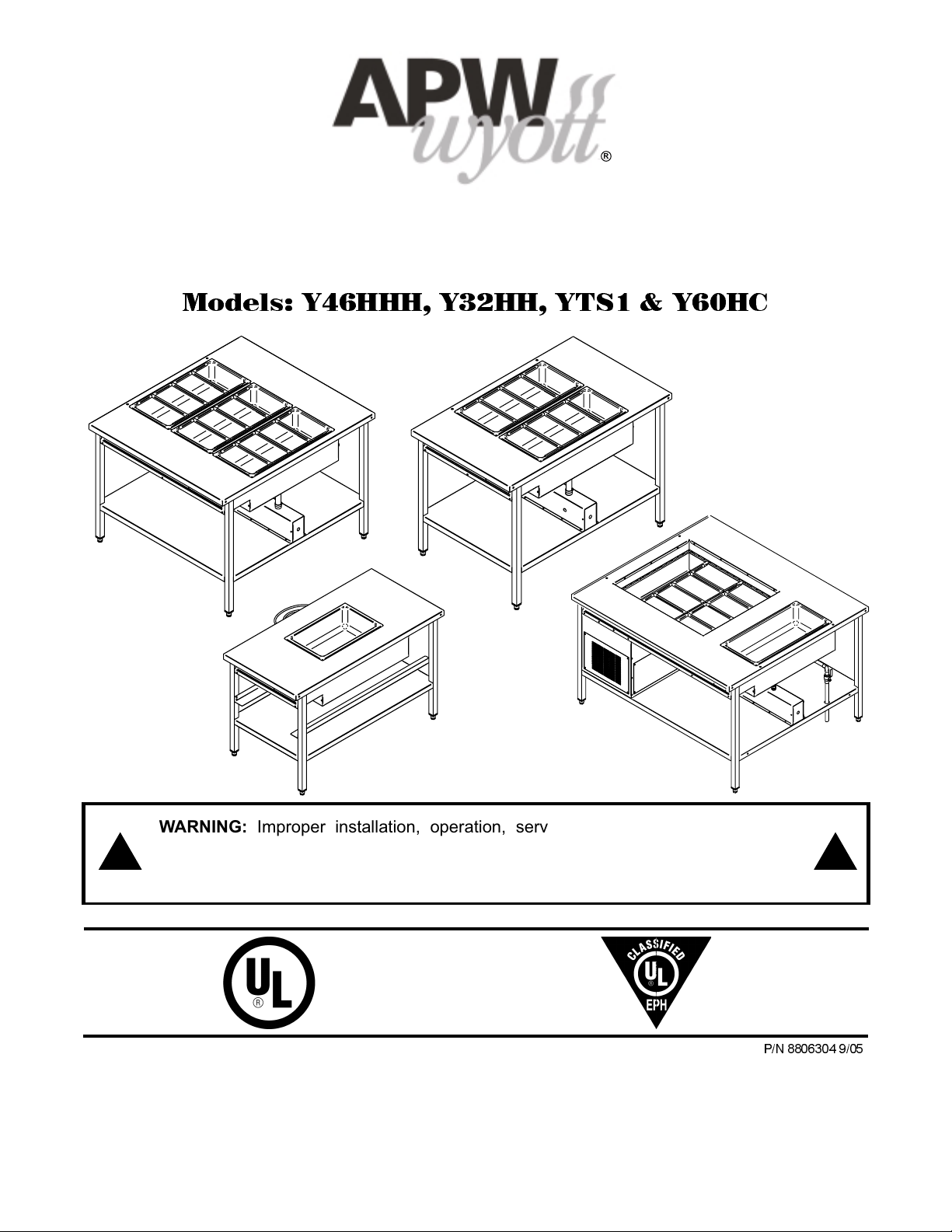

Wyott Y32HH Installation Manual

R

INSTALLATION AND OPERATING INSTRUCTIONS

HOT WELL TABLES

Models: Y46HHH, Y32HH, YTS1 & Y60HC

Y46HHH

YTS1

WARNING: Improper installation, operation, service or maintenance can cause

property damage, injury or death. Utility location is CRITICAL. Read and understand

!

these instructions thoroughly before positioning, installing, maintaining or servicing

this equipment.

