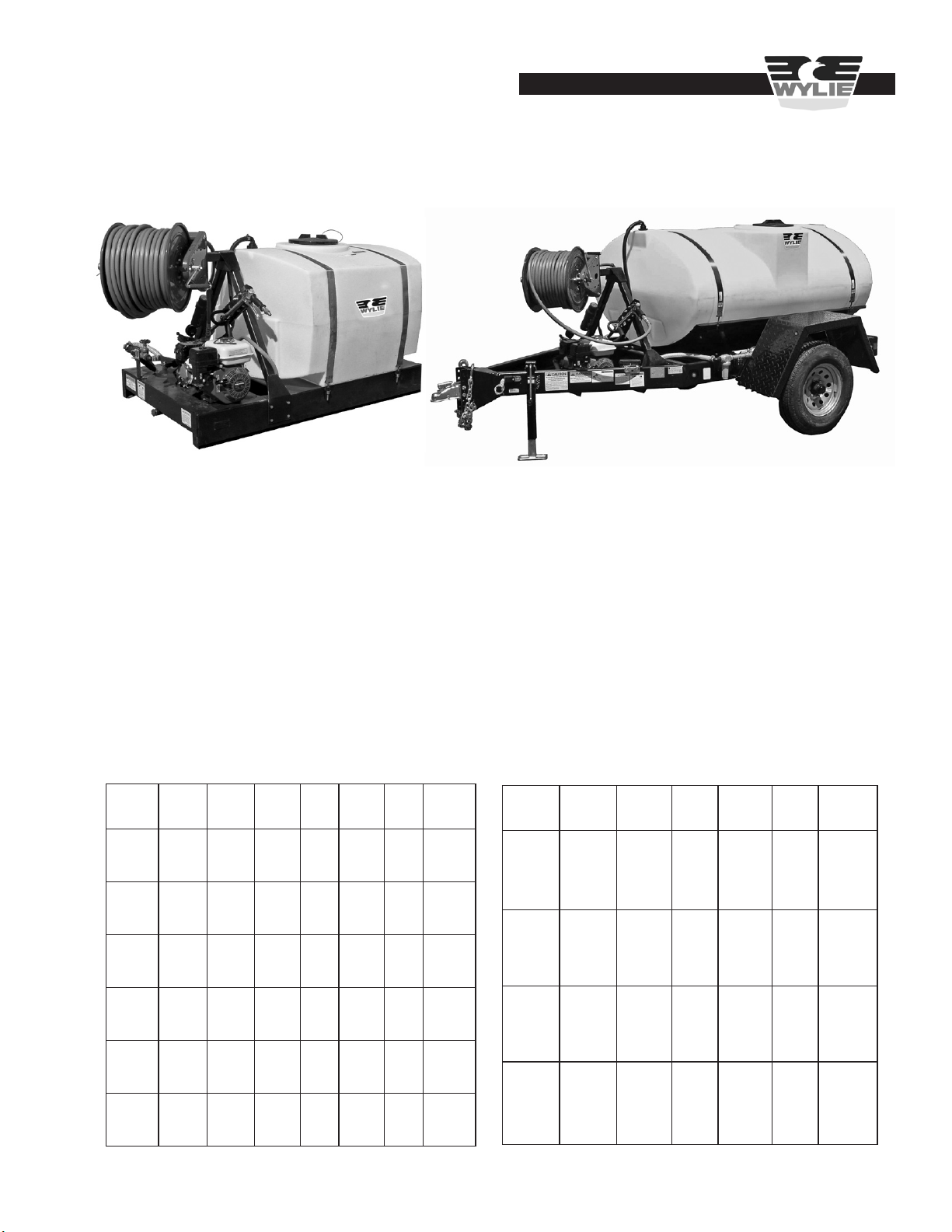

Power Sprayer Skid & Trailer

Operator’s & Parts Manual

5-15-19 02-024R5

Printed In The USA — Specications & Design Subject To Change Without Notice!

Warranty Information

A Message To The Owner And Operator

This equipment was carefully designed and manufactured to give you dependable service. To insure ecient operation of

this equipment, please read this operator’s manual carefully. Check each item and acquaint yourself with the adjustments

required to maintain optimum performance and operation. Remember, this equipment’s performance depends on

how you operate and care for it!

At the end of each season, thoroughly clean and inspect your equipment. Preventive maintenance saves time and pays

dividends. Your nearest Wylie Spray Center has original equipment parts which assure proper t and best performance.

Record your equipment’s model and serial numbers and the date you purchased this equipment in the space below.

Have this information available when you order parts or attachments.

Model Number:

Serial Number:

Date Purchased:

Limited Warranty

This is a limited warranty. It covers products manufactured by WYLIE Mfg. Co. The Warrantor is WYLIE Mfg. Co., 702 E. 40th

St., Lubbock, TX, 79404, USA. The duration of the warranty for WYLIE manufactured equipment and products (excluding

polyethylene tanks) is for one year from date of delivery to the carrier. The Warrantor warrants to the Buyer that the product(s)

sold hereunder are free from defects to material and workmanship, under normal use and service, in the hands of the original

buyer.

