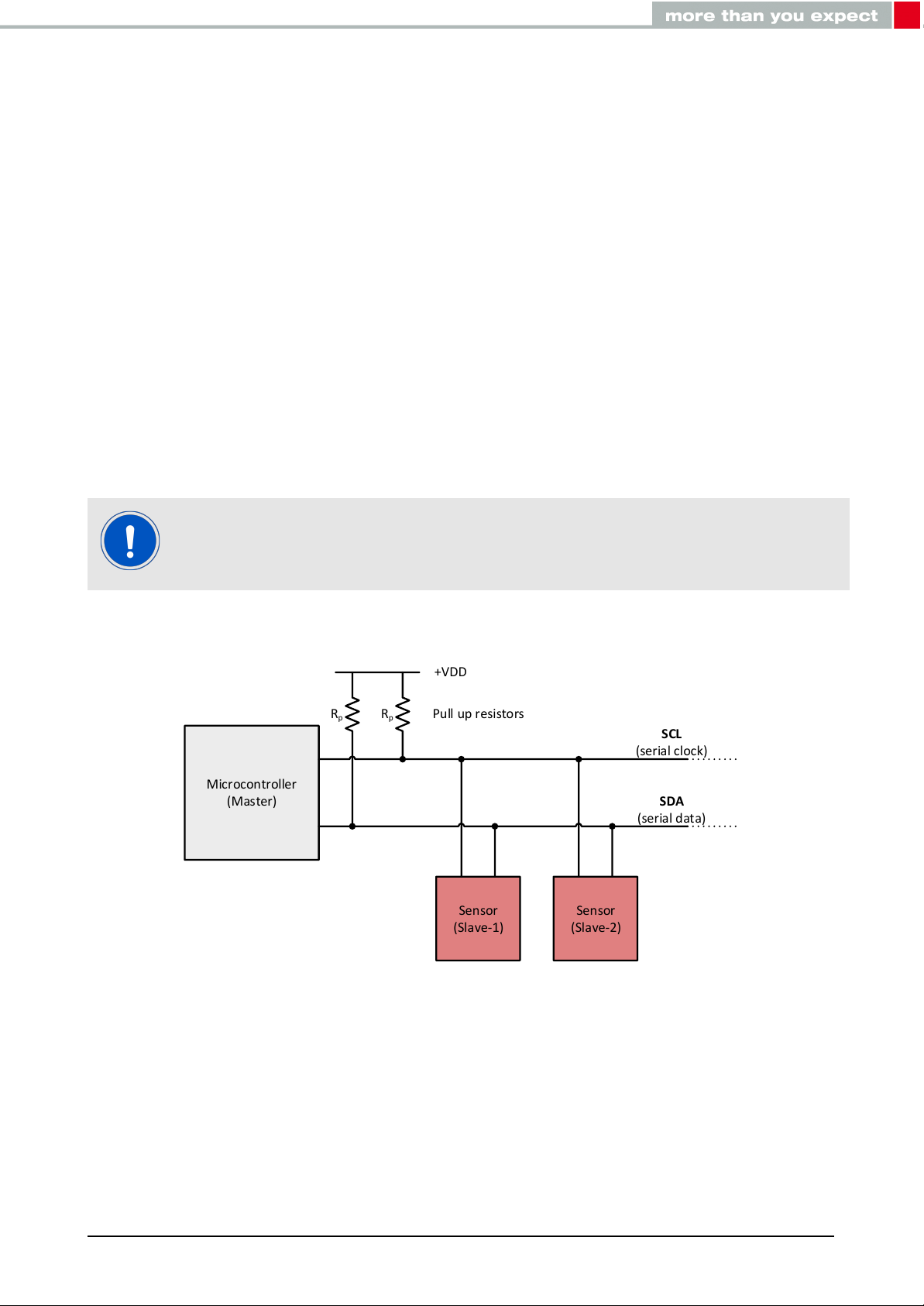

The sensor supports standard I2C (Inter-IC) bus protocol. Further information about the I2C

interface can be found at https://www.nxp.com/docs/en/user-guide/UM10204.pdf. I2C is a

serial 8-bit protocol with two-wire interface that supports communication between different

ICs, for example, between microcontrollers and other peripheral devices.

4.1 General characteristics

A serial data line (SDA) and a serial clock line (SCL) are required for the communication

between the devices connected via I2C bus. Both SDA and SCL lines are bidirectional. The

output stages of devices connected to the bus must have an open-drain or open-collector.

Hence, the SDA and SCL lines are connected to a positive supply voltage via pull-up resistors. In I2C protocol, the communication is realized through master-slave principle. A master

device generates the clock pulse, a start command and a stop command for the data transfer. Each connected device on the bus is addressable via a unique address. Master and

slave can act as a transmitter or a receiver depending upon whether the data needs to be

sent or received.

This sensor behaves like a slave device on the I2C bus

Absolute pressure sensor, Part Nr. 2511020213301

Figure 4: Master-slave concept

User manual version 2.0 © November2020

www.we-online.com/sensors 14

Page 16

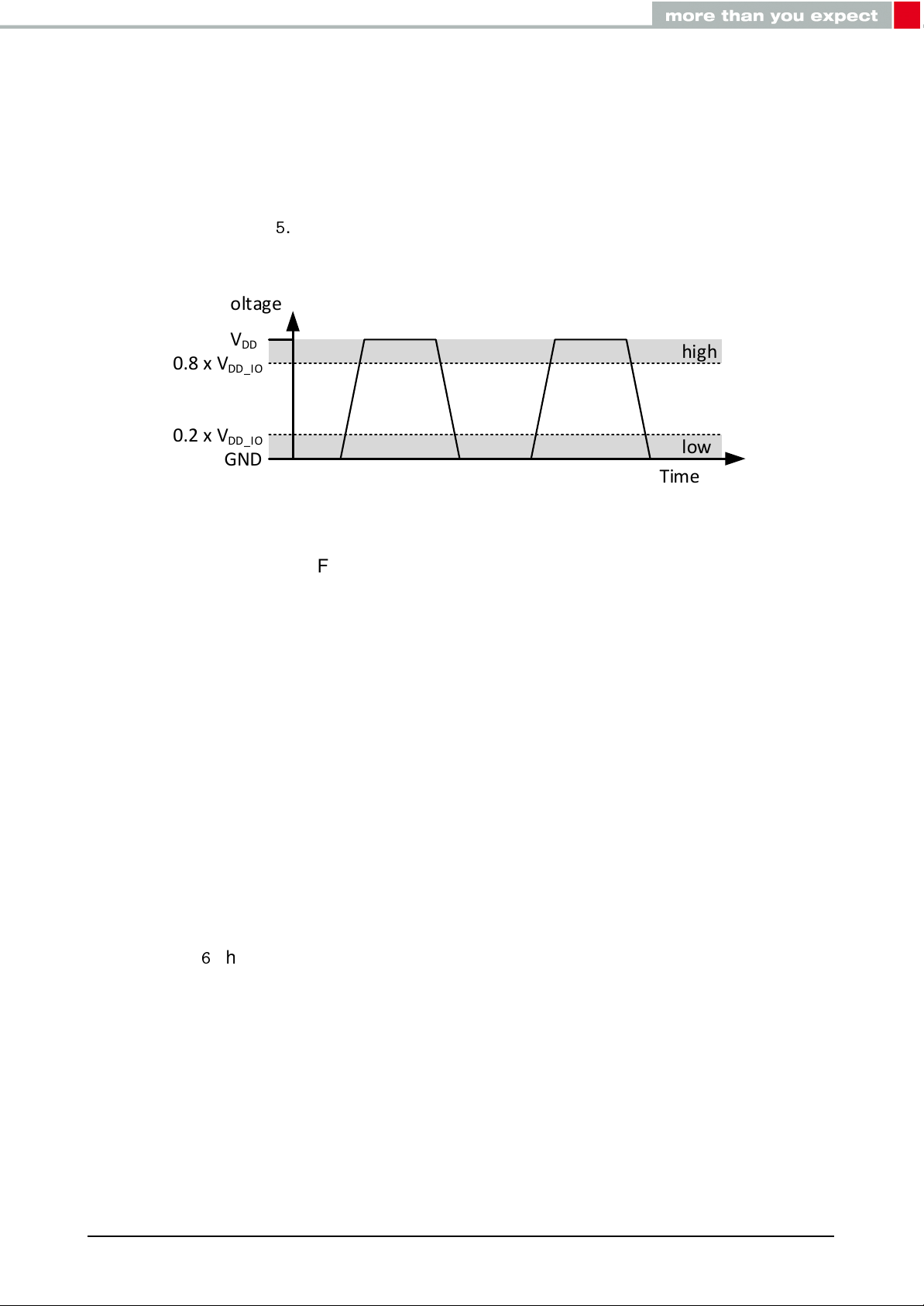

4.2 SDA and SCL logic levels

Voltage

low

high

Time

V

DD

GND

0.2 x V

DD_IO

0.8 x V

DD_IO

The positive supply voltage to which SDA and SCL lines are pulled up (through pull-up

resistors), in turn determines the high level input for the slave devices. The sensor has

separate supply voltage VDD_IO for the SDA and SCL lines. The logic high ’1’ and logic

low ’0’ levels for the SDA and SCL lines then depend on the VDD_IO. Input reference levels

for this sensor are set as 0.8 * VDD_IO (for logic high) and 0.2 * VDD_IO (for logic low).

Explained in the figure5.

Figure 5: SDA and SCL logic levels

4.3 Communication phase

4.3.1 Idle state

During the idle state, the bus is free and both SDA and SCL lines are in logic high ’1’ state.

