Page 1

R

INSTALLATION

AND

OPERATING INSTRUCTIONS

CONTACT BUN TOASTER

INTENDED FOR OTHER

THAN HOUSEHOLD USE

Model:

RETAIN THIS MANUAL FOR FUTURE REFERENCE

APPLIANCE MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY:

liquids in the vicinity of this or any other appliance.

WARNING:

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicingthis equipment.

Initial heating of appliance may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according totheinstructions in this manual and standard commercialkitchen practices.

Improper installation, adjustment, alteration, service or maintenance can

Do not store or use gasoline or other flammable vapors and

M2000-JIB

!!

!!

Phone: +1

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

(800) 733-2203

24 Hour Service Hotline

1

ANSI/NSF4

P/N 70202001 3/06

APW WYOTT

729 Third Avenue

Dallas, TX 75226

Page 2

TABLE OF CONTENTS

Safety Precautions 2

General Information 2

Installation 3

Location 4

Operating Instructions 4

Cleaning 5

Daily Parts Cleaning 5

Daily Conveyor Cleaning 5

One-Time Boil Out of Conveyor 6

Daily Griddle Cleaning 6

Troubleshooting 8

Specifications 9

Replacement Parts List w/Exploded View 10

Wiring Diagram 12

Warranty 14

SAFETY PRECAUTIONS

APW Wyott toasters are designed, built, and sold for commercial use and should be operated by trained

personnel only. Clearly post all CAUTIONS, WARNINGS and operating instructions near each unit to

insureproper operationand to reducethe chanceof personalinjury and/or equipment damage.

Always disconnect power before cleaning or servicing the toaster. Surfaces will remain hot after power has

been turned off, allow unit to cool before cleaning or servicing. Never clean the toaster by immersing it in

water. The toaster is not protected against water jets; DO NOT CLEAN TOASTER WITH A WATER JET.

Alwaysclean equipmentbefore first use.

Operatingtoaster withoutlegs will void the warranty. Insureall accessoriesand exteriorpanels areproperly

installedand adjustedbefore applyingpower andoperating.

GENERAL INFORMATION

Check the rating label for your model designation and electrical rating. Rating Label is located on the

bottomfront of the control panel.

Overalldimensions withfeeder: 23.5"(59.7cm)W x 25.9"(65.8cm) H x 17.5"(44.5cm) D

ElectricalRatings:

M2KA:208VAC,2880W,13.8A60Hz

M2KH:240VAC,3840W,16A60Hz

CordsetConfiguration:

208/250V:NEMA6-20PPlug, 4foot, 3wire grounded cord.

If the supply cord is damaged, the manufacturer or an authorized service agent or a similarly qualified

personmust replaceit to avoida hazardor warranty.

ShippingWeight:

94lbs (42.7 Kg)

2

Page 3

1. Examine carton for damage

The freight carrier has assumed responsibility for its safe transit and delivery. If equipment is

receiveddamaged, eitherapparent orconcealed, aclaim must be made withdelivering carrier.

a. Apparent damage or loss must be noted on the freight bill at the time of delivery.

The carrier representative (Driver) the freight bill. If this is not done, the

carriermay refuse the claim.The carrier can supply thenecessary forms.

b. Concealed damage or loss if not apparent until after the toaster is removed from

carton,

shouldarrange an inspection.

2. VerifyParts

Afterremoving unit from the shipping carton, unwrappingloose partsand remove any packingtape,

plasticwrap and nylon tie-down. Verify thefollowing parts:

Item Packaging Qty

Legs In plastic bag 4

Feeder/Bun Chute Wrapped, loose in top of carton 1

Conveyor In individual carton 1

Instruction Manual Loose in carton 1

Teflon Sheet Kit (optional) Loose in carton Optional

a request for inspection must be made to the carrier within 15 days. The carrier

INSTALLATION

must sign

Besure to saveall contentsand packaging material.

NOTE:

BECLEANED WITHWARM SOAPY WATERTO REMOVE MANUFACTURINGOILS,THENRINSED

AND DRIED THOROUGHLY. Apply oil (vegetable oil) to the conveyor chain after washing. (Bun oil can be

usedif it containsno animalfats, salts or dairyproducts).

