Page 1

R

INSTALLATION AND OPERATING INSTRUCTIONS

ELECTRIC FRYERS

Model: EF-30

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

OVEN MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY

! !

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

! !

cause property damage, injury or death. Read the Installation, Operating

and Maintenance Instructions thoroughly before installing or servicing this

equipment.

WARNING

Initial heating of oven may generate smoke or fumes and must be done in a

! !

This equipment has been engineered to provide you with year round dependable service when used

accordingtotheinstructions inthis manualand standardcommercial kitchenpractices.

+1 (307) 634-5801 Phone +1 (800) 752-0863 Toll Free

+1 (307) 637-8071 Fax www.apwwyott.com

well-ventilatedarea. Overexposure to smoke or fumes may cause nausea or

dizziness.

P/N 8835990 9-05

APW WYOTT Foodservice Equipment Company

P.O. Box 1829

Cheyenne, WY 82003

1

Page 2

APW Wyott

care and maintenance, you will experience years of reliable operation from this equipment. To ensure best

results, it is important that you read and follow the instructions in this manual carefully.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instruction.

If you have questions concerning the installation, operation, maintenance or service of this product, write

Technical Service Department APW Wyott Foodservice Equipment Company, P.O. Box 1829, Cheyenne,

WY 82003.

takes pride in the design and quality of our products. When used as intended and with proper

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation are fully trained

and are aware of all precautions.Accidents and problems can result by a failure to follow fundamental rules

and precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnel or theequipment. The words are defined as follows:

DANGER:

!

WARNING:

!

seriousinjuryor death.

CAUTION:

moderateinjuryor product orpropertydamage.

!

NOTICE:

eventhough not dangerous.

!

Thissymbol warns of imminenthazardwhich will resultin serious injury ordeath.

This symbol refers to a potential hazard or unsafe practice, which could result in

Thissymbol refers to a potentialhazard or unsafepractice, which mayresult inminor or

This symbol refersto information thatneeds special attentionor must be fully understood

SAFETY INFORMATION

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

CAUTION:

positioned so the general public can use the equipment make sure that cautions, warnings, and

!

operating instructions are clearly posted near each unit so that anyone using the equipment will

useit correctly andnot injure themselves or harmthe equipment.

WARNING:

!

andfrequencylisted on thedataplate. Connect onlyto1 or3 phase as listedon the dataplate.

WARNING:

!

nationalelectricalcode and/or other localelectricalcodes.

These models are designed, built, and sold for commercial use. If these models are

Checkthe data plateon this unitbefore installation. Connect the unit only tothe voltage

Electrical and grounding connections must comply with the applicable portions of the

!

!

!

!

!

!

!

WARNING:

!

powerplug, indicating that youare working on thecircuit.

WARNING:

strongly recommendhaving a competent professional install the equipment.A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

!

be used when connecting these units to electrical power. In the absence of local codes, use the

latestversionof theNationalElectricalCode.

WARNING:

codes, or in the absence of local codes, with the National Electrical code, ANSI/NFPA 70, Latest

Edition to protect the user from electrical shock. It requires a grounded system and a dedicated

!

circuit, protected by a fuse or circuit breaker of proper size and rating. Canadian installation must

complywith the CanadianElectricalCode,CSAC22.2,asapplicable

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

Installper the spacing requirementslisted in the installationsection of this manual. We

This device should be safely and adequately grounded in accordance with local

2

!

!

!

Page 3

CAUTION:

!

unlessthere is atleast 3 breathingspacebehindfryer.

Do not set the fryer with its back flat against the wall. It will not operate properly

!

WARNING:

!

maintenanceorrepair,contactAPW Wyott.

WARNING:

!

surface.

WARNING:

installationandfrom there to anindependentearth connection.

!

NOTICE:

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition.

!

Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General

Requirements-CanadianElectrical CodePartII, 109-M1981- Commercial CookingAppliances.

WARNING: -

!

equipment.

NOTICE:

!

NOTICE:

Fire ProtectionAssociation, Inc. states in its NFPA96 latest edition that local codes are Authority

Having Jurisdiction when it comes to requirement for installation of equipment. Therefore,

!

installationshouldcomplywith all localcodes.