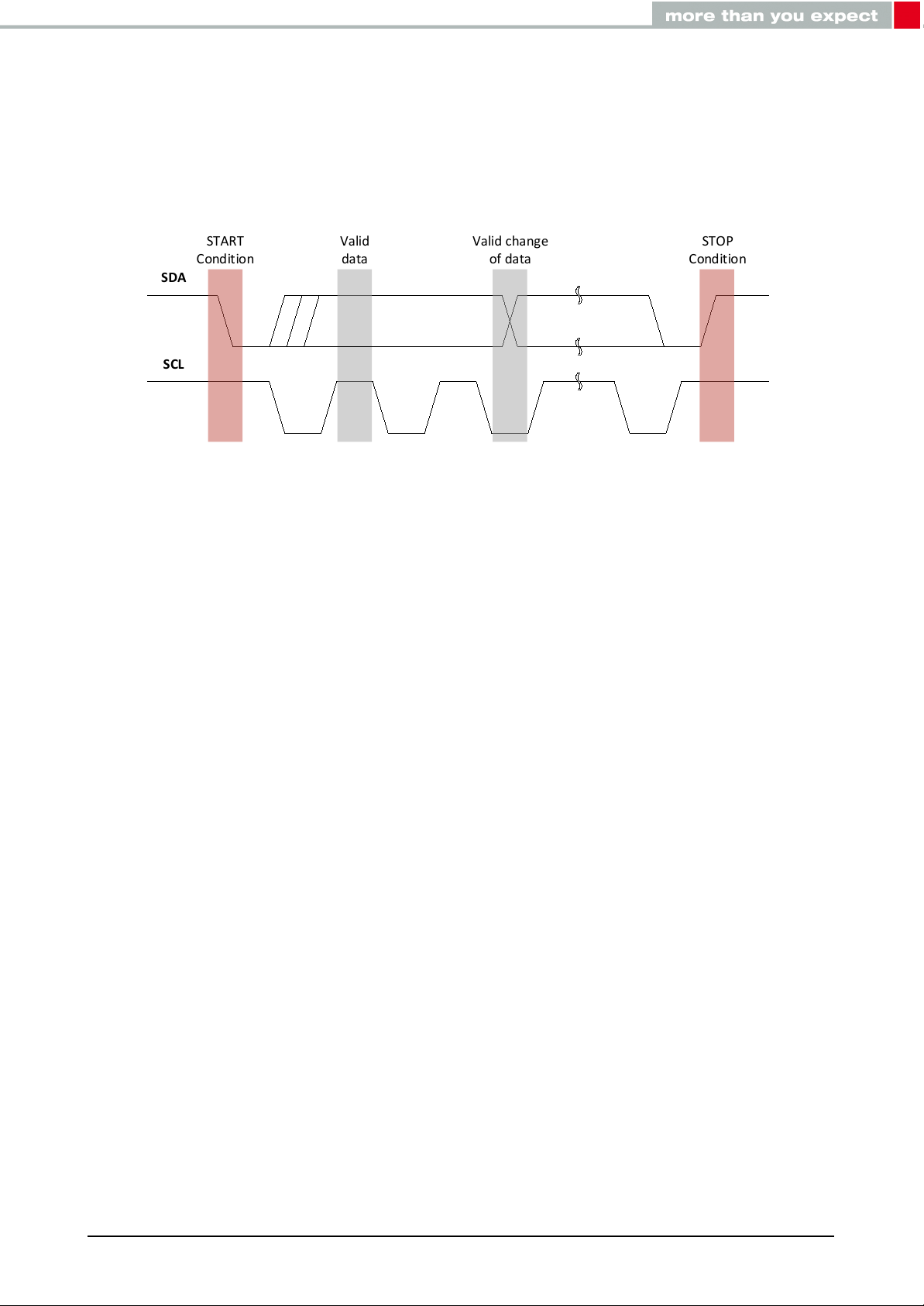

4.3.2 START(S) and STOP(P) condition

Data transfer on the bus starts with a START command, which is generated by the master.

A start condition is defined as a high-to-low transition on the SDA line while the SCL line is

held high. The bus is considered busy after the start condition.

Data transfer on the bus is terminated with a STOP command, which is also generated by

the master. A low-to-high transition on the SDA line, while the SCL line being high is defined

as a STOP condition. After the stop condition, the bus is again considered free and is in idle

state. Figure6shows the I2C bus START and STOP conditions.

Master can also send a REPEATED START (SR) command instead of STOP command.

REPEATED START condition is the same as the START condition.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 15

Page 17

4.3.3 Data validity

SDA

SCL

START

Condition

STOP

Condition

Valid

data

Valid change

of data

After the start condition, one data bit is transferred with each clock pulse. The transmitted

data is only valid when the SDA line data is stable (high or low) during the high period of the

clock pulse. High or low state of the data line can only change when clock pulse is in low

state.

Figure 6: Data validity, START and STOP condition

4.3.4 Byte format

Data transmission on the SDA line is always done in bytes, with each byte being 8-bits long.

Data is transferred with the most significant bit (MSB) followed by other bits.

If the slave cannot receive or transmit another complete byte of data, it can force the master

into a wait state by holding SCL low. Data transfer continues when the slave is ready which

is indicated by releasing the SCL line.

4.3.5 Acknowledge(ACK) and No-Acknowledge(NACK)

Each byte sent on the data line must be followed by an Acknowledge bit. The receiver (master or slave) generates an Acknowledge signal to indicate that the data byte was received

successfully and another data byte could be sent.

After one byte is transmitted, the master generates an additional Acknowledge clock pulse

to continue the data transfer. The transmitter releases the SDA line during this clock pulse

so that the receiver can pull the SDA line to low state in such a way that the SDA line

remains stable low during the entire high period of the clock pulse. This is considered as an

Acknowledge signal.

In case the receiver does not want to receive any further byte, it does not pull down the SDA

line and it remains in stable high state during the entire clock pulse. This is considered as

a No-Acknowledge signal and the master can generate either a stop condition to terminate

the data transfer or a repeated start condition to initiate a new data transfer.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 16

Page 18

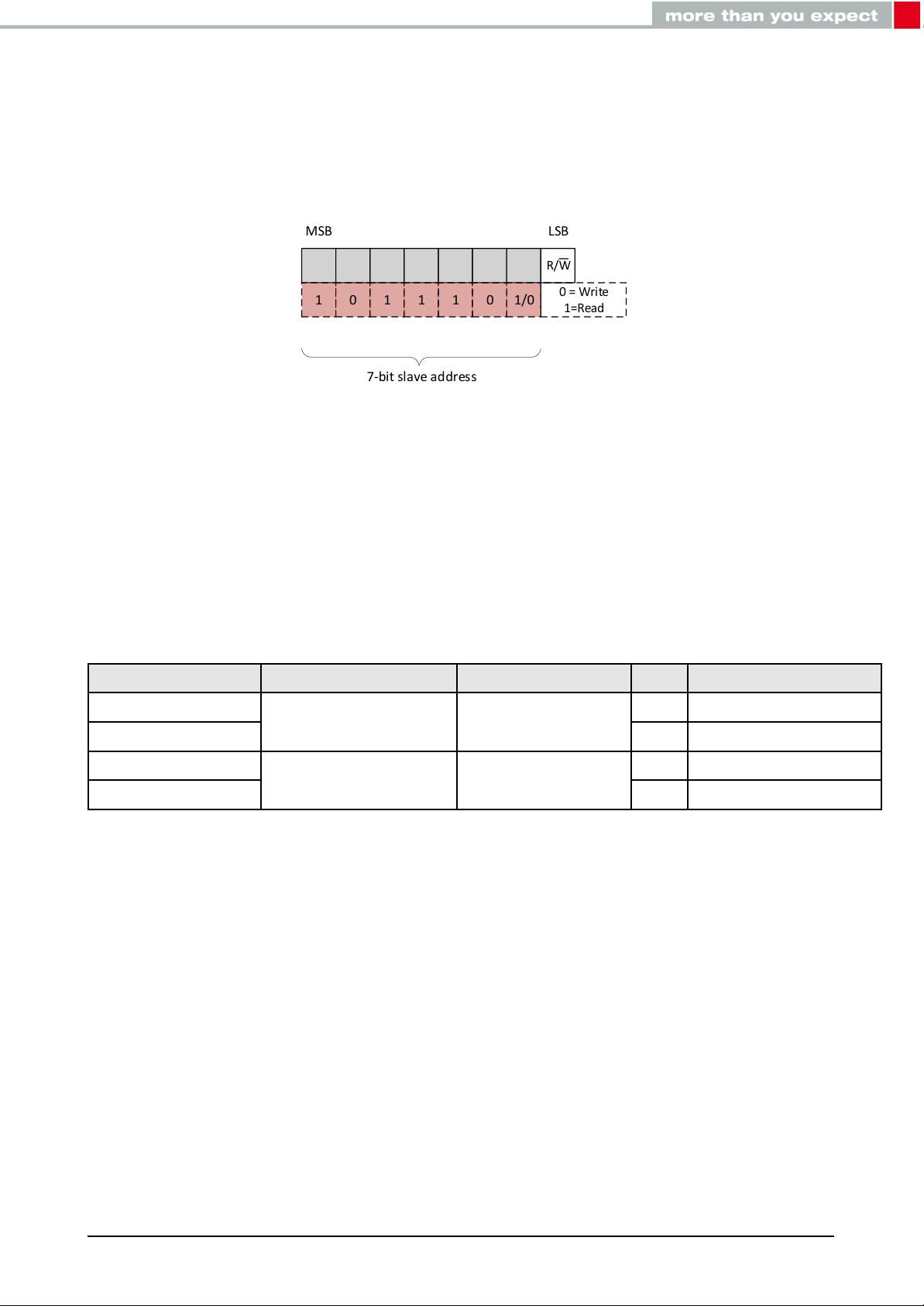

4.3.6 Slave address for the sensor

R/W

7-bit slave address

LSBMSB

1 0 1 1 1 0 1/0

0 = Write

1=Read

The slave address is transmitted after the start condition. Each device on the I2C bus has a

unique address. Master selects the slave by sending corresponding address after the start

condition. A slave address is 7 bits long followed by a Read/Write bit.

Figure 7: Slave address format

The 7-bit slave address for this sensor is 101110xb. LSB of the 7-bit slave address can be

modified with the SAO pin. When SAO is connected to positive supply voltage, the LSB is

’1’, making 7-bit slave address 1011101b (0x5D). If SAO is connected to ground, the LSB is

’0’, making 7-bit address 1011100b (0x5C).

The R/W bit determines the data direction. A ’0’ indicates a write operation (transmission

from master to slave) and a ’1’ indicates a read operation (data request from slave).

Slave address[6:1]

Slave address[0]

7-bit slave address R/W Slave address + R/W

101110 0 10111000b (0xB8)

101110

SAO=0

1011100b (0x5C)

1 10111001b (0xB9)

101110 0 10111010b (0xBA)

101110

SAO=1

1011101b (0x5D)

1 10111011b (0xBB)

