Page 1

PRODUCT GUIDE

Wärtsilä 46F

Page 2

© Copyright by WÄRTSILÄ FINLAND Oy

All rights reserved. No part of this booklet may be reproduced or copied in any form or by any means (electronic,

mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written

permission of the copyright owner.

THIS PUBLICATION IS DESIGNED TO PROVIDE AN ACCURATE AND AUTHORITATIVE INFORMATION WITH

REGARD TO THE SUBJECT-MATTER COVERED AS WAS AVAILABLE AT THE TIME OF PRINTING. HOWEVER,THE

PUBLICATION DEALS WITH COMPLICATED TECHNICAL MATTERS SUITED ONLY FOR SPECIALISTS IN THE

AREA, AND THE DESIGN OF THE SUBJECT-PRODUCTS IS SUBJECT TO REGULAR IMPROVEMENTS,

MODIFICATIONS AND CHANGES. CONSEQUENTLY, THE PUBLISHER AND COPYRIGHT OWNER OF THIS

PUBLICATION CAN NOT ACCEPT ANY RESPONSIBILITY OR LIABILITY FOR ANY EVENTUAL ERRORS OR

OMISSIONS IN THIS BOOKLET OR FOR DISCREPANCIES ARISING FROM THE FEATURES OF ANY ACTUAL ITEM

IN THE RESPECTIVE PRODUCT BEING DIFFERENT FROM THOSE SHOWN IN THIS PUBLICATION. THE PUBLISHER

AND COPYRIGHT OWNER SHALL UNDER NO CIRCUMSTANCES BE HELD LIABLE FOR ANY FINANCIAL

CONSEQUENTIAL DAMAGES OR OTHER LOSS, OR ANY OTHER DAMAGE OR INJURY, SUFFERED BY ANY

PARTY MAKING USE OF THIS PUBLICATION OR THE INFORMATION CONTAINED HEREIN.

Page 3

Introduction

This Product Guide provides data and system proposals for the early design phase of marine

engine installations. For contracted projects specific instructions for planning the installation

are always delivered. Any data and information herein is subject to revision without notice.

This 3/2017 issue replaces all previous issues of the Wärtsilä 46F Product Guides.

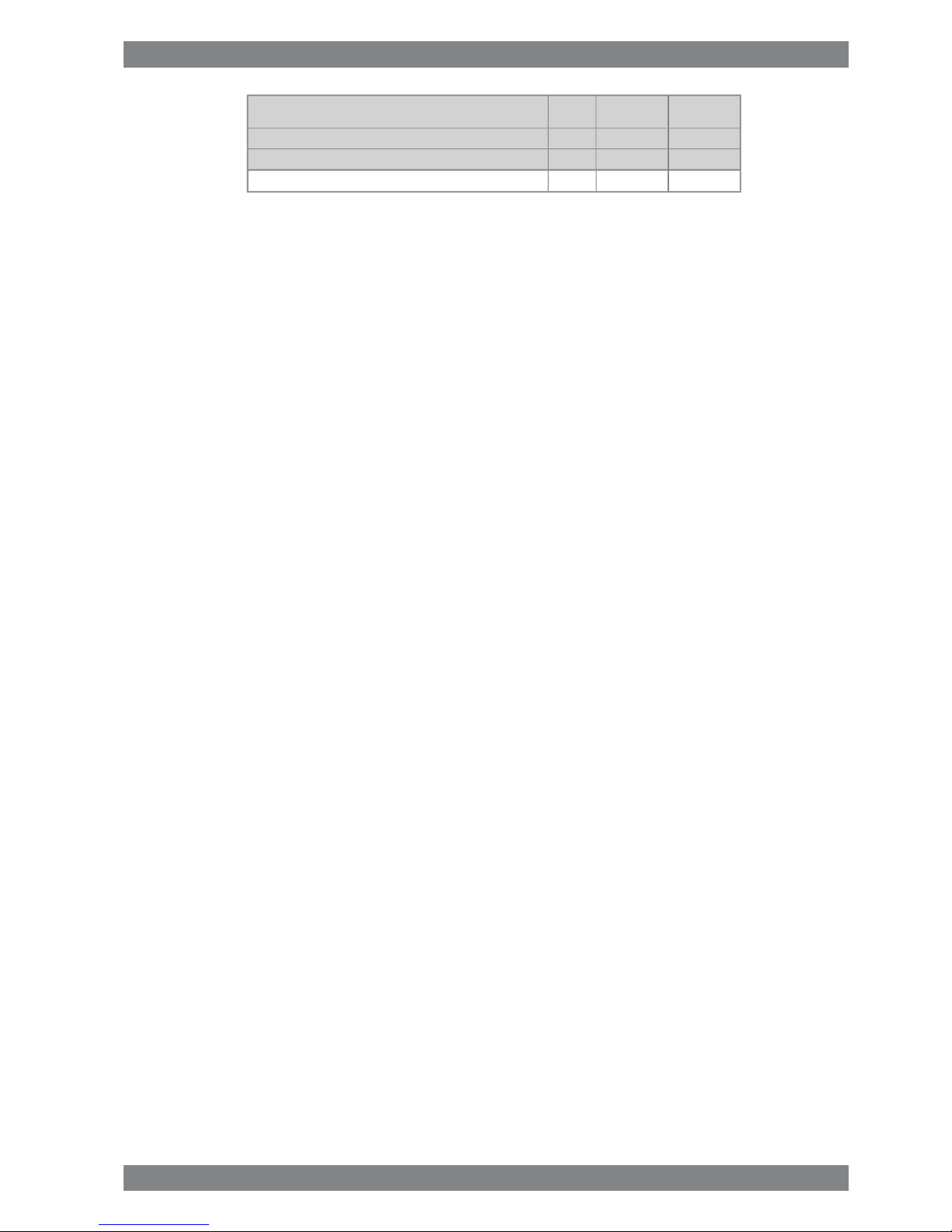

UpdatesPublishedIssue

Technical data updated07.11.20173/2017

Technical data updated27.06.20172/2017

Technical data updated10.02.20171/2017

Flow diagrams updated, other minor updates27.06.20161/2016

Several updates throughout the product guide27.08.20131/2013

Wärtsilä, Marine Solutions

Italy, November 2017

Wärtsilä 46F Product Guide - a19 - 1 December 2017 iii

IntroductionWärtsilä 46F Product Guide

Page 4

Table of contents

1-11. Main Data and Outputs .......................................................................................................................

1-11.1 Maximum continuous output .......................................................................................................

1-21.2 Reference conditions ...................................................................................................................

1-21.3 Operation in inclined position .....................................................................................................

1-31.4 Dimensions and weights .............................................................................................................

2-12. Operating Ranges ................................................................................................................................

2-12.1 Engine operating range ...............................................................................................................

2-22.2 Loading capacity .........................................................................................................................

2-32.3 Operation at low load and idling ..................................................................................................

2-42.4 Low air temperature ....................................................................................................................

3-13. Technical Data ......................................................................................................................................

3-13.1 Introduction ..................................................................................................................................

3-23.2 Wärtsilä 6L46F .............................................................................................................................

3-53.3 Wärtsilä 7L46F .............................................................................................................................

3-83.4 Wärtsilä 8L46F .............................................................................................................................

3-113.5 Wärtsilä 9L46F .............................................................................................................................

3-143.6 Wärtsilä 12V46F ...........................................................................................................................

3-173.7 Wärtsilä 14V46F ...........................................................................................................................

3-203.8 Wärtsilä 16V46F ...........................................................................................................................

4-14. Description of the Engine ....................................................................................................................

4-14.1 Definitions ....................................................................................................................................

4-14.2 Main components and systems ..................................................................................................

4-54.3 Cross section of the engine .........................................................................................................

4-74.4 Overhaul intervals and expected life times ..................................................................................

4-74.5 Engine storage .............................................................................................................................

5-15. Piping Design, Treatment and Installation .........................................................................................

5-15.1 Pipe dimensions ..........................................................................................................................

5-25.2 Trace heating ...............................................................................................................................

5-25.3 Operating and design pressure ...................................................................................................

5-35.4 Pipe class ....................................................................................................................................

5-45.5 Insulation .....................................................................................................................................

5-45.6 Local gauges ...............................................................................................................................

5-45.7 Cleaning procedures ...................................................................................................................

5-55.8 Flexible pipe connections ............................................................................................................

5-65.9 Clamping of pipes ........................................................................................................................

6-16. Fuel Oil System ....................................................................................................................................

6-16.1 Acceptable fuel characteristics ...................................................................................................

6-56.2 Internal fuel oil system .................................................................................................................

6-76.3 External fuel oil system ................................................................................................................

7-17. Lubricating Oil System ........................................................................................................................

7-17.1 Lubricating oil requirements ........................................................................................................

7-27.2 Internal lubricating oil system ......................................................................................................

7-57.3 External lubricating oil system .....................................................................................................

7-147.4 Crankcase ventilation system .....................................................................................................

7-157.5 Flushing instructions ....................................................................................................................

iv Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product GuideTable of contents

Page 5

8-18. Compressed Air System ......................................................................................................................

8-18.1 Instrument air quality ...................................................................................................................

8-18.2 Internal compressed air system ..................................................................................................

8-48.3 External compressed air system .................................................................................................

9-19. Cooling Water System .........................................................................................................................

9-19.1 Water quality ...............................................................................................................................

9-29.2 Internal cooling water system ......................................................................................................

9-79.3 External cooling water system ....................................................................................................

10-110. Combustion Air System .......................................................................................................................

10-110.1 Engine room ventilation ...............................................................................................................

10-310.2 Combustion air system design ....................................................................................................

11-111. Exhaust Gas System ............................................................................................................................

11-111.1 Internal exhaust gas system ........................................................................................................

11-311.2 Exhaust gas outlet .......................................................................................................................

11-511.3 External exhaust gas system .......................................................................................................

12-112. Turbocharger Cleaning ........................................................................................................................

12-112.1 Turbocharger cleaning system ....................................................................................................

12-212.2 Wärtsilä control unit for four engines, UNIC C2 & C3 ................................................................

13-113. Exhaust Emissions ...............................................................................................................................

13-113.1 Diesel engine exhaust components ............................................................................................

13-213.2 Marine exhaust emissions legislation ..........................................................................................

13-313.3 Methods to reduce exhaust emissions ........................................................................................

14-114. Automation System .............................................................................................................................

14-114.1 UNIC C2 .......................................................................................................................................

14-614.2 Functions ....................................................................................................................................

14-814.3 Alarm and monitoring signals ......................................................................................................

14-814.4 Electrical consumers ...................................................................................................................

14-1014.5 System requirements and guidelines for diesel-electric propulsion ............................................

15-115. Foundation ............................................................................................................................................

15-115.1 Steel structure design ..................................................................................................................

15-115.2 Engine mounting ..........................................................................................................................

16-116. Vibration and Noise ..............................................................................................................................

16-116.1 External forces and couples ........................................................................................................

16-316.2 Torque variations .........................................................................................................................

16-316.3 Mass moments of inertia .............................................................................................................

16-416.4 Structure borne noise ..................................................................................................................

16-516.5 Air borne noise .............................................................................................................................

16-616.6 Exhaust noise ..............................................................................................................................

17-117. Power Transmission ............................................................................................................................

17-117.1 Flexible coupling ..........................................................................................................................

17-117.2 Clutch ..........................................................................................................................................

17-117.3 Shaft locking device ....................................................................................................................

17-117.4 Power-take-off from the free end ................................................................................................

17-317.5 Input data for torsional vibration calculations .............................................................................

17-417.6 Turning gear .................................................................................................................................

18-118. Engine Room Layout ...........................................................................................................................

18-118.1 Crankshaft distances ...................................................................................................................

18-718.2 Space requirements for maintenance .........................................................................................

Wärtsilä 46F Product Guide - a19 - 1 December 2017 v

Table of contentsWärtsilä 46F Product Guide

Page 6

18-718.3 Transportation and storage of spare parts and tools ..................................................................

18-718.4 Required deck area for service work ...........................................................................................

19-119. Transport Dimensions and Weights ...................................................................................................

19-119.1 Lifting the in-line engine ..............................................................................................................

19-319.2 Lifting the V-engine ......................................................................................................................

19-419.3 Engine components .....................................................................................................................

20-120. Product Guide Attachments ...............................................................................................................

21-121. ANNEX ...................................................................................................................................................

21-121.1 Unit conversion tables .................................................................................................................

21-221.2 Collection of drawing symbols used in drawings ........................................................................

vi Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product GuideTable of contents

Page 7

1. Main Data and Outputs

The Wärtsilä 46F is a 4-stroke, non-reversible, turbocharged and intercooled diesel engine

with direct fuel injection (twin pump).

