Page 1

RT-flex50-D

Maintenance Manual

“Marine”

Vessel:

Type:

Engine No.:

Document ID: DBAC251330

Wärtsilä Switzerland Ltd Tel. +41 52 262 49 22

PO Box 414 Fax +41 52 212 49 17

CH-8401 Winterthur http://www.wartsila.com

Switzerland

E 2012-07 Wärtsilä Switzerland Ltd, Printed in Switzerland

Page 2

This page is intentionally left blank

Page 3

0

General Information

1

2

3

4

Bedplate and Tie Rod

Cylinder Liner and Cylinder Cover

Crankshaft, Connecting Rod and Piston

Driving Wheels and Shut-off Valve for Starting Air

5

6

7

8

Supply Unit, Injection and Exhaust Valve Control

Scavenge Air Receiver and Auxiliary Blower

Cylinder Lubrication

Piping

9

MM / RT−flex / Register

Crank Angle Sensor Unit, Tools

Page 4

This page is intentionally left blank

Page 5

RT-flex50-D

0

Maintenance

Group0

General Information Group

For Particular Attention 0000−1/A1..................................................

Preface 0001−1/A1...............................................................

Table of Contents 0002−1/A1.......................................................

Engine Numbering and Designations 0008−1/A1......................................

o General Guidelines

− for Maintenance: Safety Measures and Warnings 0011−1/A1........................

− for Lifting Tools: Wire Rope Slings, Span-sets, Eye Bolts, etc. 0012−1/A1.............

o Clearance Table 0330−1/A1....................................................................

− General Page 1...............................................................

− Crankshaft and Thrust Bearing 2, 3..............................................

− Crankshaft and Main Bearing 4, 5................................................

− Crosshead Guide 6, 7..........................................................

− Cylinder Liner 8, 9.............................................................

− Piston Rod Gland 10, 11........................................................

− Exhaust Valve 12, 13...........................................................

− Top and Bottom End Bearings to Connecting Rod 14, 15............................

− Piston Cooling and Crosshead Lubrication 16, 17..................................

− Piston and Piston Rings 18, 19..................................................

− Driving Wheels for Supply Unit 20, 21............................................

− Supply Unit 22, 23.............................................................

− Fuel Pump 24, 25..............................................................

o Tightening Values

− of Important Screwed Connections 0352−1/A1.....................................

− of Standard Screwed Connections 0352−2/A1.....................................

Masses (Weights): Individual Components per Piece in kg 0360−1/A1...................

o Dimensions

− O-rings and Round Rubber Rings 0370−1/A1......................................

− Piston and Rod Seal Rings 0370−2/A1............................................

− Un-slotted Back-up Rings Page 2................................................

Maintenance Schedule: Inspection and Overhaul Intervals (Guidelines) 0380−1/A1........

Engine Cross Section and Longitudinal Section 0803−1/A1.............................

Wärtsilä Switzerland Ltd RT−flex50−D / MM / 2010

Wärtsilä Switzerland Ltd

1/ 1

Page 6

This page is intentionally left blank

Page 7

RT-flex50-D

F

or Particular Attention

Maintenance

This manual is put at the disposal of the recipient solely for use in connection with

the corresponding type of diesel engine.

It has always to be treated as confidential.

The intellectual property regarding any and all of the contents of this manual, particularly the copyright, remains with Wärtsilä Switzerland Ltd. This document

and parts thereof must not be reproduced or copied without their written permission, and the contents thereof must not be imparted to a third party nor be used for

any unauthorized purpose.

Before the operator intends to use the engine or before maintenance work is undertaken, the Operating Instructions or the Maintenance Manual respectively is to

be read carefully.

To ensure the best efficiency, reliability and lifetime of the engine and its components, only original spare parts should be used.

It is to be ensured as well that all equipment and tools for maintenance are in good

condition.

The extent of any supplies and services is determined exclusively by the relevant

supply contract.

0000−1/A1

The data, instructions and graphical illustrations etc. in this manual are based on

drawings made by Wärtsilä Switzerland Ltd and correspond to the actual standard at the time of printing (year of printing is indicated on title page).

Those specifications and recommendations of the classification societies which

are essential for the design have been considered therein. It must be recognized

that such data, instructions and graphical illustrations may be subject to changes

due to further development, widened experience or any other reason.

This manual is primarily intended for use by the engine operating and maintenance

personnel. It must be ensured that it will always be at the disposal of such personnel for the operation of the engines and/or for the required maintenance work.

This manual has been prepared on the assumption that operation and maintenance of the engines concerned will always be carried out by qualified personnel

having the special knowledge, training and qualifications needed to handle in a

workman-like manner diesel engines of the corresponding size, the associated

auxiliary equipment, as well as fuel and other operating media.

Therefore, generally applicable rules, which may also concern such items as

protection against danger, are specified in this manual in exceptional cases only.

It must be made sure that the operating and maintenance personnel are familiar

with the rules concerned.

This manual has been prepared to the best knowledge and ability of its authors. However, neither Wärtsilä Switzerland Ltd nor their employees assume any liability − under any legal aspect whatsoever, including possible

negligence − in connection with this manual, its contents, or modifications

to it or in connection with its use.

Claims relating to any damage whatsoever or claims of other nature such as,

but not limited to, demands for additional spares supplies, service or others

are expressly excluded.

Wärtsilä Switzerland Ltd

Winterthur

Switzerland

Wärtsilä Switzerland Ltd

1/ 1

2010

Page 8

This page is intentionally left blank

Page 9

P

reface

RT-flex50-D

Maintenance

The instructions contained in this ”Maintenance Manual” are intended to help to

ensure that the maintenance which must be carried out at specific intervals is correctly carried out.

It is a precondition that the personnel charged with such important work possesses

the necessary training and experience.

Information about the operation of the engine as well as descriptions of the function of the various systems are part of a separate book, the ”Operating Manual”

containing also under 0010−1 explanations of the layout and structure of the Operating and Maintenance Manuals as well as of the used symbols, signs and special

characters.

More detailed instructions on the operation and maintenance of components from

sub-suppliers can be gathered from the instruction leaflets of the respective

manufacturers. Outside makes are, for example, such engine components, tools

or devices which are not manufactured in accordance with production drawings

from Wärtsilä Switzerland Ltd.

The ”Maintenance Manual” is divided into the following main chapters:

0001−1/A1

− General guidelines for maintenance

− Clearance tables, tightening values of screwed connections, masses

(weights), seal rings

− Maintenance schedule

− Design groups

− Tool lists

A few explanations to the above:

− The ’General Guidelines for Maintenance’ contain, in addition to recommendations on precautionary measures to be taken, also suggestions for carrying

out the work.

− The above mentioned tables inform about normal and maximum acceptable

clearances, the tightening of important screwed connections, weights of individual engine components as well as the type and use of various sealing rings.

− The ’Maintenance Schedule’ indicates nominal intervals in which various

maintenance operations are to be carried out. Please note that the maintenance intervals are based on experience and are subject to operation of the

engine under standard conditions.

− Detailed instructions are given in the ’Design Groups’ on the procedure of

maintenance work on certain engine parts.

− Tools and devices necessary to carry out maintenance are described in the

’Tool Lists’, and are generally supplied with the engine.

All information contained in the text and illustrations of this manual are valid at the

time of printing.

Modifications will be incorporated in the next edition!

Wärtsilä Switzerland Ltd

1/ 1

2010

Page 10

This page is intentionally left blank

Page 11

RT-flex50-D

Table of Contents

Maintenance

0002−1/A1

Table of Contents

General Information Group 0

For Particular Attention 0000−1/A1..................................................

Preface 0001−1/A1...............................................................

Engine Numbering and Designations 0008−1/A1......................................

o General Guidelines

− for Maintenance: Safety Measures and Warnings 0011−1/A1........................

− for Lifting Tools: Wire Rope Slings, Span-sets, Eye Bolts, etc. 0012−1/A1.............

o Clearance Table 0330−1/A1....................................................................

− General Page 1...............................................................

− Crankshaft and Thrust Bearing 2, 3..............................................

− Crankshaft and Main Bearing 4, 5................................................

− Crosshead Guide 6, 7..........................................................

− Cylinder Liner 8, 9.............................................................

− Piston Rod Gland 10, 11........................................................

− Exhaust Valve 12, 13...........................................................

− Top and Bottom End Bearings to Connecting Rod 14, 15............................

− Piston Cooling and Crosshead Lubrication 16, 17..................................

− Piston and Piston Rings 18, 19..................................................

− Driving Wheels for Supply Unit 20, 21............................................

− Supply Unit 22, 23.............................................................

− Fuel Pump 24, 25..............................................................

o Tightening Values

− of Important Screwed Connections 0352−1/A1.....................................

− of Standard Screwed Connections 0352−2/A1.....................................

Masses (Weights): Individual Components per Piece in kg 0360−1/A1...................

o Dimensions

− O-rings and Round Rubber Rings 0370−1/A1......................................

− Piston and Rod Seal Rings 0370−2/A1............................................

− Un-slotted Back-up Rings Page 2................................................

Maintenance Schedule: Inspection and Overhaul Intervals (Guidelines) 0380−1/A1........

Engine Cross Section and Longitudinal Section 0803−1/A1.............................

Wärtsilä Switzerland Ltd

1/ 5

2011-12

Page 12

Maintenance0002−1/A1

RT-flex50-D

Table of Contents

Bedplate and Tie Rod Group 1

Bedplate and Thrust Bearing: Checking the Foundation Bolts 1112−1/A1................

o Main Bearing

− Loosening and Tensioning of Waisted Studs 1132−1/A1.............................

− Removal and Fitting of a Main Bearing 1132−2/A1.................................

o Thrust Bearing

− Checking the Axial Clearance 1203−1/A1.........................................

− Removal and Fitting the Thrust Bearing Pads 1224−1/A1............................

Engine Stays with Friction Shims: Checking the Pre-tension 1715−1/A1..................

Tie Rod: Checking the Pre-tension and Tensioning the Tie Rods (M72x6) 1903−1/A2......

Cylinder Liner and Cylinder Cover Group 2

o Cylinder Liner

− Measuring Bore Wear 2124−1/A1................................................

− Removal and Fitting of Cylinder Liner or Water Guide Jacket 2124−2/A1..............

− Removing the Wear Ridge, Re-dressing Lubricating Grooves

o Lubrication Quill

− with Pulse Feed Lubrication: Removal and Fitting 2138−1/A1........................

− with Pulse Jet Lubrication: Removal and Fitting 2138−1/A2..........................

Piston Rod Gland: Dismantling and Assembling, Measuring the Wear 2303−1/A1.........

o Cylinder Cover

− Removal and Fitting of Cylinder Cover and Water Guide Jacket 2708−1/A1............

− Loosening and Tensioning of Cylinder Cover Waisted Studs 2708−2/A1...............

− Machining of Sealing Face for Injection Valve 2708−3/A1............................

Injection Valve: Checking, Dismantling, Assembling and Adjusting 2722−1/A1............

Starting Valve: Removal, Fitting and Dismantling, Grinding-in & Assembling 2728−1/A1....

Relief Valve for Cylinder Cover 2745−1/A1...........................................

and Scavenge Ports 2124−3/A1..................................................

o Exhaust Valve

2011-12

− Removal and Fitting of Exhaust Valve, Replacing of Waisted Studs 2751−1/A1.........

− Dismantling and Assembling 2751−2/A1..........................................

− Replacing and Grinding the Valve Seat 2751−3/A1.................................

− Grinding the Seating Surface on the Valve Head 2751−4/A1.........................