Table 8: Slave address and Read/Write commands

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 17

Page 19

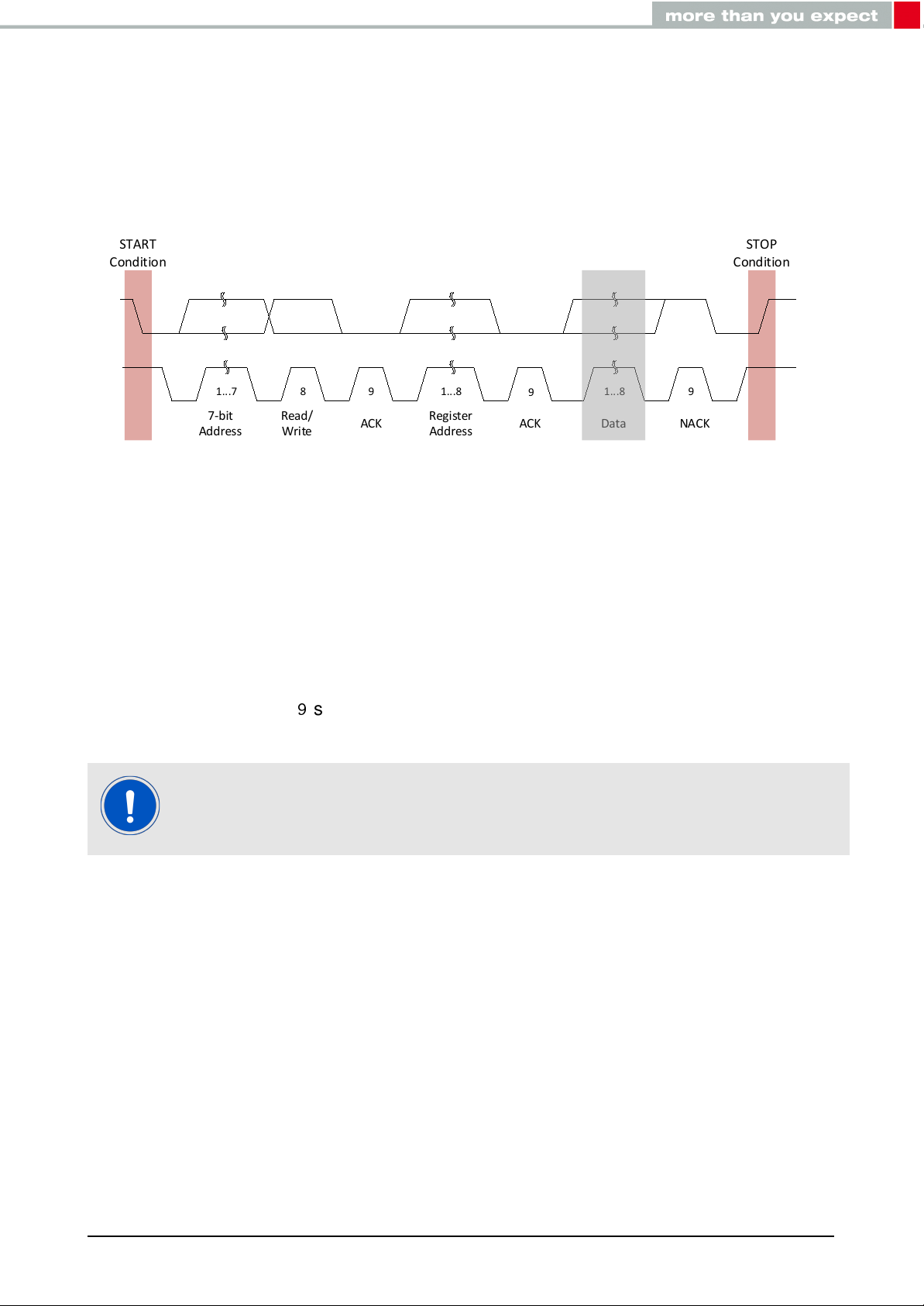

4.3.7 Read/Write operation

START

Condition

STOP

Condition

1...7 8 9 1...8

9

1...8 9

7-bit

Address

Read/

Write

ACK

Register

Address

ACK NACKData

Once the slave-address and data direction bit is sent, the slave acknowledges the master.

The next byte sent by the master must be a register-address of the sensor. This indicates

the address of the register where data needs to be written to or read from.

Figure 8: Complete data transfer

After receiving the register address, the slave sends an Acknowledgement (ACK). If the

master is still writing to the slave (R/W bit = 0), it will transmit the data to slave in the same

direction. If the master wants to read from the addressed register (R/W bit =1), a repeated

start (SR) condition must be sent to the slave. Master acknowledges the slave after receiving

each data byte. If the master no longer wants to receive further data from the slave, it would

send No-Acknowledge (NACK). Afterwards, Master can send a STOP condition to terminate

the data transfer. Figure9shows the writing and reading procedures between the master

and the slave device (sensor).

7-bit slave address of this device is 101110xb. LSB of the 7-bit slave address

depends on the SAO pin

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 18

Page 20

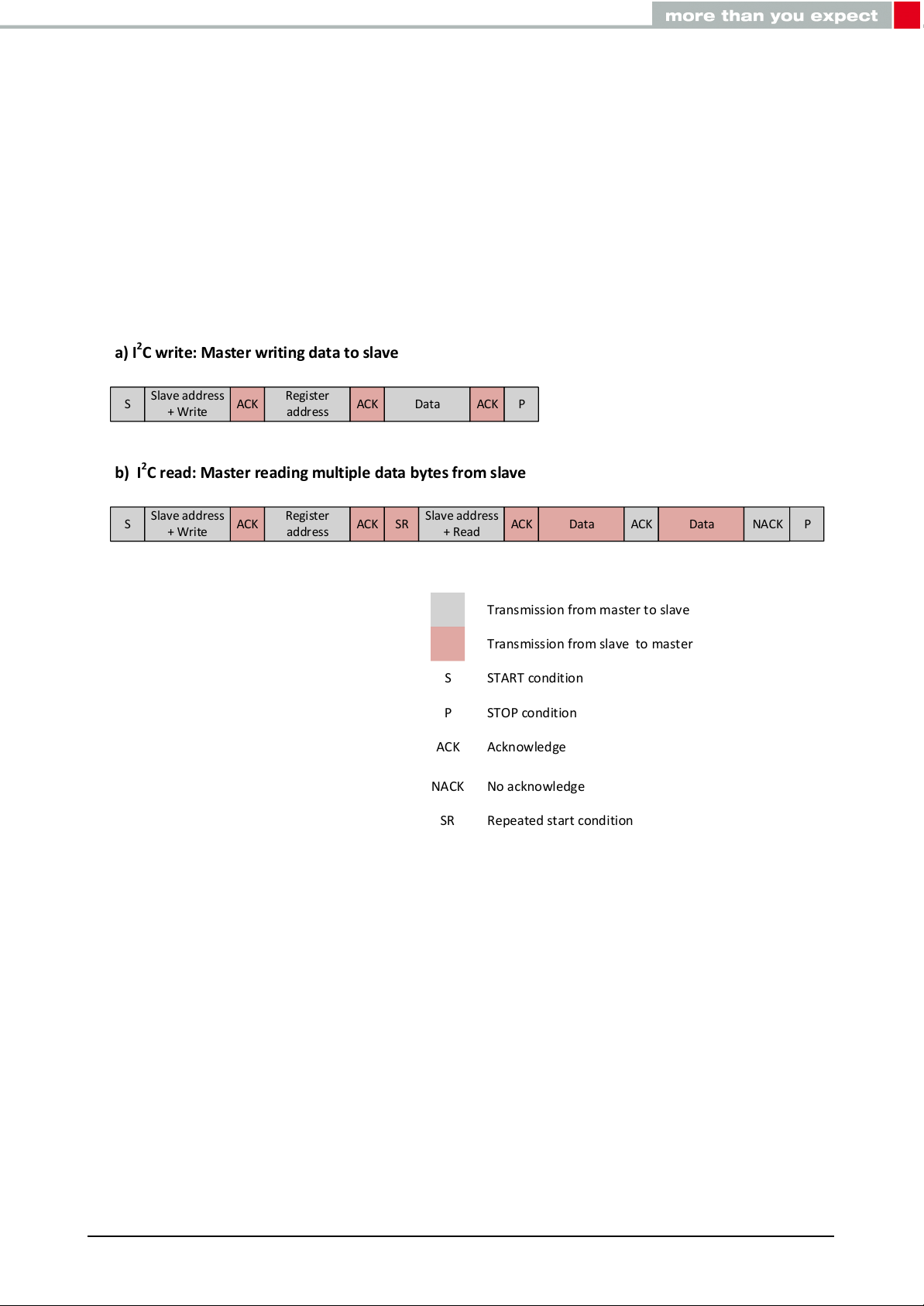

S

Slave address

+ Write

ACK

Register

address

DataACK ACK P

S

Slave address

+ Write

ACK

Register

address

Slave address

+ Read

ACK ACKSR Data Data NACKACK

Transmission from master to slave

Transmission from slave to master

S

P

ACK

NACK

SR

START condition

STOP condition

Acknowledge

No acknowledge

Repeated start condition

a) I2C write: Master writing data to slave

b) I2C read: Master reading multiple data bytes from slave

P

Figure 9: Write and read operations with the device

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 19

Page 21

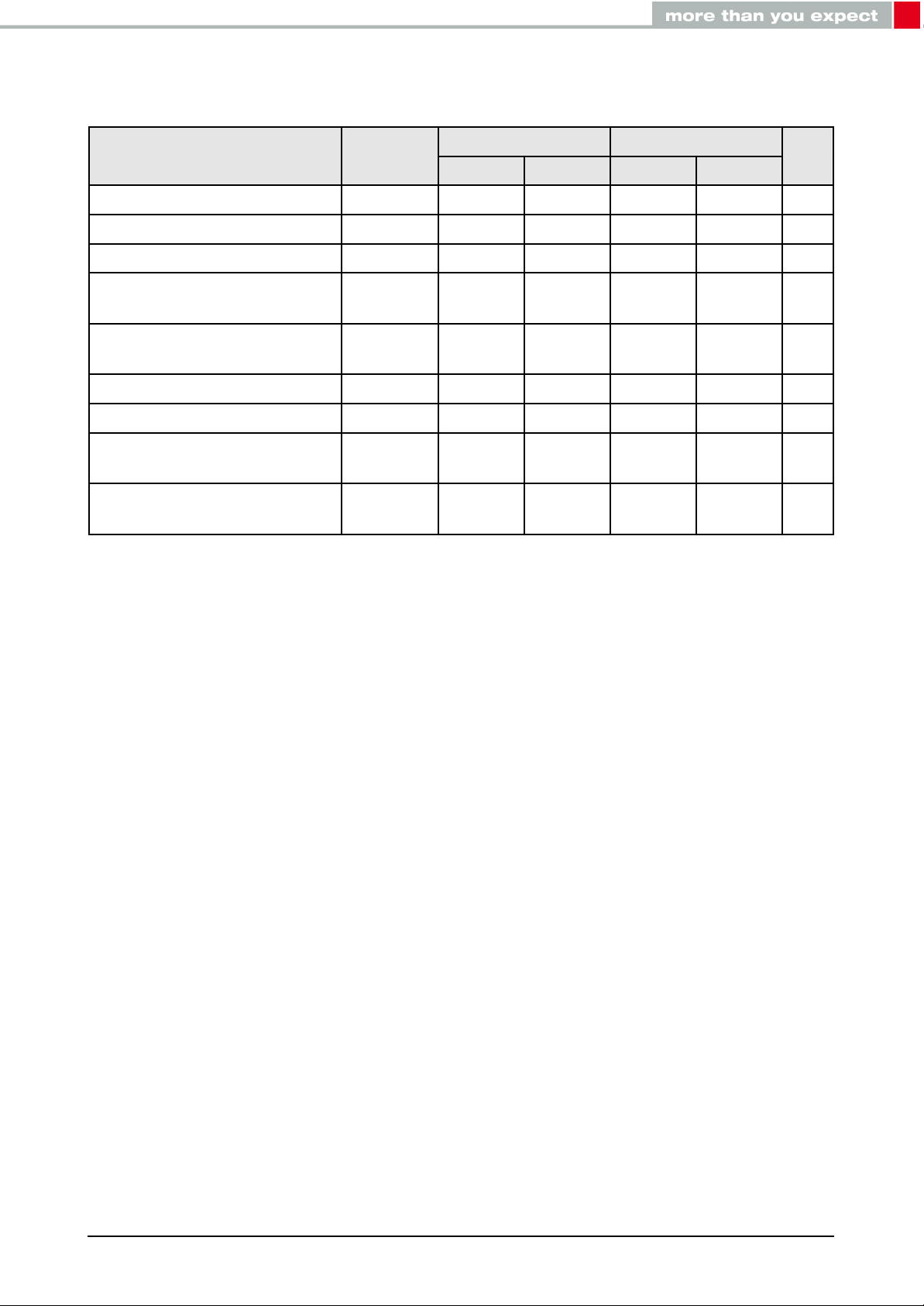

4.4 I2C timing parameters

Parameter Symbol

Standard mode Fast mode

Unit

Min Max Min Max

SCL clock frequency f

LOW period for SCL clock t

HIGH period for SCL clock t

LOW_SCL

HIGH_SCL

Hold time for START

condition

Setup time for (repeated)