If goods are defective, the defective goods will be replaced with identical goods. If identical goods are not available, the Buyer

may elect to receive a refund of the purchase price for the defective goods, or the Buyer may order similar goods. The damage

for defective goods shall not exceed the purchase price of the defective goods. No allowance shall be made for labor

or expense or repairing goods without prior approval in writing by the Warrantor. The Buyer’s remedy under this warranty

does not include incidental or consequential damages.

For products not manufactured by the Warrantor, the Warrantor warrants these products to the extent of the warranties of their

respective manufactures. There are no warranties which extend beyond this limited warranty, including the implied

warranty of merchantability. Dealers or representatives shall not make any representation in regard to particular goods except

as authorized by the Warrantor through a written warranty accompanying those particular goods.

Disclaimer of Warranty

WYLIE Mfg. Co., and its divisions, “Wylie Spray Centers,” in each location, requires as a condition of sale and coverage by its

LIMITED WARRANTY that all equipment sold by it be used in accordance with the instructions and specications of the Warrantor.

This requirement is in addition to the LIMITED WARRANTY.

Polyethylene and berglass tanks – These tanks are warranted for the storage and transport of water, herbicide solutions

(on farm), liquid fertilizer and liquid feed. Such tanks should not be used for the storage of any bulk herbicide (undiluted). Any

such use will render this warranty void.

In addition, the Warrantor makes no warranty with regard to bulkhead tank ttings used in connection with tanks containing bulk

herbicides and the use of any such ttings sold by the Warrantor or any WYLIE dealer in connection with tanks containing bulk

herbicides is improper.

Chemical Incompatibility – The Warrantor does not make any recommendations or warranties regarding chemical compatibility.

WYLIE shall not be liable for any damages due to chemical incompatibility, and any Buyer or user should rely solely on written

information furnished by the chemical manufacturer regarding chemical compatibility.

No employee of WYLIE Mfg. Co., or its representatives, agents or dealers, is authorized to vary the terms of this limited

warranty.

Wylie Manufacturing Company

702 E. 40th St.

Lubbock, TX 79404

Ph. 888-788-7753

Power Sprayer Skids and Trailers

Date of Purchase

Owner Registration

Model Number

Skid/Trailer Serial Number

Tank Serial Number

Pump Model

Wylie Invoice Number

Owner’s Name

Address

City State Zip

Phone

Email

Dealer

Primary Use of Applicator:

Herbicide Pest

Sprayer Control

Livestock Tree

Sprayer Sprayer

De-Icing Other

Owner’s Signature

Must be returned within 10 days to validate the warranty.

-- Or Register Online --

Go to: www.wyliesprayers.com

.

Table of Contents

Table Of Contents

Safety Issues .............................................................................................................................................................2-3

Reporting Safety Defects.............................................................................................................................................. 3

Safety Decals & Placement ..........................................................................................................................................4

Introduction ................................................................................................................................................................... 5

Inspection & Setup ....................................................................................................................................................6-8

Sprayer Operation ...................................................................................................................................................9-12

Maintenance ............................................................................................................................................................... 13

Troubleshooting Guidelines ........................................................................................................................................ 14

Tire Safety Information ........................................................................................................................................15 - 25

Repair Parts.........................................................................................................................................................27 - 50

Power Sprayer Trailer Frame ...........................................................................................28

Trailer Pump and Plumbing .............................................................................................. 29

Power Sprayer Skid Frame .............................................................................................. 30

Skid Pump and Plumbing ................................................................................................. 31

Twin Reel Skid Frame ......................................................................................................32

Twin Reel Skid Plumbing ..................................................................................................33

Wiring Schematic .............................................................................................................34

Brakes & Lights ................................................................................................................ 35

Axles ..........................................................................................................................35 - 36

Hose Reel ..................................................................................................................37 - 40

CDS-John Blue Pump ...............................................................................................41 - 44

Hypro Roller Pump ...........................................................................................................45

AR Diaphragm Pump ................................................................................................46 - 49

Ace Centrifugal Pump ......................................................................................................50

1

Safety Issues

Safety Precautions

Be alert when you see the above symbol in the manual. It warns of a hazard

which might lead to injury. It means: Attention! Become alert! Your safety is

Involved!

Three (3) words (Danger, Warning, and Caution) are associated with this symbol.

DANGER – Indicates a hazardous situation, which, if not avoided, will result in death or serious injury. This signal word

is to be limited to the most extreme situations.

WARNING – Indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

CAUTION – Indicates a hazardous situation, which, if not avoided, may result in minor or moderate injury.

NOTICE – Indicates information considered important, but not hazard-related (e.g., messages relating to property damage).

SAFETY INSTRUCTIONS - Indicates a type of safety sign where specic safety-related instructions or procedures are described.

Before Use

Do not operate sprayer until this manual has been read and understood!

* Thoroughly read and understand all instructions before operating this sprayer. If you have questions,

please contact Wylie Manufacturing, 702 E. 40th St., Lubbock, TX, 79404. (888) 788-7753.

You can also contact your nearest Wylie Spray Center.

* Always wear safety goggles, chemical resistant apron and rubber gloves when handling chemicals.

* Read and understand the chemical manufacturer’s safety guidelines on handling, mixing and application.

* Secure the skid to the bed of the truck to prevent the sprayer from sliding o the truck.

* Always check where you are going to spray. Be sure that people, non-targeted animals, etc. are not in the

path of the spray or overspray.

* Check on wind speed and direction. Make sure that sprayed chemical will not drift to non-target area.