460 mmCylinder bore

580 mmStroke

96.4 l/cylPiston displacement

2 inlet valves and 2 exhaust valvesNumber of valves

6, 7, 8 and 9 in-line; 12, 14 and 16 in V-formCylinder configuration

clockwise, counter-clockwise on requestDirection of rotation

600 rpmSpeed

11.6 m/sMean piston speed

1.1 Maximum continuous output

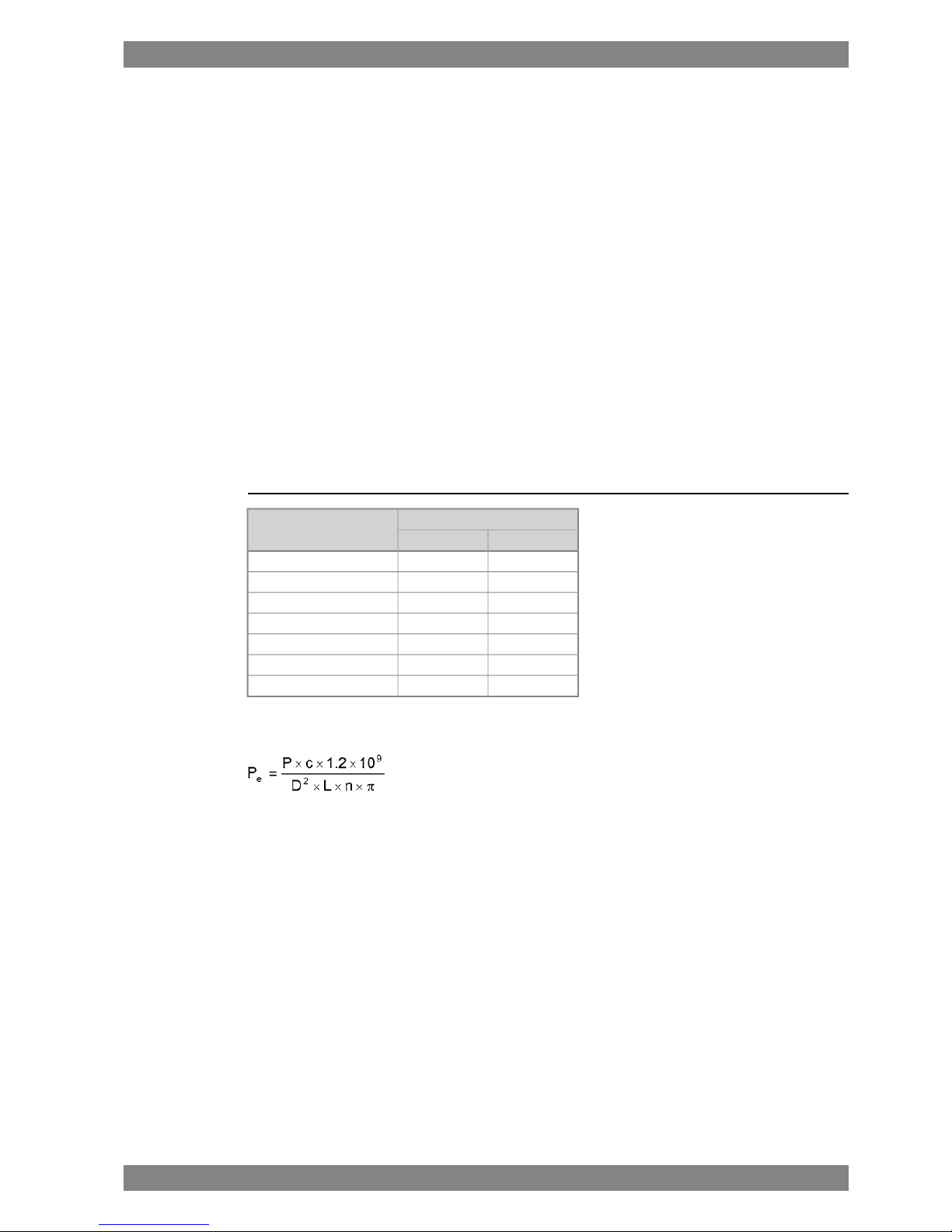

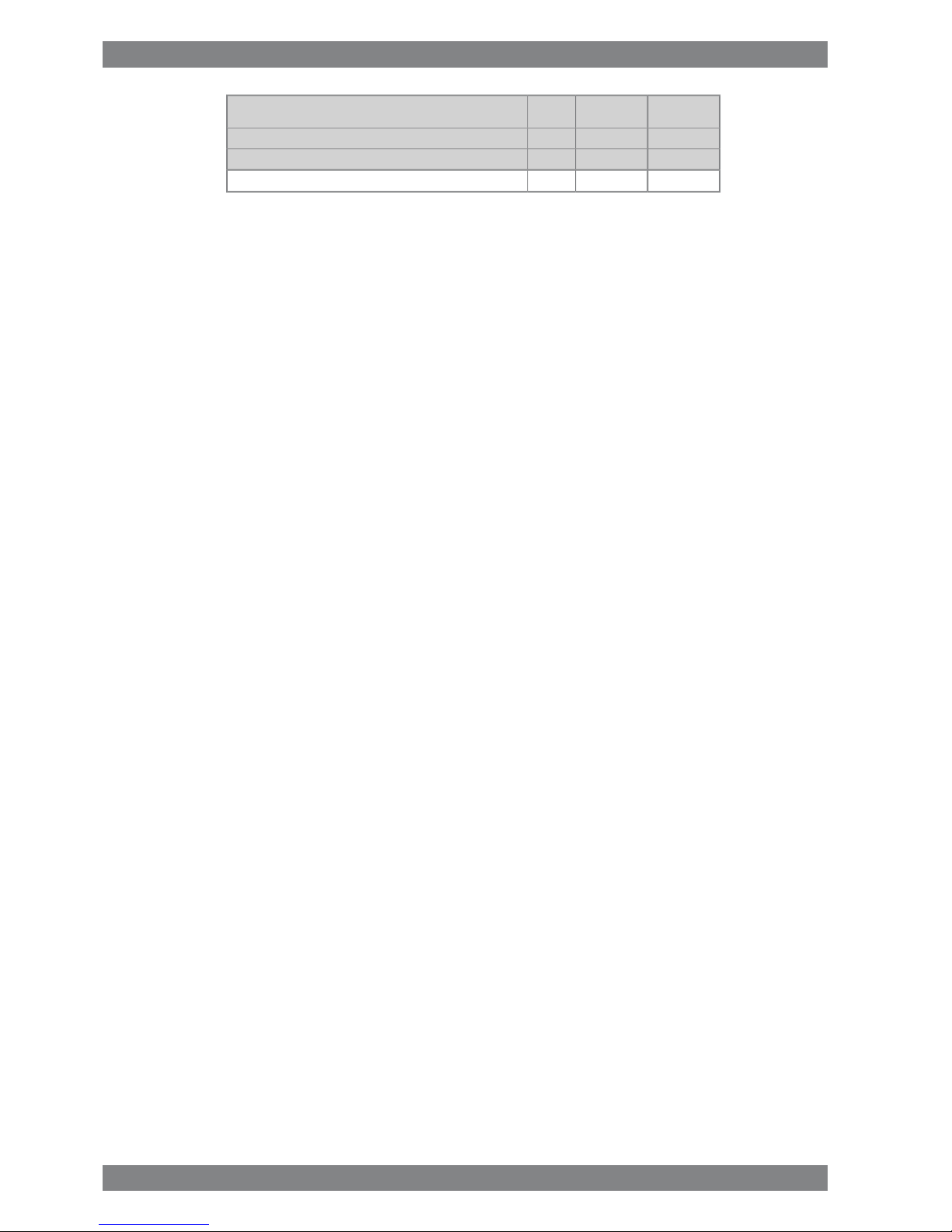

Table 1-1 Maximum continuos output

IMO Tier 2Cylinder configuration

bhpkW

97907200W 6L46F

114208400W 7L46F

130509600W 8L46F

1468010800W 9L46F

1958014400W 12V46F

2284016800W 14V46F

2611019200W 16V46F

The mean effective pressure Pecan be calculated using the following formula:

where:

mean effective pressure [bar]Pe=

output per cylinder [kW]P =

engine speed [r/min]n =

cylinder diameter [mm]D =

length of piston stroke [mm]L =

operating cycle (4)c =

Wärtsilä 46F Product Guide - a19 - 1 December 2017 1-1

1. Main Data and OutputsWärtsilä 46F Product Guide

Page 8

1.2 Reference conditions

The output is available up to an air temperature of max. 45°C. For higher temperatures, the

output has to be reduced according to the formula stated in ISO 3046-1:2002 (E).

The specific fuel oil consumption is stated in the chapter Technical data. The stated specific

fuel oil consumption applies to engines with engine driven pumps, operating in ambient

conditions according to ISO 15550:2002 (E). The ISO standard reference conditions are:

100 kPatotal barometric pressure

25°Cair temperature

30%relative humidity

25°Ccharge air coolant temperature

Correction factors for the fuel oil consumption in other ambient conditions are given in standard

ISO 15550:2002 (E).

1.3 Operation in inclined position

Max. inclination angles at which the engine will operate satisfactorily.

15°

● Permanent athwart ship inclinations

22.5°

● Temporary athwart ship inclinations

10°

● Permanent fore-and-aft inclinations

1-2 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide1. Main Data and Outputs

Page 9

1.4 Dimensions and weights

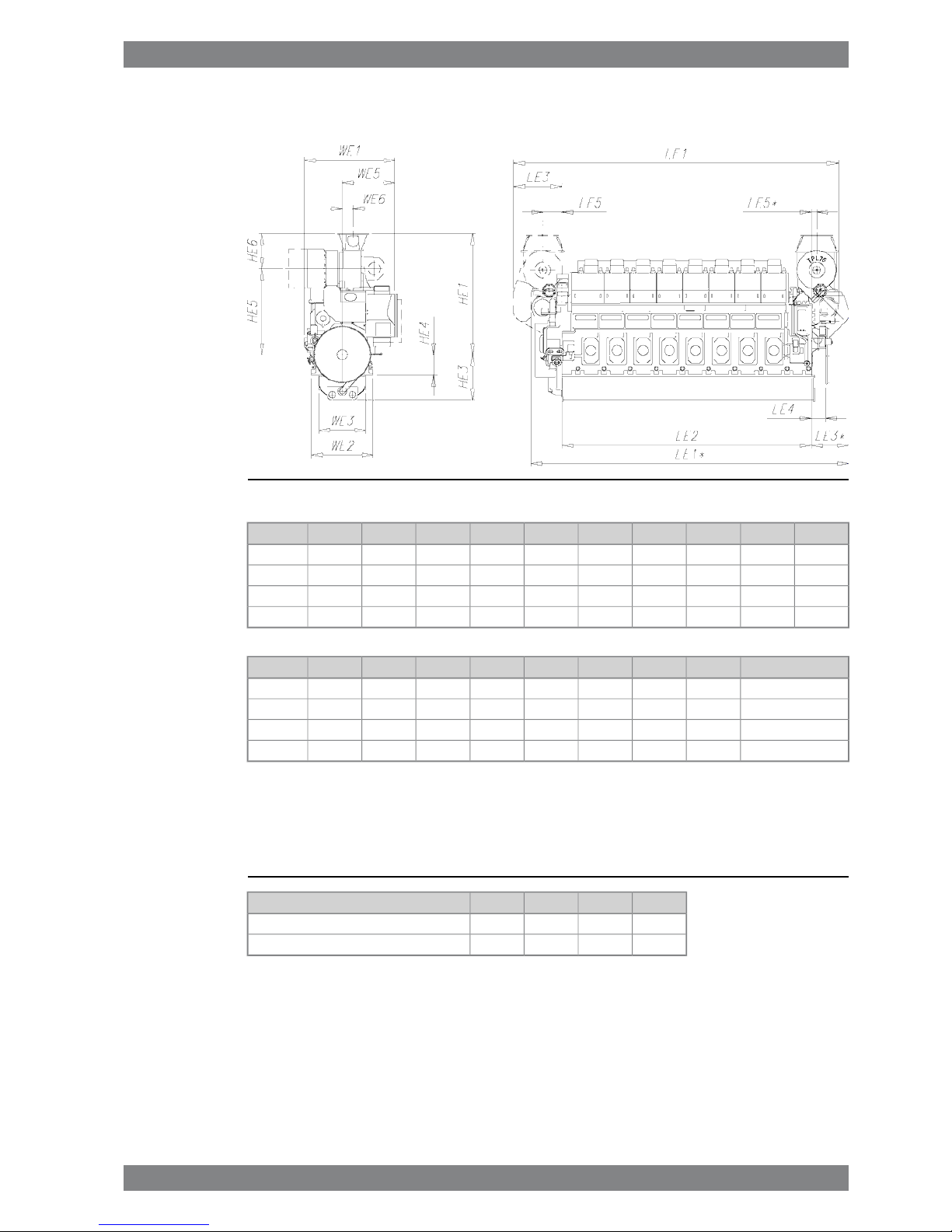

Fig 1-1 In-line engines (DAAE012051c)

HE3HE1LE5LE5*LE4LE3LE3*LE2LE1LE1*Engine

14303500690180460155013206170862084706L46F

14303800800180460155014656990944094357L46F

1430380080018046015501465781010260102558L46F

1430380080018046015501465863011080110759L46F

Weight [ton]WE6WE5WE3WE2WE1HE6HE5HE4Engine

97385153514801940290579027106506L46F

1133401760148019403130110027006507L46F

1243401760148019403130110027006508L46F

1403401760148019403130110027006509L46F

* Turbocharger at flywheel end

All dimensions in mm. The weights are dry weights of rigidly mounted engines without flywheel.

Table 1-2 Additional weights [ton]:

9L46F8L46F7L46F6L46FItem

1...21...21...21...2Flywheel

3333Flexible mounting (without limiters)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 1-3

1. Main Data and OutputsWärtsilä 46F Product Guide

Page 10

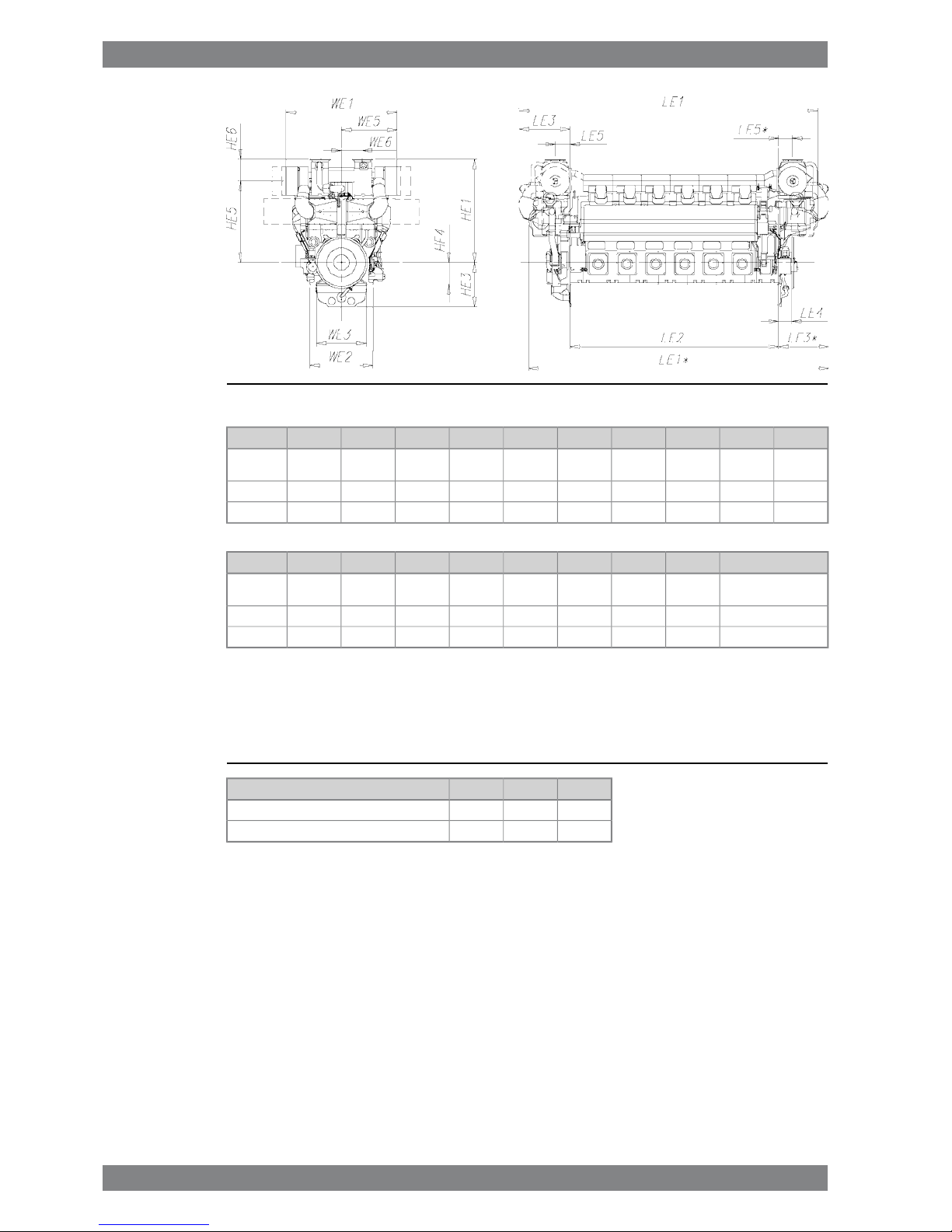

Fig 1-2 V-engines (DAAE075826B)

HE3HE1LE5LE5*LE4LE3LE3*LE2LE1LE1*Engine

16203765* /

3770

7745204601952183076001028410945

12V46F

16204234872-4852347-865011728-14V46F

16204234872-4852347-970012871-16V46F

Weight [ton]WE6WE5WE3WE2WE1HE6HE5HE4Engine

1777602825* /

3150

182022904040* /

4026

7902975* /

2980

800

12V46F

21689231501820229046781100313480014V46F

23389231501820229046781100313480016V46F

* Turbocharger in flywheel end

All dimensions in mm. The weights are dry weights of rigidly mounted engines without flywheel.