START condition

SDA setup time t

SDA data hold time t

Setup time for STOP

condition

Bus free time between

STOP and START condition

Table 9: I2C timing parameters

SCL

t

HD_S

f

SCL

SU_SDA

HD_SDA

t

SU_P

t

BUF

0 100 0 400 kHz

4.7 1.3 µs

4.0 0.6 µs

4 0.6 µs

4.7 0.6 400 µs

250 100 ns

0 3.45 0 0.9 µs

4 0.6 µs

4.7 1.3 µs

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 20

Page 22

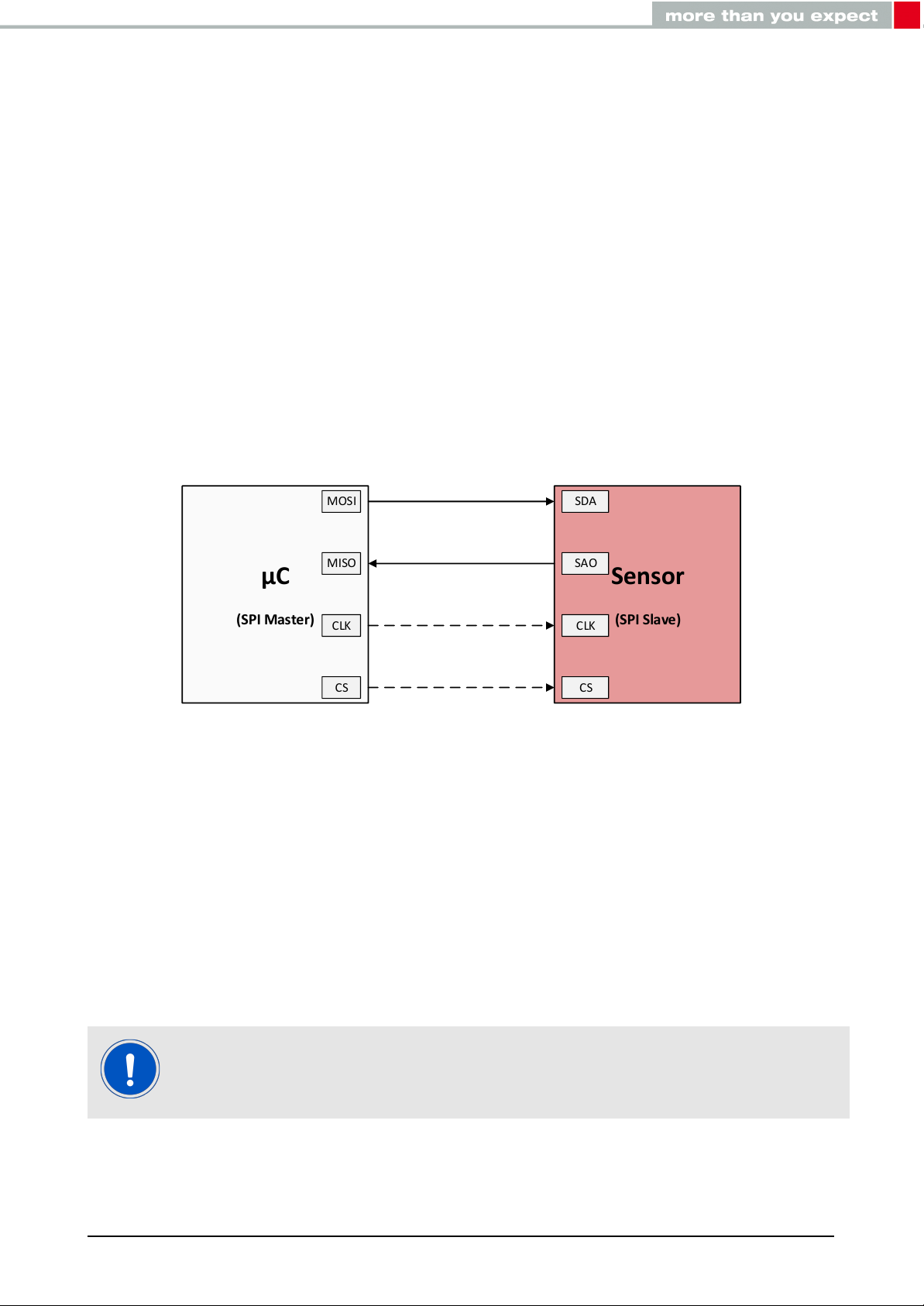

5 Serial Peripheral Interface (SPI)

µC

(SPI Master)

Sensor

(SPI Slave)

MOSI

MISO

CLK

CS

SDA

SAO

CLK

CS

Serial Peripheral Interface (SPI) is a synchronous serial communication bus system for the

communication between host microcontroller and other peripheral ICs such as ADCs, EEPROMs, sensors, etc. SPI is a full-duplex master-slave based interface allowing the communication to happen in both directions simultaneously. The data from the master or the slave

is synchronized either on the rising or falling edge of clock pulse. SPI can be either 4-wire or

3-wire interface. 4-wire interface consists of two signal lines and two data lines. All of these

bus lines are unidiretional.

1. Clock (SCL)

2. Chip select (CS)

3. Master out, slave in (MOSI)

4. Master in, slave out (MISO)

Figure 10: SPI Interface

Master generates the clock signal and is connected to all slave devices. Data transmission

between the master and salves is synchronized to the clock signal generated by the master.

One master can be connected to one or more slave devices. Each slave device is addressed

and controlled by the master via individual chip select (CS) signals. CS is controlled by the

master and is normally an active low signal.

MOSI and MISO are data lines. MOSI transmits data from the master to the slave. MISO

transmits data from the slave to the master.

This sensor supports both 3-wire and 4-wire SPI.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 21

Page 23

5.1 Data transfer

Communication begins when the master selects a slave device by pulling the CS line to

LOW. The clock and data lines (MOSI/MISO) are available for the selected slave device.

Data stored in the specific shift registers are exchanged synchronously between master and

the slave through MISO and MOSI lines. The data transmission is over when the chip select

line is pulled up to the HIGH state. 4-wire SPI uses both data lines for the synchronous data

exchange in both the direction. 3-wire SPI shares a single data line for the data transfer,

where the master and slave alternate their transmitter and receiver roles synchronously.

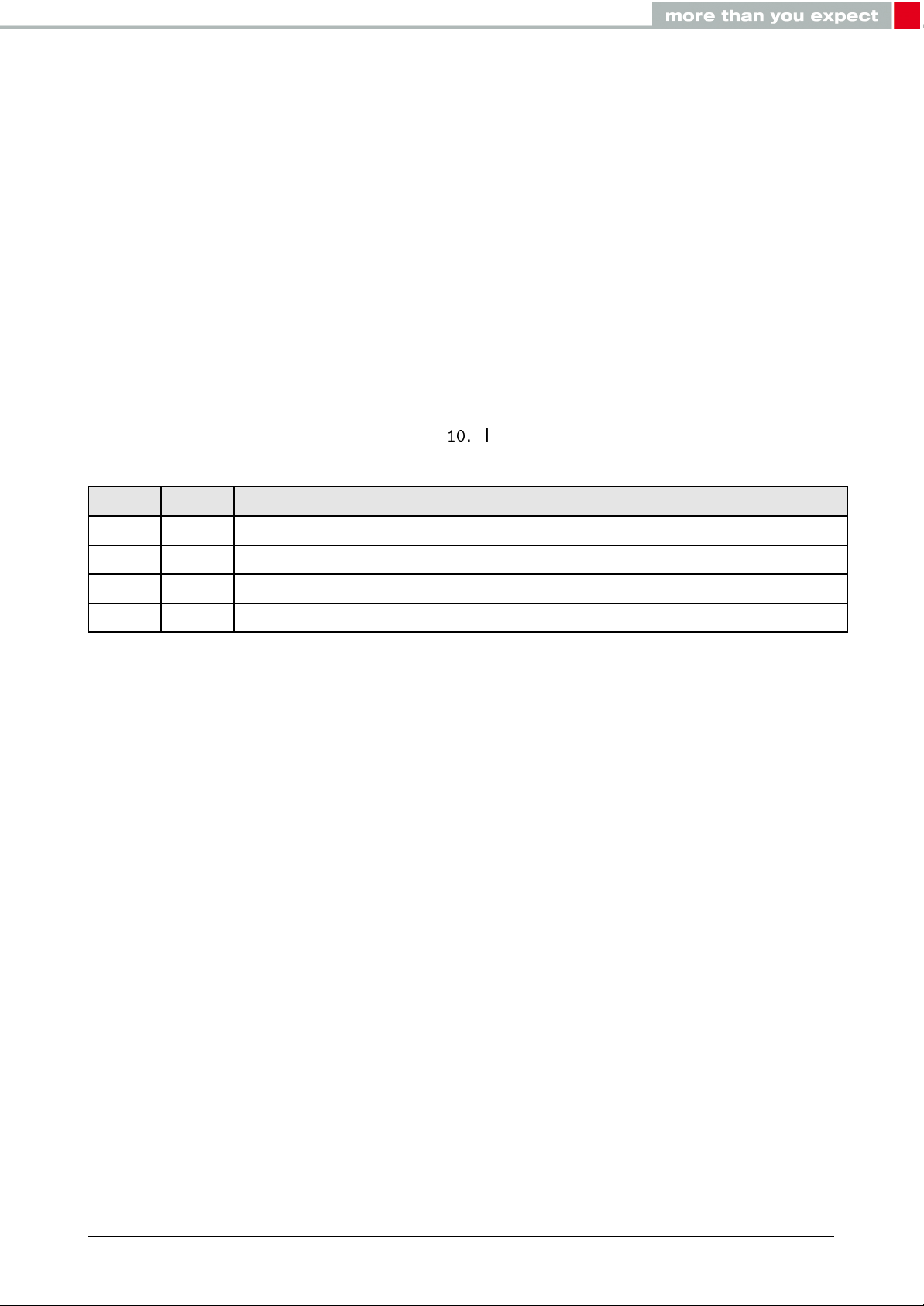

5.2 Communcation modes

In SPI, the master can select the clock polarity (CPOL) and clock phase (CPHA). The CPOL

bit sets the polarity of the clock signal during the idle state. The CPHA bit selects the clock

phase. Depending on the CPHA bit, the rising or falling clock edge is used to sample and

shift the data. Depending on the CPOL and CPHA bit selection in the SPI control registers,

four SPI modes are available as per table10. In order to ensure proper communication,

master and the slave must be set to same communication modes.

