WÄRTSILÄ JOVYSTAR HP 250 kVA, JOVYSTAR HP 800 kVA, JOVYSTAR HP 300 kVA, JOVYSTAR HP 500 kVA, JOVYSTAR HP 600 kVA Operating Manual

...

Operating manual

Wärtsilä JOVYSTAR HP

200-800kVA

BAX 4640 E

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 2 -

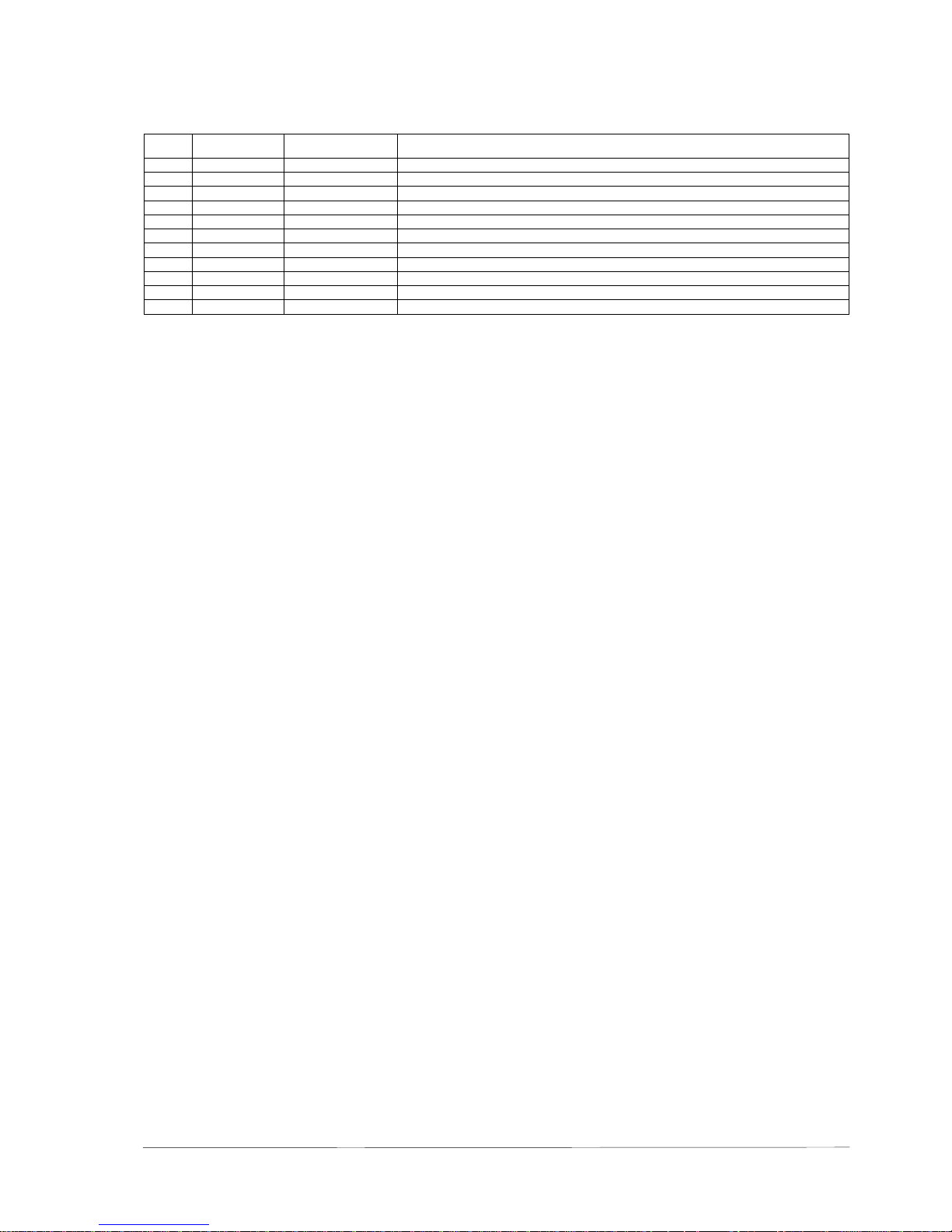

Index

Date

Name

Status

0

07.02.2012

D. Busboom

First edition

1

17.02.2012

D. Busboom

12/084

2

23.02.2012

D. Busboom

12/097

3

15.05.2012

D. Busboom

12/243

4

20.11.2012

D. Busboom

12/551

5

20.04.2015

Chr. Fechteler

15/215

6

26.06.2017

D. Busboom

17/196

7 8

9 10

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 3 -

General notes

Thank you for choosing the Uninterruptible Power Supply (UPS) of the JOVYATLAS JOVYSTAR E-series.

It represents a reliable protection for the attached loads.

Read this instruction carefully

This operating manual includes safety requirements, instructions for installation, as well as working instructions, to assist

you to get the maximum performance out of the UPS.

Keep this instruction on a safe place

It contains important rules for safe operation of this UPS and information for contacting the manufacturer service, in case

of any questions and problems regarding the UPS.

Keeping or recycling of the packing material

The packing material the UPS was projected with great attention in order to protect the UPS from damages during the

transportation. This material is also useful in case of returning the UPS to the manufacturer.

Damages during the transportation are not covered by the manufacturer guarantee.

Obligation to briefing

This operating instruction must be read carefully by all persons working on the UPS prior to installation and initial startup. It must also be read by all persons operating the UPS. This operating instruction is a composite part of the UPS. The

operator of this device is obliged to communicate these instructions to all personnel transporting, installing, operating or

maintaining the UPS.

Validity of this document

This operating instruction comprises the current technical specification of the UPS at the time of publication. The contents is informational only and do not constitute a subject of contract.

Wärtsilä JOVYATLAS EUROATLAS GmbH reserves the right to make modifications with respect to contents and technical data in these operating instructions without prior notification. Wärtsilä JOVYATLAS EUROATLAS is not committed

to continuously update this document and therefore cannot be held liable for any inaccuracies or inapplicable information

in this operation instruction.

Limited guarantee

Our goods and services are subject to the general delivery terms for products of the electrical industry and our general

sales conditions. We reserve the right to change the contents of information with respect to technical data, operation,

weights and dimensions. Claims regarding the delivery of the products should be issued within one week after reception

along with the packing slip. Later claims will not be accepted.

Wärtsilä JOVYATLAS EUROATLAS GmbH will rescind all obligations such as warranty agreements, service contracts

etc. entered into by Wärtsilä JOVYATLAS EUROATLAS GmbH or its representatives without notice in the event of

maintenance and repairs being carried out with anything other than original spare parts.

Use of this document

This operating manual for the UPS is structured, that all necessary work for starting up, maintaining, repairing and operating the UPS can be performed by qualified personnel.

Copyright

No part of this operating manual may be reproduced or transmitted by any mechanical or electronic means without the

express prior written permission of WÄRTSILÄ JOVYATLAS EUROATLAS GmbH.

Copyright Wärtsilä JOVYATLAS EUROATLAS GmbH 2015. All rights reserved.