Table 1-3 Additional weights [ton]:

16V46F14V46F12V46FItem

1...21...21...2Flywheel

333Flexible mounting (without limiters)

1-4 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide1. Main Data and Outputs

Page 11

2. Operating Ranges

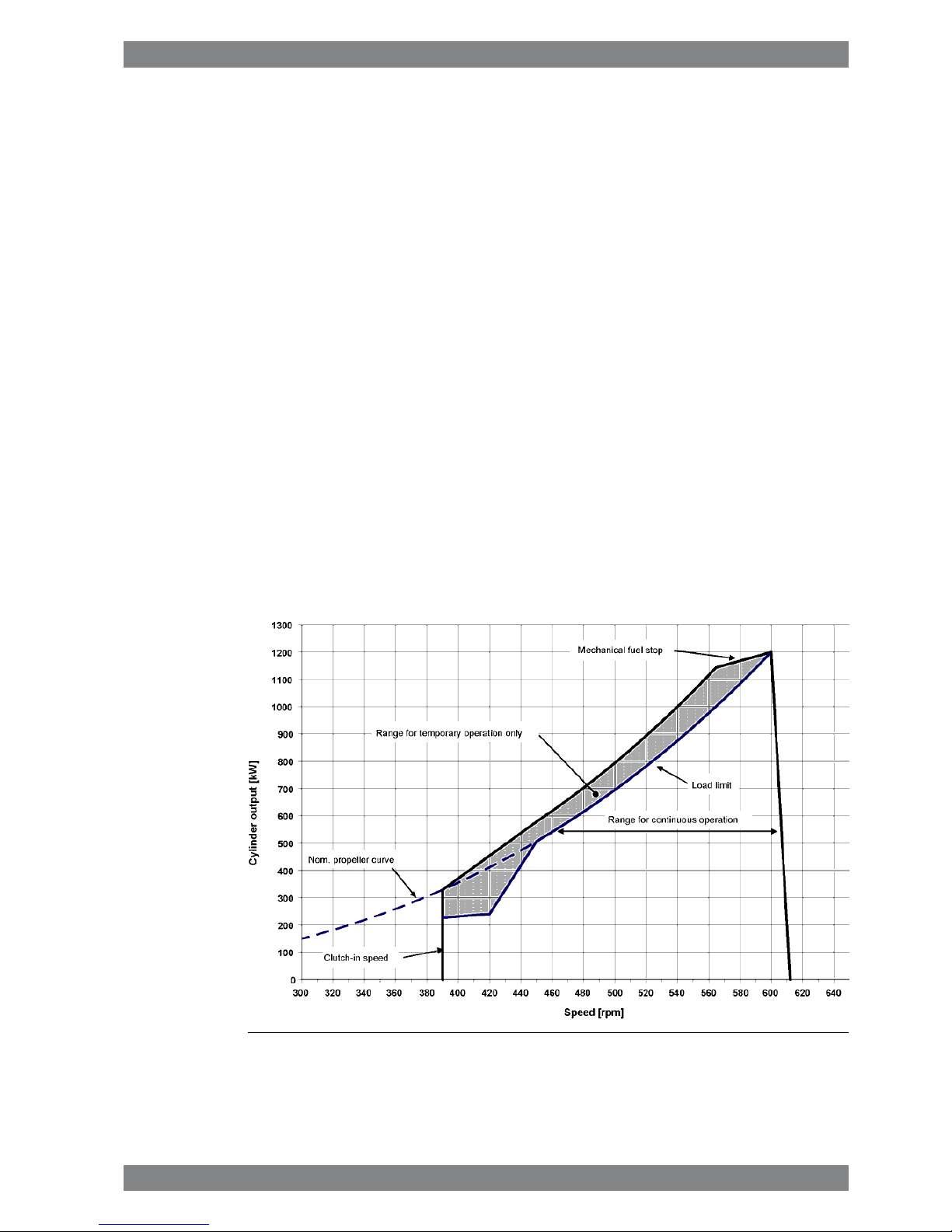

2.1 Engine operating range

Running below nominal speed the load must be limited according to the diagrams in this

chapter in order to maintain engine operating parameters within acceptable limits. Operation

in the shaded area is permitted only temporarily during transients. Minimum speed is indicated

in the diagram, but project specific limitations may apply.

2.1.1 Controllable pitch propellers

An automatic load control system is required to protect the engine from overload. The load

control reduces the propeller pitch automatically, when a pre-programmed load versus speed

curve (“engine limit curve”) is exceeded, overriding the combinator curve if necessary. The

engine load is derived from fuel rack position and actual engine speed (not speed demand).

The propulsion control must also include automatic limitation of the load increase rate.

Maximum loading rates can be found later in this chapter.

The propeller efficiency is highest at design pitch. It is common practice to dimension the

propeller so that the specified ship speed is attained with design pitch, nominal engine speed

and 85% output in the specified loading condition. The power demand from a possible shaft

generator or PTO must be taken into account. The 15% margin is a provision for weather

conditions and fouling of hull and propeller. An additional engine margin can be applied for

most economical operation of the engine, or to have reserve power.

Fig 2-1 Operating field for CP Propeller, IMO Tier 2, 1200 kW/cyl, 600 rpm

Wärtsilä 46F Product Guide - a19 - 1 December 2017 2-1

2. Operating RangesWärtsilä 46F Product Guide

Page 12

2.2 Loading capacity

Controlled load increase is essential for highly supercharged diesel engines, because the

turbocharger needs time to accelerate before it can deliver the required amount of air. Sufficient

time to achieve even temperature distribution in engine components must also be ensured.

This is especially important for larger engines.

If the control system has only one load increase ramp, then the ramp for a preheated engine

should be used. The HT-water temperature in a preheated engine must be at least 60 ºC,

preferably 70 ºC, and the lubricating oil temperature must be at least 40 ºC.

The ramp for normal loading applies to engines that have reached normal operating

temperature.

Emergency loading may only be possible by activating an emergency function, which generates

visual and audible alarms in the control room and on the bridge.

The load should always be applied gradually in normal operation. Class rules regarding load

acceptance capability of diesel generators should not be interpreted as guidelines on how to

apply load in normal operation. The class rules define what the engine must be capable of, if

an unexpected event causes a sudden load step.

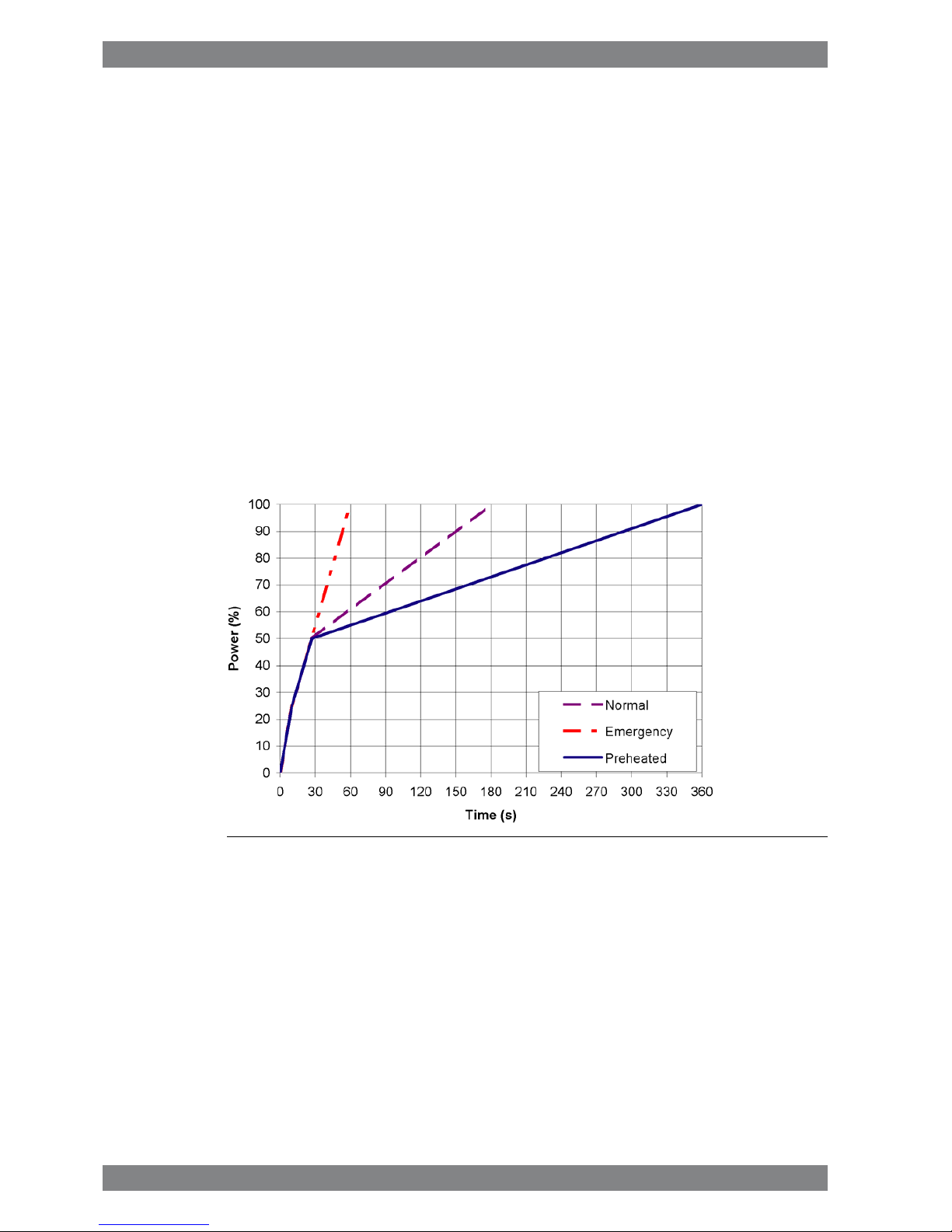

2.2.1 Mechanical propulsion, controllable pitch propeller (CPP)

Fig 2-2 Maximum load increase rates for variable speed engines

If minimum smoke during load increase is a major priority, slower loading rate than in the

diagram can be necessary below 50% load.

In normal operation the load should not be reduced from 100% to 0% in less than 15 seconds.

When absolutely necessary, the load can be reduced as fast as the pitch setting system can

react (overspeed due to windmilling must be considered for high speed ships).

2-2 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide2. Operating Ranges

Page 13

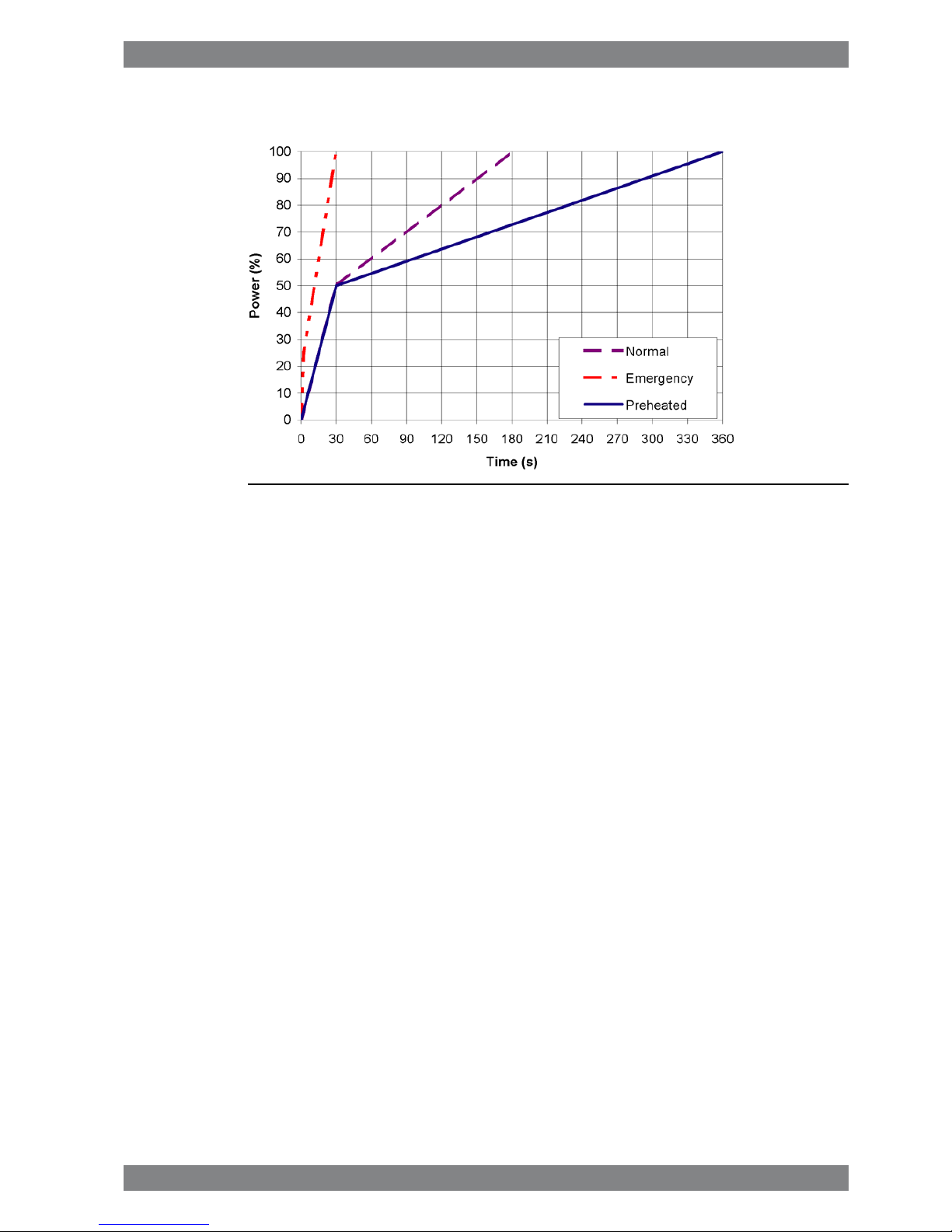

2.2.2 Diesel electric propulsion

Fig 2-3 Maximum load increase rates for engines operating at nominal speed

In normal operation the load should not be reduced from 100% to 0% in less than 15 seconds.

In an emergency situation the full load can be thrown off instantly.

The maximum deviation from steady state speed is less than 10%, when applying load

according to the emergency loading ramp. Load increase according to the normal ramp

correspondingly results in less than 3% speed deviation.

2.2.2.1 Maximum instant load steps

The electrical system must be designed so that tripping of breakers can be safely handled.

This requires that the engines are protected from load steps exceeding their maximum load

acceptance capability. The maximum permissible load step for an engine that has attained

normal operating temperature is 33% MCR. The resulting speed drop is less than 10% and

the recovery time to within 1% of the steady state speed at the new load level is max. 5

seconds.

When electrical power is restored after a black-out, consumers are reconnected in groups,

which may cause significant load steps. The engine must be allowed to recover for at least

10 seconds before applying the following load step, if the load is applied in maximum steps.

2.2.2.2 Start-up time

A diesel generator typically reaches nominal speed in about 25 seconds after the start signal.

The acceleration is limited by the speed control to minimise smoke during start-up.

2.3 Operation at low load and idling

The engine can be started, stopped and operated on heavy fuel under all operating conditions.

Continuous operation on heavy fuel is preferred rather than changing over to diesel fuel at low

load operation and manoeuvring. The following recommendations apply:

Absolute idling (declutched main engine, disconnected generator)

● Maximum 10 minutes if the engine is to be stopped after the idling. 3 minutes idling before

stop is recommended.

Wärtsilä 46F Product Guide - a19 - 1 December 2017 2-3

2. Operating RangesWärtsilä 46F Product Guide

Page 14

● Maximum 6 hours if the engine is to be loaded after the idling.

Operation below 20 % load

● Maximum 100 hours continuous operation. At intervals of 100 operating hours the engine

must be loaded to minimum 70 % of the rated output.

Operation above 20 % load

● No restrictions.

2.4 Low air temperature

In cold conditions the following minimum inlet air temperatures apply:

● Starting + 5ºC

● Idling - 5ºC

● High load - 10ºC

The two-stage charge air cooler is useful for heating of the charge air during prolonged low

load operation in cold conditions. Sustained operation between 0 and 40% load can however

require special provisions in cold conditions to prevent too low HT-water temperature. If

necessary, the preheating arrangement can be designed to heat the running engine (capacity

to be checked).

For further guidelines, see chapter Combustion air system design.

2-4 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide2. Operating Ranges

Page 15

3. Technical Data

3.1 Introduction

This chapter contains technical data of the engine (heat balance, flows, pressures etc.) for

design of auxiliary systems. Further design criteria for external equipment and system layouts

are presented in the respective chapter.