CPOL CPHA Desription

0 0 Clock polarity LOW in idle state; Data sampled on the rising clock edge

0 1 Clock polarity LOW in idle state; Data sampled on the falling clock edge

1 1 Clock polarity HIGH in idle state; Data sampled on the falling clock edge

1 0 Clock polarity HIGH in idle state; Data sampled on the rising clock edge

Table 10: SPI communication modes

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 22

Page 24

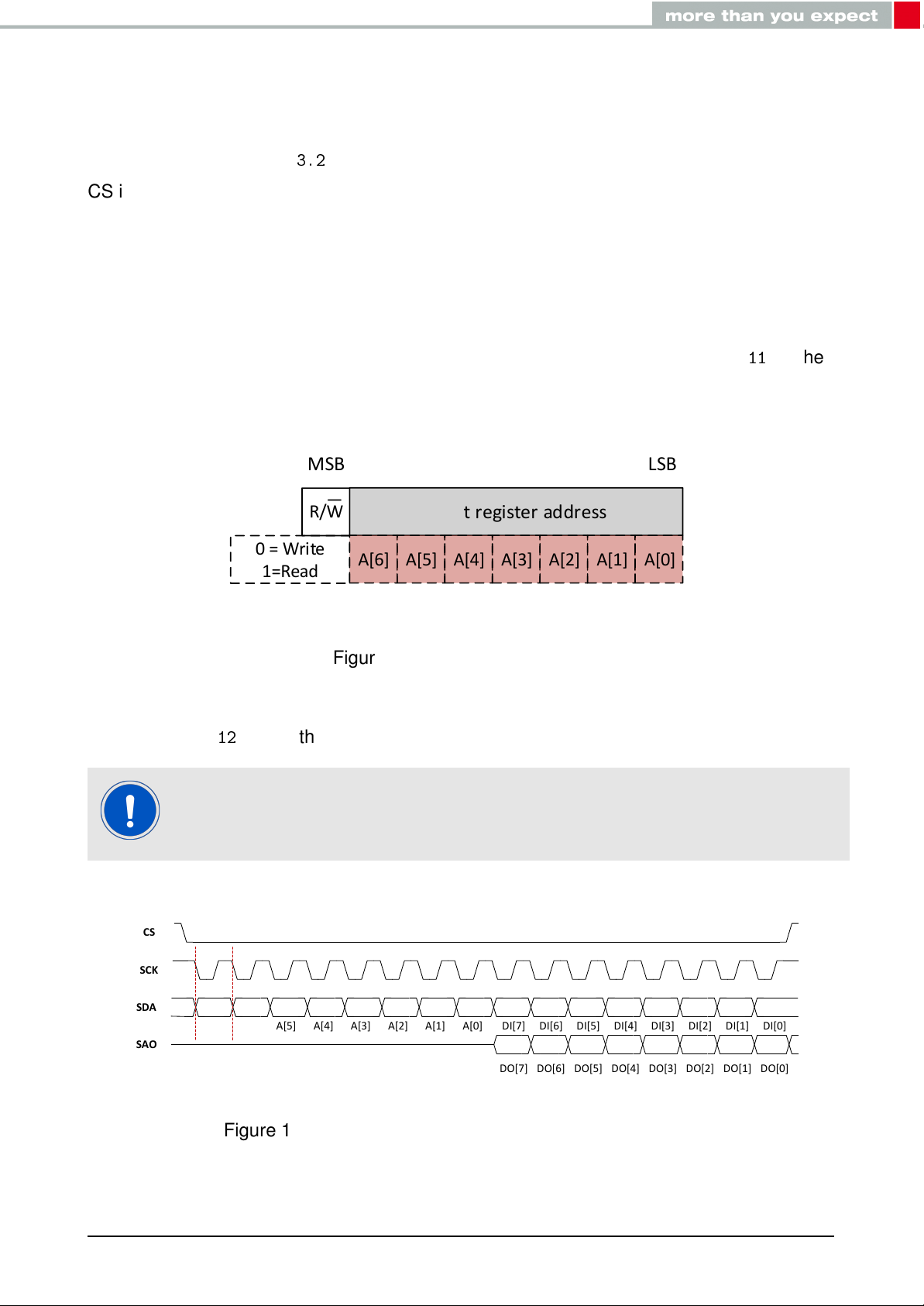

5.3 Sensor SPI Communcation

7- bit register address

R/W

LSBMSB

A[6]

A[5] A[4] A[3] A[2] A[1] A[0]

0 = Write

1=Read

R/W A[6] A[5] A[4] A[3] A[2] A[1] A[0] DI[7] DI[6] DI[5] DI[4] DI[3] DI[2] DI[1] DI[0]

DO[7] DO[6] DO[5] DO[4] DO[3] DO[2] DO[1] DO[0]

CS

SCK

SDA

SAO

4-Wire SPI of this sensor uses following lines: SDA (data input, MOSI), SAO (data output,

MISO), SCL (serial clock) and CS (chip select). For more information, please refer to pin

description in the section

CS is pulled LOW by the master at the start of communication. The SCL polarity is HIGH in

the idle state (CPOL = 1). The data lines (SDA & SAO) are sampled at the falling clock edge

and latched at the rising clock edge (CPHA = 1). Data is transmitted with MSB first and the

LSB last.

SPI read and write operations are completed in 2 or more bytes (multiple of 16 or more clock

pulses). Each block consits of a register address byte and a data byte. The first byte is the

register address. In the SPI communication, the register address is specified in the 7-bits

and the the MSB of the register address is used as an SPI read/write bit (Figure11). When

R/W is ’0’, the data is written on to the sensor. When ’1’, the data is read from the sensor.

3.2

Figure 11: SPI register address

The next bytes of data, depending on the R/W bit, is either written to or read from the indexed

register. Figure12shows the complete SPI data transfer protocol.

The sensor also supports 3-wire SPI communication. SDA is used for both

data read and write operations. Communication protocol remains the same.

Figure 12: 4-wire SPI data transfer (CPOL = 1, CPHA = 1)

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 23

Page 25

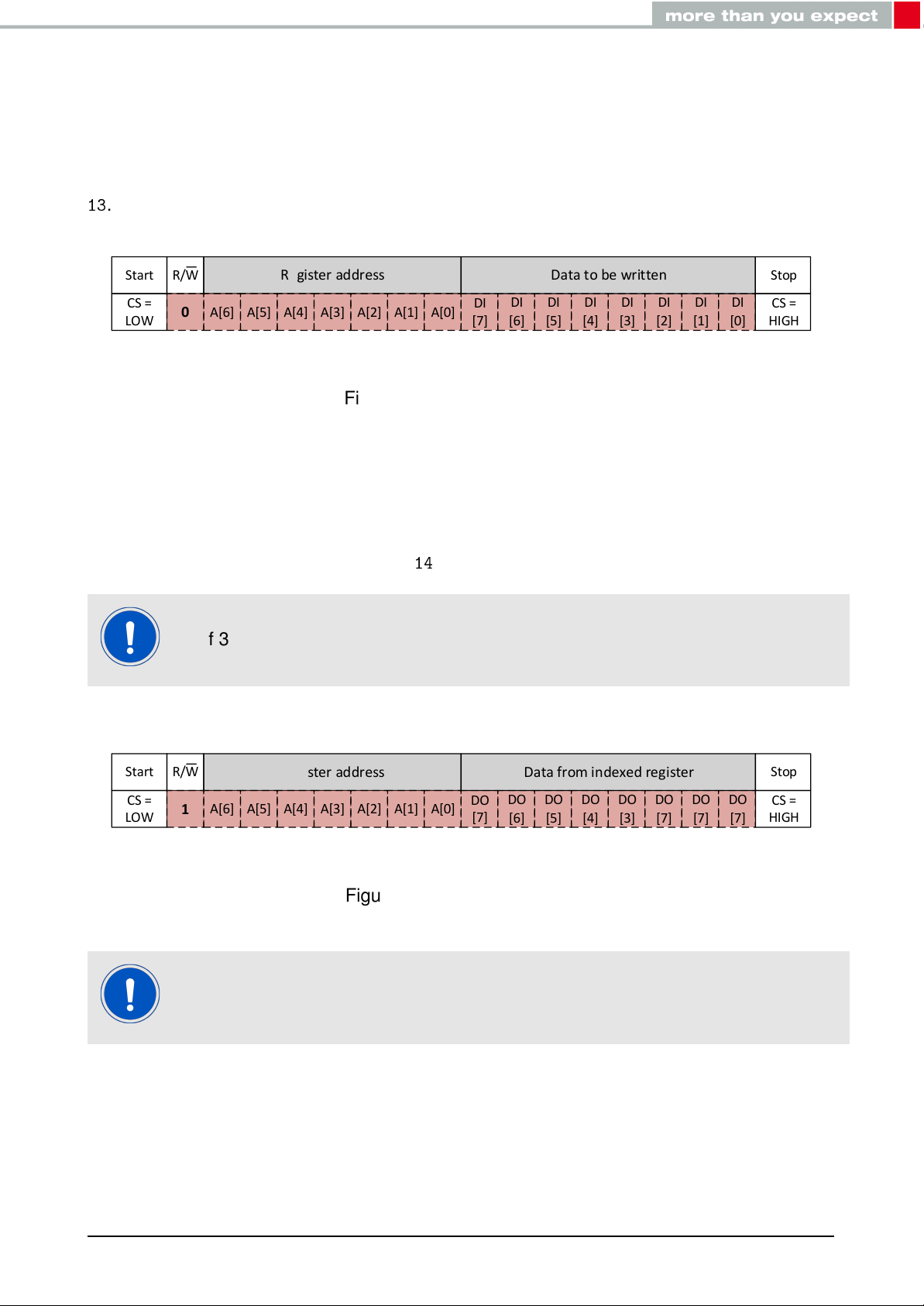

5.3.1 SPI write operation

Register address

A[6]

A[5] A[4] A[3] A[2] A[1] A[0]

R/WStart

CS =

LOW

0

DI

[6]

DI

[5]

DI

[4]

DI

[3]

DI

[2]

DI

[1]

DI

[0]

DI

[7]

Data to be written

Stop

CS =

HIGH

Register address

A[6] A[5] A[4] A[3] A[2] A[1] A[0]

R/WStart

CS =

LOW

1

DO

[6]

DO

[5]

DO

[4]

DO

[3]

DO

[7]

DO

[7]

DO

[7]

DO

[7]

Data from indexed register

Stop

CS =

HIGH

The write operation starts with the CS = LOW and sending the 7-bit register address with

R/W bit = ’0’ (write command). Next byte is the data byte that is the data to be written to the

indexed register. Several write command pairs can be sent without raising the CS back to

HIGH. The operation is ended with CS = HIGH. The SPI write protocol is shown in the figure

13

.

