Page 1

PRODUCT G U I D E

Wärtsilä 31

Page 2

© Copyright by WÄRTSILÄ FINLAND Oy

All rights reserved. No part of this booklet may be reproduced or copied in any form or by any means (electronic,

mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written

permission of the copyright owner.

THIS PUBLICATION IS DESIGNED TO PROVIDE AN ACCURATE AND AUTHORITATIVE INFORMATION WITH

REGARD TO THE SUBJECT-MATTER COVERED AS WAS AVAILABLE AT THE TIME OF PRINTING. HOWEVER,THE

PUBLICATION DEALS WITH COMPLICATED TECHNICAL MATTERS SUITED ONLY FOR SPECIALISTS IN THE

AREA, AND THE DESIGN OF THE SUBJECT-PRODUCTS IS SUBJECT TO REGULAR IMPROVEMENTS,

MODIFICATIONS AND CHANGES. CONSEQUENTLY, THE PUBLISHER AND COPYRIGHT OWNER OF THIS

PUBLICATION CAN NOT ACCEPT ANY RESPONSIBILITY OR LIABILITY FOR ANY EVENTUAL ERRORS OR

OMISSIONS IN THIS BOOKLET OR FOR DISCREPANCIES ARISING FROM THE FEATURES OF ANY ACTUAL ITEM

IN THE RESPECTIVE PRODUCT BEING DIFFERENT FROM THOSE SHOWN IN THIS PUBLICATION. THE PUBLISHER

AND COPYRIGHT OWNER SHALL UNDER NO CIRCUMSTANCES BE HELD LIABLE FOR ANY FINANCIAL

CONSEQUENTIAL DAMAGES OR OTHER LOSS, OR ANY OTHER DAMAGE OR INJURY, SUFFERED BY ANY

PARTY MAKING USE OF THIS PUBLICATION OR THE INFORMATION CONTAINED HEREIN.

Page 3

Introduction

This Product Guide provides data and system proposals for the early design phase of marine

engine installations. For contracted projects specific instructions for planning the installation

are always delivered. Any data and information herein is subject to revision without notice.

UpdatesPublishedIssue

First version of Product Guide W3118.10.20161/2016

Wärtsilä, Marine Solutions

Vaasa, October 2016

Wärtsilä 31 Product Guide - a1 - 18 October 2016 iii

IntroductionWärtsilä 31 Product Guide

Page 4

Table of contents

1-11. Main Data and Outputs .......................................................................................................................

1-11.1 Maximum continuous output .......................................................................................................

1-21.2 Reference conditions ...................................................................................................................

1-21.3 Operation in inclined position .....................................................................................................

1-31.4 Dimensions and weights .............................................................................................................

2-12. Operating Ranges ................................................................................................................................

2-12.1 Engine operating range ...............................................................................................................

2-22.2 Loading capacity .........................................................................................................................

2-42.3 Operation at low load and idling ..................................................................................................

2-42.4 Low air temperature ....................................................................................................................

3-13. Technical Data ......................................................................................................................................

3-13.1 Wärtsilä 8V31 ...............................................................................................................................

3-43.2 Wärtsilä 10V31 .............................................................................................................................

3-73.3 Wärtsilä 12V31 .............................................................................................................................

3-103.4 Wärtsilä 14V31 .............................................................................................................................

3-133.5 Wärtsilä 16V31 .............................................................................................................................

4-14. Description of the Engine ....................................................................................................................

4-14.1 Definitions ....................................................................................................................................

4-14.2 Main components and systems ..................................................................................................

4-54.3 Expected overhaul intervals and life times ..................................................................................

4-54.4 Engine storage .............................................................................................................................

5-15. Piping Design, Treatment and Installation .........................................................................................

5-15.1 Pipe dimensions ..........................................................................................................................

5-25.2 Trace heating ...............................................................................................................................

5-25.3 Pressure class ..............................................................................................................................

5-35.4 Pipe class ....................................................................................................................................

5-45.5 Insulation .....................................................................................................................................

5-45.6 Local gauges ...............................................................................................................................

5-45.7 Cleaning procedures ...................................................................................................................

5-55.8 Flexible pipe connections ............................................................................................................

5-65.9 Clamping of pipes ........................................................................................................................

6-16. Fuel Oil System ....................................................................................................................................

6-16.1 Acceptable fuel characteristics ...................................................................................................

6-56.2 Internal fuel oil system .................................................................................................................

6-86.3 External fuel oil system ................................................................................................................

7-17. Lubricating Oil System ........................................................................................................................

7-17.1 Lubricating oil requirements ........................................................................................................

7-27.2 Internal lubricating oil system ......................................................................................................

7-57.3 External lubricating oil system .....................................................................................................

7-117.4 Crankcase ventilation system ......................................................................................................

7-137.5 Flushing instructions ....................................................................................................................

8-18. Compressed Air System ......................................................................................................................

8-18.1 Instrument air quality ...................................................................................................................

8-18.2 Internal compressed air system ..................................................................................................

8-38.3 External compressed air system .................................................................................................

iv Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product GuideTable of contents

Page 5

9-19. Cooling Water System .........................................................................................................................

9-19.1 Water quality ...............................................................................................................................

9-29.2 Internal cooling water system ......................................................................................................

9-89.3 External cooling water system ....................................................................................................

10-110. Exhaust Gas System ............................................................................................................................

10-110.1 Internal exhaust gas system ........................................................................................................

10-410.2 Exhaust gas outlet .......................................................................................................................

10-610.3 External exhaust gas system .......................................................................................................

11-111. Turbocharger Cleaning ........................................................................................................................

11-111.1 Turbine cleaning system ..............................................................................................................

11-211.2 Compressor cleaning system ......................................................................................................

12-112. Exhaust Emissions ...............................................................................................................................

12-112.1 Diesel engine exhaust components ............................................................................................

12-212.2 Marine exhaust emissions legislation ..........................................................................................

12-612.3 Methods to reduce exhaust emissions ........................................................................................

13-113. Automation System .............................................................................................................................

13-113.1 Technical data and system overview ...........................................................................................

13-513.2 Functions ....................................................................................................................................

13-713.3 Alarm and monitoring signals ......................................................................................................

13-713.4 Electrical consumers ...................................................................................................................

13-913.5 System requirements and guidelines for diesel-electric propulsion ............................................

14-114. Foundation ............................................................................................................................................

14-114.1 Steel structure design ..................................................................................................................

14-114.2 Mounting of main engines ...........................................................................................................

14-814.3 Mounting of generating sets ........................................................................................................

14-1014.4 Flexible pipe connections ............................................................................................................

15-115. Vibration and Noise ..............................................................................................................................

15-115.1 External forces and couples ........................................................................................................

15-215.2 Torque variations .........................................................................................................................

15-215.3 Mass moments of inertia .............................................................................................................

15-215.4 Air borne noise .............................................................................................................................

15-315.5 Exhaust noise ..............................................................................................................................

16-116. Power Transmission ............................................................................................................................

16-116.1 Flexible coupling ..........................................................................................................................

17-117. Engine Room Layout ...........................................................................................................................

17-117.1 Space requirements for maintenance .........................................................................................

17-117.2 Transportation and storage of spare parts and tools ..................................................................

17-217.3 Required deck area for service work ...........................................................................................

18-118. Transport Dimensions and Weights ...................................................................................................

18-118.1 Lifting of main engines ................................................................................................................

18-218.2 Lifting of generating sets .............................................................................................................

18-318.3 Engine components .....................................................................................................................

19-119. Product Guide Attachments ...............................................................................................................

20-120. ANNEX ...................................................................................................................................................

20-120.1 Unit conversion tables .................................................................................................................

20-220.2 Collection of drawing symbols used in drawings ........................................................................

Wärtsilä 31 Product Guide - a1 - 18 October 2016 v

Table of contentsWärtsilä 31 Product Guide

Page 6

This page intentionally left blank

Page 7

1. Main Data and Outputs

The Wärtsilä 31 is a 4-stroke, non-reversible, turbocharged and intercooled diesel engine with

direct fuel injection.

310 mmCylinder bore ........................

430 mmStroke ...................................

2 inlet valves

2 exhaust valves

Number of valves .................

8, 10, 12, 14 and 16Cylinder configuration .........

50°V-angle .................................

Clockwise, counterclockwiseDirection of rotation .............

720, 750 rpmSpeed ...................................

10.32 - 10.75 m/sMean piston speed ...............