During Use

* Do not allow anyone to ride on sprayer during operation. Falling can cause injury.

* Reduce speed when crossing uneven or rough terrain.

* Always turn o engine before making adjustments or repairs.

* Do not point the gun toward people. Trigger might be accidentally engaged, exposing people to chemical.

* Never add gasoline to an engine that is running. Turn o engine and let cool for several minutes before

adding fuel. Adding gasoline to an operating engine could cause an explosion and re resulting in serious

injury or death.

2

Safety Issues

After Use

* Inspect sprayer for wear or damage.

* Ensure that all fasteners and ttings are tight.

* Flush tank and pump with fresh water. Dispose of ush water using appropriate means.

* Carry out maintenance and/or lubrication procedures as outlined in this manual.

* During cold weather, ush the pump and plumbing with an anti-freeze solution to prevent freeze damage

to components.

Always

* Keep hands, feet and clothing away from moving parts.

* Wear protective clothing and gloves when working with chemicals.

* Assure that the hitch is attached to the proper size ball.

* Attach the safety chains and breakaway brake cable to the tow vehicle.

* Plug the lights into the tow vehicle.

Operator’s Instructions

* Reduce speed when turning, crossing slopes and on rough, slick or muddy surfaces.

* Do not permit others to ride on sprayer.

* Roll up hoses and secure trigger gun before transporting sprayer.

* Take care to prevent spilling of chemical.

* Know where you are going to spray. Do not spray non-targeted areas.

Wylie Manufacturing, 702 E. 40th St., Lubbock, TX 79404

Reporting Safety Defects

If you believe that your vehicle has a defect which could cause a crash or could cause injury or death, you should

immediately inform the National Highway Trac Safety Administration (NHTSA) in addition to notifying Wylie

Manufacturing.

If NHTSA receives similar complaints, it may open an investigation, and if it nds that a safety defect exists in a

group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your dealer, or Wylie Manufacturing.

To contact NHTSA you may either call the Auto Safey Hotline toll-free at 1-888-327-4236 (TTY: 1-800-424-9153);

go to http://www.safercar.gov; or write to:

NHTSA

U. S. Department of Transportation

12000 New Jersey SE

Washington, DC 20590

You can also obtain other information about motor vehicle safety from the http://www.safercar.gov.