2/ 5 Wärtsilä Switzerland Ltd

Page 13

RT-flex50-D

Maintenance

0002−1/A1

Table of Contents

Crankshaft, Connecting Rod and Piston Group 3

Crankshaft: Measuring Crank Deflection 3103−1/A1..................................

o Vibration Damper

− Taking a Silicone Fluid Sample 3130−1/A1........................................

− Inspection (GEISLINGER Vibration Damper) 3130−2/A1............................

Axial Damper: Dismantling and Assembling 3146−1/A1................................

Turning Gear: Checking the Toothing 3206−1/A1......................................

Crankcase: Utilization of Working Platform 3301−1/A1................................

Upper Platform: Arrangement of Lifting Tools 3301−2/A1...............................

o Connecting Rod

− Loosening and Tensioning the Connecting Rod Studs 3303−1/A1....................

− Inspection, Removal and Fitting of Bottom End Bearing 3303−2/A1...................

− Inspection, Removal and Fitting of Top End Bearing 3303−3/A1......................

− Removal and Fitting 3303−4/A1..................................................

− Removal of Bearing Cover to Top End Bearing 3303−5/A1..........................

o Crosshead

− Checking the Clearances and Fitting the Guide Shoes 3326−1/A1....................

− Removal and Fitting of a Crosshead Pin 3326−2/A1................................

o Piston

− Removal and Fitting 3403−1/A1..................................................

− Changing the Compression Shims 3403−2/A1.....................................

− Dismantling and Assembling 3403−3/A1..........................................

− Checking Piston Top Surface 3403−4/A1..........................................

Piston Rings: Checking Piston Ring Wear 3425−1/A1..................................

Piston Cooling and Crosshead Lubrication:

Removal and Fitting of Inside Pipe 3603−1/A1........................................

Driving Wheels and Shut-off Valve for Starting Air Group 4

o Driving Wheels

− Checking the Running and Backlash Clearances and Condition of Teeth 4103−1/A1....

− Replacing the Gear Wheel on the Crankshaft 4103−3/A1............................

Wärtsilä Switzerland Ltd

Shut-off Valve for Starting Air: Cleaning and Function Check 4325−1/A1.................

3/ 5

2011-12

Page 14

Maintenance0002−1/A1

RT-flex50-D

Table of Contents

Supply Unit, Injection and Exhaust Valve Control Group 5

o Supply Unit

− Removal and Fitting of Servo Oil Pump and Servo Oil Pump Drive 5552−1/A1.........

− Removal and Fitting of Camshaft and Bearing Shells 5552−2/A1.....................

− Removing and Fitting the Gear Wheel on Camshaft 5552−3/A1......................

− Removal and Fitting 5552−4/A1..................................................

− Lubrication of Supply Unit During Maintenance Works 5552−5/A1...................

Fuel Pump: Dismantling and Assembling 5556−1/A1..................................

Fuel Pressure Control Valve: Removal, Fitting, Dismantling and Assembling 5562−1/A1....

Fuel Overpressure Safety Valve: Checking and Setting 5562−2/A1......................

Injection Control Unit: Removal and Fitting 5564−1/A1.................................

Pressure Reducing Valve 8.11−1: Checking the Gas Pre-charge Pressure 5610−1/A1.....

Exhaust Valve Control Unit:

Removal, Fitting, Dismantling and Assembling 5612−1/A1..............................

o Regulating Linkage

− Adjusting: with Heinzmann StG 10-01 Actuator 5801−1/A1..........................

− Adjusting

: with Woodward ProAct II − Analog Actuator 5801−1/A2....................

Scavenge Air Receiver and Auxiliary Blower Group 6

Scavenge Air Receiver:

Checking the Air Flaps and Cleaning the Scavenge Air Receiver 6420−1/A1..............

Auxiliary Blower: Maintenance 6545−1/A1............................................

Removal and Fitting of Scavenge Air Cooler 6606−1/A1...............................

Removal and Fitting of Water Separator 6708−1/A1...................................

Scavenge Air Waste Gate: Dismantling and Assembling 6735−1/A1.....................

Cylinder Lubrication Group 7

Lubrication Pump CLU4−C: Checking the Gas Pre-charge Pressure 7218−1/A2..........

Piping Group 8

Servo Oil Piping: Removing, Fitting and Regrinding 8447−1/A1......................

Hydraulic Piping for Exhaust Valve Drive: Removing, Fitting and Regrinding 8460−1/A1....

o Fuel Pressure Piping

− Removing, Fitting and Regrinding of Sealing Faces 8733−1/A1......................

− Removing, Fitting and Regrinding (5 and 6 Cylinder Engines) 8752−1/A1..............

− Removing, Fitting and Regrinding (7 and 8 Cylinder Engines) 8752−1/A2..............

2011-12

4/ 5 Wärtsilä Switzerland Ltd

Page 15

RT-flex50-D

Maintenance

0002−1/A1

Table of Contents

Crank Angle Sensor Unit, Tools Group 9

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting 9223−1/A1.............

Tools: Explanation 9403−1/A1......................................................

Hydraulic Jacks and Pumps: Arrangement and Application 9403−2/A1...................

o Hydraulic Pre-tensioning Jacks

− Storing, Servicing and Maintenance 9403−3/A1....................................

− General Application Instructions 9403−4/A1.......................................

o Tool List 9403−5/A1...........................................................................

− Standard Tools Pages 1 to 33...................................................

− Recommended Special Tools Pages 34 to 36......................................

− Special Tools Obtainable on Loan Pages 37 and 38................................

Wärtsilä Switzerland Ltd

5/ 5

2011-12

Page 16

This page is intentionally left blank

Page 17

RT-flex50-D

G

E

eneral

ngine Numbering and Designations

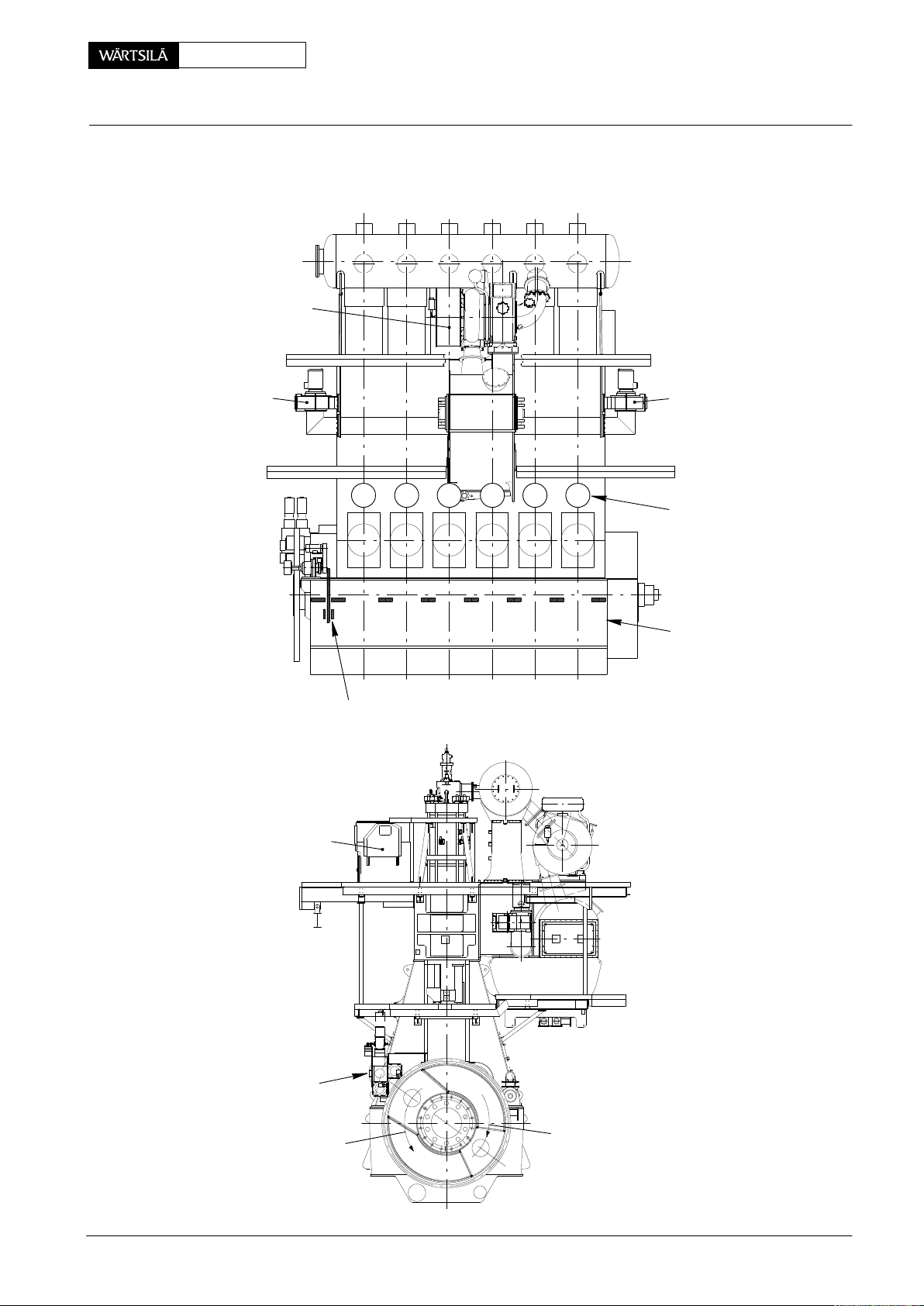

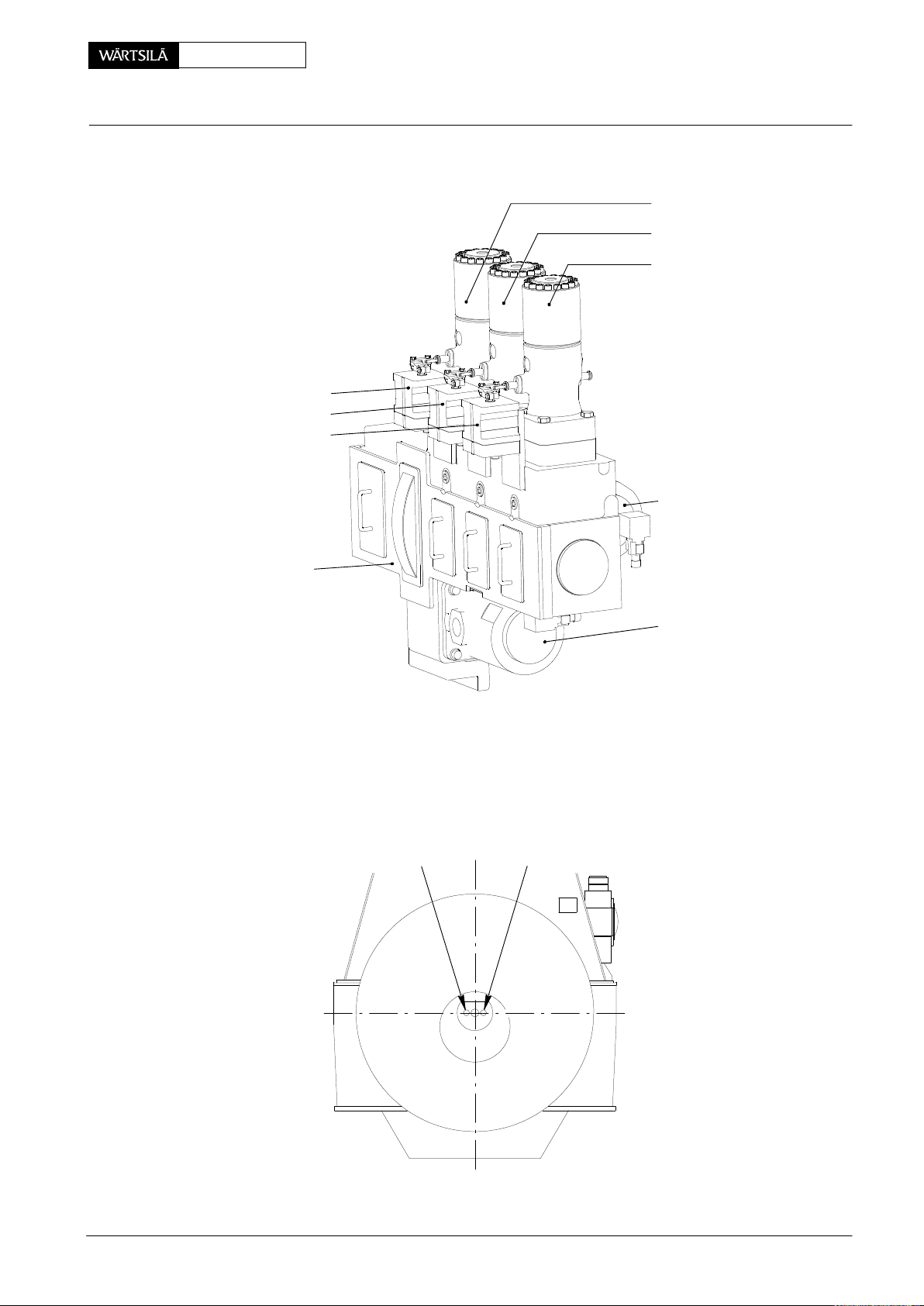

General Arrangement with One Turbocharger:

Turbocharger

Maintenance

0008−1/A1

Auxiliary

Blower 1

DRIVING END

Thrust Bearing Pads

Rail Unit

1 2 3 4 5 6

65432871

Auxiliary

Blower 2

Cylinder

Numbering

FREE END

Main Bearing

Numbering

FUEL SIDE

Wärtsilä Switzerland Ltd

Supply Unit

Counter-clockwise

Rotation

1/ 3

EXHAUST SIDE

Clockwise Rotation

018.748/09

2010

Page 18

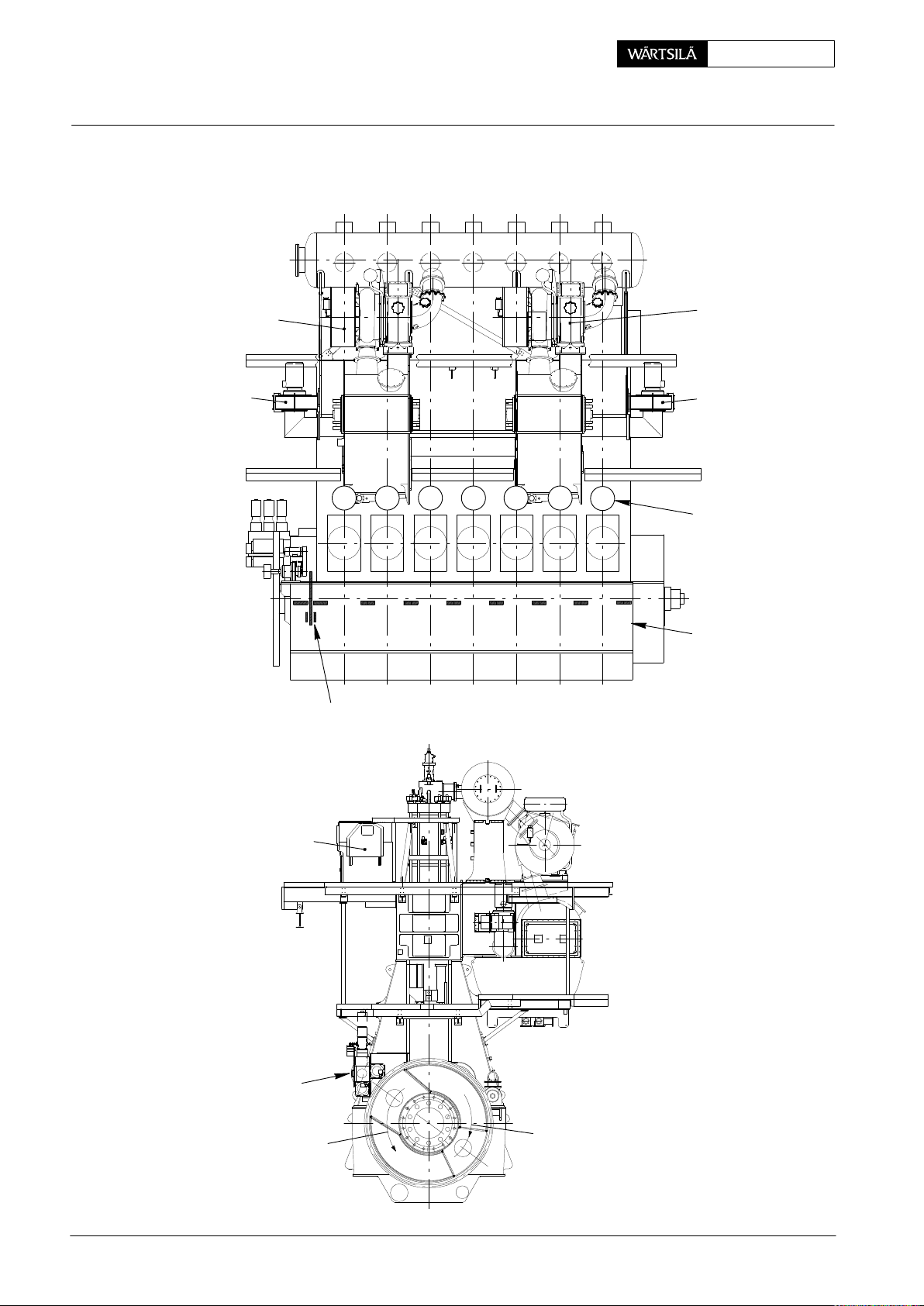

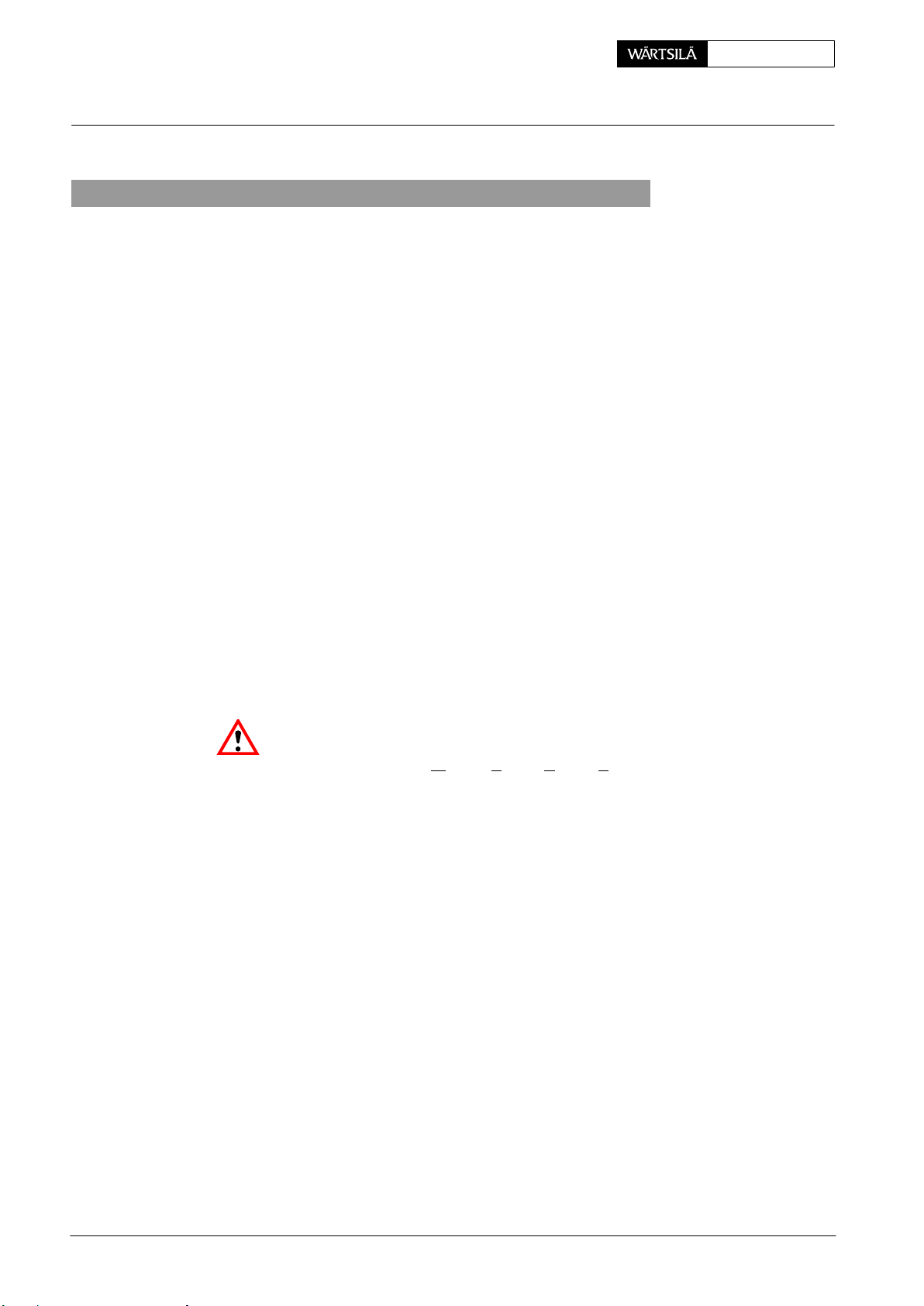

E

ngine Numbering and Designations

General Arrangement with Two Turbochargers:

Maintenance0008−1/A1 RT-flex50-D

Turbocharger 1

Auxiliary

Blower 1

DRIVING END

Thrust Bearing Pads

1 2 3 4 5 6

65432871

Turbocharger 2

Auxiliary

Blower 2

7

Cylinder

Numbering

FREE END

9

Main Bearing

Numbering

2010

Rail Unit

FUEL SIDE

Supply Unit

Counter-clockwise

Rotation

2/ 3

EXHAUST SIDE

Clockwise Rotation

018.749/09

Wärtsilä Switzerland Ltd

Page 19

RT-flex50-D

E

ngine Numbering and Designations

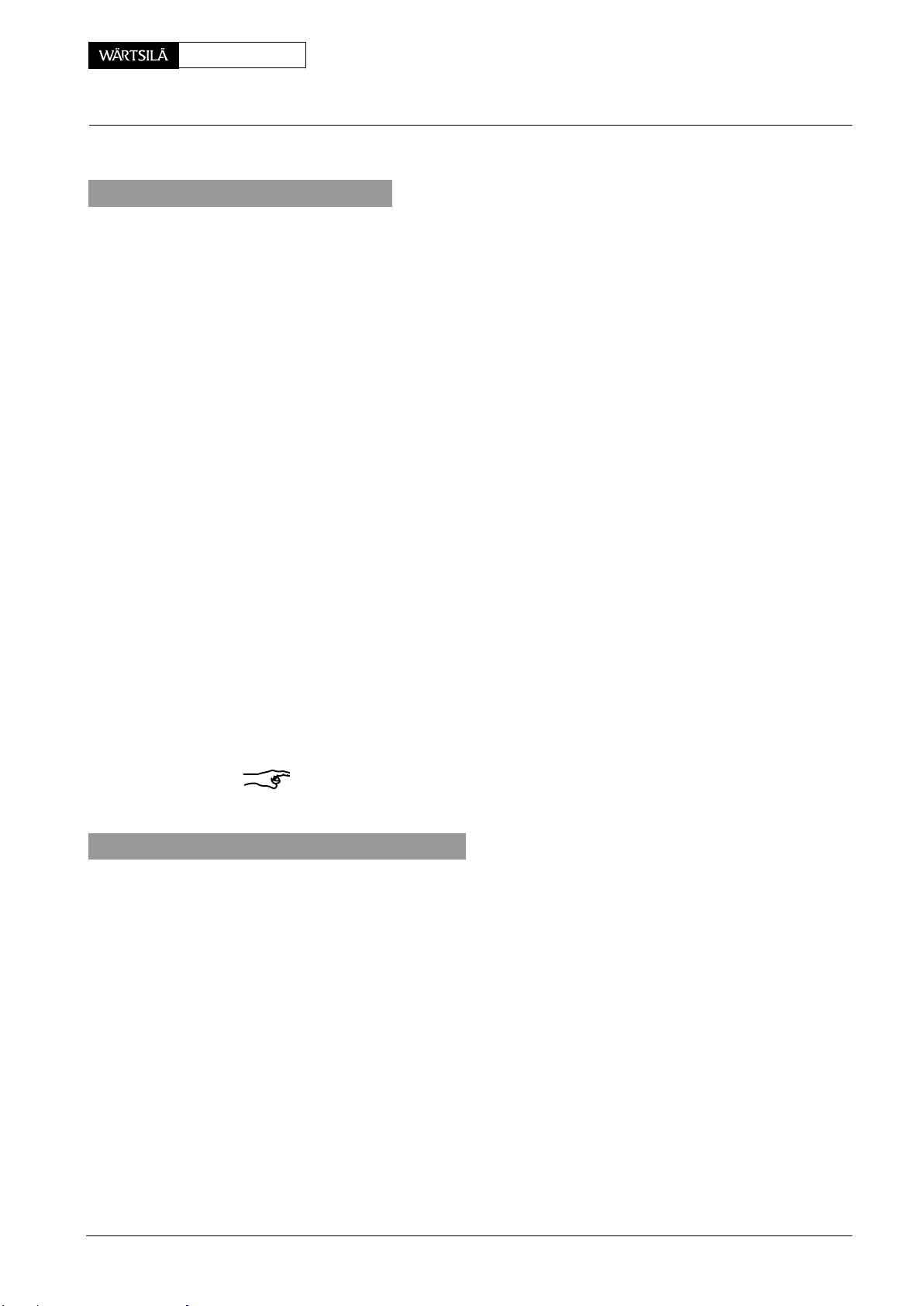

flex Parts:

Fuel Pump Actuator 1

Fuel Pump Actuator 2

Fuel Pump Actuator 3

Maintenance

0008−1/A1

Fuel Pump 1

Fuel Pump 2

Fuel Pump 3

FUEL SIDE

Supply Unit

DRAWN FOR 7 & 8

CYLINDERS

013.149/05

Crank Angle Sensors

Sensor 2

(GT5127C)

Servo Oil Pump 2

Servo Oil Pump 1

DRIVING

END

Sensor 1

(GT5126C)

FUEL SIDE

013.150/05

FREE END

Wärtsilä Switzerland Ltd

3/ 3

2010

Page 20

This page is intentionally left blank

Page 21

RT-flex50-D

G

S

eneral Guidelines for Maintenance

afety Measures and Warnings

Overview

1. General 1/4...............................................

2. General safety precautions 1/4.............................

3. Precautionary measures before beginning of

4. Special safety measures 3/4................................

5. Recommendations for performing work 3/4.................

1. General

The maintenance work which is required to be carried out on the engine at regular

intervals is described in the Maintenance Schedule 0380−1 of this manual and is to

be understood as a general guide. The maintenance intervals are dependent on

the mode of operation, on the power as well as on the quality of the fuel used. Further details are set out in the maintenance schedule.

Experience will show whether the intervals may be extended or need to be shortened.

Strict compliance with the below mentioned recommendations regarding

safety measures and maintenance work is mandatory; the recommendations are not exhaustive.

Maintenance

maintenance work 2/4.....................................

0011−1/A1

2. General safety precautions

D It is the operator’s duty to assure that all personnel is familiar with all safety,

health as well as environment protection rules released for operating and

maintaining a diesel engine plant. In particular greatest attention has to be given to the functioning, handling and dangers of cranes and lifting devices.

D The safety officer has to make sure that all precautions have been taken in

order to avoid dangerous situations.

D The operator has to nominate a person responsible for assigning work tasks

to every person who is participating in maintenance work.

D Make sure that fluids or gases draining or escaping cannot cause accidents,

fires or explosions during maintenance work. Keep the engine and the surroundings clean. Cleanliness increases the quality of the work and helps to

prevent accidents.

Before beginning maintenance work on the diesel engine the corresponding

systems which are influenced by the maintenance work must be relieved of

pressure and/or drained if necessary. A protocol must be established evidencing these activities.

D Certain media, i.e. fuels etc., are highly inflammable, therefore all precaution-

ary measures have to be taken that they do not come into in contact with fires,

glowing or hot parts. Smoking in the engine room is strictly forbidden.

Special attention has to be paid to the rules of fire fighting.

Make absolutely sure that in case of fire alarm no fire extinguishing gases can

be released into the engine room while people are still inside. Emergency escapes are to be marked and personnel is to be instructed of what to do in case

of fire.

Wärtsilä Switzerland Ltd

D Oils and other media can cause slippery surfaces. In order to avoid injury all

surfaces which can be stepped on must be kept clean and dry.

1/ 4

2010

Page 22

Maintenance0011−1/A1 RT-flex50-D

Safety Measures and Warnings

3. Precautionary measures before beginning of maintenance work

Before starting any maintenance work on the engine (particularly on the running

gear), take the following precautionary measures:

⇒ Close the shut-off valves on the starting air bottles.

⇒ Close all the shut-off valves in the control air supply unit, and open the drains

on both air bottles until it is depressurized.

⇒ Close by hand the (automatic) shut-off valve for starting air and open the vent

and drain valve to the main starting air piping on the engine as well as the vent

valves on the shut-off valve for starting air , and leave them in this position until

maintenance work is completed.

⇒ Open all indicator cocks on the cylinder covers and leave them in this position

until maintenance work is completed.

⇒ Engage turning gear (gear pinion must be in engaged position) and lock the

lever (see also 3206−1 and 0750−1 in the Operating Manual).

D Where the engine has been stopped due to overheated running gear or

bearings, wait at least 20 minutes before opening the crankcase doors.

D The crankcase doors must always be locked with all the clamps when-

ever the engine is running, even if this is only for a short time in order to

make temperature checks (e.g. after changing bearings during an overhaul,

etc.).

D In the case of a fire in the engine having been extinguished by means of CO

the spaces affected must be well ventilated before work can be carried out

within them.

Attention! When performing electric welding near or on the engine, electromagnetic fields or peak voltage may occur, which may damage the electronic components of the WECS (W

ärtsilä Engine Control System).

Therefore, prior to performing electric welding in the vicinity of the mentioned components, the following precautions must be taken:

D Stop the engine if it is in operation.

D Power off the electronic system and wait one minute.

D If the welding point is within a radius of two metres from an electronic module

and/or a sensor, disconnect the modules and/or sensors.

D Close the covers of all electric boxes and protect cables, sensors, etc. against

sparking and heat.

,

2

2010

D Shield the check and control units with a conductive material and connect

them to earth.

D Run the welding cable from the welding apparatus directly to the welding point

without any unnecessary loops; also, avoid leading the welding cable parallel

to cables of the electronic control unit.

2/ 4

Wärtsilä Switzerland Ltd

Page 23

RT-flex50-D

Safety Measures and Warnings

4. Special safety measures

D Prior to turning the crankshaft with the turning gear, make sure that no person

D At all times when somebody is inside the engine casing another person must

D The allowed load capacity of the engine room crane, the lifting tools, ropes

Maintenance

is inside the engine and no loose parts, tools or devices can get jammed. Also

bear in mind that the coupled propeller turns too (danger in surroundings).

stand by in order that he can give the necessary aid if something unexpected

happens to the person inside the engine. The person who is inside the engine

casing must be equipped with all safety gears which are required to prevent

suffocation within the limited space and atmospheric conditions. Moreover an

antifall guard must be carried at dangerous places!

and chains must be sufficient for the parts to be lifted (see 0012−1 and

0360−1).

Pay also attention to the weight distribution and attachment of the lifting tackle

in order that the part which must be lifted cannot tip over or crash down!

0011−1/A1

D Sharp edges, mating faces etc. as well as ropes are to be protected by wood-

en pieces, leather or special edge guards which are placed between the part

and the rope or chain.

D Always use gloves, a face shield and wear safety goggles when working with

hydraulic tools.

D For your own safety keep away from under hanging loads, never undersling

hanging parts with your fingers or hands and never embrace lifting ropes with

your hands.

D Removed parts must be secured in the engine room.

D For reasons of safety, openings resulting from removed engine components

must be closed!

Remark: For further instructions see also Safety Precautions and Warnings (General Information) 0210−1 in the Operating Manual.

5. Recommendations for performing work

D Pay attention to Utilization of Working Platform and Ladder 3301−1.

D Carry out all work carefully, observing utmost cleanliness!

D For maintenance work on the engine use the tools and devices intended for

the particular job, which, as a rule, are supplied with the engine (see tool list at

the end of this manual).

Wärtsilä Switzerland Ltd

⇒ Tools and devices must be made ready prior to use, make sure they are in

perfect condition.

⇒ Calibrate gauge tools before using and at periodical intervals.

⇒ Check hydraulic tools periodically for tightness and perfect functioning.

⇒ Protect running faces and sealing faces of removed parts by suitable means

to prevent damages.

3/ 4

2010

Page 24

Safety Measures and Warnings

⇒ Close all openings which form when certain parts are removed e.g. pipes, oil

⇒ Check all repaired, overhauled or replaced parts for perfect functioning before

⇒ Check all pipes which have been removed, for tightness after they are refitted.

⇒ Clearances of moving parts must be checked periodically. Should the maxi-

⇒ Arrange to replace all parts taken from spares stock. When ordering new

D When tightening studs, nuts or screws, take the utmost care not to damage

D Adhere to tightening values wherever they are indicated. Use the specified

Maintenance0011−1/A1 RT-flex50-D

holes etc. to prevent dirt from entering the engine. (This includes also the

pipes which are removed).

starting the engine.

mum permissible values (see Clearance Table 0330−1) have been reached or

even exceeded, these parts must be replaced.

parts refer to the Code Book, mention code numbers and description.

their thread. They must be screwed in by hand until metal to metal contact is

achieved. Always use the specified lubricants on the threads.

lubricant on the threads (see 0352−1 and 0352−2).

D Locking devices of bolts, nuts, etc. must be fitted correctly and secured prop-

erly. Use locking plates and locking wires only once.

D For threads of screws and studs which are getting very hot, (i.e. exhaust pipe

or turbocharger fastenings) apply a high temperature resistant lubricant before assembly, to prevent a heat seizure.

D Used rubber rings must always be replaced by new ones when an overhaul of

any engine component takes place; they must conform in dimension and

quality to the specifications in the 0370−1.

The fitting of piston seal rings and rod seal rings requires the greatest of care

to prevent damage, over expansion or deformation. Before fitting the rings

heat them first in boiling water.

2010

4/ 4

Wärtsilä Switzerland Ltd

Page 25

RT-flex50-D

G

W

eneral Guidelines for Lifting Tools

ire Rope Slings, Span-sets, Eye Bolts, etc.