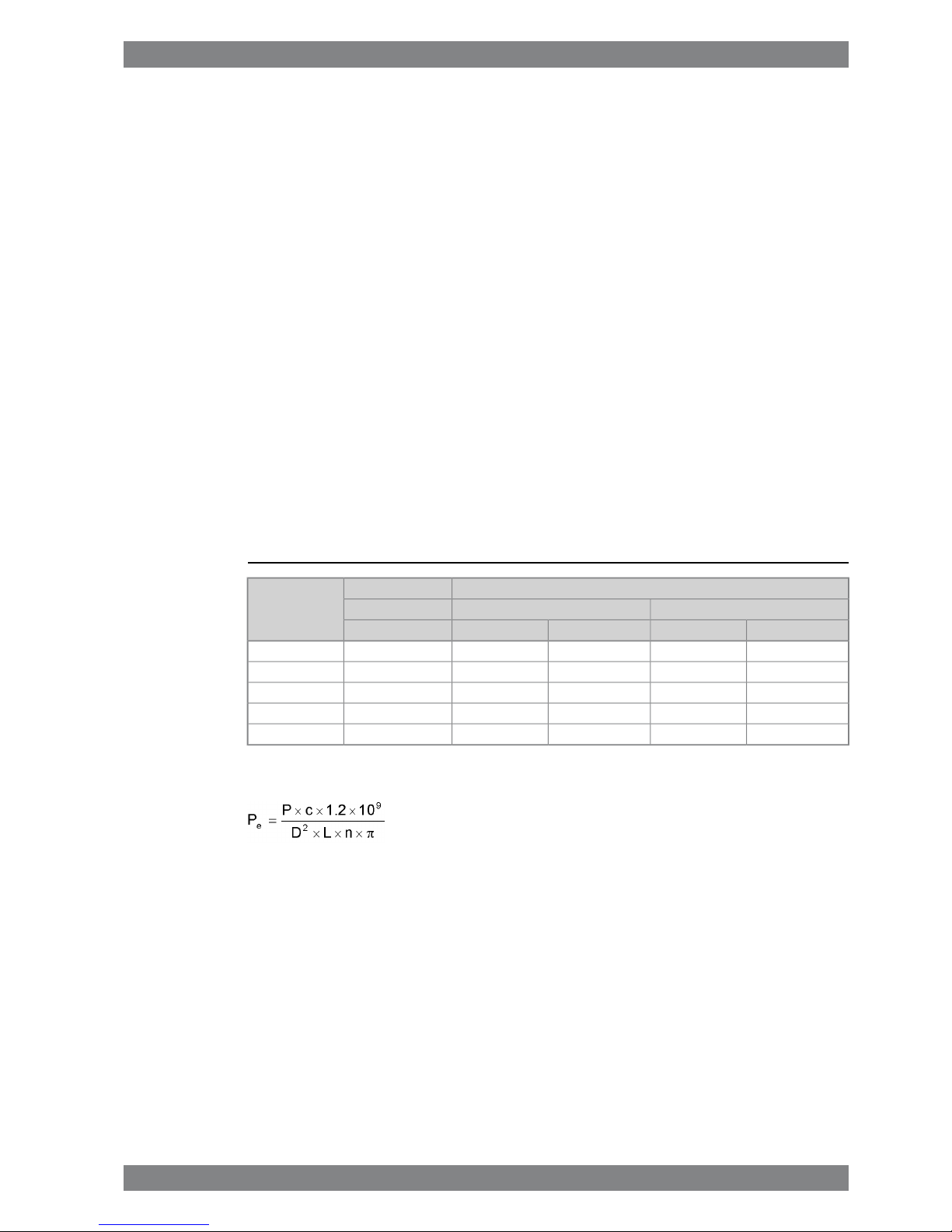

1.1 Maximum continuous output

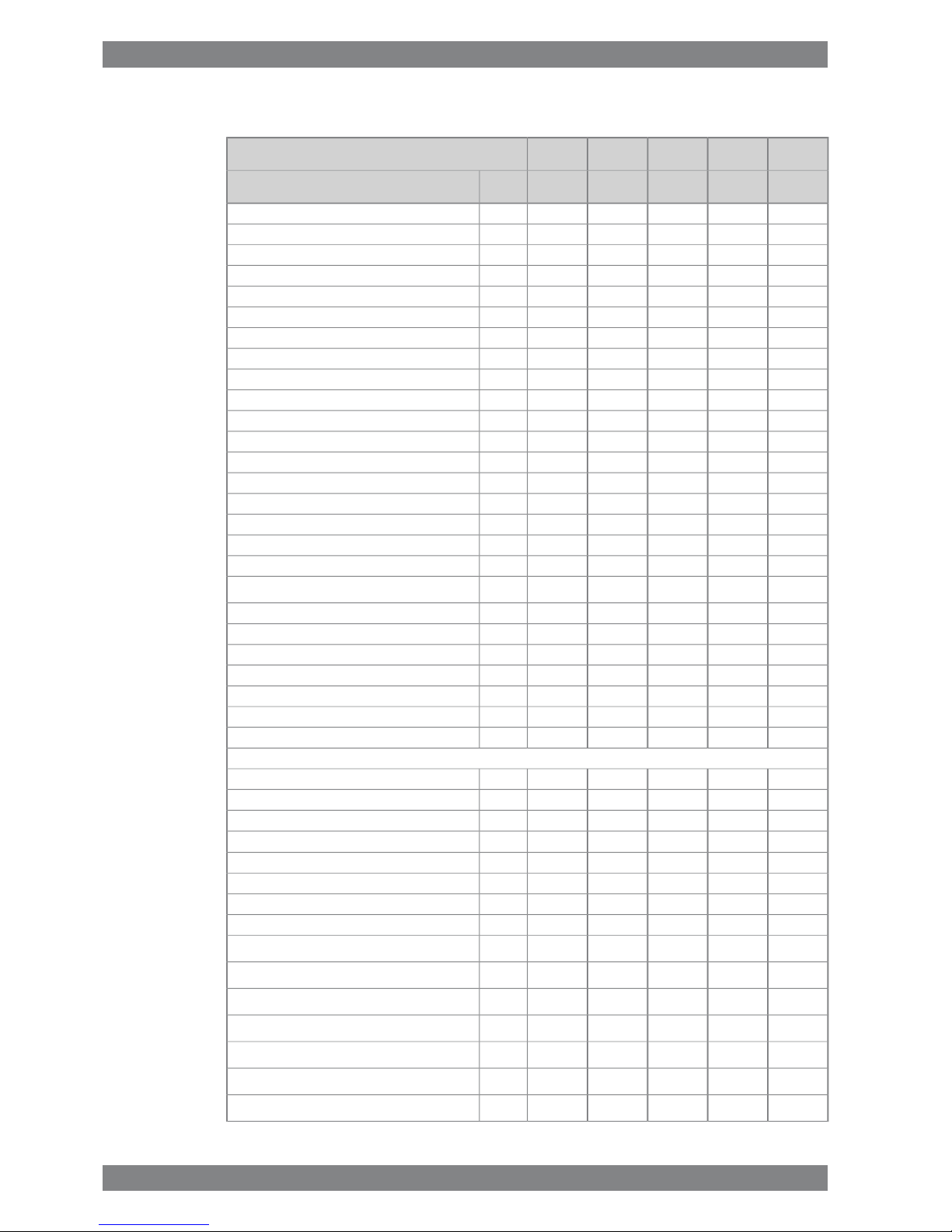

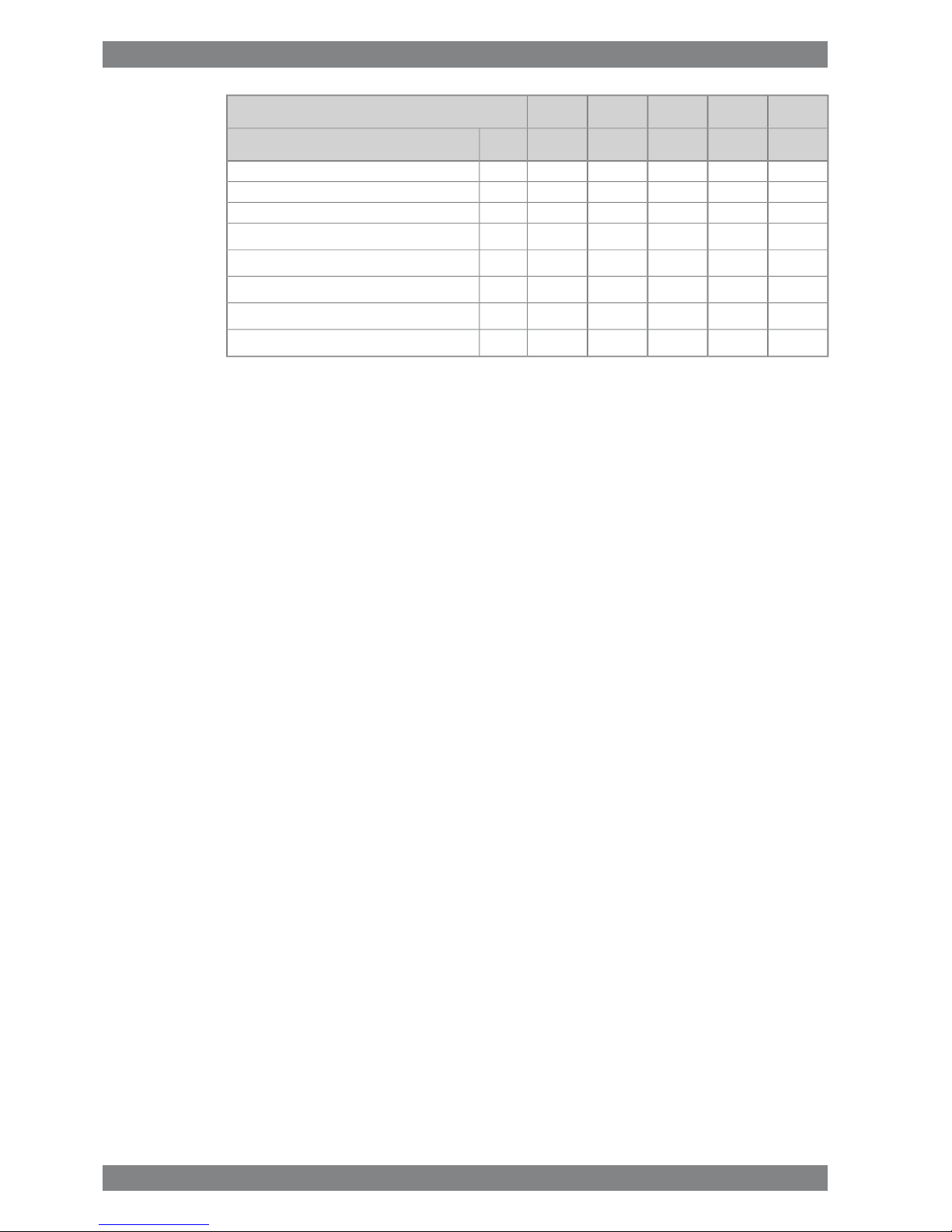

Table 1-1 Rating table for Wärtsilä 31

Generating setsMain enginesCylinder

configuration

750 rpm720 rpm750 rpm

Generator [kVA]Engine [kW]Generator [kVA]Engine [kW][kW]

58564880566447204880W 8V31

73206100708059006100W 10V31

87847320849670807320W 12V31

102488540991282608540W 14V31

1171297601132894409760W 16V31

The mean effective pressure Pe can be calculated as follows:

where:

mean effective pressure [bar]Pe =

output per cylinder [kW]P =

engine speed [r/min]n =

cylinder diameter [mm]D =

length of piston stroke [mm]L =

operating cycle (4)c =

Wärtsilä 31 Product Guide - a1 - 18 October 2016 1-1

1. Main Data and OutputsWärtsilä 31 Product Guide

Page 8

1.2 Reference conditions

The output is available up to a charge air coolant temperature of max. 38°C and an air

temperature of max. 45°C. For higher temperatures, the output has to be reduced according

to the formula stated in ISO 3046-1:2002 (E).

The specific fuel oil consumption is stated in the chapter Technical data. The stated specific

fuel oil consumption applies to engines with engine driven pumps, operating in ambient

conditions according to ISO 15550:2002 (E). The ISO standard reference conditions are:

100 kPatotal barometric pressure

25°Cair temperature

30%relative humidity

25°Ccharge air coolant temperature

Correction factors for the fuel oil consumption in other ambient conditions are given in standard

ISO 3046-1:2002.

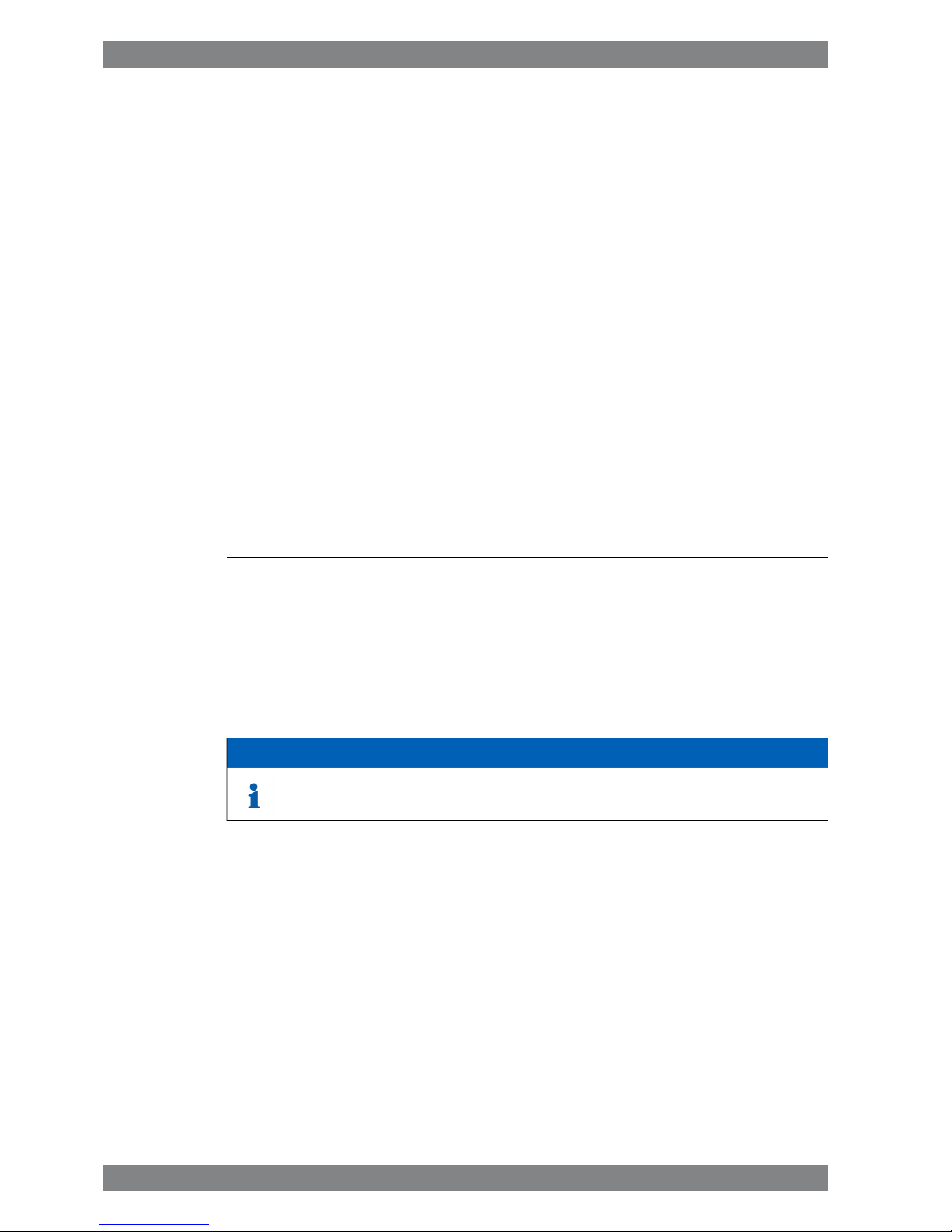

1.3 Operation in inclined position

Max. inclination angles at which the engine will operate satisfactorily.

Table 1-2 Inclination with Normal Oil Sump

15°

● Transverse inclination, permanent (list)

22.5°

● Transverse inclination, momentary (roll)

10°

● Longitudinal inclination, permanent (trim)

10°

● Longitudinal inclination, momentary (pitch)

NOTE

Inclination in all directions requires special arrangements.

1-2 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide1. Main Data and Outputs

Page 9

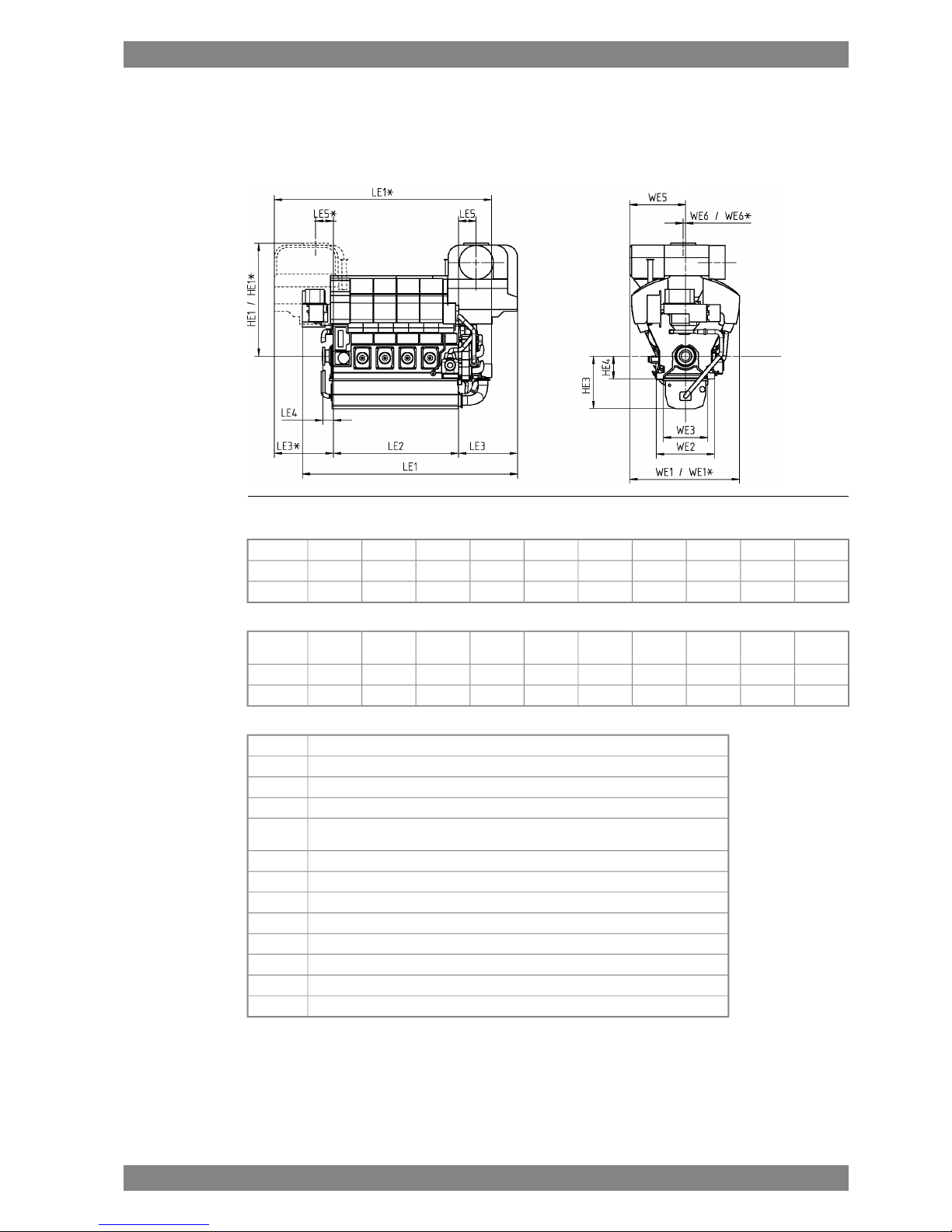

1.4 Dimensions and weights

1.4.1 Main engines

Fig 1-1 Main engine dimensions (DAAF336230)

LE4LE2HE3HE4WE1*WE1HE1*HE1LE1LE1*Engine

35035601496650311331133205320561146175W8V31

35042001496650311331133205320567546813W10V31

Weight

ton**

WE2WE3LE5LE5*WE6WE6*LE3LE3*WESEngine

56.71650115350050067-67167516751582W8V31

621650115350050067-67167516751585W10V31

Total length of engineLE1

Height from the crankshaft centerline to the highest pointHE1

Total width of the engineWE1

Height from the crankshaft centerline to the engine feetsHE4

Dimension from the crankshaft centerline to the bottom of the oil sump, when shallow oil

sump

HE3

Length of the engine blockLE2

Dimension from the end of the block to the end of the crankshaftLE4

Width of the oil sumpWE3

Width of the engine block at the engine feetWE2

Dimension from the center of the crankshaft to the outermost point of the engineWE5

Dimension from the engine block to the outermost point in turbocharger endLE3

Dimension from the center of the crankshaft to the centre of the exhaust outletWE6

Dimension from the end of the engine block to the centre of the exhaust gas outletLE5

* Turbocharger at flywheel end

** Weight with liquids (wet sump) but without flywheel

All dimensions in mm.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 1-3

1. Main Data and OutputsWärtsilä 31 Product Guide

Page 10

This page intentionally left blank

Page 11

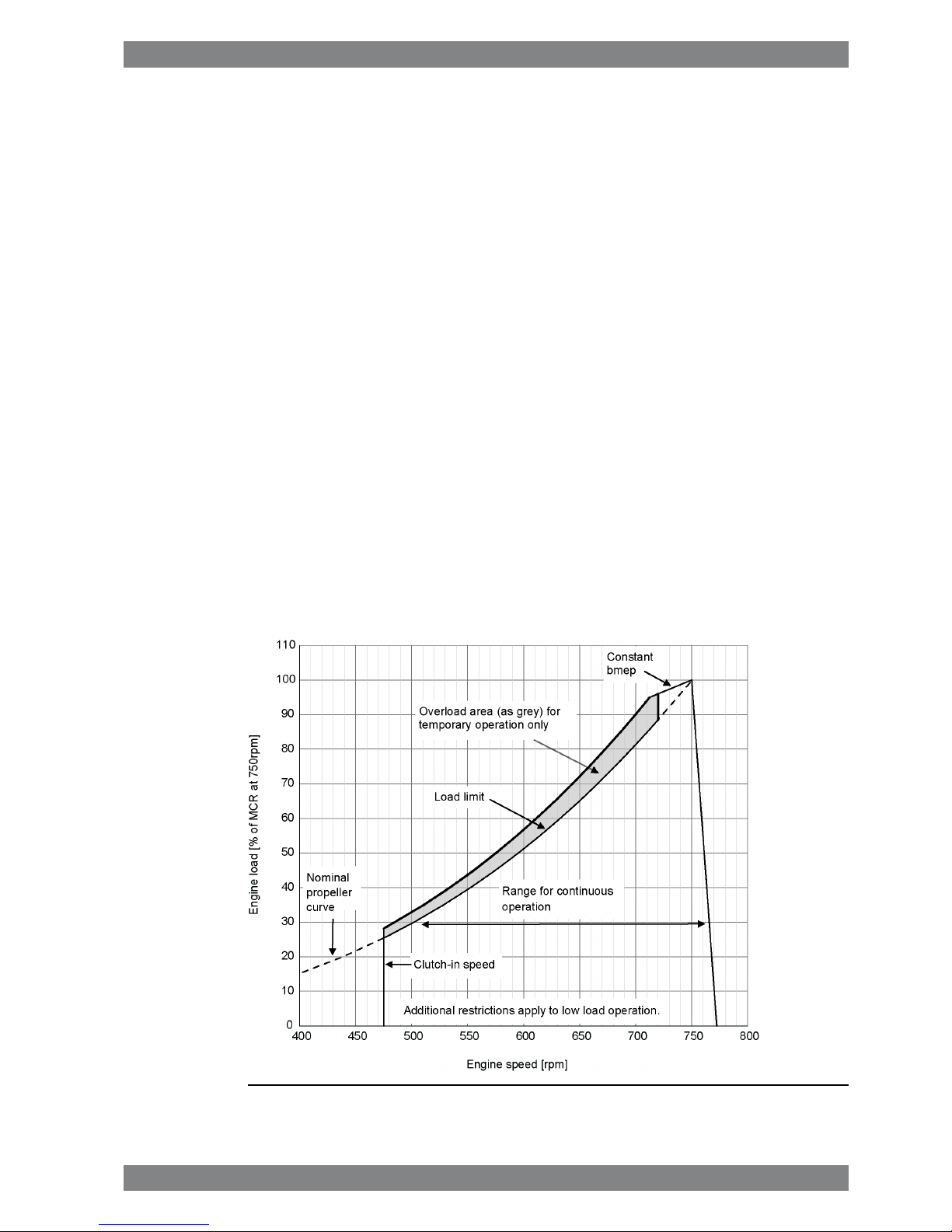

2. Operating Ranges

2.1 Engine operating range

Below nominal speed the load must be limited according to the diagrams in this chapter in

order to maintain engine operating parameters within acceptable limits. Operation in the

shaded area is permitted only temporarily during transients. Minimum speed is indicated in

the diagram, but project specific limitations may apply.

