Page 1

PRODUCT GUIDE

Wärtsilä 31DF

Page 2

© Copyright by WÄRTSILÄ FINLAND Oy

All rights reserved. No part of this booklet may be reproduced or copied in any form or by any means (electronic,

mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written

permission of the copyright owner.

THIS PUBLICATION IS DESIGNED TO PROVIDE AN ACCURATE AND AUTHORITATIVE INFORMATION WITH

REGARD TO THE SUBJECT-MATTER COVERED AS WAS AVAILABLE AT THE TIME OF PRINTING. HOWEVER,THE

PUBLICATION DEALS WITH COMPLICATED TECHNICAL MATTERS SUITED ONLY FOR SPECIALISTS IN THE

AREA, AND THE DESIGN OF THE SUBJECT-PRODUCTS IS SUBJECT TO REGULAR IMPROVEMENTS,

MODIFICATIONS AND CHANGES. CONSEQUENTLY, THE PUBLISHER AND COPYRIGHT OWNER OF THIS

PUBLICATION CAN NOT ACCEPT ANY RESPONSIBILITY OR LIABILITY FOR ANY EVENTUAL ERRORS OR

OMISSIONS IN THIS BOOKLET OR FOR DISCREPANCIES ARISING FROM THE FEATURES OF ANY ACTUAL ITEM

IN THE RESPECTIVE PRODUCT BEING DIFFERENT FROMTHOSE SHOWN IN THIS PUBLICATION. THE PUBLISHER

AND COPYRIGHT OWNER SHALL UNDER NO CIRCUMSTANCES BE HELD LIABLE FOR ANY FINANCIAL

CONSEQUENTIAL DAMAGES OR OTHER LOSS, OR ANY OTHER DAMAGE OR INJURY, SUFFERED BY ANY

PARTY MAKING USE OF THIS PUBLICATION OR THE INFORMATION CONTAINED HEREIN.

Copyright text

COPYRIGHT © 2019 BY WÄRTSILÄ FINLAND Oy

ALL RIGHTS RESERVED. NO PART OF THIS PUBLICATION MAY BE REPRODUCED OR COPIED IN ANY FORM

OR BY ANY MEANS, WITHOUT PRIOR WRITTEN PERMISSION OF THE COPYRIGHT OWNER.

Page 3

Introduction

This Product Guide provides data and system proposals for the early design

phase of marine engine installations. For contracted projects specific

instructions for planning the installation are always delivered. Any data and

information herein is subject to revision without notice. This 01/2019 issue

replaces all previous issues of the Wärtsilä 31DF Project Guides.

Wärtsilä, Marine Solutions

Vaasa, March 2019

DBAE248994 iii

IntroductionWärtsilä 31DF Product Guide

Page 4

This page intentionally left blank

Page 5

Table of contents

1-11. Main Data and Outputs ............................................................................................................................

1-11.1 Maximum continuous output ...............................................................................................................

1-21.2 Reference conditions ...........................................................................................................................

1-21.3 Operation in inclined position (only for Marine Solutions engines) ......................................................

1-31.4 Dimensions and weights .....................................................................................................................

2-12. Operating Ranges ....................................................................................................................................

2-12.1 Engine operating range ........................................................................................................................

2-22.2 Loading capacity ..................................................................................................................................

2-82.3 Low load operation ...............................................................................................................................

2-102.4 Low air temperature ............................................................................................................................

3-13. Technical Data ..........................................................................................................................................

3-13.1 Introduction ..........................................................................................................................................

3-33.2 Wärtsilä 8V31DF ...................................................................................................................................

3-113.3 Wärtsilä 10V31DF .................................................................................................................................

3-193.4 Wärtsilä 12V31DF .................................................................................................................................

3-273.5 Wärtsilä 14V31DF .................................................................................................................................

3-353.6 Wärtsilä 16V31DF .................................................................................................................................

4-14. Description of the Engine ........................................................................................................................

4-14.1 Definitions .............................................................................................................................................

4-14.2 Main components and systems ...........................................................................................................

4-64.3 Time between Inspection or Overhaul & Expected Life Time ..............................................................

4-74.4 Engine storage .....................................................................................................................................

5-15. Piping Design, Treatment and Installation .............................................................................................

5-15.1 Pipe dimensions ...................................................................................................................................

5-25.2 Trace heating ........................................................................................................................................

5-25.3 Pressure class ......................................................................................................................................

5-35.4 Pipe class .............................................................................................................................................

5-45.5 Insulation ..............................................................................................................................................

5-45.6 Local gauges ........................................................................................................................................

5-45.7 Cleaning procedures ............................................................................................................................

5-65.8 Flexible pipe connections .....................................................................................................................

5-85.9 Clamping of pipes ................................................................................................................................

6-16. Fuel Oil System .........................................................................................................................................

6-16.1 Acceptable fuel characteristics ............................................................................................................

6-96.2 Operating principles .............................................................................................................................

6-106.3 Fuel gas system ...................................................................................................................................

6-186.4 External fuel oil system ........................................................................................................................

7-17. Lubricating Oil System ............................................................................................................................

7-17.1 Lubricating oil requirements .................................................................................................................

7-27.2 External lubricating oil system .............................................................................................................

7-87.3 Crankcase ventilation system .............................................................................................................

7-107.4 Flushing instructions ............................................................................................................................

8-18. Compressed Air System ..........................................................................................................................

8-18.1 Instrument air quality ............................................................................................................................

8-18.2 External compressed air system ..........................................................................................................

DBAE248994 v

Table of contentsWärtsilä 31DF Product Guide

Page 6

9-19. Cooling Water System .............................................................................................................................

9-19.1 Water quality ........................................................................................................................................

9-29.2 External cooling water system .............................................................................................................

10-110. Combustion Air System .........................................................................................................................

10-110.1 Engine room ventilation ......................................................................................................................

10-210.2 Combustion air system design ...........................................................................................................

11-111. Exhaust Gas System ..............................................................................................................................

11-111.1 Exhaust gas outlet ..............................................................................................................................

11-311.2 External exhaust gas system .............................................................................................................

12-112. Turbocharger Cleaning ..........................................................................................................................

12-112.1 Turbine cleaning system .....................................................................................................................

12-212.2 Compressor cleaning system .............................................................................................................

13-113. Exhaust Emissions .................................................................................................................................

13-113.1 Dual fuel engine exhaust components ...............................................................................................

13-113.2 Marine exhaust emissions legislation .................................................................................................

13-113.3 Methods to reduce exhaust emissions ..............................................................................................

14-114. Automation System ................................................................................................................................

14-114.1 Technical data and system overview .................................................................................................

14-714.2 Functions ...........................................................................................................................................

14-1114.3 Alarm and monitoring signals .............................................................................................................

14-1114.4 Electrical consumers ..........................................................................................................................

14-1314.5 System requirements and guidelines for diesel-electric propulsion ..................................................

15-115. Foundation ..............................................................................................................................................

15-115.1 Steel structure design ........................................................................................................................

15-115.2 Mounting of main engines ..................................................................................................................

15-415.3 Mounting of generating sets ..............................................................................................................

15-515.4 Flexible pipe connections ...................................................................................................................

16-116. Vibration and Noise ................................................................................................................................

16-116.1 External forces & couples ...................................................................................................................

16-416.2 Mass moments of inertia ....................................................................................................................

16-416.3 Air borne noise ...................................................................................................................................

16-416.4 Exhaust noise .....................................................................................................................................

17-117. Power Transmission ...............................................................................................................................

17-117.1 Flexible coupling ................................................................................................................................

17-117.2 Torque flange ......................................................................................................................................

17-117.3 Clutch .................................................................................................................................................

17-117.4 Shaft locking device ...........................................................................................................................

17-217.5 Input data for torsional vibration calculations ....................................................................................

17-317.6 Turning gear ........................................................................................................................................

18-118. Engine Room Layout ..............................................................................................................................

18-118.1 Crankshaft distances ..........................................................................................................................

18-518.2 Space requirements for maintenance ................................................................................................

18-518.3 Transportation and storage of spare parts and tools .........................................................................

18-518.4 Required deck area for service work ..................................................................................................

19-119. Transport Dimensions and Weights .....................................................................................................

19-119.1 Lifting of main engines .......................................................................................................................

19-219.2 Lifting of generating sets ....................................................................................................................

19-319.3 Engine components ...........................................................................................................................

vi DBAE248994

Wärtsilä 31DF Product GuideTable of contents

Page 7

20-120. Product Guide Attachments ..................................................................................................................

21-121. ANNEX .....................................................................................................................................................

21-121.1 Unit conversion tables ........................................................................................................................

21-221.2 Collection of drawing symbols used in drawings ...............................................................................

DBAE248994 vii

Table of contentsWärtsilä 31DF Product Guide

Page 8

This page intentionally left blank

Page 9

1. Main Data and Outputs

The Wärtsilä 31DF is a 4-stroke, non-reversible, turbocharged and intercooled diesel engine

with direct fuel injection.

310 mmCylinder bore ........................

430 mmStroke ...................................

2 inlet valves, 2 exhaust valvesNumber of valves .................

8, 10, 12, 14 and 16Cylinder configuration .........

50°V-angle .................................

Clockwise, counterclockwiseDirection of rotation .............

720, 750 rpmSpeed ...................................

10.32 - 10.75 m/sMean piston speed ...............

1.1 Maximum continuous output

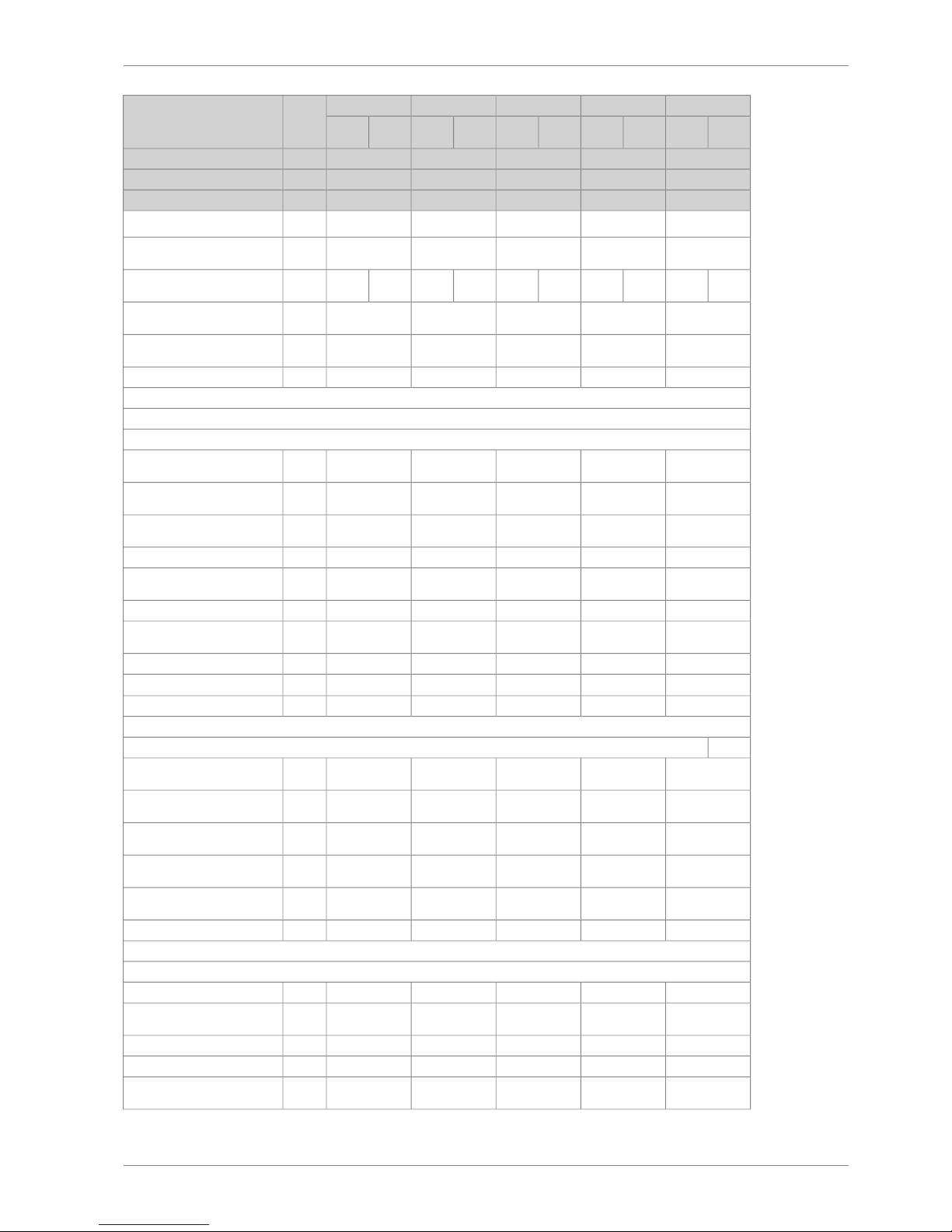

Table 1-1 Rating table for Wärtsilä 31DF

Generating setsMain enginesCylinder

configuration

750 rpm720 rpm750 rpm

Generator [kVA]Engine [kW]Generator [kVA]Engine [kW][kW]

52804400509042404400W 8V31DF

66005500636053005500W 10V31DF

79206600763063606600W 12V31DF

92407700890074207700W 14V31DF

1056088001018084808800W 16V31DF

The mean effective pressure Pe can be calculated as follows:

where:

mean effective pressure [bar]Pe =

output per cylinder [kW]P =

engine speed [r/min]n =

cylinder diameter [mm]D =

length of piston stroke [mm]L =

operating cycle (4)c =

DBAE248994 1-1

1. Main Data and OutputsWärtsilä 31DF Product Guide

Page 10

1.2 Reference conditions

The output is available within a range of ambient conditions and coolant temperatures specified

in the chapter Technical Data. The required fuel quality for maximum output is specified in the

section Fuel characteristics. For ambient conditions or fuel qualities outside the specification,

the output may have to be reduced.

The specific fuel consumption is stated in the chapter Technical Data. The statement applies

to engines operating in ambient conditions according to ISO 15550:2002 (E).

100 kPatotal barometric pressure

25 °Cair temperature

30 %relative humidity

25 °Ccharge air coolant temperature

Correction factors for the fuel oil consumption in other ambient conditions are given in standard

ISO 15550:2002 (E).