1. General

The permissible capacities of the engine crane, lifting tools, ropes, chains, lifting

eye bolts, etc. must always correspond with the weights of the parts to be lifted

(see also Masses (Weights) 0360−1).

Remark: The admissible lifting (max. loading) capacity in kg corresponds to the

WLL = W

For fitting and removal of engine components or their transportation, only the tools

which are in perfect condition and intended for this purpose may be used. Ropes

which have begun tearing or otherwise are defective and tools which are damaged

have to be exchanged.

For safe and proper handling of crane, suspension tools or transport of loads we

recommend to proceed as follows for safety reasons:

D Determination of the weight of load

D Determination of the suspension centres and weight distribution

orking Load Limit.

Maintenance

0012−1/A1

2. Attachment elements

2.1 Wire rope slings

2.2 Span-sets

2.3 Eye bolts and eye nuts

D Choice of attachment elements

D Attaching and disconnecting

The lifting capacity of the wire rope slings is listed under their tool number in Tools

List 9403−5.

Span-sets have the advantage of easy and simple handling. The code and the

colour normally indicate the maximum admissible total load. Loops and knots in

the span-sets reduce their lifting capacity by one third.

Only those eye bolts and eye nuts may be used which are in accordance with DIN

580 & 582:2003−08 or which fulfil or exceed these values, including the safety

factor.

All calculations for components and tools where eye bolts and eye nuts are used

are laid out accordingly and based on the mentioned standards.

Wärtsilä Switzerland Ltd

1/ 5

2010

Page 26

Maintenance0012−1/A1 RT-flex50-D

G

eneral Guidelines: Wire Rope Slings, Span-sets, Eye Bolts, etc.

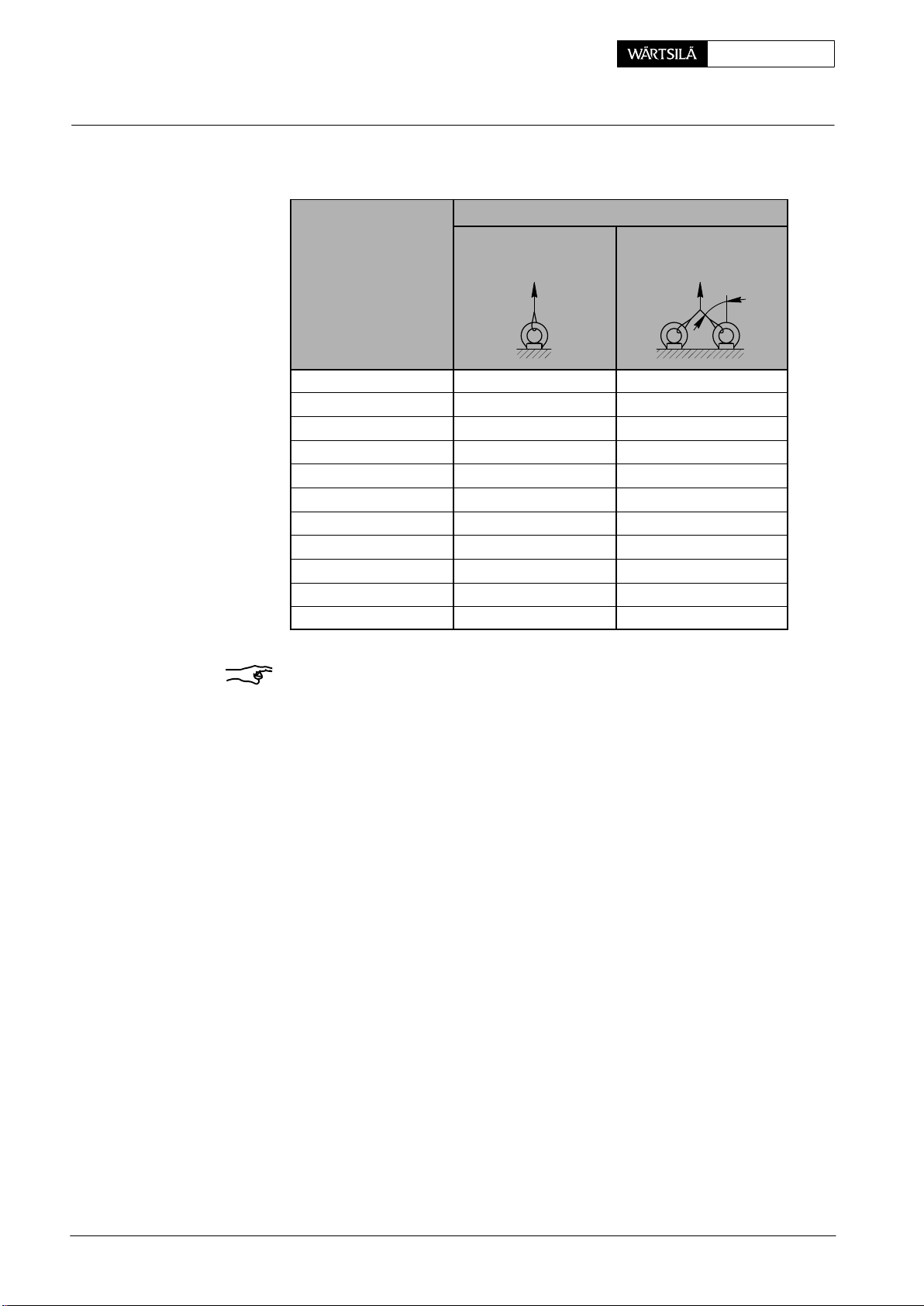

Lifting capacity (for information purposes only):

Eye bolts &

eye nuts,

single-strand double-strand (45°)

Lifting capacity [kg]

thread size

M8 140 100

M10 230 170

M12 340 240

M16 700 500

M20 1200 860

M24 1800 1290

M30 3200 2300

M36 4600 3300

M42 6300 4500

M48 8600 6100

M56 11 500 8300

45

1)

_

Remarks: The details listed in the table above are based on DIN 580 &

582:2003−08, requiring that the eye bolt or the eye nut:

− is completely turned in or screwed down;

− lies flat and fully on the seating surface;

− was checked for visible damages (

1)

−

Full load is only permissible in the direction of the ring, therefore the

eye bolts or eye nuts must be brought to the right position, if necessary by using distance rings.

D If there are through holes, a washer should be placed from the opposite side

under the nut or screw head.

D Whenever possible, do not apply an angle of inclination bigger than 45° (in all

directions with regard to the ring level), and especially avoid lateral pulling!

D For varying use on different objects to be carried, eye nuts or eye bolts with

thread diameters one size higher should be used.

2.4 RUD-eye bolts and RUD-swivel lugs

Only those RUD-eye bolts & RUD-swivel lugs may be used with a safety factor 4.

Manufacturer:

RUD Ketten

Rieger & Dietz GmbH u. Co

Friedensinsel

D−73432 Aalen

Germany

http://www.rud.com

e.g. corrosion, deformation) before using it.

2010

2/ 5

Wärtsilä Switzerland Ltd

Page 27

RT-flex50-D

G

Maintenance

eneral Guidelines: Wire Rope Slings, Span-sets, Eye Bolts, etc.

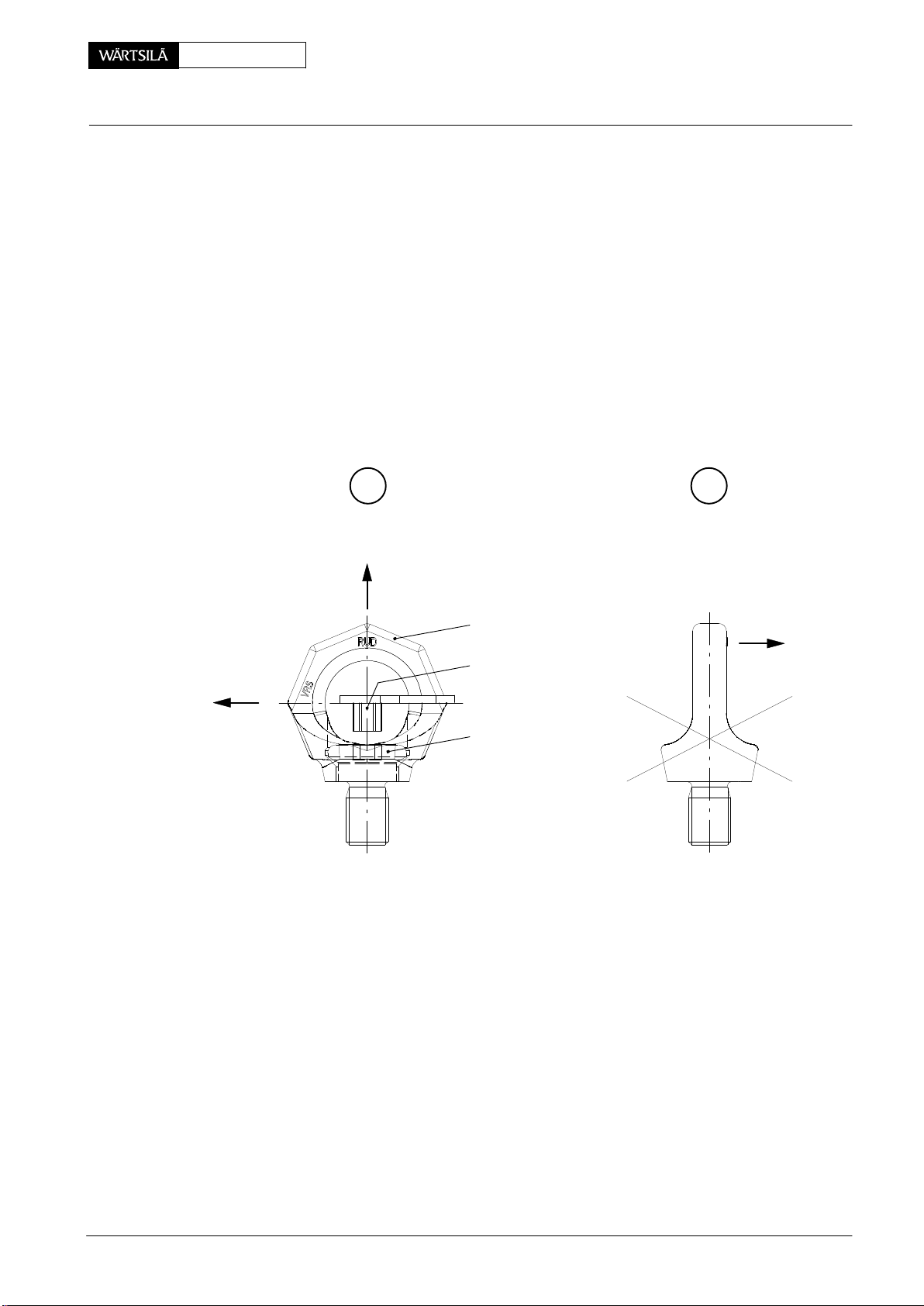

2.4.1 Remarks on the use of RUD-eye bolts

− they must be completely screwed down, lying fully on the seating surfaces.

− they are hand-screwed with their own star-profile wrenches (do not use any

extension).

D In order that after tightening the ring of the RUD-eye bolt is freely rotatable, the

star-profile wrench must be removed from the inner hexagon of the screw as

shown in Fig. ’A’.

D Prior to loading the RUD-eye bolt adjust it in force direction (RUD-eye bolts

are not suitable to be turned under load).

D Lateral loading is permitted in no circumstances! (Fig. ’B’)

0012−1/A1

FORCE

DIRECTION

A

FORCE

DIRECTION

Ring

Star-profile

wrench

Screw

B

FORCE

DIRECTION

013.444/05

Wärtsilä Switzerland Ltd

3/ 5

2010

Page 28

Maintenance0012−1/A1 RT-flex50-D

G

eneral Guidelines: Wire Rope Slings, Span-sets, Eye Bolts, etc.