2.1.1 Controllable pitch propellers

The engine load must be limited according to the diagram below when operating below nominal

speed, in order to maintain engine operating parameters within acceptable limits. Operation

in the shaded area is permitted only temporarily during transients to permit smooth overload

control.

Note that project specific vibration calculations may result in higher minimum speed than in

the diagram below.

The propulsion control must also include automatic limitation of the load increase rate.

Maximum loading rates can be found later in this chapter.

The propeller efficiency is highest at design pitch. It is common practice to dimension the

propeller so that the specified ship speed is attained with design pitch, nominal engine speed

and 85% output in the specified loading condition. The power demand from a possible shaft

generator or PTO must be taken into account. The 15% margin is a provision for weather

conditions and fouling of hull and propeller. An additional engine margin can be applied for

most economical operation of the engine, or to have reserve power.

Fig 2-1 Operating field for CP Propeller

Wärtsilä 31 Product Guide - a1 - 18 October 2016 2-1

2. Operating RangesWärtsilä 31 Product Guide

Page 12

2.2 Loading capacity

Controlled load increase is essential for highly supercharged diesel engines, because the

turbocharger needs time to accelerate before it can deliver the required amount of air. A slower

loading ramp than the maximum capability of the engine permits a more even temperature

distribution in engine components during transients.

The engine can be loaded immediately after start, provided that the engine is pre-heated to

a HT-water temperature of min 70ºC, and the lubricating oil temperature is min. 40 ºC.

The ramp for normal loading applies to engines that have reached normal operating

temperature.

2.2.1 Mechanical propulsion

Fig 2-2 Maximum recommended load increase rates for variable speed engines

The propulsion control must include automatic limitation of the load increase rate. If the control

system has only one load increase ramp, then the ramp for a preheated engine should be

used. In tug applications the engines have usually reached normal operating temperature

before the tug starts assisting. The “emergency” curve is close to the maximum capability of

the engine.

Large load reductions from high load should also be performed gradually. In normal operation

the load should not be reduced from 100% to 0% in less than 15 seconds. When absolutely

necessary, the load can be reduced as fast as the pitch setting system can react (overspeed

due to windmilling must be considered for high speed ships).

2-2 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide2. Operating Ranges

Page 13

2.2.2 Diesel electric propulsion and auxiliary engines

Fig 2-3 Maximum recommended load increase rates for engines operating at

nominal speed

In diesel electric installations loading ramps are implemented both in the propulsion control

and in the power management system, or in the engine speed control in case isochronous

load sharing is applied. If a ramp without knee-point is used, it should not achieve 100% load

in shorter time than the ramp in the figure. When the load sharing is based on speed droop,

the load increase rate of a recently connected generator is the sum of the load transfer

performed by the power management system and the load increase performed by the

propulsion control.

The “emergency” curve is close to the maximum capability of the engine and it shall not be

used as the normal limit. In dynamic positioning applications loading ramps corresponding to

20-30 seconds from zero to full load are however normal. If the vessel has also other operating

modes, a slower loading ramp is recommended for these operating modes.

In typical auxiliary engine applications there is usually no single consumer being decisive for

the loading rate. It is recommended to group electrical equipment so that the load is increased

in small increments, and the resulting loading rate roughly corresponds to the “normal” curve.

In normal operation the load should not be reduced from 100% to 0% in less than 15 seconds.

If the application requires frequent unloading at a significantly faster rate, special arrangements

can be necessary on the engine. In an emergency situation the full load can be thrown off

instantly.

2.2.2.1 Maximum instant load steps

The electrical system must be designed so that tripping of breakers can be safely handled.

This requires that the engines are protected from load steps exceeding their maximum load

acceptance capability. The load steps are in three equal steps. The resulting speed drop is

less than 10% and the recovery time to within 1% of the steady state speed at the new load

level is max. 5 seconds.

When electrical power is restored after a black-out, consumers are reconnected in groups,

which may cause significant load steps. The engine must be allowed to recover for at least

10 seconds before applying the following load step, if the load is applied in maximum steps.

2.2.2.2 Start-up time

A diesel generator typically reaches nominal speed in about 20 seconds after the start signal.

The acceleration is limited by the speed control to minimise smoke during start-up. If requested

faster starting times can be arranged.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 2-3

2. Operating RangesWärtsilä 31 Product Guide

Page 14

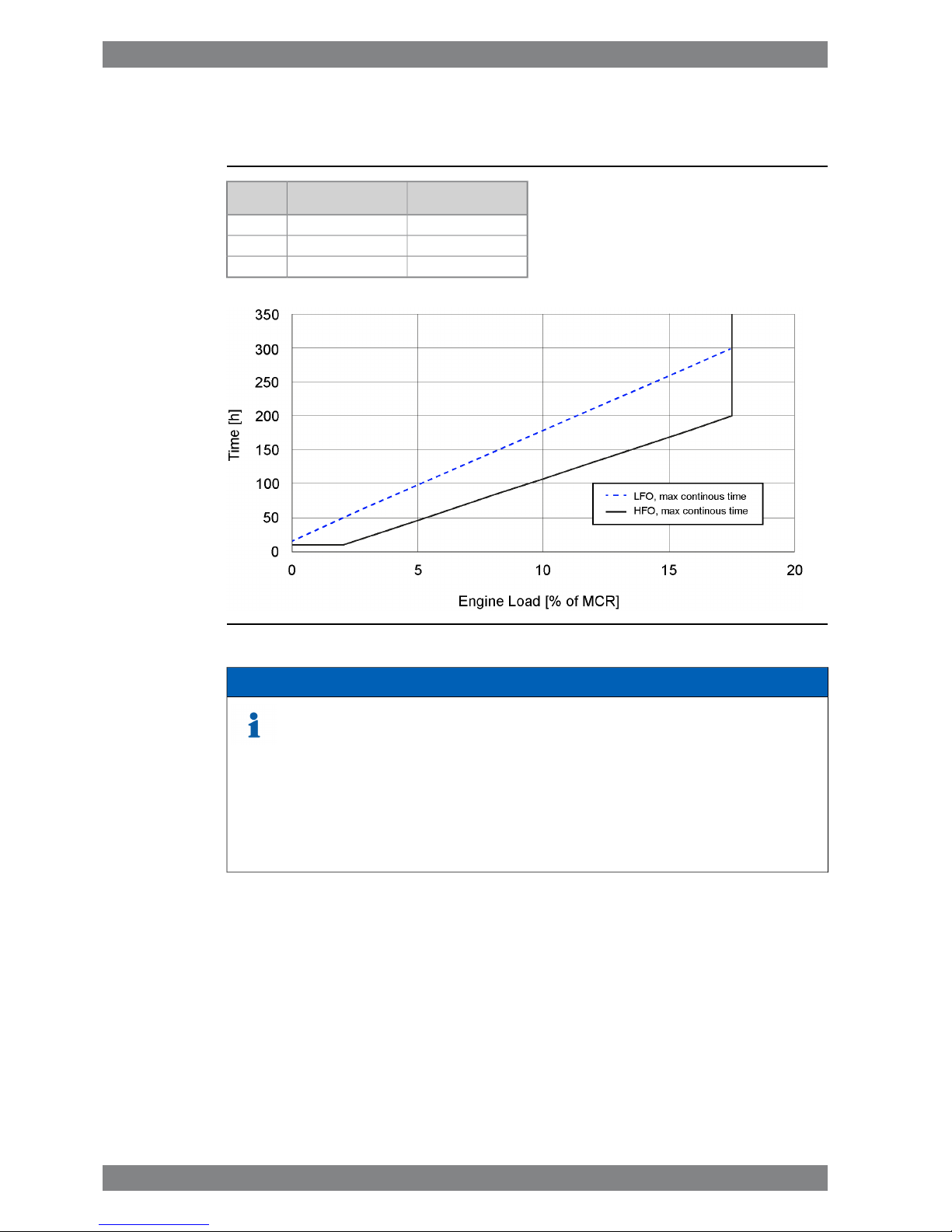

2.3 Operation at low load and idling

Table 2-1 Idling and low load operation restrictions

HFO, max continous

time [h]

LFO, max continous

time [h]

Load

10150%

10502%

20030017.5%

Fig 2-4 Low load operating restrictions

NOTE

Above 17.5% load there is no additional restriction from low load operation.1)

Duration of low load only applies if charge air temp in receiver is at:2)

- LFO: 35C or above

- HFO: 45C or above

High load running (minimum 70%) is to be followed for a minimum of 60 minutes to clean up the engine

after maximum allowed low load running time has been reached.

3)

2.4 Low air temperature

In cold conditions the following minimum inlet air temperatures apply:

● Min 5ºC

For lower suction air temperatures engines shall be configured for arctic operation.

For further guidelines, see chapter Combustion air system design.