1.3 Operation ininclined position (onlyfor Marine Solutions

engines)

The engine is designed to ensure proper engine operation at inclination positions. Inclination

angle according to IACS requirement M46.2 (1982) (Rev.1 June 2002) - Main and auxiliary

machinery.

Max. inclination angles at which the engine will operate satisfactorily:

Table 1-2 Inclination with Normal Oil Sump

15°

●

Permanent athwart ship inclinations (list)

22.5°

●

Temporary athwart ship inclinations (roll)

10°

●

Permanent fore and aft inclinations (trim)

10°

●

Temporary fore and aft inclinations (pitch)

1-2 DBAE248994

Wärtsilä 31DF Product Guide1. Main Data and Outputs

Page 11

1.4 Dimensions and weights

1.4.1 Main engines

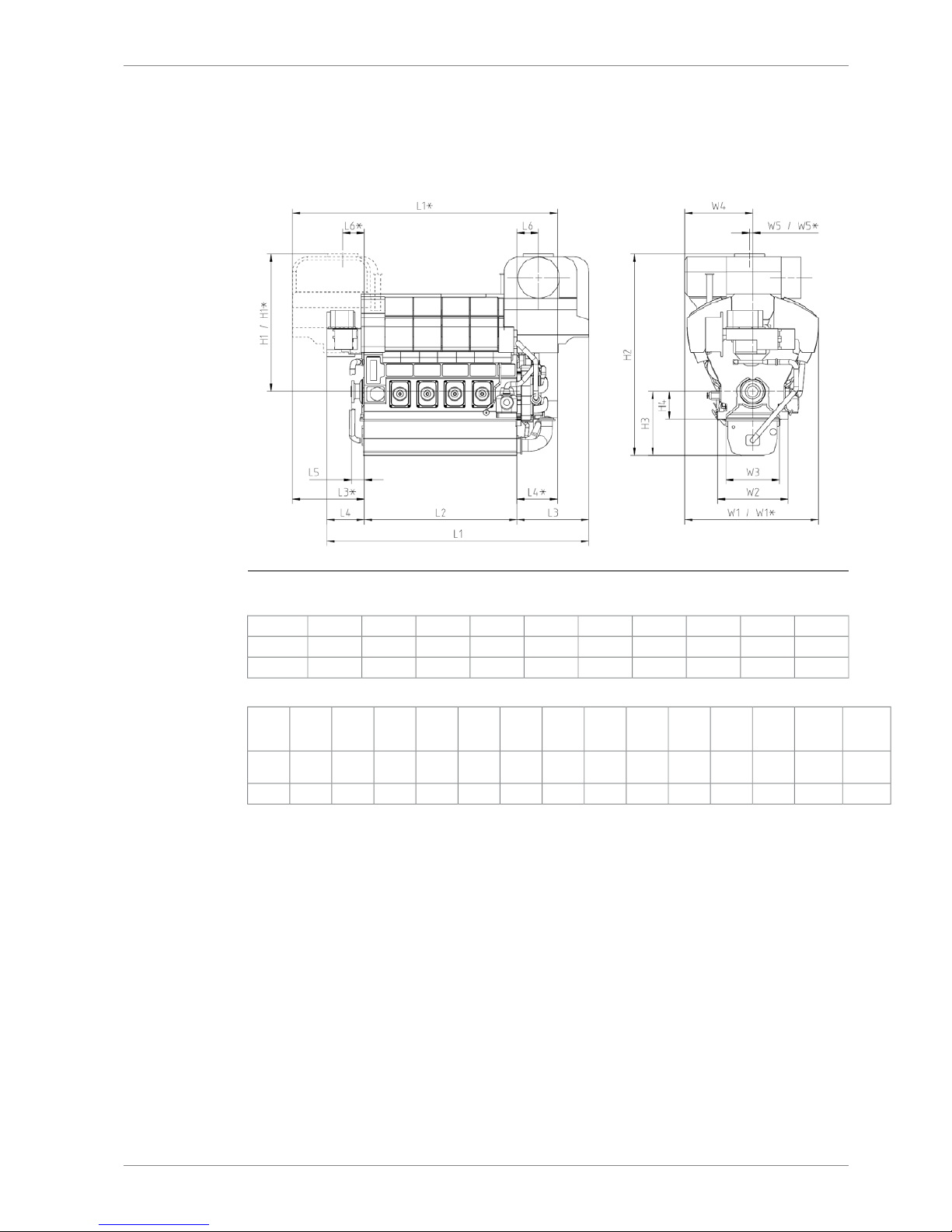

Fig 1-1 W8V31 & W10V31 Main engine dimensions

L6*L6L5L4*L4L3*L3L2L1*L1Engine

50050030098687716501650356061966087W8V31

50050030098687716501650420068366727W10V31

Weight

Liquids

Weight

Engine

**

W5*W5W4W3W2W1*W1H4H3H2H1*H1Engine

3.353.5 /

54.2*

-6767158511531600311531156501496470132053205W8V31

3.9562,2-6767158511531600311531156501496470132053205W10V31

DBAE248994 1-3

1. Main Data and OutputsWärtsilä 31DF Product Guide

Page 12

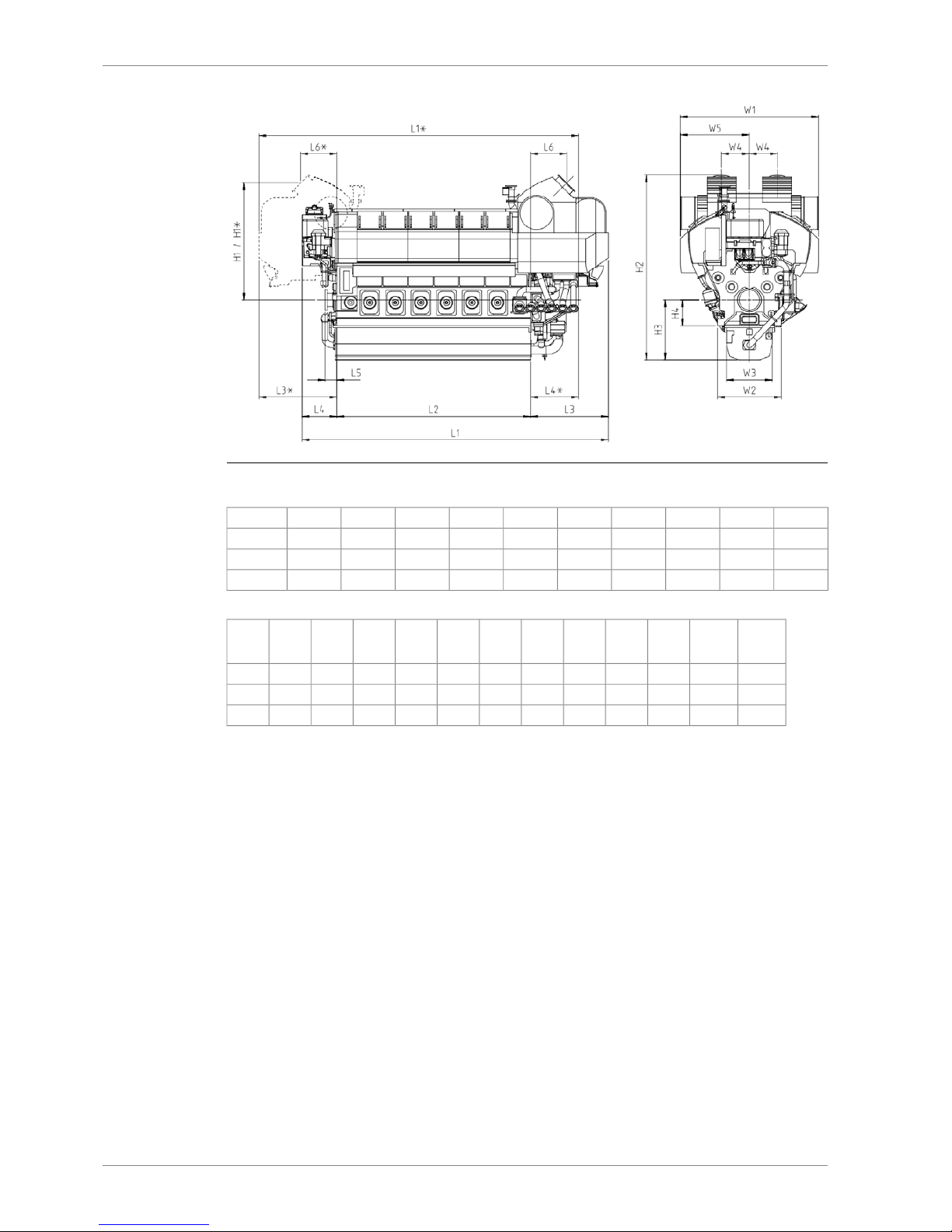

Fig 1-2 W12V31, W14V31 & W16V31 Main engine dimensions

L6*L6L5L4*L4L3*L3L2L1*L1Engine

9089083001250100020002000484080907840W12V31

9089083001250100020002000548087308480W14V31

9089083001250100020002000612093709120W16V31

Weight

Liquids

Weight

Engine

**

W5W4W3W2W1H4H3H2H1*H1Engine

4.9572.817506981153160035006501496463329262926W12V31

5.579.817506981153160035006501496463329262926W14V31

6.2587.917506981153160035006501496463329262926W16V31

1-4 DBAE248994

Wärtsilä 31DF Product Guide1. Main Data and Outputs

Page 13

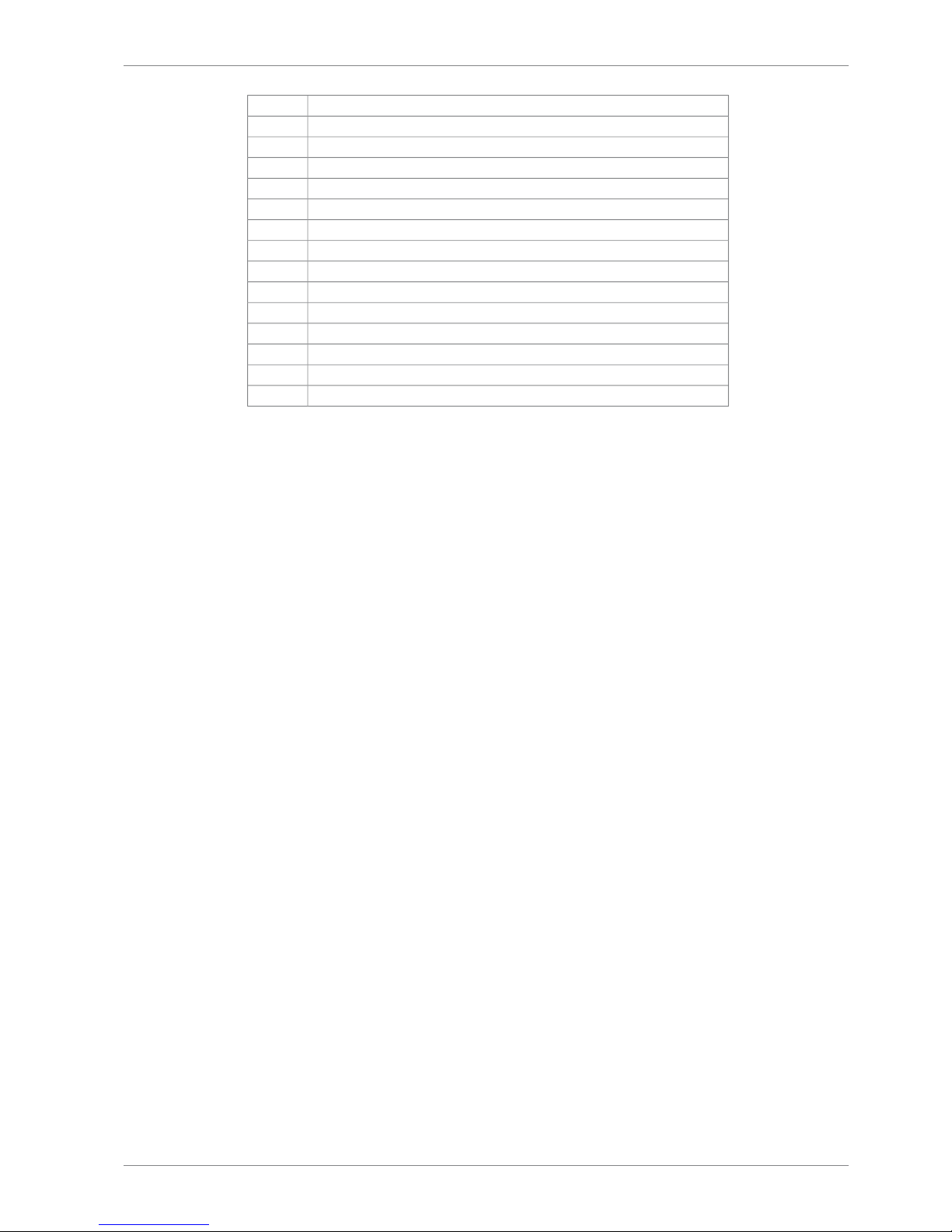

Total length of engineL1

Length of the engine blockL2

Length from the engine block to the outer most point in turbocharger endL3

Length from the engine block to the outer most point in non-turbocharger endL4

Length from engine block to crankshaft flangeL5

Length from engine block to center of exhaust gas outletL6

Height from the crankshaft centerline to center of exhaust gas outletH1

Total height of engine (normal wet sump)H2

Height from crankshaft centerline to bottom of the oil sump (normal wet sump)H3

Height from the crankshaft centerline to engine feet (fixed mounted)H4

Total width of engineW1

Width of engine block at the engine feetW2

Width of oil sumpW3

Width from crankshaft centerline to center of exhaust gas outletW4

Width from crankshaft centerline to the outer most point of the engineW5

* Turbocharger at flywheel end;

** Weight without liquids, damper and flywheel (as a rule of thumb, add 60kg per cylinder on

top of 8 and or 10V engine weight or, add 50kg per cylinder for 12, 14 and 16V engines for

additional gas components weight);

All dimensions in mm, weights in tonne.