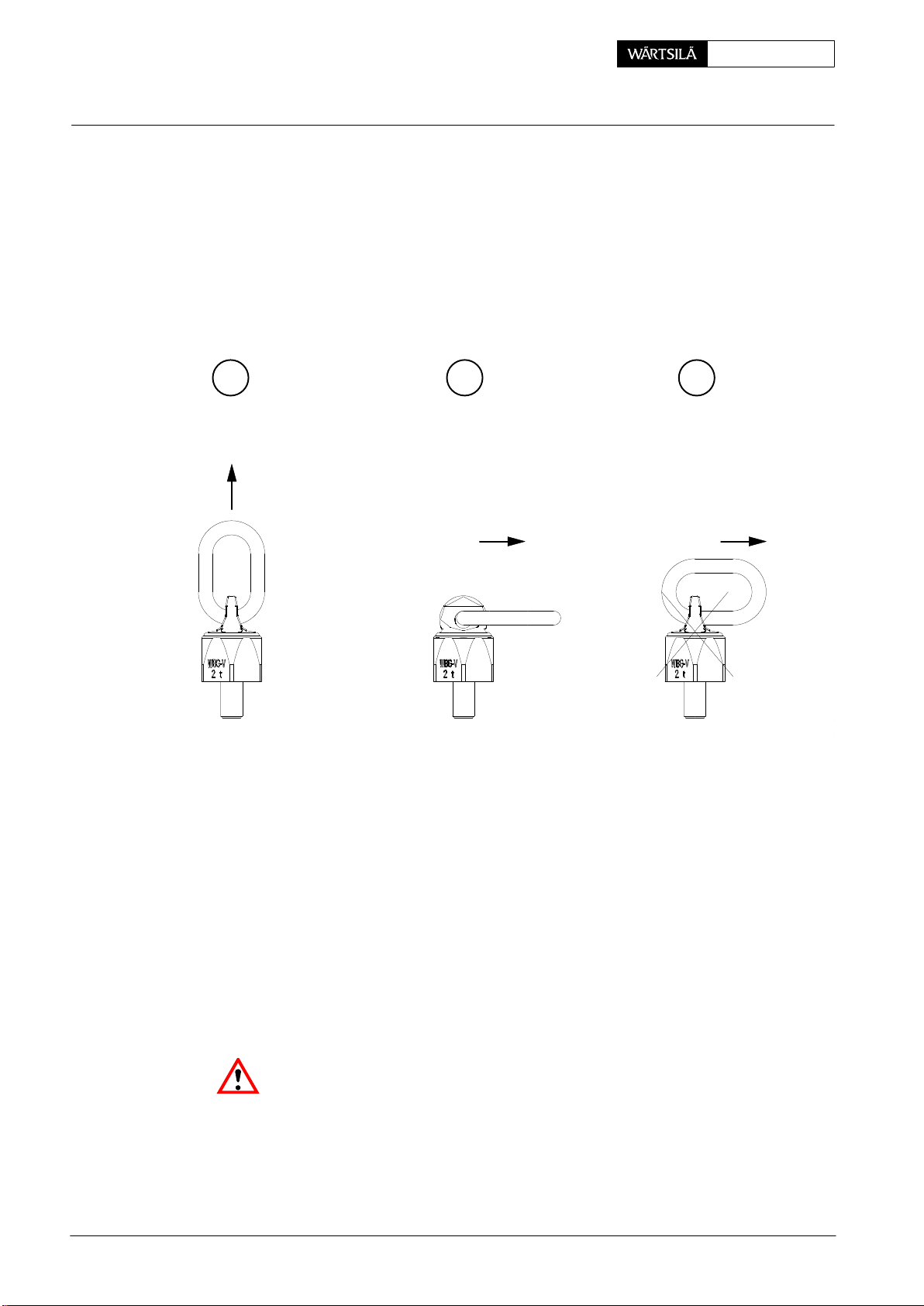

2.4.2 Remarks on the use of RUD-swivel lugs

− they must be completely screwed down, lying fully on the seating surfaces.

− they are hand-screwed with an open end wrench.

D Prior to loading the RUD-swivel lug adjust it in force direction (Fig. ’C’ and ’D’).

D Loading as shown in Fig. ’E’ should be be avoided if possible!

C D E

FORCE

DIRECTION

2.5 Shackles

FORCE

DIRECTION

013.445/05

Only those shackles may be used which are in accordance with American Standard RR−C−271A or which fulfil or exceed these values, including the safety factor .

All calculations for components and tools where shackles are used are laid out accordingly and based on the mentioned standards.

Normally, the permissible lifting capacity of the shackles is specified for one single

strand.

FORCE

DIRECTION

2010

Attention! If tools are combined (e.g. beams with shackles, RUD-eye bolts or

RUD-swivel lugs and ropes, etc.), it is always the weakest element which deter-

mines the maximum lifting capacity (see details in Tools List 9403−5).

4/ 5

Wärtsilä Switzerland Ltd

Page 29

RT-flex50-D

G

Maintenance

eneral Guidelines: Wire Rope Slings, Span-sets, Eye Bolts, etc.

3. Attaching and disconnecting

The following must be observed:

D Distribution of load:

− one strand carries the total of load weight

− two strands carry each one half of the load weight

− four strands carry each one quarter of the load weight if the load is distrib-

uted equally.

D Angle of strand:

− the flatter the strand angle, the more the strand is stressed

− the more acute the strand angle is, the less the strand is stressed.

D Place a soft-wood board between rope and engine component, because the

ropes tend to slide on smooth surfaces (e.g. tubes, shafts).

0012−1/A1

D Protect the ropes against damages by providing a wooden pallet or a rag.

Sharp edges may even cut steel cables!

D If possible always tie down the load. (danger of fall)

D Wrapping the rope twice increases friction and adhesion in such a manner

that even a smooth, oily shaft is sliding less.

D Hemp rope strands, wrapped around the hook, prevent sliding. Do not wrap

steel cables, but cross them instead.

Danger of injuries! For your own safety never stand beneath loads!

Hold the ropes in the flat of your hands and keep your fingers stretched out. Never

seize the load at the bottom, but always lead it laterally. Always put down the loads

on a perfect ground, and use sufficiently sized bases.

Wärtsilä Switzerland Ltd

5/ 5

2010

Page 30

This page is intentionally left blank

Page 31

RT-flex50-D

C

learance Table

Overview

Maintenance

− General 1/25..............................................

− Crankshaft and Thrust Bearing 2, 3/25......................

− Crankshaft and Main Bearing 4, 5/25........................

− Crosshead Guide 6, 7/25...................................

− Cylinder Liner 8, 9/25......................................

− Piston Rod Gland 10, 11/25.................................

− Exhaust Valve 12, 13/25....................................

− Top and Bottom End Bearings to Connecting Rod 14, 15/25...

− Piston Cooling and Crosshead Lubricating Link 16, 17/25.....

− Piston and Piston Rings 18, 19/25...........................

− Driving Wheels for Supply Unit 20, 21/25....................

− Supply Unit 22, 23/25.......................................

− Fuel Pump 24, 25/25........................................

0330−1/A1

1. General

The clearances listed in the column ’Nominal dimension’ of the following table correspond to design and manufacturing values or to the settings on the new engine.

The values listed in the column ’Maximum clearance, dimension’ are such values

as may be reached after a lengthy operating period, which however may not be

allowed to be exceeded or fall below. On components where the clearance is adjustable by modifying the thickness of shims, discs, spacers etc. the value given as

’Normal Clearance’ should always be arrived at, or striven to attain. Where this is

not possible, worn parts must be replaced by standard new ones or reconditioned

by suitable material buildup.

If, during an overhaul, clearances are measured which have almost reached the

permissible limit, it must be left to individual judgement to decide whether a component part should be replaced or remain fitted till the next overhaul. This depends for

example on the duration of the next operation period till the next overhaul and what

wear has to be expected based on experience gained.

Wärtsilä Switzerland Ltd

1/ 25

2010

Page 32

C

learance Table

C

rankshaft and Thrust Bearing

Maintenance0330−1/A1 RT-flex50-D

2

013.025/05

1

2010

2/ 25

Wärtsilä Switzerland Ltd

Page 33

RT-flex50-D

C

C

learance Table

rankshaft and Thrust Bearing

Maintenance

0330−1/A1

1203

1224

Group

Key No.

Description Measuring

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

Maximum clearance,

Thrust bearing

Thrust bearing pad thickness

67

− 0.5

− 0.6

1 Thrust bearing clearance axial (total) 0.8−1.3 2.5

2 Thrust bearing pad, lateral clearance total 6

dimension

(due to wear)

[mm]

Wärtsilä Switzerland Ltd

3/ 25

2010

Page 34

C

learance Table

C

rankshaft and Main Bearing

Maintenance0330−1/A1 RT-flex50-D

1

MAIN BEARING

No. 1

1

018.600/09

MAIN BEARING No. 2

AND FOLLOWING

2

3

018.663/09

2010 / 50−D

4/ 25

Wärtsilä Switzerland Ltd

Page 35

RT-flex50-D

C

C

learance Table

rankshaft and Main Bearing

Maintenance

0330−1/A1

Description Measuring

Group

Key No.

1132 Main bearing No. 1

Crankshaft outer ∅

Main bearing inner ∅ 600

1 Bearing clearance vertical 0.3−0.6 0.9

1132 Main bearing No. 2 and following

Crankshaft outer ∅

Main bearing inner ∅ 600

1 Bearing clearance vertical 0.2−0.5 0.8

All main bearing clearances are only valid with tie rods and main bearing studs

tightened.

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

0

600

− 0.07

0

600

− 0.07

Maximum clearance,

dimension

(due to wear)

[mm]

Wärtsilä Switzerland Ltd

5/ 25

50−D / 2010

Page 36

C

learance Table

C

rosshead Guide

Maintenance0330−1/A1 RT-flex50-D

4 HB4HB

x x

5

5

1

2

6

7

3

013.027/05

FUEL SIDE

2010

6/ 25

Wärtsilä Switzerland Ltd

Page 37

RT-flex50-D

C

C

learance Table

rosshead Guide

Maintenance

0330−1/A1

Description Measuring

Group

Key No.

3326 Crosshead guide

1 Guide way (column) transverse 812

2 Guide shoe transverse

3 Guide shoe clearance 0.20−0.90 1.0

4 Guide rail, lateral clearance total 0.80−1.60 2.0

*5 Guide shoe, lateral clearance total 0.10−0.60

6 Guide shoe, bearing pin outer ∅

Guide shoe, bearing bore inner ∅

7 Bearing clearance radial 0.064−0.145 0.25

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

− 0.20

812

− 0.30

−0

532

− 0.044

+ 0.101

532

0.640

Maximum clearance,

dimension

(due to wear)

[mm]

For measuring of clearances see instructions in 3326−1.

Clearance 3 is only valid with tie rods tightened.

* Clearance 5 refers to spacing between white metal of guide shoe and con-

necting rod and must be measured nearby holding plates ’HB’ which must rest

on crosshead pin at ’x’.

Wärtsilä Switzerland Ltd

7/ 25

2010

Page 38

C

learance Table

C

ylinder Liner

1

2

Maintenance0330−1/A1 RT-flex50-D

3

5

approx. 43 − 75 mm

4

016.555/08

2010

8/ 25

Wärtsilä Switzerland Ltd

Page 39

RT-flex50-D

C

C

learance Table

ylinder Liner

Maintenance

0330−1/A1

Description Measuring

Group

Key No.