3. AssembleLegs

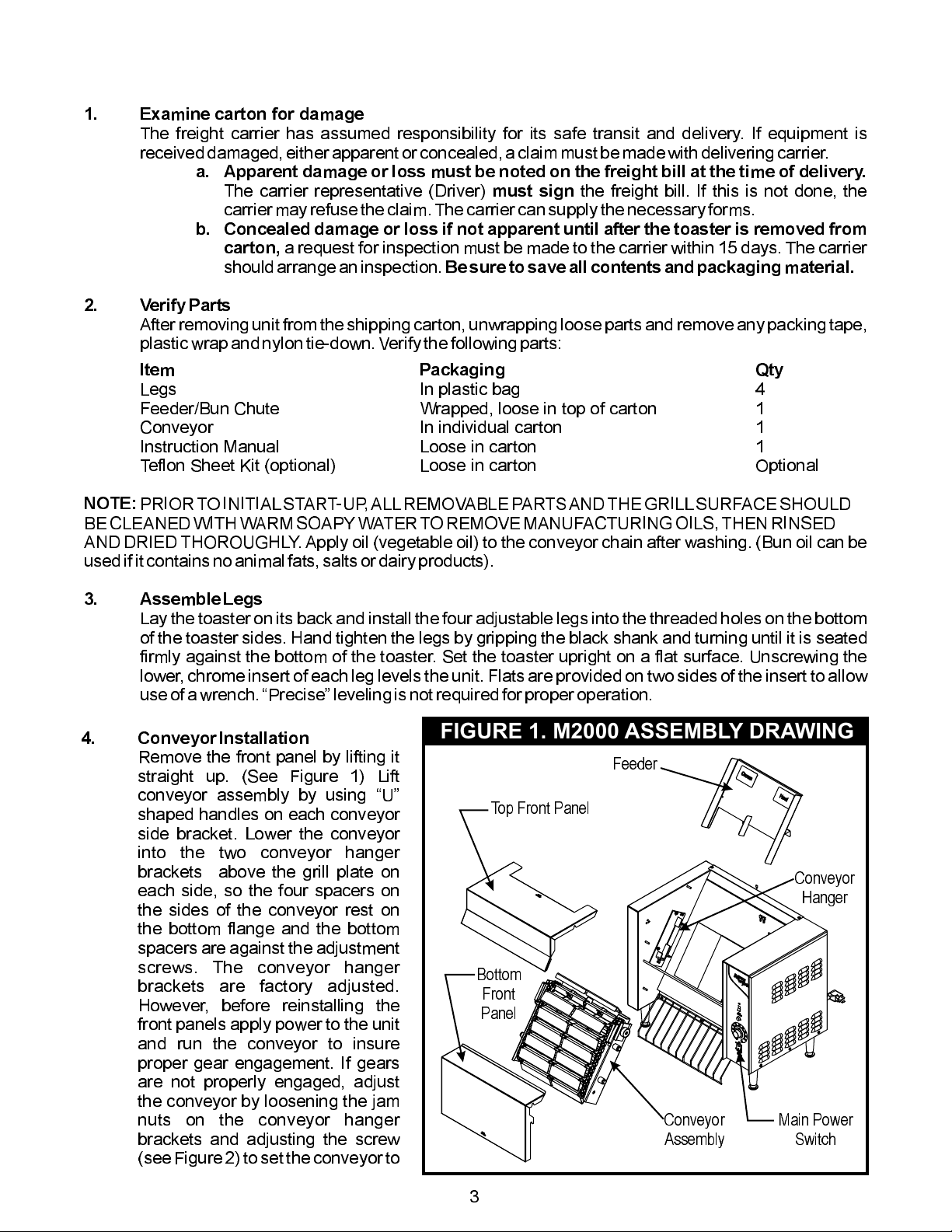

4. ConveyorInstallation

PRIORTO INITIAL START-UP,ALLREMOVABLEPARTSANDTHE GRILLSURFACE SHOULD

Lay the toaster on its back and install the four adjustable legs into the threaded holes on the bottom

of the toaster sides. Hand tighten the legs by gripping the black shank and turning until it is seated

firmly against the bottom of the toaster. Set the toaster upright on a flat surface. Unscrewing the

lower, chrome insert of each leg levels the unit. Flats are provided on two sides of the insert to allow

useof a wrench.Precise levelingis notrequired for proper operation.

FIGURE 1. M2000 ASSEMBLY DRAWING

Remove the front panel by lifting it

straight up. (See Figure 1) Lift

conveyor assembly by using U

shaped handles on each conveyor

side bracket. Lower the conveyor

into the two conveyor hanger

brackets above the grill plate on

each side, so the four spacers on

the sides of the conveyor rest on

the bottom flange and the bottom

spacers are against the adjustment

screws. The conveyor hanger

brackets are factory adjusted.