Afactoryauthorizedagent should handleall maintenance andrepair. Beforedoingany

Never clean any electrical unit by immersing it in water. Turn off before cleaning

An earthing cable must connect the appliance to all other units in the complete

The unit when installed,must be electrically groundedand complywith local codes, or in

SHOCK HAZARD

Thisproduct is intendedforcommercialuse only.Notfor household use.

Local codes regarding installation vary greatly from one area to another. The National

De-energize all power to equipment before cleaning the

!

!

!

!

!

!

!

CAUTION:

!

Disconnectallpower supplies before servicing.

CAUTION:

!

provided.

WARNING: -

!

This product when stacked, has more than one power supply connection point.

Suitable for installation on combustible floor when installed with legs or casters

SHOCKHAZARD

Donot open anypanelsthat require the useof tools.

!

!

!

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

IMMEDIATELY INSPECT FORSHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, aclaim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed

by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can

supply the necessaryforms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection

must be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all

contents and packaging material.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instructions.

3

Page 4

TABLE OF CONTENTS

SECTION ITEM PAGE

Safety Precautions/Safety Information 2

1 General Information 4

2 Description 5

3 Installation & Supply Connections 5

4 Thermostat Calibration 6

5

6

7 Service 8

8

9

10 Replacement Parts List & Exploded Views 12

11

12 Warranty 16

Maintenance 6

Cleaning 7

Troubleshooting Guide 10

Suggested Temperature & Times 11

Wiring Diagram 15

1. GENERAL INFORMATION

General Installation:

1. Always clean equipmentthoroughly before first use (see “General Cleaning Instructions”).

2. Check rating labelfor your model designation & electrical rating.

3. For best results, use stainless steel countertops.

4. Attach legs to unit.

General Operation Instructions:

1. All foodservice equipmentshould be operated by trained personnel.

2. Do not allowyour customers to come in contact with any surface labeled“CAUTION HOT”.

3. Where applicable, neverpour cold water into dry heated units.

4. Where applicable, do not cook, warm or hold food directly in liner pans (well) pans. Always use

steamtable pans/insets, etc.

5.

General Cleaning Instructions:

1. NEVER clean any electrical unit by immersing it in water. Turn unit off and allow it to cool down

2. Always clean equipment thoroughly before first use. Clean unit daily. Except where noted on charts:

3. Unplug electrical units before cleaning or servicing. All service should be performed by an APW

General Troubleshooting:

Always ask andcheck:

1. Is the unitconnected to a live power source?

2. Check circuit breaker.

3. Is power switch“ON” and pilot light glowing?

4. Check rating label.Are youoperating unit on proper voltage?

NEVER hold foodbelow 140°F.

before surface cleaning.

Use warm, soapy water. Mild cleansers & PLASTIC scouring pads may be used to remove bakedon food andwater scale on metal units.

Wyott authorized service agency.

If the abovechecks out and you still have problems, callanAPW Wyott authorized service agency.

4

Page 5

2. DESCRIPTION

Electric Fryers:

These electric units are designed for countertop operation. They are used for producing evenly cooked,

perfectly fried products.

3. INSTALLATION & SUPPLY CONNECTION

Installation

1. Follow General Installation Instructions on previous page.

Screw legs into the permanently fastened nuts on the four corners of the unit and tighten by

hand. Level the fryer by turning the adjustment screw at the bottom of each leg. Do not slide unit with

legs mounted, lift if necessary to move unit.