2124 Water guide jacket on cylinder

cover

Water guide jacket Ø

1 Clearance total 0.40−0.80

Water guide jacket Ø

2 Clearance total 1.50−1.90

2124 Water guide jacket on cylinder

liner

Water guide jacket Ø 690

3 Clearance total 1.40−1.80

Water guide jacket Ø

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

+ 0.3

706

+ 0.1

+ 1.40

700

+ 1.20

− 0.20

695

− 0.40

Maximum clearance,

dimension

(due to wear)

[mm]

4 Clearance total 0.40−0.80

2124 Cylinder liner

*5 Cylinder liner bore radial 500 503.50

* Pay attention to measuring point!

Wärtsilä Switzerland Ltd

9/ 25

2010

Page 40

C

learance Table

P

iston Rod Gland

Maintenance0330−1/A1 RT-flex50-D

1

4

1

5

6

2

6

6

6

6

013.225/05

3

2010

10/ 25

Wärtsilä Switzerland Ltd

Page 41

RT-flex50-D

C

P

learance Table

iston Rod Gland

Maintenance

0330−1/A1

Description Measuring

Group

2303 Piston rod gland

Key No.

*1 Ring width radial 31 min. 25

*2 Ring width radial 22 min. 20.20

*3 Ring width radial 5 min. 3.20

4 Ring clearance axial 0.10−0.26 0.50

5 Ring clearance axial 0.05−0.16 0.40

6 Ring clearance axial 0.10−0.17 0.40

Nominal

direction

(method of

measuring)

* Ring wear

The differential value between nominal dimension and max. wear is equal for

all rings, i.e. also for undersize rings.

dimension

(normal, new)

[mm]

Maximum clearance,

dimension

(due to wear)

[mm]

Wärtsilä Switzerland Ltd

11/ 25

2010

Page 42

C

learance Table

E

xhaust Valve

Maintenance0330−1/A1 RT-flex50-D

VALVE SPINDLE

GUIDE BUSH

1

2

3

L = LENGTH

~ 1/3 L ~ 2/3 L

012.999/05

2010

12/ 25

Wärtsilä Switzerland Ltd

Page 43

RT-flex50-D

C

E

learance Table

xhaust Valve

Maintenance

0330−1/A1

Description Measuring

Group

Key No.

2751 Valve spindle

1 Spindle outer ∅

2751 Guide bush

*2 Bore inner ∅

*3 Bore inner ∅

direction

(method of

measuring)

* Pay attention to measuring point!

Nominal

dimension

(normal, new)

[mm]

− 0.14

55

− 0.17

+ 0.03

55

0

+ 0.03

55

0

Maximum clearance,

dimension

(due to wear)

[mm]

54.40

55.35

56.20

Wärtsilä Switzerland Ltd

13/ 25

2010

Page 44

Maintenance0330−1/A1 RT-flex50-D

C

T

learance Table

op and Bottom End Bearings to Connecting Rod

1

2

3

2

10 mm

3

10 mm

5

6

5

60 mm

6

60 mm

4

2010

14/ 25

013.028/05

Wärtsilä Switzerland Ltd

Page 45

RT-flex50-D

C

T

Maintenance

learance Table

op and Bottom End Bearings to Connecting Rod

0330−1/A1

Description Measuring

Group

3303

Key No.

Top end bearing

3326

Crosshead pin outer ∅

Bearing inner ∅ 532

1 Bearing clearance vertical 0.20−0.40 0.60

*2 Lateral clearance total 0.40−0.60

*3 Lateral clearance total 0.20−0.40

3303 Bottom end bearing

Crankshaft outer ∅

Bearing inner ∅ 600

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

600

0

− 0.04

4

0

− 0.07

532

Maximum clearance,

dimension

(due to wear)

[mm]

4 Bearing clearance vertical 0.30−0.50 0.65

*5 Lateral clearance total 0.20−0.40

*6 Lateral clearance total 0.30−0.50

* Pay attention to measuring point!

For measuring clearances 1 the crank must be in B.D.C.

Wärtsilä Switzerland Ltd

15/ 25

2010

Page 46

C

learance Table

P

iston Cooling and Crosshead Lubrication

Maintenance0330−1/A1 RT-flex50-D

2

1

013.029/05

2011-12

16/ 25

Wärtsilä Switzerland Ltd

Page 47

RT-flex50-D

C

P

learance Table

iston Cooling and Crosshead Lubrication

Maintenance

0330−1/A1

Description Measuring

Group

Key No.

3603 Piston cooling and crosshead

lubrication

Sleeve inner ∅

Sleeve length

1 Radial clearance total 0.30−0.39 0.42

2 Clearance vertical 0.08−0.20 0.25

Inside (telescopic) pipe outer ∅

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

+ 0.15

56

+ 0.12

− 0.08

115

− 0.10

− 0.18

56

− 0.24

Maximum clearance,

dimension

(due to wear)

[mm]

Wärtsilä Switzerland Ltd

17/ 25

2010

Page 48

C

learance Table

P

iston and Piston Rings

Maintenance0330−1/A1 RT-flex50-D

1

2

9

10

5

6

3

8

7

4

8

C

BA

40

40

l [mm]

16

15

14

13

PISTON RING WIDTH

12

500 501 502 503 504 [mm]

CYLINDER LINER BORE

l

min

l

min N

2010 / 50−D

18/ 25

Wärtsilä Switzerland Ltd

Page 49

RT-flex50-D

C

P

learance Table

iston and Piston Rings

Maintenance

0330−1/A1

Description Measuring

Group

Key No.

3403 Piston crown

1 Crown outer ∅

2 Crown outer ∅

3403

Piston ring grooves

3425

3 Height of the uppermost groove vertical

4 Height of the two lower grooves vertical

5 Groove depth radial 17.50

3425 Piston rings

Ring height vertical

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

495

497.7

15

15

15

0

− 0.2

0

− 0.2

+ 0.38

+ 0.33

+ 0.33

+ 0.28

0

− 0.03

Maximum clearance,

dimension

(due to wear)

[mm]

6 Ring clearance vertical 0.33−0.41 0.63

7 Ring clearance vertical 0.28−0.36 0.58

*8 Ring width radial

3403 Piston skirt

9 Skirt outer ∅

3403 Piston rod

10 Rod outer ∅

16.5 ± 0.25

for Running-in Coated

(RC) piston ring see

diagram on page 18

499.4

200

−0

− 0.2

− 0.050

− 0.096

min. 497.7

min. 199.30

The ring width at positions A, B and C is the decisive criterion for refitting of used

piston rings.

Used piston rings may be refitted if they will keep within their min. ring width till the

next overhaul (for judging and reusing piston rings see also 3425−1).

* Pay attention to measuring point!

Wärtsilä Switzerland Ltd

19/ 25

50−D / 2010

Page 50

3

C

learance Table

D

riving Wheels for Supply Unit

Maintenance0330−1/A1 RT-flex50-D

2

4

1

5

WCH00139

013.030/05

2010

20/ 25

Wärtsilä Switzerland Ltd

Page 51

RT-flex50-D

C

D

learance Table

riving Wheels for Supply Unit

Maintenance

0330−1/A1

Description Measuring

Group

4103 Intermediate wheel

Key No.

1 Shaft outer ∅ 160

2 Bearing clearance vertical 0.082−0.147 0.25

3 Axial clearance total 0.6−1.1 1.5

4 Tooth backlash 0.20−0.33 0.55

5 Tooth backlash 0.28−0.42 0.65

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

Maximum clearance,

dimension

(due to wear)

[mm]

Wärtsilä Switzerland Ltd

21/ 25

2010

Page 52

C

learance Table

S

upply Unit

Maintenance0330−1/A1 RT-flex50-D

6

8

5

4

013.031/05

1327

2010

22/ 25

Wärtsilä Switzerland Ltd

Page 53

RT-flex50-D

C

S

learance Table

upply Unit

Maintenance

0330−1/A1

Description Measuring

Group

Key No.

5552 Supply unit

1 Pinion outer ∅

Bearing (fitted) inner ∅

2 Bearing clearance radial 0.085−0.119

3 Axial clearance total 0.25−0.54 0.7

5552 Camshaft unit

4 Cam shaft outer ∅

5 Bearing clearance radial 0.10−0.19

6 Axial clearance total 0.2−0.5 0.7

7 Tooth backlash 0.12−0.22

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

0

80

− 0.019

+ 0.10

80

+ 0.085

120

0

− 0.022

Maximum clearance,

dimension

(due to wear)

[mm]

*8 Minimum clearance 2

* Minimum clearance between cam and roller with fuel pump cut out.

Wärtsilä Switzerland Ltd

23/ 25

2010

Page 54

C

learance Table

F

uel Pump

Maintenance0330−1/A1 RT-flex50-D

PLUNGER & CYLINDER

A

1

B

3

171 mm 30 mm

C

012.098/04

8

7

2

4

6

5

013.032/05

2010

24/ 25

Wärtsilä Switzerland Ltd

Page 55

RT-flex50-D

C

F

learance Table

uel Pump

Maintenance

0330−1/A1

Group

5556 Fuel pump

5556 Roller guide

Key No.

1 Clearance (plunger / cylinder) A−B radial 0.028−0.030 0.037

Clearance (plunger / cylinder) B−C radial 0.018−0.020 0.027

Guide piston outer ∅ 130

Lower housing inner ∅ 130

2 Clearance radial 0.070−0.125 0.149

3 Piston / lower spring carrier axial 0.02−0.06 0.08

Bush outer ∅ 60

Roller inner ∅ 60

4 Clearance radial 0.06−0.09 0.10

Pin outer ∅ 50

Description Measuring

direction

(method of

measuring)

Nominal

dimension

(normal, new)

[mm]

Maximum clearance,

dimension

(due to wear)

[mm]

Bush inner ∅ 50

5 Clearance radial 0.025−0.08 0.10

Pin outer ∅ 50

Guide piston (bore) inner ∅ 50

6 Clearance radial 0.009−0.050 0.080

7 Axial clearance of bush total 0.2−0.4 0.5

8 Total clearance between guide piston

and roller with pressure discs

axial 0.26−0.54

0.7

Wärtsilä Switzerland Ltd

25/ 25

2010

Page 56

This page is intentionally left blank

Page 57

RT-flex50-D

T

Maintenance

0352−1/A1

ightening Values of Important Screwed Connections

Group Description Thread Tightening values Lubricant

1

1112−1

1132−1

1715−1

1903−1

2

2106 *

2138−1

2708−2

1

[bar]2[Nm]

1

Foundation bolt

(metal and synthetic chocks)

2

Main bearing, nut for waisted stud

3

Engine stay (friction type)

4

Tie rod

(see instructions in 1903−1)

5

Cylinder jacket bolting-up / bolt

*

5

Cylinder jacket bolting-up / fitted bolt

6

Lubricating quill (Pulse Jet), screw

(see instructions in 2138−1)

7

Cylinder cover, nut for waisted stud

M48 1500

1st step 900 bar

nd

step 1500 bar

2

M42

1st step 1000 Nm

nd

step 1500 Nm

2

st

step to 2nd step (20_)

1

M48 310

M72x6 1500

M36

M36

Elongation 0.50± 0.04 mm Oil

Elongation 0.30 ± 0.04 mm Oil

M10x50 10

M56 1500

3

[_(; mm]

(255_)

MOLYKOTE G

Oil

MOLYKOTE G

MOLYKOTE G

Oil

Oil

2722−1

8

Injection valve, screwed connection

with cylinder cover

(see instructions in 2722−1)

9

Injection valve, retaining nut, nozzle

body − nozzle holder

(see instructions in 2722−1 with OBEL test

bench)

2728−1

2745−1

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

10

Starting valve spindle, nut

(spindle thread not to be lubricated in region

of locking ring)

Starting valve, screw

11

12

Indicator valve, screw

f refer to illustrations on pages 7 to 16.