However, before reinstalling the

front panels apply power to the unit

and run the conveyor to insure

proper gear engagement. If gears

are not properly engaged, adjust

the conveyor by loosening the jam

nuts on the conveyor hanger

brackets and adjusting the screw

(see Figure 2) toset the conveyorto

Top Front Panel

Bottom

Front

Panel

Feeder

Conveyor

Assembly

Conveyor

Hanger

Main Power

Switch

3

Page 4

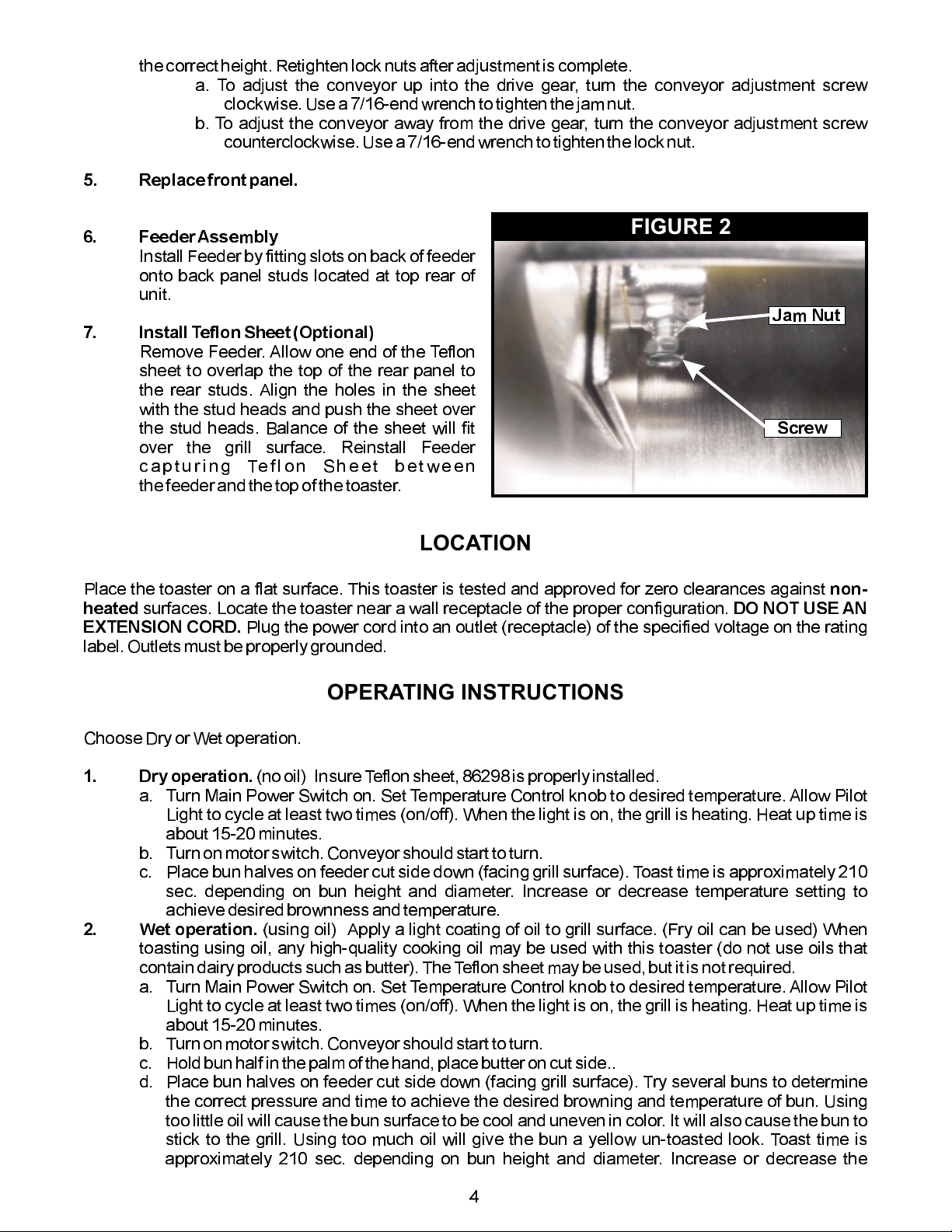

thecorrect height. Retighten lock nuts afteradjustment iscomplete.

a. To adjust the conveyor up into the drive gear, turn the conveyor adjustment screw

clockwise.Use a 7/16-end wrench to tighten thejam nut.

b. To adjust the conveyor away from the drive gear, turn the conveyor adjustment screw

counterclockwise.Use a7/16-end wrenchto tighten the lock nut.

5. Replacefront panel.

6. FeederAssembly

Install Feeder by fitting slots on back of feeder

onto back panel studs located at top rear of

unit.

7. InstallTeflonSheet(Optional)

Remove Feeder. Allow one end of the Teflon

sheet to overlap the top of the rear panel to

the rear studs. Align the holes in the sheet

with the stud heads and push the sheet over

the stud heads. Balance of the sheet will fit

over the grill surface. Reinstall Feeder

capturing Teflon Sheet between

thefeeder and the top ofthe toaster.