Y32HH

Y60HC

!

P/N 8806304 9/05

APW WYOTT Foodservice Equipment Company

P.O. Box 1829

Cheyenne, WY 82003

+1 (307) 634-5801 Phone +1 (800) 752-0863 Toll Free

+1 (307) 637-8071 Fax www.apwwyott.com

1

GENERAL INFORMATION

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

Congratulations on your purchase ofAPW Wyott Modular Assembly Pack Station. APW Wyott takes pride

in the design and quality of our products. When used as intended and with proper care and maintenance,

you will experience years of reliable operation from this equipment. To ensure best results, it is important

that you read and follow the instructions in this manual carefully.

Before installing and operating this equipment be sure everyone involved in this operation is fully trained

and is aware of all precautions. Accidents and problems can result by a failure to follow fundamental rules

and precautions.

The following words and symbols, found in this manual, alert you to the hazards to the operator, service

personnel or the equipment. The wordsare defined as follows.

WARNING: This symbolrefers to a potential hazard or unsafe practice, which could result

in serious injury or death.

!

CAUTION: This symbol refers to a potential hazard or unsafe practice, whichmay result in

minor or moderate injury or product or property damage.

!

NOTICE: This symbol refers to information that needs special attention or must be fully

understood even though not dangerous.

!

!

!

!

SAFETY PRECAUTIONS

CAUTION: These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so that

!

anyone using the equipment will use it correctly and not injure themselves or harm the

equipment.

IMPORTANT: We strongly recommend having a licensed electrician install this

equipment. The electrician should be familiar with all local and national codes.

!

WARNING: Check the data plate on this unit before installation. Connect the unit only to

the voltage and frequency listed on the data plate. Connect only to 1 or 3 phase as listed on

!

the data plate.

WARNING: Electrical and grounding connections must comply with the applicable

portions of the national electrical code and/or other local electrical codes.

!

WARNING: Disconnect device from electrical power supply and place a Tag Out-Lockout

on the power plug, indicating that you are working on the circuit.

!

!

!

!

!

!

WARNING:Afactory authorized agent should handle all maintenance and repair. Before

!

doing any maintenance or repair, contactAPW Wyott.

WARNING: An earthing cable must connect the appliance to all other units in the

!

complete installation and from there to an independent earth connection.

2

!

!

NOTICE: This productis intended for commercial use only.Not for household use.

!

WARNING:SHOCK HAZARD: Do not open any panels that require the use of tools.

!

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read installation, operating and maintenance

!

instructions thoroughly before installing or servicingthis equipment.

NOTICE: The unit when installed, must be electrically grounded and comply with local

codes, or in the absence of local codes, with the national electrical code ANSI/NFPA70latest edition. Canadian installation must comply with CSA-STANDARD C.22.2 Number0

!

M1982 General Requirements-Canadian Electrical Code Part II, 109-M1981Commercial CookingAppliances.

NOTICE: Local codes regarding installation vary greatly from one area to another. The

National Fire Protection Association, Inc. states in its NFPA96 latest edition that local

!

codes are “Authority Having Jurisdiction” when it comes to requirement for installation of

equipment. Therefore, installation shouldcomply with all local codes.

!

!

!

!

!

SECTION

1

2

3

4

5

6

TABLE OF CONTENTS

ITEM

General Information

Safety Precautions

Installation Check List

Installation

Electrical Wiring

Operation & Maintenance

A Initial Cleaning

B Cleaning

C Maintenance

Troubleshooting Chart

Specifications

A Y46HHH

B Y32HH

C YTS1

D YDS5

PAGE

2

2

4

4

6

11

11

11

12

13

14

14

15

16

17

Parts Lists & Exploded Views

7

8

Warranty

A

B Y32HH

C YTS1

D YDS5

Y46HHH

3

18

18

19

20

21

24

1. INSTALLATION CHECK LIST

Examine Equipment for Damage

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, eitherapparent or

concealed, a claim must be made with the delivering carrier.