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 4 -

Table of contents

1 Technical Data 6

1.1 Autonomy Times, Dimensions And Weights 8

2 General Notes 9

2.1 Introduction 9

2.2 Why Using A UPS? 9

3 System description 11

3.1 Rectifier 12

3.2 Inverter 12

3.3 Battery and Battery Charger 12

3.4 Static Bypass 12

3.5 Manual Bypass 12

3.6 Front Panel 12

3.7 Operating status 13

3.7.1 Normal operation 13

3.7.2 Load supplied by bypass due to inverter fault 13

3.7.3 Rectifier failure or mains failure 13

3.7.4 Internal Manual bypass 14

4 Installation 15

4.1 Reception of the UPS 15

4.2 Transport 15

4.3 Setting up 16

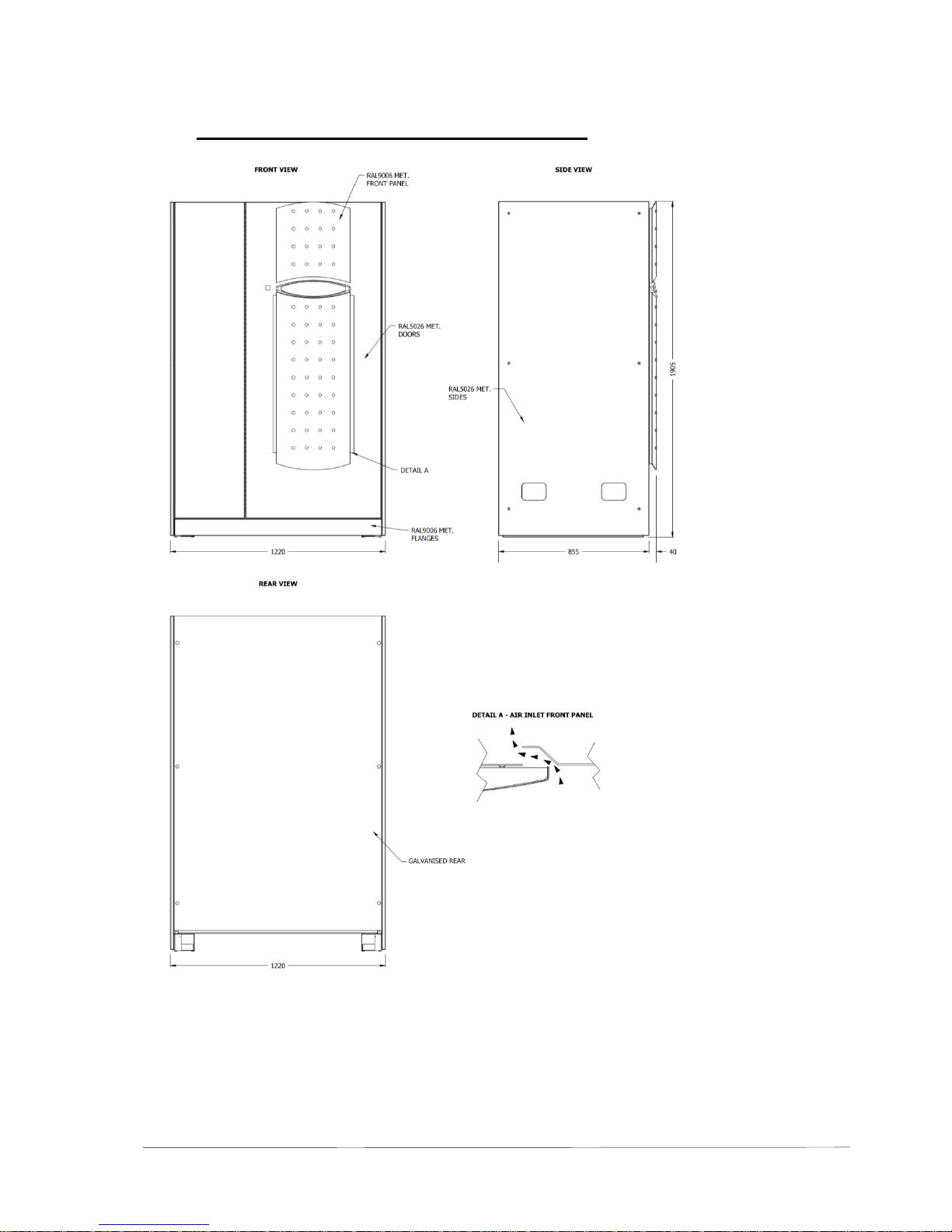

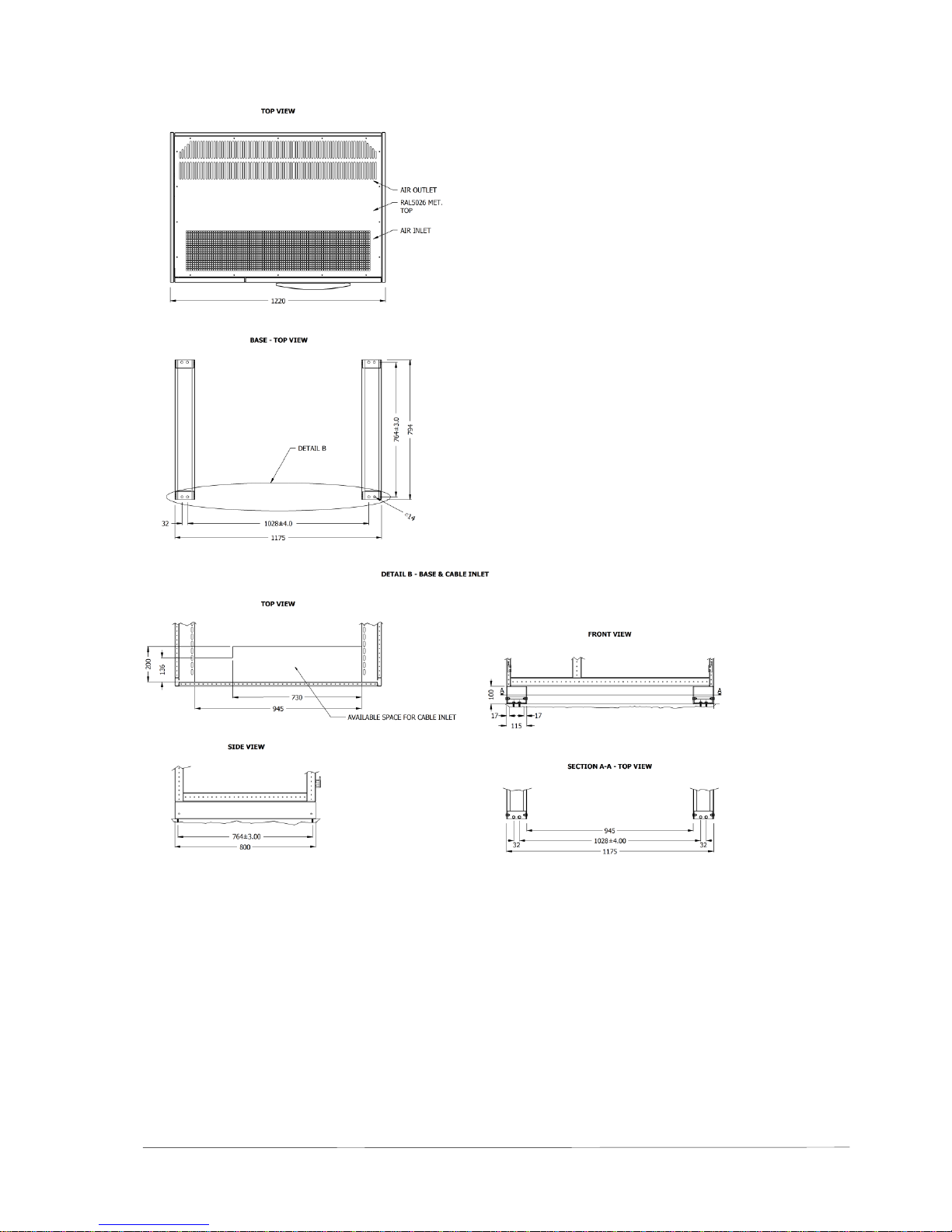

4.3.1 Dimensions Wärtsilä JOVYSTAR HP 200-300 kVA 17

4.3.2 Dimensions Wärtsilä JOVYSTAR HP 400 kVA 19

4.3.3 Dimensions Wärtsilä JOVYSTAR HP 500-600 kVA 21

4.3.4 Dimensions Wärtsilä JOVYSTAR HP 800 kVA 23

4.4 Electrical Connections 26

4.4.1 Terminal Board 27

4.4.2 Internal Connections between both switch cabinets: 30

4.4.3 Battery connection 31

5 Operation 32

5.1 Setting Up 32

5.1.1 Start-up troubleshooting 32

5.2 Shut down procedure 33

5.3 Starting the Parallel Redundant System 33

5.4 Switch Off the Parallel Redundant System 33

5.5 Manual bypass procedure 33

5.5.1 Start-up from manual bypass (Single UPS) 34

5.5.2 Initiation of the Manual Bypass in Parallel Redundant Operation 35

5.5.3 Switch Off the Manual Bypass in Parallel Redundant Operation 35

5.6 Front Panel 35

5.6.1 Mimic description 35

5.7 Menu structure 37

5.7.1 Measures 37

5.7.2 Alarms 39

5.7.3 Special 40

5.7.4 Info 43

6 Options 46

6.1 Parallel redundant system 46

6.1.1 Additional hardware 46

6.1.2 System layouts 46

6.2 Battery symmetry monitoring 46

6.3 Relay PCB 47

6.4 SNMP-Adaptor 47

6.5 Shut-down software 48

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 5 -

6.6 Temperature compensation 48

6.7 MODBUS-Adapter 48

6.8 Manual Bypass for JST HP 400-800 kVA 48

7 Maintenance 49

7.1 Visual checks 49

7.2 Functional test 49

7.3 Inspection of battery 50

7.3.1 Information about battery operation 50

7.3.2 Battery operating instructions 51

8 Status messages and alarms 51

8.1 Measures in case of problems 57

9 Customer service 58

10 Appendix 58

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 6 -

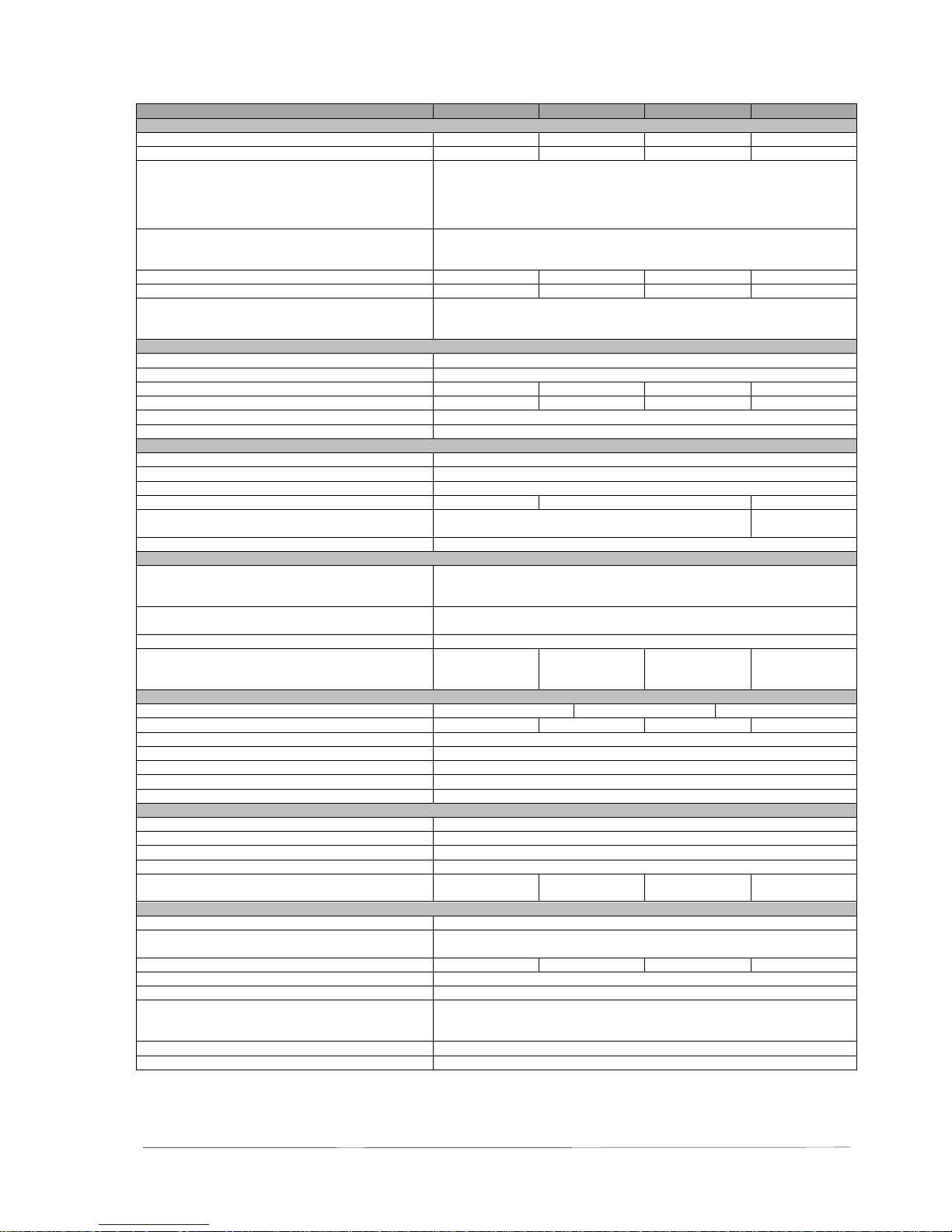

1 Technical Data

Wärtsilä JOVYSTAR HP

Online UPS-Type

200 kVA

250 kVA

300 kVA

Output

Output apparent power (cos φ = 0,9)

200 kVA

250 kVA

300 kVA

Output active power (cos φ = 1)

180 kW

225 kW

270 kW

Rated output voltage

- Tolerance static, symmetric load

- Tolerance static, asymmetric load

- Tolerance dynamic load (20 % → 100 % → 20 %)

- Correction time after load step

3 x 380/220 V 3 x 400/230 V 3 x 415/240 V

±1 %

±2 %

±5 %

< 20 ms

Rated output frequency

- Tolerance at free running quartz oscillator

- Tolerance at inverter-synchronization with mains

50/60 Hz

±0,001 Hz

±2 Hz

Rated output current (cos φ = 0,9)

290 A

362 A

435 A

Rated output current (cos φ = 1,0)

261 A

325 A

391 A

THDU (according to IEC EN 62040-3)

- Linear load

- Non linear load

< 1 %

< 5 %

Input

Input voltage

3 x 400/230 V +15 % -20 %

Input frequency

50/60 Hz ±5 Hz

Input current (at 100 % load, without battery charging)

273 A

341 A

410 A

Input current (at 100 % load, max. battery current)

303 A

383 A

450 A

Input power factor (at 100 % load)

> 0,99

Input current THD (at 100 % load)

< 3 %

Battery

Number of battery cells

300

Compensation charging voltage

680 V (2,27 V/Z)

Cut-off voltage

496 V (1,65 V/Z)

Max. battery charging current (at 100 % load)

30 A

40 A

Max. battery charging current with activated DCM

(Dynamic charging mode, only at partial load)

100 A

Battery charging characteristic

IU (DIN 41773)

Overload capability/Output short circuit characteristic

Overload capability inverter

>100 % to 125 % to 10 min

> 125 % to 150 % to 1 min

> 150 % to 199 % to 10 s

= 200 % for 100 ms

Overload capability static bypass

150 % continuously

1000 % to 1 cycle

Short circuit characteristic (Bypass is available)

Immediate transfer to the bypass

Short circuit characteristic (Bypass is not available)

1. Current limitation to 200 % for 100 ms

2. Current limitation to 125 % for another 5 s

462 A

289 A

580 A

363 A

694 A

434 A

Design/Conformity

Dimensions (W x H x D)

1220 x 1905 x 895 mm

Weight (without battery)

970 kg

1090 kg

1170 kg

Paint

RAL 5026 / RAL 9006

Noise level

< 62 dB

EMV-class according to IEC EN 62040-2

C3

Class of protection according to IEC EN 62040-3

VFI SS 111

International protection

IP 20

Other data

Efficiency normal mode (at 100 % load)

> 95 %

Efficiency battery mode (at 100 % load)

> 96 %

Efficiency eco-mode (Offline-mode)

> 98 %

Max. crest factor without power reduction

3 : 1

Heat dissipation

(at 100 % load and rated input voltage)

11,0 kW

13,7 kW

16,5 kW

Requirements to the installation position

Max. installation altitude without power reduction

< 1000 m

Power reduction for installation altitude according to

IEC EN 62040-3

1 % every 100 m above 1000 m up to 5000 m

Required air cooling volume

3500 m³/h

4100 m³/h

4500 m³/h

UPS operating ambient temperature

0 to +40 °C

UPS storage temperature

-10 to +70 °C

Battery ambient temperature

(recommended battery ambient temperature, see also

battery operating instruction)

0 to +25 °C

+20 °C

Battery storage temperature

0 to +25 °C

Relative humidity (non condensing)

< 95 %

Wärtsilä JOVYSTAR HP E

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 7 -

Online UPS-Type

400 kVA

500 kVA

600 kVA

800 kVA

Output

Output apparent power (cos φ = 0,9)

400 kVA

500 kVA

600 kVA

800 kVA

Output active power (cos φ = 1)