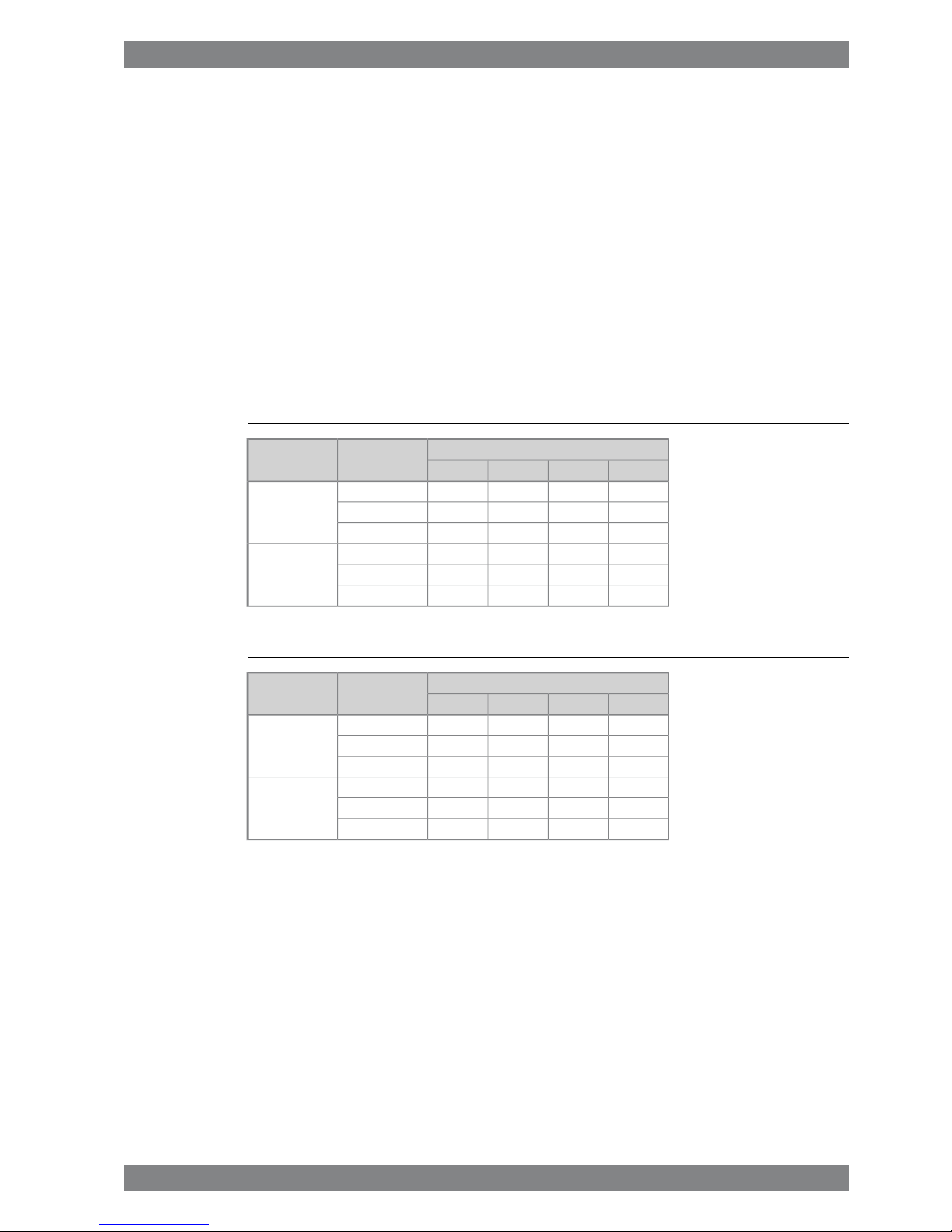

3.1.1 Engine driven pumps

The fuel consumption stated in the technical data tables is with engine driven pumps. The

increase in fuel consumption with engine driven pumps is given in the table below; correction

in g/kWh.