2-4 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide2. Operating Ranges

Page 15

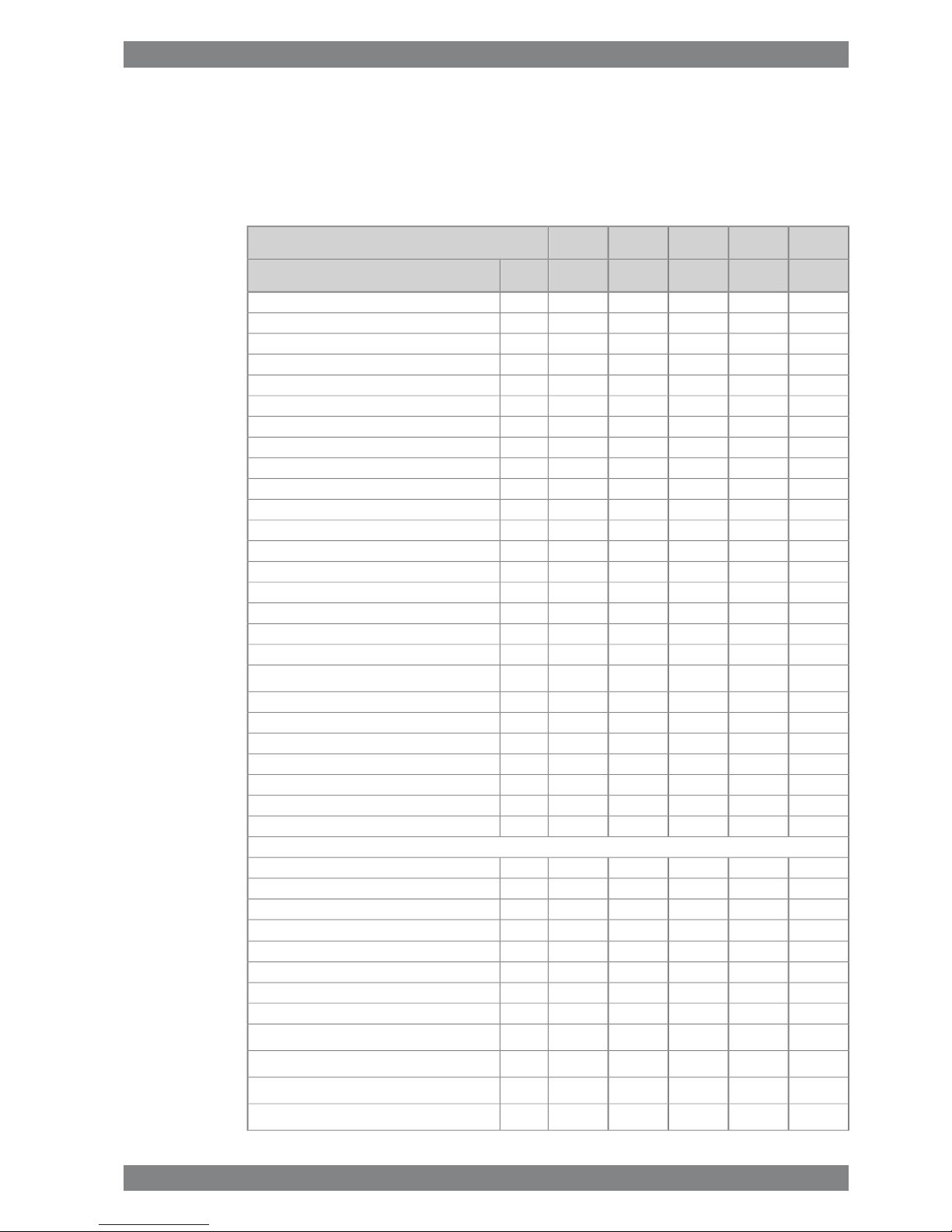

3. Technical Data

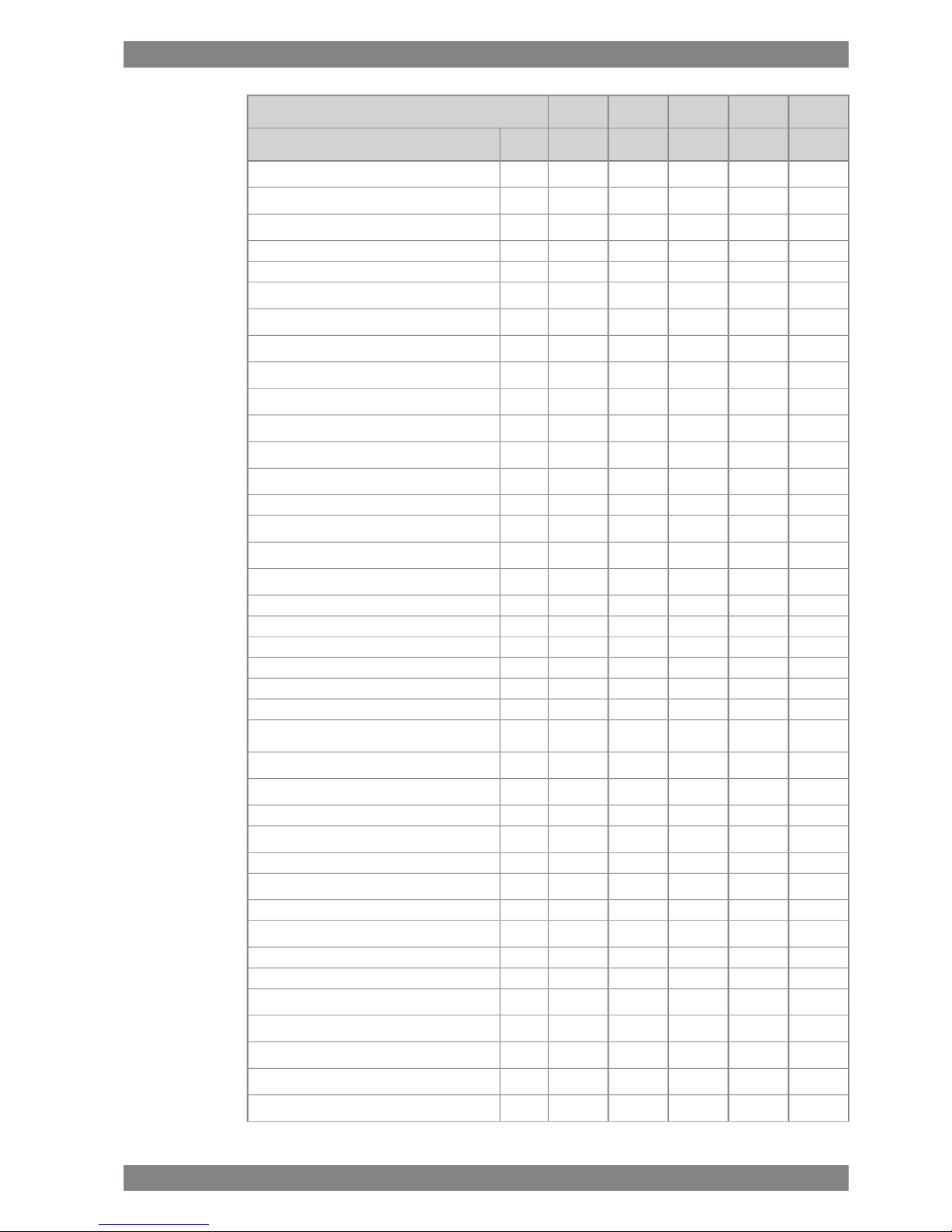

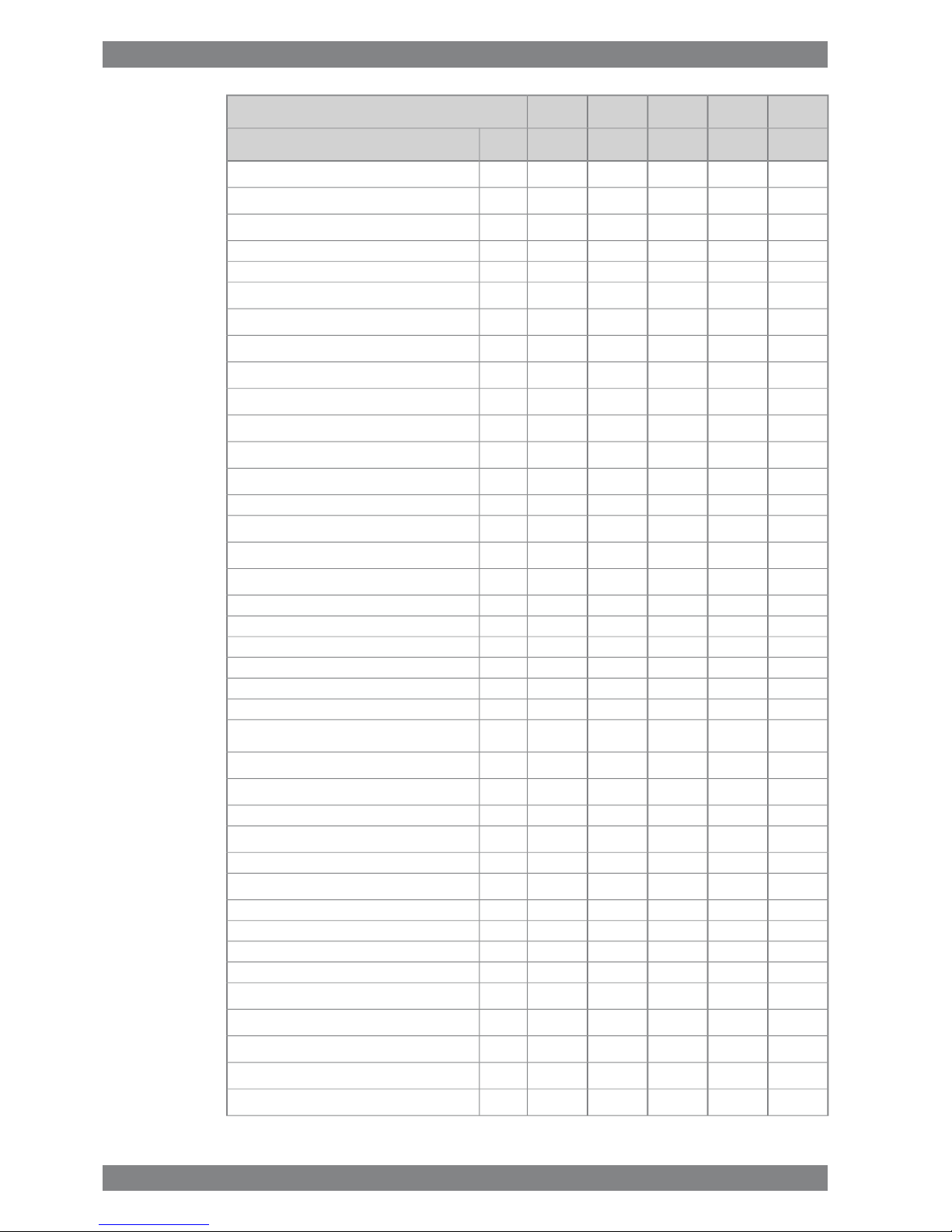

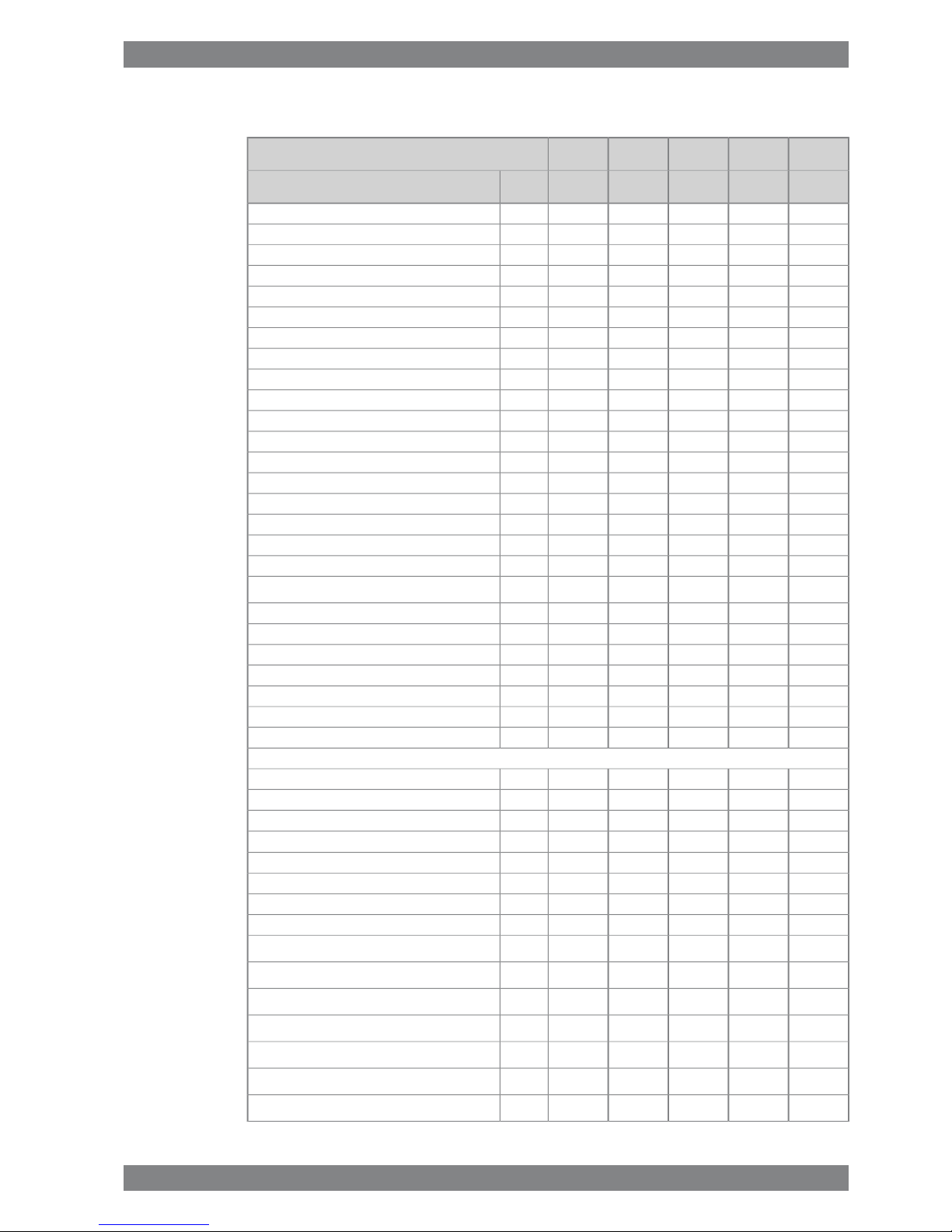

3.1 Wärtsilä 8V31

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 8V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

48804880472048804720kWEngine output

3.013.013.033.013.03MPaMean effective pressure

Combustion air system (Note 1)

8.638.638.328.638.32kg/sFlow at 100% load

4545454545°CTemperature at turbocharger intake, max.

6565656565°CAir temperature after air cooler (TE 601)

Exhaust gas system (Note 2)

8.888.888.568.888.56kg/sFlow at 100% load

7.527.67.287.67.28kg/sFlow at 85% load

6.486.86.566.86.56kg/sFlow at 75% load

4.565.24.965.24.96kg/sFlow at 50% load

273273275273275°CTemperature after turbocharger, 100% load (TE 517)

277275277275277°CTemperature after turbocharger, 85% load (TE 517)

295282284282284°CTemperature after turbocharger, 75% load (TE 517)

320286288286288°CTemperature after turbocharger, 50% load (TE 517)

5.05.05.05.05.0kPaBackpressure, max.

705705693705693

mmCalculated pipe diameter for 35m/s

Heat balance (Note 3)

494494460494460kWJacket water, HT-circuit

926926858926858kWCharge air, HT-circuit

12301230119512301195kWCharge air, LT-circuit

522522487522487kWLubricating oil, LT-circuit

137137131137131kWRadiation

For optional engineversions heat balances may differ

Fuel system (Note 4)

1000±1001000±1001000±1001000±1001000±100kPaPressure before injection pumps (PT 101)

60.060.060.060.060.0m3/hEngine driven pump capacity (MDF only)

16...2416...2416...2416...2416...24cStHFO viscosity before engine

140140140140140°CHFO temperature before engine, max. (TE 101)

2.02.02.02.02.0cStMDF viscosity, min

4545454545°CMDF temperature before engine, max. (TE 101)

174.4174.9173.9174.4173.4

g/kWhFuel consumption at 100% load, HFO

171.6172.0171.1171.6170.6

g/kWhFuel consumption at 85% load, HFO

171.6174.0173.0173.5172.5

g/kWhFuel consumption at 75% load, HFO

178.5183.8182.8183.3182.3

g/kWhFuel consumption at 50% load, HFO

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-1

3. Technical DataWärtsilä 31 Product Guide

Page 16

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 8V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

173.5174.0173.0173.5172.5

g/kWhFuel consumption at 100% load, MDF

170.6171.1170.1170.6169.7

g/kWhFuel consumption at 85% load, MDF

170.6173.0172.0172.5171.6

g/kWhFuel consumption at 75% load, MDF

176.6181.9180.9181.4180.4

g/kWhFuel consumption at 50% load, MDF

17.717.717.017.717.0

kg/hClean leak fuel quantity, MDF at 100% load

3.63.63.43.63.4

kg/hClean leak fuel quantity, HFO at 100% load

Lubricating oil system

420420420420420

kPaPressure before bearings, nom. (PT 201)

4040404040

kPaSuction ability main pump, including pipe loss, max.

6060606060

kPaPriming pressure, nom. (PT 201)

3535353535

kPaSuction ability priming pump, including pipeloss, max.

7070707070

°CTemperature before bearings, nom. (TE 201)

8282828282

°CTemperature after engine, approx.

144130125130125

m³/hPump capacity (main), engine driven

100100100100100

m³/hPump capacity (main), stand-by

20.0 / 20.020.0 / 20.020.0 / 20.020.0 / 20.020.0 / 20.0m³/hPriming pump capacity, 50Hz/60Hz

2.542.542.542.542.54

m³Oil volume, wet sump, nom.

6.66.66.46.66.4

m³Oil volume in separate system oil tank, nom.

0.450.450.450.450.45

g/kWhOil consumption (100% load), approx.

19601960196019601960l/minCrankcase ventilation flow rate at full load

0.10.10.10.10.1kPaCrankcase ventilation backpressure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8litersOil volume in turning device

Cooling water system

High temperature cooling water system

358 + stat-

ic

358 + stat-

ic

358 + stat-

ic

358 + stat-

ic

358 + stat-

ic

kPaPressure at engine, after pump, nom. (PT 401)

600600600600600

kPaPressure at engine, after pump, max. (PT 401)

8383838383

°CTemperature before cylinders, approx. (TE 401)

9696969696°CHT-water out from engine, nom (TE432)

8080808080

m³/hCapacity of engine driven pump, nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system, max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

0.6030.6030.6030.6030.603

m³Water volume in engine

Low temperature cooling water system

25 ... 3825 ... 3825 ... 3825 ... 3825 ... 38°CTemperature before engine (TE 451)

8080808080

m³/hCapacity of engine driven pump, nom.

4141414141

kPaPressure drop over charge air cooler (one-stage)

3-2 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide3. Technical Data

Page 17

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 8V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

110110110110110

kPaPressure drop over charge air cooler (two-stage)

115115115115115

kPaPressure drop over oil cooler

100100100100100

kPaPressure drop in external system, max.

70 ... 15070 ... 15070 ... 15070 ... 15070 ... 150kPaPressure from expansion tank

Starting air system

30003000300030003000

kPaPressure, nom.

15001500150015001500

kPaPressure at engine during start, min. (20°C)

30003000300030003000

kPaPressure, max.

16001600160016001600

kPaLow pressure limit in air vessels

4.94.94.94.94.9

Nm

3

Air consumption per start

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

10°C.

Note 2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat

exchangers. In arctic option charge air coolers in LT circuit.

Note 3

At ambient conditions according to ISO 15550.Lower calorific value 42 700 kJ/kg. With engine driven pumps (two cooling

water + one lubricating oil pump). Tolerance 5%.