3

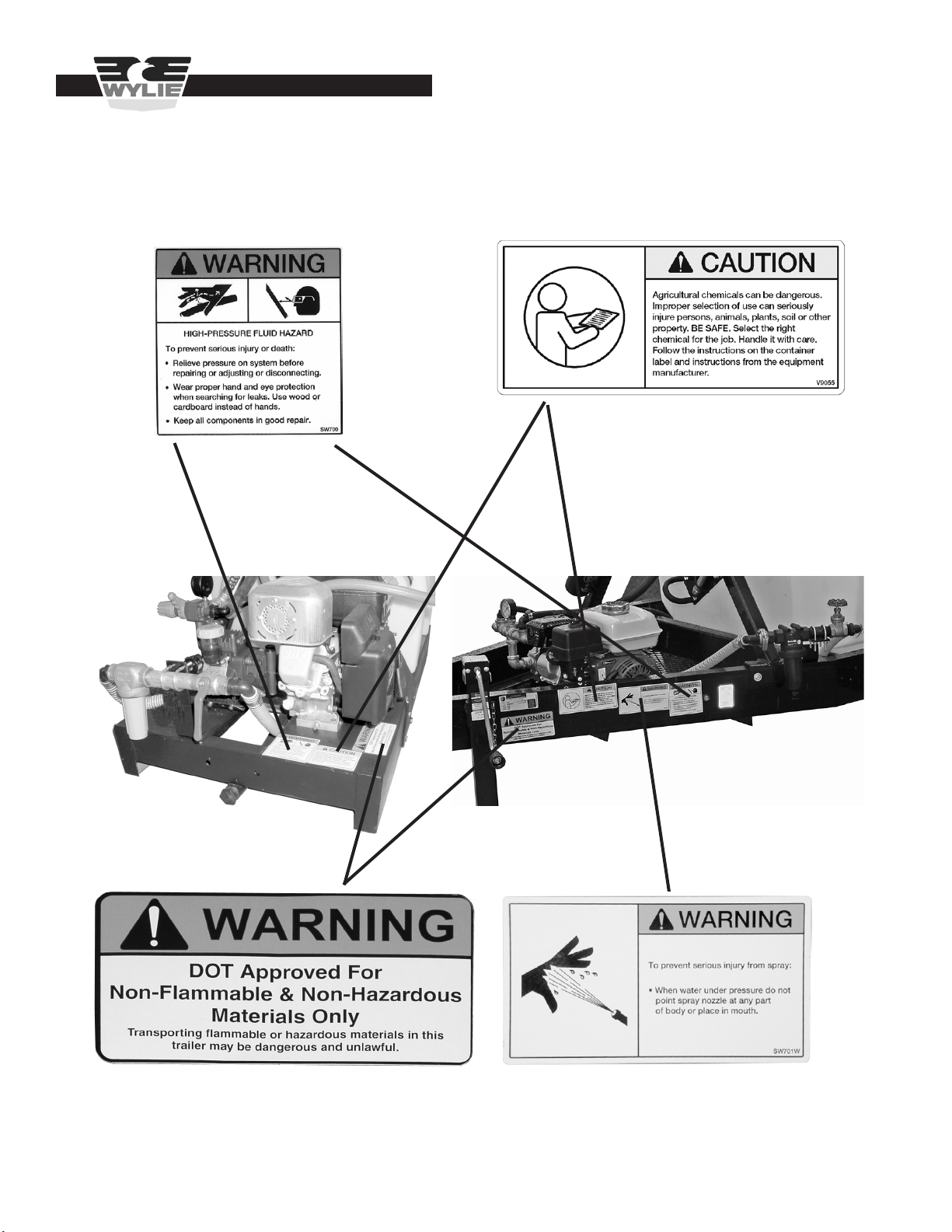

Safety Issues

Safety Decals & Placement

Power Sprayer Skids and Trailers

Decal #V9055

Decal #SW700

Decal #V9020

Contact us at mail@wyliesprayers.com or 888-788-7753 to order safety decal

or manual replacements.

4

Decal #SW701W

Introduction & Specs

Introduction

The Wylie Power Sprayer Skids and Trailers are the result of years of testing and eld proven experience. They are

built of the nest materials and expert workmanship to provide you with years of reliable service. The Power Sprayer is

available in either a skid or trailer version, in capacities from 50-500 gallons.

The Power Sprayers are designed to be versatile sprayers in the areas of landscape spraying, pest control, livestock

spraying, tree spraying, washing and cleaning, remote spot watering, de-icing and a host of other uses.

This manual explains where and how to make necessary adjustments to your sprayer for safe and proper operation.

Thoroughly read and understand the contents of this manual before operating your sprayer. If you have questions or do

not understand particular items, contact your nearest Wylie Spray Center or call Wylie Manufacturing at (888) 788-7753.

Please keep this manual handy to answer questions you may have as they arise.

Pay Particular Attention To All Safety Suggestions – Their purpose is to assure safe operation of the sprayer and

prevent injury or damage to yourself or the unit.

Power Sprayer Skid Specications Power Sprayer Trailer Specications

Model Capacity

PS50 50 50” 63” 27” 27” 41” 270 lb

PS100L

PS100

PS200 200 67” 80” 40” 44” 44” 420 lb

PS300F 300 60” 61” 65½” 68” 62” 535 lb

(gal.)

100

100

Frame

Length

68”

51½”

Overall

Length

w/reel

81”

64½”

Frame

Width

29½”

47½”

Overall

Width

31½”

47½”

Height Empty

Weight

41”

320 lb

41”

330 lb

Model Capacity

(gal.)

Overall

Length

Track

Width

Overall

Width

Height GVWR

PS100T 100 118” 53½” 61” 56” 2,350 lb

PS200T 200 116” 64” 72” 58” 2,950 lb

PS300T 300 140” 64” 73” 59” 4,100 lb

PS300 300 95½” 110” 37½” 51” 41” 700 lb

PS500 500 101” 115½” 48” 57” 46” 805 lb

PS500T 500 147” 66” 78” 62” 5,975 lb

5

Inspection & Setup

Inspection & Setup

Your Wylie Power Sprayer was manufactured to the highest standards of quality. It is necessary though, to check

to make sure that nothing was damaged during shipping.

Check bolts and fasteners for tightness, especially lug

nuts. Check the motor/pump, plumbing and hose reel for

any signs of damage.

Your Wylie Power Sprayer was completely assembled at

the factory and should not need any additional assembly

before use.

Check the engine for proper oil level (see engine owner’s

manual for proper procedure).

Skid sprayer must be secured to the bed of the truck.

Failure to do so could result in the sprayer falling o

the truck or damage to the sprayer and truck.

Carefully set the skid on the truck bed or slide the skid

between the wheel wells of a pickup. It is suggested that

the tank is positioned close to the cab for best weight

distribution as well as better accessibility to the engine

and hose reel.

Mounting Skid on Truck/Pickup

Make sure that the vehicle that will carry the skid Power

Sprayer is designed to carry the unit when full of water. Water

weighs 8.34 lb/gal. Therefore, a 500 gallon Power Sprayer

skid can weigh almost 5,000 lbs. when fully loaded.

Figure A1

Mounted Skid Sprayer in Truck

Use caution when picking up the skid from the side.

Assure that the center of gravity is between the

forks of a forklift to prevent tipping.

Firmly secure the sprayer to the vehicle to prevent damage

to the sprayer or vehicle.

Figure A2

200 Gallon Skid Properly Mounted With Tailgate Closed

Attaching Trailer to Vehicle

Power Sprayer trailers require a 2” ball for proper t. Open

the 2” hitch by depressing the trigger and rotating the hitch

handle upward until the hitch locks open. Align the truck

under the hitch and lower the hitch onto the ball by rotating

the jack handle counterclockwise. Rotate the hitch handle

until the trigger locks in place. Secure the hitch handle

with a clip pin. (See Figure A3)

When picking up a skid sprayer from the side, be aware

that the center of gravity is not at the center of the frame

due to the weight of the engine and pump.

DOT regulations in some states require the safety

chains to be crossed. Check the regulations in your

state for specic instructions.

Attach the safety chains to the eyelets.