DBAE248994 1-5

1. Main Data and OutputsWärtsilä 31DF Product Guide

Page 14

This page intentionally left blank

Page 15

2. Operating Ranges

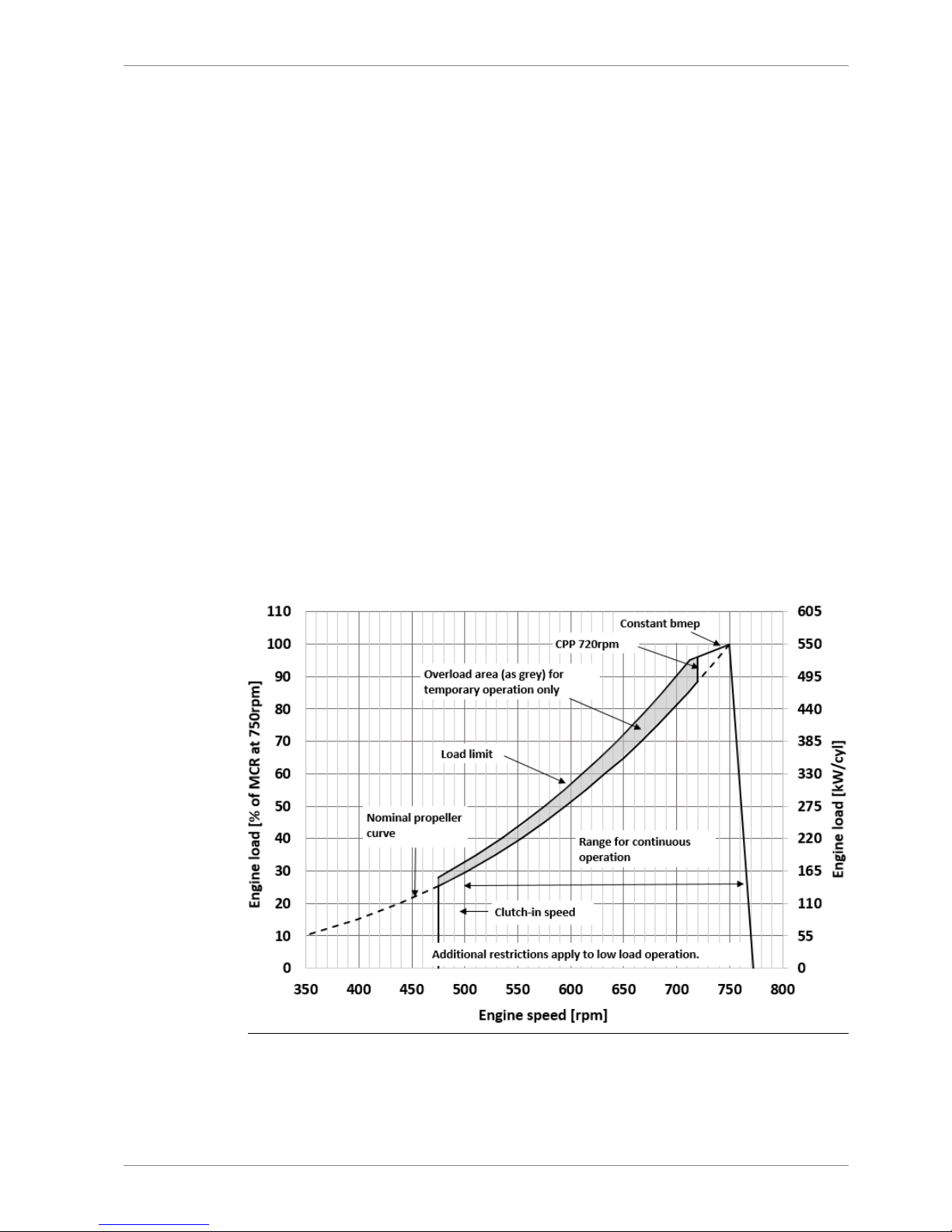

2.1 Engine operating range

Running below nominal speed the load must be limited according to the diagrams in this

chapter in order to maintain engine operating parameters within acceptable limits. Operation

in the shaded area is permitted only temporarily during transients. Minimum speed is indicated

in the diagram, but project specific limitations may apply.

2.1.1 Controllable pitch propellers

An automatic load control system is required to protect the engine from overload. The load

control reduces the propeller pitch automatically, when a pre-programmed load versus speed

curve (“engine limit curve”) is exceeded, overriding the combinator curve if necessary. Engine

load is determined from measured shaft power and actual engine speed. The shaft power

meter is Wärtsilä supply.

The propeller efficiency is highest at design pitch. It is common practice to dimension the

propeller so that the specified ship speed is attained with design pitch, nominal engine speed

and 85% output in the specified loading condition. The power demand from a possible shaft

generator or PTO must be taken into account. The 15% margin is a provision for weather

conditions and fouling of hull and propeller. An additional engine margin can be applied for

most economical operation of the engine, or to have reserve power.

The propulsion control must also include automatic limitation of the load increase rate.

Maximum loading rates can be found later in this chapter.

Fig 2-1 Operating field for CP Propeller (DAAF389037B)

DBAE248994 2-1

2. Operating RangesWärtsilä 31DF Product Guide

Page 16

NOTE

1) Valid for both gas operation and diesel operation.

2) Minimum engine speed is restricted to 472rpm with engine driven oil pump.

3) Additional restrictions apply to low load operation.

4) Project specific idling and clutch in speed depends on clutch, gearbox and the

Torsional Vibration Calculations.

Remarks: The maximum output may have to be reduced depending on gas properties and

gas pressure. The permissible output will in such case be reduced with same percentage at

all revolution speeds.

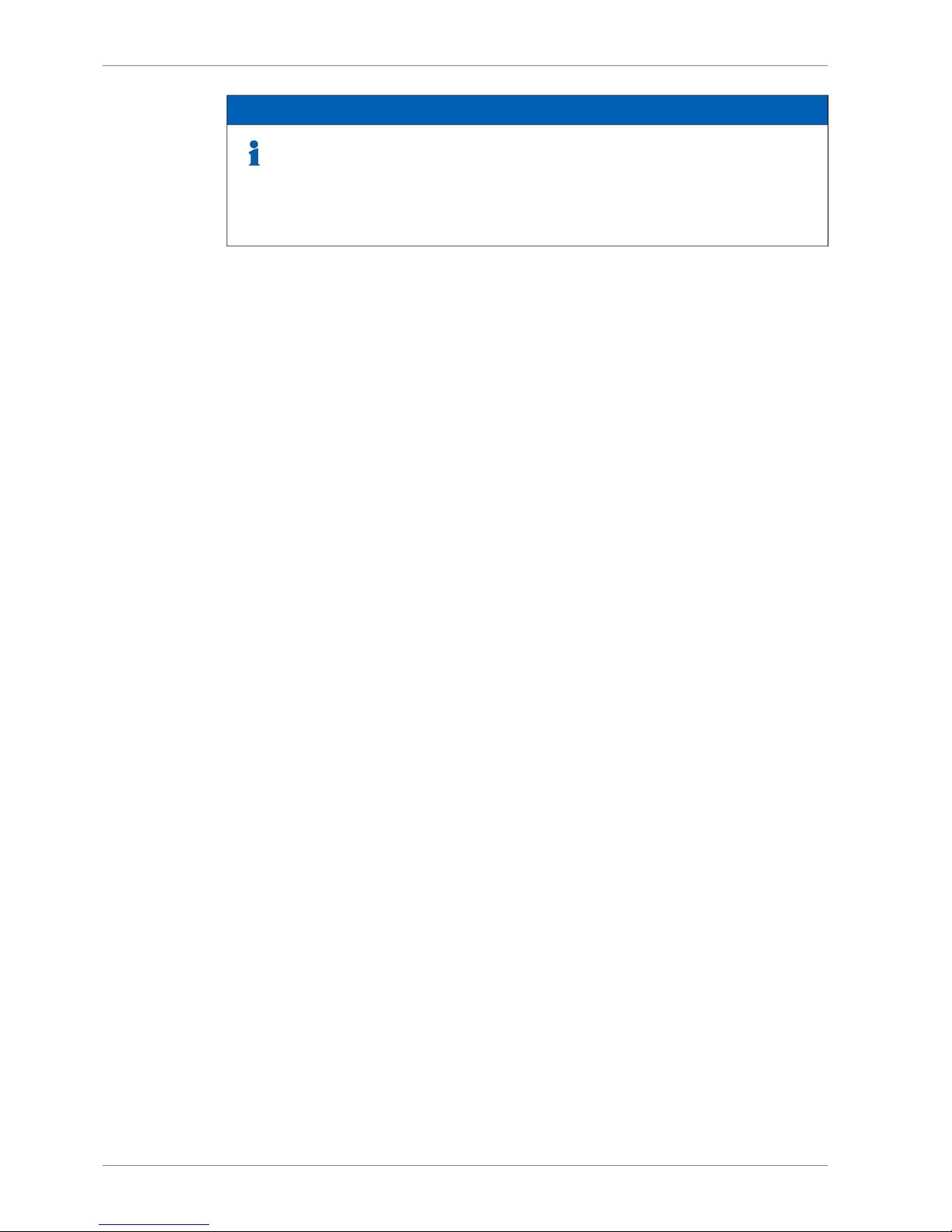

2.2 Loading capacity

Controlled load increase is essential for highly supercharged diesel engines, because the

turbocharger needs time to accelerate before it can deliver the required amount of air. A slower

loading ramp than the maximum capability of the engine permits a more even temperature

distribution in engine components during transients.

The engine can be loaded immediately after start, provided that the engine is pre-heated to:

● High Temperature (HT) water temperature is minimum 70°C

● Lubricating oil temperature is minimum 40°C

The ramp for normal loading applies to engines that have reached normal operating

temperature.

2-2 DBAE248994

Wärtsilä 31DF Product Guide2. Operating Ranges

Page 17

2.2.1 Mechanical propulsion

2.2.1.1 Loading Rates Variable speed engines (CPP)

Normal loading rate, variable speed engines, 750 rpm

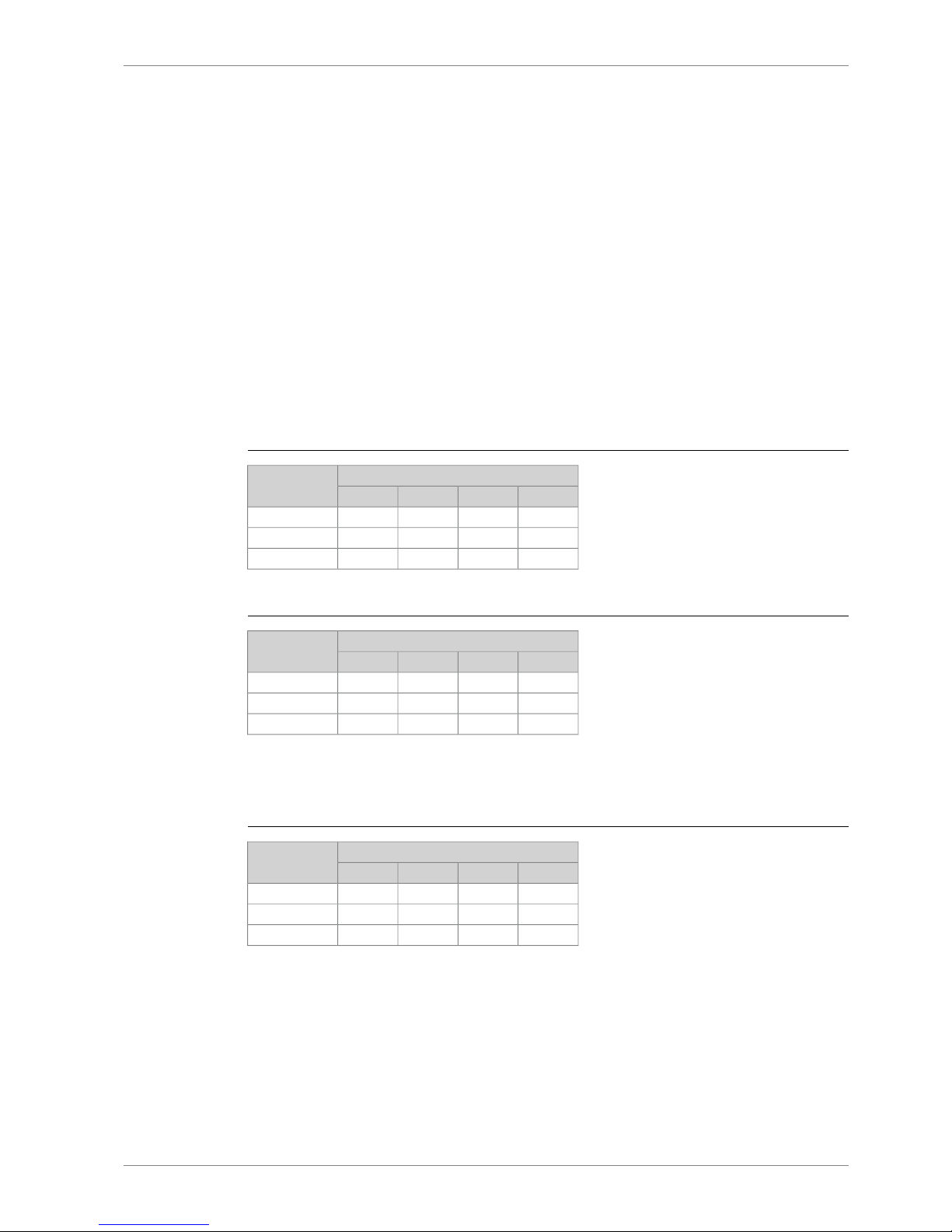

Table 2-1 Loading rate

Emergency,

diesel operation only

[s]

Fast loading

[s]

Nominal

loading

[s]

Engine load

[% of MCR]

0000

30120300100

Fig 2-2 Normal Loading rate, variable speed engines, 750 rpm

NOTE

If normal loading rate is chosen low load running is limited to normal low load

restriction curve. Please see chapter 2.3.1.

