Page 1

INSTRUCTIONS

INSTALLATION

AND

OPERATING

MODELS: ST, PST, SST, PSST, ASST, APSST

Steam Table

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or

death. Read the Installation, Operating and Maintenance Instructions thoroughly before installing or

servicing this equipment.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Phone: +1 (214) 421-7366

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

1

APWWYOTT

729 Third Avenue

Dallas, TX 75226

P/N 8898750 REV. A 10/12

Page 2

TABLE OF CONTENTS

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment.

For Warranty Service and/or Parts, this information is required.

SECTION ITEM PAGE SECTION ITEM PAGE

1 Owner’s Information 2 7 Cleaning 8

2 Safety Information 2 8 Troubleshooting 9

3 Specifications 3 9

4 Installation Instructions 4 11 Wiring Diagrams 12

5 Operations Instructions for

6 Operations Instructions for

Model Number Serial Number Date Purchased

Preventative Maintenance

10

5 12 Parts Lists & Exploded

ST and PST

7 13 Warranty 17

SST AND PSST

Autofill Instructions

Views

9

14

WARNING: In Europe, appliance must be connected by an earthing cable to all other

units in the complete installation and thence to an independent earth connection in

compliance with EN 60335-1 and/or local codes.

WARNING: An earthing cable must connect the appliance to all other units in the

complete installation and from there to an independent earth connection.

1) OWNER’S INFORMATION

General Information:

1. Always clean equipment thoroughly before first use. (See general cleaning instructions).

2. Check rating label for your model designation and electrical rating.

3. For best results, use stainless steel counter tops.

General Operation Instructions:

14. All food-service equipment should be operated by trained personnel.

14. Do not allow your customers to come in contact with any surface labeled "CAUTION HOT".

14. Never pour cold water into dry heated units.

14. Do not cook, or hold food directly in wells. Always use steam table pans or inserts.

14. Never hold food below 150°F

Warranty Information:

Reliability Backed By APW Wyott’s Warranty:

All APW Wyott’s Steam Tables are backed by a one year parts and labor warranty, including On-Site

Service calls within 50 miles of authorized service technicians.

Service Information:

Service Hotline (800) 733-2203

2

Page 3

APW Wyott equipment is designed,

personnel only. Clearly post all CAUTIONS, WARNINGS and OPERATING INSTRUCTIONS near each

unit to insure proper operation and to reduce the chance of personal injury and/or equipment damage. This

product is used for the cooking, defr

Always disconnect power before servicing the unit. Surfaces will remain hot after power has been turned

off. Allow unit to cool before cleaning or servicing. Never clean the unit by immersing it in water.

s; DO NOT CLEAN THE STEAM TABLE

clean equipment properly before first use.

The following Safety signs and messages are placed in this manual to provide instruc

specific areas where potential hazards exist and special precautions should be taken. Know and

understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or

serious injury to you or other persons ma

This message indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not

d result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

This message is used when special inf

identification are required relating to procedures, equipment, tools,

capacities and other special data.

SST,PSST MODEL

2, PSST

3, PSST

4, PSST

5, PSST

2, PSST

PSST

4, PSST

5, PSST

2, PSST

3, PSST

4, PSST

5, PSST

The Data plate is located on the right hand side bottom panel

SST,PSST MODEL

2, P

2)

SAFETY INFORMATION

Safety Signs and Messages

: SST AND PSST

: ST AND PST

and sold for commercial use and should

thermalization of food products only.

WITH A WATER JET. Always

y result if these messages are not followed.

ormation, instructions or

PH

1

1

1

1

1

1

1

1

1

1

1

1

where the power cord comes into the unit.