Note 4

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-3

3. Technical DataWärtsilä 31 Product Guide

Page 18

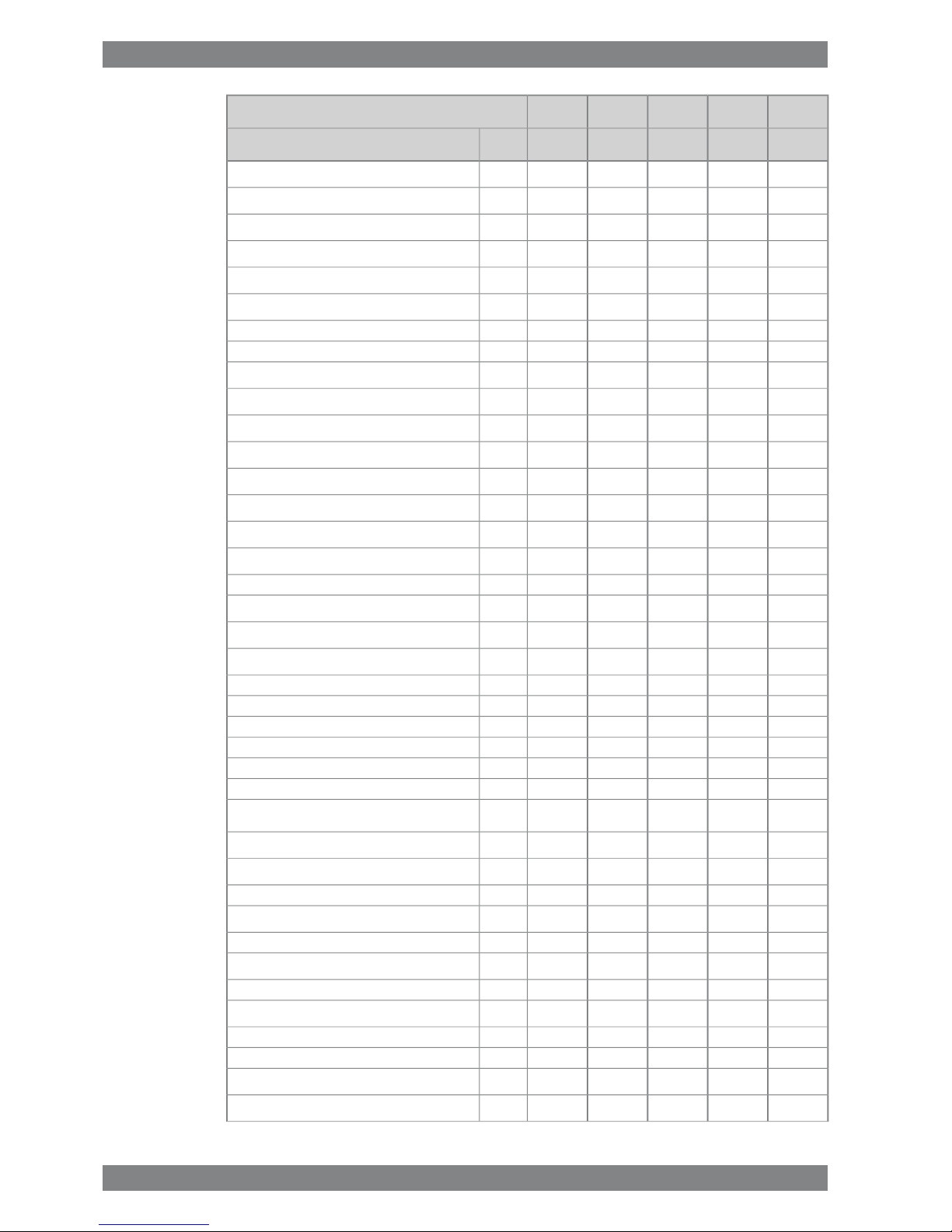

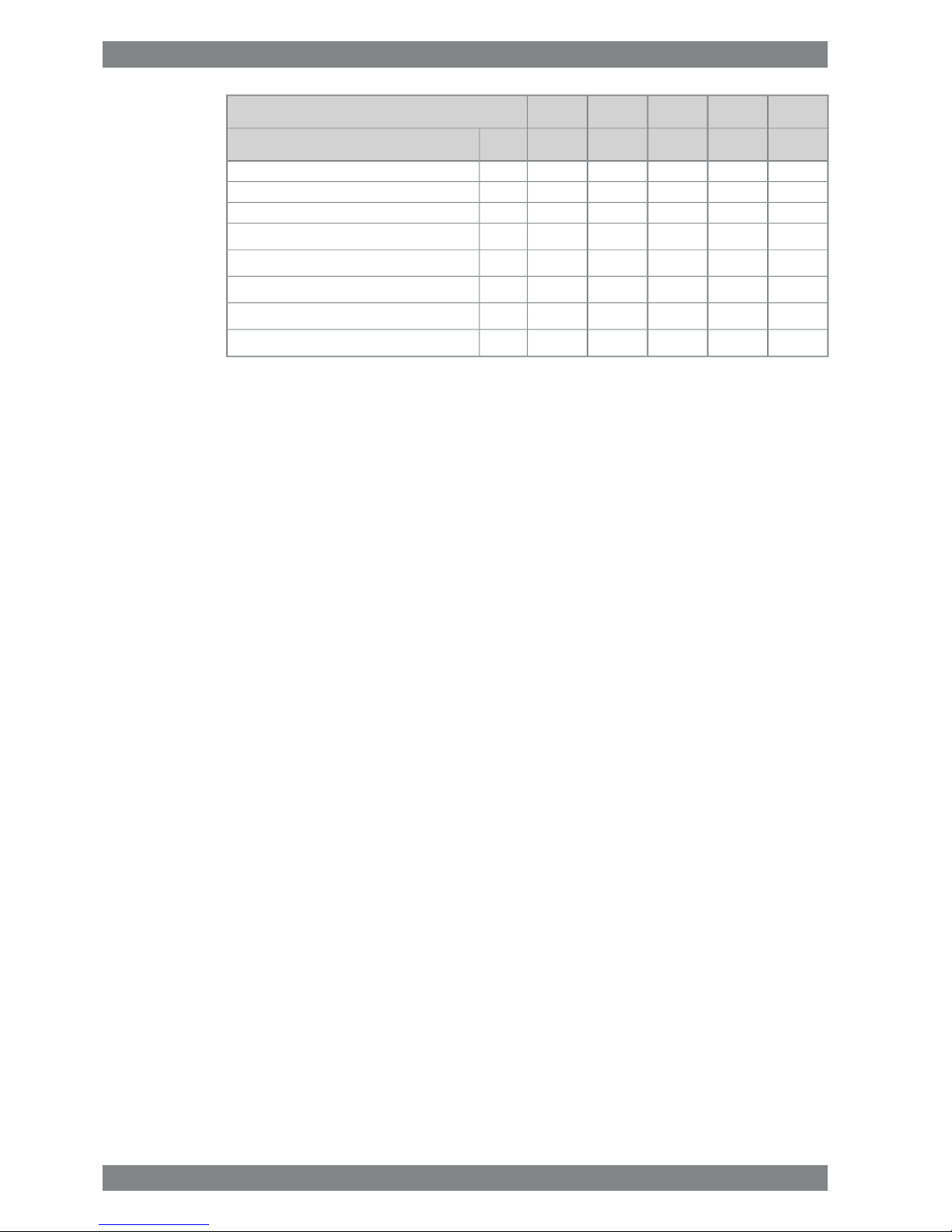

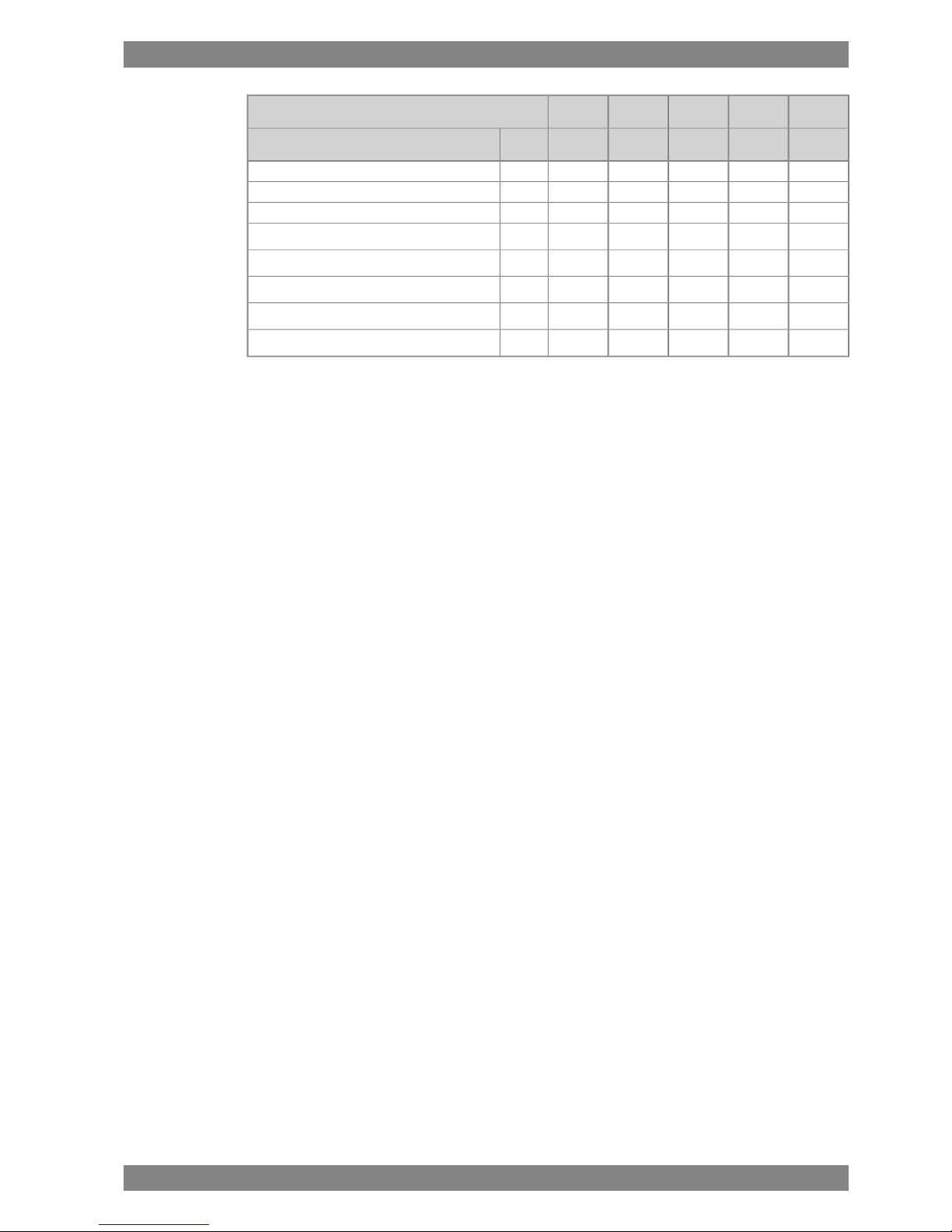

3.2 Wärtsilä 10V31

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 10V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

61006100590061005900kWEngine output

3.013.013.033.013.03MPaMean effective pressure

Combustion air system (Note 1)

10.7910.7910.410.7910.4kg/sFlow at 100% load

4545454545°CTemperature at turbocharger intake, max.

6565656565°CAir temperature after air cooler (TE 601)

Exhaust gas system (Note 2)

11.111.110.711.110.7kg/sFlow at 100% load

9.49.59.19.59.1kg/sFlow at 85% load

8.18.58.28.58.2kg/sFlow at 75% load

5.76.56.26.56.2kg/sFlow at 50% load

273273275273275°CTemperature after turbocharger, 100% load (TE 517)

277275277275277°CTemperature after turbocharger, 85% load (TE 517)

295282284282284°CTemperature after turbocharger, 75% load (TE 517)

320286288286288°CTemperature after turbocharger, 50% load (TE 517)

5.05.05.05.05.0kPaBackpressure, max.

788788775788775

mmCalculated pipe diameter for 35m/s

Heat balance (Note 3)

618618575618575kWJacket water, HT-circuit

11571157107311571073kWCharge air, HT-circuit

15371537149415371494kWCharge air, LT-circuit

653653609653609kWLubricating oil, LT-circuit

171171164171164kWRadiation

For optional engineversions heat balances may differ

Fuel system (Note 4)

1000±1001000±1001000±1001000±1001000±100kPaPressure before injection pumps (PT 101)

60.060.060.060.060.0m3/hEngine driven pump capacity (MDF only)

16...2416...2416...2416...2416...24cStHFO viscosity before engine

140140140140140°CHFO temperature before engine, max. (TE 101)

2.02.02.02.02.0cStMDF viscosity, min

4545454545°CMDF temperature before engine, max. (TE 101)

174.4174.9174.0174.4173.5

g/kWhFuel consumption at 100% load, HFO

171.6172.0171.1171.6170.6

g/kWhFuel consumption at 85% load, HFO

171.6174.0173.0173.5172.5

g/kWhFuel consumption at 75% load, HFO

178.5183.8182.8183.3182.3

g/kWhFuel consumption at 50% load, HFO

173.5174.0173.0173.5172.5

g/kWhFuel consumption at 100% load, MDF

170.6171.1170.1170.6169.7

g/kWhFuel consumption at 85% load, MDF

170.6173.0172.0172.5171.6

g/kWhFuel consumption at 75% load, MDF

3-4 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide3. Technical Data

Page 19

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 10V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

176.6181.9180.9181.4180.4

g/kWhFuel consumption at 50% load, MDF

22.122.121.322.121.2

kg/hClean leak fuel quantity, MDF at 100% load

4.44.54.34.44.3

kg/hClean leak fuel quantity, HFO at 100% load

Lubricating oil system

420420420420420

kPaPressure before bearings, nom. (PT 201)

4040404040

kPaSuction ability main pump, including pipe loss, max.

6060606060

kPaPriming pressure, nom. (PT 201)

3535353535

kPaSuction ability priming pump, including pipeloss, max.

7070707070

°CTemperature before bearings, nom. (TE 201)

8282828282

°CTemperature after engine, approx.

144130125130125

m³/hPump capacity (main), engine driven

120120120120120

m³/hPump capacity (main), stand-by

24.0 / 24.024.0 / 24.024.0 / 24.024.0 / 24.024.0 / 24.0m³/hPriming pump capacity, 50Hz/60Hz

3.03.03.03.03.0

m³Oil volume, wet sump, nom.

8.28.28.08.28.0

m³Oil volume in separate system oil tank, nom.

0.450.450.450.450.45

g/kWhOil consumption (100% load), approx.

24502450245024502450l/minCrankcase ventilation flow rate at full load

0.10.10.10.10.1kPaCrankcase ventilation backpressure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8litersOil volume in turning device

Cooling water system

High temperature cooling water system

382 + stat-

ic

382 + stat-

ic

382 + stat-

ic

382 + stat-

ic

382 + stat-

ic

kPaPressure at engine, after pump, nom. (PT 401)

600600600600600

kPaPressure at engine, after pump, max. (PT 401)

8383838383

°CTemperature before cylinders, approx. (TE 401)

9696969696°CHT-water out from engine, nom (TE432)

9090909090

m³/hCapacity of engine driven pump, nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system, max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

0.6420.6420.6420.6420.642

m³Water volume in engine

Low temperature cooling water system

25 ... 3825 ... 3825 ... 3825 ... 3825 ... 38°CTemperature before engine (TE 451)

9090909090

m³/hCapacity of engine driven pump, nom.

00000

kPaPressure drop over charge air cooler

4141414141

kPaPressure drop over charge air cooler (one-stage)

110110110110110

kPaPressure drop over charge air cooler (two-stage)

100100100100100

kPaPressure drop in external system, max.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-5

3. Technical DataWärtsilä 31 Product Guide

Page 20

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 10V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

70 ... 15070 ... 15070 ... 15070 ... 15070 ... 150kPaPressure from expansion tank

Starting air system

30003000300030003000

kPaPressure, nom.

15001500150015001500

kPaPressure at engine during start, min. (20°C)

30003000300030003000

kPaPressure, max.

16001600160016001600

kPaLow pressure limit in air vessels

5.15.15.15.15.1

Nm

3

Air consumption per start

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

10°C.

Note 2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat

exchangers. In arctic option charge air coolers in LT circuit.

Note 3

At ambient conditions according to ISO 15550.Lower calorific value 42 700 kJ/kg. With engine driven pumps (two cooling

water + one lubricating oil pump). Tolerance 5%.