360 kW

450 kW

540 kW

720 kW

Rated output voltage

- Tolerance static, symmetric load

- Tolerance static, asymmetric load

- Tolerance dynamic load (20 % → 100 % → 20 %)

- Correction time after load step

3 x 380/220 V 3 x 400/230 V 3 x 415/240 V

±1 %

±2 %

±5 %

< 20 ms

Rated output frequency

- Tolerance at free running quartz oscillator

- Tolerance at inverter-synchronization with mains

50/60 Hz

±0,001 Hz

±2 Hz

Rated output current (cos φ = 0,9)

580 A

724 A

870 A

1060 A

Rated output current (cos φ = 1,0)

522 A

651 A

783 A

954 A

THDU (according to IEC EN 62040-3)

- Linear load

- Non linear load

< 1 %

< 5 %

Input

Input voltage

3 x 400/230 V +15 % -20 %

Input frequency

50/60 Hz ±5 Hz

Input current (at 100 % load, without battery charging)

550 A

687 A

824 A

1099 A

Input current (at 100 % load, max. battery current)

610 A

767 A

904 A

1220A

Input power factor (at 100 % load)

> 0,99

Input current THD (at 100 % load)

< 3 %

Battery

Number of battery cells

300

Compensation charging voltage

680 V (2,27 V/Z)

Cut-off voltage

496 V (1,65 V/Z)

Max. battery charging current (at 100 % load)

60 A

80 A

120 A

Max. battery charging current with activated DCM

(Dynamic charging mode, only at partial load)

100 A

200 A

Battery charging characteristic

IU (DIN 41773)

Overload capability/Output short circuit characteristic

Overload capability inverter

>100 % to 125 % for 10 min

> 125 % to 150 % for 1 min

= 150 % for 10 s

Overload capability static bypass

150 % continuously

1000 % for 1 cycle

Short circuit characteristic (Bypass is available)

Immediate transfer to the bypass

Short circuit characteristic (Bypass is not available)

1. Current limitation to 150 % for 150 ms

2. Current limitation to 125 % for another 5 s

695 A

579 A

870 A

725 A

1044 A

870 A

1390 A

1158 A

Design/Conformity

Dimensions (W x H x D)

1990 x 1920 x 990 mm

2440 x 2020 x 990 mm

3640 x 1920 x 990 mm

Weight (without battery)

1820 kg

2220 kg

2400 kg

3600 kg

Paint

RAL 5026 / RAL 9006

Noise level

< 60 dB

EMV-class according to IEC EN 62040-2

C3

Class of protection according to IEC EN 62040-3

VFI SS 111

International protection

IP 20

Other data

Efficiency normal mode (at 100 % load)

> 94,5 %

Efficiency battery mode (at 100 % load)

> 96 %

Efficiency eco-mode (offline-mode)

> 98 %

Max. crest factor without power reduction

3 : 1

Heat dissipation

(at 100 % load and rated input voltage)

22,0 kW

27,5 kW

33,0 kW

43,3 kW

Requirements to the installation position

Max. installation altitude without power reduction

< 1000 m

Power reduction for installation altitude according to

IEC EN 62040-3

1 % every 100 m above 1000 m up to 5000 m

Required air cooling volume

3500 m³/h

4000 m³/h

4500 m³/h

7000 m³/h

UPS operating ambient temperature

0 to +40 °C

UPS storage temperature

-10 to +70 °C

Battery ambient temperature

(recommended battery ambient temperature, see also

battery operating instruction)

0 to +25 °C

+20 °C

Battery storage temperature

0 to +25 °C

Relative humidity (non condensing)

< 95 %

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 8 -

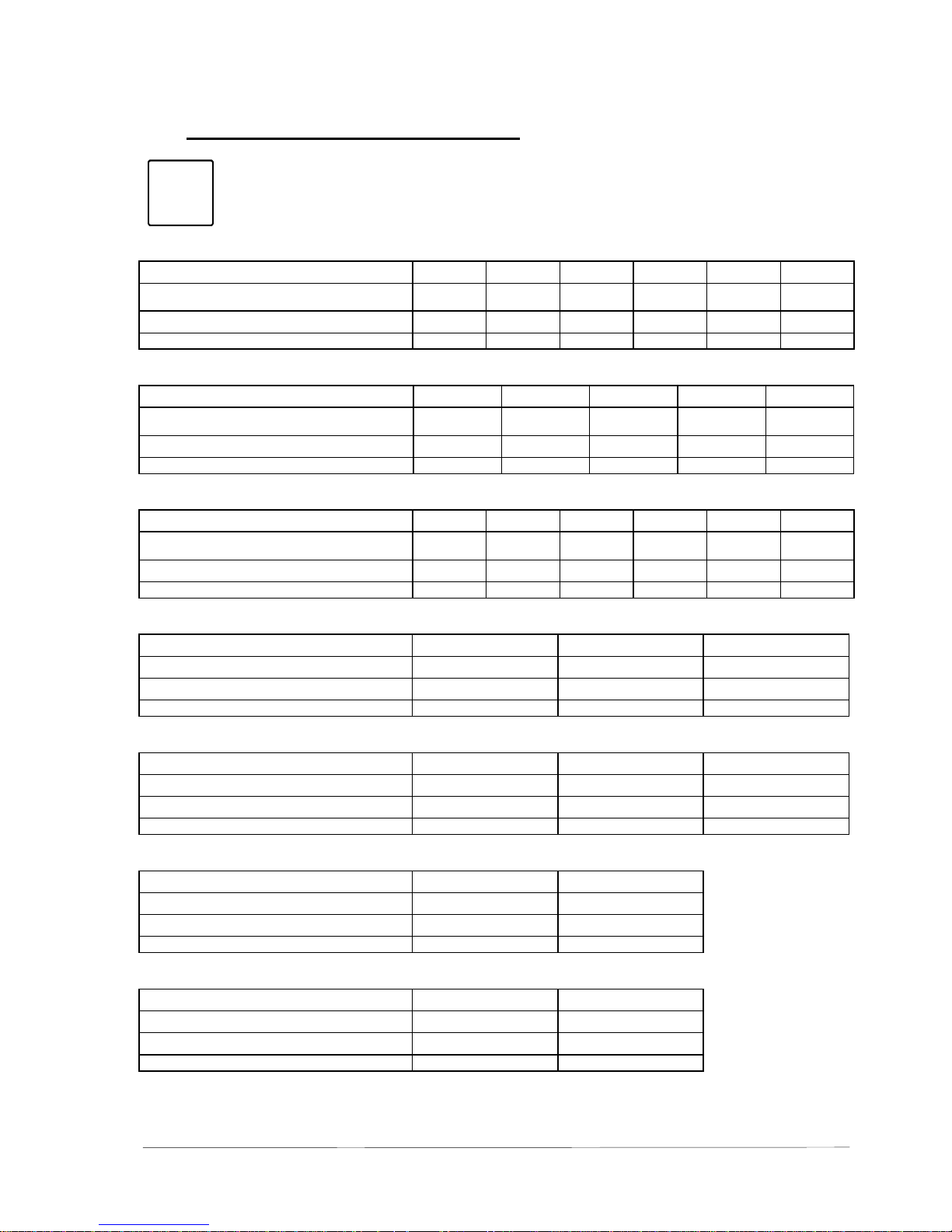

1.1 Autonomy Times, Dimensions And Weights

NOTE:

Up to five charging/discharging cycles are necessary for obtaining the specified autonomy times. Afterwards the battery is well formatted and its maximum capacity is available.

200kVA

Autonomy times [min]

6

13

20

27

40

60

Battery type

50 x

JL205580

100 x

JL205560

100 x

JL205580

100 x

JL205600

150 x

JL205600

200 x

JL205600

Type of battery cabinet

1 x B14

2 x B14

2 x B14

2 x B14

3 x B14

4 x B14

Total weight of battery cabinet [kg]

Ca. 1770

Ca. 2740

Ca. 3530

Ca. 4030

Ca. 6040

Ca. 8050

250kVA

Autonomy times [min]

6

14

25

50

70

Battery type

50 x JL205600

100 x

JL205580

150 x

JL205580

200 x

JL205600

250 x

JL205600

Type of battery cabinet

1 x B14

2 x B14

3 x B14

4 x B14

5 x B14

Total weight of battery cabinet [kg]

Ca. 2020

Ca. 3530

Ca. 5290

Ca. 8050

Ca. 10060

300kVA

Autonomy times [min]

6

11

15

27

40

55

Battery type

100 x

JL205570

100 x

JL205580

100 x

JL205600

150 x

JL205600

200 x

JL205600

250 x

JL205600

Type of battery cabinet

2 x B14

2 x B14

2 x B14

3 x B14

4 x B14

5 x B14

Total weight of battery cabinet [kg]

Ca. 2900

Ca. 3530

Ca. 4030

Ca. 6040

Ca. 8050

Ca. 10060

400kVA

Autonomy times [min]

5

12

20

Battery type

150 x JL205560

150 x JL205570

200 x JL205580

Type of battery cabinet

3 x B14

3 x B14

4 x B14

Total weight of battery cabinet [kg]

Ca. 4200

Ca. 4440

Ca. 7140

500kVA

Autonomy times [min]

6

10

15

Battery type

150 x JL205580

150 x JL205590

200 x JL205580

Type of battery cabinet

3 x B14

3 x B14

4 x B14

Total weight of battery cabinet [kg]

Ca. 5380

Ca. 5710

Ca. 7140

600kVA

Autonomy times [min]

5

10

Battery type

150 x JL205580

200 x JL205580

Type of battery cabinet

3 x B14

4 x B14

Total weight of battery cabinet [kg]

Ca. 5380

Ca. 7140

800kVA

Autonomy times [min]

5

10

Battery type

200 x JL205580

250 x JL205580

Type of battery cabinet

4 x B14

5 x B14

Total weight of battery cabinet [kg]

Ca. 7140

Ca. 8925

All data refer to standard-battery (lifetime 10-12 years)

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 9 -

2 General Notes

It is mandatory to fulfil al works and safety requirements according to rules and instructions described herein for protecting the personnel working at the UPS as well as maintaining optimal duty-cycles of the UPS. All personnel installing/deinstalling, starting up, and maintaining the unit must be familiar with and observe these safety regulations. Only qualified

personnel may carry out the described work with suitable and intact tools, equipment, test equipment and materials.

Important instructions are highlighted by "CAUTION:", "ATTENTION:", "NOTE:" and indented text.

CAUTION:

This symbol identifies all working and operational procedures requiring absolute compliance to avoid any

danger to personnel.

ATTENTION:

This symbol identifies all working and operational procedures requiring absolute compliance to prevent

any damage to the UPS or some of its components.

NOTE:

This symbol identifies technical requirements and additional information requiring the operator's attention.

2.1 Introduction

Congratulations for chosen a UPS out of the JOVYSTAR E series! This type of static UPS incorporates the latest state of

technology in power electronics and digital signal processing. The UPS offers the optimal solution for problems in power

supply of computer-systems. UPS of this series are capable to communicate with different computer operating systems

through a standardized RS232-interface. The necessary software as well as additional hardware like SNMP-adapter or

MODBUS-adapter for remote control of the UPS is available as an option.

JOVYSTAR E UPS are real online systems (UPS-classification VFI SS 111 acc. IEC 62040-3), which prevents the attached loads from mains disturbances like spikes, blackouts and voltage variations. The products are screened by an

effective quality management system.

Therefore the JOVYSTAR E offers a perfect solution for various power supply problems; the reliability of the product is

our major goal since over 60 years of experience in secured power supply and techniques.

The scope of this manual is to describe the UPS and to guide the installer and the user through the correct installation.

The installer and the user will have to read this manual with care and attention and correctly carry-out the instructions

provided, especially those relevant to security according to the local standards and regulations.

NOTE:

The manufacturer declines all responsibility for damages to people or equipment deriving from nonfulfilment of the instructions mentioned in this manual.

2.2 Why Using A UPS?

The reliable power supply is one of the major issues when installing computer-based process controlling systems. The

main reasons of all disturbances are:

- Spikes, produced by switching devices in the mains distribution

- High frequency superposition caused by welding machines, fluorescence radiation, copy machines and other,

- Voltage variations, due to load variations of big inductive consumers, such as lifts, transformers, machines

and others,

- Voltage breakdown, due to disturbances in the mains,

- Frequency variations, caused by using separate power supply units.