FIGURE 2

Jam Nut

Screw

LOCATION

Place the toaster on a flat surface. This toaster is tested and approved for zero clearances against

heated DO NOT USE AN

EXTENSION CORD.

label.Outlets mustbe properlygrounded.

surfaces. Locate the toaster near a wall receptacle of the proper configuration.

Plug the power cord into an outlet (receptacle) of the specified voltage on the rating

non-

ChooseDry or Wet operation.

1. Dryoperation.

a. Turn Main Power Switch on. Set Temperature Control knob to desired temperature. Allow Pilot

Light to cycle at least two times (on/off). When the light is on, the grill is heating. Heat up time is

about15-20 minutes.

b. Turnon motorswitch. Conveyorshould startto turn.

c. Place bun halves on feeder cut side down (facing grill surface). Toast time is approximately 210

sec. depending on bun height and diameter. Increase or decrease temperature setting to

achievedesired brownnessand temperature.

2. Wet operation.

toasting using oil, any high-quality cooking oil may be used with this toaster (do not use oils that

containdairy productssuch asbutter). The Teflon sheet may beused, butit is notrequired.

a. Turn Main Power Switch on. Set Temperature Control knob to desired temperature. Allow Pilot

Light to cycle at least two times (on/off). When the light is on, the grill is heating. Heat up time is

about15-20 minutes.

b. Turnon motorswitch. Conveyorshould startto turn.

c. Holdbun halfin thepalm ofthe hand, place butter oncut side..

d. Place bun halves on feeder cut side down (facing grill surface). Try several buns to determine

the correct pressure and time to achieve the desired browning and temperature of bun. Using

too little oil will cause the bun surface to be cool and uneven in color.It will also cause the bun to

stick to the grill. Using too much oil will give the bun a yellow un-toasted look. Toast time is

approximately 210 sec. depending on bun height and diameter. Increase or decrease the

(nooil) InsureTeflonsheet, 86298is properlyinstalled.

(using oil) Apply a light coating of oil to grill surface. (Fry oil can be used) When

OPERATING INSTRUCTIONS

4

Page 5

temperaturesetting toachieve desiredbrownness and temperature.

NOTE:

Should the temperature setting be changed, allow several cycles for the grill plate to adjust.

Oncethe desired setting has beenachieved, notethe temperatureand keepit set there.

CLEANING

WARNING:Make sure the toaster is in the off position and has been off at least 15 30 minutes. Do

notattempt this cleaning procedureif the toastercomponentsare toohot to touch.

Never spray water on the toaster or controls. Damage to the toaster as well as injury could occur.

Severeinjury and burns may occurif youdo not follow this instructionsheet.

DISASSEMBLY

Turnoffmain power switchand conveyorswitch. Disconnectthe power supply cord fromthe wall outlet. The

toasterwill be hotwhen turnedoff.Allow thetoaster to cool for atleast 15 30 minutes before handling.

CAUTION

NOTE:Do not use any chlorideor chlorine-based productsto cleanor rinsetoaster ortoaster parts.

DailyParts Cleaning:

The Feeder, and Top and Bottom Front Panel can be placed in a dishwasher or sink and washed with

detergentand warmwater.

DailyConveyor Cleaning:

Conveyor may be hot and is heavy, use caution when lifting and removing.

assembly by gripping the two handles at the top and lifting forward until it clears the gears. Lift it up and out

gently placing it in a sink with the drain stopped, or in a suitable container to soak over night. Conveyor can

be placed in the sink or container while warm. The soak

solution is a mix of 10 parts hot water (120ºF or more) to 1 part (minimum) INSIDE OUT brand 3-IN-1. Fill

the sink or suitable container with thesolution, to completelycover the conveyorby approximately one inch.

Allow the conveyor to soak in the solution over night. Remove the conveyor from the solution. Use a stiff

non- metalbrush or plastic pad to remove residualbun oil. Insure the chains are clean and free from debris.

Use a brush to remove any soil or debris remaining on the chain. Rinse conveyor with plain hot water and

allow to drain. Lubricate both chains thoroughly with vegetable oil. Bun oil may be used if it contains no

animal fats, salts or dairy products.

Gently replace conveyor into toaster.

afterover nightuse!

duringdisassembly andcleaning. Removethe Topand Bottom Front Panels.

Remove the conveyor

Use caution when handling a hot conveyor.

Note: Chain Lubrication is critical to chain life. Oil the chain daily.

Discard used soak solution. Clean and sanitize sink or container

USE

Replace all removed toaster parts.Plug power supplycord into wall outlet.Turn mainpower switch on.Turn

conveyorswitch on.