DBAE248994 2-3

2. Operating RangesWärtsilä 31DF Product Guide

Page 18

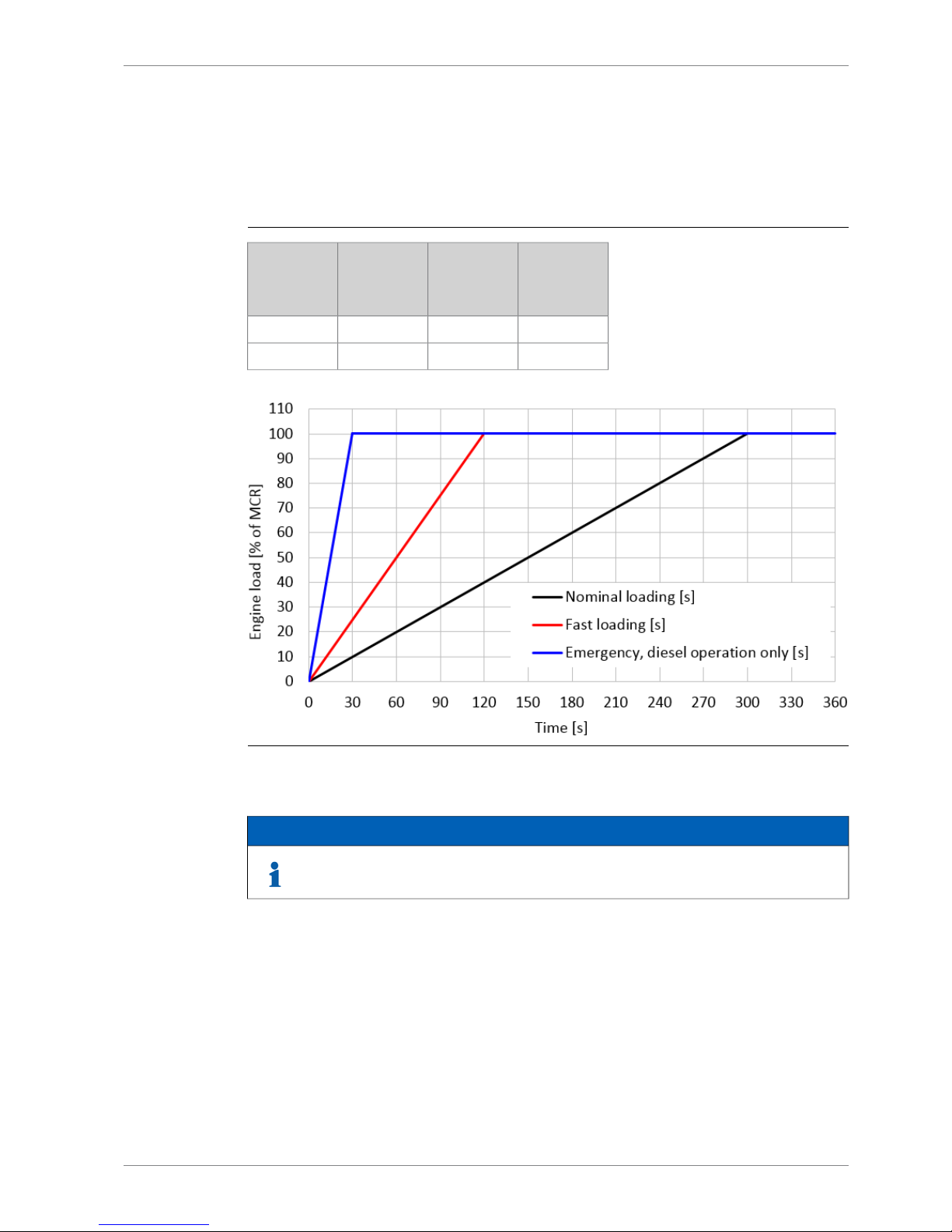

Unloading rate, variable speed engines, 750 rpm

Table 2-2 Unloading rate

Emergency,

diesel opera-

tion only

[s]

Fast loading

[s]

Nominal

loading

[s]

Engine load

[% of MCR]

0N/A

0

100

0N/A

60

0

Fig 2-3 Unloading rate, variable speed engines, 750 rpm

The propulsion control must include automatic limitation of the load increase rate. If the control

system has only one load increase ramp, then the ramp for a preheated engine should be

used. In tug applications the engines have usually reached normal operating temperature

before the tug starts assisting. The “emergency” curve is close to the maximum capability of

the engine.

Large load reductions from high load should also be performed gradually. In normal operation

the load should not be reduced from 100% to 0% in less than 15 seconds. When absolutely

necessary, the load can be reduced as fast as the pitch setting system can react (overspeed

due to windmilling must be considered for high speed ships).

2-4 DBAE248994

Wärtsilä 31DF Product Guide2. Operating Ranges

Page 19

2.2.2 Diesel electric propulsion and auxiliary engines

2.2.2.1 Loading rates Constant speed engines (DE / Aux / CPP)

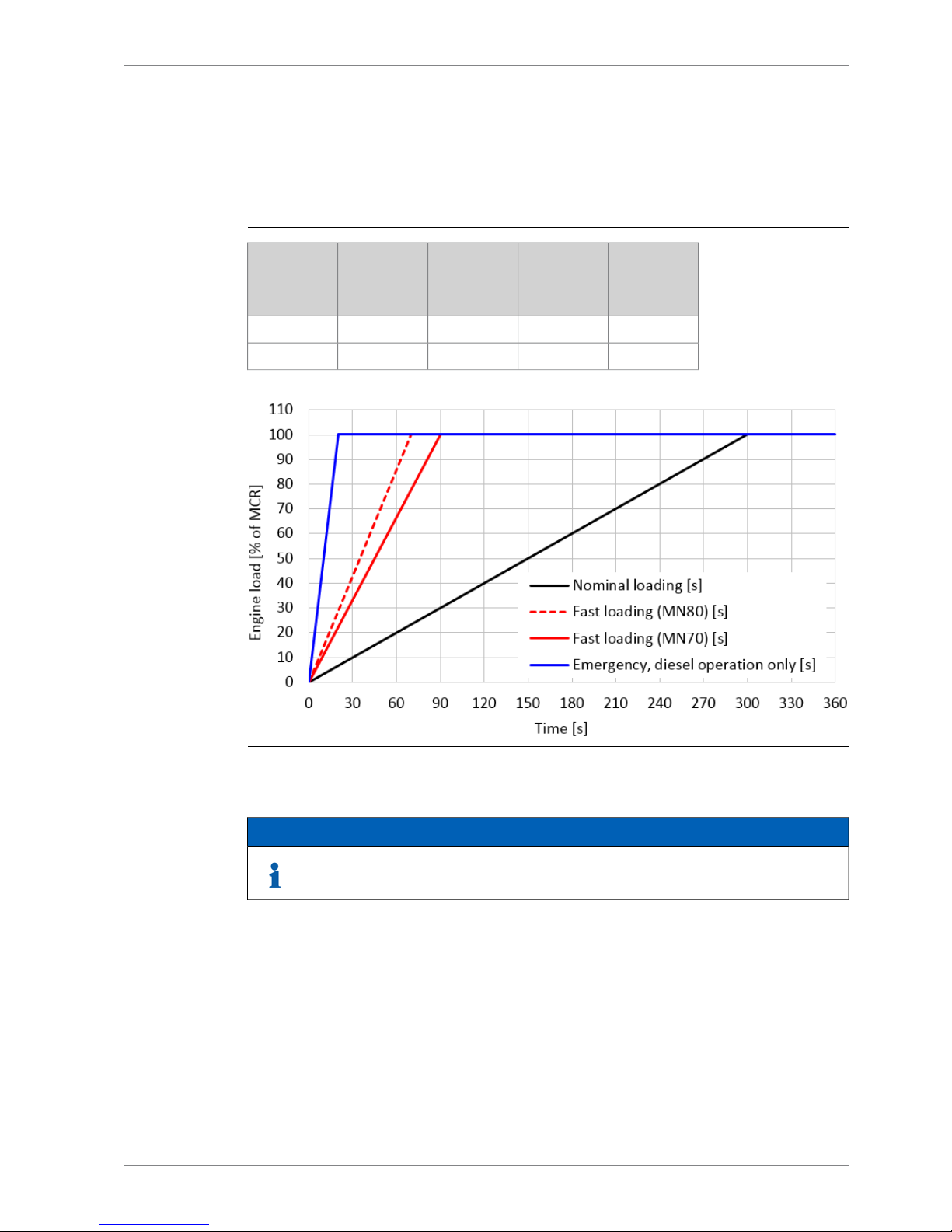

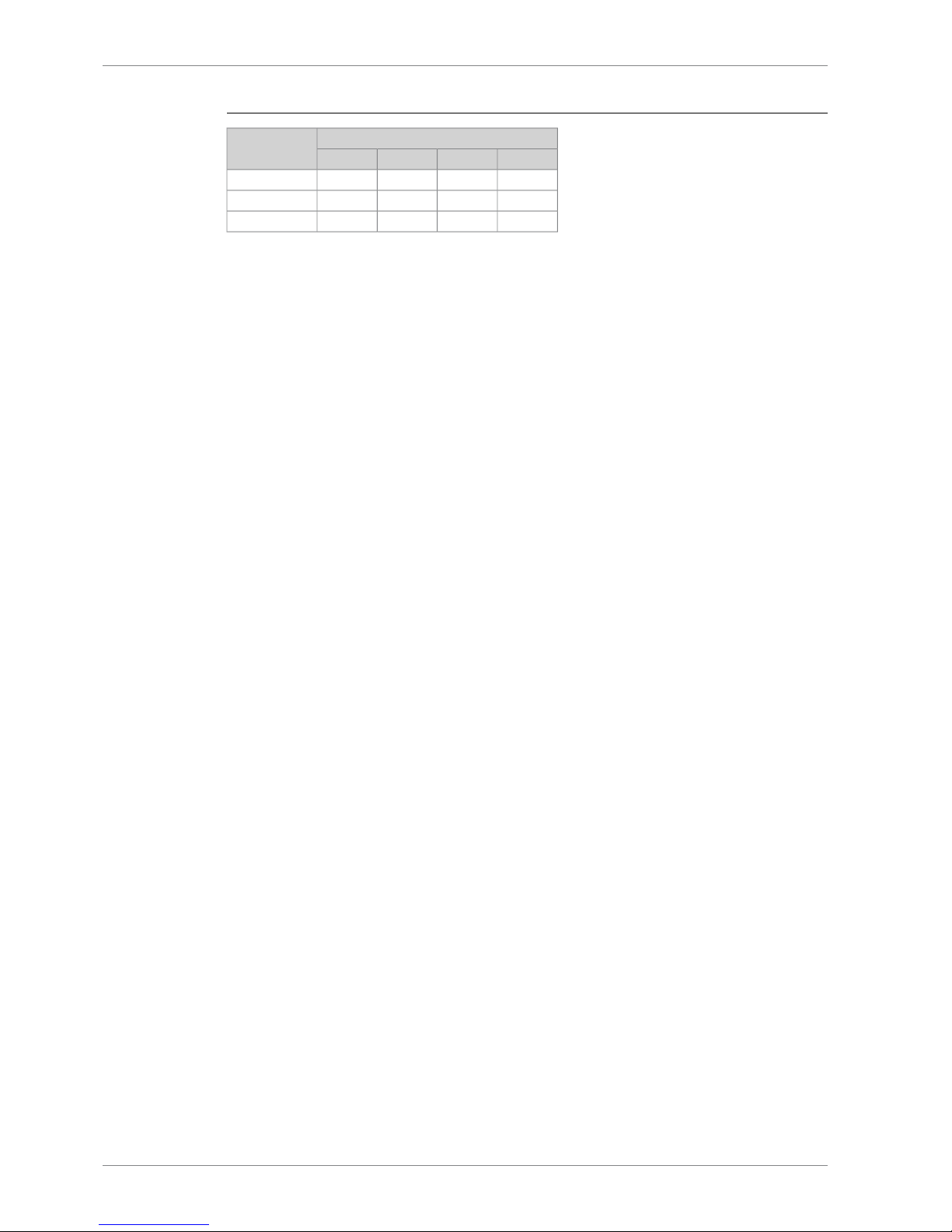

Normal loading rate, constant speed engines, 720/750 rpm (DE / Aux / CPP)

Table 2-3 Normal Loading rate

Emergency,

diesel operation only

[s]

Fast loading

(MN80)

[s]

Fast loading

(MN70)

[s]

Nominal

loading

[s]

Engine load

[% of MCR]

00000

207090300100

Fig 2-4 Normal Loading rate, constant speed engines, 720/750 rpm (DE / Aux / CPP)

NOTE

If normal loading rate is chosen low load running is limited to normal low load

restriction curve. Please see chapter 2.3.1.