1. Apparent damage or loss must be noted on the freight bill at the time of delivery. The carrier

representative (Driver) the freight bill. If this is not done, the carrier may refuse the

claim. The carriercan supply the necessary forms.

2. Concealed damage or loss if not apparent until after the equipment is uncrated; a request for

inspection must be made to the carrier within 15 days. The carrier should arrange an inspection.

sure to hold all contents and packaging material.

NOTICE: Installation and start-up should be performed by a qualified installer who

!

thoroughly read, understands and followsthese instructions.

NOTICE: If you have questions concerning the installation, operation, maintenance or

service of this product, write Technical Service Department APW WYOTT Foodservice

!

Equipment Company, P.O. Box 1829, Cheyenne, WY 82003.

IMPORTANT: Check Store Layout for Placement and Location of MAPS2 System -Hot

Table, Cold Table, Fries Table, and Toaster Table.

!

must sign

Be

!

!

!

IMPORTANT:Check Store Layout for Placement and Location of Utilities.

!

NOTE: All electrical connections to be hardwired by electrician.

!

!

!

2. INSTALLATION

A qualified installer who thoroughly reads, understands and follows these instructions should perform

installation and start-up.

If you have questions concerning the installation, operation, maintenance or service of this product,

Call: APW Wyott Technical Services Department 1-800-752-0863, ask for Technical Service Department Monday through Friday 9AM 6:30PM Eastern Time.