Figure 13: SPI write protocol

5.3.2 SPI read operation

The read operation starts with the CS = LOW and sending the 7-bit register address with

R/W bit = ’1’ (read command). Data is sent out from the sensor through the SAO line. The

SPI read protocol is shown in the figure14.

If 3-wire SPI is used, the data is sent out through the SDA line.

Figure 14: SPI read protocol

During multiple read/write operation, the register address is automatically incremented after each block. This feature is enabled by default with the bit

IF_ADD_INC set to ’1’ in the CTRL_2 register.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 24

Page 26

3-wire SPI can be enabled by setting bit SIM to ’1’ in the CTRL_1 register.

5.3.3 SPI timing parameters

Table11shows general SPI timing parameters. They are subject to VDD and the operating

temperature.

Parameter Symbol Min Max Unit

SCL clock frequency f

SCL

10

(1)

MHz

SPI clock cycle t

CS setup time t

CS hold time t

SDA input setup time t

SDA input hold time t

SAO valid output time t

SAO output hold time t

SAO output disable time t

SCL

SU_CS

h_CS

SU_SDA

h_SDA

v_SAO

h_SAO

dis_SAO

Table 11: SPI timing parameters

1. Recommended maximum SPI clock frequency for ODR ≤ 50 Hz is 8 MHz

100 ns

6 ns

6 ns

5 ns

15 ns

50 ns

9 ns

50 ns

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 25

Page 27

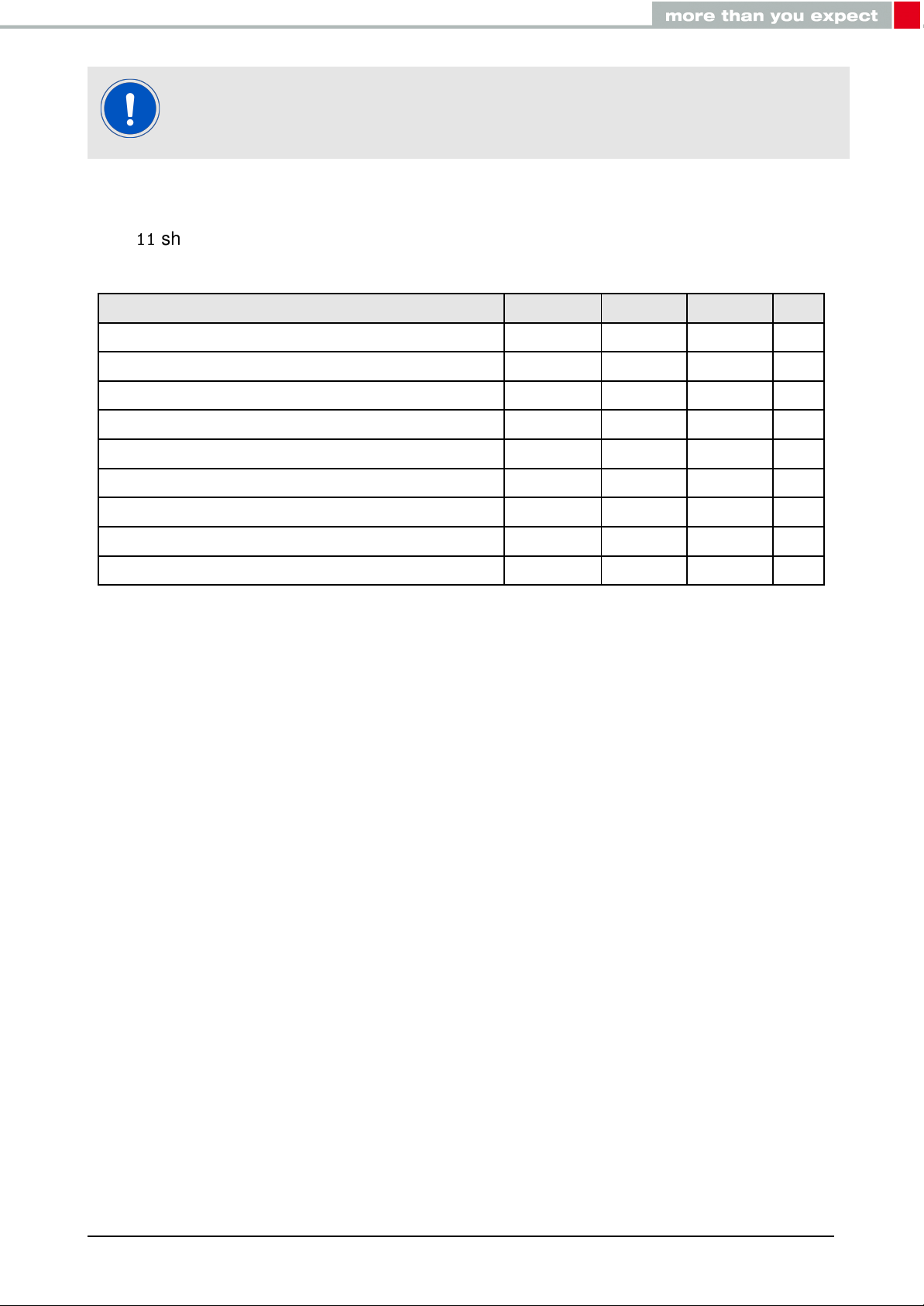

6 Application circuit

VDD_IO

SCL

SDA

RSVD

SAO

CS

INT

GND

VDD

GND

R

p

R

p

V

DD

VDD_IO

VDD_IO

VDD_IO

Optional

100 nF

4.7 µ F

Figure 15: Application circuit with I2C interface (top view)

The sensor has two separate supply pins: VDD and VDD_IO. VDD pin is the central supply pin for the MEMS cell and internal circuits. VDD_IO provides the supply to the digital

interface.

VDD_IO voltage level must be equal to or lower than VDD+0.1 V.

In order to prevent ripple from the power supply, a decoupling capacitor of 100 nF must be

placed as close to the VDD pad of the sensor as possible. An optional decoupling capacitor

(4.7 µF) could placed as shown in the figure15. If VDD_IO is not connected to the VDD line,

a separate decoupling capacitor of 10nF should be added on the VDD_IO line.

Figure15shows a typical application circuit for I2C communication. For proper I2C functionality, the CS pin must be connected to VDD. Least significant bit of the 7-bit slave address

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 26

Page 28

can be modified based on the status of the SAO pin. In order to optimize the power consumption, it is recommended to connect SAO pin to VDD (SAO = 1) if only one sensor is

used on the I2C line. This sets the 7 bit slave address as 0x5D (1011101b). SCL and SDA

must be connected to VDD_IO through the pull-up resistors. Proper value of the pull-up

resistors must be chosen depending on the I2C bus speed and load.

Pins SDA and SCL have internal pull up resistors. By default they are disabled and can

be enabled through bits SDA_PU_EN and SAO_PU_EN in InNTERFACE_CTRL register

(0x0E). Value of the internal pull up varies between 30kΩ 50kΩ, depending on VDD_IO.

Sensor communication with the master controller remains active even if VDD is disconnected

while VDD_IO is maintained. However, in this situation, the internal measurement cycle is

turned off.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 27

Page 29

7 Quick start guide

BOOT_ON bit

VDD_IO

VDD

power off

power

on

boot process

4.5 ms (max)

sensor ready for

communication

Time [s]

BOOT_ON bit = '1' ;

self cleared when boot ends

7.1 Power-up sequence

The sensor is powered up when supply voltage is applied to VDD and VDD_IO pins. During the power up sequence, it is recommended to keep the I2C interface pins in the high

impedance state from the host controller side.

During the power up sequence of the sensor, the sensor performs a boot process. During

this process, trimming parameters and calibration coefficients are loaded to the internal

registers from the embedded non-volatile memory. The booting process lasts for a maximum

of 4.5 milliseconds. During this period, the internal registers are not accessible to read or

write the data. However, the status of the boot procedure can be checked by reading the

BOOT bit in the INT_SOURCE register (0x24). This bit is set to ’1’ during the boot procedure

and automatically goes back to ’0’ once it has ended. At the end of the power-up sequence

the sensor automatically enters into power-down mode and is ready for data measurements.

Figure 16: Power-up sequence

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 28

Page 30

7.2 Communication with host controller

Power up

Wait for

4.5 ms

Device Id=

0xB3 ?

Read DEVICE_ID register

Address: 0x0F

Communication

successfull

No communication

with the device

Yes

No

No Yes

Communication with the host controller via I2C interface can be checked by reading the

DEVICE_ID register (0x0F). Device ID for this sensor is 0xB3.

Figure 17: Communication check with host controller

7.3 Reboot

Reboot procedure can be also performed by the user in case the trimming parameters are

somehow modified during operations. The Reboot procedure restores the correct values

and resets the offset calibration registers OPC_L (0x18) and OPC_H (0x19) to ’0’

When the BOOT bit in the CTRL_2 register (0x11) is set to ’1’, the trimming parameters are

copied to the corresponding internal registers and are used to calibrate the device. At the

end of the reboot process the BOOT bit is self cleared to ’0’.

Status of the reboot procedure can be checked by the BOOT_ON bit as mentioned in the

section

7.1

7.4 Software reset

To set the internal registers to the default values, software reset can be performed. It is done

by setting the SWRESET bit in the CTRL_2 register (0x11) to ’1’. Following registers are

reset to their default values during the software reset.

• INTERRUPT_CFG (0x0B)

• THR_P_L (0x0C)

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 29

Page 31

• THR_P_H (0x0C)

BOOT bit

BOOT_ON bit

SWRESET bit

Boot process

4.5 ms (max)

SW reset

50µs

Time [s]

• INTERFACE_CTRL (0x0E)

• CTRL_1 (0x10)

• CTRL_2 (0x11)

• CTRL_3 (0x12)

• FIFO_CTRL (0x13)

• FIFO_WTM (0x14)

• INT_SOURCE (0x24)

• FIFO_STATUS1 (0x25)

• FIFO_STATUS2 (0x26)

• STATUS (0x27)

The software reset procedure lasts for a maximum of 50 µs. At the end of the software reset,

the SWRESET bit in CTRL_2 register (0x11) is automatically set back to ’0’.

The reboot and software reset procedure must not be executed simultaneously. Both processes can be executed serially as shown in Figure

18

Figure 18: Reboot and software reset sequence

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 30

Do not set BOOT and SWRESET bits to ’1’ at the same time.

Page 32

7.5 Sensor operation: single conversion mode

Power-down

mode

Read pressure and temperature

data registers (0x28 – 0x2C)

No

Yes

Set bit ONE_SHOT=‘1‘

in CTRL_2 register (0x11)

Power-down

mode

Trigger one set of data conversion by

setting ONE_SHOT bit to '1'

(Automatic increment register

address enabled by default)

Get pressure and temperature

values in SI unit

Combine corresponding data

registers and multiply with the

sensitivity parameter; SENP= 1/

40960; SENT=0.01

New set of data?

Flow chart shows sensor operation in the single conversion mode.