DBAE248994 2-5

2. Operating RangesWärtsilä 31DF Product Guide

Page 20

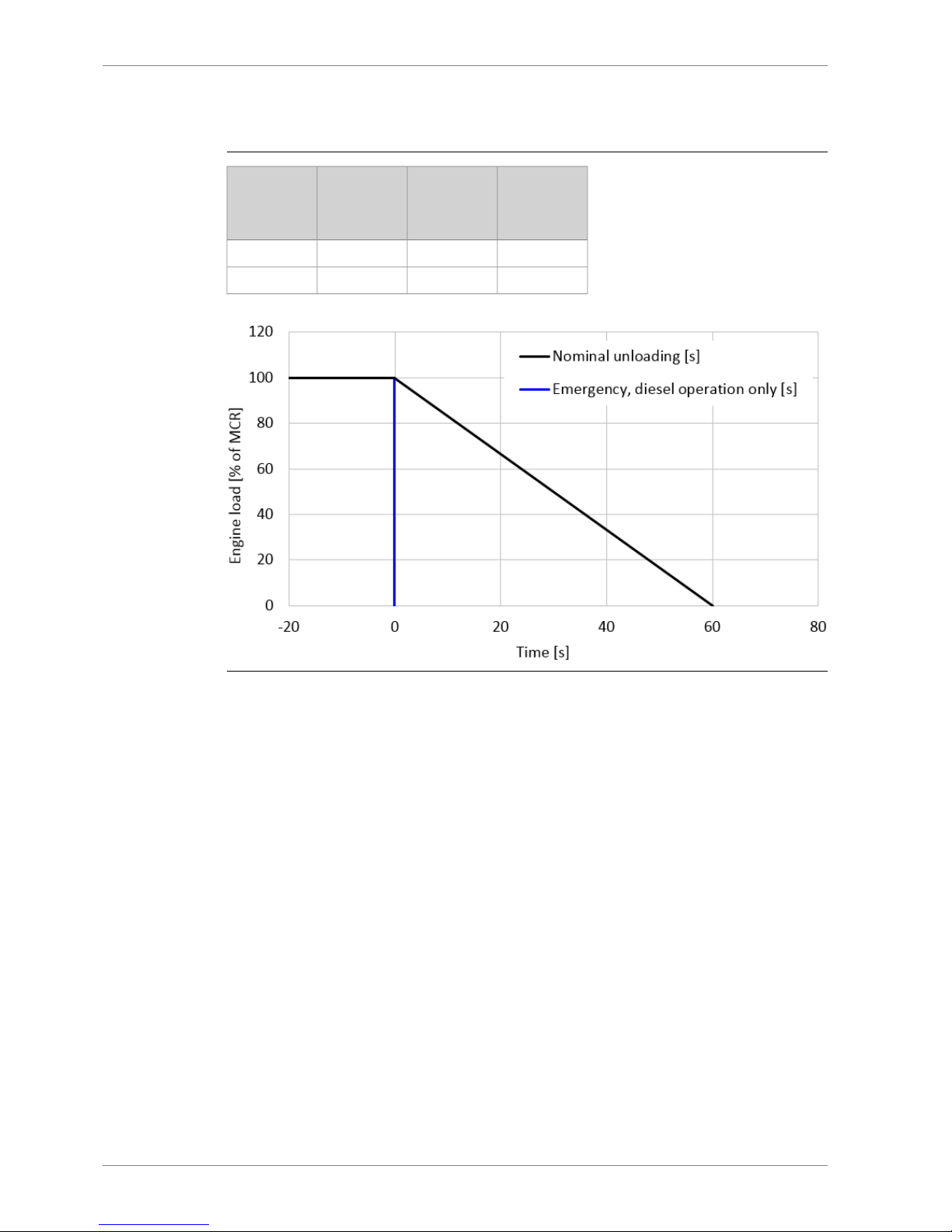

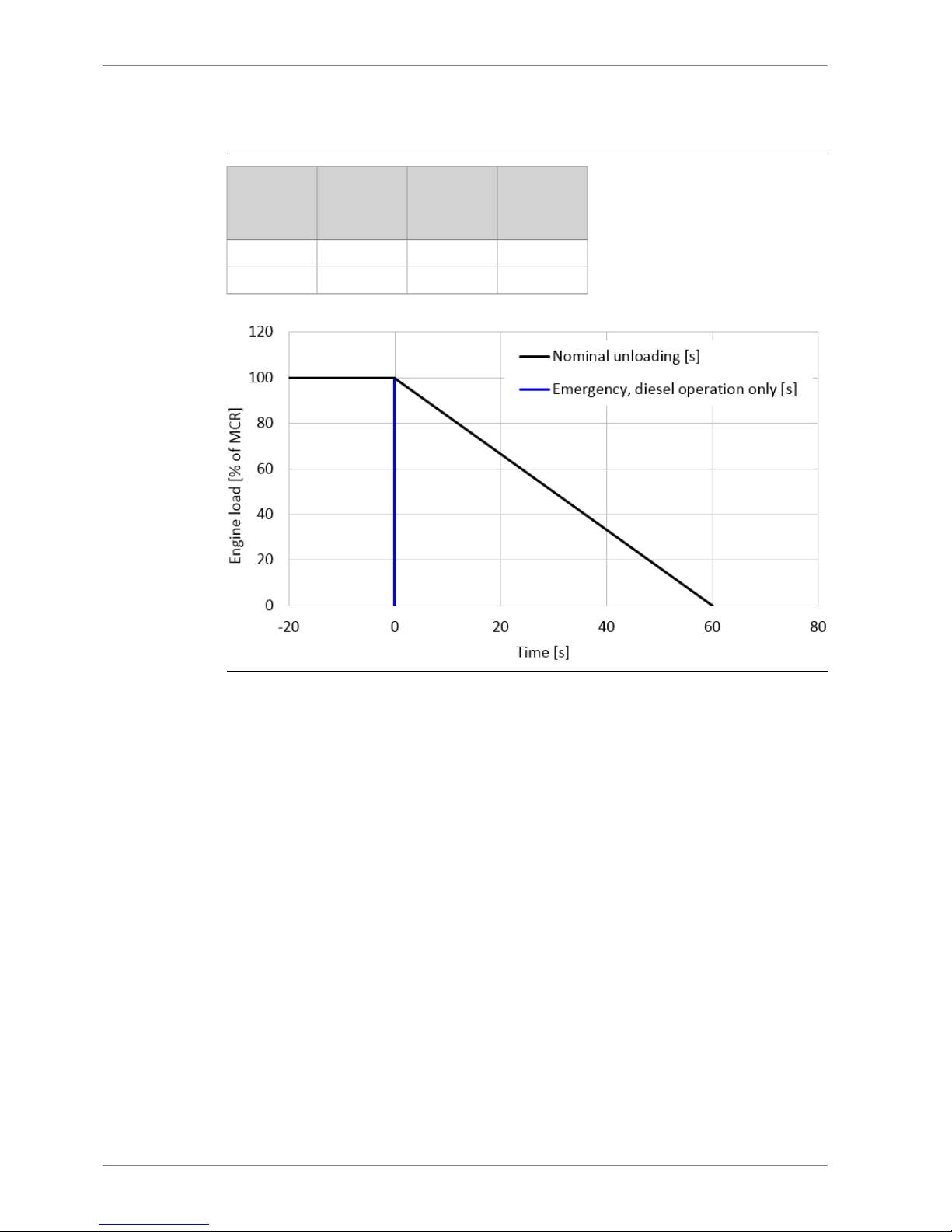

Unloading rate, constant speed engines, 720/750 rpm (DE / Aux / CPP)

Table 2-4 Unloading rate

Emergency,

diesel opera-

tion only

[s]

Fast loading

[s]

Nominal

loading

[s]

Engine load

[% of MCR]

0N/A

0

100

0N/A

60

0

Fig 2-5 Unloading rate, constant speed engines, 720/750 rpm (DE / Aux / CPP)

In diesel electric installations loading ramps are implemented both in the propulsion control

and in the power management system, or in the engine speed control in case isochronous

load sharing is applied. If a ramp without knee-point is used, it should not achieve 100% load

in shorter time than the ramp in the figure. When the load sharing is based on speed droop,

the load increase rate of a recently connected generator is the sum of the load transfer

performed by the power management system and the load increase performed by the

propulsion control.

The “emergency” curve is close to the maximum capability of the engine and it shall not be

used as the normal limit. In dynamic positioning applications loading ramps corresponding to

20-30 seconds from zero to full load are however normal. If the vessel has also other operating

modes, a slower loading ramp is recommended for these operating modes.

In typical auxiliary engine applications there is usually no single consumer being decisive for

the loading rate. It is recommended to group electrical equipment so that the load is increased

in small increments, and the resulting loading rate roughly corresponds to the “normal” curve.

In normal operation the load should not be reduced from 100% to 0% in less than 15 seconds.

If the application requires frequent unloading at a significantly faster rate, special arrangements

can be necessary on the engine. In an emergency situation the full load can be thrown off

instantly.

2-6 DBAE248994

Wärtsilä 31DF Product Guide2. Operating Ranges

Page 21

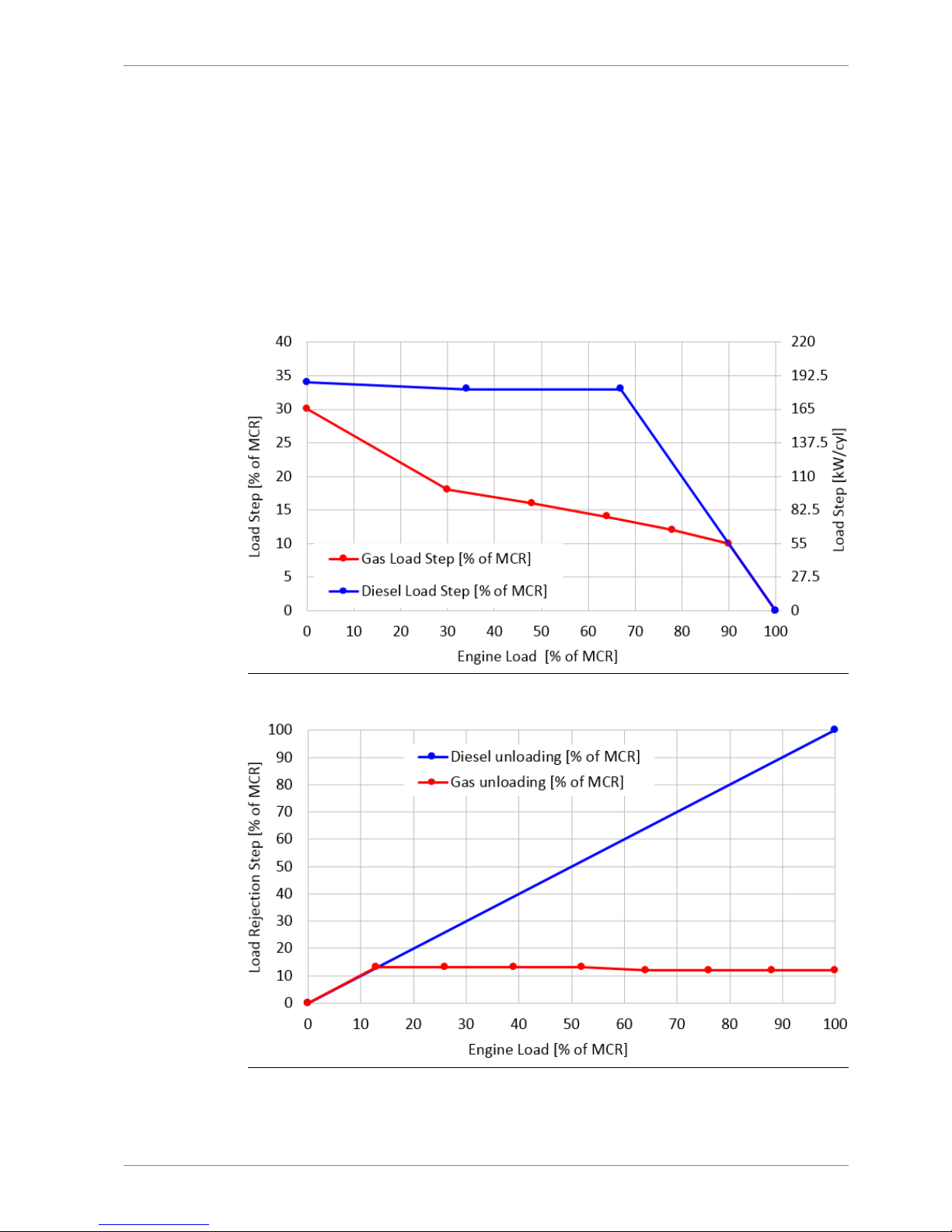

2.2.2.2 Instant Load Application

The maximum permissible load step which may be applied at any given load can be read from

the figure below. The values are valid for engines operating in island mode (speed control).

Furthermore the stated values are limited to a running engine that has reached nominal

operating temperatures, or for an engine which has been operated at above 30% load within

the last 30 minutes.

Cyclic (wave) load-taking capability can be evaluated from the figures below:

● Max instant load step = cyclic load amplitude

○ Example: With cyclic loading at average load 57% the load variation amplitude can be

14%, i.e ±7% (=50% + 14%/2)

Fig 2-6 Load Steps, CS 750 rpm

Fig 2-7 Unloading Steps, CS 750 rpm

DBAE248994 2-7

2. Operating RangesWärtsilä 31DF Product Guide

Page 22

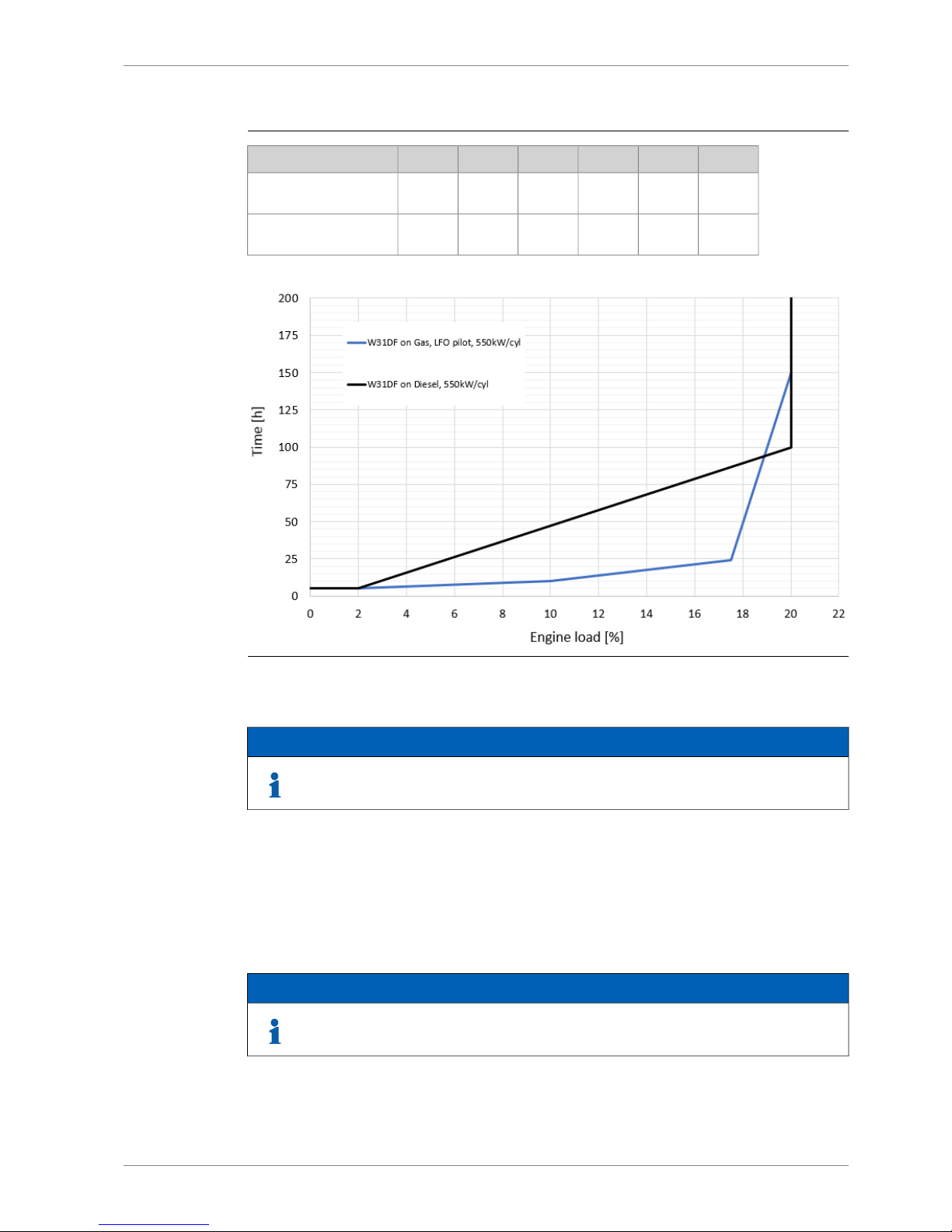

2.3 Low load operation

2.3.1 Normal Low load operation - Normal load acceptance

In order to avoid fouling of the engine, recommended limits to the low load operation are given.