6

Hitch Handle >

< Trigger

Figure A3

Rotate Lock Tab To Open 2” Hitch

Electric brake trailers have a battery powered breakaway

brake system that activates the trailer brakes if the trailer

becomes unhitched from the truck while travelling. Attach

the brake cable to the hitch.

Inspection & Setup

A seven prong plug is provided with the trailer. If your

vehicle is not equipped with a corresponding receptacle,

change either the vehicle or trailer to match. If your vehicle

does have a seven prong receptacle, insert the trailer plug

and check to make sure that the two plugs are properly

matched i.e. brakes, lights and turn signals operate in the

correct order.

The DOT trailer is equipped with a breakaway brake kit that

will engage the electric trailer brakes if the trailer comes

unhooked from the truck. The breakaway brake kit consists

of a battery that is charged by the electrical system and an

engaging switch that is activated when a plug is pulled from

the switch by a cable. The breakaway brake cable should

be attached to the truck.

< Electric Cable

Crossed >

Safety

Chains

< Clip Pin

Breakaway >

Brake System

< Breakaway

Brake Cable

Figure A4

Trailer Hitch Details

Plug the light cable into the truck light socket. Check the

lights to make sure that the clearance, turn, brake and tail

lights are working properly.

Pull the jack pin and rotate the jack or remove the jack

from the mount collar.

The Wylie DOT tag trailer is equipped with a height adjustable hitch. The trailer should travel level when the tank is

full. To level the hitch, lower the jack to support the tongue,

remove the hitch bolts, adjust the tongue height as needed,

and reinsert the hitch bolts.

Figure A5

Test Button on Breakaway Brake System

The breakaway brake system is equipped with a test button and lights to show the status of the breakaway system

battery. Depress the test button to see the status.

Electric Hose Reel

If your sprayer is equipped with an electric hose reel, you

may or may not need additional set-up. Sprayers that

include an electric start engine will have the reel wired to

the sprayer motor battery and will not need any additional

set-up.

Sprayers with a pull start engine will require an auxiliary

power source for the electric hose reel. If an optional battery was ordered with the sprayer, the necessary wiring

has been completed and the reel is ready for operation.

7

Inspection & Setup

Powering the electric hose reel through the trailer

electrical system can damage the trailer wiring.

Connect to vehicle battery with 4 gauge cable.

The hose reel can be powered by the vehicle battery. It

will be necessary to route 4 gauge battery cables from the

reel to the vehicle battery. Do not try to power the hose

reel directly through the trailer electrical system. The wires

are not heavy enough to carry the current. A charger for

an auxiliary battery can be powered through the trailer

electrical system.

Inspecting Motor and Pump

Check the oil level in the gasoline engine before initial startup. Some pumps such as the CDS/John Blue diaphragm

pumps have an oil bath crankcase. Check the oil level in

the sight glass to assure proper operation.

Initial Start-up of CDS/John Blue Diaphragm

Pump

Open the pressure hose ball valve and the agitator ball

valve. Rotate the blue by-pass handle counter-clockwise

so that the pump is in full by-pass.

Pressure Hose >

By-Pass Hose >

By-Pass Control Handle >

Agitator Hose >

Initial Start-up

Add enough water to the spray tank to get above the level

of the strainer and ball valve. Do not add any chemical

to the spray tank until the sprayer has been checked

for proper operation.

Open the ball valve between the tank and pump to allow

water to ow to the pump. The valve is open when the valve

handle is in line with the valve. Inspect the system for any

leaks. Tighten any ttings necessary to stop any leaks. Any

water leaking from supply lines before the pump is started,

will result in an air leak when the pump is engaged, resulting in low operating pressure.

< Strainer

< Supply Valve (in “o” position)

< Pressure Regulating

Control Knob

< Discharge Ball Valves

Figure A7

Discharge Controls

Remove the trigger gun from the gun holder and start the

engine. Engage the trigger gun and allow water to ow

through the whole system. The pressure may not rise to the

desired level until the pressure regulating valve is adjusted.

Once the system has been checked for any leaks in a low

pressure setting, the sprayer can be changed to high pressure operation. Close the agitator ball valve and rotate the

blue by-pass control handle clockwise to the “pressure” setting. Rotate the pressure regulating control knob to adjust

the pressure. Screw the knob “in” to increase the pressure.

Check the system carefully for any leaks. Tighten ttings

as necessary.

Figure A6

Supply Valve & Strainer

8

Operation

Operation

Adding Chemical

Many applications for Wylie Power Sprayers require chemical agents to be added to a carrier solution.

Protective clothing and equipment must be worn

any time chemicals are being handled. This may

include, but not be limited to, rubber gloves, rubber

apron, face/eye shield, and respirator. Failure to use

protective clothing could result in chemical

exposure causing sickness or death.

Read the chemical manufacturer’s label for directions for

the proper procedure and amount of chemical to add. Once

the chemical has been added to the spray tank, start the

pump in by-pass mode to allow the chemical to thoroughly

mix. (See “Operation” section for detailed instructions.)

Swivel Hose Reel

All of the hose reels are mounted on a 180º swivel. This

swivel can be locked in one of ve positions or the pins

can be removed to allow the reel to swivel freely.

The Coxreel reels are equipped with a lock pin to prevent

the reel from unrolling during transport. Set the lock pin in

the unlock position before unrolling the hose.