PH

1

built,

be operated by trained

not protected against water jet

avoided, coul

osting or re-

The unit is

tions and identify

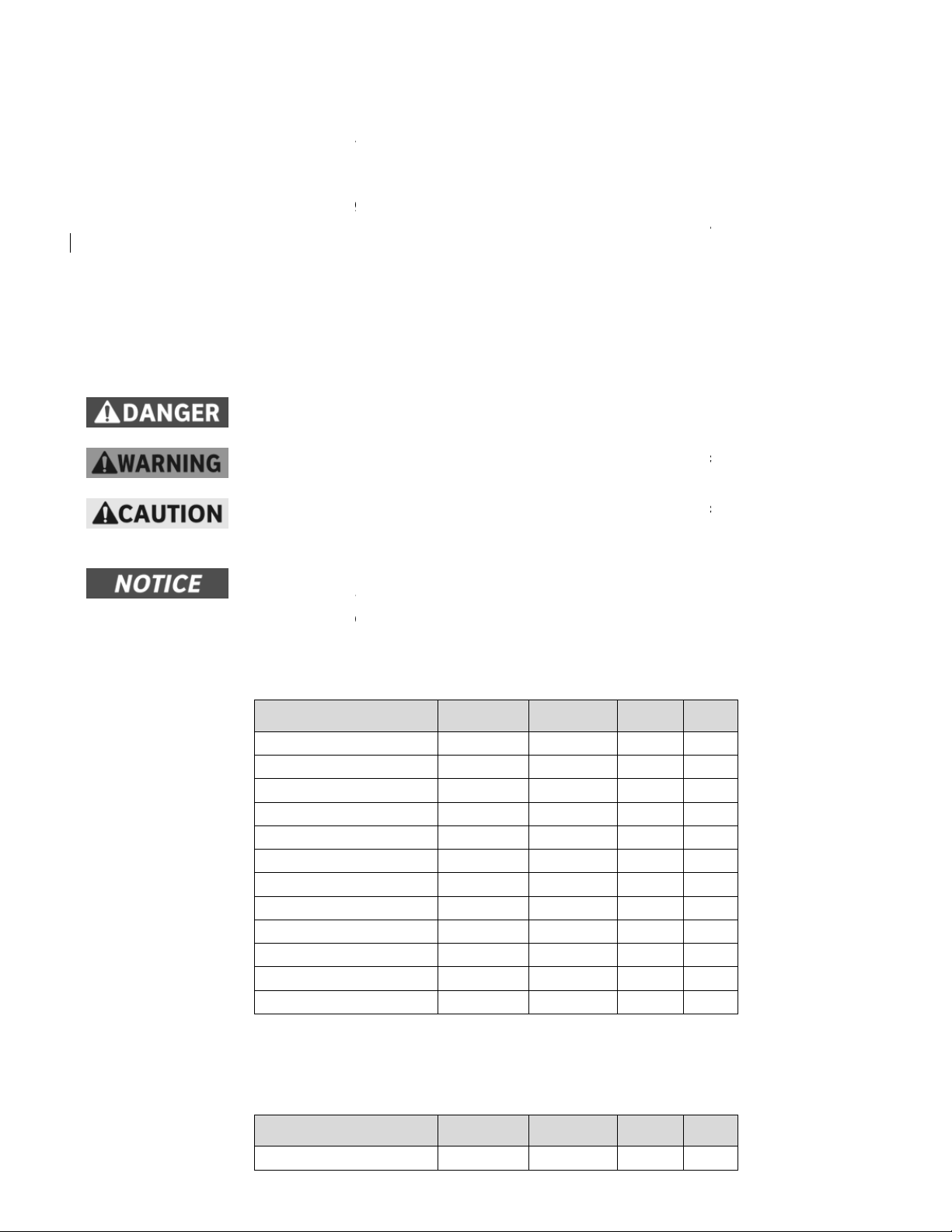

3) SPECIFICATIONS

SSTSSTSSTSSTSSTSST-3,

SSTSSTSSTSSTSSTSST-

SPECIFICATIONS

VOLTS WATTS AMPS

-2

-3

-4

-5

-2

-3

-4

-5

-2

-3

-4

-5

120 1500 12.5

120 2250 18.75

120 3000 25

120 3750 31.25

208 1500 7.2

208 2250 10.8

208 3000 14.4

208 3750 18.0

240 1500 6.3

240 2250 9.4

240 3000 12.5

240 3750 15.6

,

VOLTS WATTS AMPS

ST-

ST-2

120 1000 8.3

3

Page 4

ST-3, PST-3

ST-4, PST-4

ST-5, PST-5

ST-2, PST-2

ST-3, PST-3

ST-4, PST-4

ST-5, PST-5

ST-2, PST-2

ST-3, PST-3

ST-4, PST-4

ST-5, PST-5

120 1500 12.5 1

120 2000 16.7 1

120 2500 20.8 1

208 1500 7.2 1

208 2250 10.8 1

208 3000 14.4 1

208 3750 18.0 1

240 1500 6.3 1

240 2250 9.4 1

240 3000 12.5 1

240 3750 15.6 1

Power Cord:

Six (6) foot, 3 wire grounded cord. If the supply cord is damaged, the manufacturer, or an authorized

service agent, must replace it in order to avoid a hazard and warranty. Please contact the factory by calling

the 800 # located on the unit.

4) INSTALATION INSTRUCTIONS SST and PSST

If the carton appears damaged, or damage is discovered once the carton is opened, stop

immediately and contact the freight company to file a damage claim.