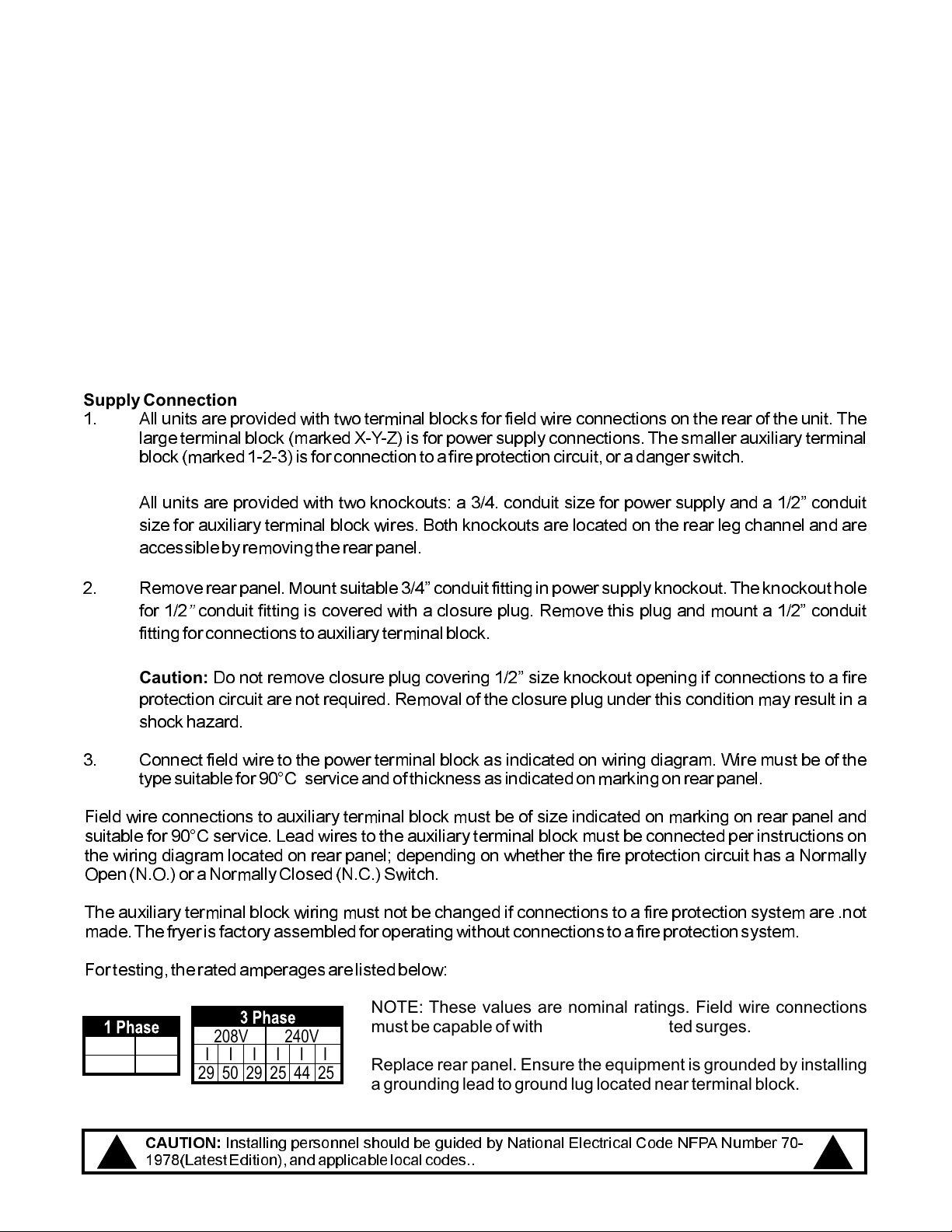

Supply Connection

1. All units are provided with two terminal blocks for field wire connections on the rear of the unit. The

large terminal block (marked X-Y-Z)is for power supply connections. The smaller auxiliary terminal

block(marked 1-2-3)is for connection to a fire protectioncircuit, or a dangerswitch.

All units are provided with two knockouts: a 3/4. conduit size for power supply and a 1/2 conduit

size for auxiliary terminal block wires. Both knockouts are located on the rear leg channel and are

accessibleby removingthe rearpanel.

2. Removerear panel. Mount suitable 3/4conduit fitting inpower supply knockout.The knockouthole

50

Do not remove closure plug covering 1/2 size knockout opening if connections to a fire

NOTE: These values are nominal ratings. Field wire connections

208V 240V

IIIIII

29 50 29 25

44

25

must be capable of withstanding anticipated surges.

Replace rear panel. Ensure the equipment is grounded by installing

a grounding leadto ground lug located near terminal block.

for 1/2 conduit fitting is covered with a closure plug. Remove this plug and mount a 1/2 conduit

fittingfor connectionsto auxiliaryterminal block.