< Lock Pin

Figure B2

Hose Reel Lock Pin

Operation

Check the area to be sprayed to make sure that people or

non-targeted animals will not be in the path of the spray

or drift.

If hazardous chemicals are being sprayed, protective

clothing should be worn for protection from chemical

exposure.

Figure B1

Swivel Hose Reel Mount

Never point the spray toward any part of your body.

The high pressure discharge could cause

serious bodily injury.

Operation of CDS/John Blue Diaphragm Pump

Always open the main tank valve before starting the engine

and pump. Running the pump without uid will quickly

damage the pump.

Figure B3

Open Main Tank Valve

9

Operation

Always start the engine with the pump in the bypass mode.

Rotate the blue bypass handle counterclockwise to put the

pump in the bypass mode.

Figure B4

Bypass Valve

Starting procedures will vary for dierent engines (see engine owner’s manual). The Honda manual start engine is

very popular on the Wylie Power Sprayers. Turn the engine

switch “on” before pulling the rope to start the engine.

Once the chemical is thoroughly mixed, close the agitator valve. Remove the trigger gun from the storage frame

and unroll a sucient length of pressure hose. Open the

pressure hose ball valve.

Figure B7

Open Pressure Ball Valve

Change the pump from bypass mode to pressure mode by

rotating the blue handle clockwise.

Figure B5

Honda Engine Start Switch

If chemicals need further mixing in the tank, open the

agitator ball valve.

Figure B6

Open Agitator Ball Valve

Figure B8

Change To Pressure Mode By Rotating Clockwise

Adjust the pressure by turning the pressure adjustment

knob. Screw the knob “in” to increase pressure, “out” to

decrease pressure. The maximum pressure built by the

CDS/John Blue diaphragm pump in 580 psi. Do not set

the pressure above 600 psi.

10

Figure B9

Adjusting Pressure

The agitator valve can be partially opened, if desired,

to keep the chemical in suspension. Opening the valve

completely, though, will prevent spraying at maximum

pressure.

Operation

Special Operating Instructions For Twin Tank

Power Sprayers

If agitation is used, it is imperative that the suction

and agitator valves be open for the same tank.

Failure to do so could mix the chemicals and

overow the agitated tank.

The Twin Tank Power Sprayers are equipped with separate

agitator systems for each tank. Open the suction ball valve

for the desired tank. To prevent contamination between the

tanks, make sure that only one suction valve is opened at

a time. Opening both valves, especially when the pump is

turned o, will allow uid to ow between the tanks until

the volume is equalized.

Operating Other Pump Styles

Other pump styles are available for the Wylie Power Sprayers such as roller and centrifugal pumps. The controls for

the roller pump will be similar to the diaphragm pump, i.e.

an adjusting valve varies pressure and provides bypass.

The centrifugal pump has an agitator valve. The primary

point to remember is that the main tank valve must be open

to feed uid to the pump and any air leak on the suction

side of the pump will prevent the pump from achieving

operating pressure.

Operating The Trigger Gun

The Hypro Long-Throw trigger gun sprays in a range from

a powerful straight stream to a wide angle mist. The rear

trigger handle turns the spray on or o. The front handle

adjusts the angle of the spray by rotating the handle forward

or backward. Pulling the handle back creates a straight

stream. Push the handle forward for a wide angle spray.

Left Tank Suction Valve >

Main Suction Valve >

< Right Tank Suction Valve

< Right Tank Agitator Valve

< Left Tank Agitator Valve

Figure B11

Twin Tank Suction & Agitator Valves

When the pump is operating and agitation is desired,

make sure that the agitator valve and suction valve for the

same tank are open. Opening the wrong agitator valve will

contaminate the tank being agitated and could overow

that tank.

Figure B10

Handle Back -- Straight Handle Forward -- Wide Angle

11

Operation

A variety of options can be added to the Power Sprayer

for specic applications.

Walking Boom

The walking boom can be quick coupled to the pressure

hose for even applications on lawns and landscape. Check

the TeeJet nozzle manual for recommended pressure and

tip selection for specic applications. Generally, broadcast

spraying requires less than 50 psi.

Figure B12

Walking Boom

The walking boom can be adjusted for proper boom height

and folded for easy access through gates.

Flat Fold Boom

The at fold boom mounts to the receiver hitch on many

pickups. The Power Sprayer trailers have mounting holes

for a at fold boom mount. The at fold boom height can be

adjusted with several holes in the mount tube. The boom

is equipped with breakaway springs to protect the boom

when an obstruction is hit as well as to fold the boom for

transport. To unfold the boom for spraying, manually unfold each section of the boom 180º, then unfold the outer

extensions vertically.

Fresh Water Tank

A fresh water tank is designed especially for the twin tank

power sprayer but can be mounted to other models as well.

The fresh water tank features a spigot for hand washing.

Additionally, the fresh water tank can ush chemical from

the tank and lines when two chemicals are stored in the

twin tanks. Close the tank ball valve and open the fresh

water tank valve. Start the engine and pump fresh water

through the system.

Figure B14

Fresh Water Tank

End of Day Procedure

Some chemicals may require the pump to be ushed at

the end of each day to prevent corrosion. If so, add several

gallons of fresh water to the spray tank and pump through

the system. Check the oil level in the engine and pump

as well as for any loose or damaged ttings. Repair as

necessary.