The range of disturbances for the attached loads begins with data errors or storing-loss and extends to hardware failure

or even production blackouts. Therefore the quality of power supply is an important factor for the reliability of electronic

data processing equipment or any other sensitive loads.

i

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 10 -

The best solution for a secure and safe power supply of critical loads is the use of an Uninterruptible Power Supply

(UPS). The UPS:

- Generates a constant voltage supply and frequency,

- Filters, respective suppresses mains disturbances down to a negligible value,

- Guarantees an uninterruptible power supply of the attached loads during a mains

failure for a specified period.

The UPS of the series JOVYSTAR E is a system, is being connected between the mains and the load. It always guarantees a secure power supply to the load over a specified period of time. In comparison to conventional power sources

(mains, motor aggregates, generators*)) the main advantages of the JOVYSTAR E series are as follows:

- Optimal quality of the output voltage,

- Prevention from spikes, superposition, transient over-voltages etc.,

- Prevention from voltage variations and mains failures,

- Prevention from frequency variations,

- Low noise,

- Small, compact design,

- Remote control facility by SNMP-Adapter or MODBUS-Adapter (option)

*) NOTE:

The operation of a UPS system or other electronic consumers at a generator assumes that the planner

was informed of whether an interworking of the generator with the power electronics is without problems

possible before the installation of the entire system.

Some generators are so laid out that an operation with power electronic consumers is not possible because of the additional load with harmonics, power factor and commutation notches. In some cases can it

to troubles as tension imbalance, tendency towards oscillations and to the shut-off of the generator come.

Here it can help, to consult the generator manufacturer and to change the regulator of the generator where

appropriate or to make from the first so-called damping windings into the generator.

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 11 -

3 System description

UPS of this series are true on-line, double conversion UPS (classification-code VFI-SS-111); the inverter supplies the

load under normal operating conditions, whether mains is available or not (according to the battery autonomy time).

ATTENTION:

The UPS output is energized even during mains failure, therefore in compliance with the prescriptions of

EN 62040, the installer must label the outlets, plugs or lines supplied by the UPS, making the user aware

of this fact.

This true online concept guarantees great advantage to the user, as it supplies clean, continuously regulated power and

guarantees a stabilized voltage. Thanks to the double conversion principle, the load will be protected from microinterruptions due to excessive mains variation. It prevents damage to the critical load.

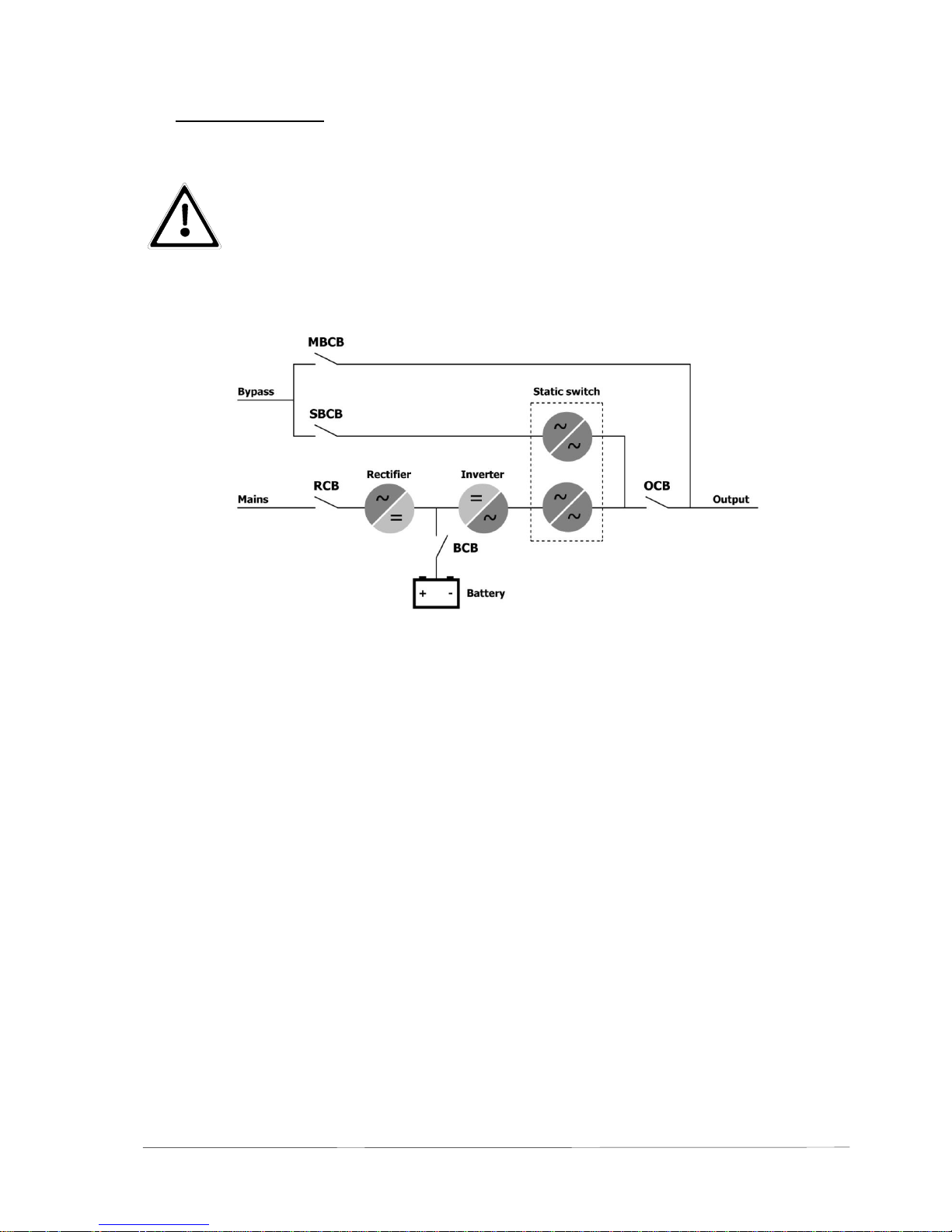

Block diagram

Legend of the block diagram:

Input UPS Input terminals (1L1, 1L2, 1L3, PE.)

Input Bypass Bypass input terminals (2L1, 2L2, 2L3, 2N, PE.)

RCB Rectifier Circuit Breaker

SBCB Static Bypass Circuit Breaker

MBCB Manual Bypass Circuit Breaker; only available at 200-300 kVA as standard

equipment, available at 400-800 kVA as option)

BCB Battery Circuit Breaker

OCB Output Circuit Breaker

UPS Output Output terminals (3L1, 3L2, 3L3, 3N, PE.)

Rectifier The IGBT rectifier converts the input AC-voltage into a regulated DC-voltage supply-

ing the inverter and charging the batteries.

Inverter The inverter converts the DC-voltage delivered by the rectifier or by the battery into

an AC-voltage, regulated by Pulse-Width-Modulation. The output of the inverter is

short circuit proof by electronic short-circuit-protection.

Static Switch The static bypass consists of a thyristor-switch. It switches the mains over to the UPS

output. During normal operation the inverter output is switched to the UPS output

while the bypass is blocked. During overload at the UPS output or an inverter failure

the attached loads will be supplied immediately by the bypass.

Manual Bypass The manual bypass feeds the load in case of maintenance or disturbances of the

UPS. The manual bypass is to be used only by qualified personnel under consideration of the described instructions in this manual!

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 12 -

ATTENTION:

A handling error of the internal or (if applicable) any external manual bypass could lead to a total

blackout at the output of the UPS!

3.1 Rectifier

It converts the three phase voltage of the AC mains into continuous DC voltage. It uses a three phase fully-controlled

IGBT bridge with a low harmonic absorption. The control electronics uses a 32 bit uP of latest generation that allows to

reduce the distortion of the current absorbed by mains (THDi) to less than 5%. This ensures that the rectifier does not

distort the supply mains, with regard to the other loads; it also avoids unlikely overheating of the cables due to the harmonics circulation.

The rectifier is so sized as to supply the inverter at full load and the battery at the maximum charging current.

3.2 Inverter

It converts the direct voltage coming from the rectifier or from the DC battery into alternating AC voltage stabilized in

amplitude and frequency. The inverter uses IGBT technology with a high changeover frequency of approximately 10

KHz. The control electronics uses a 32 Bit uP of latest generation that, thanks to its Processing capability, generates an

excellent output sine-wave.

Moreover, the fully digitized control of the output sine-wave allows to achieve high performances, among which a very

low voltage distortion even in presence of loads with high crest factor currents.

3.3 Battery and Battery Charger

The battery is installed outside the UPS. It is generally housed in an external battery cabinet. The battery charger logic is

completely integrated in the rectifier’s control electronics. The battery is charged, according to the DIN 41773 Standard,

every time it has been partially or completely discharged. When its full capacity is restored, it is kept floating so as to

compensate for any autodischarge.

3.4 Static Bypass

It serves to transfer the load between INVERTER and MAINS, and vice-versa, without interruption, and uses SCR’s as

power commutation elements.

3.5 Manual Bypass

It provides a solution of bypassing the UPS by itself, supplying the load directly by the mains in case of maintenance or

serious failure.

ATTENTION:

The sequence of switching to bypass must be carried out with respect to the procedure indicated on the

UPS and in the chapter “Operating the UPS”. The manufacturer cannot accept responsibility for damages

arising from incorrect operation.

3.6 Front Panel

The front panel of the UPS, consists of a double row alphanumeric display including 5 function keys, allows the complete

monitoring of the UPS status. A mimic diagram helps to understand the operating status of the UPS. For more information see the chapter “Operation”.

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 13 -

3.7 Operating status

The following paragraphs show all the possible operating status of the UPS.

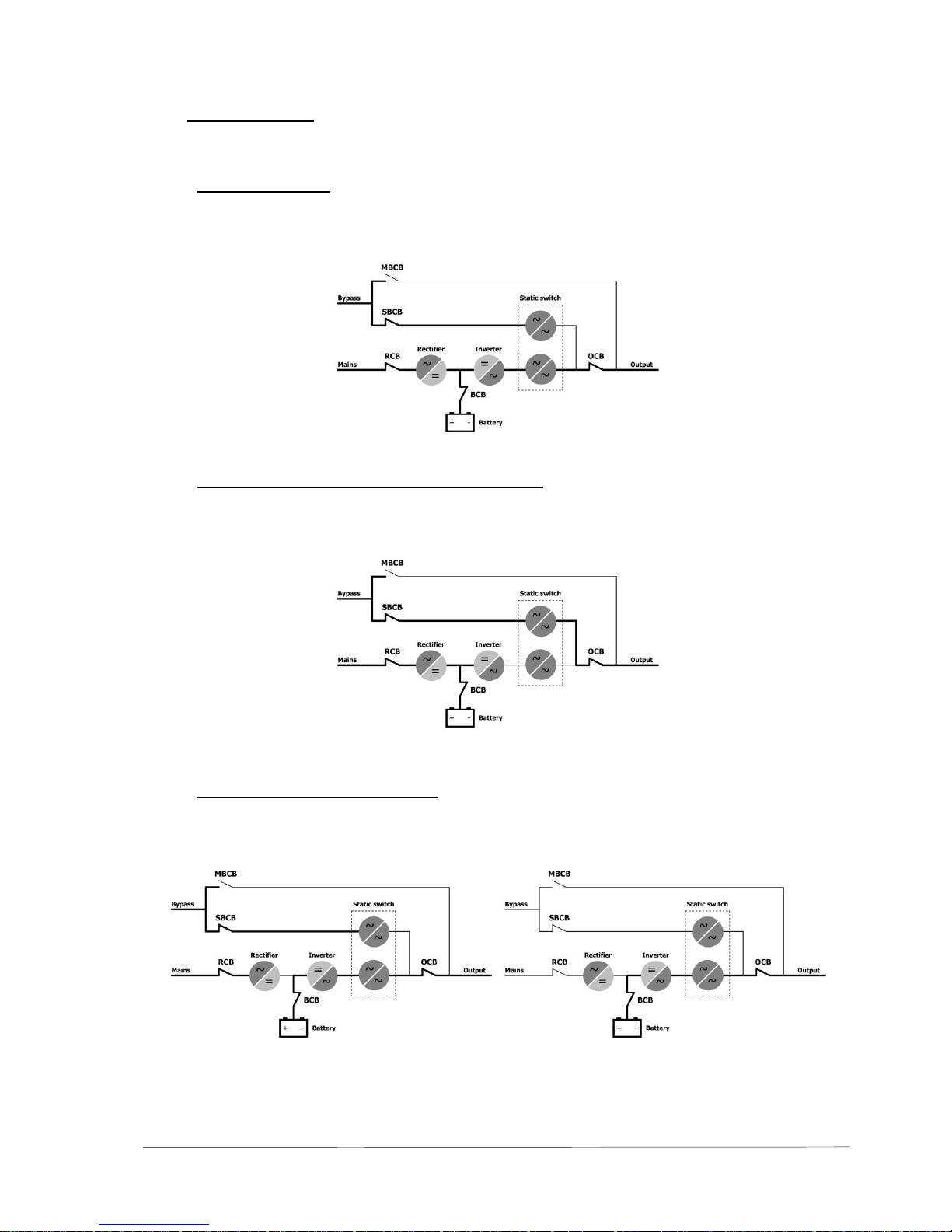

3.7.1 Normal operation

The inverter is supplied by the rectifier, which also charges the battery. The load is supplied by the inverter output directly, via the inverter static switch SSI. The load is in the best conditions in terms of supply Protection.