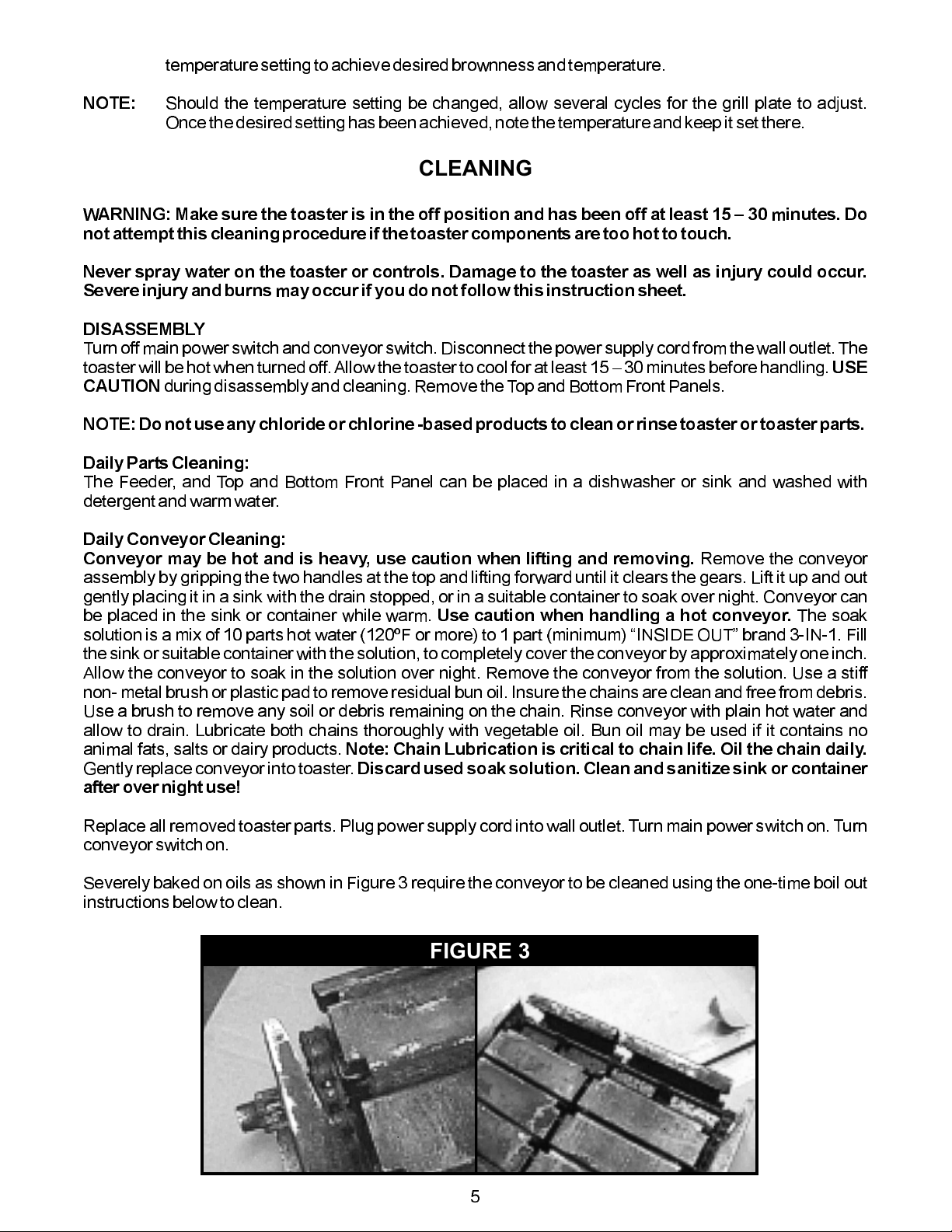

Severely baked on oils as shown in Figure 3 require the conveyor to be cleaned using the one-time boil out

instructionsbelow toclean.

FIGURE 3

5

Page 6

ONE-TIME BOIL OUT OF CONVEYOR

NOTE:This is for experienced operators only, and instores thatapprove thisoperation.

1. Turnoff power and drainthe oilfrom one ofthe Fryers,and allow it to cool.

2. TurnToaster main power switch off. Remove power supply plug fromthe walloutlet.

3. Some surfaces will remain hot after toaster is turned off. Allow time for toaster to cool. (15-30

minutes)Use cautionduring disassemblyand cleaning.

4. Remove the Top and Bottom FrontPanels.

5. When thefryer hascooled and has drained, close the drainvalve.

6. Remove the Conveyor assemblyby grasping the two handles at the top, and lifting forward until

it clears the gears.

7. placethe ConveyorAssemblyinto theFryer.

Gently

8. Add water to the cooledFryer leaving enough room to add two (2) gallons of INSIDE OUT 3 IN

1 HEAVYDUTYCLEANER andthe ConveyorAssembly.

9. Add additionalwater tothe Fryer, if necessary, tocompletely coverthe ConveyorAssembly.

10. Set the temperature of the Fryer to 200ºF, and allow the conveyor to soak in the solution for 60

minutes.