Caution:

protection circuit are not required. Removal of the closure plug under this condition may result in a

shockhazard.

3. Connect field wire to the power terminal block as indicated on wiring diagram. Wire must be of the

typesuitable for90°C service and of thicknessas indicatedon markingon rearpanel.

Field wire connections to auxiliary terminal block must be of size indicated on marking on rear panel and

suitable for 90°C service. Lead wires to the auxiliary terminal block must be connected per instructions on

the wiring diagram located on rear panel; depending on whether the fire protection circuit has a Normally

Open(N.O.) or a Normally Closed (N.C.) Switch.

The auxiliary terminal block wiring must not be changed if connections to a fire protection system are .not

made.The fryeris factoryassembled foroperating withoutconnections to a fireprotection system.

Fortesting, the rated amperagesare listedbelow:

240V

208V

58

CAUTION:

!

1978(LatestEdition),and applicable local codes..

Installing personnel should be guided by National Electrical Code NFPA Number 70-

!

5

Page 6

4. THERMOSTAT CALIBRATION

Checking Thermostat Calibration:

The fryer thermostat is carefully calibrated at the factory so that dial settings match actual frying compound

temperatures. Field re-calibration is seldom necessary unless the unit has been mishandled in transit or

abused. Re-calibration should not be resorted to unless considerable experience with cooking results

definitely proves thatthe control is not maintaining the temperature to which thedial is set.

1. To check compound frying temperatures when re-calibrating, use a precision test instrument, or a

good grade mercurythermometer. Fill fry tank with frying compound to “FULL”mark.

2. Frying compound temperature should be checked at the center of the tank, approximately 1” to

1 1/2” below surface of frying compound.

3. Turn the dial of the thermostat being checked to the 350°Fmark.

4. Allow temperature to stabilize, or until the thermostat cycles to “OFF” three times after starting

with cold frying compound. With power “ON”, read highest and lowest frying compound

temperature, as thermostat cycles through at least two cycles.Averagethe reading.

5. Thermostat should be re-calibrated if temperature reading is not within 10 degrees of the

control knob setting (350°F +/- 10°F). If re-calibration is required, continue with steps 6, 7,8 and 9.

6. Remove control knob by grasping outer edge and pulling straight out, without twisting or turning.

7. Hold thermostat dial shaft “B” (Figure 1) stationary with pliers, and with a screwdriver, turn screw “A”

clockwise to obtain a lower temperature; or counter-clockwise for higher temperature. Each ¼ turn

(90° rotation) of screw “A” represents 18°F.

8. Replace thermostat control knob.

9. Recheck thermostat as in Steps 4 and 5 above. If the fat temperature is not within 20 degrees of dial

setting (350°F +/- 20°F), it means that the sensing element is inoperative and the thermostatic

control should be replaced.

5. MAINTENANCE

FIGURE 1

“A” SCREW

“A” SCREW

1/4” TURN

“B” DIAL SHAFT

Removing Fry Tanks

a. Remove fry baskets.

b. Carefully grasp the black handle, CAUTION: may be hot, on the end post on top rear corner of the

fryer with theleft hand, and the elementlift handle resting on frytank front, with right hand.

c. Lift the element handle while at the same time. pulling the plastic handle. This will permit lifting the

elements to just above frying compound level in tank. The element can be left in this position for

draining frying compound.

d. Again, lift the element handle while pulling the plastic handle, until the elements lock themselves at

a higher position.

e. Firmly grasp bothhandles of fry tank and lift it out. ,

f. After replacing the fry tank, simply pull the plastic handle; and at the same time, pull down the

element handle untilthe elements rest on frytank bottom.

g. Both the lifting out and lowering of elements can be done in one swing, without stopping at the

intermediate position.

INCREASE

DECREASE

6

Page 7

Filling Fry Tank

1. Ensure circuit breaker is at the -ON- position. This is done by pressing the “RESET” or “ON”. part of

the red rockerhandle on the front panel.

2. Set the thermostat to “OFF” and push in the red switch marked “ON-OFF” to turn unit on. Red

indicating light on the switch will come on. Turn the thermostat knob to the 300° mark and a yellow

cycling light marked “HEAT ON” will come on. Push the red switch to turn it “OFF”. The fryer control

circuit has nowbeen checked and the fryer is ready foruse.