Figure 19: Sensor operation: single-conversion mode

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 31

Page 33

7.6 Sensor operation: continuous mode

Power-down mode

Read pressure and temperature data

registers (0x28 – 0x2C)

Set sensor in continuous mode with ODR = 50Hz;

Get pressure and temperature

values in SI unit

Combine corresponding data registers and multiply

with the sensitivity parameter; SENP= 1/40960;

SENT=0.01

Set bit LOW_NOISE_ENABLE= ‘1‘

in CTRL_2 register (0x11)

Enable Low-noise configuration

(Automatic increment register address enabled by

default)

Set bits ODR[2:0]= ‘100‘

in CTRL_1 register (0x10)

Wait t=1/ODR

Set bits EN_LPFP= ‘1‘, LPFP_CFG=‘1‘

and BDU= ‘1‘

in CTRL_1 register (0x10)

Additional low pass filter enabled & BW=ODR/20 ;

Enable block data update

Flow chart shows sensor operation in continuous mode with 50Hz ODR and low-noise configuration enabled.

Figure 20: Sensor operation: continuous mode

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 32

Page 34

7.7 Power-off sequence

VDD rise/fall time for the sensor varies between 10 µs and 100 ms. For proper device power

off, it is recommended to drive the VDD pin to GND or less than 0.2 V and keep it stable at

this level for at least 10 ms.

This procedure is also necessary to guarantee the next power-on and boot procedure to be

successful.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 33

Page 35

8 Modes of operation

Power off

VDD & VDD_IO applied

Single Conversion mode

One measurement

Continuous mode

Periodic measurements as per

selected ODR

Power on

&

Boot process

Power-down mode

ODR[2:0] ≠ '000'

ODR[2:0] = '000'

ONE_SHOT = '1'

The sensor can be configured to be used in the following 3 different modes.

1. Power-down mode

2. Single conversion mode

3. Continuous mode

Additionally, the device can be operated in either low-power or low-noise configuration. Transition to/from one of the operating modes and configurations can be executed by writing to

specific registers.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 34

Figure 21: Operating modes

Page 36

8.1 Power-down mode

The power-down mode can be configured by setting the ODR[2:0] bits of CTRL_1 register

(0x10) to ’000’.

In power-down mode the digital chain that samples the pressure and temperature values is

turned off. No new measurement is performed during this mode. Hence, the data registers

containing pressure and temperature values are not updated. The data registers contain the

last sampled pressure and temperature data before going into power-down mode. Current

consumption is at the minimum during this mode.

However, serial communication with the host controller via I2C bus is still possible. This

allows the user to configure the device by accessing the configuration/control registers. Data

of the control registers remains unaffected when the sensor is configured to power-down

mode from another mode.

Sensor is in power-down mode by default after the power-up sequence.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 35

Page 37

8.2 Single conversion mode

Pressure

data

Temperature

data

Time [s]

1

st

Measurement

2

nd

Measurement

3

rd

Measurement

P P P T T P P P T T P P P T T

Power down

mode

ONE_SHOT bit =1

Measurement

in progress

In this mode single measurement of pressure and temperature is performed according to

the request of the host controller. This mode can be activated only when the sensor is in

the power-down mode. When ONE_SHOT bit of CTRL_2 register (0x11) is set to ’1’, the

digital chain is turned on, data conversion starts and a single measurement of pressure and

temperature is acquired. This measurement data is written in the respective pressure and

temperature data registers. Afterwards, the digital chain is turned off again and the sensor

enters the power-down mode. The ONE_SHOT bit of CTRL_2 register (0x11) automatically

returns to ’0’ (default value). The data registers are not updated until another data acquisition

is requested by the host controller. This mode is useful when the application demands

reduced power consumption.

During this mode the output data rate (ODR) of new measurement depends on the new

measurement request from the host controller (frequency at which the ONE_SHOT bit is set

to ’1’).

Figure 22: Single conversion mode

Figure12shows typical data conversion time in low-power and low-noise configuration.

Configuration Conversion time [ms]

Low-power 4.7

Low-noise 13.2

Table 12: Data conversion time

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 36

Page 38

8.3 Continuous mode

Pressure

data

Temperature

data

t=1/ODR

Time [s]

1

st

Measurement

2

nd

Measurement

3

rd

Measurement

t=1/ODR t=1/ODR

P P P T T P P P T T P P P T T

The sensor is configured in the continuous mode when the ODR[2:0] bits of CTR_1 register

(0x10) are set to a value other than ’000’. The continuous mode constantly samples new

pressure and temperature measurements and writes the data to the corresponding data

registers. The measurement rate is defined by the user selectable output data rate (ODR)

which can be set by ODR[2:0] bits of CTRL_1 register. Selectable ODR and corresponding

register settings are shown in the table

13

Figure 23: Continuous mode

ODR[2:0] Output data rate [Hz]

000 Power-down mode / One-shot mode

001 1

010 10

011 25

100 50

101 75

110 100

111 200

Table 13: Output data rate selection

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 37

Page 39

8.4 Additional configurations

During continuous mode and single conversion mode, additional configurations can be selected. These include enabling the additional low pass filter; selecting either low-power or

low-noise configuration.

8.4.1 Low-power or low-noise configuration

In the low-power configuration, the device is configured to minimize the current consumption.

In the low-noise configuration, the device is configured to reduce the noise. During the

continuous mode and single conversion mode, either one of these configurations can be

selected as shown in Table14. By default the sensor operates in the low-power configuration.

Address Register Bit Bit value Configuration

0x11 CTRL_2 LOW_NOISE_EN 0 Low-power (default)

0x11 CTRL_2 LOW_NOISE_EN 1 Low-noise

Table 14: Low-power/low-noise configuration

To ensure the proper behaviour of the device, LOW_NOISE_EN bit must

changed only when it is in the power-down mode.

Table

mode.

15

shows typical conversion time and maximum allowable ODR in each operating

Maximum ODR [Hz]

Configuration

Low-power 4.7 200 200

Low-noise 13.2 50 75

Low-noise configuration is not available at ODR 100 Hz or 200Hz. If ODR is

set to 100Hz or 200Hz, LOW_NOISE_EN bit must be set to ’0’.

Typical data conversion time

[ms]

Table 15: Typical conversion time and maximum ODR

Single

conversion mode

Continuous

mode

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 38

Page 40

8.4.2 Enabling additional low-pass filter

The sensor embeds two digital low-pass filters. First low-pass filter LPF1 is always applied

to the pressure and temperature data. The second low-pass filter LPF2 can be optionally

enabled and applied to the pressure data. This configuration is available for both continuous

mode and single conversion mode.

The second low-pass filter LPF2 can be enabled by setting the EN_LPFP bit in the CTRL_1

register (0x10) to ’1’. Further, overall device bandwidth can also be configured by changing

LPFP_CFG bit of the CTRL_1 (0x10) register. LPF2 is applied only to the pressure data.

EN_LPFP LPFP_CFG LPF2 status Device Bandwidth

0 x Disabled/reset filter ODR/2

1 0 Enabled ODR/9

1 1 Enabled ODR/20

Samples to be

discarded

0

2

2

Table 16: Additional low-pass filter setting

When EN_LPF bit in the CTRL_1 (0x10) is changed from ’1’ to ’0’, the filter is reset. The

filter is also reset when the ODR or device bandwidth is changed. Table

16

indicates the

number of samples to be discarded when the filter is enabled or reset. The output data is

not considered meaningful before the filter reaches the settling condition.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 39

Page 41

9 Reading output data

Once the device is configured in one of the operating modes, pressure and temperature

values are sampled and stored in the respective data registers, available for the user to

read.

It is recommended to read the data registers starting from the lower address

to the higher address.

9.1 Reading pressure values

Pressure values are stored in the three data registers: DATA_P_XL, DATA_P_L and DA-

TA_P_H. Each register contains 8-bits data. The complete pressure data is represented as

a 24-bit signed 2’s complement word. This can be obtained by concatenating the three 8-bit

pressure data registers: DATA_P_H, DATA_P_L & DATA_P_XL, with DATA_P_H being most

significant byte and DATA_P_XL being least significant byte.

After calculating the 24-bit digital pressure value, it must be multiplied with the sensitivity

parameter, SENP(see table4) in order to obtain the corresponding pressure in SI unit (Pa).

Step 1: Reading raw data from the three pressure data registers

1. DATA_P_XL (0x28)

2. DATA_P_L (0x29)

3. DATA_P_H (0x2A)

Step 2: Concatenating pressure data registers to obtain complete 24-bit pressure value

P

= DATA_P_H & DATA_P_L & DATA_P_XL

24bit

Step 3: Obtaining pressure value in SI unit (Pa) by multiplying with sensitivity parameter

Pressure [Pa] = P

24bit

[digit] ×

1

40960

[Pa/digit]

Example:

If values obtained from pressure data registers are:

DATA_P_XL = 0x00

DATA_P_L = 0x54

DATA_P_H = 0x3F

Concatenating these 3 registers (0x3F5400) to obtain 24-bit signed decimal value and multiplying with the sensitivity parameter

P

[digit] = 4150272 [digit]

24bit

P[kPa] = 4150272 [digit] * 1/40960 [kPa/digit] = 101.325 kPa

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 40

Page 42

9.2 Reading temperature values

Temperature values are stored in the two data registers: DATA_T_L and DATA_P_H. Each

register contains 8-bits data. The complete temperature data is a 16-bit signed 2’s complement word. This can be obtained by concatenating the two 8-bit temperature data registers:

DATA_T_H & DATA_P_L, with DATA_T_H being most significant byte and DATA_T_L being

least significant byte.

After calculating the 16-bit digital temperature value, it must be multiplied with the sensitivity

parameter, SENT(see table5) in order to obtain the corresponding temperature in SI unit

(°C).

Step 1: Reading raw data from the two temperature data registers

1. DATA_T_L (0x2B)

2. DATA_T_H (0x2C)

Step 2: Concatenating the temperature data registers to obtain complete 16-bit temperature

value

T

= DATA_T_H & DATA_T_L

16bit

Step 3: Obtaining temperature value in SI unit [°C] by multiplying with sensitivity parameter

Temperature [°C] = T

[digit] ×0.01 [°C/digit]

16bit

Example:

If values obtained from temperature data registers are:

DATA_T_L = 0x42

DATA_T_H = 0x0E

Concatenating these 2 registers (0x0E42)to obtain 16-bit signed decimal value and multiplying with sensitivity parameter

T

[digit] = 3650 [digit]

16bit

T[°C] = 3650 [digit] * 0.01 [°C/digit] = 36.50 °C

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 41

Page 43

9.3 Status register for reading the data

Pressure sample

Pressure

data

P_DA

P_OR

Data read

Previous measurement

overwritten

DATA_P_H is read

The sensor has a STATUS register (0x27) that can be used to check when a new set of

pressure or temperature data is available in the corresponding data register.

P_DA bit is set to ’1’ whenever a new sample is available in the pressure data registers.

P_DA bit is self cleared and set back to ’0’ when the corresponding pressure data (most

significant byte, DATA_P_H) has been read.