1. Remove all external packaging that is protecting top portion of unit

2. Remove all internal packaging to the unit, if present.

3. Visually inspect all external and internal portions of unit for damage.

4. Wipe down the exterior of the unit using a damp cloth with warm water. Do not use abrasive pads or

5. A ¾ ball valve is supplied with every unit. The installer must provide a suitable drain connection.

6. Before plugging unit into wall outlet or permanently electrical connecting, the unit should be

7. The voltage and wattage ratings of this steam table are given on the device nameplate. Connect the

CAUTION: The Steam Table is shipped without the legs, under shelf or cutting board

shelf attached. Please read the installation and operation instruction before operating

the unit. Remove all supports and packaging materials before operating the unit.

Failure to remove all packaging materials may lead to a fire and / or damage to the

appliance.

cleaners as they will damage the stainless steel surface.

Note: Ambient Conditions - Make sure that the operating location is in an area where the

ambient temperature is held constant (minimum 70°F). Please avoid areas such as near

exhaust fans and air conditioning ducts.

Warning! Operating environment

Ensure that operation location is at a reasonable distance from combustible walls and materials

otherwise combustion or discoloration could occur.

Caution! Operating environment

Place unit on a stable, level floor. The unit must be level, both front and back and left to right, in

order to maintain an equal water depth throughout the wells. To eliminate rocking or adjust

height turn the adjustable feet in the proper direction until the desired results are obtained.

Note: Maximum adjustment is 1 inch

This equipment is to be installed to comply with applicable federal, State or local plumbing

codes.

adjusted to the desired height and align with other equipment.

steam table to a circuit having a voltage and type of current similar to that stamped on the device

nameplate. For movable equipment a proper cord and plug are included for connection to the

matching power supply outlet.

4

Page 5

8.

Plug unit into grounded electrical outlet with correct voltage, and plug con

Using any receptacle that is not designed to match the attached cord and plug

MAY cause personal injury and WILL void your warranty. Please attach the Steam Table, to

an individual branch circuit

For permanent installations, connection

cable. For supply connections use No. 12 AWG or larger wires suitable for at least

Use copper wire for power supply or suitable copper to aluminum wire connector.

nce should be grounded by connecting the ground stud provided in the

junction box to a good electrical ground, such as a water pipe, a steam pipe, or a grounded supply

The steam table is not fused and consequently must be connected to a fused circ

suitable disconnect means, as required by local code authorities.

units follow

The bottom adjustable shelf assembly shall be installed such that there is a minimum

clearance of 6 inches between

After the bottom adjustable shelf assembly is installed, the

with the supplied plastic screw caps.

UNIT IS SHIPPED UNASSEMBLED. TO MEET NATIONAL SANITATION

FOUNDATION STANDARDS, THE I

SILICONE SEALANT TO SEAL THE SEAMS BETWEEN THE

Insert the bullet leg into the 4 tubes. If the unit was supplied with caster skip

soft mallet only. To avoid damaging the leg

figuration.

s to supply line may be made through conduit or armored

screws shall be capped

this step and install caster before

a. Warning!

9.

10. The body of the applia

conduit.

11.

12.

To assemble the

14.

14.

UNIT AND ASSEMBLED PARTS

steps 1 thru 6 listed below.

the shelf and the supporting surface.

Allen

NSTALLER MUST USE A NSF APPROVED

90°C (194°F).

uit equipped with

Step 1

turning the unit over.

When inserting bullet legs use a

5

inserts.