Note 4

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

3-6 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide3. Technical Data

Page 21

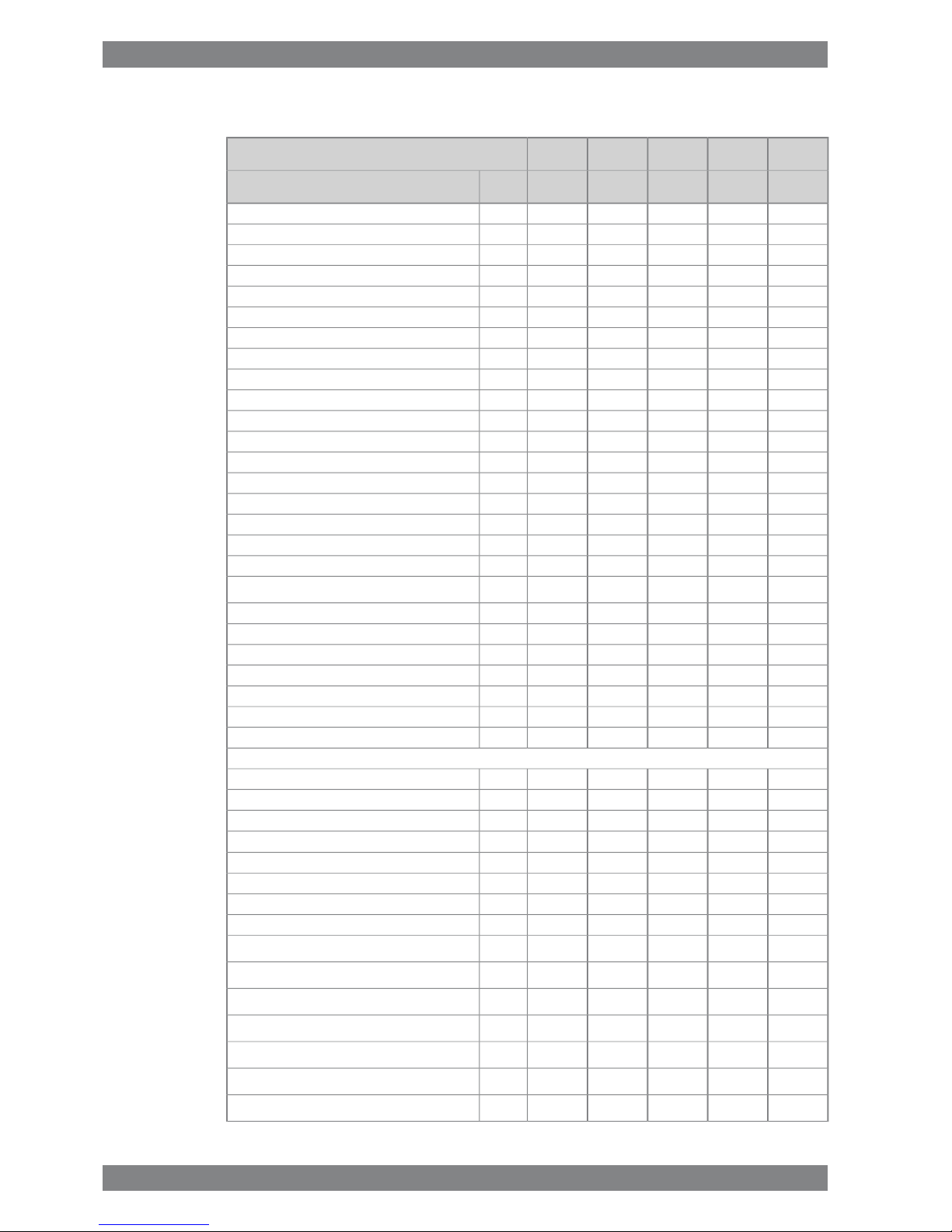

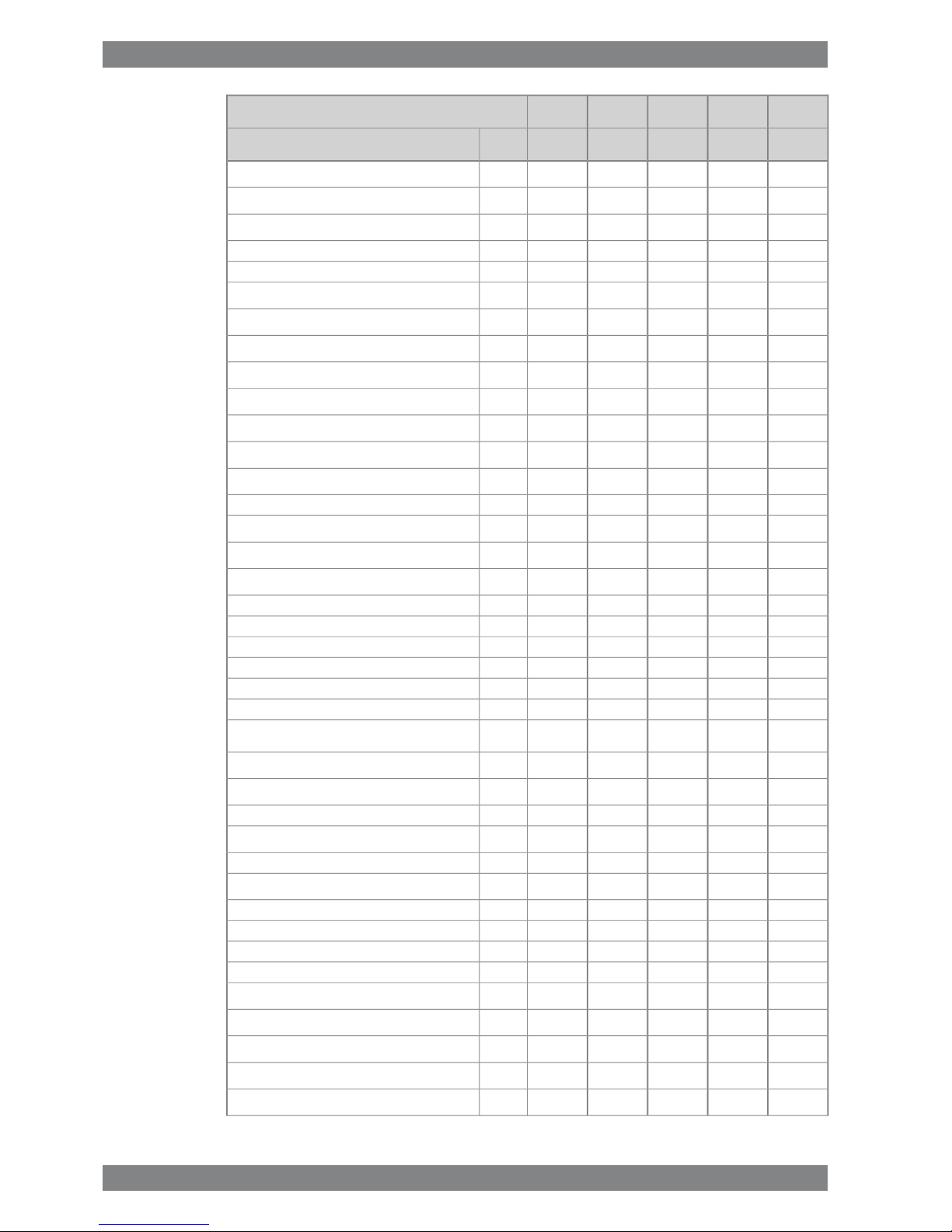

3.3 Wärtsilä 12V31

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 12V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

73207320708073207080kWEngine output

3.013.013.033.013.03MPaMean effective pressure

Combustion air system (Note 1)

12.9512.9512.4812.9512.48kg/sFlow at 100% load

4545454545°CTemperature at turbocharger intake, max.

6565656565°CAir temperature after air cooler (TE 601)

Exhaust gas system (Note 2)

13.3213.3212.8413.3212.84kg/sFlow at 100% load

11.2811.410.9211.410.92kg/sFlow at 85% load

9.7210.29.8410.29.84kg/sFlow at 75% load

6.847.87.447.87.44kg/sFlow at 50% load

273273275273275°CTemperature after turbocharger, 100% load (TE 517)

277275277275277°CTemperature after turbocharger, 85% load (TE 517)

295282284282284°CTemperature after turbocharger, 75% load (TE 517)

320286288286288°CTemperature after turbocharger, 50% load (TE 517)

5.05.05.05.05.0kPaBackpressure, max.

863863849863849

mmCalculated pipe diameter for 35m/s

Heat balance (Note 3)

742742690742690kWJacket water, HT-circuit

13881388128813881288kWCharge air, HT-circuit

18441844179318441793kWCharge air, LT-circuit

784784731784731kWLubricating oil, LT-circuit

205205197205197kWRadiation

For optional engine versions heat balances may differ

Fuel system (Note 4)

1000±1001000±1001000±1001000±1001000±100kPaPressure before injection pumps (PT 101)

120.0120.0120.0120.0120.0m3/hEngine driven pump capacity (MDF only)

16...2416...2416...2416...2416...24cStHFO viscosity before engine

140140140140140°CHFO temperature before engine, max. (TE 101)

2.02.02.02.02.0cStMDF viscosity, min

4545454545°CMDF temperature before engine, max. (TE 101)

174.4174.9174.0174.4173.5

g/kWhFuel consumption at 100% load, HFO

171.6172.0171.1171.6170.6

g/kWhFuel consumption at 85% load, HFO

171.6174.0173.0173.5172.5

g/kWhFuel consumption at 75% load, HFO

178.5183.8182.8183.3182.3

g/kWhFuel consumption at 50% load, HFO

173.5174.0173.0173.5172.5

g/kWhFuel consumption at 100% load, MDF

170.6171.1170.1170.6169.7

g/kWhFuel consumption at 85% load, MDF

170.6173.0172.0172.5171.6

g/kWhFuel consumption at 75% load, MDF

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-7

3. Technical DataWärtsilä 31 Product Guide

Page 22

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 12V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

176.6181.9180.9181.4180.4

g/kWhFuel consumption at 50% load, MDF

26.526.625.626.525.5

kg/hClean leak fuel quantity, MDF at 100% load

5.35.35.15.35.1

kg/hClean leak fuel quantity, HFO at 100% load

Lubricating oil system

420420420420420

kPaPressure before bearings, nom. (PT 201)

4040404040

kPaSuction ability main pump, including pipe loss, max.

6060606060

kPaPriming pressure, nom. (PT 201)

3535353535

kPaSuction ability priming pump, including pipeloss, max.

7070707070

°CTemperature before bearings, nom. (TE 201)

8282828282

°CTemperature after engine, approx.

170144138144138

m³/hPump capacity (main), engine driven

137137137137137

m³/hPump capacity (main), stand-by

29.0 / 29.029.0 / 29.029.0 / 29.029.0 / 29.029.0 / 29.0m³/hPriming pump capacity, 50Hz/60Hz

3.33.33.33.33.3

m³Oil volume, wet sump, nom.

9.99.99.69.99.6

m³Oil volume in separate system oil tank, nom.

0.450.450.450.450.45

g/kWhOil consumption (100% load), approx.

29402940294029402940l/minCrankcase ventilation flow rate at full load

0.10.10.10.10.1kPaCrankcase ventilation backpressure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8litersOil volume in turning device

Cooling water system

High temperature cooling water system

363 + stat-

ic

363 + stat-

ic

363 + stat-

ic

363 + stat-

ic

363 + stat-

ic

kPaPressure at engine, after pump, nom. (PT 401)

600600600600600

kPaPressure at engine, after pump, max. (PT 401)

8383838383

°CTemperature before cylinders, approx. (TE 401)

9696969696°CHT-water out from engine, nom (TE432)

110110110110110

m³/hCapacity of engine driven pump, nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system, max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

m³Water volume in engine

Low temperature cooling water system

25 ... 3825 ... 3825 ... 3825 ... 3825 ... 38°CTemperature before engine (TE 451)

110110110110110

m³/hCapacity of engine driven pump, nom.

4141414141

kPaPressure drop over charge air cooler (one-stage)

110110110110110

kPaPressure drop over charge air cooler (two-stage)

115115115115115

kPaPressure drop over oil cooler

100100100100100

kPaPressure drop in external system, max.

3-8 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide3. Technical Data

Page 23

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 12V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

70 ... 15070 ... 15070 ... 15070 ... 15070 ... 150kPaPressure from expansion tank

Starting air system

30003000300030003000

kPaPressure, nom.

15001500150015001500

kPaPressure at engine during start, min. (20°C)

30003000300030003000

kPaPressure, max.

16001600160016001600

kPaLow pressure limit in air vessels

5.45.45.45.45.4

Nm

3

Air consumption per start

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

10°C.

Note 2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat

exchangers. In arctic option charge air coolers in LT circuit.

Note 3

At ambient conditions according to ISO 15550.Lower calorific value 42 700 kJ/kg. With engine driven pumps (two cooling

water + one lubricating oil pump). Tolerance 5%.