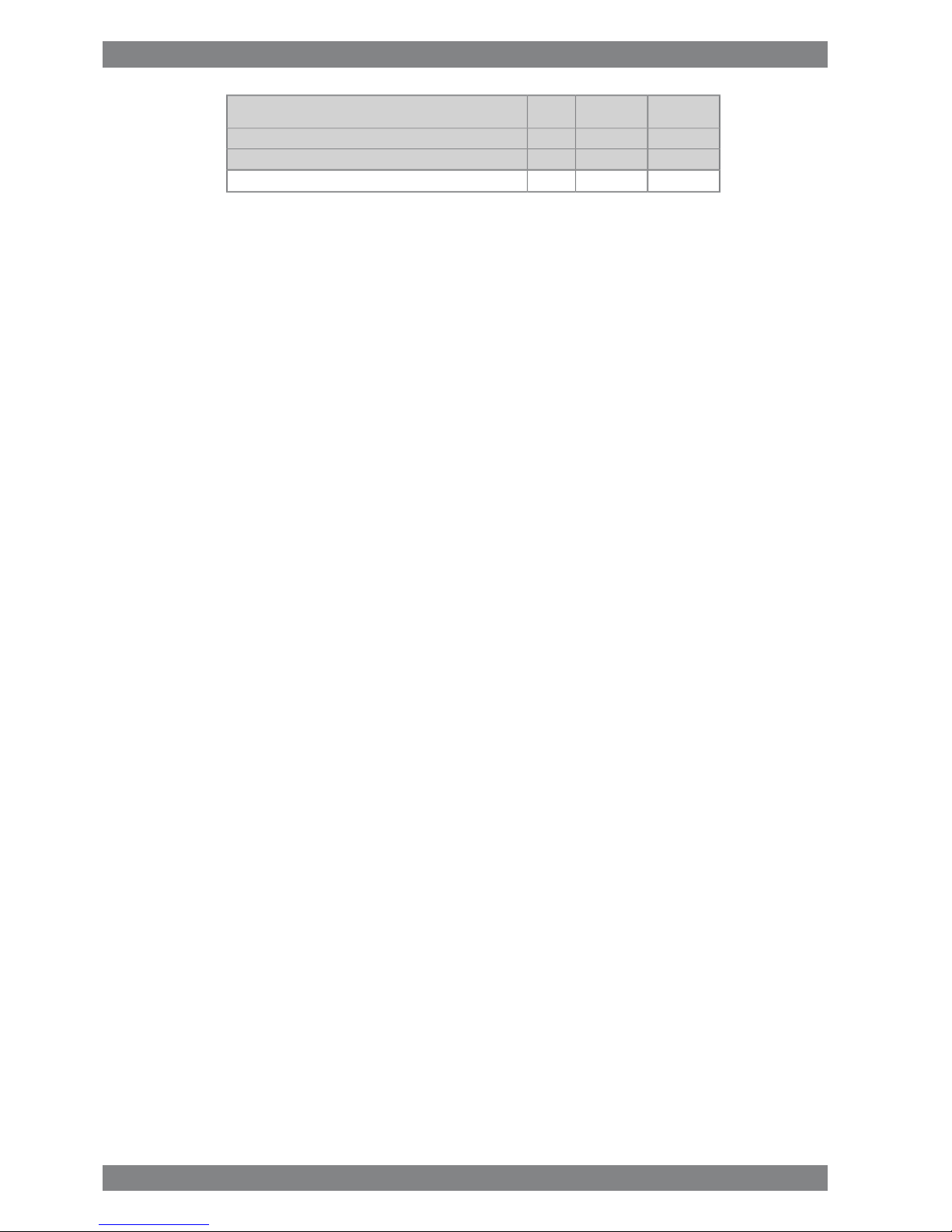

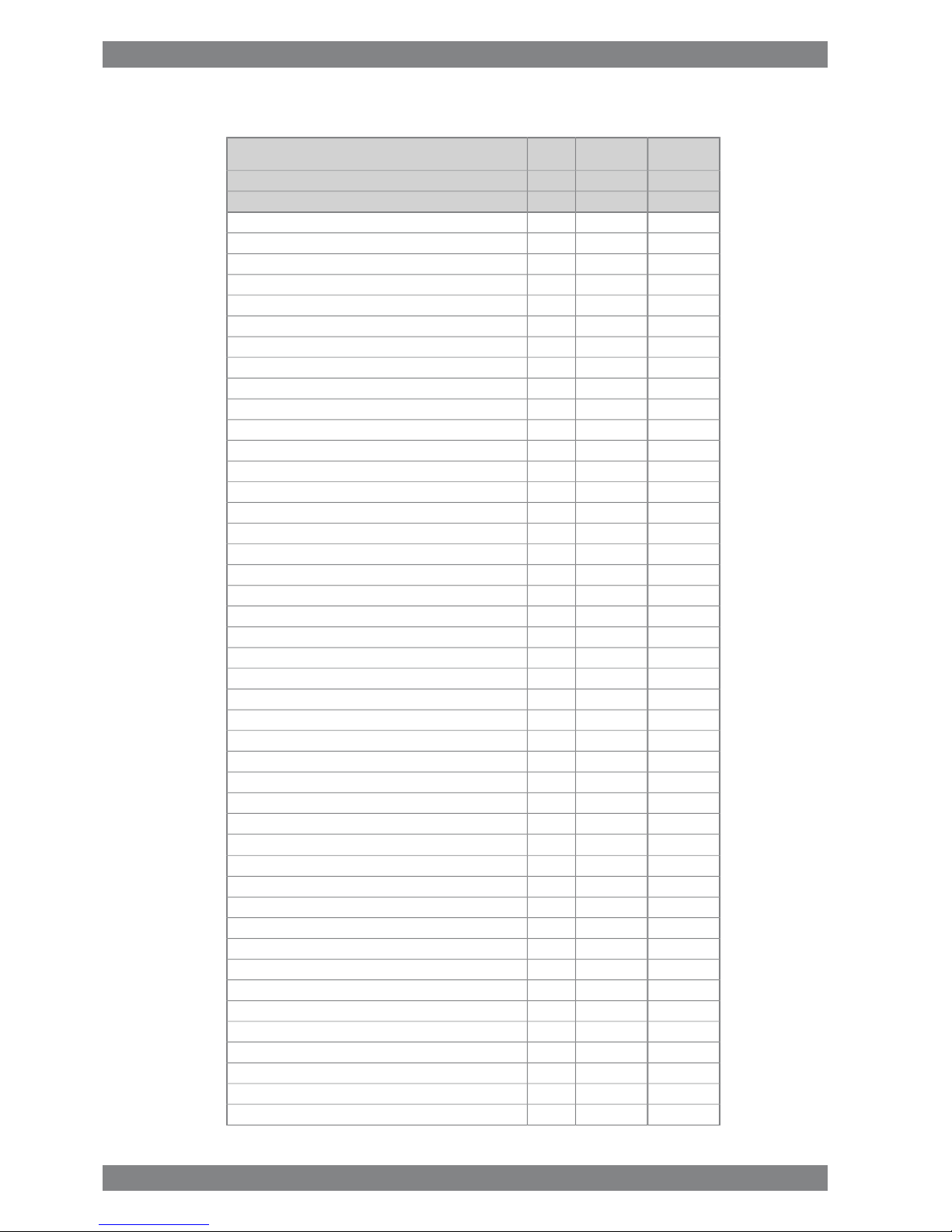

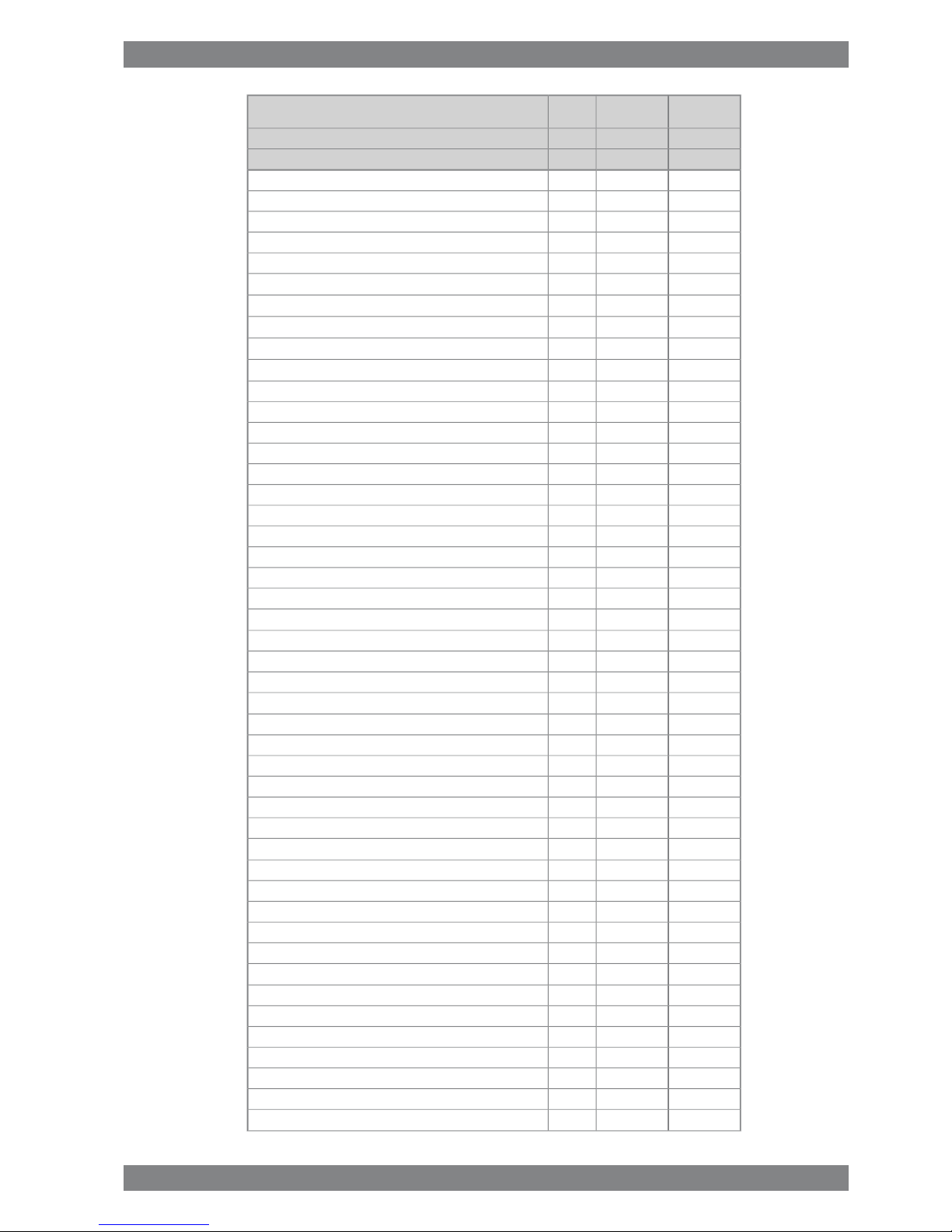

Table 3-1 Constant speed engines

Engine load [%]Engine driven

pumps

Application

507585100

-2.4-1.5-1.3-1.1Lube oil

Inline -0.7-0.4-0.4-0.3LT Water

-0.7-0.4-0.4-0.3HT Water

-1.6-1.2-1.0-1.0Lube oil

V-engine -0.3-0.3-0.3-0.3LT Water

-0.3-0.3-0.3-0.3HT Water

Table 3-2 Variable speed engines

Engine load [%]Engine driven

pumps

Application

507585100

-1.9-1.4-1.3-1.2Lube oil

Inline -0.3-0.3-0.3-0.3LT Water

-0.3-0.3-0.3-0.3HT Water

-1.6-1.2-1.0-1.0Lube oil

V-engine -0.3-0.3-0.3-0.3LT Water

-0.3-0.3-0.3-0.3HT Water

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-1

3. Technical DataWärtsilä 46F Product Guide

Page 16

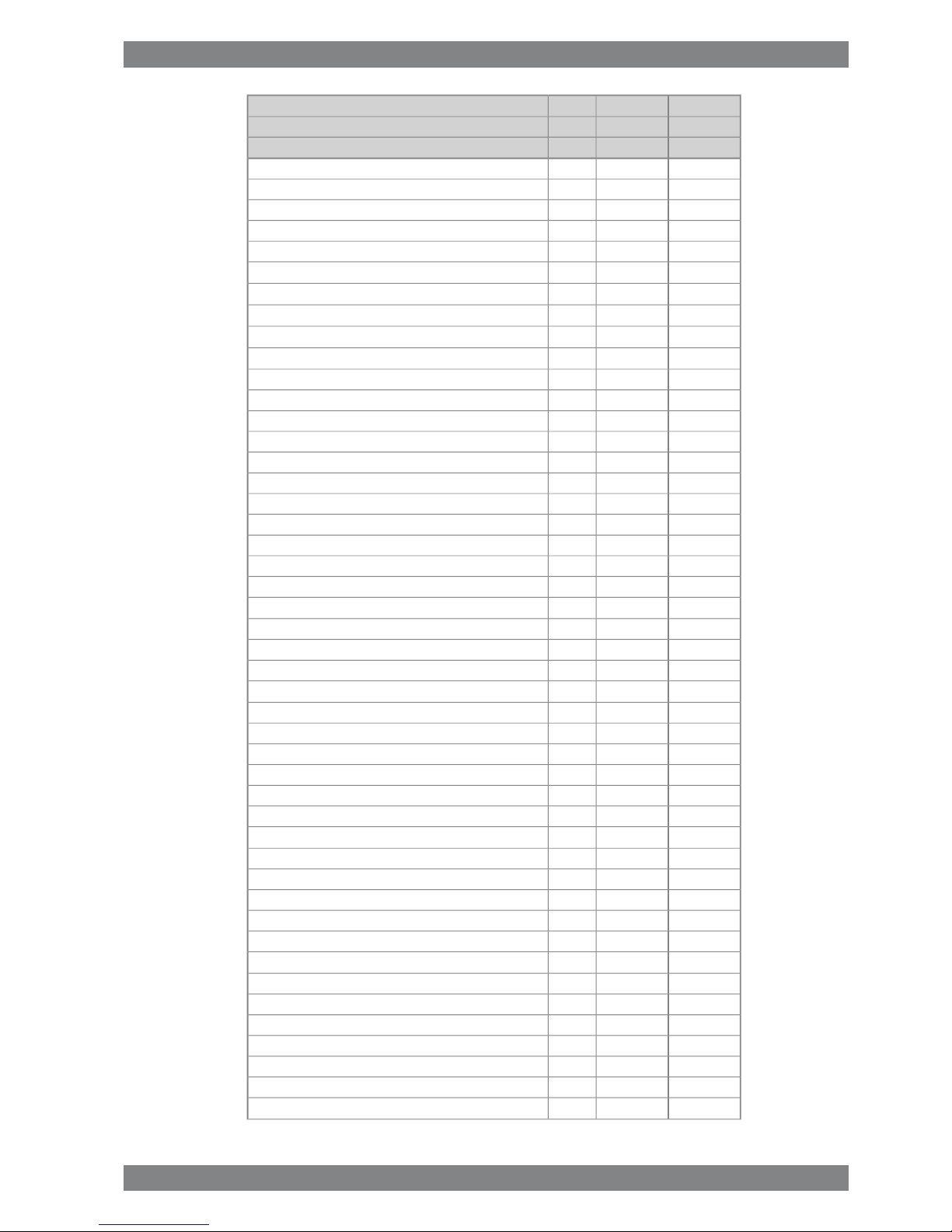

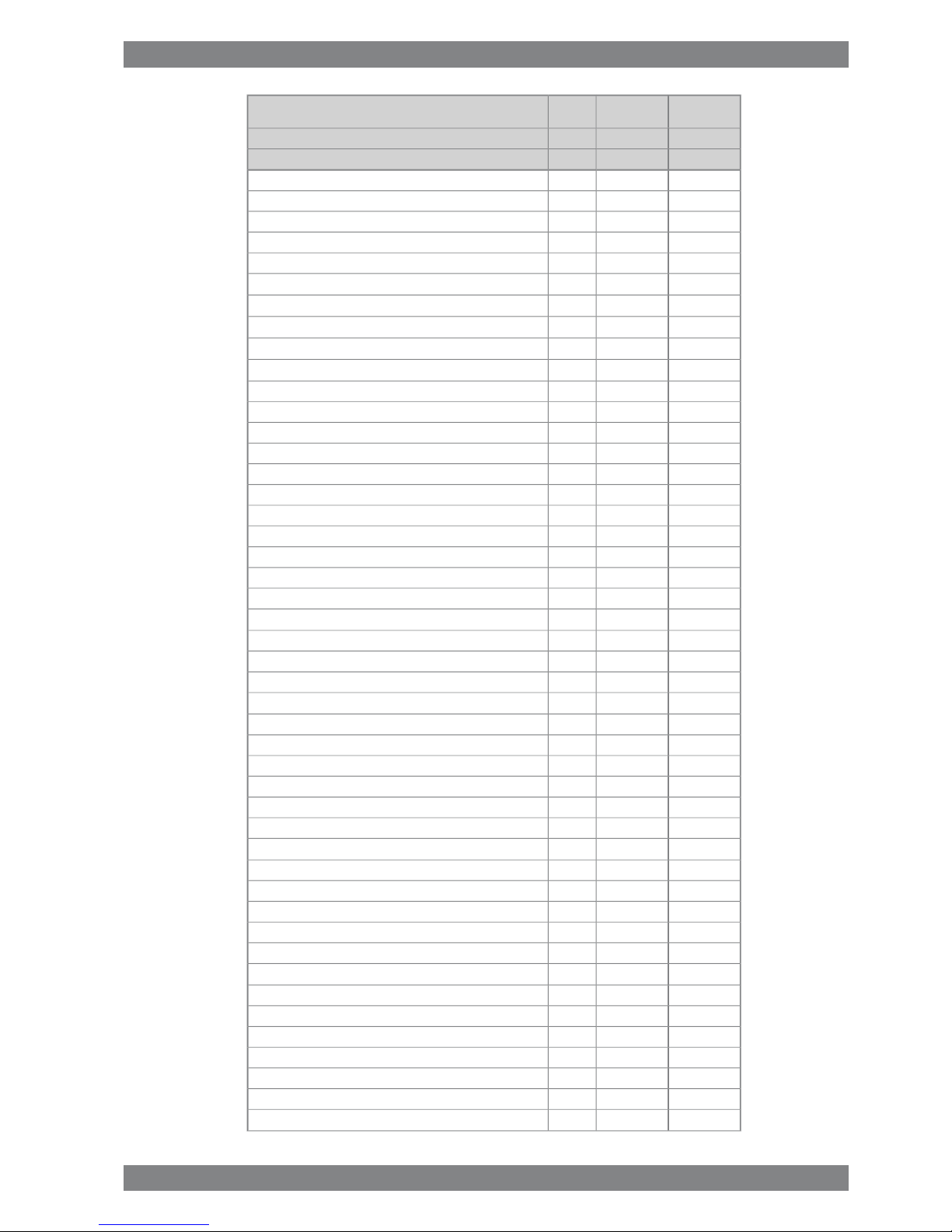

3.2 Wärtsilä 6L46F

DEMEWärtsilä 6L46F

12001200kWCylinder output

600600rpmEngine speed

72007200kWEngine output

2.492.49MPaMean effective pressure

Combustion air system (Note 1)

12.412.4kg/sFlow at 100% load

4545°CTemperature at turbocharger intake, max. (TE 600)

5050°CTemperature after air cooler, nom. (TE 601)

Exhaust gas system (Note 2)

13.0813.08kg/sFlow at 100% load

11.711.4kg/sFlow at 85% load

11.710.8kg/sFlow at 75% load

9.427.44kg/sFlow at 50% load

368368°CTemp. after turbo, 100% load (TE 517)

318322°CTemp. after turbo, 85% load (TE 517)

310323°CTemp. after turbo, 75% load (TE 517)

275327°CTemp. after turbo, 50% load (TE 517)

33kPaBackpressure, max.

927927mmCalculated pipe diameter for 35 m/s

Heat balance at 100% load (Note 3)

846846kWJacket water, HT-circuit

14881488kWCharge air, HT-circuit

762762kWCharge air, LT-circuit

756756kWLubricating oil, LT-circuit

210210kWRadiation

Fuel system (Note 4)

880...930880...930kPaPressure before injection pumps (PT 101) at 100% load - HFO

900...950900...950kPaPressure before injection pumps (PT 101) at 85% load - HFO

4.9...5.44.9...5.4m3/hFlow to engine, approx. - HFO

16...2416...24cStHFO viscosity before engine

140140°CMax. HFO temperature before engine (TE 101)

2.02.0cStMDF viscosity, min.

4545°CMax. MDF temperature before engine (TE 101)

4.54.5kg/hLeak fuel quantity (HFO), clean fuel at 100% load

22.522.5kg/hLeak fuel quantity (MDF), clean fuel at 100% load

179.6179.6g/kWhFuel consumption at 100% load

174.7173.4g/kWhFuel consumption at 85% load

183.6177.9g/kWhFuel consumption at 75% load

191.5181.0g/kWhFuel consumption at 50% load

Lubricating oil system

500500kPaPressure before bearings, nom. (PT 201)

3-2 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 17

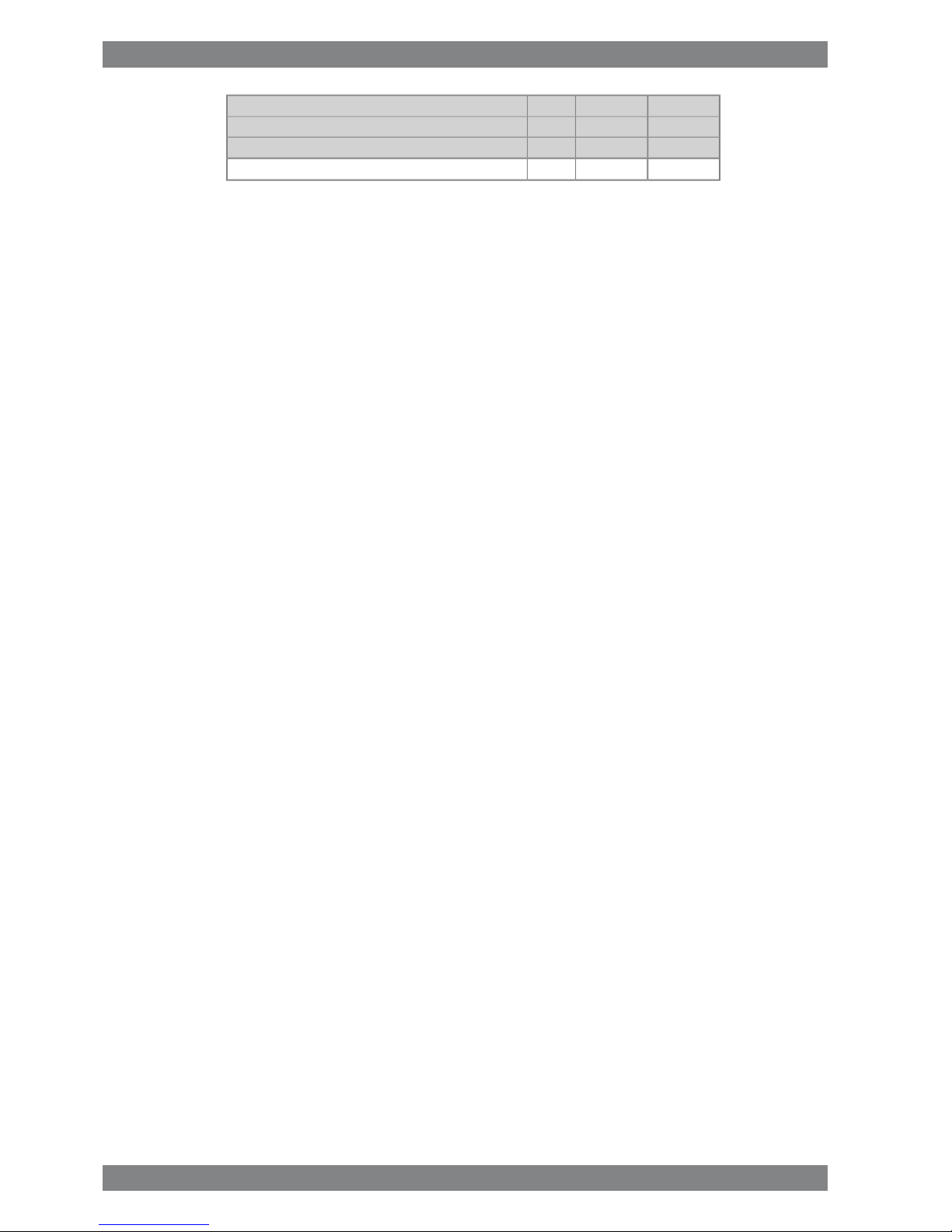

DEMEWärtsilä 6L46F

12001200kWCylinder output

600600rpmEngine speed

800800kPaPressure after pump, max.

4040kPaSuction ability main pump, including pipe loss, max.

8080kPaPriming pressure, nom. (PT 201)

5656°CTemperature before bearings, nom. (TE 201)

7575°CTemperature after engine, approx.

175191m3/hPump capacity (main), engine driven

158191m3/hPump capacity (main), electrically driven

130130m3/hOil flow through engine

3535m3/hPriming pump capacity

13.013.0m

3

Oil tank volume in separate system, min

0.70.7g/kWhOil consumption at 100% load, approx.

13501350l/minCrankcase ventilation flow rate at full load

0.40.4kPaCrankcase ventilation backpressure, max.

9.59.5lOil volume in turning device

1.71.7lOil volume in speed governor

High temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 401)

530530kPaPressure at engine, after pump, max. (PT 401)

7474°CTemperature before cylinders, approx. (TE 401)

91...9591...95°CTemperature after charge air cooler, nom.

115115m3/hCapacity of engine driven pump, nom.

150150kPaPressure drop over engine, total

100100kPaPressure drop in external system, max.

70...15070...150kPaPressure from expansion tank

1.01.0m

3

Water volume in engine

Low temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 451)

530530kPaPressure at engine, after pump, max. (PT 451)

3838°CTemperature before engine, max. (TE 451)

2525°CTemperature before engine, min. (TE 451)

115115m3/hCapacity of engine driven pump, nom.

5050kPaPressure drop over charge air cooler

2020kPaPressure drop over built-on lube oil cooler

3030kPaPressure drop over built-on temp. control valve

150150kPaPressure drop in external system, max.

70 ... 15070 ... 150kPaPressure from expansion tank

0.30.3m

3

Water volume in engine

Starting air system (Note 5)

30003000kPaPressure, nom. (PT 301)

15001500kPaPressure at engine during start, min. (20°C)

30003000kPaPressure, max. (PT 301)

18001800kPaLow pressure limit in air vessels

6.06.0Nm

3

Consumption per start at 20°C (successful start)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-3

3. Technical DataWärtsilä 46F Product Guide

Page 18

DEMEWärtsilä 6L46F

12001200kWCylinder output

600600rpmEngine speed

7.07.0Nm

3

Consumption per start at 20°C, (with slowturn)

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note

1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

15°C.

Note

2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 30%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers.

Note

3

According to ISO 15550, lower calorific value 42700 kJ/kg, with engine driven pumps (two cooling water + one lubricating

oil pumps). Tolerance 5%. The fuel consumption at 85 % load is guaranteed and the values at other loads are given for indication only.

Note

4

At manual starting the consumption may be 2...3 times lower.Note

5

ME = Engine driving propeller, variable speed

DE = Engine driving generator

Subject to revision without notice.