Page 6

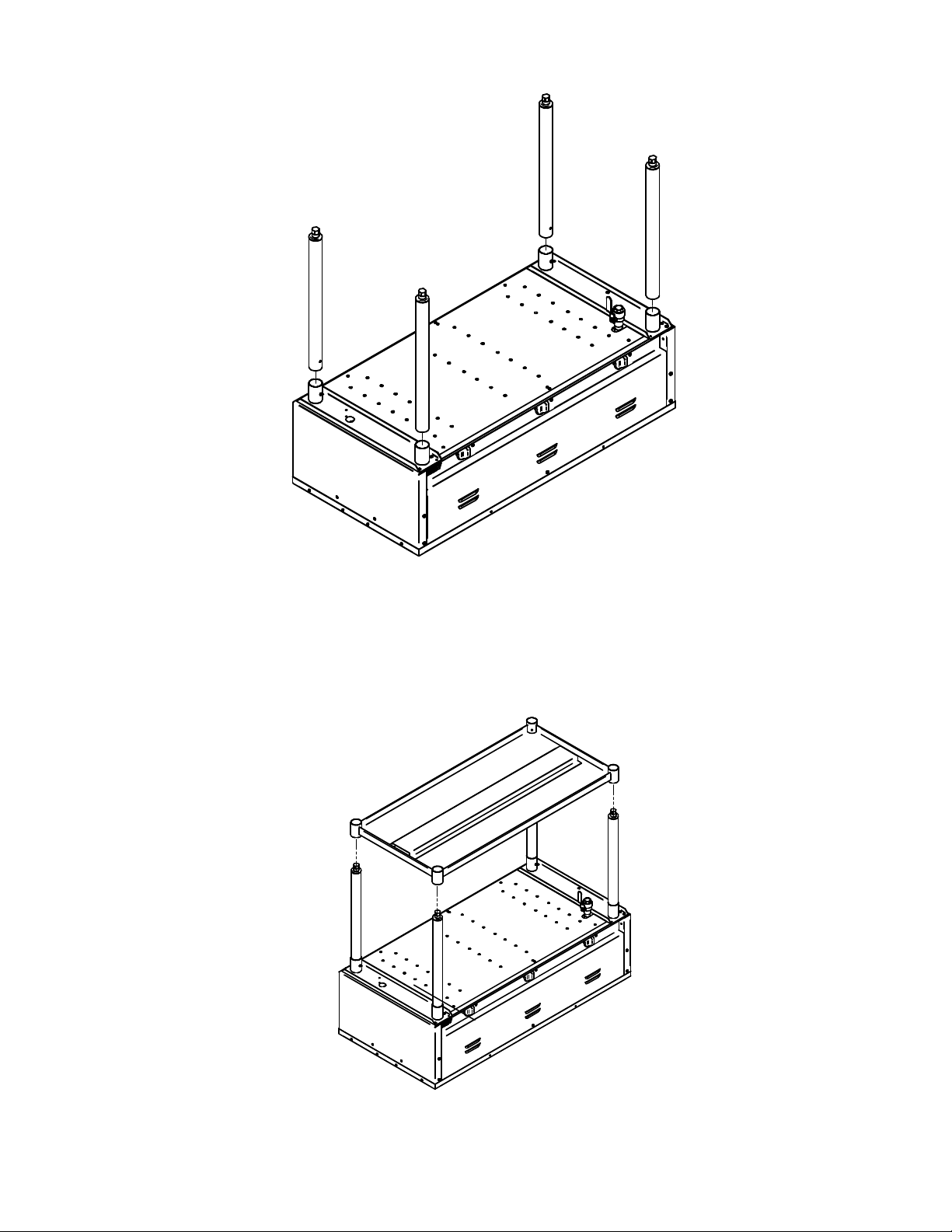

Step 2

Place the unit on the floor upside down. Be sure to protect the top surface and well from damage when the unit is

placed on it top on the floor. Once the legs are in place tighten the set screws in the leg inserts

.