Note 4

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-9

3. Technical DataWärtsilä 31 Product Guide

Page 24

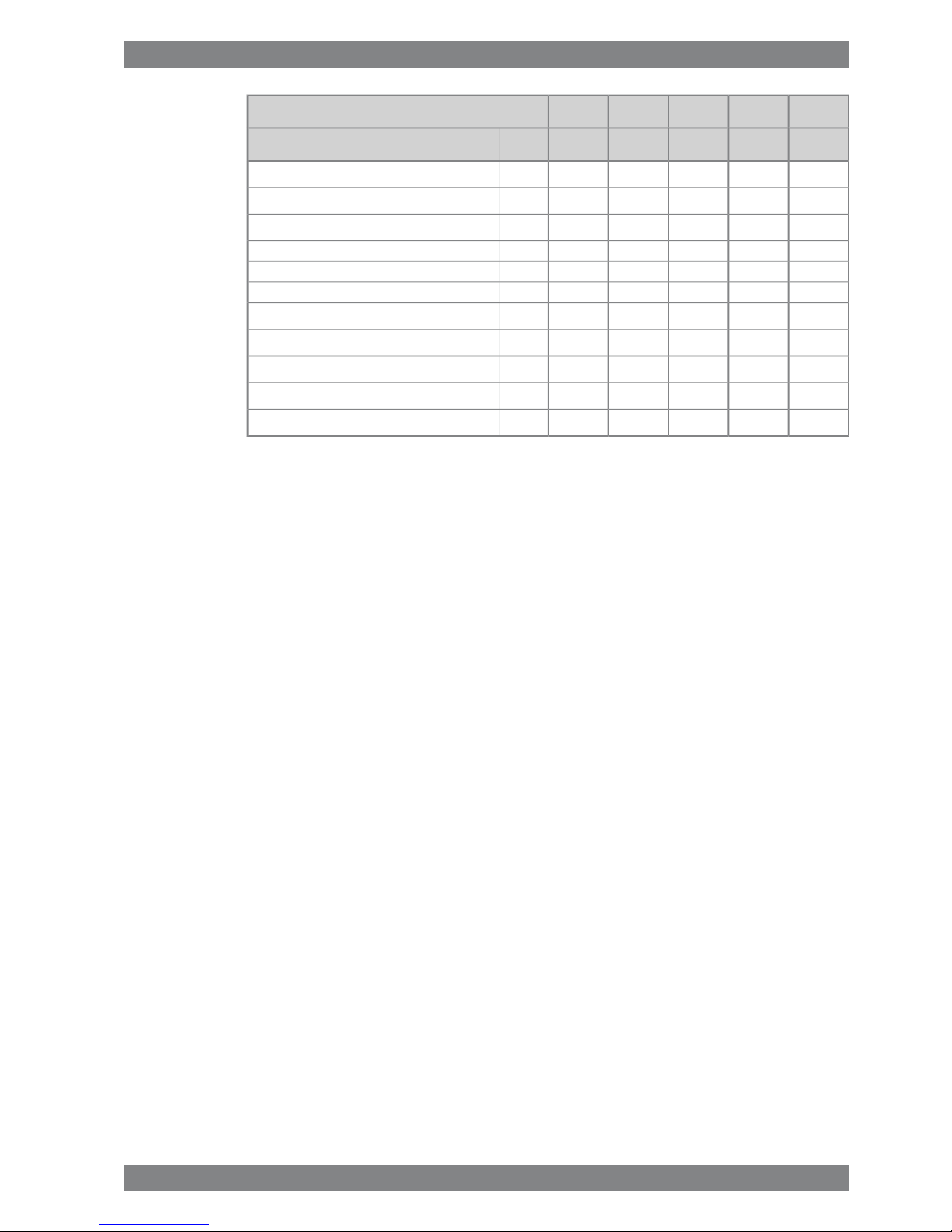

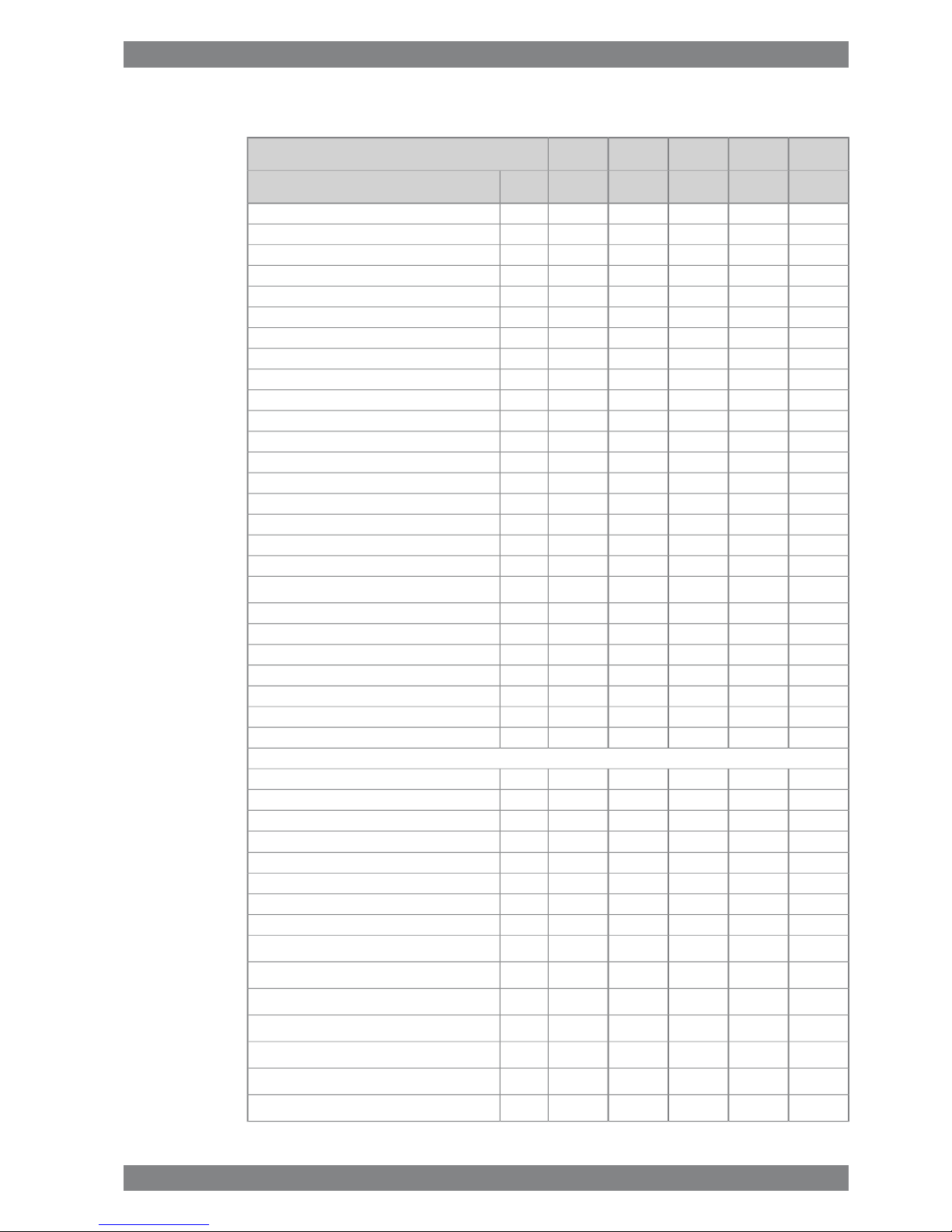

3.4 Wärtsilä 14V31

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 14V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

85408540826085408260kWEngine output

3.013.013.033.013.03MPaMean effective pressure

Combustion air system (Note 1)

15.1115.1114.5615.1114.56kg/sFlow at 100% load

4545454545°CTemperature at turbocharger intake, max.

6565656565°CAir temperature after air cooler (TE 601)

Exhaust gas system (Note 2)

15.5415.5414.9815.5414.98kg/sFlow at 100% load

13.1613.312.7413.312.74kg/sFlow at 85% load

11.3411.911.4811.911.48kg/sFlow at 75% load

7.989.18.689.18.68kg/sFlow at 50% load

273273275273275°CTemperature after turbocharger, 100% load (TE 517)

277275277275277°CTemperature after turbocharger, 85% load (TE 517)

295282284282284°CTemperature after turbocharger, 75% load (TE 517)

320286288286288°CTemperature after turbocharger, 50% load (TE 517)

5.05.05.05.05.0kPaBackpressure, max.

933933917933917

mmCalculated pipe diameter for 35m/s

Heat balance (Note 3)

865865805865805kWJacket water, HT-circuit

16201620150216201502kWCharge air, HT-circuit

21522152209221522092kWCharge air, LT-circuit

914914853914853kWLubricating oil, LT-circuit

239239230239230kWRadiation

For optional engineversions heat balances may differ

Fuel system (Note 4)

1000±1001000±1001000±1001000±1001000±100kPaPressure before injection pumps (PT 101)

120.0120.0120.0120.0120.0m3/hEngine driven pump capacity (MDF only)

16...2416...2416...2416...2416...24cStHFO viscosity before engine

140140140140140°CHFO temperature before engine, max. (TE 101)

2.02.02.02.02.0cStMDF viscosity, min

4545454545°CMDF temperature before engine, max. (TE 101)

174.4174.9174.0174.4173.5

g/kWhFuel consumption at 100% load, HFO

171.6172.0171.1171.6170.6

g/kWhFuel consumption at 85% load, HFO

171.6174.0173.0173.5172.5

g/kWhFuel consumption at 75% load, HFO

178.5183.8182.8183.3182.3

g/kWhFuel consumption at 50% load, HFO

173.5174.0173.0173.5172.5

g/kWhFuel consumption at 100% load, MDF

170.6171.1170.1170.6169.7

g/kWhFuel consumption at 85% load, MDF

170.6173.0172.0172.5171.6

g/kWhFuel consumption at 75% load, MDF

3-10 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide3. Technical Data

Page 25

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 14V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

176.6181.9180.9181.4180.4

g/kWhFuel consumption at 50% load, MDF

30.931.029.830.929.7

kg/hClean leak fuel quantity, MDF at 100% load

6.26.26.06.26.0

kg/hClean leak fuel quantity, HFO at 100% load

Lubricating oil system

420420420420420

kPaPressure before bearings, nom. (PT 201)

4040404040

kPaSuction ability main pump, including pipe loss, max.

6060606060

kPaPriming pressure, nom. (PT 201)

3535353535

kPaSuction ability priming pump, including pipeloss, max.

7070707070

°CTemperature before bearings, nom. (TE 201)

8282828282

°CTemperature after engine, approx.

189170164170164

m³/hPump capacity (main), engine driven

160160160160160

m³/hPump capacity (main), stand-by

34.0 / 34.034.0 / 34.034.0 / 34.034.0 / 34.034.0 / 34.0m³/hPriming pump capacity, 50Hz/60Hz

3.853.853.853.853.85

m³Oil volume, wet sump, nom.

11.511.511.211.511.2

m³Oil volume in separate system oil tank, nom.

0.450.450.450.450.45

g/kWhOil consumption (100% load), approx.

34303430343034303430l/minCrankcase ventilation flow rate at full load

0.10.10.10.10.1kPaCrankcase ventilation backpressure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8litersOil volume in turning device

Cooling water system

High temperature cooling water system

397 + stat-

ic

397 + stat-

ic

397 + stat-

ic

397 + stat-

ic

397 + stat-

ic

kPaPressure at engine, after pump, nom. (PT 401)

600600600600600

kPaPressure at engine, after pump, max. (PT 401)

8383838383

°CTemperature before cylinders, approx. (TE 401)

9696969696°CHT-water out from engine, nom (TE432)

189189130189130

m³/hCapacity of engine driven pump, nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system, max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

m³Water volume in engine

Low temperature cooling water system

25 ... 3825 ... 3825 ... 3825 ... 3825 ... 38°CTemperature before engine (TE 451)

130130130130130

m³/hCapacity of engine driven pump, nom.

4141414141

kPaPressure drop over charge air cooler (one-stage)

110110110110110

kPaPressure drop over charge air cooler (two-stage)

115115115115115

kPaPressure drop over oil cooler

100100100100100

kPaPressure drop in external system, max.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-11

3. Technical DataWärtsilä 31 Product Guide

Page 26

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 14V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

70 ... 15070 ... 15070 ... 15070 ... 15070 ... 150kPaPressure from expansion tank

Starting air system

30003000300030003000

kPaPressure, nom.

15001500150015001500

kPaPressure at engine during start, min. (20°C)

30003000300030003000

kPaPressure, max.

16001600160016001600

kPaLow pressure limit in air vessels

5.85.85.85.85.8

Nm

3

Air consumption per start

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

10°C.

Note 2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat

exchangers. In arctic option charge air coolers in LT circuit.

Note 3

At ambient conditions according to ISO 15550.Lower calorific value 42 700 kJ/kg. With engine driven pumps (two cooling

water + one lubricating oil pump). Tolerance 5%.

Note 4

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

3-12 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide3. Technical Data

Page 27

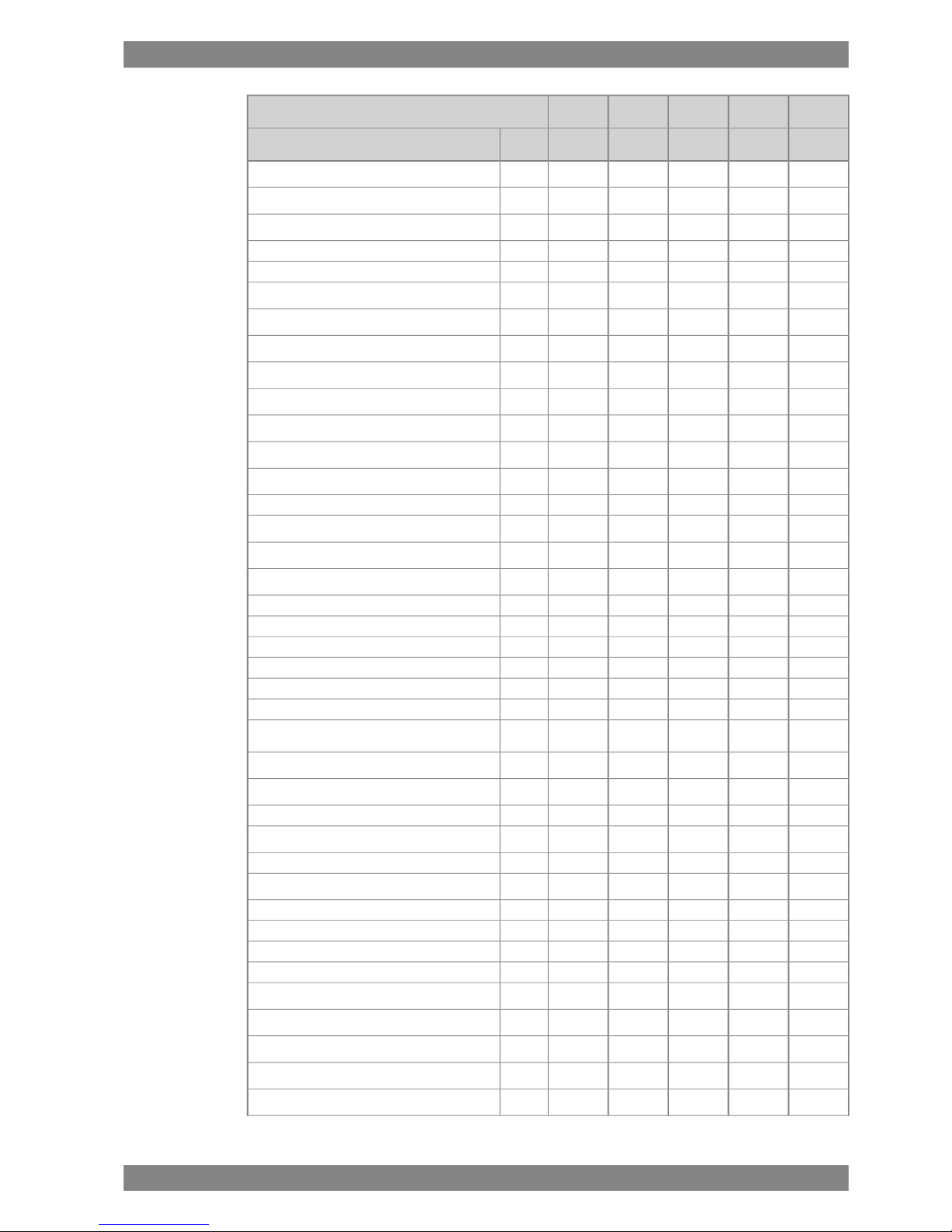

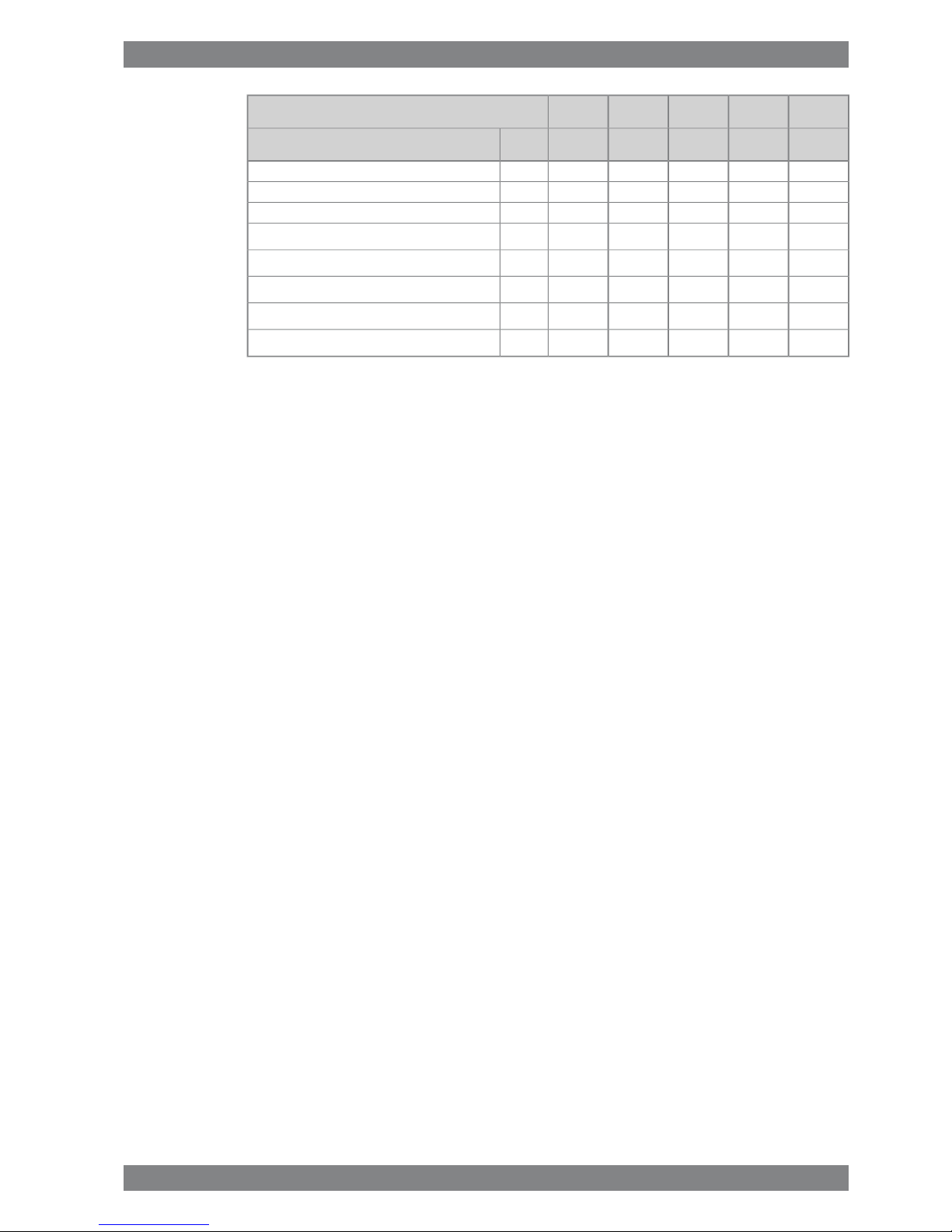

3.5 Wärtsilä 16V31

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 16V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

97609760944097609440kWEngine output

3.013.013.033.013.03MPaMean effective pressure

Combustion air system (Note 1)

17.2717.2716.6517.2716.65kg/sFlow at 100% load

4545454545°CTemperature at turbocharger intake, max.