3.7.2 Load supplied by bypass due to inverter fault

In case of inverter fault, the load is transferred to bypass, emergency line, through the static bypass switch SSB; the

transfer is carried out without interruption.

3.7.3 Rectifier failure or mains failure

The inverter is supplied by the battery for the stated autonomy time; the load, through the inverter static switch SSI, is

supplied directly by the inverter output.

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 14 -

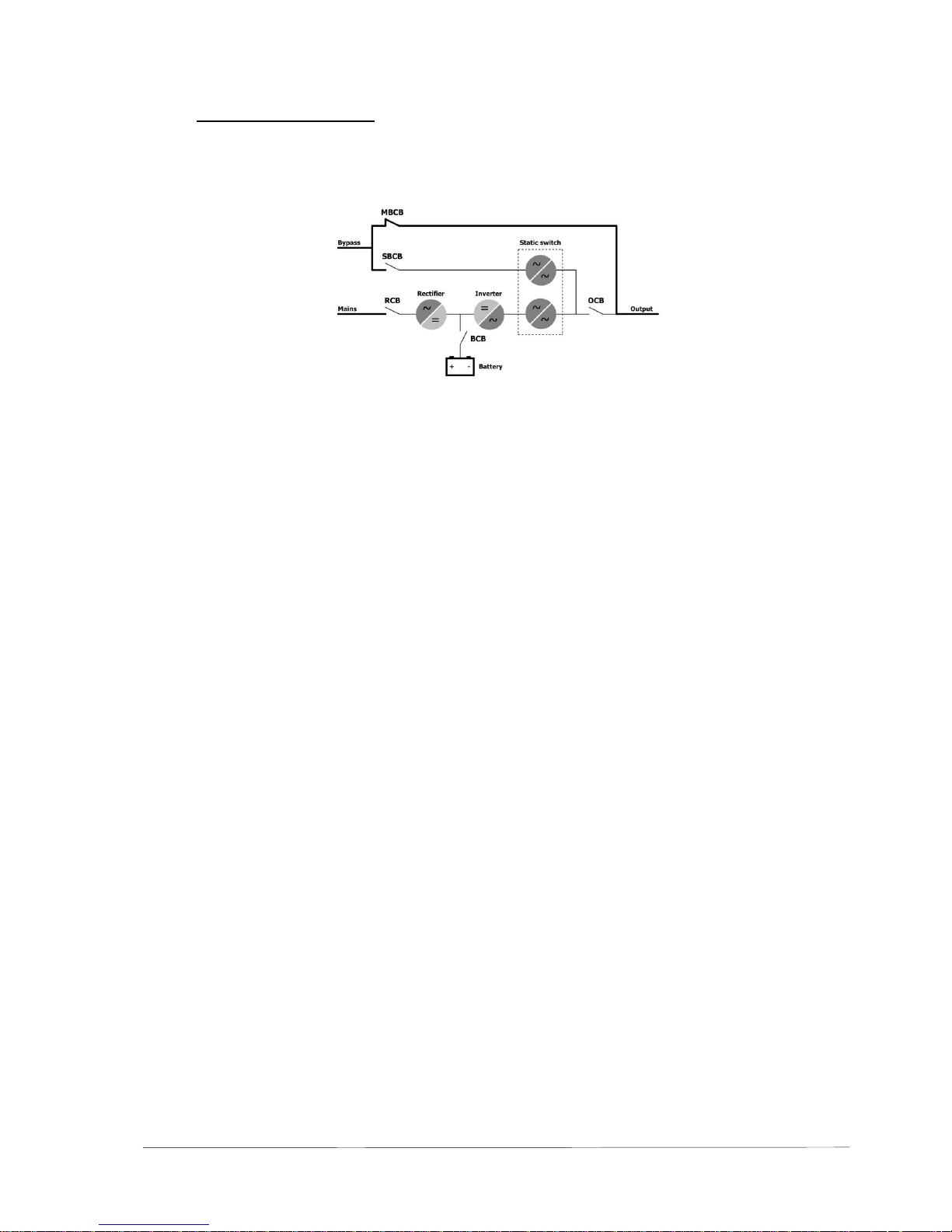

3.7.4 Internal Manual bypass

The load is supplied by the input mains through the manual bypass. The operator can work in safety on the UPS to carry

out maintenance or repairing operations.

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 15 -

4 Installation

4.1 Reception of the UPS

After reception of the UPS, unpack immediately and carry-out an accurate visual check for any transport-damages.

IMPORTANT:

In case of objections relating to damage incurred during transport these must be immediately notified to

the transportation company after reception of the product.

When the UPS is not installed immediately it must be stored carefully in vertical position, as indicated on

the packing and conserved in a dry and sheltered room in its box so that it is protected from dust.

4.2 Transport

Before positioning the UPS, in order to avoid risks of turnover, it is recommended to move the system only while mounted on the wood pallet. Before the positioning in the final location, remove the pallet from the UPS. The UPS can be lifted

and handled using a pallet truck or a forklift.

ACHTUNG:

Paying attention to the center of gravity of the UPS! The brackets must be long sufficient and far enough

from each other stand.

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 16 -

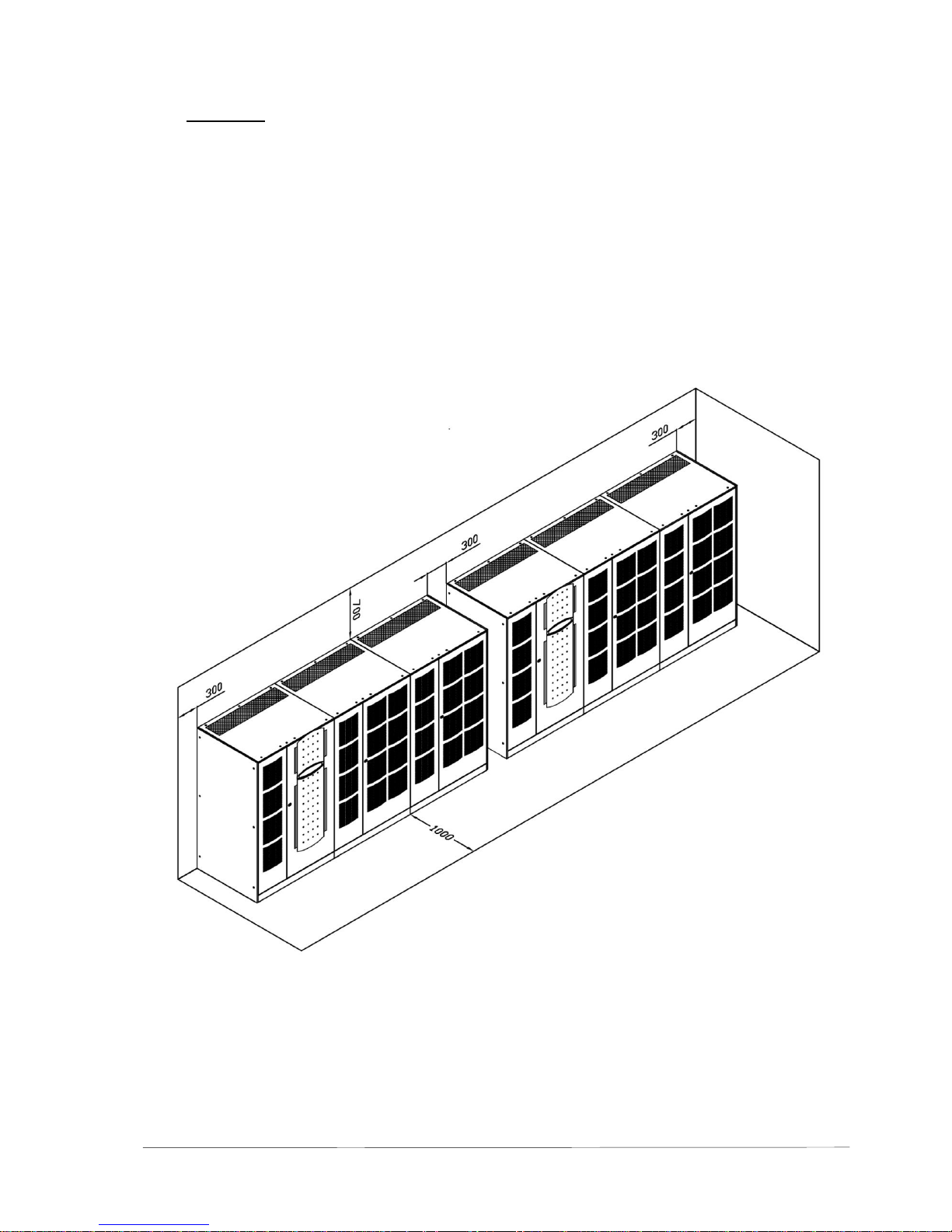

4.3 Setting up

The UPS must be installed in a clean and dry room, preferably not dusty. The user must ensure a proper air conditioning

for cooling the equipment. If the UPS contains the batteries internally the air exchange with the external ambient must

comply with EN 62040, annex N.

Pay attention, that through the weight of the UPS and the batteries the maximum floor loading will not exeeded. You find

informations to the weights and the measurements in the technical data. In addition the site must fulfil the following requests:

- The UPS may be installed only in dry rooms.

- None caustic or acid steam may escape.

- The device supply air temperature may be maximally 40°C.

- Whem batteries are supplied to this UPS installation, the air exchange for these batteries with the external surroundings must according to EN 62040 appendix N.

- The vent holes at the device must not be covered by construction measures or other factors.

- The device is to be protected against direct solar radiation and action of other heat springs.

- The wall- and ceiling-distances as well as the recommended air flow volume (see also technical data) are complying for an optimum cooling of the UPS. An overheating of the system is thus avoided.

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 17 -

4.3.1 Dimensions Wärtsilä JOVYSTAR HP E 200-300 kVA

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 18 -

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 19 -

4.3.2 Dimensions Wärtsilä JOVYSTAR HP E 400 kVA

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 20 -

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 21 -

4.3.3 Dimensions Wärtsilä JOVYSTAR HP E 500-600 kVA

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 22 -

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 23 -

4.3.4 Dimensions Wärtsilä JOVYSTAR HP E 800 kVA

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 24 -

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 25 -

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 26 -

4.4 Electrical Connections

ATTENTION:

Even with switched off mains there is a dangerous high battery voltage inside the UPS. All installations

and connections may only be carried out by qualified technicians. The technician must familiarize himself

with the special features of this UPS by carefully reading and understanding this manual.

Please observe the special notices for connections of a parallel-system.

The work for electrical connection is a part of an electrician who installs the whole electric installation. It is not part of the

UPS manufacturer. For this reason, the following recommendations are only an indication, as the UPS manufacturer is

not responsible for the electrical installation.

In any case we recommend carrying out the installation and the electrical connections to the UPS in accordance to the

local rules and standards.

During the electrical installation make sure a right phase rotation at the three-phase input terminals of the UPS.

In case of strong electromagnetic fields emission it is recommended to use a shielded cable between UPS and the load.

In accordance to EN 62040-1 a mains-feed-back protection has to be provided for the UPS, preventing a current flow

from the output of the UPS back into mains at a single fault of the system. Therefore both the lines for the main input and

the bypass lines have to be fed via a contactor, which opens in case of a mains blackout.