6

Page 7

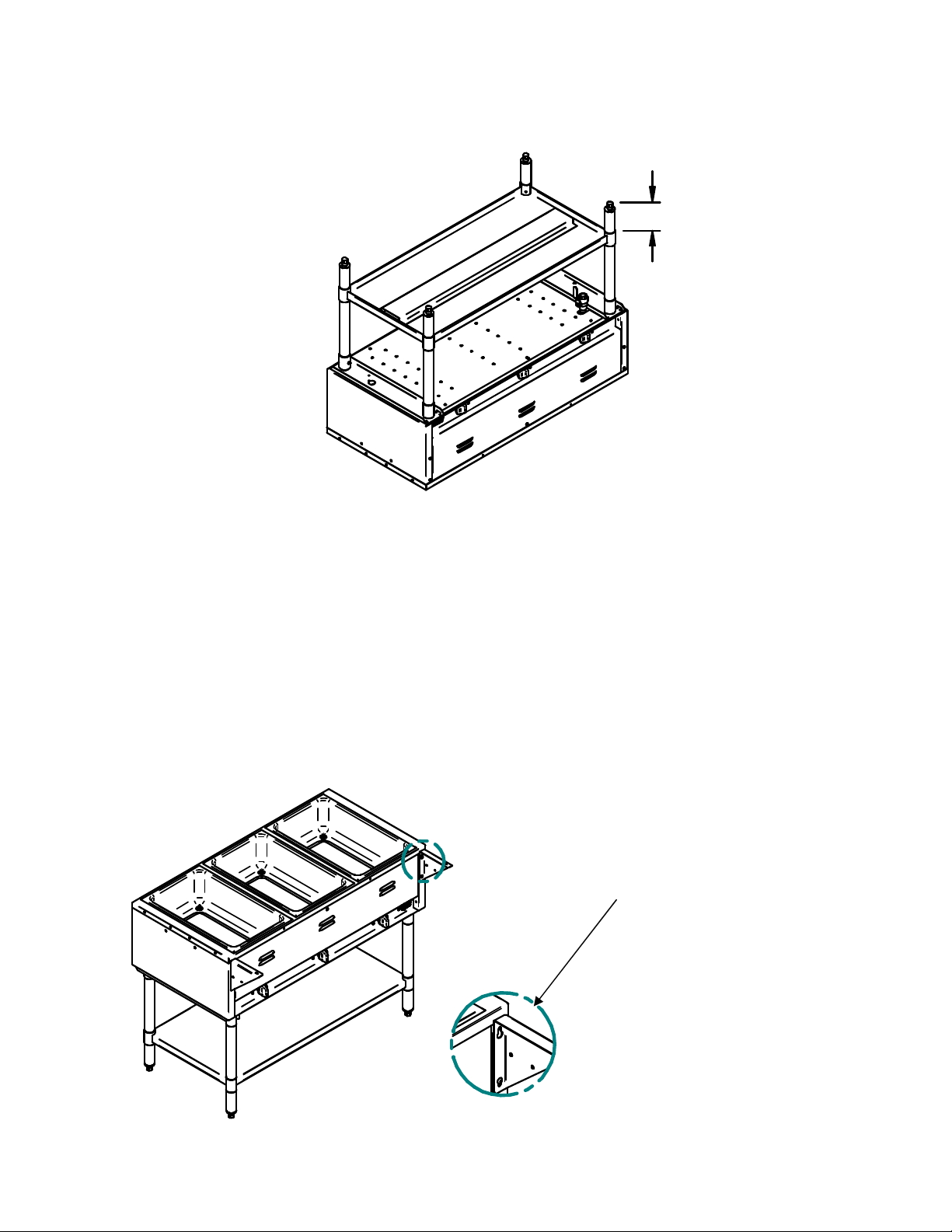

Step 3

Slide the shelf over the legs.

6"

Step 4

Locate the shelf at minimum 6 inches from the floor to allow for cleaning and to comply with NSF standards. Tighten

the 4 set screws located in each corner of the shelf leg inserts.

A

DETAIL A

7

Page 8

Step 5

Install the shelf support brackets on each end. When positioning the bracket only put the bottom screw in place. Do

not install the top screw until the shelf has been installed.

B

DETAIL B

Step 6

Place the shelf over the support brackets and install the top screw in each shelf bracket. Install the cut board stops

through the shelf and the shelf support brackets at each end as shown.

5) OPERATION INSTRUCTION FOR ST AND PST

1. PREHEAT - To preheat individual sections, turn the switch dial to high for 10 - 20 minutes before

the foods are placed in the compartments. Insure that pan openings are covered to prevent loss of

heat.

2. Water – Is not necessary in the ST OR PST models.

a. Note – If water is used the ST or PST models a spillage pan is required. When air is

used the spillage is not required or recommended.

b. Air. Being easier and quicker to heat than water makes the waterless steam table faster and

more economical to operate than a table using water. Foods can be kept moist by keeping

them at the correct temperature. Foods dry out only when excessive temperatures are

reached, so when foods tend to dry out, REDUCE HEAT.

3. If only part of the food warmers is needed, the compartment not in use does not need to be heated.

4. SWITCH SETTINGS

a. The most satisfactory switch settings must be determined by experience based on the

nature of the foodservice and the type of operation as well as individual preference of the

restaurant operator. The proper switch setting necessary to keep foods at the desired

temperature will vary dependent upon the frequency of turnover, size of food containers,

amount of food in each container, room temperature, location of food warmer with respect to

range or other heated equipment, air outlets, fans, doors and passageways.

8

Page 9

6) OPERATION INSTRUCTION FOR SST AND PSST

1. Before the unit is used for the first time, turn the temperature knob to "10" and heat the well for 2030 minutes. Do not be alarmed if smoke appears; this preheat should burn off any residue or dust

on the heating element.

WARNING: Steam can cause serious burns. Always wear some type of protective

covering on your hands and arms when removing lids or pans from the unit. Lift the

lid or pan in a way that will direct escaping steam away from your face and body.

2. Never place food directly into the well. Always use pans.

3. Wet operation is recommended.

4. Always place covers on pans when not serving to prevent food from drying out and to reduce your

operating costs.

5. For most efficient operation, keep empty, covered insets in each well during preheating and when

the well is not in use.

a. WET OPERATION

1. Fill food well with two (2) quarts of water. For quicker pre-heating, use hot water to till the

well.

2. Turn the control to "HIGH" and pre-heat the warmer for 30 minutes.

3. After pre-heating, set the control to your desired serving temperature.

4. Never pour water into a well that has been heated dry. This may cause well to crack

and leak.