Low load operation is all loads below 20% load. Cumulative low load operation should not

exceed the recommended values given in the chart and table. The time is reset after a cleaning

run at minimum 70% load for a minimum of 1 hour.

Black line (diesel mode) limit is valid in diesel mode when intention is to continue in diesel

mode. In case the intention is to transfer to gas mode and continue operating in gas mode

then blue line (gas mode limit) is valid also for diesel mode.

The loading rates according to Normal low load load operations, chapter load performance

are allowed with these low load operation limits.

If recommended time limits are exceeded then engine shall not be loaded faster than the

nominal loading curve in the chapter loading performance.

Absolute idling time 10 minutes if the engine is to be stopped, 5 hours in gas mode or 10 hours

in diesel mode if engine is loaded afterwards.

2-8 DBAE248994

Wärtsilä 31DF Product Guide2. Operating Ranges

Page 23

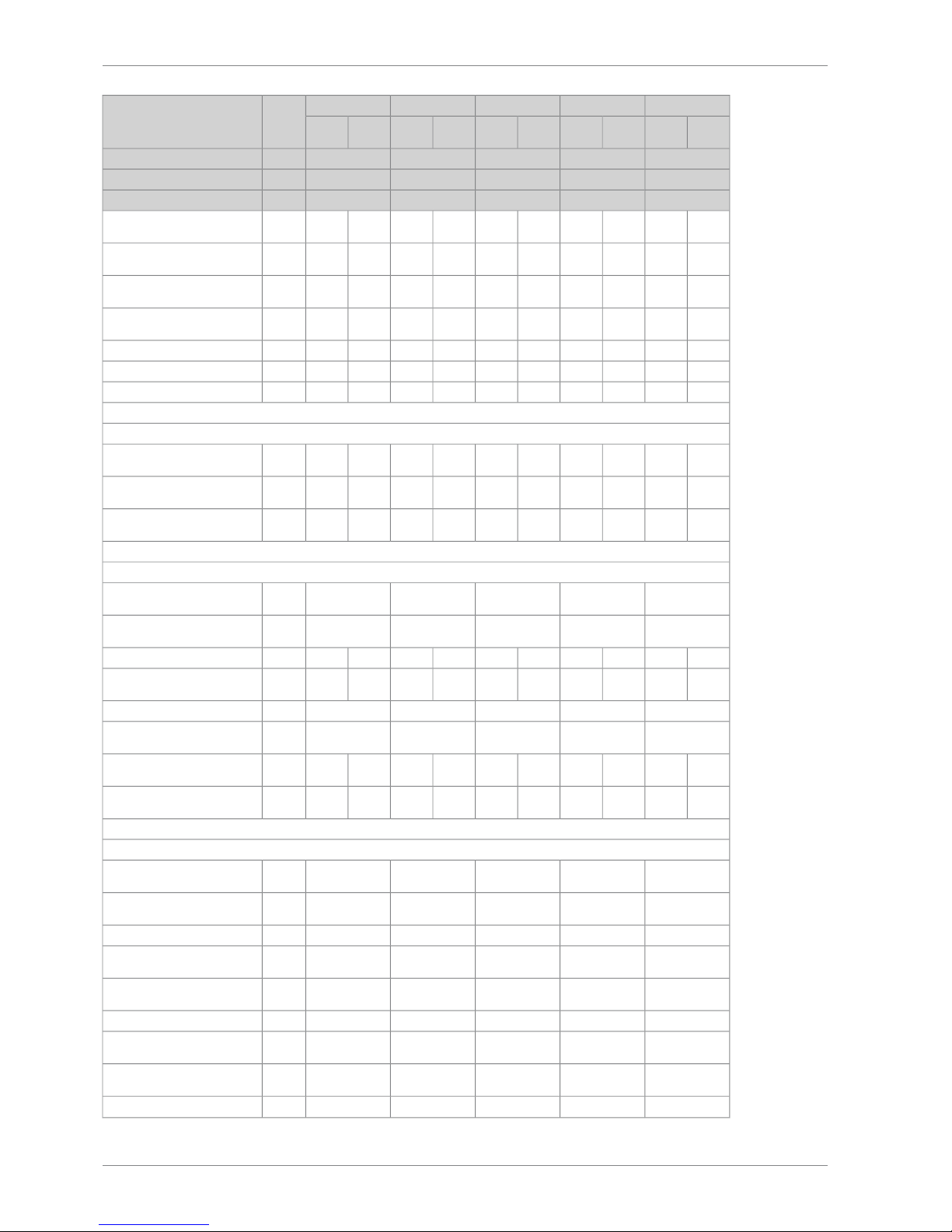

Table 2-5 Max continous low load operation time for load acceptance according to

Normal Load acceptance chapter

2017.510

20%

Load

150

241055h

W31DF on Gas, LFO pilot, 550kW/cyl

100

874755h

W31DF on Diesel,

550kW/cyl

Fig 2-8 Low load operating restrictions

NOTE

Black line is intended for diesel mode operation and blue line is intended for gas

mode operation.

2.3.2 Absolute idling

Absolute idling (declutched main engine, disconnected generator)

- Maximum 10 minutes if the engine is to be stopped after the idling. 3-5 minutes idling before

stop is recommended.

- Maximum 5 hours in gas mode and 10 hours in diesel mode if the engine is to be loaded

after the idling.

NOTE

Operating restrictions on SCR applications in low load operation to be observed.

DBAE248994 2-9

2. Operating RangesWärtsilä 31DF Product Guide

Page 24

2.4 Low air temperature

In standard conditions the following minimum inlet air temperatures apply:

Gas mode:

● Low load + 5ºC

● High load -10ºC

Diesel mode:

● Starting + 5ºC

● Idling - 5ºC

● High load - 10ºC

For further guidelines, see chapter Combustion air system design.

NOTE

Air Waste Gate (AWG) is needed when suction air temperature is below +5°C.

2-10 DBAE248994

Wärtsilä 31DF Product Guide2. Operating Ranges

Page 25

3. Technical Data

3.1 Introduction

This chapter contains technical data of the engine (heat balance, flows, pressures etc.) for

design of auxiliary systems. Further design criteria for external equipment and system layouts

are presented in the respective chapter.

3.1.1 Engine driven pumps

The fuel consumption stated in the technical data tables is with engine driven pumps. The

increase in fuel consumption with engine driven pumps is given in the table below; correction

in g/kWh (Diesel mode) and or kJ/kWh (Gas mode).

3.1.1.1 Diesel mode

Table 3-1 Constant speed engines (DE, CPP, Aux), 750/720rpm, MDF/HFO

Engine load [%]Engine driven

pumps

507585100

-2.6-1.6-1.4-1.2Lube oil

-1.0-0.7-0.6-0.5LT Water

-1.0-0.7-0.6-0.5HT Water

Table 3-2 Variable speed engines (CPP), 750rpm, MDF/HFO

Engine load [%]Engine driven

pumps

507585100

-1.4-1.4-1.3-1.4Lube oil

-0.5-0.5-0.5-0.5LT Water

-0.5-0.5-0.5-0.5HT Water

3.1.1.2 Gas mode

Table 3-3 Constant speed engines (DE, CPP, Aux), 750/720rpm, MDF/HFO

Engine load [%]Engine driven

pumps

507585100

-108.6-68.6-60.0-50.5Lube oil

-44.8-27.6-24.8-21.0LT Water

-44.8-27.6-24.8-21.0HT Water

DBAE248994 3-1

3. Technical DataWärtsilä 31DF Product Guide

Page 26

Table 3-4 Variable speed engines (CPP), 750rpm, MDF/HFO

Engine load [%]Engine driven

pumps

507585100

-58.1-57.1-57.1-57.1Lube oil

-21.0-21.0-21.0-21.0LT Water

-21.0-21.0-21.0-21.0HT Water

3-2 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 27

3.2 Wärtsilä 8V31DF

MEAUXAUXDEDE

Wärtsilä 8V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

44004400424044004240kWEngine output

2.712.712.722.712.72MPaMean effective pressure

Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3IMO compliance

Combustion air system (Note 1)

8.46.68.46.68.16.48.46.68.16.4kg/sFlow at 100% load

4545454545°CTemperature at turbocharger in-

take, max.

60606060606060606060°CTemperature after air cooler (TE

601)

Exhaust gas system (Note 2)

8.77.48.77.48.17.18.77.48.17.1kg/sFlow at 100% load

7.46.17.46.16.95.97.46.16.95.9kg/sFlow at 85% load

6.65.56.95.46.45.26.95.46.45.2kg/sFlow at 75% load

5.03.84.93.84.63.74.93.84.63.7kg/sFlow at 50% load

270300270300270300270300270300°CTemperature after turbocharger

at 100% load (TE 517)

260320270350270350270350270350°CTemperature after turbocharger

at 85% load (TE 517)

270310260350260350260350260350°CTemperature after turbocharger

at 75% load (TE 517)

270330280370280370280370280370°CTemperature after turbocharger

at 50% load (TE 517)

77777kPaBackpressure, max.

697657697657671647697657671647mmCalculated exhaust diameter for

35 m/s

Heat balance at 100% load (Note 3)

424360424360408344424360408344kWJacket water, HT-circuit

768504768504680472768504680472kWCharge air, HT-circuit

1296106413041072120810241304107212081024kWCharge air, LT-circuit

488408488408472392488408472392kWLubricating oil, LT-circuit

120120120120120120120120120120kWRadiation

Fuel consumption (Note 4)

(Note 5)

-7280-7280-7250-7280-7250kJ/kWhTotal energy consumption at

100% load

-7230-7350-7300-7350-7300kJ/kWhTotal energy consumption at 85%

load

-7250-7500-7430-7500-7430kJ/kWhTotal energy consumption at 75%

load

-7330-7820-7790-7820-7790kJ/kWhTotal energy consumption at 50%

load

-7128-7128-7097-7128-7097kJ/kWhFuel gas consumption at 100%

load

DBAE248994 3-3

3. Technical DataWärtsilä 31DF Product Guide

Page 28

MEAUXAUXDEDE

Wärtsilä 8V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

-7059-7171-7121-7171-7121kJ/kWhFuel gas consumption at 85%

load

-7082-7294-7226-7294-7226kJ/kWhFuel gas consumption at 75%

load

-7157-7515-7484-7515-7484kJ/kWhFuel gas consumption at 50%

load

177.23.8177.23.8176.33.8177.23.8176.33.8g/kWhFuel oil consumption at 100%

load

172.54.2174.44.5173.14.4174.44.5173.14.4g/kWhFuel oil consumption at85% load

176.34.1177.05.1176.85.0177.05.1176.85.0g/kWhFuel oil consumption at75% load

180.44.3185.07.6184.37.6185.07.6184.37.6g/kWhFuel oil consumption 50% load

Fuel gas system

-895-895-895-895-895kPa (a)Gas pressure at engine inlet, min

(PT901)

-1015-1015-1015-1015-1015kPa (a)Gas pressure to Gas Valve Unit,

min

-0...60-0...60-0...60-0...60-0...60°CGas temperature beforeGas Valve

Unit

Fuel oil system

1000±1001000±1001000±1001000±1001000±100kPaPressure before HP pumps (PT

101)

3.63.63.63.63.6m3/hEngine driven pump capacity

(MDF only)

16...24-16...24-16...24-16...24-16...24-cStHFO viscosity before the engine

140-140-140-140-140-°CMax. HFO temperature before

engine (TE 101)

2.02.02.02.02.0cStMDF viscosity, min.

4545454545°CMax. MDF temperature before

engine (TE 101)

0.50.50.50.50.5kg/hLeak fuel quantity (HFO), clean

fuel at 100% load

1.50.91.50.91.50.91.50.91.50.9kg/hLeak fuel quantity (MDF), clean

fuel at 100% load

Lubricating oil system

420420420420420kPaPressure before bearings, nom.

(PT 201)

4040404040kPaSuction ability, including pipe

loss, max.

150150150150150kPaPriming pressure, nom. (PT 201)

3535353535kPaSuction ability priming pump, in-

cluding pipe loss, max.

7070707070°CTemperature before bearings,

nom. (TE 201)

8282828282°CTemperature after engine, approx.

144130125130125m3/hPump capacity (main), engine

driven

100100100100100m3/hPump capacity (main), electrically

driven

40.0 / 40.040.0 / 40.040.0 / 40.040.0 / 40.040.0 / 40.0m3/hPriming pump capacity (50/60Hz)

3-4 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 29

MEAUXAUXDEDE

Wärtsilä 8V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

2.82.82.82.82.8

m

3

Oil volume, wet sump, nom.

55555m

3

Oil volume in separate system oil

tank

0.450.350.450.350.450.350.450.350.450.35g/kWhOil consumption at 100% load,

approx.

19601960196019601960l/minCrankcase ventilation flow rate at

full load

0.10.10.10.10.1kPaCrankcase ventilation backpres-

sure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8lOil volume in turning device

Cooling water system

HT cooling water system

358 + static358 + static358 + static358 + static358 + statickPaPressure at engine, after pump,

nom. (PT 401)

600600600600600kPaPressure at engine, after pump,

max. (PT 401)

8383838383°CTemperature before cylinders,

approx. (TE 401)

9696969696°CTemperature after engine, nom.

8080808080m3/hCapacity of engine driven pump,

nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

0.350.350.350.350.35m

3

Water volume in engine

365365365365365kPaDelivery head of stand-by pump

LT cooling water system

650+ static650+ static650+ static650+ static650+ statickPaPressure at engine, after pump,

nom. (PT 451)

40/ 4540/ 4540/ 4540/ 4540/ 45°CTemperature before engine, nom

(TE 451)

8080808080m3/hCapacity of engine driven pump,

nom.

110110110110110kPaPressure drop over charge air

cooler (two-stage)

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

Starting air system

30003000300030003000kPaPressure, nom.

15001500150015001500kPaPressure at engine during start,

min. (alarm) (20°C)

30003000300030003000kPaPressure, max.

15001500150015001500kPaLow pressure limit in air vessels

5.95.95.95.95.9Nm

3

Starting air consumption, start

(successful)

DBAE248994 3-5

3. Technical DataWärtsilä 31DF Product Guide

Page 30

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9% and temperature tolerance 10°C in gasmodeoperation. Flow tolerance 9%andtemperaturetolerance 15°C in dieselmode operation.