11. Shut off the Fryer and allowthe conveyorto cool.

12. After the conveyor

NOTE: Drain the solution prior to removing the Conveyor Assembly.

has cooled, remove the conveyor from the Fryer. If there are areas with bun oil, use a stiff non-

metal brush or plastic pad to remove. Insure the chains are clean and free from impediment.

Usea brush toremove anysoil or impediment remainingon the chain.

13. Rinse conveyor with hot water and allow to drain. Lubricate both chains thoroughly with

vegetableoil. Bunoil may be used ifit containsno animalfats,

saltsor dairyproducts.

14. Before assembly of the conveyor check the Following: Conveyor Assembly hardware to insure

fasteners are tight and there are no signs of wear,Gears are tight on the Conveyor shaft and the

Motor Shaft and the Hanger Bracket screws are tight and the brackets have not shifted during

use.

15. Gently replace conveyor into toaster. Replace all removed parts. Plug power supply cord into

wall.Turnmain powerswitch on.Turnconveyor switch on.

Note:Chain Lubricationis critical to chain life.Oil chaindaily.

LAST IMPORTANT NOTE:

Theconveyor must stay cleanto optimize speed and bun

temperature.

DailyGriddle Cleaning:

Dry Operation:

collectedon the sheet. If thesheet is worn, replace it with anew sheet.

Wet Operation:

freeof burned on bread thatmay causebuns to stick.

Tools neededfor cleaning:

Alsoneeded:

(Wet)terry towel Catchpan forfood soil Commonkitchen scraper

KEEPCONVEYOR LOOKING NEW.

Wipe off the Teflon sheet with a damp cloth to remove any debris or particles that have

It is not necessary to completely remove residue, as long as the grill surface is smooth and

Scotch-BriteTMQuick CleanSmallAppliance CleanerNo. 702or Equivalent

Scotch-BriteTMMulti-Purpose Pad Holder No.405 or Equivalent

Scotch-BriteTMSqueegee No.410 orEquivalent

Scotch-BriteTMGriddle PolishingPad No.46 or Scotch-BriteGeneral Purpose

ScrubbingPad No. 9650 or Equivalent

Daily-cleaning instructions of conveyor should be followed after this boil out.

6

Page 7

If Teflon sheet is installed remove it when Bun Grill Toaster is cool. Set the toaster temperature to 350°F.

Scrapeloose food particles withscraper into a pan under grill plate.

Squeeze 1 to 2 ounces of Scotch-BriteTM Quick Clean SmallAppliance Cleaner No. 702 or equivalent into

measuringreservoir ofbottle. Pour cleaner onto pad.Do notpour directlyonto grill surface.

FIGURE 4 FIGURE 5 FIGURE 6

FIGURE 7

Scourusing Scotch-Brite Multi-PurposePad HolderNo. 405or equivalent,and Scotch-Brite

TM TM

FIGURE 8

GriddlePolishing PadNo. 46 (or9650). (SeeFigure 4)

Afterscouring, Squeegeethe surfaceclean withthe Scotch-Brite SqueegeeNo. 410 (SeeFigure 5)

Turn off Bun Grill Toaster and wipe surface with clean wet towel. If the surface is still hot, use the Scotch-

TM

Brite MultiPurpose PadHolder to movethe towelover the surface. (See Figure 6)

TM

.

Drythe grill thoroughly. Coat the grillplate witha light filmof cookingoil. See Figure7)

Rinseall cleaning tools with hotwater.(See Figure8)

Wipedown all external stainlesssteel surfaces with a dampcloth.

RE-ASSEMBLY

Before assembling the conveyor check the following: Fasteners on the Conveyor Assembly hardware

should be tight with no signs of wear. Conveyor Shaft Gear and Motor Shaft Gear are tight. Hanger Bracket

Screwsare tight and the bracketshave notshifted during use.

7

Page 8

TROUBLESHOOTING GUIDE

Alwaysask and check the following:

1.

2.

3.

4.

If the above checks out, and you still have problems, call an APW Wyott authorized service agent.

APWSERVICE HOTLINE 1-800-733-2203

Is the unit connectedto alive power source of theproper voltage?

Checkthe circuit breaker.

Is power switch ON and pilotlight glowing?

Checkthe rating label. Is theunit connectedto the correctpower source?

PROBLEM

PROBLEM CAUSE SOLUTION

Buns wont toast Wrong temperature setting

Excessive cupping of bun

surface

Buns toast unevenly Excessive cupping of bun

surface

Conveyor pressure too light

Buns stick to grill Teflon sheet worn.

Doughy buns or excessive

sugar and moisture, plus grill

temperature too high.