3-4 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 19

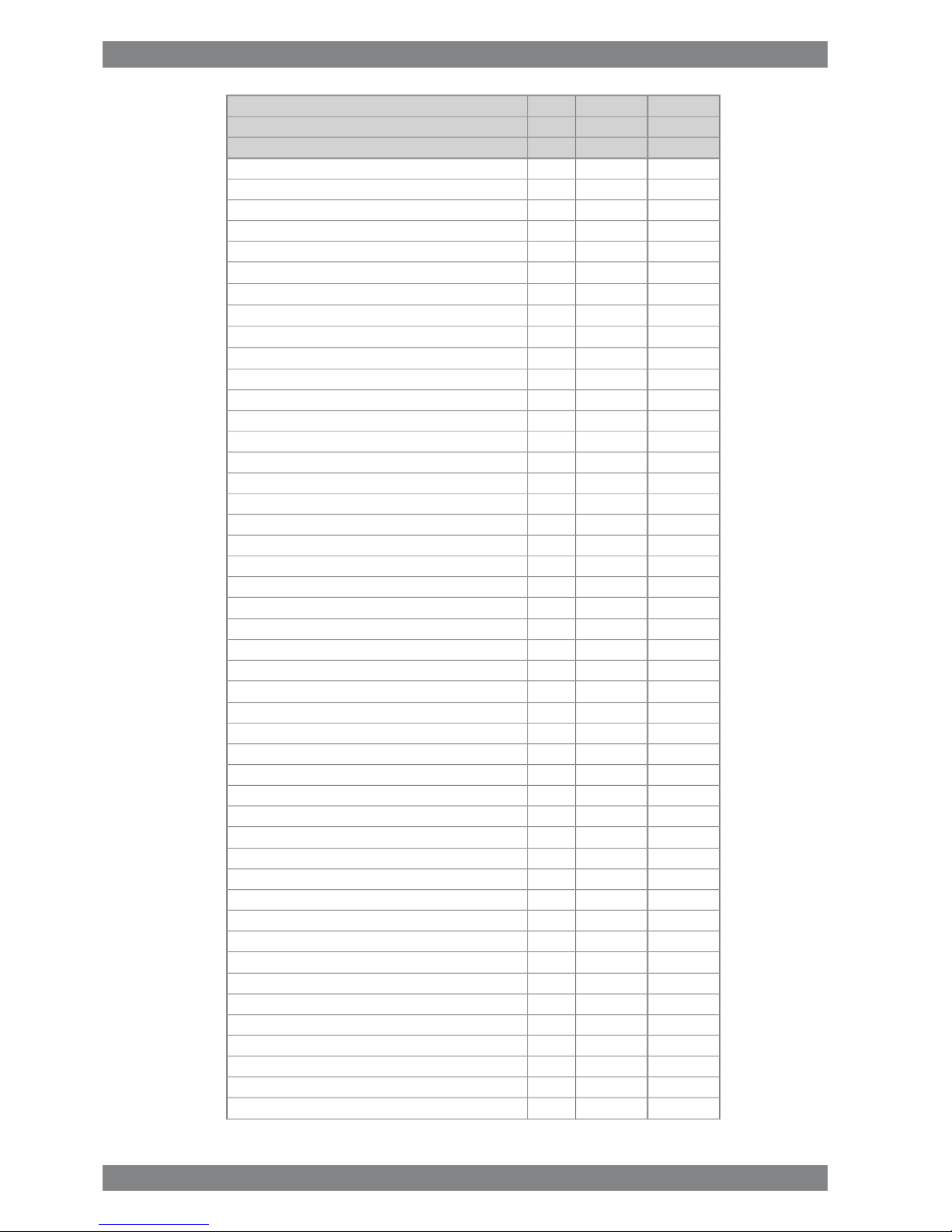

3.3 Wärtsilä 7L46F

DEMEWärtsilä 7L46F

12001200kWCylinder output

600600rpmEngine speed

84008400kWEngine output

2.492.49MPaMean effective pressure

Combustion air system (Note 1)

14.614.6kg/sFlow at 100% load

4545°CTemperature at turbocharger intake, max. (TE 600)

5050°CTemperature after air cooler, nom. (TE 601)

Exhaust gas system (Note 2)

15.2615.26kg/sFlow at 100% load

13.6513.3kg/sFlow at 85% load

13.6512.6kg/sFlow at 75% load

10.998.68kg/sFlow at 50% load

368368°CTemp. after turbo, 100% load (TE 517)

318322°CTemp. after turbo, 85% load (TE 517)

310323°CTemp. after turbo, 75% load (TE 517)

275327°CTemp. after turbo, 50% load (TE 517)

33kPaBackpressure, max.

10011001mmCalculated pipe diameter for 35 m/s

Heat balance at 100% load (Note 3)

987987kWJacket water, HT-circuit

17361736kWCharge air, HT-circuit

889889kWCharge air, LT-circuit

882882kWLubricating oil, LT-circuit

245245kWRadiation

Fuel system (Note 4)

880...930880...930kPaPressure before injection pumps (PT 101) at 100% load - HFO

900...950900...950kPaPressure before injection pumps (PT101) at 85% load - HFO

5.7...6.35.7...6.3m3/hFlow to engine, approx - HFO

16...2416...24cStHFO viscosity before engine

140140°CMax. HFO temperature before engine (TE 101)

2.02.0cStMDF viscosity, min.

4545°CMax. MDF temperature before engine (TE 101)

5.25.2kg/hLeak fuel quantity (HFO), clean fuel at 100% load

26.526.5kg/hLeak fuel quantity (MDF), clean fuel at 100% load

179.6179.6g/kWhFuel consumption at 100% load

174.7173.4g/kWhFuel consumption at 85% load

183.6177.9g/kWhFuel consumption at 75% load

191.5181.0g/kWhFuel consumption at 50% load

Lubricating oil system

500500kPaPressure before bearings, nom. (PT 201)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-5

3. Technical DataWärtsilä 46F Product Guide

Page 20

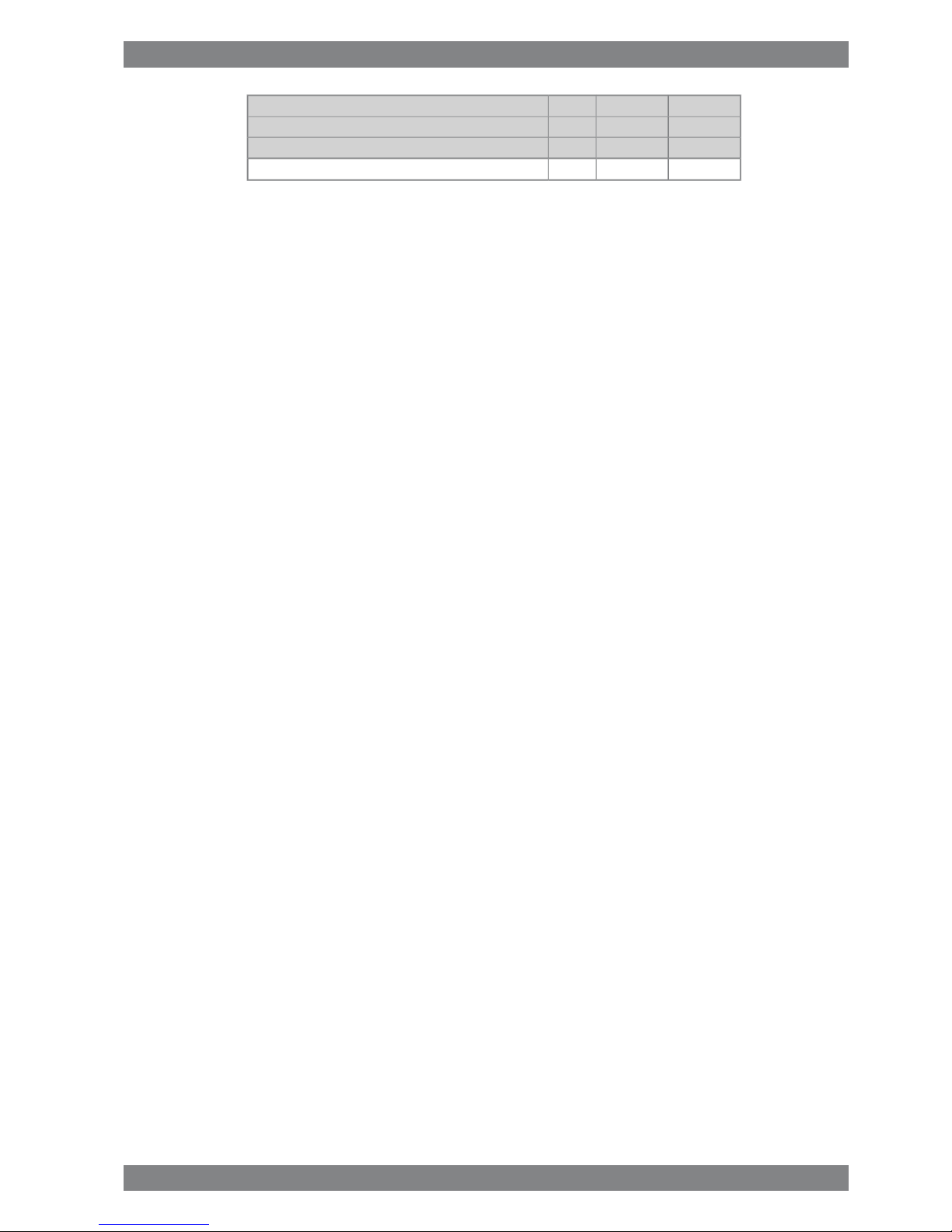

DEMEWärtsilä 7L46F

12001200kWCylinder output

600600rpmEngine speed

800800kPaPressure after pump, max.

4040kPaSuction ability main pump, including pipe loss, max.

8080kPaPriming pressure, nom. (PT 201)

5656°CTemperature before bearings, nom. (TE 201)

7575°CTemperature after engine, approx.

191207m3/hPump capacity (main), engine driven

179207m3/hPump capacity (main), electrically driven

150150m3/hOil flow through engine

4545m3/hPriming pump capacity

15.015.0m

3

Oil tank volume in separate system, min

0.70.7g/kWhOil consumption at 100% load, approx.

16001600l/minCrankcase ventilation flow rate at full load

0.40.4kPaCrankcase ventilation backpressure, max.

9.59.5lOil volume in turning device

1.71.7lOil volume in speed governor

High temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 401)

530530kPaPressure at engine, after pump, max. (PT 401)

7474°CTemperature before cylinders, approx. (TE 401)

91...9591...95°CTemperature after charge air cooler, nom.

150150m3/hCapacity of engine driven pump, nom.

150150kPaPressure drop over engine, total

100100kPaPressure drop in external system, max.

70...15070...150kPaPressure from expansion tank

1.31.3m

3

Water volume in engine

Low temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 451)

530530kPaPressure at engine, after pump, max. (PT 451)

3838°CTemperature before engine, max. (TE 451)

2525°CTemperature before engine, min. (TE 451)

150150m3/hCapacity of engine driven pump, nom.

5050kPaPressure drop over charge air cooler

2020kPaPressure drop over built-on lube oil cooler

3030kPaPressure drop over built-on temp. control valve

150150kPaPressure drop in external system, max.

70 ... 15070 ... 150kPaPressure from expansion tank

0.40.4m

3

Water volume in engine

Starting air system (Note 5)

30003000kPaPressure, nom. (PT 301)

15001500kPaPressure at engine during start, min. (20°C)

30003000kPaPressure, max. (PT 301)

18001800kPaLow pressure limit in air vessels

7.07.0Nm

3

Consumption per start at 20°C (successful start)

3-6 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 21

DEMEWärtsilä 7L46F

12001200kWCylinder output

600600rpmEngine speed

8.08.0Nm

3

Consumption per start at 20°C, (with slowturn)

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note

1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

15°C.

Note

2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 30%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers.

Note

3

According to ISO 15550, lower calorific value 42700 kJ/kg, with engine driven pumps (two cooling water + one lubricating

oil pumps). Tolerance 5%. The fuel consumption at 85 % load is guaranteed and the values at other loads are given for indication only.

Note

4

At manual starting the consumption may be 2...3 times lower.Note

5

ME = Engine driving propeller, variable speed

DE = Engine driving generator

Subject to revision without notice.

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-7

3. Technical DataWärtsilä 46F Product Guide

Page 22

3.4 Wärtsilä 8L46F

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 8L46F

12001200kWCylinder output

600600rpmEngine speed

96009600kWEngine output

2.492.49MPaMean effective pressure

Combustion air system (Note 1)

16.616.6kg/sFlow at 100% load

4545°CTemperature at turbocharger intake, max. (TE 600)

5050°CTemperature after air cooler, nom. (TE 601)

Exhaust gas system (Note 2)

17.4417.44kg/sFlow at 100% load

15.615.2kg/sFlow at 85% load

15.614.4kg/sFlow at 75% load

12.569.92kg/sFlow at 50% load

368368°CTemp. after turbo, 100% load (TE 517)

318322°CTemp. after turbo, 85% load (TE 517)

310323°CTemp. after turbo, 75% load (TE 517)

275327°CTemp. after turbo, 50% load (TE 517)

33kPaBackpressure, max.

10701070mmCalculated pipe diameter for 35 m/s

Heat balance at 100% load (Note 3)

11281128kWJacket water, HT-circuit

19841984kWCharge air, HT-circuit

10161016kWCharge air, LT-circuit

10081008kWLubricating oil, LT-circuit

280280kWRadiation

Fuel system (Note 4)

880...930880...930kPaPressure before injection pumps (PT 101) at 100% load - HFO

900...950900...950kPaPressure before injection pumps (PT101) at 85% load - HFO

6.5...7.26.5...7.2m3/hFlow to engine, approx HFO

16...2416...24cStHFO viscosity before engine

140140°CMax. HFO temperature before engine (TE 101)

2.02.0cStMDF viscosity, min.

4545°CMax. MDF temperature before engine (TE 101)

6.06.0kg/hLeak fuel quantity (HFO), clean fuel at 100% load

30.030.0kg/hLeak fuel quantity (MDF), clean fuel at 100% load

179.6179.6g/kWhFuel consumption at 100% load

174.7173.4g/kWhFuel consumption at 85% load

183.6177.9g/kWhFuel consumption at 75% load

191.5181.0g/kWhFuel consumption at 50% load

Lubricating oil system

500500kPaPressure before bearings, nom. (PT 201)

3-8 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 23

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 8L46F

12001200kWCylinder output

600600rpmEngine speed

800800kPaPressure after pump, max.

4040kPaSuction ability main pump, including pipe loss, max.

8080kPaPriming pressure, nom. (PT 201)

5656°CTemperature before bearings, nom. (TE 201)

7575°CTemperature after engine, approx.

207228m3/hPump capacity (main), engine driven

198228m3/hPump capacity (main), electrically driven

170170m3/hOil flow through engine

4545m3/hPriming pump capacity

17.017.0m

3

Oil tank volume in separate system, min

0.70.7g/kWhOil consumption at 100% load, approx.

17001700l/minCrankcase ventilation flow rate at full load

0.40.4kPaCrankcase ventilation backpressure, max.

9.59.5lOil volume in turning device

1.71.7lOil volume in speed governor

High temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 401)

530530kPaPressure at engine, after pump, max. (PT 401)

7474°CTemperature before cylinders, approx. (TE 401)

91...9591...95°CTemperature after charge air cooler, nom.

150150m3/hCapacity of engine driven pump, nom.

150150kPaPressure drop over engine, total

100100kPaPressure drop in external system, max.

70...15070...150kPaPressure from expansion tank

1.41.4m

3

Water volume in engine

Low temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 451)

530530kPaPressure at engine, after pump, max. (PT 451)

3838°CTemperature before engine, max. (TE 451)

2525°CTemperature before engine, min. (TE 451)

150150m3/hCapacity of engine driven pump, nom.

5050kPaPressure drop over charge air cooler

2020kPaPressure drop over built-on lube oil cooler

3030kPaPressure drop over built-on temp. control valve

150150kPaPressure drop in external system, max.

70 ... 15070 ... 150kPaPressure from expansion tank

0.40.4m

3

Water volume in engine

Starting air system (Note 5)

30003000kPaPressure, nom. (PT 301)

15001500kPaPressure at engine during start, min. (20°C)

30003000kPaPressure, max. (PT 301)

18001800kPaLow pressure limit in air vessels

8.08.0Nm

3

Consumption per start at 20°C (successful start)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-9

3. Technical DataWärtsilä 46F Product Guide

Page 24

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 8L46F

12001200kWCylinder output

600600rpmEngine speed

9.09.0Nm

3

Consumption per start at 20°C, (with slowturn)

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note

1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

15°C.

Note

2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 30%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers.

Note

3

According to ISO 15550, lower calorific value 42700 kJ/kg, with engine driven pumps (two cooling water + one lubricating

oil pumps). Tolerance 5%. The fuel consumption at 85 % load is guaranteed and the values at other loads are given for indication only.

Note

4

At manual starting the consumption may be 2...3 times lower.Note

5

ME = Engine driving propeller, variable speed

DE = Engine driving generator

Subject to revision without notice.