CAUTION:

a. Fill the fry tank to the “FULL” mark with approximately 30 Ibs. of liquid or melted frying

b. Do not allow frying compound level to drop more than 1/2" below the "FULL" mark. For

c. Usea quality frying compound.

d. Filter the fryingcompound frequently at least once a day.

e. Skim out foodparticles frequently with the strainer/skimmer.

f. Add at least 15% (of fry tank capacity) of fresh frying compound daily - more if possible -

g. Do not overload the fry baskets. Approximately half-full or even less is correct. If foods are

h. Prepare the food properly:

i. Keep saltout of the frying compound. Do not saltfoods with the basket above the kettle.

j. Assure agood thermostat operation.

k. Keep thefry tank and elements clean.

Do not leaveelements on without frying compoundin the tank.

compound. Do notoverfill.

NOTE:

option. Air holes caused when packing solid frying compound into the fryer can cause hot

spots on the heating element sheath, resulting in momentary overheating of some of the

frying compound and premature frying compound breakdown. It can also damage the

heating elements. If it is necessary to use solid frying compound, it must be melted before

adding to frytank.

Turn the thermostat to the desired frying temperature and push in the red “ON-OFF" switch

to "ON". The yellow "HEAT ON" light will stay on until the temperature set on the thermostat

is reached, then the light cycles off. The fryer is now ready to begin frying. After a load has

been fried, do not lower the next load into the frying. compound until the "HEAT ON" light

cycles off.

proper operation of the fryer and good frying results, the frying compound level should be

maintained. .

without overloading the tank. If 15% of the frying compound is not used during frying,

remove some of the frying compound for other use (gravy, griddle frying. etc.) to permit

adding fresh fryingcompound.

taking longer to fry than the chart shows. or are not browning. overloading is a probable

cause.

Do not use solid frying compound unless the fryer is equipped with a melt cycle

3. If the fryer is equipped with the "Automatic Melt Cycle" option, the fry tank can be filled with solid

frying compound. The melt cycle can also be used to melt frying compound which has solidified

since its last usage.

To operate the melt cycle, push the white switch marked “MELT ON" to "ON". The fryer may be left

unattended during the melt cycle operation. It takes approximately 18 minutes to melt30 Ibs. of solid

frying compound. After the solid frying compound has melted, push the melt cycle switch to "OFF".

The fryer willthen heat the frying compound to the temperatureset on the thermostat.

6. Cleaning

1. Follow General CleaningInstructions on Page 4.

a. Before the first time use, clean the protective oil from the bright parts and interior of tank with

a solution ofwashing soda or other grease dissolving material.

2. The frequency of cleaning should depend on the load conditions. Set a definite cleaning schedule

corresponding to howhard the kettle is used. Cleaning should bedone at least once a week.

a. Turn the thermostat to “OFF” and allow unit tocool down.

7

Page 8

b. Lift the elements to drain position. Wire brush or scrape elements to remove any solids

adhering to theelements.

c. Raise the elements. Lift out fry tank. Strain the frying compound into a clean container.

.

d. Replace empty frytank, lower elements to rest inside thetank.

e. Add water tothe "FULL" mark on tank.

f. Add any good grade of Cleaner,following cleaner instructions.

g. Turn the thermostat to 250°F and let the heatingunit bring thesolution to a boil.

h. Boil long enough to loosen or dissolve all varnish or carbon deposits, approximately 30

minutes.

i. Turn the unit off and lift out the elements to drain position.

j. If necessary, clean the thermostat bulbs using a long-handled fiber or plastic brush and mild

soap solution.

k. Rinse with cleanwater to remove all cleaning mixture. .

I. Lift out the fry tank and drain. Repeatsteps j and k withfry tank.

m. Rinse the insideof the tank with 2cups of vinegar.

n. Rinse with clean water until the vinegar odor is gone. The fry tank must be thoroughly rinsed,

since even atrace of cleaner left inside the tank will ruin frying compound.

o. Dry thoroughly. Replace the tank and lower the elements.

p. Shut the unit off and cover tank until ready for further use.

q. Thin films of oil subjected to frying temperatures quickly form into a gummy consistency. In

order to avoid these gum formations, keep all other surfaces of the unit clean by polishing

stainless steel surfaces with a damp cloth. To remove discolorations or oil film, a non-

abrasive cleaner maybe used.

