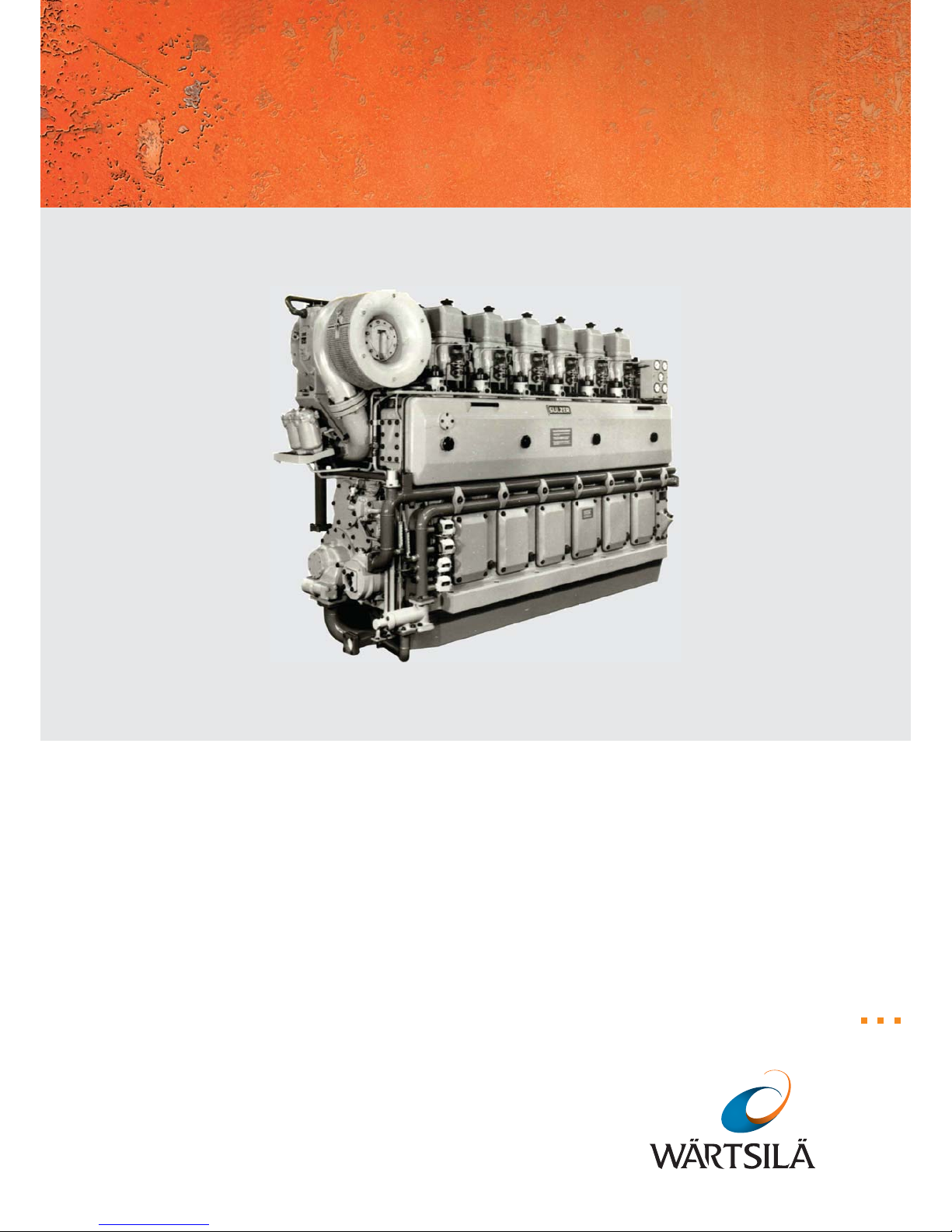

WÄRTSILÄ AL20 Service

CHARACTERISTICS

Water-cooled 6-, and 8-cylinder in-line-engines. •

Four stroke, direct fuel injection. •

Turbocharger and charge air cooling. •

Cylinder heads with 4-valve technology. •

Power-take off on both ends of crankshaft. •

Engine driven pumps on free end of crankshaft. •

BENEFITS

High reliability of the engine. •

Low operational costs due to easy maintenance and long maintenance intervals. •

Low fuel and lubricating oil consumption. •

Clean combustion, even on part load •

AL20

MDO: 450-820 kW at 720-1000 min

-1

HFO: 420-760 kW at 720-1000 min-1

TOTAL SERVICE

SULZER 4-stroke ENGINES

ENGINE DESCRIPTION

Crankcase

Single-piece cast-iron crankcase with underslung crankshaft.

Drillings in the block for water and oil distribution to reduce the pipe work.

Crankshaft

The crankshaft is of low alloy steel, forged in one piece and fully machined.

Counterweights on all cranks. A torsional vibration damper can be fitted to the free end.

Main bearings

Thin-walled bearing shells fitted to both the main bearings and the big end bearings.

Connecting rods

Drop-forged from alloyed steel and fully machined.

The big ends have a serrated joint.

Big end bearings

Identical to the main bearings.

Pistons

One part piston for operation on MDO, two part piston for HFO operation. With 3 chromium

plated piston rings and 2 scraper rings. Fully floating piston pin.

Cylinder heads

The cylinder heads are made of special cast iron and are fitted with two inlet and two exhaust

valves. Nimonic alloy valves with rotators for engines operating on HFO.

Camshaft

The camshaft consists of individual segments, one for each cylinder.

Fuel injection pumps

Individual helix-controlled fuel injection pump for each cylinder.

Governor

The governor is of Woodward UG8 / PGA12 type.

Turbocharger

The turbocharger is mounted on the front end. ABB VTR type or Napier.

Pump drive

The oil pump, cooling water pump and fuel booster pump are mounted on the front end.

Provision is made for driving an extra cooling water pump.

Fuel system

The fuel system is pressurized by a built-on feed pump. Fuel circulates over the fuel day tank.

Optionally, external fuel supply is possible.

Lubricating oil system

A built-on gear pump supplies oil flow and pressure. Oil flows through a cooler and filter before

entering the engine. Optionally, a centrifugal filter is installed.

Starting air system

The engine is started by means of direct air starting. The system supplies starting air to the

individual cylinder heads via the main starting valve. Control air derived from the starting air is

used to control the individual starting valves.

Cooling water system

The cooling water system is divided in a high temperature and a low temperature system. High

temperature cooling water is used for jacket cooling, low temperature is used for charge air

cooling and lubricating oil cooling.

Exhaust gas system

Exhaust system is of pulse type.

Classification

Classification performed by engine manufacturer.

Emission regulations

Emission regulations are not applicable for these engines, because most engines were built

before the IMO / EIAPP era (before 2000).

Loading...

Loading...