Build up on Grill Surface

No power No power at the wall

receptacle

Power cord disconnected

Main switch

Conveyor will not turn (Motor

turns)

Drive gears not engaged

Gear set screws not tight

CAUSE

SOLUTION

Increase temperature setting

and allow two cycles to warm

up.

Buns are stale, use fresher

buns

Buns may be stale. Try fresher

buns

Adjust conveyor tension

Replace Teflon sheet

Reduce grill temperature

Allow buns to age.

Clean Grill per instructions

Check circuit breaker or fuse

Check plug at receptacle

Check that switch is ON and

operative

Check gear alignment and

engagement

Check screws and tighten if

required

8

Page 9

17.447

17.447

17.447

23.498

23.498

SPECIFICATIONS

21.888

21.888

21.888

APPROX.

19.340

20.590

21.840

19.340

20.590

21.840

00

APPROX.

16.272

16.272

16.272

4.000

15.002

15.002

15.002

9.500

9.500

10.750

10.750

12.000

12.000

9

Page 10

37

37

43

43

48

48

PARTS LIST w/EXPLODED VIEW

EXPLODED VIEW

71

62

62

71

69

69

40

40

26

26

19

19

24

24

57

65

65

57

27

27

6

6

25

25

53

53

55

66

66

38

38

55

41

41

42

58

58

60

60

42

39

39

3

3

12

45

45

44

44

12

23

23

20

20

13

13

63

63

54

54

1

11

11

1

2

2

9

9

5

5

16

16

67

51

51

70

70

67

22

22

59

59

68

68

56

56

46

46

21

21

10

52

31

31

52

10

61

32

32

61

33

33

49

49

39

39

14

14

30

50

50

30

29

29

28

28

64

64

18

18

34

34

47

47

8

8

4

4

17

17

15

15

35

35

36

36

7

7

Page 11

PARTS LIST

ITEM PART NUMBER DESCRIPTION QUANTITY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

86260

86219P

86204

70202012

86210

86207

86261

70202009

86233

94200095

83733

86235

83065 SON

86259

86234

70200052

86206

86211

85033

85043

89057

88984

89143

86265

84559

89120

87074

94200089

70200051

94000172

89408

63012

89491

70900009

34236

34237

89003

89073

88889

39100

89071

89061

88993

89164

89163

86202

39099

89059

88901

88948

89054

89029

89111

60113

85647

86491

88961

85284

88923

89063

88705

86284

86253

85285

89182

86256

70439098

69147

89042

70202016

70202015

PANEL, TOP FRONT

ELEMENT, GRILL 208/240V

PLATE, MOTOR MOUNTING

PANEL, CONTROL M-2000 JIB

PANEL, LEFT SIDE OUTER

PANEL, BACK

PANEL, BOTTOM FRONT

LABEL, M2K JIB CONTROL

ANGLE, GRILL PLATE

KIT, POWER SUPPLY, 5V/24V OUTPUT

ROD, FRONT AND TOP

W/ASS'Y, LEFT SIDE PANEL

W/A Hanger Arm LH

SHIELD, FRONT GRILL

W/ASS'Y, RIGHT SIDE PANEL

CHAIN/WEIGHT CONV.ASS'Y (COMP) M-95-2

PANEL, BOTTOM

PANEL, RIGHT SIDE OUTER

GEAR, 13 TOOTH 3/8 BORE

GEAR, 19 TOOTH

WASHER, LOCK #6 INTERNAL

SCREW 6-32 X 3/8 PAN HD

PLUG, HYCO # DP-187

W/ASS'Y, SUPER FEEDER

PLUG, HOLE HEYCO #DP687

CLIP, JIFFY

PIN, HANGER

MERKLE-KORFF MOTOR

SPEED CONTROL BRACKET

10K OHM POTENTIOMETER

SWITCH, LIGHTED ROCKER

S/A, PILOT LIGHT

SWITCH,ROCK,DPST,20A 250VAC,BLK (TEXT)