For improving the quality of connection of the UPS flexible cables are recommended. A cable clamp must be provided by

the end-user directly at the structure of the frame or right below the UPS cabinet.

The wire diameters given in the below table refer to a distance of 20m between load and UPS. These values are recommendations only. They have to be recalculated particularly considering the actual environment conditions!

At larger distances the permissible voltage drop, the environmental temperature and the cable grounding have to be

dimensioned according to VDE or local rules. Local rules for the protection ground-wires have to be considered.

The suitable diameters of cables and the sizes of the fuses are to be designed with regard to the environmental temperature, the cable grouping and length of cables according to the local rules and according to VDE.

The terminals are positioned at the lower part of the UPS and they can be accessed by opening the front door.

ATTENTION:

The input lines to the UPS must be fuse protected. The use of residual current switches in the line supplying the UPS is not recommended. The leakage current due to the RFI filters is rather high and it can

cause spurious tripping of the protection device.

If any residual-current-switch has to be used, it is recommended the use of a device with short-time delay for differential currents higher than 300mA.

The following table represents a summary about the current carrying capacity acc. DIN VDE- and EN-rules at an environmental temperature of 30°C. The necessary diameters of cable and the sizes of the fuses are to be designed with

regard to the environmental temperature, the cable grouping and length of cables according to the local rules and according to VDE.

NOTE:

The suitable cable cross-sections and sizes of the fuses must be determined considering the ambient

temperature, the cable grouping and the cable lengths according to the local rules and the local regulations of the electrician or planner. Since the manufacturer of the installation does not know the local

factors, a liability of the manufacturer is impossible concerning the electrical installation.

The given values of cable diameters do not reflect the required diameters of the protective earth cable! They

have to be calculated in accordance to VDE 0100 part 540 or an applicable local rule.

UPS size

200kVA

250kVA

300kVA

Input fuses [AgL]

Rectifier

3 x 315

3 x 400

3 x 500

Bypass

3 x 315

3 x 400

3 x 500

Input cables (mm²)

Rectifier

3 x 185

3 x 240

3 x 2 x 150

Bypass

4 x 185

4 x 240

4 x 2 x 150

Output cables (mm²)

4 x 185

4 x 240

4 x 240

Battery cables (mm²)

2 x 240

2 x 240

2 x 2 x 185

External battery cabinet, circuit breaker / fuses [AgL]*

2 x 400

2 x 400

2 x 500

* applicable for DC-applications

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 27 -

UPS size

400kVA

500kVA

600kVA

800kVA

Input fuses

Rectifier

3x 630AgL

3x 800AgL

3x 1000AgL

3x 1250AgL

Bypass

3x 800AgL

3x 1000AgL

3x 1250AgL

3x 1600AgL

Input cables

Rectifier (1L1-1L2-1L3)

2x3x150mm²

3x3x150mm²

4x3x150mm²

3x3x240mm²

Bypass (2L1-2L2-2L3-2N)

2x4x185mm²

3x4x185mm²

4x4x185mm²

3x4x240mm²

Output cables (3L1-3L2-3L3-3N)

2x4x185mm²

3x4x185mm²

4x4x185mm²

3x4x240mm²

Set value for circuit-breakers( for 3 battery strings)

3x250A

3x315A

3x355A

-

Battery cables (±B1…±B3) ( for 3 battery strings)

3x2x95mm²

3x2x120mm²

3x2x150mm²

-

Set value for circuit-breakers( for 4 battery strings)

4x200A

4x250A

4x315A

4x355A

Battery cables (±B1…±B4) ( for 4 battery strings)

4x2x70mm²

4x2x95mm²

4x2x120mm²

4x2x150mm²

Set value for circuit-breakers( for 5 battery strings)

- - -

5x315A

Battery cables (±B1…±B5) ( for 5 battery strings)

- - -

5x2x20mm²

ATTENTION:

For ensuring the selectivity all fuses should have the utilization category “gL”. When using higher fuse

ratings or circuit breakers a selectivity calculation must be carried out according to the local requirements. For battery fuses a suitable breaking capability must be ensured.

4.4.1 Terminal Board

WARNING:

The UPS requires the neutral of the bypass input only (2N). When using the neutral of the main input too,

both neutrals have to be connected together.

Terminal board 200-300 kVA:

300 (200 kVA) / 195 (250

-300 kVA)

214

3-L1 3-L2 3-L3 3-N 2-L1 2-L2 2-L3 2-N +B -B

(R) (S) (T) (N) (R) (S) (T) (N)

1-L1 1-L2 1-L3

(R) (S) (T)

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 28 -

Terminal board 400 kVA:

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 29 -

Terminal board 500-800 kVA:

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 30 -

4.4.2 Internal Connections between both switch cabinets:

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 31 -

4.4.3 Battery connection

IMPORTANT:

Prior to connecting to any external battery the standard EN62040, par. 4.5 must be observed. For ensuring the maximum lifetime for the battery, according to the statements of the battery manufacturer, the

operating temperature of the battery must be held between 20°C and 25°C. Otherwise the lifetime will be

reduced drastically, even in the case that the battery can work at temperatures of up to 40°C. For preventing of forming explosive gases of hydrogen/oxygen mixtures a suitable air-ventilation has to be installed according to EN62040, Annex N).

It is recommended install the battery, only if the UPS will be able to recharge it. Consider that a battery which is not being

charged within 2-3 months can be irreversibly damaged.

IMPORTANT:

A battery must be maintained periodically. Observe the instruction manual of the battery manufacturer. It

will be found in the annex of this manual.

WARNING:

After switching off the UPS, please open the battery circuit breakers and, if present, the fuses for the

battery symmetry monitoring resp. the charging circuit monitoring fuses. In other case, the power supply

consume a little current from the Battery. After a couple of hours, the battery will be deep discharged.

IMPORTANT:

If the batteries are not supplied in complete battery cabinets, extra fuses or circuit breakers are to be

planned for the battery. Alternatively a BAU (Battery adapter unit) is available as an option.

Type of battery cabinet

B14

Dimensions Width [mm]

Height [mm]

Depth [mm]

1072

1900

910

Weight of cabinet without batteries [kg]

260

Protection degree

IP 20 according to DIN 40050

Protection class

1 according to VDE 0106 / part 1

For information about the connection of a row of battery cabinets please refer to the wiring diagram in annex.

Battery connection 200-300 kVA:

Battery connection 400-800 kVA:

See wiring diagram U88 034 00.VP3 in appendix!

i

i

i

USV

Ext. Batterie-

schrank „1“

Ext. Batterie-

schrank „n“

UPS

Ext. Battery

cabinet „1“

Ext. Battery

cabinet „n“

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 32 -

5 Operation

Prior to carrying out whatever procedure described in this chapter, read carefully the instructions, in order to avoid possible damages to persons or the UPS due to wrong manoeuvre.

5.1 Setting Up

NOTE:

The battery circuit breakers BCB may be switched only when the rectifier is running. Otherwise the rectifier

could be damaged. The BCBs are installed inside the battery cabinets.

Procedure:

Close RCB and wait until display is coming up. Follow the instructions shown on the display to close the circuit breakers

and/or isolator switches as indicated. Do not close any switches before they were not called for that through the display.

If the start-up procedure has been carried out correctly, the display will show:

No.

LCD DISPLAY

ACTION

UPS OPERATION

1

BLANK

Close RCB

2 BOOT LOADING

3

EEPROM READING

4

UPS START UP

WAIT PLEASE

The rectifier is supplied and the DC voltage increases up to the nominal value. All

LED’s in the front panel are lit green. The microprocessor checks all the start-up

conditions are ok. LED’s #1 and #3 are lit green.

5

RECTIFIER START UP

WAIT PLEASE

The IGBT rectifier bridge starts to modulate and the inverter input voltage reaches

the nominal value. LED #3 green light on.

6

INVERTER START

WAIT PLEASE

The inverter bridge starts to modulate and the AC voltage reaches the nominal

value. After a few seconds the static inverter switch closes. LED #5 green light on.

7

BYPASS START UP

CLOSE SBCB

Close SBCB

8

BYPASS START UP

WAIT PLEASE

The microprocessor checks that all the bypass parameters (voltage, phase sequence, frequency) are within the tolerance limits. LED #2 green light on.

9

BATTERY START UP

CLOSE BCB

Close BCB *)

10

BATTERY START UP

WAIT PLEASE

The microprocessor checks that all the conditions for the following steps are ok.

LED #4 green light on.

11

UPS START UP

CLOSE OCB

Close OCB

12

START UP END

WAIT PLEASE

The microprocessor checks that all the output parameters (voltage, current, frequency) are within the tolerance limits. LED #7 green light on.

13

UPS MODEL

OUTPUT POWER

After a short time the default screen is displayed.

*) In this way the battery circuit-breakers are to be closed in the external battery cabinets. If in the installation a battery charging circuit symmetry supervision is built-in, the reset key S1 is to be pressed additional on everyone of the built-in monitorings (see options chapters).

5.1.1 Start-up troubleshooting

This paragraph provides the basic information if any alarms occur during the start-up procedure. In case the problem

cannot be solved contact the service department.

1. After having closed the RCB the LCD display is still blank

a. Check the input phase rotation.

b. Check the rectifier protection fuses; these are installed inside the UPS.

2. After Step #2 the UPS does not go on to Step #3 and displays the alarm A1 – Network failure

a. Make sure alarm A2 is functioning. Check the input phase rotation.

b. Check the rectifier protection fuses F1-F2-F3.

3. After Step #3 the UPS displays alarm messages

a. Open RCB and check the connections.

b. Close RCB and try to restart the UPS.

4. After Step #4 the UPS displays alarm messages

a. Check that the EPO button, if provided on the outside of the UPS, is in the release position

b. Open RCB and control the connections.

c. Close RCB and try restarting the UPS.

5. After Step #5 the display does not go to Step #6 and displays the alarm A15 – BYP NOT AVLB

a. Check the protection fuses of the Bypass static switch; they are installed inside the UPS.

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 33 -

b. Control the phase rotation voltage.

c. Check that the voltage and frequency are within the tolerance limits.

6. After Step #7 the display does not go on to Step #8 and the alarm A7 – BCB OPEN is displayed.

a. Check the battery fuses.

b. Control the inter-connection between the auxiliary contact of the battery switch (in the external cabinet)

and the clamps Bac1-Bac2 of the UPS.

WARNING:

Please contact our Service department after a failure. WÄRTSILÄ JOVYATLAS EUROATLAS does not

take over any liability for late error reports.

5.2 Shut down procedure

Nr.

ACTION

LCD DISPLAY

UPS OPERATION

1

Open OCB

A30 GENERAL ALARM

The supply to the load is interrupted. LED #7 lit orange

2

Open BCB

A30 GENERAL ALARM

The battery is disconnected from the rectifier. LED #4 flashing red light.

3

Open SBCB

A30 GENERAL ALARM

The bypass line is disconnected. LED #2 off.

4

Open RCB

A30 GENERAL ALARM

Booster and Inverter are switched off.

5

BLANK

End of shut down procedure.

CAUTION:

Even at switched off input mains, a dangerous high voltage is still present inside the UPS!

5.3 Starting the Parallel Redundant System

At commissioning of UPS units in parallel-redundant operation the SLAVE-UPS(s) have to be started first exactly in the

same manner it is described for a single unit. The last UPS to be started is the master-UPS.

5.4 Switch Off the Parallel Redundant System

All instructions also apply for parallel-redundant operation.

5.5 Manual bypass procedure

ATTENTION:

Switching the MBCB in a wrong sequence could lead to a blackout for the loads. The use of the manual

bypass is only designated for qualified personnel. Please consult our service department or your dealer

before using the manual bypass!

We strongly point out that the load is not supplied with a secure power-supply when using either the

internal or an external bypass. A mains blackout could lead to an interruption of the power-supply to the

load.

The UPS has to operate synchronously to the mains if you want to activate the manual bypass. This is guaranteed if the

status S5 is active!

Nr.

ACTION

LCD DISPLAY

UPS OPERATION

1

Move the bypass

selector SW to BYPASS

A30 GENERAL ALARM

The load is transferred to the bypass line. LED #5 off, LED #6 lit

orange.

2

Close MBCB

A30 GENERAL ALARM

The inverter is switched off. The load is supplied by the input mains

through the manual bypass switch. The static bypass switch is still

closed. Led #8 lit orange.