End of Season Procedure

Figure B13

Flat Fold Boom

Check the TeeJet nozzle manual for recommended pressure and tip selection for specic applications. Generally,

broadcast spraying requires less than 50 psi.

The sprayer must be protected from freezing during winter

months. If the sprayer is not to be used, drain the spray

tank and add an anti-freeze solution. Start the pump and

circulate the anti-freeze solution through the sprayer. Simply draining water from the spray tank will not adequately

protect the sprayer from freezing.

12

Maintenance

Maintenance

Strainer Maintenance

From time to time it may be necessary to clean the strainer

of debris that has collected. Low pump pressure and

volume is an indication that the strainer is clogged and

needs cleaning.

Figure C1

Removing Strainer

With the engine shut o, close the suction ball valve and

remove the strainer bowl. Empty and rinse the bowl and

clean the screen as needed. Make sure the O-ring that

seals the bowl to the base is not lost when the bowl is

removed. Firmly hand tighten the bowl to the base and

open the suction ball valve.

Engine/Pump Maintenance

The engine and pump each has an owner’s manual printed

by the respective manufacturer that has been included

with this manual. If you did not receive a pump or engine

manual, contact Wylie Customer Service at 888-788-7753

to request a manual.

Refer to the manufacturer’s manual for recommended

service and maintenance.

Spray Tank

The spray tank may be manufactured from either natural

white or “algae resistant” black resin. If water only is to be

sprayed from a white tank it may be necessary to add a

small amount of bleach to the tank to prevent the growth of

algae which will discolor the interior of a white tank.

13

Troubleshooting

Troubleshooting Guidelines

Problem Cause Solution

Engine Will Not

Operate

Pump Will Not

Operate

Pump will not

move solution

Pump output is

very low; erratic

(1) Engine out of gasoline

(2) Engine controls not set properly

(3) Malfunctioning engine

(1) Malfunctioning pump

(1) Spray tank empty

(2) Tank ball valve closed

(3) Plugged strainer

(4) Malfunctioning pump

(1) Spray tank low; air getting in pump

(2) Tank ball valve partially closed

(3) Plugged strainer

(4) Collapsed suction hose

(5) Air leak in suction system

(6) Control bypass engaged

(7) Pressure control knob set too low

(8) Malfunctioning pump

(1) Add gasoline to fuel tank

(2) See manufacturer’s manual

(3) See manufacturer’s manual

(1) See pump owner’s manual or contact Wylie

(1) Fill tank

(2) Open ball valve

(3) Clean strainer screen

(4) See pump owner’s manual or contact Wylie

Spray Center

(1) Fill tank; bleed air by removing top plug

(2) Open ball valve

(3) Clean strainer screen

(4) Replace suction hose

(5) Tighten ttings;

Check for cracked or cut components;

Apply thread sealant to pipe threads.

(6) Close “blue” bypass lever

(7) Screw pressure control knob “in” to increase

pressure

(8) See pump owner’s manual or contact Wylie

Spray Center

No output or

insucient

pressure at

spray tip(s)

Hypro trigger

gun spray pattern is incor-

rect

(1) Air leak in suction side of system

(2) Problem with pump

(3) Control valve malfunctioning

(4) Control bypass engaged

(5) Pressure hose ball valve closed

(6) Spray tips not proper size

(1) Front handle in wrong position

(1) See above

(2) See above

(3) Replace pressure adjusting valve;

See controller owner’s manual or

contact Wylie Spray Center

(4) Close “blue” bypass lever

(5) Open pressure hose ball valve

(6) Replace with proper tip

(1) Pull front handle “back” for straight stream

Push front handle “forward” for wide stream

14

Tire Safety Information

Tire Safety Information

1. TIRE SAFETY INFORMATION

This portion of the User’s Manual contains tire safety information as required by 49 CFR 575.6.

Section 2.1 contains “Steps for Determining Correct Load Limit - Trailer”

Section 2.2 contains “Steps for Determining Correct Load Limit – Tow Vehicle”

Section 2.3 contains a Glossary of Tire Terminology

pressure”, “recommended inflation pressure”, and other non -technical terms.

Section 2.4 contains information from the NHTSA brochure entitled “Tire Safety – Everything Rides On It”.

This brochure This brochure, as well as the preceding subsections, describes the following items;

Tire labeling, including a description and explanation of each marking on the tires, and information

about the DOT Tire Identification Number (TIN).

Recommended tire inflation pressure, including a description and explanation of:

A. Cold inflation pressure.

B. Vehicle Placard and location on the vehicle.

C. Adverse safety consequences of under inflation (including tire failure).

D. Measuring and adjusting air pressure for proper inflation.

Tire Care, including maintenance and safety practices.

Vehicle load limits, including a description and explanation of the following items:

A. Locating and understanding the load limit information, total load capacity, and cargo capacity.

B. Calculating total and cargo capacities with varying seating configurations including quantitative examples

showing / illustrating how the vehicles cargo and luggage capacity decreases as combined number and size

of occupants’ increases. This item is also discussed in Section 3.

C. Determining compatibility of tire and vehicle load capabilities.

D. Adverse safety consequences of overloading on handling and stopping on tires.

, including “cold inflation pressure”, “maximum inflation

.

.