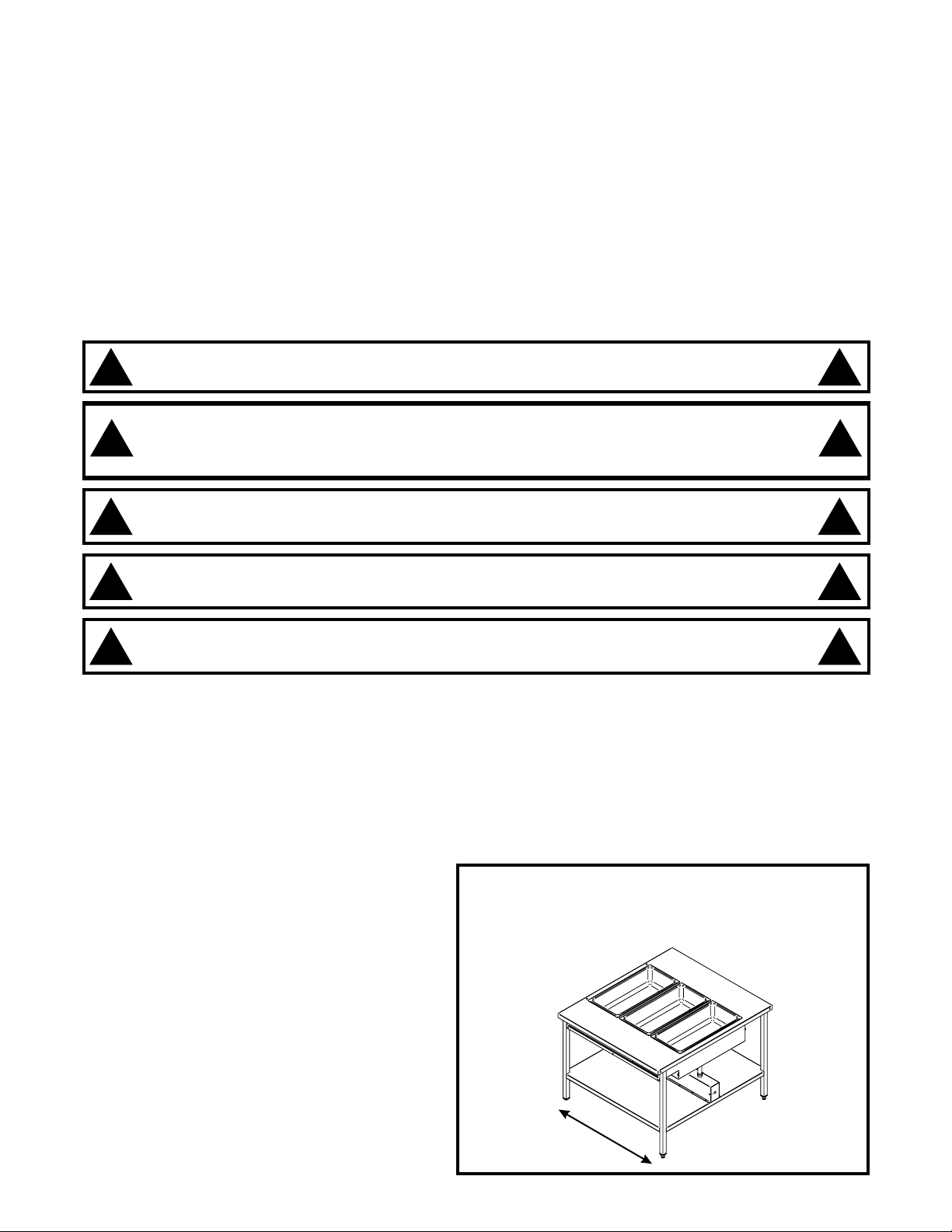

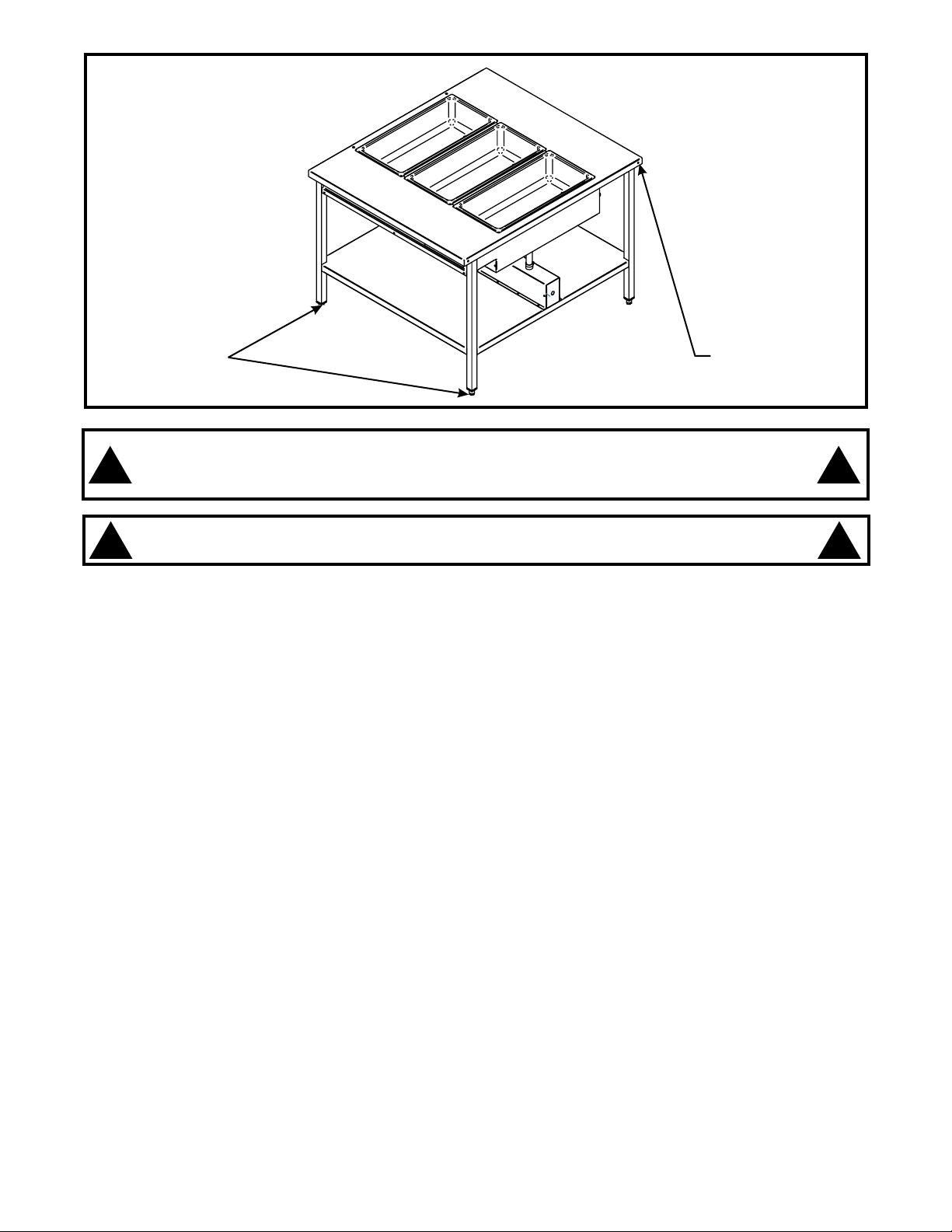

STEP 1. POSITIONTABLE

REVIEW STORE LAYOUT FOR EXACT

LOCATION OFTABLE

Place the over shelf in the designated area.

Level table by using a level and turning the

footpad on theadjustable legs.

Plumbing and electrical wiring must run parallel to,

or under center channel. (It must run in the

direction of arrow)

If table is being used in conjunction with other

tables bolt tables together thru holes in corners

of the top using provided hardware. Make sure

tables all face the same direction (control panels

should be on same side).

4

Adjust Legs

WARNING: Check the data plate on this unit before installation. Connect the unit only to

the voltage and frequencylisted on the data plate. Connect only to 1 or 3 phase as listed on

!

the data plate.

WARNING: Electrical and grounding connections must comply with the applicable

portions of the national electrical code and/or other local electrical codes.

!

Holes for bolting

tables together

!

!