7. SERVICE

Caution:

1.

a. Before servicing the unit, make certain the fry tank. frying compound and elements are cool

enough to avoidburns.

b. Before opening component access panels, ensure the electrical power supply cord to main

terminal block and power supply to the auxiliary terminal block BOTH have been

disconnected.

2. To replace red “ON-OFF" switch, yellow cycling light or circuit breaker, white “MELT ON” switch and

melt cycle controlassembly for melt cycle option:

a. Remove the thermostat control knob by grasping outer edge andpulling straight out, without

twisting or turning.

b. Remove two screws at topof front panel. Pull top edge to open.

c. Disconnect leads to switch, light or circuit breaker and remove the damaged component.

Mark disconnected leadsto identify them.

d. Mount the new circuit breaker (or melt cycle control) with fasteners provided. The new

switch or lightis snapped into place from the front ofthe panel.

e. Connect leads to corresponding terminals on new component. Check completed circuit

against circuit diagramon rear panel.

f. Reverse steps a and b to close front panel.

3. To replace magnetic contactor, terminal block, ground lug or auxiliary terminal block:

a. Remove four screws securing the rear panel to the unit. Let the rear panel fall down straight

before pulling itout.

b. Disconnect leads to the damagedcomponent.

c. Connect the leads to corresponding terminal on the new component.

d. Remove screws securing the damagedcomponent to themounting panel.

e. Remove the damaged. component .andinstall a new component, inthe same position.

f. Check completed circuit against circuitdiagram on rearpanel.

g. Mount the rear panel and put unit in operation.

8

Page 9

4. To replace blown fusesor fuse block:

a. Open rear panel as in step 3a above.

b. Remove damaged fuses and replacewith 40 ampereone-time fuse.

c. To replace fuse block, remove fuse and disconnect wire leads to the damaged fuse block.

Mark disconnected leadsto identify them.

d. Replace new fuse block inthe same position.

e. Connect leads to corresponding terminal on new fuse block. Check completed circuit

against circuit diagramon rear panel.

5. To replaceelement:

a. Remove screws securing pivotal head cover to pivotal head. Remove pivotal head cover

andgasket.

b. Liftup theelements todrain position.

c. Remove thermostatbulb andcapillary tubeclamps.

d. Removeelement supportassembly.

e. Disconnectleads toelement andmark themfor identification.

f. Removethe elementretaining nuts insidethe pivotalhead.

g. Removeelement. Mount the new element and reverse steps athrough f to reassemble.

6. To replace hi-limit thermostat:

a. Removepivotalhead coverand gasketas in step 5a.

b. Removehi-limit thermostat bulband capillarytube clampsfrom element.

c. Dislodge capillarybushing from hole inpivotal head.

d. Remove bushing and thread the thermostat capillary and bulb through hole in pivotal head.

e. Disconnect leads to the damaged hi-limit thermostat and transfer them to corresponding

leadson the new thermostat.

f. Removescrews securing the thermostat.

g. Secure new hi-limit thermostatwith screwsand reversesteps a through dto reassemble.

7 . Toreplace cyclingthermostat:

a. Remove front panel (steps 2a and 2b), rear panel (step 3a), pivotal head cover, and gasket

(step5a).

b. Removecover on back of end post,located onright rearcomer ofthe unit.

c. Remove thermostatcapillaryand bulbfrom the pivotal headas in steps 6bthrough 6d.

d. Disconnect nuts securing the thermostat coil to end post and to pivotal head. Both are

accessiblefrom rearof end post.

e. Disconnectleads to the damaged thermostatand markthem foridentification.

f. Removescrews securing the thermostat tofront panel.

g. Maneuver the thermostat to rear of the unit (through right side passage) and then into the

rightside end post (through opening on top panel).

h. Removethermostat along with bulb and capillary from the opening on back of right side end

post.

i. Wind the thermostat coil (supplied with new thermostat) around the capillary of new

thermostat,at approximatelythe sameposition from bulb ason thedamaged thermostat.