LEG, 4" METAL ADJ. LEG

TERMINAL BLOCK END MTG

TERMINAL BLOCK .250 MALE

BOLT,1/4-20 X 1/2" SS HEX

SCREW, #8 X 1/2 HEX TAPIT SHT MTL TYPE AB

SCREW #8 X 1/2 AB SMS PHL TRUSS LGM NI PLT

PROBE, THERMOSTAT

WASHER, #10 FLAT

NUT, HEX 10-24

SCREW 10-32X3/8 TRS HD PHILLIPS NYLK MS

SCREW, 1/4-20 X 5/8 HEX SL NCK PL

NUT, JAM HEX 1/4-20 N.P. SS

COVER, INSULATION

T'STAT, FASTRON G6

WASHER #10 EXTERNAL LOCK

SCREW 6/32 X 1/4 PAN HD M/S BLKZC

SCREW 6-32 X 3/4 PAN HD

NUT, KEPS 6-32

SCREW, 10-24 X 3/8 PH PAN SS

BUSHING, STRAIN RELIEF SR-7W-2

INSULATION, 21X19X1

CORDSET, 14/3 600V .440 HSJO 620P

W/A Hanger Arm RH

NUT, HEX 10-24, GREEN

FAN, COOLING 4.5" 105CFM 208/230V

SCREW, 8-32x1-3/4 SLT PAN MS SS

NUT, HEX 8-32

KNOB 039-266 8A BLACK

SCREW, 8-32x1/4 PHIL PAN TYPE 23 ZINK

RACK, BOTTOM WIRE

ASSY, FAN CORD(FAN CORD 85283)

BUSHING, .5 HEYCO 2058

BRACKET, CAPILARY

RELAY,SLD ST 50A 280V OUT,90-280VAC IN

PAD, THERMAL FOR SSR 69146 (TEXT)

SCREW 8-32 X 1/2 PH SL SS

LABEL, CROWN

LABEL, HEEL

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

4

4

3

1

1

2

2

1

1

1

1

1

1

4

1

5

10

7

27

1

9

7

13

2

2

1

1

12

2

2

4

1

1

1

1

1

1

1

4

4

1

8

1

1

1

1

1

1

2

1

1

11

Page 12

WIRING DIAGRAM

RTD PROBE 39100

RTD PROBE 39100

L2

WHITE

BLACK

IN LINE RE SISTOR

ORANGE

RED

4

L1

L1

6

LIGHTED ROCKER SWI TCH 89408

RED

RED

WIRE NUT

89149

10

10 10

PILOT LIGHT 6301 2

WIRES NOT IN WIRE SET

88

9

9

7

7

THERMOSTAT 39099

5

L2

5

3

ORANGE

GREEN

6 PIN HARNESS 94100134

3 PIN HARNESS 94100061

POWER SUPPLY 941 00140

GREEN

6

LIGHTED ROCKER SWI TCH 89406

BLUE

SPEED POT. 94000172

WHITE

BLACK

9

L2

5

7

L1 L1

6

4

L1

3

L2

WIRE HARNESS 94200093

BLUE

WHITE

RED

BLACK

11

RED

BLACK

RED

12

12

11

MOTOR 94200089

RELAY 70439098

13

10

11

BLACK

RED

14

13

BLACK

L2

14

RED

11

L1

1

14

L2

2

11

L1 B ROWN

L2 BL UE

13

GRILL PLATEN 86219-P

CORDSET 85640

14

1

2

GRND

FAN 85284

FAN CORD 85283

M2K TE RMINAL BLOCK ASSY

34236 (1) 34237 (5)

Page 13

Notes:

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

WarrantyServiceand/or Parts,this informationis required.

ModelNumber SerialNumber DatePurchased

13

Page 14

Notes:

14

Page 15

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty,at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyottwill not be responsible for such work or any charges associated

with same. The closestAPWWyottAuthorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas ofAlaska and Canada. There

will be no labor coverage for equipment located on any island not connected byroadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary.ContacttheinternationalAPWWyottdistributor,dealer, or service agencyfor details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inall cases, parts covered by extended warranty will be shipped FOB the factoryafter the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott'soptionoritsAuthorized ServiceAgency,itwillbeservicedonsiteorreplaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs.No mileage or travel charges are allowed onportable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which arecovered under the Enhanced WarrantyProgram, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions are notcovered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or toany property, which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime orpremium labor rates, the ownershall be charged for the difference betweennormal service rates and such

premium rates.APWWyottdoesnotassumeanyliability for extended delays in replacing orrepairing any items beyond itscontrol.

Inall cases, the use of other than APWWyottAuthorized OEM Replacement Parts will void thiswarranty.

This equipment is intended for commercial use only.Warranty is void ifequipment is installed in other than commercial application.

WaterQualityRequirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OFAPW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.

*Gas/Electric Cookline:

component parts, except switches andthermostats. (2 additional yearsonparts only.Nolaboronsecond or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, LightBulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, deliveryorinstallation, fire, flood, riot oractofgod.

*Equipment that has the model numberor serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2)YearWarranty on element only. Nolaborsecond year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

RockGrates,CookingGrates,BurnerShields,Fireboxes:

90Day Material Only. No Labor.

90DayMaterialOnly.NoLabor.

9/05

15

Page 16

R

Phone: +1

(214) 421-7366

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(800) 733-2203

24 Hour Service Hotline

16

APW WYOTT

729 Third Avenue

Dallas, TX 75226

Loading...

Loading...