5

3. ELECTRICAL WIRING

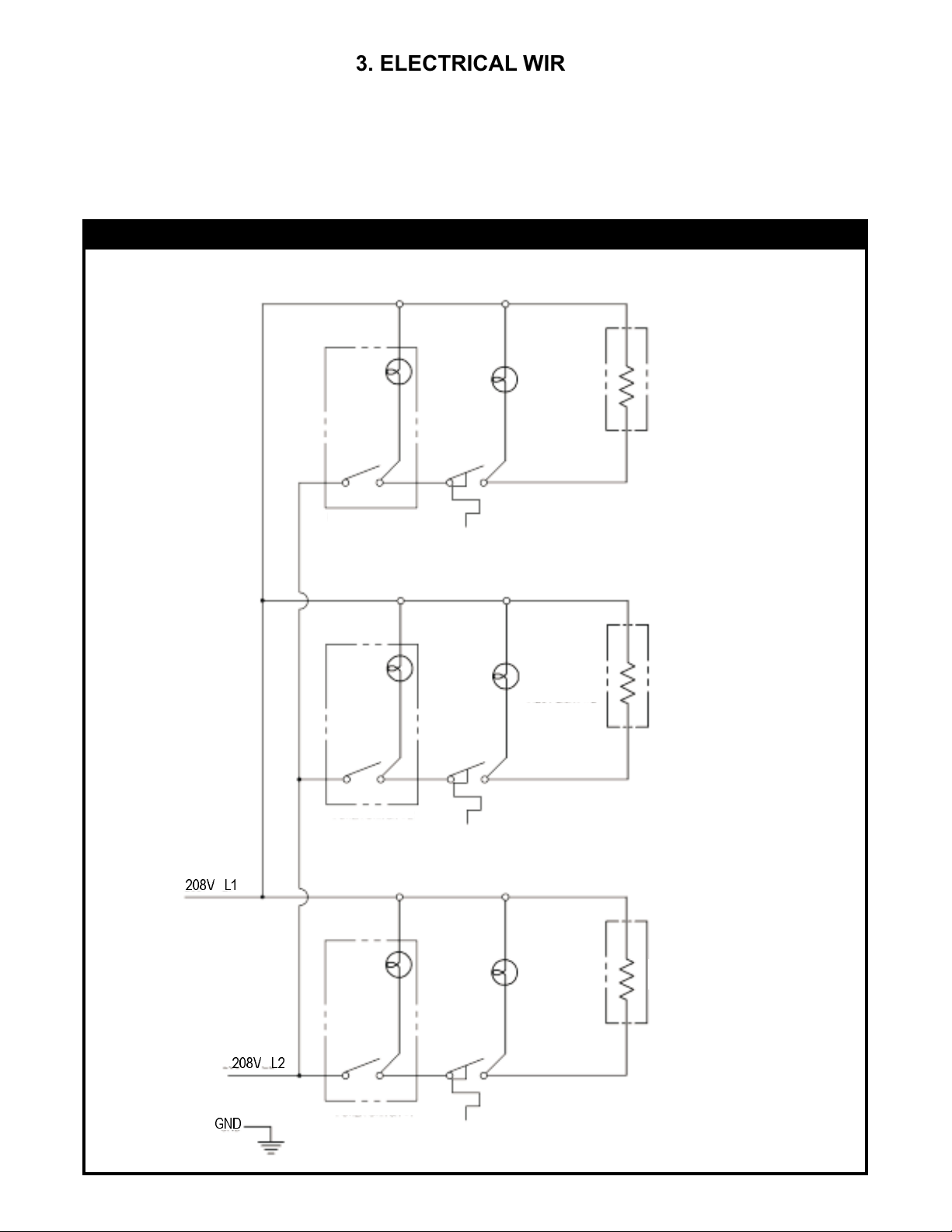

ELECTRICAL CONNECTIONS FOR Y46HHH

Check the data plate to determine what voltage this

unit is wired for and what voltage service is to be used.

SUPPLY REQUIREMENT:

Y46HHH WIRING SCHEMATIC

POWER SWITCH #3

5400W, 208V, 26Amp, 1 Ph

PILOT

LIGHT #3

ELEMENT 1800W

HOTWELL #3

208V L1

GND

208V L2

POWER SWITCH #2

POWER SWITCH #1

PILOT

LIGHT #2

PILOT

LIGHT #1

HOTWELL #2

ELEMENT 1800W

HOTWELL #1

ELEMENT 1800W

6

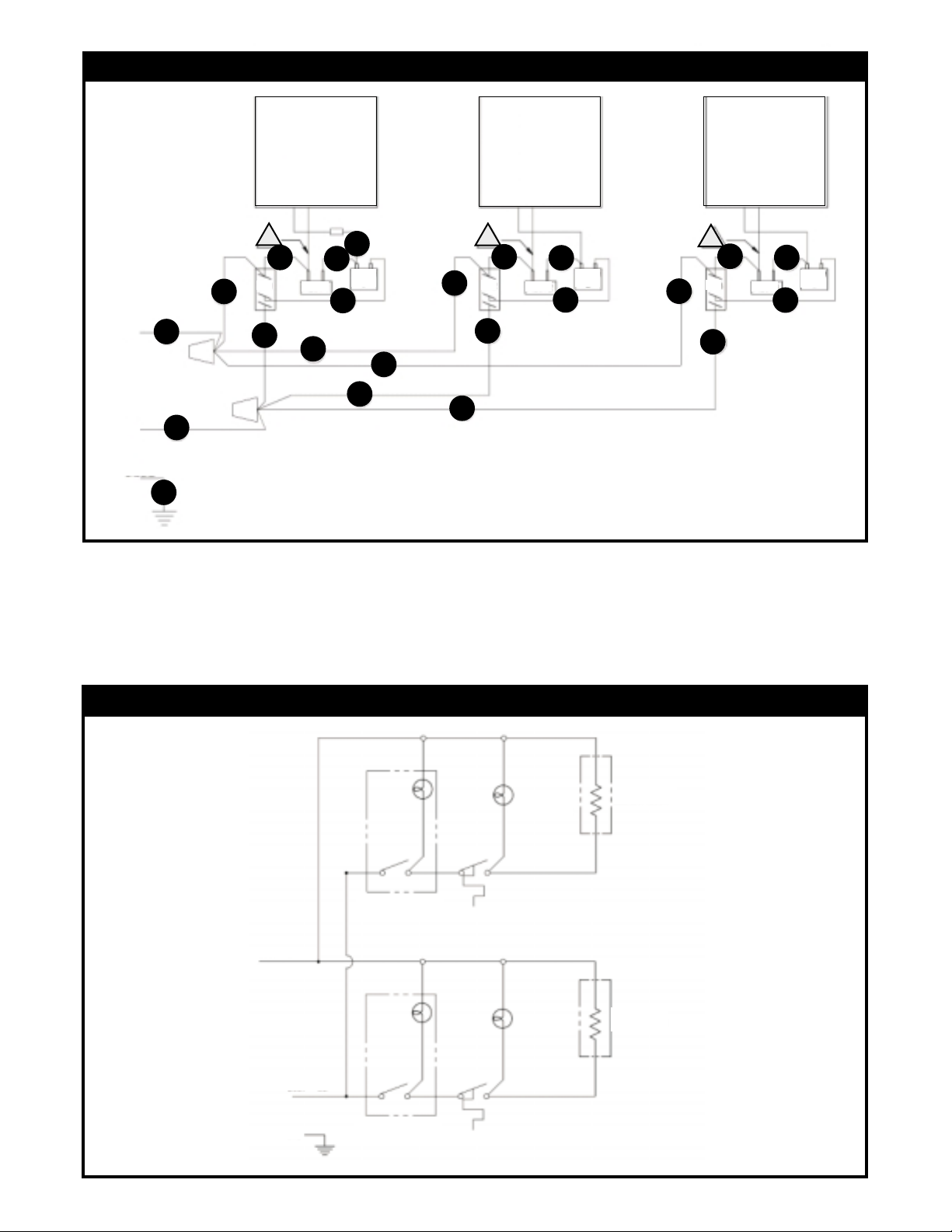

Y46HHH WIRING DIAGRAM

L1

L2

GND

19

17

18

H

O

T

W

E

L

L

1

3

SW 1

1

PILOT 1

6

5

THERM 1

4

2

1

SW 2

7

8

7

H

O

T

W

E

L

L

1

9

PILOT 2

11

10

THERM 2

12

SW 3

13

14

H

O

T

W

E

L

L

PILOT 3

16

THERM 3

15

12

8

13

ELECTRICAL CONNECTIONS FOR Y32HH

Check the data plate to determine what voltage this

unit is wired for and what voltage service is to be used.

SUPPLY REQUIREMENT:

3600 W, 208V, 17.3 Amp, 1 Ph

Y32HH WIRING SCHEMATIC

PILOT

LIGHT #2

POWER

SWITCH #2

208V L1

PILOT

LIGHT #1

ELEMENT 1800W

ELEMENT 1800W

HOTWELL #2

HOTWELL #1

208V L2

GND

POWER

SWITCH #1

7

Y32HH WIRING DIAGRAM

L1

L2

GND

14

12

13

H

O

T

W

E

L

L

1

3

SW 1

1

PILOT 1

6

5

THERM 1

SW 2

7

4

2

H

O

T

W

E

L

L

1

9

PILOT 2

11

THERM 2

10

8

7

8

20V15A

CIRCUI T

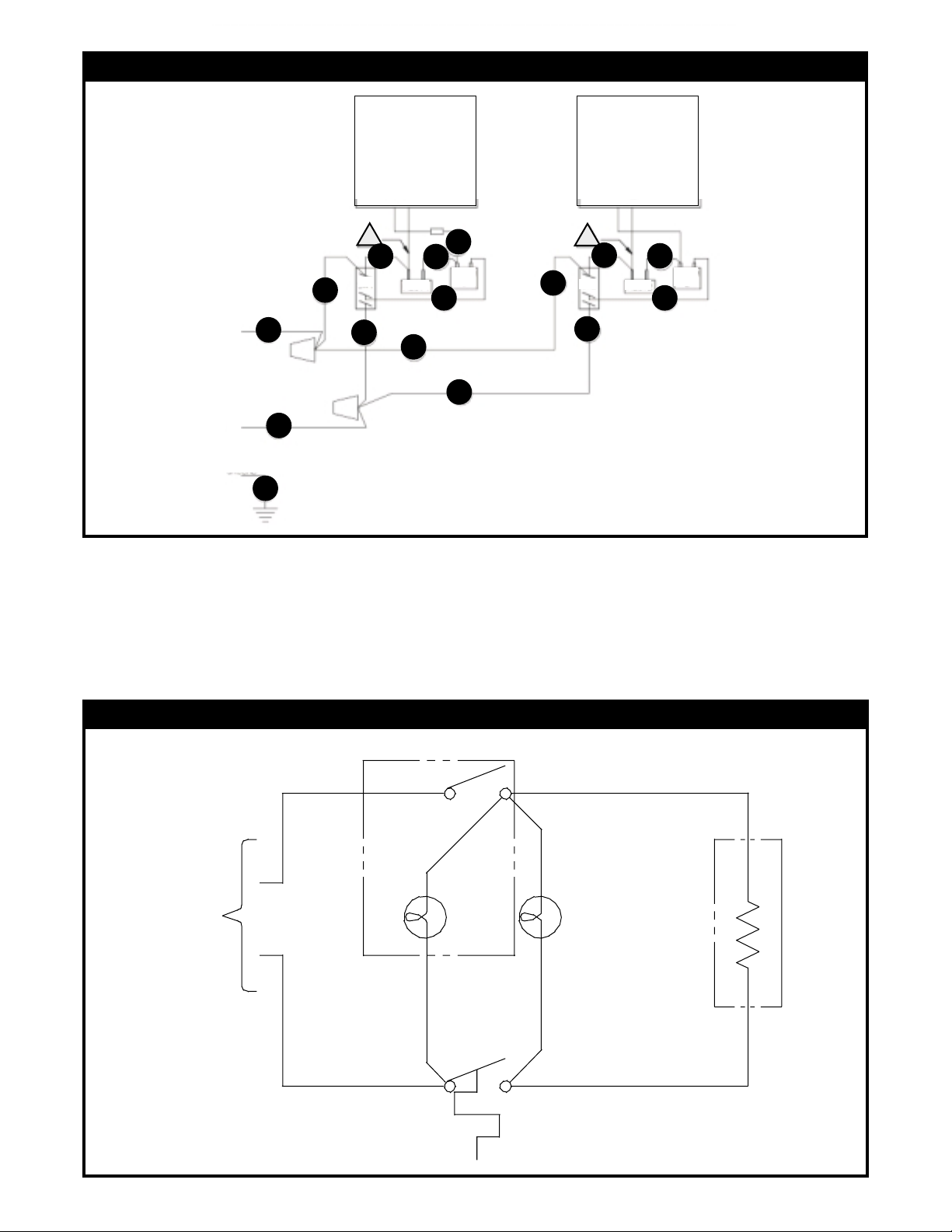

ELECTRICAL CONNECTIONS FOR YTS1

Check the data plate to determine what voltage this

unit is wired for and what voltage service is to be used.

SUPPLY REQUIREMENT:

YTS1 WIRING SCHEMATIC

POWER S WIT CH # 1

208/240V, 900/1200W, 4.33/5.0 Amp, 1 Ph

HOTWELL #1

ELEMENT

900/1200W

PILOT LIGHT #1

8

Loading...

Loading...