Note:

Thethermostat coilshould coverapproximately 11 to 12 of capillary length.

j. Wrap the portion of thermostat capillary which is covered by the thermostat coil, into

approximatelytwo turnsof 1 ½ to 2 diameter.

k Reassemble the thermostatby reversingsteps 7athrough 7h.

9

Page 10

8. TROUBLESHOOTING GUIDE

Possible Cause

Problem

10

Excessive and premature

foaming.

Greasy food/excessive frying

compound absorption.

“Objectionable” odor or flavor

of frying compound.

“Objectionable” flavor of fried

food.

Excessive smoking of frying

compound.

Excessive darkening of frying

compound.

Frying compound won’t hold

heat.

Food crust color not brown.

Rapid breakdown of frying

compound.

Frying temperature too

X

X

X

X

high/overheating. (Check thermostat)

Frying temperature too low.

X

X

X

(Check thermostat)

X

X

XX

X

X

X

X

X

X

X

Inadequate frying compound

fried.

turnover.

X

XX

X

XX

X

X

X

X

X

X

Improper preparation of food.

Contamination of frying compound.

(Due to salt or other foreign material)

X

X

X

X

Frying in foam.

Food being fried may be of poor

XX

X

(Either initially or after excessive use)

Cooking time too short.

Inadequate filtering of frying compound.

Excessive crumbs in fry tank

X

Keeping food in frying compound

Inadequate cleaning of fry tank.

after cooking.

X

Poor quality of frying compound

Drip-back from exhaust stack.

quality.

X

X

X

X

X

X

X

X

X

X

XX

X

X

X

X

X

X

X

X

X

X

X

X

X

XXX

High moisture content in food being

Improper draining of food after frying.

Overloading the fry tank.

Page 11

9. SUGGESTED TEMPERATURES & TIMES

CONTROL

FOOD

DOUGHNUTS

Cake Type 375° 1½-2

Yeast Raised 375° 2-2½

MEAT

Cutlets (Less than 1/2” thick) 350° 5 - 8

Chicken Fried Steak 350° 5 - 8

Chops (Very lean) 350° 5 - 8

MISCELLANEOUS

Chinese Noodles 375° 1 - 2

Croquettes 350° 2 - 3

French Toast 350° 2 - 3

Glazed Cinnamon Apples 300° 5 - 10

French Fried Sandwiches 350° 1 - 2

POULTRY

Chicken (Large pieces) 325° 10 - 15

Chicken (Small pieces) 350° 7 - 10

Chicken (Pre-cooked) 325°-350° 3 - 5

Turkey (Small pieces) 325° 9 - 10

SETTING

(FAHRENHEIT)

TIME IN

MINUTES

CONTROL

FOOD

SEAFOOD

Fish Cakes 350° 2 - 3

Clams 350° 1 - 3

Fillets (Small) 350° 3 - 5

Oysters 350° 2 - 5

Scallops 350° 3 - 5

Shrimp 350° 4 - 6

Smelts 350° 4 - 6

VEGETABLES

Egg Plant 350° 5 - 7

Onion Rings 350° 3 - 5

Potatoes

(1/2” Strips, one-operation) 350° 6 - 9

Potatoes (Blanch) 350° 4 - 6

Potatoes (Brown) 350° 2 - 3

Potatoes (Julienne) 350° 3 - 5

SETTING

(FAHRENHEIT)

TIME IN

MINUTES

11

Page 12

10. REPLACEMENT PARTS LIST & EXPLODED VIEWS

Item

Part Number

Description

Quan

Item

47

48

49

50

51

52

54

55

58

59

60

61

62

66

67

68

69

70

71

72

72a

73

74

75

76

77

78

79

80

83

84

86

87

88

89

90

91

92

95

96

97

Part Number

81624-00

84029-00

86321-00

84555-00

85075-00

83266-00

31007-97

88370-02

88370-15

88370-18

88370-26

88370-66

88370-67

31007-22

11072-02

11072-03

11964-02

13016-03

13016-16

14044-03

14044-04

14798-04

14798-05

15016-00

15030-05

15030-06

15037-03

15125-04

84236-01

81971-00

84237-00

84131-00

81411-00

88370-68

11141-00

820547-00

81459-00

84091-00

300465-50

820351-30

83530-00

Description

H.H.C.S. 10-24 X 1/2" S.S.