5. Always fill well before preheating or before water level is below 1/2".

b. DRY OPERATION

1. Pre- heat the well on "HIGH" for approximately 15 minutes.

2. After pre-heating, set the control to your desired serving temperature.

7) CLEANING

Insure the appliance has been turned off and has had sufficient time for all surfaces to cool down before

cleaning.

WARNING – Wooden cutting boards, Butcher Blocks, and Bakers Tables are not intended

to be soaked for a prolonged length of time during the cleaning and sanitizing process.

DAILY CLEANING

1. Turn the control knob to the OFF position and allow unit to cool before cleaning.

2. Drain or remove water from the well.

CAUTION: Do not allow water to splash or run on to the controls or wiring.

3. Use a soft cloth or sponge with a mild detergent to clean the entire warmer assembly. Rinse

completely with warm water and then dry.

4. A plastic scouring pad and a mild detergent may be used to remove hardened food.

NOTICE: Do not use steel wool.

WEEKLY CLEANING

1. Scale deposits due to the mineral content of the water may be removed using a plastic scouring

pad and a de-scaling agent approved for use on stainless steel. It is important to keep these

deposits from building up as they may cause corrosion of the stainless steel well.

2. After de-scaling, the well assembly should be rinsed thoroughly with a solution of vinegar and

water to neutralize all cleaner residues.

3. Wipe the well assembly dry and leave uncovered.

WARNING

9

Page 10

Do not use any highly caustic cleaners, acids or ammonia. These may cause corrosion and/or

damage to the stainless steel well. Do not allow water to stand in the well for long periods of time.

Water must be removed from the well and the well cleaned after each use.

CLEANING PROCEDURES FOR

POLYETHYLENE OR ABS (RUBBER) COMPOSITION TABLE TOPS

OR CUTTING BOARDS

When high pressure cleaning equipment is not available; use hot water, a granular cleanser or detergent

and a stiff bristle brush. (Abrasive action is necessary, as simply wiping the board will not suffice.) After

Scrubbing, rinse thoroughly with hot water. Allow to lie flat.

Several excellent germicidal cleaners are also available, including Calgon's "Big Cat" and Johnson's

"Break Up". Clorox is another good cleaner and is USDA approved.

The tabletop material is cut into sections not larger than 36" in any plane, and no section weighs more

than fifty (50) pounds. These are stipulations of the National Sanitation Foundation to facilitate cleaning.

The tops should be turned over daily to reduce possibility of warping and should never be stood on end.

Periodically, go over the board with a clean, flat stainless steel scraper to help seal some of the knife

marks.

The use of cleavers on synthetic boards or tabletops is not recommended.

8) TROUBLESHOOTING

Always ask and check the following:

TROUBLE SHOOTING GUIDE

1. Problem: Pilot light off and unit does not heat:

a. Has unit been connected to a proper electrical source of the proper voltage?

b. Is electric turned on at the main? Check the circuit breaker or fuse.

c. Are the master switch and/or control knobs set to the "ON" position?

2. Problem: Unit does not maintain proper food temperature.

a. Are the controls set to the proper setting?

b. If used with water, was hot water used to fill well? If not, allow extra pre-heat time.

c. Has unit been pre-heated for 30-45 minutes?

d. Were pans of food placed into unit at or above desired temperature?

e. Has the food been kept covered?

f. Are there air conditioning ducts, take-up air ducts or fans located near or over unit, causing cool

drafts?

g. Has unit been connected to a proper electrical source of the proper voltage? If so, is there a

"low" voltage condition?

9) PREVENTATIVE MAINTENANCE SCHEDULE

• Please follow the cleaning section for the daily and weekly preventative maintenance schedule.

1 Use the proper tools.

• When cleaning stainless steel products, use non-abrasive tools. Soft cloths and plastic

scouring pads will not harm steel’s passive layer. Stainless steel pads also can be used but

the scrubbing motion must be in the direction of the manufacturers’ polishing marks.

2. Clean with the polish lines

• Some stainless steel comes with visible polishing lines or “grain.” When visible lines are

present, always scrub in a motion parallel to the lines. When the grain cannot be seen, play

it safe and use a soft cloth or plastic scouring pad.

10

Page 11

3. Use alkaline, alkaline chlorinated or non-chloride containing cleaners.

• While many traditional cleaners are loaded with chlorides, the industry is providing an everincreasing choice of non-chloride cleaners. If you are not sure of chloride content in the

cleaner used, contact your cleaner supplier. If your present cleaner contains chlorides, ask

your supplier if they have an alternative. Avoid cleaners containing quaternary salts; it also

can attack stainless steel and cause pitting and rusting.

4. Treat your water.

• Though this is not always practical, softening hard water can do much to reduce deposits.