M12 Equally tighten Allen

screws until spring guides

are flush with spring cages

M60x2

1st step 100 Nm

st

step to 2nd step 30_

1

(loosen retaining nut after initial

assembly and then repeat tightening procedure)

M20 140

M20x150

1st step 80 Nm

st

step to 2nd step 90_

1

M20 80

2

MOLYKOTE G

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Wärtsilä Switzerland Ltd

1/ 16

50−D / 2011-12

Page 58

Maintenance0352−1/A1 RT-flex50-D

T

ightening Values of Important Screwed Connections

Group Description Thread Tightening values Lubricant

2751−1

2751−2

3

3103 *

3114 *

3130−2 *

3146−1

3303−1

13

Exh. valve cage, nut for waisted stud

14

Exhaust valve, screw for measuring

1

[bar]2[Nm]

M64 1500

M8 35

3

[_(; mm]

(155_)

Oil

Oil

cone − piston

15

Lower − upper housings, nut for

M16 125

Oil

waisted stud

16

Coupling bolt for flywheel

17

Coupling bolt for propeller shaft

18

Crankshaft − vibration damper, nut

M48

M85x4

M85x4

20_

40_

35_

MOLYKOTE G

MOLYKOTE G

MOLYKOTE G

for coupling bolt

*

19

Crankshaft − counterweight, nut for

M85x4

35_

MOLYKOTE G

coupling bolt

20

Axial damper − bedplate, fixing bolt

21

Connecting rod, stud for top end

bearing

Check: 1st step to 2nd step

M24 (540)

M48x5 1500

1st step 1000 bar (gap = 0 mm)

nd

2

step 1500 bar

45_

(15_)

Oil

Oil

M56x6 1500

1st step 950 bar (gap = 0 mm)

nd

2

step 1500 bar

M27x2 1500

(30_)

(80_)

3403−1

Connecting rod, stud for bottom end

22

bearing

Check: 1st step to 2nd step

23

Piston rod − crosshead, nut to

waisted stud

3403−3

24

Piston rod − piston crown, nut to

M27x2 1500

(115_)

waisted stud

25

Spraying plate − piston rod, waisted

screw

M10x90 1

st

step 15 Nm

1st step to 2nd step 40_

no additional

lubricant required

4

4103 *

Intermediate gear bearing − column,

26

waisted bolt

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

f refer to illustrations on pages 7 to 16.

M30 (1200

2

45_

)

Oil

Oil

Oil

Oil

2010

2/ 16

Wärtsilä Switzerland Ltd

Page 59

RT-flex50-D

T

Maintenance

0352−1/A1

ightening Values of Important Screwed Connections

Group Description Thread Tightening values Lubricant

4103−3

5

5552−2

5552−3

5556−1

5562 *

27

Gear wheel on crankshaft, nut for

waisted bolt to flanged connection

(secured with LOCTITE No. 262)

28

Gear wheel (2-part) on crankshaft

(spare wheel), waisted stud

29

Bearing cover − supply unit, waisted

screw

30

Camshaft − gear wheel, head screw

31

Fuel pump cover − upper housing,

screw

32

Fuel pump − supply unit, screw

33

Fuel pump, bush to lower housing

34

Non-return valve, transition nipple −

fuel rail

1

[bar]2[Nm]

M24x2 (800)

M30x2

Elongation 1.20± 0.06mm

M30 1450

M16 200

M16 115

M24 600

M80x2 200

M36x2 450

3

[_(; mm]

70_

see details in

4103−3

see details in

4103−3

Oil

Oil

Never-Seez

NSBT-8

Oil

see details in

5556−1

Never-Seez

NSBT-8

*

35

Non-return valve, nipple − transition

M36x2 400

nipple

*

36

Non-return valve, screw plug −

M27x2 300

nipple

*

37

Transition nipple

*

38

Pressure transmitter

*

39

Screwed connection to end cover −

M27x2 300

M14x1.5 25

M16 180

fuel rail

*

40

Screwed connection to intermediate

M16 190

piece − fuel rail

5562−1

41

Fuel pressure control valve − inter-

M16 190

mediate piece, screwed connection

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

f refer to illustrations on pages 7 to 16.

2

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Wärtsilä Switzerland Ltd

3/ 16

2010

Page 60

Maintenance0352−1/A1 RT-flex50-D

T

ightening Values of Important Screwed Connections

Group Description Thread Tightening values Lubricant

5564−1

5564 *

5610 *

1

[bar]2[Nm]

42

Injection control unit − fuel rail, screw

43

Injection control unit − fuel rail, screw

44

Screw to pre-control valve

45

Filter holder

46

Connecting nipple

47

Fuel quantity sensor − fuel quantity

M16 110

M12 55

M4 2.5

R ¾”

120

M42x2 350

M8 20

housing, screw

*

48

Fuel quantity housing − intermediate

M10 25

flange, screw

*

49

Fuel quantity sensor − fuel quantity

M12 75

housing, screw

50

Pressure transmitter

G¼”

25

3

[_(; mm]

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Oil

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Oil

*

51

Screwed connection to end cover −

M16 160

servo oil rail

M20 200

M16 170

5612−1

52

Drain screw

53

Exhaust valve control unit − servo oil

rail, screw

54

Cover − valve housing, screw

55

Orifice

56

Oil filter

57

Screw to pre-control valve

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

f refer to illustrations on pages 7 to 16.

M10

M10 10

M33 225

M4 2.5

2

40

Oil

Oil

Oil

Oil

Oil

Oil

Oil

2011-12

4/ 16

Wärtsilä Switzerland Ltd

Page 61

RT-flex50-D

T

Maintenance

0352−1/A1

ightening Values of Important Screwed Connections

Group Description Thread Tightening values Lubricant

8

8447−1

8460−1

8733−1

8752−1

9

9223−1

1

[bar]2[Nm]

58

Screwed connection to servo oil pipe

59

Non-return valve

60

Screwed connection to hydr. pipe

61

Flange − injection valve, screw

62

Fuel pressure piping, screw

*

63

Valve housing − fuel rail, screw

64

Nut to waisted screw

65

Shaft nut

66

Shaft nut

67

Screw to shaft encoder − bearing

M10 & 12 40

G¼”

25

M8x90 20

M10 40

M12 55

M16 150

M16 140

M40x1.5 25

M35x1.5 25

M8 16

3

[_(; mm]

Oil

Oil

Oil

Never-Seez

NSBT-8

Never-Seez

NSBT-8

Never-Seez

NSBT-8

MOLYKOTE G

MOLYKOTE G

MOLYKOTE G

MOLYKOTE G

housing

68

Screw to distance piece

69

Screw to connecting unit − driving

M12 60

M12 60

MOLYKOTE G

MOLYKOTE G

wheel

70

Screw to spring tensioner − coupling

M12 60

MOLYKOTE G

disc

MOLYKOTE G

MOLYKOTE G

9923 *

71

Screw to spring tensioner

72

Connecting unit, adjusting disc −

M10 35

M10 35

coupling disc, screw

9314 *

73

Clamping nut to oil mist detector

*

Screws for opening head of oil mist

74

G ¾”

15

5

detector

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

f refer to illustrations on pages 7 to 16.

2

Oil

Oil

Wärtsilä Switzerland Ltd

5/ 16

2011-12

Page 62

Maintenance0352−1/A1 RT-flex50-D

)

T

ightening Values of Important Screwed Connections

Group Description Thread Tightening values Lubricant

(2124−2)

1

[bar]2[Nm]

3

[_(; mm]

Tools

75

Lifting gear 94202, screw

(see instructions in 2124−2)

M24 200

no additional

lubricant required

Lifting tool 94559 for supply unit

76

*

*

*

*

*

RUD-eye bolt

77

RUD-eye bolt

78

Screw

79

Screw

80

Blank flanges 94569 / 94569a, screw

(see instructions in Operating Manual 5556−2

M24 190

M36 190

M20 450

M20 450

M12x50 /

80

55

Oil

Oil

Oil

Oil

Never-Seez

NSBT-8

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

f refer to illustrations on pages 7 to 16.

2010

2

6/ 16

Wärtsilä Switzerland Ltd

Page 63

RT-flex50-D

T

Maintenance

ightening Values of Important Screwed Connections

0352−1/A1

LIFTING GEAR FOR

CYLINDER LINER

013.633/05

ENGINE STAY

(FRICTION TYPE)

75

013.634/05

3

008.570/01

7

6

4

013.636/05

5

21

22

2626

1

016.589/08a

Wärtsilä Switzerland Ltd

7/ 16

50−D / 2010

Page 64

Maintenance0352−1/A1 RT-flex50-D

9

T

ightening Values of Important Screwed Connections

16

2 17

25

24

23

18

1

018.723/09

28

2010 / 50−D

27

8/ 16

20

016.590/08a

Wärtsilä Switzerland Ltd

Page 65

RT-flex50-D

T

ightening Values of Important Screwed Connections

Maintenance

0352−1/A1

60

15

14

11

10

60

13

61

8

7

61

016.591/08

12

Wärtsilä Switzerland Ltd

9/ 16

9

2010

Page 66

Maintenance0352−1/A1 RT-flex50-D

T

ightening Values of Important Screwed Connections

SUPPLY UNIT

31

30

32

33

016.592/08

013.645/05

29

2010

10/ 16

Wärtsilä Switzerland Ltd

Page 67

RT-flex50-D

T

Maintenance

ightening Values of Important Screwed Connections

0352−1/A1

46

45

FUEL RAIL

49 48 47

I

43 44424041

013.647/05

I

39

63

62

II

013.646/05

II

39 34 35 36

013.648/05

37 38

Wärtsilä Switzerland Ltd

11/ 16

2010

Page 68

Maintenance0352−1/A1 RT-flex50-D

T

ightening Values of Important Screwed Connections

63

62

2010

62

12/ 16

013.649/05

Wärtsilä Switzerland Ltd

Page 69

RT-flex50-D

T

Maintenance

ightening Values of Important Screwed Connections

SERVO OIL RAIL

I

51

I

I - I

0352−1/A1

IV

51

WCH00678

52

55

57

56

50

013.651/05

53

IVIII

54

III

WCH00678

Wärtsilä Switzerland Ltd

13/ 16

2011-12

Page 70

Maintenance0352−1/A1 RT-flex50-D

T

ightening Values of Important Screwed Connections

58

I - I

701.013.655

013.655/05

II

58

013.656/05

59

58

013.654/05

2010

14/ 16

Wärtsilä Switzerland Ltd

Page 71

RT-flex50-D

CRANK ANGLE SENSOR UNIT

02

T

Maintenance

ightening Values of Important Screwed Connections

F

I

0352−1/A1

66

008.566/01

69

65

CONNECTING UNIT TO CRANK

ANGLE SENSOR UNIT

G

72

68

64

I - I

I

010.293/

67

71

70

G

008.750/01

008.567/01

Wärtsilä Switzerland Ltd

15/ 16

2010

Page 72

Maintenance0352−1/A1 RT-flex50-D

T

ightening Values of Important Screwed Connections

013.659/05

74

73

76

LIFTING TOOL

FOR RAIL UNIT

016.593/08

ARRANGEMENT OF BLANK

FLANGES 94569 / 94569a

80

77

80

2010

79

013.658/05

78

16/ 16

016.594/08

Wärtsilä Switzerland Ltd

Page 73

RT-flex50-D

T

Maintenance

ightening Values of Standard Screwed Connections

1. Standard screws

This table is valid for all screws that are not considered in 0352−1.

It is recommended to lubricate the threads for screws which come into contact with