HEX NUT 6-32

LEGS

NUT,

5/S"-lS

FLAT WASHER, 1/4"

POP RIVET 1/8" X 1/8" S.S

MARKER, SUPPLY

MARKER, DISCONNECT

LABEL, GROUND WRNG

LABEL, RESET

WIRING DIAGRAM

LABEL

LABEL, FUSE WARNING

CONTACTOR, MAGNETIC

BLOCK, TERMINAL

BLOCK, TERMINAL

WIRE CONNECTOR

SWITCH, LIGHTED P/B

SWITCH, HIGH LIMIT

ELEMENT, 6000W 208V

ELEMENT, 240 V

THERMOSTAT

SPRING, THERMOSTAT

WIRE TIES

FUSE BLOCK

FUSE

CIRCUIT BREAKER

INDICATOR LIGHT, AMBER

NUT "U" #10 ZN

#10 X 3/8" SHT MET SCREW

#10-24 HEX NUT S.S.

TINNERMAN NUT

M/S PN HD 8-32 X 1/2 S/S

LABEL, CONNECTION

SOLDERLESS LUG

CAP BULB CLAMP

M/S 8-32 X 1 S/S RD

NUT 8-32 HEX MET LOCK

GRAPHICS APW WYOTT

INSULATION

RIVET POP 1/8" X 15/64" S/S

ELASTIC STOP

Quan

8

10

4

1

8

20

1

1

1

2

1

1

1

2

1

1

7

1

1

2

2

1

1

2

2

4

1

1

2

6

23

2

15

1

1

1

2

2

1

1

2

12

Page 13

EXPLODED VIEW

13

31

50

LH

27

26

8

34

33

35

32

RH

19

44

20

84

13

Ref.

8

7

33

22

46

91

25

47

4

37

71

38

90

2

72

72

5

52

80

23

44

92

16

44

52

10

51

6

97

96

83

11

14

17

29

84

1

84

11

3

44

5

28

39

52

Page 14

EXPLODED VIEW

14

12

87

66

66

REAR VIEW

68

76

77

61

89

62

76

46

39

46

88

24

84

43

48

42

40

48

Bulb to Element Attachment

LH Side Shown.

RH Side Mirror Image

78

44

40

59

73

95

FRONT VIEW

74

16

Top of Bull Nose

to Bottom

of Decal 4 5/32”

15

41

36

60

55

83

54

58

67

44

79

70

Page 15

15

11. WIRING DIAGRAM

Page 16

12. APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owneronlyand is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same. The closestAPWWyottAuthorized ServiceAgent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment locatedonany island not connected by roadway tothemainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas ofAlaska and Canada

may vary.ContacttheinternationalAPWWyott distributor, dealer, or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inall cases, parts covered by extended warrantywill be shipped FOB the factory after thefirstyear.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott'soptionoritsAuthorized ServiceAgency, it will be serviced on site orreplaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs. Nomileage or travel charges are allowed on portable unitsafterthe first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers andcookers, which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions are not coveredbywarranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime orpremium labor rates, the owner shallbechargedfor the difference between normal servicerates and such

premium rates.APWWyottdoes notassumeany liability for extended delays inreplacingorrepairing any items beyond its control.

Inall cases, the use of other thanAPWWyottAuthorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only.Warranty is void if equipment is installed inotherthancommercial application.

WaterQualityRequirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT.IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATEDHEREIN.

*Gas/Electric Cookline:

component parts, except switches andthermostats. (2 additional years on parts only.No laboronsecond or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, LightBulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery orinstallation, fire, flood, riot or act of god.

*Equipment that has the model number orserialnumber removed or altered.

Models FD, FDL, FDD, FDDL. Two(2)YearWarranty on element only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

RockGrates,CookingGrates,BurnerShields,Fireboxes:

90Day Material Only. No Labor.

90DayMaterialOnly.NoLabor.

9/05

16

Loading...

Loading...