There are certain filters that can be installed to remove distasteful and corrosive elements.

To insure proper water treatment, call a treatment specialist.

5. Keep your food equipment clean.

• Use alkaline, alkaline chlorinated or non-chloride cleaners at recommended strength. Clean

frequently to avoid build-up of hard, stubborn stains. If you boil water in stainless steel

equipment, remember the single most likely cause of damage is chlorides in the water.

Heating cleaners that contain chlorides have a similar effect.

6. Rinse.

• If chlorinated cleaners are used, rinse and wipe equipment and supplies dry immediately.

The sooner you wipe off standing water, especially when it contains cleaning agents, the

better. After wiping equipment down, allow it to air dry; oxygen helps maintain the stainless

steels passivity film.

7. Never use hydrochloric acid (muriatic acid) on stainless steel.

8. Regularly restore/passivate stainless steel.

11

Page 12

10) Installation and Operation ASST and APSST Models

Instillation instructions for EZ Well supply line:

1) Install PIN 54508, brass fitting in each end of the senoid using PTFE Tape (not supplied).

2) Wrap the threads of the fitting as shown below

3) Remove the nut from the brass fitting and the sleeve from the inside of the fitting

4) Place the seeve and the nut, nut first, over the W copper tubing, supplied.

5) Install the line into the solenoid and tighten the nut finger tight

6) Using a wrench, tighten the nut far enough to crush the sleeve and attach the line. NOTE Do not

overtighten nut. Just enough pressure is required to stop water leaks

7) Install the 3/8 x ¼ adapter to the 3/8 stainless steel tube fitting using PTFE Tape as shown.

8) Using the other end of the copper tube, install the line, nut, and sleeve to the adapter.

9) Tighten using the same procedure as before.

10) Turn on water supply and look for leaks. If any leaks are found, tighten the nuts until leak is stopped.

INSTALLATION MUST BE DONE BY AUTHRIZED PLUMBER

PTFE Tape

Operation:

Operation of the wells is the same as a SST/PSST steam table. To operate the auto fill, close ball valve and

flip auto fill switch to the on position. The light next to the switch should light up indication that the auto fill

is in operation.

12

Page 13

WIRING DIAGRAM – SST

WIRING DIAGRAMS/SCHEMATICS

13

Page 14

WIRING DIAGRAM

–

14

Page 15

Wiring Diagram ASST APSST

Green

White

Black

78

1

2

PILOT

3

6

5

4

L2

R LOAD

L1

PILOT

H2 H1

SOLENOID

COMMON

L2

L2

PILOT

PILOT L1

PILOT L1

H2 H1

H2 H1

R LOAD

PILOT

L1

L2

L2

L1

PILOT

PILOT

H2 H1

H2 H1

R LOAD

PILOT

L1

L2

L2

PROBE

R LOAD

L1

PILOT

PILOT

H2 H1

H2 H1

PILOT

L1

L2

L2

R LOAD

L1

PILOT

PILOT

H2 H1

H2 H1

15

Page 16

12) PARTS LISTS & EXPLODED VIEWS

ST-PST

13

6

3

2

1

9

8

7

10

5

4

12

11

16

Page 17

PARTS LISTS & EXPLODED VIEWS

Parts List ST-PST

Item # Description Part Number ST-2 Part Number ST-3 Part Number ST-4 Part Number ST-5