3

Open BCB

A30 GENERAL ALARM

The battery is disconnected from the DC bus bar. Led #4 red flashing.

4

Open RCB

A30 GENERAL ALARM

The supply input is opened; the rectifier shuts down. LED #1 off.

5

Open OCB

A30 GENERAL ALARM

The load remains fed by the manual bypass switch. LED #8 off.

6

Open SBCB

A30 GENERAL ALARM

The bypass line is disconnected. The display goes out.

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 34 -

7

BLANK

The load is supplied directly by the mains through the manual bypass

switch. The UPS is isolated.

CAUTION:

Even at switched off input mains, a dangerous high voltage is still present inside the UPS!

NOTE:

The load is powered now by the mains. Any blackout in the mains will lead to a blackout for the loads.

5.5.1 Start-up from manual bypass (Single UPS)

Before the start-up from manual by-pass (after maintenance or repairing) check that the “NORMAL-BYPASS” switch is in

BYPASS position.

Nr.

LCD DISPLAY

ACTION

UPS OPERATION

1

BLANK

Close RCB

2

BOOT LOADING

“BOOT” phase where the UPS firmware can be updated following the

appropriate procedure. All the LED’s on the front panel are on.

3

EEPROM READING

Reading of the configuration parameters stored in the EEPROM.

All the LED’s on the front panel are off.

2

UPS START UP

WAIT PLEASE

The rectifier is supplied and the DC voltage reaches the nominal value.

All the LED’s on the front panel are on.

The microprocessor checks that all the start-up conditions are good for

restart.

Led #1 lit green. Led #8 lit orange.

5

RECTIFIER START UP

WAIT PLEASE

The IGBT rectifier bridge starts to modulate; VDC voltage reaches the

nominal value. LED #3 is lit green: DC voltage present.

6

START UP FROM MBCB

CLOSE BCB

Close SBCB

7

BYPASS START UP

WAIT PLEASE

The microprocessor checks that all the bypass parameters (voltage,

phase rotation, frequency) are within tolerance. Led #2 lit green. The

static bypass switch is closed. LED #6 lit orange.

8

START UP FROM MBCB

CLOSE BCB

Close BCB

Closing of the battery circuit breaker.

Led #4 lit green.

9

START UP FROM MBCB

CLOSE OCB

Close OCB

The load is fed by the static bypass switch. Circuit breaker MBCB is still

closed. Led #7 lit green.

10

START UP FROM MBCB

OPEN MBCB

Open MBCB

The load is fed by the static bypass switch and the inverter can be started. LED #8 off.

11

INVERTER START

WAIT PLEASE

The modulation of the inverter bridge is started. The AC voltage reaches

the nominal value. The microprocessor checks the synchronization with

the bypass line.

12

START UP FROM MBCB

MOVE BYP - SWITCH

Move the selector

“NORMAL-BYPASS” to

NORMAL

The load is transferred to the inverter. Led #5 lit green.

13

START UP END

WAIT PLEASE

The microprocessor checks that all the output parameters (voltage,

current, frequency) are within the tolerance limits.

14

UPS MODEL

OUTPUT Power

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 35 -

5.5.2 Initiation of the Manual Bypass in Parallel Redundant Operation

The procedure must be carried out at every UPS unit:

- Set the service switch into Bypass position, wait and acknowledge the alarm as described for a single UPS

- Close MBCB, wait and acknowledge the alarms as described for a single UPS operation

- Open OCB.

- Open BCB.

- Open SBCB.

- Open RCB

5.5.3 Switch Off the Manual Bypass in Parallel Redundant Operation

Conditions:

- The UPS system is already switched off, the manual bypass MBCB is active.

- The service switch is set in bypass position.

- During start-up check the messages on the display!

Procedure:

… in SLAVE-UPS: - Close the RCB.

after request on the display - Close the SBCB.

after request on the display - Close the BCB.

after request on the display - Close the OCB.

… in both UPS

after request on the display - Open MBCB.

after request on the display - Service switch on “Normal” position.

…(in MASTER-UPS) - Close the RCB.

after request on the display - Close the SBCB.

after request on the display - Close the BCB.

after request on the display - Close the OCB.

5.6 Front Panel

The front panel of the UPS, consisting of a double row alphanumeric display plus 5 function keys, allows the complete

monitoring of the UPS status. The mimic flow helps to understand the operating status of the UPS.

5.6.1 Mimic description

The above picture shows the mimic present on the display, with the names of the circuit breakers/isolator switches of the

UPS. Also the led's and blocks that comprise the UPS are clearly identified.

LED-No.

LED-Display

Description

LED 1

green bright

Mains on rectifier input available and within the tolerance

green flashing

Wrong phase rotation of the input mains

off

Mains fault on rectifier input

LED 2

green bright

Bypass mains available and within the tolerance

green flashing

Wrong phase rotation of the bypass mains

off

Bypass mains fault or bypass mains out of the tolerance

LED 3

green bright

Rectifier on and rectifier output voltage within the tolerance

green flashing

Rectifier off or rectifier fault

red bright

Rectifier outputs voltage out of the tolerance

LED 4

green bright

BCB (Battery-breaker) closed and battery will charged

green flashing

Battery discharging or battery test

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 36 -

orange flashing

BCB (Battery-breaker) opened

red bright

Battery test failed

off

Batterie nicht verfügbar

LED 5

green bright

Inverter outputs voltage within the Tolerance and static switch closed

green flashing

Inverter overload or short circuit

off

Inverter off or inverter outputs voltage out of the tolerance

LED 6

orange bright

Static switch bypass closed

orange flashing

switching over blocked

off

Static switch bypass opened

LED 7

green bright

OCB (Outputs switch) closed

off

OCB (Outputs switch) opened

LED 8

orange bright

MBCB (Manuel bypass switch) closed

off

MBCB (Manuel bypass switch) opened

LED 9

red bright

EPO (Emergency switch) activated

off

Normal mode

LED 10

orange langsam

flashing

Requirement maintenance

orange schnell

flashing

Critical alarm - service contact

off

Normal mode

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 37 -

5.7 Menu structure

5.7.1 Measures

The measured data of the UPS are saved in the main menu under “Measures”. It can be displayed the input,

output and bypass values, as well as data about the assemblies rectifier, inverter and battery.

„UPS-NAME“

MEASURES

„UPS-NAME“

ALARMS

Password-entry is required!

„UPS-NAME“

SPECIAL

„UPS-NAME“

INFO

Sub menu

Display

Voltage is based on N-connector

MEASURES

INPUT

INPUT VOLTAGE

xxx yyy zzz V

INPUT FREQUENCY

xx.x Hz

INPUT POWER

xxx kVA

INPUT

EXIT

Main menu

„UPS-NAME“

xxx kVA

INPUT CURRENT

xxx yyy zzz A

RESET

RESET

Voltage is based on N-connector

MEASURES

OUTPUT

OUTPUT VOLTAGE

xxx yyy zzz V

OUTPUT FREQUENCY

xx.x Hz

OUTPUT POWER

xxx kW

OUTPUT POWER

yyy kVA

OUTPUT CURRENT

xxx yyy zzz A

LOAD

xxx yyy zzz %

RESET

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 38 -

Sub menu

Display

Voltage is based on N-connector

MEASURES

BYPASS

BYPASS VOLTAGE

xxx yyy zzz V

BYPASS

EXIT

Main menu

BYPASS FREQUENCY

xx.x Hz

RESET

Voltage is based on N-connector

MEASURES

INVERTER

INVERTER VOLTAGE

xxx yyy zzz V

INVERTER

EXIT

INVERTER FREQUENCY

xx.x Hz

RESET

MEASURES

AC / DC

AC / DC VOLTAGE

xxx V

AC / DC

EXIT

RESET

MEASURES

BATTERY

BATTERY VOLT/CURR

xxx V xxx A

BATTERY AUTONOMY

xxx Min yyy %

BATTERY TYPE

xx.x Ah

RESET

BATTERY

EXIT

MEASURES

EXIT

OUTPUT

EXIT

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 39 -

5.7.2 Alarms

The menu “Alarms” displays the status of the UPS and the alarms. All active alarms and status reports will be displayed

in the sub menu “UPS Status”. If a fault occurs, the status menu automatically appears and presents the relevant report

on the display. In addition, an acoustic signal will sound, which can be disabled by pressing the buzzer button. Occurred

and removed faults are saved and can be displayed in the sub menu “History” at any time.

(See also list of status reports)

(See also list of alarms)

Star (*) next to fault code means:

Fault was removed at the specified time

„UPS-NAME“

MEASURES

„UPS-NAME“

ALARMS

Password-entry is required!

„UPS-NAME“

SPECIAL

„UPS-NAME“

INFO

Sub menu

Display

ALARMS

UPS STATUS

USV STATUS

(First status report)

Main menu

„UPS-NAME“

xxx kVA

USV STATUS

(Last status report)

RESET

RESET

Fault was detected at the specified time

ALARMS

HISTORY

HISTORY

HISTORY: xxx/yyyy

Code Date/Time

HISTORY

HISTORY: xxx/yyyy

Code* DATE/TIME

RESET

ALARMS

EXIT

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 40 -

5.7.3 Special

Different settings to the UPS can be made in the “Special”-menu. For that a password entry is necessary, to

prevent a change of the system data by unauthorized persons. Then the following settings can be made:

Reset of the UPS, set Date/Time, select language, perform an UPS test, enter battery data, perform a battery test, install new battery, delete history, set modbus address and reset running time.

UPS automatically switches from Inverter

mode to bypass mode and returns

Caution: In bypass fault, an immediate-

ly inverter operating during the test

phase cannot be guaranteed! A failure

of the load is possible!

Change language of the display output

Set date and time

„UPS-NAME“

MEASURES

„UPS-NAME“

ALARMS

Password-entry is required!

„UPS-NAME“

SPECIAL

„UPS-NAME“

INFO

Sub menu

Display

Main menu

„UPS-NAME“

xxx kVA

RESET

SPECIAL

CLOCK SETTINGS

CURSOR-Keys: Selection of a digit (0-9)

RETURN: Confirmation of a digit

RESET: Cancel current selection of digit

and back to previous digit

CLOCK SETTINGS

DD-MM-YY hh:mm

SPECIAL

SELECT LANGUAGE

CURSOR-Keys: Selection of the language

RETURN: Confirmation of the language

More languages

2 – DEUTSCH, 3 – FRANCAIS,

4 – ENGLISH, 5 – PORTUGUES,

6 – ESPANOL, 7 – POLSKI,

8 – TURKCE

SELECT LANGUAGE

1 – ITALIANO

Note: Lower interventions are made in

the system

(Input wrong password: Exit)

CURSOR-Keys: change digit

RETURN: Confirmation of a digit

ENTER PASSWORD

123

Reset of the UPS: Active fault conditions

are reset

SPECIAL

RESET

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

RESET DEVICE?

YES / NO

RESET

RESET

RESET

SPECIAL

UPS TEST

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

UPS TEST

YES / NO

RESET

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 41 -

Caution: The test can affect the supply

of the load if the battery is not fully

charged

Short discharge test of the battery;

“Battery fault” appears, if battery not O.K.

Set the battery properties:

Capacity, charging current, autonomy time

Sub menu

Display

Main menu

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

CONFIRM AUTON BATT?

YES / NO

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

SAVE BATT SETTINGS?

YES / NO

BATT SETTINGS SAVED

SPECIAL

BATTERY SETTING

CURSOR-Keys: Selection of a digit (0-9)

RETURN: Confirmation of a digit

RESET: Cancel current selection of digit

and back to previous digit

BAT CAPACITY SETTING

xxx.x Ah

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

CONFIRM BATT CAP.?

YES / NO

CURSOR-Keys: Selection of a digit (0-9)

RETURN: Confirmation of a digit

RESET: Cancel current selection of digit

and back to previous digit

BAT RECHAR CURR SET

xx.x A

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

CONFIRM RECHAR CURR?

YES / NO

CURSOR-Keys: Selection of a digit (0-9)

RETURN: Confirmation of a digit

RESET: Cancel current selection of digit

and back to previous digit

AUTONOMY BAT SETTING

xxxx min

RESET

(4x)

(2x)

(4x)

SPECIAL

BATTERY TEST

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

BATTERY TEST?

YES / NO

RESET

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 42 -

Reset running time to zero

Set modbus address

Delete history

Sub menu

Display

Main menu

SPECIAL

RESET RUNNING HOURS

SPECIAL

EXIT

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

RESET HISTORY?