3-10 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 25

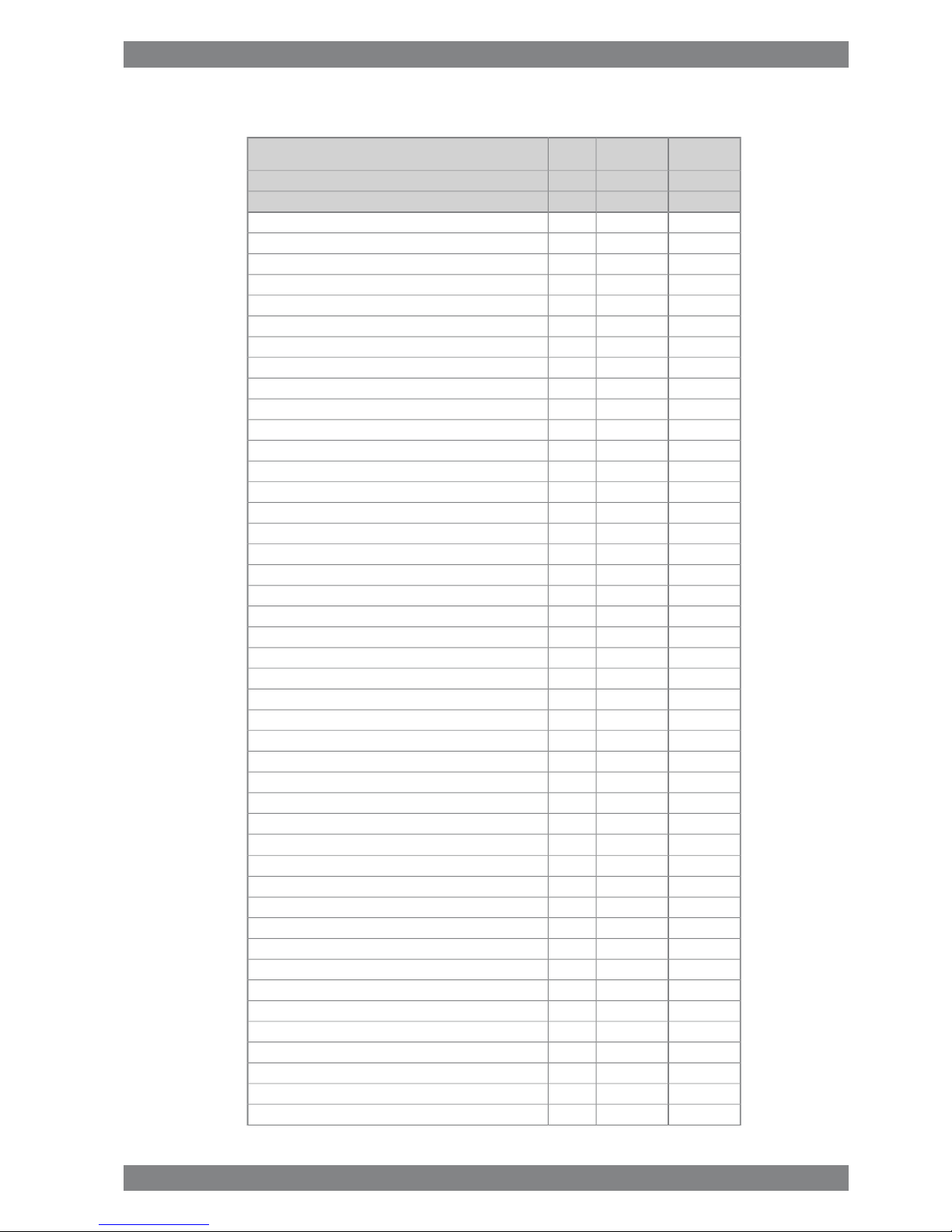

3.5 Wärtsilä 9L46F

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 9L46F

12001200kWCylinder output

600600rpmEngine speed

1080010800kWEngine output

2.492.49MPaMean effective pressure

Combustion air system (Note 1)

18.818.8kg/sFlow at 100% load

4545°CTemperature at turbocharger intake, max. (TE 600)

5050°CTemperature after air cooler, nom. (TE 601)

Exhaust gas system (Note 2)

19.6219.62kg/sFlow at 100% load

17.5517.1kg/sFlow at 85% load

17.5516.2kg/sFlow at 75% load

14.1311.16kg/sFlow at 50% load

368368°CTemp. after turbo, 100% load (TE 517)

318322°CTemp. after turbo, 85% load (TE 517)

310323°CTemp. after turbo, 75% load (TE 517)

275327°CTemp. after turbo, 50% load (TE 517)

33kPaBackpressure, max.

11351135mmCalculated pipe diameter for 35 m/s

Heat balance at 100% load (Note 3)

12691269kWJacket water, HT-circuit

22322232kWCharge air, HT-circuit

11431143kWCharge air, LT-circuit

11341134kWLubricating oil, LT-circuit

315315kWRadiation

Fuel system (Note 4)

880...930880...930kPaPressure before injection pumps (PT 101) at 100% load - HFO

900...950900...950kPaPressure before injection pumps (PT101) at 85% load -HFO

7.3...8.17.3...8.1m3/hFlow to engine, approx - HFO

16...2416...24cStHFO viscosity before engine

140140°CMax. HFO temperature before engine (TE 101)

2.02.0cStMDF viscosity, min.

4545°CMax. MDF temperature before engine (TE 101)

6.86.8kg/hLeak fuel quantity (HFO), clean fuel at 100% load

34.034.0kg/hLeak fuel quantity (MDF), clean fuel at 100% load

179.6179.6g/kWhFuel consumption at 100% load

174.7173.4g/kWhFuel consumption at 85% load

183.6177.9g/kWhFuel consumption at 75% load

191.5181.0g/kWhFuel consumption at 50% load

Lubricating oil system

500500kPaPressure before bearings, nom. (PT 201)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-11

3. Technical DataWärtsilä 46F Product Guide

Page 26

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 9L46F

12001200kWCylinder output

600600rpmEngine speed

800800kPaPressure after pump, max.

4040kPaSuction ability main pump, including pipe loss, max.

8080kPaPriming pressure, nom. (PT 201)

5656°CTemperature before bearings, nom. (TE 201)

7575°CTemperature after engine, approx.

228253m3/hPump capacity (main), engine driven

218253m3/hPump capacity (main), electrically driven

190190m3/hOil flow through engine

5050m3/hPriming pump capacity

19.019.0m

3

Oil tank volume in separate system, min

0.70.7g/kWhOil consumption at 100% load, approx.

18001800l/minCrankcase ventilation flow rate at full load

0.40.4kPaCrankcase ventilation backpressure, max.

70.070.0lOil volume in turning device

1.71.7lOil volume in speed governor

High temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 401)

530530kPaPressure at engine, after pump, max. (PT 401)

7474°CTemperature before cylinders, approx. (TE 401)

91...9591...95°CTemperature after charge air cooler, nom.

180180m3/hCapacity of engine driven pump, nom.

150150kPaPressure drop over engine, total

100100kPaPressure drop in external system, max.

70...15070...150kPaPressure from expansion tank

1.51.5m

3

Water volume in engine

Low temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 451)

530530kPaPressure at engine, after pump, max. (PT 451)

3838°CTemperature before engine, max. (TE 451)

2525°CTemperature before engine, min. (TE 451)

180180m3/hCapacity of engine driven pump, nom.

5050kPaPressure drop over charge air cooler

2020kPaPressure drop over built-on lube oil cooler

3030kPaPressure drop over built-on temp. control valve

150150kPaPressure drop in external system, max.

70 ... 15070 ... 150kPaPressure from expansion tank

0.50.5m

3

Water volume in engine

Starting air system (Note 5)

30003000kPaPressure, nom. (PT 301)

15001500kPaPressure at engine during start, min. (20°C)

30003000kPaPressure, max. (PT 301)

18001800kPaLow pressure limit in air vessels

9.09.0Nm

3

Consumption per start at 20°C (successful start)

3-12 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 27

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 9L46F

12001200kWCylinder output

600600rpmEngine speed

10.010.0Nm

3

Consumption per start at 20°C, (with slowturn)

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note

1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

15°C.

Note

2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 30%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers.

Note

3

According to ISO 15550, lower calorific value 42700 kJ/kg, with engine driven pumps (two cooling water + one lubricating

oil pumps). Tolerance 5%. The fuel consumption at 85 % load is guaranteed and the values at other loads are given for indication only.

Note

4

At manual starting the consumption may be 2...3 times lower.Note

5

ME = Engine driving propeller, variable speed

DE = Engine driving generator

Subject to revision without notice.

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-13

3. Technical DataWärtsilä 46F Product Guide

Page 28

3.6 Wärtsilä 12V46F

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 12V46F

12001200kWCylinder output

600600rpmEngine speed

1440014400kWEngine output

2.492.49MPaMean effective pressure

Combustion air system (Note 1)

25.025.0kg/sFlow at 100% load

4545°CTemperature at turbocharger intake, max. (TE 600)

5050°CTemperature after air cooler, nom. (TE 601)

Exhaust gas system (Note 2)

26.1626.16kg/sFlow at 100% load

23.422.8kg/sFlow at 85% load

23.421.6kg/sFlow at 75% load

18.8414.88kg/sFlow at 50% load

366366°CTemp. after turbo, 100% load (TE 517)

316320°CTemp. after turbo, 85% load (TE 517)

309322°CTemp. after turbo, 75% load (TE 517)

273325°CTemp. after turbo, 50% load (TE 517)

33kPaBackpressure, max.

13091309mmCalculated pipe diameter for 35 m/s

Heat balance at 100% load (Note 3)

16321632kWJacket water, HT-circuit

29762976kWCharge air, HT-circuit

15241524kWCharge air, LT-circuit

14641464kWLubricating oil, LT-circuit

420420kWRadiation

Fuel system (Note 4)

880...930880...930kPaPressure before injection pumps (PT 101) at 100% load - HFO

900...950900...950kPaPressure before injection pumps (PT101) at 85% load - HFO

9.8...10.89.8...10.8m3/hFlow to engine, approx - HFO

16...2416...24cStHFO viscosity before engine

140140°CMax. HFO temperature before engine (TE 101)

2.02.0cStMDF viscosity, min.

4545°CMax. MDF temperature before engine (TE 101)

9.09.0kg/hLeak fuel quantity (HFO), clean fuel at 100% load

45.045.0kg/hLeak fuel quantity (MDF), clean fuel at 100% load

178.7178.7g/kWhFuel consumption at 100% load

173.7172.5g/kWhFuel consumption at 85% load

182.7177.0g/kWhFuel consumption at 75% load

190.6180.1g/kWhFuel consumption at 50% load

Lubricating oil system

500500kPaPressure before bearings, nom. (PT 201)

3-14 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 29

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 12V46F

12001200kWCylinder output

600600rpmEngine speed

800800kPaPressure after pump, max.

4040kPaSuction ability main pump, including pipe loss, max.

8080kPaPriming pressure, nom. (PT 201)

5656°CTemperature before bearings, nom. (TE 201)

7575°CTemperature after engine, approx.

260306m3/hPump capacity (main), engine driven

210259m3/hPump capacity (main), electrically driven

200200m3/hOil flow through engine

7070m3/hPriming pump capacity

22.522.5m

3

Oil tank volume in separate system, min

0.70.7g/kWhOil consumption at 100% load, approx.

35403540l/minCrankcase ventilation flow rate at full load

0.40.4kPaCrankcase ventilation backpressure, max.

70.070.0lOil volume in turning device

7.17.1lOil volume in speed governor

High temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 401)

530530kPaPressure at engine, after pump, max. (PT 401)

7474°CTemperature before cylinders, approx. (TE 401)

91...9591...95°CTemperature after charge air cooler, nom.

210210m3/hCapacity of engine driven pump, nom.

150150kPaPressure drop over engine, total

100100kPaPressure drop in external system, max.

70...15070...150kPaPressure from expansion tank

2.02.0m

3

Water volume in engine

Low temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 451)

530530kPaPressure at engine, after pump, max. (PT 451)

3838°CTemperature before engine, max. (TE 451)

2525°CTemperature before engine, min. (TE 451)

210210m3/hCapacity of engine driven pump, nom.

5050kPaPressure drop over charge air cooler

2020kPaPressure drop over built-on lube oil cooler

3030kPaPressure drop over built-on temp. control valve

150150kPaPressure drop in external system, max.

70 ... 15070 ... 150kPaPressure from expansion tank

0.60.6m

3

Water volume in engine

Starting air system (Note 5)

30003000kPaPressure, nom. (PT 301)

15001500kPaPressure at engine during start, min. (20°C)

30003000kPaPressure, max. (PT 301)

18001800kPaLow pressure limit in air vessels

12.012.0Nm

3

Consumption per start at 20°C (successful start)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-15

3. Technical DataWärtsilä 46F Product Guide

Page 30

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 12V46F

12001200kWCylinder output

600600rpmEngine speed

15.015.0Nm

3

Consumption per start at 20°C, (with slowturn)

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note

1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

15°C.

Note

2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 30%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers.

Note

3

According to ISO 15550, lower calorific value 42700 kJ/kg, with engine driven pumps (two cooling water + one lubricating

oil pumps). Tolerance 5%. The fuel consumption at 85 % load is guaranteed and the values at other loads are given for indication only.

Note

4

At manual starting the consumption may be 2...3 times lower.Note

5

ME = Engine driving propeller, variable speed

DE = Engine driving generator

Subject to revision without notice.

3-16 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 31

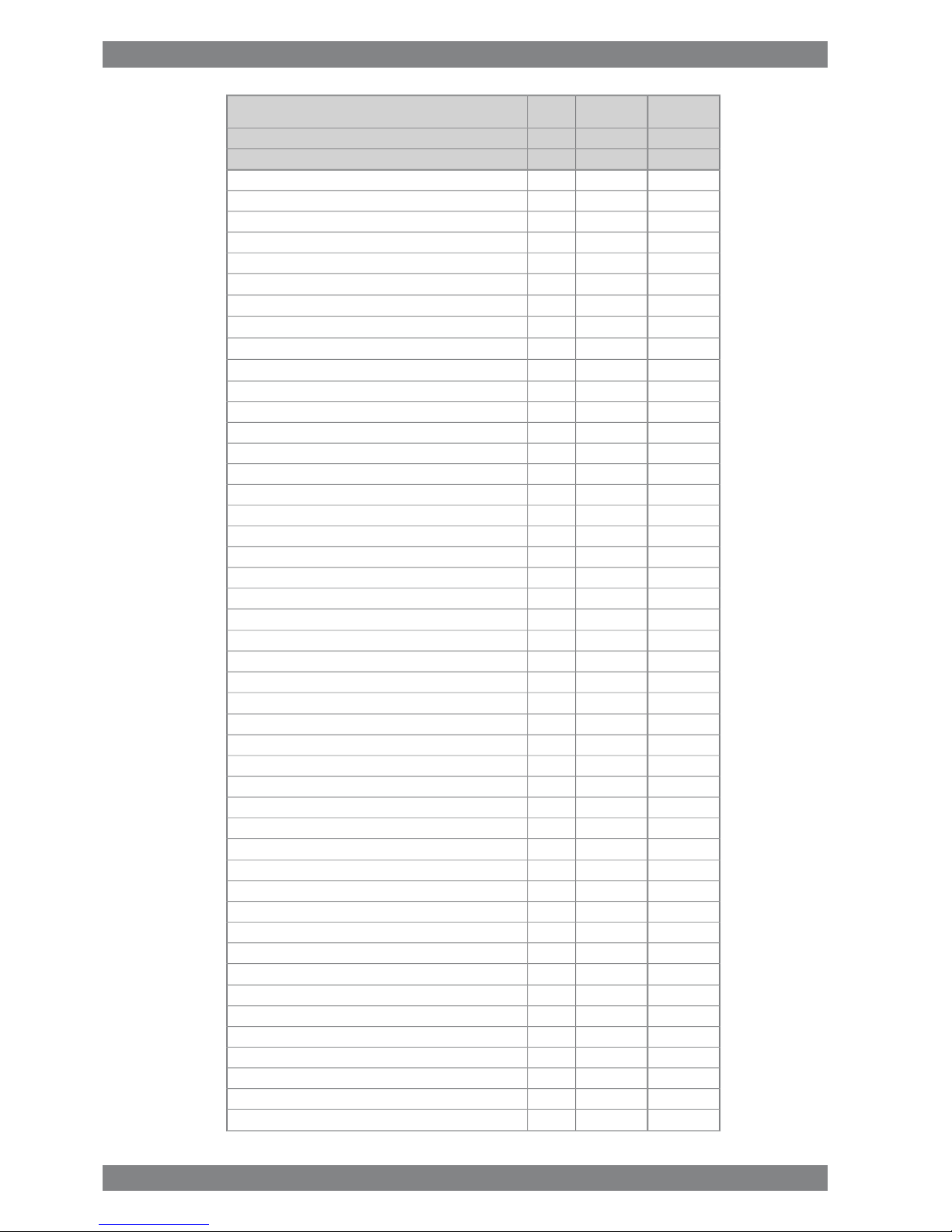

3.7 Wärtsilä 14V46F

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 14V46F

12001200kWCylinder output

600600rpmEngine speed

1680016800kWEngine output

2.492.49MPaMean effective pressure

Combustion air system (Note 1)

29.229.2kg/sFlow at 100% load

4545°CTemperature at turbocharger intake, max. (TE 600)

5050°CTemperature after air cooler, nom. (TE 601)

Exhaust gas system (Note 2)

30.5230.52kg/sFlow at 100% load

27.326.6kg/sFlow at 85% load

27.325.2kg/sFlow at 75% load

21.9817.36kg/sFlow at 50% load

366366°CTemp. after turbo, 100% load (TE 517)

316320°CTemp. after turbo, 85% load (TE 517)

309322°CTemp. after turbo, 75% load (TE 517)

273325°CTemp. after turbo, 50% load (TE 517)

33kPaBackpressure, max.