Note 2

At 100% output and nominal speed. The figures are valid for ambient conditions according to ISO 15550 except for LTwater temperature, which is corresponding to charge air receiver temperature 55ºC in gas operation and 60 ºC in diesel

mode. With engine driven water and lubricating oil pumps. Tolerance for cooling water heat 10%, tolerance for radiation

heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers. In arctic option

all charge air coolers are in LT circuit.

Note 3

Validity of the data in diesel mode operation: at ambient conditions according to ISO 15550. Lower calorific value 42700

kJ/kg. With engine driven pumps (two cooling water + one lubricating oil pump). Tolerance 5%.

Note 4

Validity of the data in gas fuel operation: total barometric pressure, air temperature and relative humidity according to

ISO 15550:2002(E), LT water temperature corresponding to receiver temperature 55°C, pilot fuel cetane index minimum

50 according to ISO 4264. Lower calorific value 42 700 kJ/kg for pilot fuel and 49 700 kJ/kg for gas fuel. With engine

driven pumps (two cooling water pumps, one lubricating oil pump). Tolerance 5%.

Note 5

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

3-6 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 31

MEAUXAUXDEDE

Wärtsilä 8V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

44004400424044004240kWEngine output

2.712.712.722.712.72MPaMean effective pressure

Tier 3Tier 3Tier 3Tier 3Tier 3IMO compliance

Combustion air system (Note 1)

7.96.67.96.67.66.47.96.67.66.4kg/sFlow at 100% load

4545454545°CTemperature at turbocharger in-

take, max.

60606060606060606060°CTemperature after air cooler (TE

601)

Exhaust gas system (Note 2)

8.67.48.67.47.97.18.67.47.97.1kg/sFlow at 100% load

7.26.17.46.16.85.97.46.16.85.9kg/sFlow at 85% load

6.55.56.75.46.25.26.75.46.25.2kg/sFlow at 75% load

5.03.84.93.84.63.74.93.84.63.7kg/sFlow at 50% load

285300285300285300285300285300°CTemperature after turbocharger

at 100% load (TE 517)

285320285350285350285350285350°CTemperature after turbocharger

at 85% load (TE 517)

285310285350285350285350285350°CTemperature after turbocharger

at 75% load (TE 517)

285330285370285370285370285370°CTemperature after turbocharger

at 50% load (TE 517)

77777kPaBackpressure, max.

700657700657673647700657673647mmCalculated exhaust diameter for

35 m/s

Heat balance at 100% load (Note 3)

424360424360408344424360408344kWJacket water, HT-circuit

744504736504648472736504648472kWCharge air, HT-circuit

1280106412881072119210241288107211921024kWCharge air, LT-circuit

488408488408472392488408472392kWLubricating oil, LT-circuit

120120120120120120120120120120kWRadiation

Fuel consumption (Note 4)

(Note 5)

-7280-7280-7250-7280-7250kJ/kWhTotal energy consumption at

100% load

-7230-7350-7300-7350-7300kJ/kWhTotal energy consumption at 85%

load

-7250-7500-7430-7500-7430kJ/kWhTotal energy consumption at 75%

load

-7330-7820-7790-7820-7790kJ/kWhTotal energy consumption at 50%

load

-7128-7128-7097-7128-7097kJ/kWhFuel gas consumption at 100%

load

-7059-7171-7121-7171-7121kJ/kWhFuel gas consumption at 85%

load

DBAE248994 3-7

3. Technical DataWärtsilä 31DF Product Guide

Page 32

MEAUXAUXDEDE

Wärtsilä 8V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

-7082-7294-7226-7294-7226kJ/kWhFuel gas consumption at 75%

load

-7157-7515-7484-7515-7484kJ/kWhFuel gas consumption at 50%

load

177.73.8177.73.8177.23.8177.73.8177.23.8g/kWhFuel oil consumption at 100%

load

173.44.2175.04.5174.04.4175.04.5174.04.4g/kWhFuel oil consumption at85% load

177.24.1178.15.1177.85.0178.15.1177.85.0g/kWhFuel oil consumption at75% load

180.44.3185.37.6184.57.6185.37.6184.57.6g/kWhFuel oil consumption 50% load

Fuel gas system

-895-895-895-895-895kPa (a)Gas pressure at engine inlet, min

(PT901)

-1015-1015-1015-1015-1015kPa (a)Gas pressure to Gas Valve Unit,

min

-0...60-0...60-0...60-0...60-0...60°CGas temperature beforeGas Valve

Unit

Fuel oil system

1000±1001000±1001000±1001000±1001000±100kPaPressure before HP pumps (PT

101)

3.63.63.63.63.6m3/hEngine driven pump capacity

(MDF only)

16...24-16...24-16...24-16...24-16...24-cStHFO viscosity before the engine

140-140-140-140-140-°CMax. HFO temperature before

engine (TE 101)

2.02.02.02.02.0cStMDF viscosity, min.

4545454545°CMax. MDF temperature before

engine (TE 101)

0.50.50.50.50.5kg/hLeak fuel quantity (HFO), clean

fuel at 100% load

1.50.91.50.91.50.91.50.91.50.9kg/hLeak fuel quantity (MDF), clean

fuel at 100% load

Lubricating oil system

420420420420420kPaPressure before bearings, nom.

(PT 201)

4040404040kPaSuction ability, including pipe

loss, max.

150150150150150kPaPriming pressure, nom. (PT 201)

3535353535kPaSuction ability priming pump, in-

cluding pipe loss, max.

7070707070°CTemperature before bearings,

nom. (TE 201)

8282828282°CTemperature after engine, approx.

144130125130125m3/hPump capacity (main), engine

driven

100100100100100m3/hPump capacity (main), electrically

driven

40.0 / 40.040.0 / 40.040.0 / 40.040.0 / 40.040.0 / 40.0m3/hPriming pump capacity (50/60Hz)

2.82.82.82.82.8

m

3

Oil volume, wet sump, nom.

3-8 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 33

MEAUXAUXDEDE

Wärtsilä 8V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

55555m

3

Oil volume in separate system oil

tank

0.450.350.450.350.450.350.450.350.450.35g/kWhOil consumption at 100% load,

approx.

19601960196019601960l/minCrankcase ventilation flow rate at

full load

0.10.10.10.10.1kPaCrankcase ventilation backpres-

sure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8lOil volume in turning device

Cooling water system

HT cooling water system

358 + static358 + static358 + static358 + static358 + statickPaPressure at engine, after pump,

nom. (PT 401)

600600600600600kPaPressure at engine, after pump,

max. (PT 401)

8383838383°CTemperature before cylinders,

approx. (TE 401)

9696969696°CTemperature after engine, nom.

8080808080m3/hCapacity of engine driven pump,

nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

0.350.350.350.350.35m

3

Water volume in engine

365365365365365kPaDelivery head of stand-by pump

LT cooling water system

650+ static650+ static650+ static650+ static650+ statickPaPressure at engine, after pump,

nom. (PT 451)

40/ 4540/ 4540/ 4540/ 4540/ 45°CTemperature before engine, nom

(TE 451)

8080808080m3/hCapacity of engine driven pump,

nom.

110110110110110kPaPressure drop over charge air

cooler (two-stage)

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

Starting air system

30003000300030003000kPaPressure, nom.

15001500150015001500kPaPressure at engine during start,

min. (alarm) (20°C)

30003000300030003000kPaPressure, max.

15001500150015001500kPaLow pressure limit in air vessels

5.95.95.95.95.9Nm

3

Starting air consumption, start

(successful)

Notes:

DBAE248994 3-9

3. Technical DataWärtsilä 31DF Product Guide

Page 34

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9% and temperature tolerance 10°C in gasmodeoperation. Flow tolerance 9%andtemperaturetolerance 15°C in dieselmode operation.

Note 2

At 100% output and nominal speed. The figures are valid for ambient conditions according to ISO 15550 except for LTwater temperature, which is corresponding to charge air receiver temperature 55ºC in gas operation and 60 ºC in diesel

mode. With engine driven water and lubricating oil pumps. Tolerance for cooling water heat 10%, tolerance for radiation

heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers. In arctic option

all charge air coolers are in LT circuit.

Note 3

Validity of the data in diesel mode operation: at ambient conditions according to ISO 15550. Lower calorific value 42700

kJ/kg. With engine driven pumps (two cooling water + one lubricating oil pump). Tolerance 5%.

Note 4

Validity of the data in gas fuel operation: total barometric pressure, air temperature and relative humidity according to

ISO 15550:2002(E), LT water temperature corresponding to receiver temperature 55°C, pilot fuel cetane index minimum

50 according to ISO 4264. Lower calorific value 42 700 kJ/kg for pilot fuel and 49 700 kJ/kg for gas fuel. With engine

driven pumps (two cooling water pumps, one lubricating oil pump). Tolerance 5%.

Note 5

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

3-10 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 35

3.3 Wärtsilä 10V31DF

MEAUXAUXDEDE

Wärtsilä 10V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

55005500530055005300kWEngine output

2.712.712.722.712.72MPaMean effective pressure

Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3IMO compliance

Combustion air system (Note 1)

10.58.310.58.310.18.010.58.310.18.0kg/sFlow at 100% load

4545454545°CTemperature at turbocharger in-

take, max.

60606060606060606060°CTemperature after air cooler (TE

601)

Exhaust gas system (Note 2)

10.99.210.99.210.18.910.99.210.18.9kg/sFlow at 100% load

9.27.69.37.68.67.49.37.68.67.4kg/sFlow at 85% load

8.36.98.66.78.06.58.66.78.06.5kg/sFlow at 75% load

6.24.86.14.75.74.66.14.75.74.6kg/sFlow at 50% load

270300270300270300270300270300°CTemperature after turbocharger

at 100% load (TE 517)

260320270350270350270350270350°CTemperature after turbocharger

at 85% load (TE 517)

270310260350260350260350260350°CTemperature after turbocharger

at 75% load (TE 517)

270330280370280370280370280370°CTemperature after turbocharger

at 50% load (TE 517)

77777kPaBackpressure, max.

779735779735750723779735750723mmCalculated exhaust diameter for

35 m/s

Heat balance at 100% load (Note 3)

530450530450510430530450510430kWJacket water, HT-circuit

960630960630850590960630850590kWCharge air, HT-circuit

1620133016301340151012801630134015101280kWCharge air, LT-circuit

610510610510590490610510590490kWLubricating oil, LT-circuit

150150150150150150150150150150kWRadiation

Fuel consumption (Note 4)

(Note 5)

-7280-7280-7250-7280-7250kJ/kWhTotal energy consumption at

100% load

-7230-7350-7300-7350-7300kJ/kWhTotal energy consumption at 85%

load

-7250-7500-7430-7500-7430kJ/kWhTotal energy consumption at 75%

load

-7330-7820-7790-7820-7790kJ/kWhTotal energy consumption at 50%

load

-7128-7128-7097-7128-7097kJ/kWhFuel gas consumption at 100%

load

DBAE248994 3-11

3. Technical DataWärtsilä 31DF Product Guide

Page 36

MEAUXAUXDEDE

Wärtsilä 10V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

-7059-7171-7121-7171-7121kJ/kWhFuel gas consumption at 85%

load

-7082-7294-7226-7294-7226kJ/kWhFuel gas consumption at 75%

load

-7157-7515-7484-7515-7484kJ/kWhFuel gas consumption at 50%

load

177.23.8177.23.8176.33.8177.23.8176.33.8g/kWhFuel oil consumption at 100%

load

172.54.2174.44.5173.14.4174.44.5173.14.4g/kWhFuel oil consumption at85% load

176.34.1177.05.1176.85.0177.05.1176.85.0g/kWhFuel oil consumption at75% load

180.44.3185.07.6184.37.6185.07.6184.37.6g/kWhFuel oil consumption 50% load

Fuel gas system

-895-895-895-895-895kPa (a)Gas pressure at engine inlet, min

(PT901)

-1015-1015-1015-1015-1015kPa (a)Gas pressure to Gas Valve Unit,

min

-0...60-0...60-0...60-0...60-0...60°CGas temperature beforeGas Valve

Unit

Fuel oil system

1000±1001000±1001000±1001000±1001000±100kPaPressure before HP pumps (PT

101)

3.63.63.63.63.6m3/hEngine driven pump capacity

(MDF only)

16...24-16...24-16...24-16...24-16...24-cStHFO viscosity before the engine

140-140-140-140-140-°CMax. HFO temperature before

engine (TE 101)

2.02.02.02.02.0cStMDF viscosity, min.

4545454545°CMax. MDF temperature before

engine (TE 101)

0.50.50.50.50.5kg/hLeak fuel quantity (HFO), clean

fuel at 100% load

1.50.91.50.91.50.91.50.91.50.9kg/hLeak fuel quantity (MDF), clean

fuel at 100% load

Lubricating oil system

420420420420420kPaPressure before bearings, nom.

(PT 201)

4040404040kPaSuction ability, including pipe

loss, max.

150150150150150kPaPriming pressure, nom. (PT 201)

3535353535kPaSuction ability priming pump, in-

cluding pipe loss, max.

7070707070°CTemperature before bearings,

nom. (TE 201)

8282828282°CTemperature after engine, approx.

144130125130125m3/hPump capacity (main), engine

driven

120120120120120m3/hPump capacity (main), electrically

driven

50.0 / 50.050.0 / 50.050.0 / 50.050.0 / 50.050.0 / 50.0m3/hPriming pump capacity (50/60Hz)

3-12 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 37

MEAUXAUXDEDE

Wärtsilä 10V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

3.43.43.43.43.4

m

3

Oil volume, wet sump, nom.

66666m

3

Oil volume in separate system oil

tank

0.450.350.450.350.450.350.450.350.450.35g/kWhOil consumption at 100% load,

approx.

24502450245024502450l/minCrankcase ventilation flow rate at

full load

0.10.10.10.10.1kPaCrankcase ventilation backpres-

sure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8lOil volume in turning device

Cooling water system

HT cooling water system

383 + static383 + static383 + static383 + static383 + statickPaPressure at engine, after pump,

nom. (PT 401)

600600600600600kPaPressure at engine, after pump,

max. (PT 401)

8383838383°CTemperature before cylinders,

approx. (TE 401)

9696969696°CTemperature after engine, nom.