YES / NO

SPECIAL

RESET HISTORY

SPECIAL

MODBUS

CURSOR-Keys: Selection of a digit (0-9)

RETURN: Confirmation of a digit

RESET: Cancel current selection of digit

and back to previous digit

(Address range: 1… 247)

MODBUS ADDRESS

xxx

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

RESET RUNNING HOURS?

YES / NO

RESET

RESET

RESET

Set autonomy time of the new installed

battery to 100 %

CURSOR-Keys: Selection YES/NO

RETURN: Confirmation YES/NO

SPECIAL

NEW BATTERY INSTALL

NEW BATTERY INSTAL?

YES / NO

RESET

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 43 -

5.7.4 Info

The menu “Info” include all relevant information of the UPS as the serial numbers (Device and job number),

the device type (Online-/Eco mode and single or parallel system), the device data at a parallel system (Only

active, if available), the modbus address, the versions of the installed firmware, the service remark (Only

active, if available) and the running time.

„UPS-NAME“

MEASURES

„UPS-NAME“

ALARMS

Password-entry is required!

„UPS-NAME“

SPECIAL

„UPS-NAME“

INFO

Sub menu

Display

Main menu

„UPS-NAME“

xxx kVA

RESET

INFO

DEVICE TYPE

Display the device serial number

UPS SERIAL NUMBER

xxxxxxxxxx

Display the job number

OEM SERIAL-NUMBER

xxxxxxxxxx

SERIAL-NUMBER

EXIT

INFO

SERIAL NUMBER

Possibility: On Line/Eco mode

DEVICE TYPE

UPS – ON LINE

Possibility: Single/Parallel

DEVICE TYPE

SINGLE

RESET

RESET

DEVICE TYPE

EXIT

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 44 -

CAN bus statistic static switch:

Number of received data and number of

correctly received data in percent

All UPS devices send data;

All UPS devices receive data

Sub menu

Display

Main menu

Parallel menu only visible, if the UPS

belongs to a parallel system!

POWER: All UPS devices supply the load

REDUNDANT+X: X = Number of the UPS

devices in the parallel-standby mode

Digit = Device number in the parallel

system; M = Master, S = Slave;

? = No communication exists on the data

bus in the parallel system;

[ ] = Identify position/configuration of the

current UPS in the parallel system

Position of the current UPS in the parallel

system/Number of UPS devices in the

parallel system

PARALLEL

x / y

Possibility: Master/Slave

Only a master possible, or faults in the data

communication bus

PARALLEL

MASTER

PARALLEL

EXIT

INFO

PARALLEL

PARALLEL

1- S 2- M 3-[S] 4- ?

PARALLEL

REDUNDANT+X

PARALLEL

CAN STATISTICS SSW

MSG RX: xxxxx xxx.x%

RESET

CAN bus inverter:

Number of received data and number of

correctly received data in percent

Only the master sends data;

Only the slaves receive data

PARALLEL

CAN STATISTICS INV

SYNC RX: xxxxx xxx.x%

CAN bus inverter:

Number of received data and number of

correctly received data in percent

All UPS devices send data;

All UPS devices receive data

PARALLEL

CAN STATISTIK INV

MSG RX: xxxxx xxx.x%

Display the modbus address

INFO

MODBUS

Settable address range: 1… 247

MODBUS

ADDRESS: xxx

RESET

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 45 -

Siehe Kontaktdaten/Service informieren

Service menu only visible, if a service

remark is active

Sub menu

Display

Main menu

See contact data/Notify the service

INFO

SERVICE

FIRMWARE RELEASE

EXIT

SERVICE

---------- Sliding text ----------

SERVICE

EXIT

INFO

RUNNING HOURS

RUNNING HOURS

xxxxxx

RUNNING HOURS

EXIT

Microcontroller of the static switch

FIRMWARE RELEASE

uC S: vv.xx.yy.zz

RESET

RESET

INFO

EXIT

Digital signal processor of the inverter

Digital signal processor of the rectifier

INFO

FIRMWARE RELEASE

FIRMWARE RELEASE

DSP1 R: vv.xx.yy.zz

FIRMWARE RELEASE

DSP2 I: vv.xx.yy.zz

RESET

MODBUS

EXIT

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 46 -

6 Options

6.1 Parallel redundant system

The parallel system can consist of up to 5+1 (redundant parallel) or 6 (power parallel) units. Each unit is equipped with

an additional parallel-redundant kit for controlling the parallel related functions.

In addition to the standard functions such as uninterruptible power supply to the load, total power control and protection

of the load from mains distortion, the parallel redundant system guarantees an uninterrupted power supply even in case

of an internal failure in one of the UPS units.

The current sharing regulation circuitry controls the currents of the “n” units and therefore balances the currents to better

than 10%, under all load conditions. The load supplied by the inverters in parallel may have an instantaneous overload

up to “n x 200%” of the nominal load of the single unit. In case of a failure in one unit, the load is still supplied by the

other units. The load transferred to the static bypass only in case of failure of more than one unit.

NOTE:

For obtaining a balanced load-sharing between the single UPS-systems, it is mandatory to keep the input(i.e. Bypass-) lines as well as the output lines of the single units with the same length to each other and to

the distribution. In cases of extremely short length of wires, and also in cases of a very high diameter of the

cables, it is possible, that the load sharing between the single units is weak. In these cases an adjustment

at the final operating place of the units will be necessary.

6.1.1 Additional hardware

To transform “n” standard units into a parallel redundant system the following additional hardware is required:

“n” PCB SLOT-PAR (PB214)

“n” CANBUS-Cable (SUB-D9, 1:1)

The outputs of the “n” units must be connected in parallel to the load bus bar. “n” is the number of the UPS systems in

parallel.

NOTE:

The standard units must be special programmed to work in parallel redundant. Please contact our service

department!

6.1.2 System layouts

The parallel redundant system has better static and dynamic performances in comparison to a single unit since, owing to

the redundancy, the total amount of power available his higher than the nominal load of the overall system.

Overload

The overload limit of a parallel redundant system depends on the number of the units which are connected to the load:

Imax = n x In, where “n” = number of the units, “In” = nominal current of each unit.

If the load exceeds this limit the thermal image protection is activated and, after a certain time the load is transferred to

bypass (if available).

Short circuit

In case of a short circuit at system output the load is transferred to bypass (if it is available).

6.2 Battery symmetry monitoring

The correct charging of the batteries are monitored by the PCB P0037401. In case of more than one ropes, each rope

must have is own monitoring-module. The following faults will be detected:

- Asymmetrical voltage between the battery blocks in a row (e.g. a defective battery cell within one block)

- In case of using voltage sensors connected directly to the output terminals of the charger, am open line as well as a

too high impedance will be detected.

These problems might arise as a matter of corrosive contacts defective battery fuses or weak contacts.

In case of a detected fault, the red LED V9 on the PCB will light up. In addition the UPS will signalize „BCB open“ due to

the fact that a relay contact is connected in a row together with the monitoring contact of the BCB.

After fixing the fault the monitoring circuit has to be reset by pushing the reset button S1 on the PCB.

i

i

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 47 -

NOTE:

When starting up the UPS this PCB has also to be reset when a message for closing the BCB appears.

CAUTION:

Even at switched off input mains, a dangerous high voltage is still present inside the UPS!

The interconnection of the battery symmetry monitoring PCB is shown in a wiring diagram in annex.

6.3 Relay PCB

The relay PCB is used to for transferring alarm and status messages to a remote location.

Alarm PCB

The currently used definition of the contacts and LED is at hand on a adhesive label adjacent to the PCB.

The default setting is as follows:

Relay

Description

Alarm / Status

Contacts

RL1

Collective fault

A30

1 – 2 closed

RL2

Mains fault

A01

4 – 5 closed

RL3

Battery discharged

A09

7 – 8 closed

RL4

Inverter out of tolerance

A13

10 – 11 cosed

RL5

Load supplied by bypass

A16

13 – 14 closed

RL6

Rectifier OK

S01

16 – 17 open

RL7

Load supplied by inverter

S04

19 – 20 open

RL8

Bypass OK

S06

22 – 23 open

6.4 SNMP-Adaptor

The standard UPS can be monitored by using an SNMP-adaptor. It is provided with two serial interfaces. Interface COM1

is for communication with the UPS of WÄRTSILÄ JOVYATLAS EUROATLAS. Interface COM2 is for configuration purposes, for connection of an additional (special) modem or for MODBUS-applications.

CHARACTERISTICS:

- 32-Bit RISC-processor, 8MB-RAM, 4MB Flash

- supported protocols: SNMP, HTTP, Telnet, UPSMON, PPP/ SLIP, SMTP und FTP

- 10/100 Mbit Ethernet-connection

- 2 serial RS-232 Interfaces

- Integrated WEB-Server

- Visualisation by UPSMON, JAVAMON, UNMS, NMS, WEB-Browser or TELNET

- Support UPS-MIB RFC1628

- To be updated through the network

- Fits to all JOVYATLAS UPS-series

The connection of a SNMP adaptor is shown in diagram X0012400.VP3 in appendix.

i

i

CN1

PB218002A

PB218004A

M1

1 3 5 7 9 11 13 15 17 19 21 23

2 4 6 8 10 12 14 16 18 20 22 24

DL1 DL2 DL3 DL4 DL5 DL6 DL7 DL8

RL1 RL2 RL3 RL4 RL5 RL6 RL7 RL8

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 48 -

6.5 Shut-down software

A controlled shutdown of computer-systems which are being attached to the UPS is possible by using a shutdownsoftware. Using this option either the relay-PCB, a SNMP-adaptor or a direct connection between the PC and the serial

interface is necessary. The shutdown software is available for various operating systems. Please contact our sales department for further details. Please provide information about the operating system, the type and amount of PC’s being

used.

6.6 Temperature compensation

With this option the charging voltage for the battery can be regulated by means of the temperature. A sensor is placed

adjacent to the battery and connected to the rectifier of the UPS. The battery charging voltage gets reduced about –

1mV/°C per cell, e.g. a Ups with a 192 cell battery will therefore reduce the charging voltage of about -192mV/°C. The

minus sign indicates the declination of the battery charging voltage at rising temperature.

The interconnection of the temperature sensor is shown in diagram X0013800.VP3 in annex.

6.7 MODBUS-Adapter

The application of the Modbus-Adapter is described in the operating manual BAX 2408.

6.8 Manual Bypass for JST hp E 400-800 kVA

The manual Bypass (MBCB) is only available as an Option and is housed in an external cabinet.

Wärtsilä JOVYSTAR HP 200-800kVA BAX 4640 E - 49 -

7 Maintenance

A UPS is subject to an aging process of several components (resistors, capacitors, and so on) like every other electronic

equipment, too.

NOTE:

A UPS system should be maintained regularly.

For this reason we strongly recommend a contract of maintenance.

We strongly recommend regular visual and functional tests on the UPS to obtain its operational reliability and availability.

Also the battery charge should be checked. For verification a log should be kept.

CAUTION:

Maintenance work must sometimes be performed when the UPS is connected to the power supply. Always observe the safety regulations and secure the work area!

The following maintenance work must be performed if no other instructions are given by the battery manufacturer:

Action

Inspection interval

Visual check

6 months

Functional test

6 months

Electrolyte level of the batteries *)

3 months

Replace the fans

Approx. 40.000 hours

*) Note: Not applicable for maintenance free valve regulated batteries.

7.1 Visual checks

Visual inspections should include:

- Check for any unusual noise or odour.

- Check of the front control panel and verify that no alarm is pending.

- Inspect the fan assembly and air filter and replace if necessary.

- Check for any partial damage and foreign substance in the unit.

- Check for any conductive dirt or dust.

- Check for any accumulation of dust which affects heat dissipation.

CAUTION:

The UPS must be disconnected from the power supply prior to carrying out the following work. Always

observe the safety regulations!

If large quantities of dust have accumulated, the unit should be cleaned with a vacuum cleaner to ensure adequate heat

dissipation. The intervals at which visual checks should be performed are determined by the site conditions.

7.2 Functional test

The functional test of the UPS should be performed every six months and include the following tasks:

- Activate the manual bypass according to chapter 4 of this manual.

- Disconnect the UPS according to chapter 4 of this manual and check display and LED’s when restarting the

system as well as :

o Correct start of the rectifier and inverter,

o Function of the static switch,