1 Poly Cutting Board 32010011 32010021 32010031 32010041

2 Stud Assembly 32010108 32010108 32010108 32010108

3 Bracket, Board Left 32010102 32010102 32010102 32010102

4 Bracket, Board Right 32010101 32010101 32010101 32010101

5 Bracket, Board Left 32010102 32010102 32010102 32010102

6 Support, Carving Board 32010016 32010026 32010036 32010046

7 Knob, 2” 8705610 8705610 8705610 8705610

8 Switch, Infinite 208-240V 1328200 1328200 1328200 1328200

8 Switch, Infinite 120V 1327900 1327900 1327900 1327900

9 Indicator Light 1513903 1513903 1513903 1513903

10 Leg, Galvanized for Caster 32010109 32010109 32010109 32010109

10 Leg, Stainless for Caster 32010097 32010097 32010097 32010097

10 Leg, Galvanized for Bullet Leg 32010008 32010008 32010008 32010008

10 Leg, Stainless for Bullet Leg 32010007 32010007 32010007 32010007

11 Caster with Brake 8671300 8671300 8671300 8671300

11 Caster without Brake 8671200 8671200 8671200 8671200

11 Bullet Leg 8656600 8656600 8656600 8656600

12 Adjustable Under shelf (Aluminized) 32010211 32010212 32010213 32010214

12 Adjustable Under shelf (Stainless) 32010111 32010112 32010113 32010114

13 Heater Element, 120V 500W 32010002 32010002 32010002 32010002

13 Heater Element, 208V 750W 32010003 32010003 32010003 32010003

13 Heater Element, 240V 750W 32010004 32010004 32010004 32010004

17

Page 18

PARTS LISTS & EXPLODED VIEWS

SST-PSST

14

13

15

2

16

1

6

3

9

7

10

5

4

8

18

12

11

Page 19

PARTS LISTS & EXPLODED VIEWS

SST-PSST Parts List

Item # Description Part Number SST-2 Part Number SST-3 Part Number SST-4 Part Number SST-5

1 Poly Cutting Board 32010051 32010061 32010071 32010081

2 Stud Assembly 32010108 32010108 32010108 32010108

3 Bracket, Board Left 32010102 32010102 32010102 32010102

4 Bracket, Board Right 32010101 32010101 32010101 32010101

5 Bracket, Board Left 32010102 32010102 32010102 32010102

6 Support, Carving Board 32010056 32010066 32010076 32010086

7 Knob, 2” 8705610 8705610 8705610 8705610

8 Switch, Infinite 208-240V 1328200 1328200 1328200 1328200

8 Switch, Infinite 120V 1327900 1327900 1327900 1327900

9 Indicator Light 1513903 1513903 1513903 1513903

10 Leg, Galvanized for Caster 32010109 32010109 32010109 32010109

10 Leg, Stainless for Caster 32010097 32010097 32010097 32010097

10 Leg, Galvanized for Bullet Leg 32010008 32010008 32010008 32010008

10 Leg, Stainless for Bullet Leg 32010007 32010007 32010007 32010007

11 Caster with Brake 8671300 8671300 8671300 8671300

11 Caster without Brake 8671200 8671200 8671200 8671200

11 Bullet Leg 8656600 8656600 8656600 8656600

12 Adjustable Under shelf (Aluminized) 32010215 32010216 32010217 32010218

12 Adjustable Under shelf (Stainless) 32010115 32010116 32010117 32010118

13 Heater Element, 120V 500W 55445 55445 55445 55445

13 Heater Element, 120V 1200W 55446 55446 55446 55446

13 Heater Element, 208V 750W 45547800 45547800 45547800 45547800

13 Heater Element, 208V 1200W 55441 55441 55441 55441

13 Heater Element, 240V 750W 45547700 45547700 45547700 45547700

13 Heater Element, 240V 1600W 55441 55441 55441 55441

14 WELL PAN W/DR 55607 55607 55607 55607

15 REFLECTOR, PLATE WELD ASSY 55567 55567 55567 55567

16 BOTTOM COVER ASSY 55608 55608 55608 55608

Not shown THERMOSTAT, LIMITING 69106 69106 69106 69106

19

Page 20

NOTES:

20

Page 21

13. APW WYOTT EQUIPMENT LIMITED WARRANTY

9/05

APW Wyott Food service Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott Authorized

Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated with same. The

closest APW Wyott Authorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There will

be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada may

vary. Contact the international APW Wyott distributor, dealer, or service agency for details.

Time Period

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency may,

at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the original

product warranty only.

Exceptions

* Gas/Electric Cookline: Models HCB, HCRB, HMG, HTG, HHP, HHPS, GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG,

EHP. Three (3) Year Warranty on all component parts, except switches and thermostats. (2 additional years on parts only.

No labor on second or third year.)

* Broiler Briquettes, Rock Grates, Cooking Grates, Burner Shields, Fireboxes: 90 Day Material Only. No Labor.

* Heat Strips: Models FD, FDL, FDD, FDDL. Two (2)Year Warranty on element only. No labor second year.

* Glass Windows, Doors, Seals, Rubber Seals, Light Bulbs: 90 Day Material Only. No Labor.

In all cases, parts covered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to the

following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of connection, or

use, at APW Wyott's option or its Authorized Service Agency, it will be serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use. If

the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which have in

store service.

Exclusions

The following conditions are not covered by warranty:

* Equipment failure relating to improper installation, improper utility connection or supply and problems due to ventilation.

* Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning and

water damage to controls.

* Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect, abuse,

accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

* Equipment that has the model number or serial number removed or altered.

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the warranty

period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the use of the

equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which normally

involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such premium

rates. APW Wyott does not assume any liability for extended delays in replacing or repairing any items beyond its control.

In all cases, the use of other than APW Wyott Authorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application.

Water Quality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before being

used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES AND

CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND

BEYOND THE TERMS STATED HEREIN."

21

Loading...

Loading...