Same way, T_DA bit is set to ’1’ whenever a new set of data is available in the temperature data registers. T_DA bit is self cleared and set back to ’0’ when the corresponding

temperature data (Most significant byte, DATA_T_H) has been read.

Bits P_OR and T_OR of the STATUS register (0x27) are overrun flags for pressure and

temperature data respectively. Whenever a previous pressure or temperature sample in the

data register is overwritten without being read by the user, P_OR and T_OR bits are set to

’1’, indicating that previous value has been lost. P_OR and T_OR bit will be set to ’1’ in case

a new pressure or temperature data is measured while the corresponding x_DA bit is still ’1’.

They are automatically set to ’0’ when all data from the corresponding data registers have

been read and no new measurement is generated in the meantime.

Figure 24: Reading pressure data using STATUS register

Since, pressure and temperature data are synchronously generated, P_DA and T_DA synchronously rises to ’1’ (unless one of the bit is already one). However, they would not synchronously reset to ’0’ as it depends on when the corresponding data is read.

Reading the data registers (pressure and temperature) before 1/ODR time period allows acquisition of all data and resetting P_DA and T_DA before the

overrun flags are set.

If the sensor is configured in the single conversion mode, the STATUS register

will not be updated after the first measurement because the sensor goes to

power down mode after the first acquisition.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 42

Page 44

10 FIFO buffer

The sensor has an embedded first-in, first-out (FIFO) buffer that can store upto 128 sets of

pressure and temperature data. Each data set consists of 5 bytes of data (3 bytes pressure

and 2 bytes temperature). This allows considerable power saving of the system because

the host controller does not have to continuously poll for new data from the sensor. The

host controller can be notified via the INT pin when it is required to read the data from FIFO

buffer. FIFO events can be used to generate interrupt via INT pin.

FIFO can be operated in six different user selectable modes.

• Bypass mode

• FIFO mode

• Continuous mode

• Bypass-to-FIFO mode

• Bypass-to-continuous mode

• Continuous-to-FIFO mode

Figure 25: First-In-First-Out buffer

FIFO behaves as a circular buffer. The buffer is filled with new data set (pressure and

temperature) in the first available empty slot. Once the buffer is full, FIFO either stops filling

the new data sets or the oldest data set is replaced by the new data sets.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 43

Page 45

When FIFO is enabled, pressure and temperature data is sent to the FIFO buffer at the

selected ODR in the CTRL_1 register. The host controller can read the data stored in FIFO buffer. The oldest data set is always read first. FIFO modes can be configured from

FIFO_CTRL register. (0x13).

FIFO_CTRL [2:0]

TRIG_MODE F_MODE[1] F_MODE[0]

x 0 0 Bypass mode

0 0 1 FIFO mode

0 1 x Continuous mode

1 0 1 Bypass-to-FIFO mode

1 1 0 Bypass-to-Continuous mode

1 1 1 Continuous-to-FIFO mode

Table 17: FIFO mode settings

FIFO Mode

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 44

Page 46

10.1 Bypass mode

FIFO buffer is not in operation in the bypass mode. By default the FIFO buffer is in bypass

mode and FIFO remains empty. Each new data set is directly available in the respective

data (DATA_P_x, DATA_T_x) registers (See Figure26)

The device can be configured in the bypass mode by writing ’000’ or ’100’ to register FIFO_CTRL[2:0].

Enabling bypass mode clears the FIFO buffer and must be used while switching

between other FIFO modes.

Figure 26: Bypass mode

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 45

Page 47

10.2 FIFO mode

This mode is enabled by settings bits [2:0] of FIFO_CTRL (0x13) to ’001’.

In this mode, each data set (pressure and temperature) is stored in the FIFO buffer at se-

lected ODR. The FIFO buffer keeps filling untill it is full or reaches the user-defined FIFO

threshold (see section

FSS[7:0] bits in FIFO_STATUS_1 register (0x25) shows the number of data sets stored in

FIFO buffer. This register is updated every 1/ODR period.

Once the FIFO is full, bit FIFO_FULL_IA or FIFO_WTM_IA (if user defined FIFO threshold

level is enabled) in the FIFO_STATUS_2 register (0x26) will be set to ’1’, and buffer stops

storing new data sets. At this point data in the FIFO buffer will remain unchanged and

further measured data sets will be lost. Data stored in FIFO buffer can be read from five

FIFO_DATA_x_x registers(0x78-0x7C). See section (see section

10.7.1

).

10.7.2

)

Figure 27: FIFO mode

In order to fill the FIFO buffer with new sets of measurement data, the device

must be first configured in the bypass mode to reset the FIFO buffer and then

again in the FIFO mode.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 46

Page 48

10.3 Continuous mode

This mode is enabled by settings bits [2:0] of FIFO_CTRL (0x13) to ’010’ or ’011’.

In this mode, each data set (pressure and temperature) is stored in the FIFO buffer at se-

lected ODR. Once the FIFO buffer is full or reaches the user-defined FIFO threshold, oldest

data sets will be overwritten by the new data sets, meaning older data sets will be lost.

FSS[7:0] bits in FIFO_STATUS_1 register (0x25) indicate the number of data sets stored in

FIFO buffer. This register is updated every 1/ODR period.

Once the FIFO is full, bit FIFO_FULL_IA or FIFO_WTM_IA (if user defined FIFO threshold

level is enabled) in the FIFO_STATUS_2 register (0x26) will be set to ’1’. At this point, older

data sets are replaced by new data sets and FIFO_OVR_IA bit in the FIFO_STATUS_2

register (0x26) goes to ’1’, indicating that at least one data set has been overwritten.

Figure 28: Continuous mode

If FIFO buffer is overwritten without a read operation, bits FIFO_FULL_IA and

FIFO_WTM_IA are set back to ’0’ after the first data set is overwritten.

New data sets will continue to overwrite the old data sets until a read operation is initiated

by the host controller or the FIFO is reset. In order to avoid losing the older data sets, data

must be read faster than the ODR. Host controller can be alerted about FIFO full or FIFO

overwritten event by routing the status of FIFO_FULL_IA, FIFO_WTM_IA or FIFO_OVR_IA

to the INT pin of the device through corresponding bits of CTRL_3 register (0x12).

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 47

Page 49

10.4 Bypass-to-FIFO mode

This mode is enabled by settings bits [2:0] of FIFO_CTRL (0x13) to ’101’.

In this mode, initially FIFO buffer is in bypass mode. When an interrupt trigger event is

generated, FIFO switches from bypass mode to FIFO mode and starts filling the slots with

measurement data sets until the buffer is full.

Switching from the bypass mode to the FIFO mode can be triggered by an interrupt event

selected by user through INT_CFG (0x0B) register. The selected event generation leads IA

bit of INT_SOURCE (0x24) register to rise to ’1’. When this bit rises to ’1’ for the first time,

the buffer switches to FIFO mode.

When the IA bit goes back to ’0’, FIFO does not switch back to bypass mode.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 48

Page 50

10.5 Bypass-to-continuous mode

This mode is enabled by settings bits [2:0] of FIFO_CTRL (0x13) to ’110’.

In this mode, initially FIFO buffer is in bypass mode. When an interrupt trigger event is

generated, FIFO switches from bypass mode to continuous mode and starts filling the slots

with measurement data sets; once FIFO is full, it will overwrite old data sets with the new

data.

Switching from the bypass mode to the continuous mode can be triggered by an interrupt

event selected by the user through INT_CFG (0x0B) register. The selected event generation

leads IA bit of INT_SOURCE (0x24) register to rise to ’1’. When this bit rises to ’1’ for the

first time, FIFO switches to continuous mode.

Figure 29: Bypass-to-Continuous mode

When the IA bit goes back to ’0’, FIFO does not switch back to bypass mode.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 49

Page 51

10.6 Continuous-to-FIFO mode

This mode is enabled by settings bits [2:0] of FIFO_CTRL (0x13) to ’111’.

In this mode, initially FIFO buffer is in continuous mode. When an interrupt trigger event is

generated, FIFO switches from continuous mode to FIFO mode and continues to fill the slots

with the data sets; once FIFO is full, it will stop storing the data in the FIFO buffer.

Switching from continuous to FIFO mode can be triggered by an interrupt event selected by

the user through INT_CFG (0x0B) register. The selected event generation leads IA bit of

INT_SOURCE (0x24) register to rise to ’1’. When this bit rises to ’1’ for the first time, the

buffer switches to FIFO mode.

Figure 30: Continuous-to-FIFO mode

When the IA bit goes back to ’0’, FIFO does not switch back to continuous

mode.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 50

Page 52

10.7 FIFO status monitoring and control

When FIFO is in operation, its status can be monitored by reading two registers, FIFO_STATUS_1

(0x25) and FIFO_STATUS_2 (0x26).

FIFO_STATUS_1 register shows the current number of data sets stored in the FIFO buffer.

0000000b indicates FIFO is empty and 1000000b indicates FIFO is full with 128 data sets.

FIFO_STATUS_2 register has 3 FIFO buffer flags.

• FIFO_WTM_IA flag indicates when FIFO buffer is equal to or higher than user defined

FIFO threshold level (only if this feature is enabled through FIFO_CTRL register). The

status of this flag can be routed to INT pad of the sensor via CTRL_3 register by setting

INT_F_WTM bit to ’1’.

• FIFO_OVER_IA flag indicates when FIFO is full and at least one data set is overwritten

with a new one. The status of this flag can be routed to INT pad of the sensor via

CTRL_3 register by setting INT_F_OVR bit to ’1’.

• FIFO_FULL_IA flag indicates when FIFO is completely filled with 128 data sets. The

status of this flag can be routed to INT pad of the sensor via CTRL_3 register by setting

INT_F_FULL bit to ’1’.

Absolute pressure sensor, Part Nr. 2511020213301

User manual version 2.0 © November2020

www.we-online.com/sensors 51

Page 53

10.7.1 User-defined FIFO threshold

Normally, FIFO can be filled with 128 sets of data. However, user can limit the FIFO buffer

depth with FIFO_WTM (0x14) register. The user can define the required FIFO threshold

level by setting bits WTM[6:0] of FIFO_WTM registers to the corresponding value. Maximum

allowable value in this register is 0x7F.

The user-defined FIFO threshold has to be enabled by setting STOP_ON_WTM bit of FI-

FO_CTRL (0x13) register to ’1’. When enabled, the FIFO level size will be considered as

the value defined im the FIFO_WTM register.

User-defined FIFO threshold level can not be changed when FIFO is already

in operation.

10.7.2 Reading data from FIFO buffer

When FIFO buffer is in operation, the data stored in FIFO is available to read from dedicated FIFO data registers. Pressure values can be read from FIFO_P_x (0x78 to 0x7A) and

temperature values can be read from FIFO_T_x (0x7B to 0x7C) registers. Every time a data

set is read, remaining oldest entry in the FIFO buffer is placed in the FIFO data registers,

available to be read. FIFO status registers FIFO_STATUS_1 (0x0x25) and FIFO_STATUS_2

(0x0x26) are also updated accordingly.