14141414mmCalculated pipe diameter for 35 m/s

Heat balance at 100% load (Note 3)

19041904kWJacket water, HT-circuit

34723472kWCharge air, HT-circuit

17781778kWCharge air, LT-circuit

17081708kWLubricating oil, LT-circuit

490490kWRadiation

Fuel system (Note 4)

880...930880...930kPaPressure before injection pumps (PT 101) at 100% load - HFO

900...950900...950kPaPressure before injection pumps (PT101) at 85% load - HFO

11.4...12.611.4...12.6m3/hFlow to engine, approx - HFO

16...2416...24cStHFO viscosity before engine

140140°CMax. HFO temperature before engine (TE 101)

2.02.0cStMDF viscosity, min.

4545°CMax. MDF temperature before engine (TE 101)

10.510.5kg/hLeak fuel quantity (HFO), clean fuel at 100% load

53.053.0kg/hLeak fuel quantity (MDF), clean fuel at 100% load

178.7178.7g/kWhFuel consumption at 100% load

173.7172.5g/kWhFuel consumption at 85% load

182.7177.0g/kWhFuel consumption at 75% load

190.6180.1g/kWhFuel consumption at 50% load

Lubricating oil system

500500kPaPressure before bearings, nom. (PT 201)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-17

3. Technical DataWärtsilä 46F Product Guide

Page 32

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 14V46F

12001200kWCylinder output

600600rpmEngine speed

800800kPaPressure after pump, max.

4040kPaSuction ability main pump, including pipe loss, max.

8080kPaPriming pressure, nom. (PT 201)

5656°CTemperature before bearings, nom. (TE 201)

7575°CTemperature after engine, approx.

306335m3/hPump capacity (main), engine driven

250297m3/hPump capacity (main), electrically driven

230230m3/hOil flow through engine

8080m3/hPriming pump capacity

26.326.3m

3

Oil tank volume in separate system, min

0.70.7g/kWhOil consumption at 100% load, approx.

41804180l/minCrankcase ventilation flow rate at full load

0.40.4kPaCrankcase ventilation backpressure, max.

70.070.0lOil volume in turning device

7.17.1lOil volume in speed governor

High temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 401)

530530kPaPressure at engine, after pump, max. (PT 401)

7474°CTemperature before cylinders, approx. (TE 401)

91...9591...95°CTemperature after charge air cooler, nom.

240240m3/hCapacity of engine driven pump, nom.

150150kPaPressure drop over engine, total

100100kPaPressure drop in external system, max.

70...15070...150kPaPressure from expansion tank

2.32.3m

3

Water volume in engine

Low temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 451)

530530kPaPressure at engine, after pump, max. (PT 451)

3838°CTemperature before engine, max. (TE 451)

2525°CTemperature before engine, min. (TE 451)

240240m3/hCapacity of engine driven pump, nom.

5050kPaPressure drop over charge air cooler

2020kPaPressure drop over built-on lube oil cooler

3030kPaPressure drop over built-on temp. control valve

150150kPaPressure drop in external system, max.

70 ... 15070 ... 150kPaPressure from expansion tank

0.70.7m

3

Water volume in engine

Starting air system (Note 5)

30003000kPaPressure, nom. (PT 301)

15001500kPaPressure at engine during start, min. (20°C)

30003000kPaPressure, max. (PT 301)

18001800kPaLow pressure limit in air vessels

14.014.0Nm

3

Consumption per start at 20°C (successful start)

3-18 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 33

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 14V46F

12001200kWCylinder output

600600rpmEngine speed

17.017.0Nm

3

Consumption per start at 20°C, (with slowturn)

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note

1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

15°C.

Note

2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 30%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers.

Note

3

According to ISO 15550, lower calorific value 42700 kJ/kg, with engine driven pumps (two cooling water + one lubricating

oil pumps). Tolerance 5%. The fuel consumption at 85 % load is guaranteed and the values at other loads are given for indication only.

Note

4

At manual starting the consumption may be 2...3 times lower.Note

5

ME = Engine driving propeller, variable speed

DE = Engine driving generator

Subject to revision without notice.

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-19

3. Technical DataWärtsilä 46F Product Guide

Page 34

3.8 Wärtsilä 16V46F

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 16V46F

12001200kWCylinder output

600600rpmEngine speed

1920019200kWEngine output

2.492.49MPaMean effective pressure

Combustion air system (Note 1)

33.333.3kg/sFlow at 100% load

4545°CTemperature at turbocharger intake, max. (TE 600)

5050°CTemperature after air cooler, nom. (TE 601)

Exhaust gas system (Note 2)

34.8834.88kg/sFlow at 100% load

31.230.4kg/sFlow at 85% load

31.228.8kg/sFlow at 75% load

25.1219.84kg/sFlow at 50% load

366366°CTemp. after turbo, 100% load (TE 517)

316320°CTemp. after turbo, 85% load (TE 517)

309322°CTemp. after turbo, 75% load (TE 517)

273325°CTemp. after turbo, 50% load (TE 517)

33kPaBackpressure, max.

15111511mmCalculated pipe diameter for 35 m/s

Heat balance at 100% load (Note 3)

21762176kWJacket water, HT-circuit

39683968kWCharge air, HT-circuit

20322032kWCharge air, LT-circuit

19521952kWLubricating oil, LT-circuit

560560kWRadiation

Fuel system (Note 4)

880...930880...930kPaPressure before injection pumps (PT 101) at 100% load- HFO

900...950900...950kPaPressure before injection pumps (PT101) at 85% load -HFO

13.0...14.413.0...14.4m3/hFlow to engine, approx - HFO

16...2416...24cStHFO viscosity before engine

140140°CMax. HFO temperature before engine (TE 101)

2.02.0cStMDF viscosity, min.

4545°CMax. MDF temperature before engine (TE 101)

12.012.0kg/hLeak fuel quantity (HFO), clean fuel at 100% load

60.060.0kg/hLeak fuel quantity (MDF), clean fuel at 100% load

178.7178.7g/kWhFuel consumption at 100% load

173.7172.5g/kWhFuel consumption at 85% load

182.7177.0g/kWhFuel consumption at 75% load

190.6180.1g/kWhFuel consumption at 50% load

Lubricating oil system

500500kPaPressure before bearings, nom. (PT 201)

3-20 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 35

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 16V46F

12001200kWCylinder output

600600rpmEngine speed

800800kPaPressure after pump, max.

4040kPaSuction ability main pump, including pipe loss, max.

8080kPaPriming pressure, nom. (PT 201)

5656°CTemperature before bearings, nom. (TE 201)

7575°CTemperature after engine, approx.

335335m3/hPump capacity (main), engine driven

260331m3/hPump capacity (main), electrically driven

250250m3/hOil flow through engine

9090m3/hPriming pump capacity

30.030.0m

3

Oil tank volume in separate system, min

0.70.7g/kWhOil consumption at 100% load, approx.

45204520l/minCrankcase ventilation flow rate at full load

0.40.4kPaCrankcase ventilation backpressure, max.

70.070.0lOil volume in turning device

7.17.1lOil volume in speed governor

High temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 401)

530530kPaPressure at engine, after pump, max. (PT 401)

7474°CTemperature before cylinders, approx. (TE 401)

91...9591...95°CTemperature after charge air cooler, nom.

280280m3/hCapacity of engine driven pump, nom.

150150kPaPressure drop over engine, total

100100kPaPressure drop in external system, max.

70...15070...150kPaPressure from expansion tank

2.62.6m

3

Water volume in engine

Low temperature cooling water system

250 + static250 + statickPaPressure at engine, after pump, nom. (PT 451)

530530kPaPressure at engine, after pump, max. (PT 451)

3838°CTemperature before engine, max. (TE 451)

2525°CTemperature before engine, min. (TE 451)

280280m3/hCapacity of engine driven pump, nom.

5050kPaPressure drop over charge air cooler

2020kPaPressure drop over built-on lube oil cooler

3030kPaPressure drop over built-on temp. control valve

150150kPaPressure drop in external system, max.

70 ... 15070 ... 150kPaPressure from expansion tank

0.80.8m

3

Water volume in engine

Starting air system (Note 5)

30003000kPaPressure, nom. (PT 301)

15001500kPaPressure at engine during start, min. (20°C)

30003000kPaPressure, max. (PT 301)

18001800kPaLow pressure limit in air vessels

16.016.0Nm

3

Consumption per start at 20°C (successful start)

Wärtsilä 46F Product Guide - a19 - 1 December 2017 3-21

3. Technical DataWärtsilä 46F Product Guide

Page 36

DE

IMO Tier 2

ME

IMO Tier 2

Wärtsilä 16V46F

12001200kWCylinder output

600600rpmEngine speed

19.019.0Nm

3

Consumption per start at 20°C, (with slowturn)

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 5%.Note

1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C). Flow tolerance 5% and temperature tolerance

15°C.

Note

2

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Tolerance for cooling water heat

10%, tolerance for radiation heat 30%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers.

Note

3

According to ISO 15550, lower calorific value 42700 kJ/kg, with engine driven pumps (two cooling water + one lubricating

oil pumps). Tolerance 5%. The fuel consumption at 85 % load is guaranteed and the values at other loads are given for indication only.

Note

4

At manual starting the consumption may be 2...3 times lower.Note

5

ME = Engine driving propeller, variable speed

DE = Engine driving generator

Subject to revision without notice.

3-22 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide3. Technical Data

Page 37

4. Description of the Engine

4.1 Definitions

Fig 4-1 In-line engine and V-engine definitions (1V93C0029 / 1V93C0028)

4.2 Main components and systems

Main dimensions and weights are presented in the chapter Main Data and Outputs.

4.2.1 Engine block

The engine block is made of nodular cast iron and it is cast in one piece.

The block has a stiff and durable design, which makes it suitable for resilient mounting without

intermediate foundations.

The engine has an underslung crankshaft supported by main bearing caps made of nodular

cast iron. The bearing caps are guided sideways by the engine block, both at the top and at

the bottom. Hydraulically tensioned bearing cap screws and horizontal side screws secure

the main bearing caps.

At the driving end there is a combined thrust bearing and radial bearing for the camshaft drive

and flywheel. The bearing housing of the intermediate gear is integrated in the engine block.

The cooling water is distributed around the cylinder liners with water distribution rings at the

lower end of the cylinder collar. There is no wet space in the engine block around the cylinder

liner, which eliminates the risk of water leakage into the crankcase.

4.2.2 Crankshaft

Low bearing loads, robust design and a crank gear capable of high cylinder pressures were

set out to be the main design criteria for the crankshaft. The moderate bore to stroke ratio is

a key element to achieve high rigidity.

The crankshaft line is built up from three-pieces: crankshaft, gear and end piece. The crankshaft

itself is forged in one piece. Each crankthrow is individually fully balanced for safe bearing

function. Clean steel technology minimizes the amount of slag forming elements and guarantees

superior material properties.

Wärtsilä 46F Product Guide - a19 - 1 December 2017 4-1

4. Description of the EngineWärtsilä 46F Product Guide

Page 38

All crankshafts can be equipped with a torsional vibration damper at the free end of the engine,

if required by the application. Full output is available also from the free end of the engine

through a power-take-off (PTO).

The main bearing and crankpin bearing temperatures are continuously monitored.

4.2.3 Connecting rod

The connecting rods are of three-piece design, which makes it possible to pull a piston without

opening the big end bearing. Extensive research and development has been made to develop

a connecting rod in which the combustion forces are distributed to a maximum area of the

big end bearing.

The connecting rod of alloy steel is forged and has a fully machined shank. The lower end is

split horizontally to allow removal of piston and connecting rod through the cylinder liner. All

connecting rod bolts are hydraulically tightened. The gudgeon pin bearing is solid aluminium

bronze.

Oil is led to the gudgeon pin bearing and piston through a bore in the connecting rod.

4.2.4 Main bearings and big end bearings

The main bearings and the big end bearings have steel backs and thin layers for good resistance

against fatigue and corrosion. Both tri-metal and bi-metal bearings are used.

4.2.5 Cylinder liner

The centrifugally cast cylinder liner has a high and rigid collar preventing deformations due to

the cylinder pressure and pretension forces. A distortion-free liner bore in combination with

wear resistant materials and good lubrication provide optimum running conditions for the

piston and piston rings. The liner material is a special grey cast iron alloy developed for excellent

wear resistance and high strength.

Accurate temperature control is achieved with precisely positioned longitudinal cooling water

bores.

An anti-polishing ring removes deposits from piston top land, which eliminates increased

lubricating oil consumption due to bore polishing and liner wear.

4.2.6 Piston

The piston is of two-piece design with nodular cast iron skirt and steel crown. Wärtsilä patented

skirt lubrication minimizes frictional losses and ensure appropriate lubrication of both the

piston skirt and piston rings under all operating conditions.

4.2.7 Piston rings

The piston ring set consists of two compression rings and one spring-loaded conformable oil

scraper ring. All piston rings have a wear resistant coating.Two compression rings and one

oil scraper ring in combination with pressure lubricated piston skirt give low friction and high

seizure resistance. Both compression ring grooves are hardened for good wear resistance.

4.2.8 Cylinder head

A rigid box/cone-like design ensures even circumferential contact pressure and permits high

cylinder pressure. Only four hydraulically tightened cylinder head studs simplify the maintenance

and leaves more room for optimisation of the inlet and outlet port flow characteristics.

The exhaust valve seats are water cooled. Closed seat rings without water pocket between

the seat and the cylinder head ensure long lifetime for valves and seats. Both inlet and exhaust

valves are equipped with valve rotators.

4-2 Wärtsilä 46F Product Guide - a19 - 1 December 2017

Wärtsilä 46F Product Guide4. Description of the Engine

Page 39

4.2.9 Camshaft and valve mechanism

The camshaft is built of forged pieces with integrated cams, one section per cylinder. The

camshaft sections are connected through separate bearing journals, which makes it possible

to remove single camshaft sections sideways. The bearing housings are integrated in the

engine block casting and thus completely closed.

4.2.10 Camshaft drive

The camshaft is driven by the crankshaft through a gear train. The gear wheel on the crankshaft

is clamped between the crankshaft and the end piece with expansion bolts.

4.2.11 Fuel injection equipment

The low pressure fuel lines consist of drilled channels in cast parts that are firmly clamped to

the engine block. The entire fuel system is enclosed in a fully covered compartment for