6565656565°CAir temperature after air cooler (TE 601)

Exhaust gas system (Note 2)

17.7617.7617.1217.7617.12kg/sFlow at 100% load

15.0415.214.5615.214.56kg/sFlow at 85% load

12.9613.613.1213.613.12kg/sFlow at 75% load

9.1210.49.9210.49.92kg/sFlow at 50% load

273273275273275°CTemperature after turbocharger, 100% load (TE 517)

277275277275277°CTemperature after turbocharger, 85% load (TE 517)

295282284282284°CTemperature after turbocharger, 75% load (TE 517)

320286288286288°CTemperature after turbocharger, 50% load (TE 517)

5.05.05.05.05.0kPaBackpressure, max.

997997981997981

mmCalculated pipe diameter for 35m/s

Heat balance (Note 3)

989989920989920kWJacket water, HT-circuit

18511851171718511717kWCharge air, HT-circuit

24592459239024592390kWCharge air, LT-circuit

104510459741045974kWLubricating oil, LT-circuit

274274262274262kWRadiation

For optional engineversions heat balances may differ

Fuel system (Note 4)

1000±1001000±1001000±1001000±1001000±100kPaPressure before injection pumps (PT 101)

120.0120.0120.0120.0120.0m3/hEngine driven pump capacity (MDF only)

16...2416...2416...2416...2416...24cStHFO viscosity before engine

140140140140140°CHFO temperature before engine, max. (TE 101)

2.02.02.02.02.0cStMDF viscosity, min

4545454545°CMDF temperature before engine, max. (TE 101)

174.4174.9174.0174.4173.5

g/kWhFuel consumption at 100% load, HFO

171.7172.0171.1171.6170.6

g/kWhFuel consumption at 85% load, HFO

171.7174.0173.0173.5172.5

g/kWhFuel consumption at 75% load, HFO

178.6183.8182.8183.3182.3

g/kWhFuel consumption at 50% load, HFO

173.5174.0173.0173.5172.5

g/kWhFuel consumption at 100% load, MDF

170.7171.1170.1170.6169.7

g/kWhFuel consumption at 85% load, MDF

170.7173.0172.0172.5171.6

g/kWhFuel consumption at 75% load, MDF

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-13

3. Technical DataWärtsilä 31 Product Guide

Page 28

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 16V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

176.7181.9180.9181.4180.4

g/kWhFuel consumption at 50% load, MDF

35.335.434.135.334.0

kg/hClean leak fuel quantity, MDF at 100% load

7.17.16.97.16.8

kg/hClean leak fuel quantity, HFO at 100% load

Lubricating oil system

420420420420420

kPaPressure before bearings, nom. (PT 201)

4040404040

kPaSuction ability main pump, including pipe loss, max.

6060606060

kPaPriming pressure, nom. (PT 201)

3535353535

kPaSuction ability priming pump, including pipeloss, max.

7070707070

°CTemperature before bearings, nom. (TE 201)

8282828282

°CTemperature after engine, approx.

223189182189182

m³/hPump capacity (main), engine driven

176176176176176

m³/hPump capacity (main), stand-by

38.0 / 38.038.0 / 38.038.0 / 38.038.0 / 38.038.0 / 38.0m³/hPriming pump capacity, 50Hz/60Hz

4.44.44.44.44.4

m³Oil volume, wet sump, nom.

13.213.212.713.212.7

m³Oil volume in separate system oil tank, nom.

0.450.450.450.450.45

g/kWhOil consumption (100% load), approx.

39203920392039203920l/minCrankcase ventilation flow rate at full load

0.10.10.10.10.1kPaCrankcase ventilation backpressure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8litersOil volume in turning device

Cooling water system

High temperature cooling water system

373 + stat-

ic

373 + stat-

ic

373 + stat-

ic

373 + stat-

ic

373 + stat-

ic

kPaPressure at engine, after pump, nom. (PT 401)

600600600600600

kPaPressure at engine, after pump, max. (PT 401)

8383838383

°CTemperature before cylinders, approx. (TE 401)

9696969696°CHT-water out from engine, nom (TE432)

150150150150150

m³/hCapacity of engine driven pump, nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system, max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

m³Water volume in engine

Low temperature cooling water system

25 ... 3825 ... 3825 ... 3825 ... 3825 ... 38°CTemperature before engine (TE 451)

150150150150150

m³/hCapacity of engine driven pump, nom.

4141414141

kPaPressure drop over charge air cooler (one-stage)

110110110110110

kPaPressure drop over charge air cooler (two-stage)

115115115115115

kPaPressure drop over oil cooler

100100100100100

kPaPressure drop in external system, max.

3-14 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide3. Technical Data

Page 29

ME

IMO Tier 2

AUX

IMO Tier 2

AUX

IMO Tier 2

DE

IMO Tier 2

DE

IMO Tier 2

Wärtsilä 16V31

750

610

750

610

720

590

750

610

720

590

RPM

kW/cyl

Engine speed

Cylinder output

70 ... 15070 ... 15070 ... 15070 ... 15070 ... 150kPaPressure from expansion tank

Starting air system

30003000300030003000

kPaPressure, nom.

15001500150015001500

kPaPressure at engine during start, min. (20°C)

30003000300030003000

kPaPressure, max.

16001600160016001600

kPaLow pressure limit in air vessels

6.36.36.36.36.3

Nm

3

Air consumption per start

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

10°C.

Note 2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat

exchangers. In arctic option charge air coolers in LT circuit.

Note 3

At ambient conditions according to ISO 15550.Lower calorific value 42 700 kJ/kg. With engine driven pumps (two cooling

water + one lubricating oil pump). Tolerance 5%.

Note 4

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 3-15

3. Technical DataWärtsilä 31 Product Guide

Page 30

This page intentionally left blank

Page 31

4. Description of the Engine

4.1 Definitions

Fig 4-1 Engine definitions (V93C0028)

4.2 Main components and systems

The dimensions and weights of engines are shown in section 1.4 Dimensions and weights .

4.2.1 Engine block

The engine block, made of nodular cast iron, is cast in one piece for all cylinder numbers and

it supports the underslung crankshaft. The block has been given a stiff and durable design to

absorb internal forces and the engine can therefore also be resiliently mounted not requiring

any intermediate foundations. It incorporates water and charge air main and side channels.

Also camshaft bearing housings are incorporated in the engine block. The engines are equipped

with crankcase explosion relief valve with flame arrester.

The main bearing caps, made of nodular cast iron, are fixed with two hydraulically tensioned

screws from below. They are guided sideways and vertically by the engine block. Hydraulically

tensioned horizontal side screws at the lower guiding provide a very rigid crankshaft bearing

assembly.

A hydraulic jack, supported in the oil sump, offers the possibility to lower and lift the main

bearing caps, e.g. when inspecting the bearings. Lubricating oil is led to the bearings through

this jack.

The oil sump, a light welded design, is mounted on the engine block from below. The oil sump

is available in two alternative designs, wet or dry sump, depending on the type of application.

The wet oil sump includes a suction pipe to the lubricating oil pump. For wet sump there is a

main distributing pipe for lubricating oil, suction pipes and return connections for the separator.

For the dry sump there is a main distributing oil pipe for lubricating oil and drains at either end

to a separate system oil tank.

The engine holding down bolts are hydraulically tightened in order to facilitate the engine

installation to both rigid and resilient foundation.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 4-1

4. Description of the EngineWärtsilä 31 Product Guide

Page 32

4.2.2 Crankshaft

Crankshaft line is built up from several pieces: crankshaft, counter weights, split camshaft

gear wheel and pumpdrive arrangement.

Crankshaft itself is forged in one piece. Both main bearings and big end bearings temperatures

are continuously monitored.

Counterweights are fitted on every web. High degree of balancing results in an even and thick

oil film for all bearings.

The connecting rods are arranged side-by-side and the diameters of the crank pins and journals

are equal irrespective of the cylinder number.

All crankshafts can be provided with torsional vibration dampers or tuning masses at the free

end of the engine, if necessary. Main features of crankshaft design: clean steel technology

minimizes the amount of slag forming elements and guarantees superior material durability.

The crankshaft alignment is always done on a thoroughly warm engine after the engine is

stopped.

4.2.3 Main bearings and big end bearings

The main bearings and the big end bearings are of tri-metal design with steel back, lead-bronze

lining and a soft running layer. The bearings are covered with a Sn-flash for corrosion protection.

Even minor form deviations can become visible on the bearing surface in the running in phase.

This has no negative influence on the bearing function. A wireless system for real-time

temperature monitoring of connecting rod big end bearings, "BEB monitoring system", is as

standard.

4.2.4 Cylinder liner

The cylinder liners are centrifugally casted of a special alloyed cast iron. The top collar of the

cylinder liner is provided with a water jacket for distributing cooling water through the cylinder

liner cooling bores. This will give an efficient control of the liner temperature.

A jet cooling nozzle inside the cylinder liner is injecting oil to the underside of the piston and

is then cooling the piston and lubricating the gudgeon pin bearing through the oil channels in

the top of the connecting rod.

4.2.5 Piston

The piston is of composite type with steel crown and nodular cast iron skirt. A piston skirt

lubricating system, featuring oil bores in a groove on the piston skirt, lubricates the piston

skirt/cylinder liner. The piston top is oil cooled by the jet cooling as mentioned above. The

piston ring grooves are hardened.

4.2.6 Piston rings

The piston ring set are located in the piston crown and consists of two directional compression

rings and one spring-loaded conformable oil scraper ring. Running face of compression rings

are chromium-ceramic-plated.

4.2.7 Cylinder head

The cross flow cylinder head is made of cast iron. The mechanical load is absorbed by a flame

plate, which together with the upper deck and the side walls form a rigid box section. There

are four hydraulically tightened cylinder head bolts. The exhaust valve seats and the flame

deck are efficiently and direct water-cooled. The valve seat rings are made of alloyed steel,

for wear resistance. All valves are hydraulic controlled with valve guides and equipped with

valve springs and rotators.

4-2 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide4. Description of the Engine

Page 33

A small side air receiver is located in the hot box, including charge air bends with integrated

hydraulics and charge air riser pipes.

Following components are connected to the cylinder head:

● Charge air components for side receiver

● Exhaust gas pipe to exhaust system

● Cooling water collar

● Quill pipe with High Pressure (HP) fuel pipe connections

4.2.8 Camshaft and valve mechanism

The cams are integrated in the drop forged shaft material. The bearing journals are made in

separate pieces, which are fitted, to the camshaft pieces by flange connections. The camshaft

bearing housings are integrated in the engine block casting and are thus completely closed.

The bearings are installed and removed by means of a hydraulic tool. The camshaft covers,

one for each cylinder, seal against the engine block with a closed O-ring profile. The valve

tappets are of piston type with self-adjustment of roller against cam to give an even distribution

of the contact pressure. Inlet and exhaust valves have a special steam coating and hard facing

on the seat surface, for long lifetime. The valve springs make the valve mechanism dynamically

stable.

The step-less valve mechanism makes it possible to control the timing of both inlet & exhaust

valves. It allows to always use a proper scavenging period. This is needed to optimize and

balance emissions, fuel consumption, operational flexibility & load taking, whilst maintaining

thermal and mechanical reliability. The design enables clearly longer maintenance interval,

due to the reduced thermal and mechanical stress on most of the components in the valve

mechanism.

4.2.9 Camshaft drive

The camshafts are driven by the crankshaft through a gear train.

4.2.10 Turbocharging and charge air cooling

The selected 2-stage turbocharging offers ideal combination of high-pressure ratios and good

efficiency both at full and part load. The turbochargers can be placed at the free end or flywheel

end of the engine. For cleaning of the turbochargers during operation there is, as standard, a

water washing device for the air (compressor) and exhaust gas (turbine) side of the LP stage

and for the exhaust gas (turbine) side of the HP stage. The water washing device is connected

to an external washing unit. The turbochargers are supplied with inboard plain bearings, which

offers easy maintenance of the cartridge from the compressor side. The turbochargers are

lubricated by engine lubricating oil with integrated connections.

An Exhaust gas Waste Gate (EWG) system controls the exhaust gas flow by-passing for both

high pressure (HP) and low pressure (LP) turbine stages. EWG is needed also in case of engines

equipped with exhaust gas after treatment based on Selective Catalytic Reaction (SCR).

By using Air Waste Gate (AWG) for bleeding air out from the charge air system, the charge air

pressure and the margin from LP compressor surging is controlled. The charge air pressure

control is used to avoid excessive charge air pressure preventing excessive firing pressure.

A step-less Air By-pass valve (ABP) system is used in all engine applications for preventing

surging of turbocharger compressors in case of rapid engine load reduction. When the ABP

valve is open part of charge air is released to the exhaust side.

The Charge Air Coolers (CAC) consist of a 2-stage type cooler (LP CAC) between the LP and

HP compressor stages and a 1-stage cooler (HP CAC) between the HP compressor stage

and the charge air receiver. The LP CAC is cooled with LT-water or in some cases by both

HT- and LT-water. The HP CAC is always cooled by LT-water. Fresh water is used for both

circuits.

Wärtsilä 31 Product Guide - a1 - 18 October 2016 4-3

4. Description of the EngineWärtsilä 31 Product Guide

Page 34

See chapter Exhaust gas & charge air systems for more information.

4.2.11 Fuel injection equipment

The fuel injection equipment and system piping are located in a hotbox, providing maximum

reliability and safety when using preheated heavy fuels. In the Wärtsilä electronic fuel injection

rate optimized nozzles system, the fuel is pressurized in the high pressure HP-pumps from

where the fuel is fed to the injection valves. The fuel system consists of different numbers of

fuel oil HP pumps, depending of the cylinder configuration, located at the engine pump cover.

From the HP pumps, high pressure pipes are connected to the cylinder heads.

A valve block is mounted at the fuel outlet pipe, including Pressure Drop and Safety Valve

(PDSV), Circulation Valve (CV) and a fuel pressure discharge volume. The PDSV acts as

mechanical safety valve and the fuel volume lowers the system pressure. The injection valves

are electronic controlled and the injection timing is pre-set in the control system software. The

injector solenoids have a own cooling system.

4.2.12 Lubricating oil system

The engine internal lubricating oil system include the engine driven lubricating oil pump, the

electrically driven prelubricating oil pump, thermostatic valve, filters and lubricating oil cooler.

The lubricating oil pumps are located in the free end of the engine, while the automatic filter,

cooler and thermostatic valve are integrated into one module.

4.2.13 Cooling water system

The fresh water cooling system is divided into a high temperature (HT) and a low temperature

(LT) circuit.

For engines operating in normal conditions the HT-water is cooling the cylinders (jacket) and

the first stage of the low pressure 2-stage charge air cooler. The LT-water is cooling the

lbricating oil cooler, the second stage of the low pressure 2-stage charge air cooler and the

high pressure 1-stage charge air cooler.

For engines operating in cold conditions the HT-water is cooling the cylinders (Jacket). A

HT-water pump is circulating the cooling water in the circuit and a thermostatic valve mounted

in the internal cooling water system, controls the outlet temperature of the circuit. The LT-circuit

is cooling the Lubricating Oil Cooler (LOC), the second stage of the Low Pressure 2-stage

charge air cooler, the High Pressure 1-stage charge air cooler and the first stage of the low

pressure 2-stage charge air cooler. An LT-thermostatic valve mounted in the external cooling

water system, controls the inlet temperature to the engine for achieving correct receiver

temperature.

4.2.14 Exhaust pipes

The exhaust manifold pipes are made of special heat resistant nodular cast iron alloy.

The complete exhaust gas system is enclosed in an insulating box consisting of easily

removable panels. Mineral wool is used as insulating material.

4.2.15 Automation system

The Wärtsilä 31 engine is equipped with an UNIC electronic control system. UNIC have

hardwired interface for control functions and a bus communication interface for alarm and

monitoring. Additionally UNIC includes fuel injection control for engines with electronic fuel

injection rate optimized nozzles.

For more information, see chapter Automation System.

4-4 Wärtsilä 31 Product Guide - a1 - 18 October 2016

Wärtsilä 31 Product Guide4. Description of the Engine

Page 35

4.3 Expected overhaul intervals and life times