9090909090m3/hCapacity of engine driven pump,

nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

0.40.40.40.40.4m

3

Water volume in engine

390390390390390kPaDelivery head of stand-by pump

LT cooling water system

650+ static650+ static650+ static650+ static650+ statickPaPressure at engine, after pump,

nom. (PT 451)

40/ 4540/ 4540/ 4540/ 4540/ 45°CTemperature before engine, nom

(TE 451)

9090909090m3/hCapacity of engine driven pump,

nom.

110110110110110kPaPressure drop over charge air

cooler (two-stage)

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

Starting air system

30003000300030003000kPaPressure, nom.

15001500150015001500kPaPressure at engine during start,

min. (alarm) (20°C)

30003000300030003000kPaPressure, max.

15001500150015001500kPaLow pressure limit in air vessels

6.16.16.16.16.1Nm

3

Starting air consumption, start

(successful)

DBAE248994 3-13

3. Technical DataWärtsilä 31DF Product Guide

Page 38

Notes:

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9% and temperature tolerance 10°C in gasmodeoperation. Flow tolerance 9%andtemperaturetolerance 15°C in dieselmode operation.

Note 2

At 100% output and nominal speed. The figures are valid for ambient conditions according to ISO 15550 except for LTwater temperature, which is corresponding to charge air receiver temperature 55ºC in gas operation and 60 ºC in diesel

mode. With engine driven water and lubricating oil pumps. Tolerance for cooling water heat 10%, tolerance for radiation

heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers. In arctic option

all charge air coolers are in LT circuit.

Note 3

Validity of the data in diesel mode operation: at ambient conditions according to ISO 15550. Lower calorific value 42700

kJ/kg. With engine driven pumps (two cooling water + one lubricating oil pump). Tolerance 5%.

Note 4

Validity of the data in gas fuel operation: total barometric pressure, air temperature and relative humidity according to

ISO 15550:2002(E), LT water temperature corresponding to receiver temperature 55°C, pilot fuel cetane index minimum

50 according to ISO 4264. Lower calorific value 42 700 kJ/kg for pilot fuel and 49 700 kJ/kg for gas fuel. With engine

driven pumps (two cooling water pumps, one lubricating oil pump). Tolerance 5%.

Note 5

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

3-14 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 39

MEAUXAUXDEDE

Wärtsilä 10V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

55005500530055005300kWEngine output

2.712.712.722.712.72MPaMean effective pressure

Tier 3Tier 3Tier 3Tier 3Tier 3IMO compliance

Combustion air system (Note 1)

9.98.39.98.39.58.09.98.39.58.0kg/sFlow at 100% load

4545454545°CTemperature at turbocharger in-

take, max.

60606060606060606060°CTemperature after air cooler (TE

601)

Exhaust gas system (Note 2)

10.79.210.79.29.98.910.79.29.98.9kg/sFlow at 100% load

9.07.69.27.68.57.49.27.68.57.4kg/sFlow at 85% load

8.16.98.46.77.86.58.46.77.86.5kg/sFlow at 75% load

6.24.86.14.75.74.66.14.75.74.6kg/sFlow at 50% load

285300285300285300285300285300°CTemperature after turbocharger

at 100% load (TE 517)

285320285350285350285350285350°CTemperature after turbocharger

at 85% load (TE 517)

285310285380285350285380285350°CTemperature after turbocharger

at 75% load (TE 517)

285330285370285370285370285370°CTemperature after turbocharger

at 50% load (TE 517)

77777kPaBackpressure, max.

782735782735752723782735752723mmCalculated exhaust diameter for

35 m/s

Heat balance at 100% load (Note 3)

530450530450510430530450510430kWJacket water, HT-circuit

930630920630810590920630810590kWCharge air, HT-circuit

1600133016101340149012801610134014901280kWCharge air, LT-circuit

610510610510590490610510590490kWLubricating oil, LT-circuit

150150150150150150150150150150kWRadiation

Fuel consumption (Note 4)

(Note 5)

-7280-7280-7250-7280-7250kJ/kWhTotal energy consumption at

100% load

-7230-7350-7300-7350-7300kJ/kWhTotal energy consumption at 85%

load

-7250-7500-7430-7500-7430kJ/kWhTotal energy consumption at 75%

load

-7330-7820-7790-7820-7790kJ/kWhTotal energy consumption at 50%

load

-7128-7128-7097-7128-7097kJ/kWhFuel gas consumption at 100%

load

-7059-7171-7121-7171-7121kJ/kWhFuel gas consumption at 85%

load

DBAE248994 3-15

3. Technical DataWärtsilä 31DF Product Guide

Page 40

MEAUXAUXDEDE

Wärtsilä 10V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

-7082-7294-7226-7294-7226kJ/kWhFuel gas consumption at 75%

load

-7157-7515-7484-7515-7484kJ/kWhFuel gas consumption at 50%

load

177.73.8177.73.8177.23.8177.73.8177.23.8g/kWhFuel oil consumption at 100%

load

173.44.2175.04.5174.04.4175.04.5174.04.4g/kWhFuel oil consumption at85% load

177.24.1178.15.1177.85.0178.15.1177.85.0g/kWhFuel oil consumption at75% load

180.44.3185.37.6184.57.6185.37.6184.57.6g/kWhFuel oil consumption 50% load

Fuel gas system

-895-895-895-895-895kPa (a)Gas pressure at engine inlet, min

(PT901)

-1015-1015-1015-1015-1015kPa (a)Gas pressure to Gas Valve Unit,

min

-0...60-0...60-0...60-0...60-0...60°CGas temperature beforeGas Valve

Unit

Fuel oil system

1000±1001000±1001000±1001000±1001000±100kPaPressure before HP pumps (PT

101)

3.63.63.63.63.6m3/hEngine driven pump capacity

(MDF only)

16...24-16...24-16...24-16...24-16...24-cStHFO viscosity before the engine

140-140-140-140-140-°CMax. HFO temperature before

engine (TE 101)

2.02.02.02.02.0cStMDF viscosity, min.

4545454545°CMax. MDF temperature before

engine (TE 101)

0.50.50.50.50.5kg/hLeak fuel quantity (HFO), clean

fuel at 100% load

1.50.91.50.91.50.91.50.91.50.9kg/hLeak fuel quantity (MDF), clean

fuel at 100% load

Lubricating oil system

420420420420420kPaPressure before bearings, nom.

(PT 201)

4040404040kPaSuction ability, including pipe

loss, max.

150150150150150kPaPriming pressure, nom. (PT 201)

3535353535kPaSuction ability priming pump, in-

cluding pipe loss, max.

7070707070°CTemperature before bearings,

nom. (TE 201)

8282828282°CTemperature after engine, approx.

144130125130125m3/hPump capacity (main), engine

driven

120120120120120m3/hPump capacity (main), electrically

driven

50.0 / 50.050.0 / 50.050.0 / 50.050.0 / 50.050.0 / 50.0m3/hPriming pump capacity (50/60Hz)

3.43.43.43.43.4

m

3

Oil volume, wet sump, nom.

3-16 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 41

MEAUXAUXDEDE

Wärtsilä 10V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

66666m

3

Oil volume in separate system oil

tank

0.450.350.450.350.450.350.450.350.450.35g/kWhOil consumption at 100% load,

approx.

24502450245024502450l/minCrankcase ventilation flow rate at

full load

0.10.10.10.10.1kPaCrankcase ventilation backpres-

sure, max.

6.0...6.86.0...6.86.0...6.86.0...6.86.0...6.8lOil volume in turning device

Cooling water system

HT cooling water system

383 + static383 + static383 + static383 + static383 + statickPaPressure at engine, after pump,

nom. (PT 401)

600600600600600kPaPressure at engine, after pump,

max. (PT 401)

8383838383°CTemperature before cylinders,

approx. (TE 401)

9696969696°CTemperature after engine, nom.

9090909090m3/hCapacity of engine driven pump,

nom.

210210210210210kPaPressure drop over engine, total

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

0.40.40.40.40.4m

3

Water volume in engine

390390390390390kPaDelivery head of stand-by pump

LT cooling water system

650+ static650+ static650+ static650+ static650+ statickPaPressure at engine, after pump,

nom. (PT 451)

40/ 4540/ 4540/ 4540/ 4540/ 45°CTemperature before engine, nom

(TE 451)

9090909090m3/hCapacity of engine driven pump,

nom.

110110110110110kPaPressure drop over charge air

cooler (two-stage)

100100100100100

kPaPressure drop in external system,

max.

70...15070...15070...15070...15070...150kPaPressure from expansion tank

Starting air system

30003000300030003000kPaPressure, nom.

15001500150015001500kPaPressure at engine during start,

min. (alarm) (20°C)

30003000300030003000kPaPressure, max.

15001500150015001500kPaLow pressure limit in air vessels

6.16.16.16.16.1Nm

3

Starting air consumption, start

(successful)

Notes:

DBAE248994 3-17

3. Technical DataWärtsilä 31DF Product Guide

Page 42

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9%.Note 1

At ISO 15550 conditions (ambient air temperature 25°C, LT-water 25°C) and 100% load. Flow tolerance 9% and temperature tolerance 10°C in gasmodeoperation. Flow tolerance 9%andtemperaturetolerance 15°C in dieselmode operation.

Note 2

At 100% output and nominal speed. The figures are valid for ambient conditions according to ISO 15550 except for LTwater temperature, which is corresponding to charge air receiver temperature 55ºC in gas operation and 60 ºC in diesel

mode. With engine driven water and lubricating oil pumps. Tolerance for cooling water heat 10%, tolerance for radiation

heat 20%. Fouling factors and a margin to be taken into account when dimensioning heat exchangers. In arctic option

all charge air coolers are in LT circuit.

Note 3

Validity of the data in diesel mode operation: at ambient conditions according to ISO 15550. Lower calorific value 42700

kJ/kg. With engine driven pumps (two cooling water + one lubricating oil pump). Tolerance 5%.

Note 4

Validity of the data in gas fuel operation: total barometric pressure, air temperature and relative humidity according to

ISO 15550:2002(E), LT water temperature corresponding to receiver temperature 55°C, pilot fuel cetane index minimum

50 according to ISO 4264. Lower calorific value 42 700 kJ/kg for pilot fuel and 49 700 kJ/kg for gas fuel. With engine

driven pumps (two cooling water pumps, one lubricating oil pump). Tolerance 5%.

Note 5

ME = Engine driving propeller, variable speed

AE = Auxiliary engine driving generator

DE = Diesel-Electric engine driving generator

Subject to revision without notice.

3-18 DBAE248994

Wärtsilä 31DF Product Guide3. Technical Data

Page 43

3.4 Wärtsilä 12V31DF

MEAUXAUXDEDE

Wärtsilä 12V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

66006600636066006360kWEngine output

2.712.712.722.712.72MPaMean effective pressure

Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3Tier 2Tier 3IMO compliance

Combustion air system (Note 1)

12.69.912.69.912.29.612.69.912.29.6kg/sFlow at 100% load

4545454545°CTemperature at turbocharger in-

take, max.

60606060606060606060°CTemperature after air cooler (TE

601)

Exhaust gas system (Note 2)

13.111.013.111.012.110.713.111.012.110.7kg/sFlow at 100% load

11.09.111.29.110.38.911.29.110.38.9kg/sFlow at 85% load

10.08.310.38.09.67.810.38.09.67.8kg/sFlow at 75% load

7.45.87.35.66.85.57.35.66.85.5kg/sFlow at 50% load

270300270300270300270300270300°CTemperature after turbocharger

at 100% load (TE 517)

260320270350270350270350270350°CTemperature after turbocharger

at 85% load (TE 517)

270310260350260350260350260350°CTemperature after turbocharger

at 75% load (TE 517)

270330280370280370280370280370°CTemperature after turbocharger

at 50% load (TE 517)

77777kPaBackpressure, max.

853805853805821792853805821792mmCalculated exhaust diameter for

35 m/s

Heat balance at 100% load (Note 3)

636540636540612516636540612516kWJacket water, HT-circuit

11527561152756102070811527561020708kWCharge air, HT-circuit

1944159619561608181215361956160818121536kWCharge air, LT-circuit

732612732612708588732612708588kWLubricating oil, LT-circuit

180180180180180180180180180180kWRadiation

Fuel consumption (Note 4)

(Note 5)

-7280-7280-7250-7280-7250kJ/kWhTotal energy consumption at

100% load

-7230-7350-7300-7350-7300kJ/kWhTotal energy consumption at 85%

load

-7250-7500-7430-7500-7430kJ/kWhTotal energy consumption at 75%

load

-7330-7820-7790-7820-7790kJ/kWhTotal energy consumption at 50%

load

-7128-7128-7097-7128-7097kJ/kWhFuel gas consumption at 100%

load

DBAE248994 3-19

3. Technical DataWärtsilä 31DF Product Guide

Page 44

MEAUXAUXDEDE

Wärtsilä 12V31DF

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

Diesel

mode

Gas

mode

750750720750720rpmEngine speed

550550530550530kWCylinder output

VariableConstantConstantConstantConstantSpeed mode

-7059-7171-7121-7171-7121kJ/kWhFuel gas consumption at 85%

load

-7082-7294-7226-7294-7226kJ/kWhFuel gas consumption at 75%

load

-7157-7515-7484-7515-7484kJ/kWhFuel gas consumption at 50%

load

177.23.8177.23.8176.33.8177.23.8176.33.8g/kWhFuel oil consumption at 100%

load

172.54.2174.44.5173.14.4174.44.5173.14.4g/kWhFuel oil consumption at85% load

176.34.1177.05.1176.85.0177.05.1176.85.0g/kWhFuel oil consumption at75% load

180.44.3185.07.6184.37.6185.07.6184.37.6g/kWhFuel oil consumption 50% load

Fuel gas system

-895-895-895-895-895kPa (a)Gas pressure at engine inlet, min

(PT901)

-1015-1015-1015-1015-1015kPa (a)Gas pressure to Gas Valve Unit,

min

-0...60-0...60-0...60-0...60-0...60°CGas temperature beforeGas Valve

Unit

Fuel oil system

1000±1001000±1001000±1001000±1001000±100kPaPressure before HP pumps (PT

101)

7.27.27.27.27.2m3/hEngine driven pump capacity

(MDF only)

16...24-16...24-16...24-16...24-16...24-cStHFO viscosity before the engine

140-140-140-140-140-°CMax. HFO temperature before

engine (TE 101)

2.02.02.02.02.0cStMDF viscosity, min.

4545454545°CMax. MDF temperature before

engine (TE 101)

1.11.11.11.11.1kg/hLeak fuel quantity (HFO), clean

fuel at 100% load