1.1. STEPS FOR DETERMINING CORRECT LOAD LIMIT – TRAILER

Determining the load limits of a trailer includes more than understanding the load limits of the tires alone. On all trailers

there is a Federal certification/VIN label that is located on the forward half of the left (road) side of the unit. This

certification/VIN label will indicate the trailer’s Gross Vehicle Weight Rating (GVWR). This is the most weight the fully

loaded trailer can weigh. It will also provide the Gross Axle Weight Rating (GAWR). This is the most a particular axle

can weigh. If there are multiple axles, the GAWR of each axle will be pro vided.

If your trailer has a GVWR of 10,000 pounds or less, there is a vehicle placard located in the same location as the

certification label described above. This placard provides tire and loading information. In addition, this placard will show

a statement regarding maximum cargo capacity. Cargo can be added to the trailer, up to the maximum weight specified on

the placard. The combined weight of the cargo is provided as a single number. In any case, remember: the total weight of

a fully loaded trailer can not exceed the stated GVWR.

For trailers with living quarters installed, the weight of water and propane also need to be considered. The weight of fully

filled propane containers is considered part of the weight of the trailer before it is loaded with cargo, and is not

part of the disposable cargo load. Water however, is a disposable cargo weight and is treated as such. If there is a fresh

water storage tank of 100 gallons, this tank when filled would weigh about 800 pounds. If more cargo is being

transported, water can be off-loaded to keep the total amount of cargo added to the vehicle within the limits of the GVWR

so as not to overload the vehicle. Understanding this flexibility will allow you, the owner, to make choices that fit your

travel needs.

When loading your cargo, be sure it is distributed evenly to prevent overloading front to back and side to side. Heavy

items should be placed low and as close to the axle positions as reasonable. Too many items on one side may overload a

tire. The best way to know the actual weight of the vehicle is to weigh it at a public scale. Talk to your dealer to discuss

the weighing methods needed to capture the various weights related to the trailer. This would include the weight empty or

unloaded, weights per axle, wheel, hitch or king-pin, and total weight.

considered

15

Tire Safety Information

Excessive loads and/or underinflation cause tire overloading and, as a result, abnormal tire flexing occurs. This situation

can generate an excessive amount of heat within the tire. Excessive heat may lead to tire failure. It is the air pressure that

enables a tire to support the load, so proper inflation is critical. The proper air pressure may be found on the

certification/VIN label and/or on the Tire Placard. This value should never exceed the maximum cold inflation pressure

stamped on the tire.

1.1.1. T

RAILERS 10,000 POUNDS GVWR OR LESS

Tire and Loading Information Placard – Figure 1-1

1. Locate the statement, “The weight of cargo should never exceed XXX kg or XXX lbs.,” on your vehicle’s

placard. See figure 1-1.

2. This figure equals the available amount of cargo and luggage load capacity.

3. Determine the combined weight of luggage and cargo being loaded on the vehicle. That weight may not

safely exceed the available cargo and luggage load capacity.

The trailer’s placard refers to the Tire Information Placard attached adjacent to or near the trailer’s VIN

(Certification) label at the left front of the trailer.

1.1.2. T

1. Determine the empty weight of your trailer by weighing the trailer using a public scale or other means.

2. Locate the GVWR (Gross Vehicle Weight Rating) of the trailer on your trailer’s VIN (Certification) label.

3. Subtract the empty weight of your trailer from the GVWR stated on the VIN label. That weight is the

RAILERS OVER 10,000 POUNDS GVWR (NOTE: THESE TRAILERS ARE NOT REQUIRED TO HAVE A TIRE

INFORM ATIO N PL ACAR D ON THE VEHICLE)

This step does not have to be repeated.

maximum available cargo capacity of the trailer and may not be safely exceeded.

1.2. STEPS FOR DETERMINING CORRECT LOAD LIMIT – TOW VEHICLE

1. Locate the statement, “The combined weight of occupants and cargo should never exceed XXX lbs.,” on

your vehicle’s placard.

2. Determine the combined weight of the driver and passengers who will be riding in your vehicle.

3. Subtract the combined weight of the driver and passengers from XXX kilograms or XXX pounds.

4. The resulting figure equals the available amount of cargo and luggage capacity. For example, if the “XXX”

amount equals 1400 lbs. and there will be five 150 lb. passengers in your vehicle, the amount of available

cargo and luggage capacity is 650 lbs. (1400 -750 (5 x 150) = 650 lbs.).

5. Determine the combined weight of luggage and cargo being loaded on the vehicle. That weight may not

safely exceed the available cargo and luggage capacity calculated in Step # 4.

6. If your vehicle will be towing a trailer, load from your trailer will be transferred to your vehicle. Consult the

tow vehicle’s manual to determine how this weight transfer reduces the available cargo and luggage

capacity of your vehicle.

1.3. GLOSSARY OF TIRE TERMINOLOGY

Accessory weight

The combined weight (in excess of those standard items which may be replaced) of automatic transmission,

power steering, power brakes, power windows, power seats, radio and heater, to the extent that these items

are available as factory-installed equipment (whether installed or not).

16

Tire Safety Information

Bead

The part of the tire that is made of steel wires, wrapped or reinforced by ply cords and that is shaped to fit the

rim.

Bead separation

This is the breakdown of the bond between components in the bead.

Bias ply tire

A pneumatic tire in which the ply cords that extend to the beads are laid at alternate angles substantially less

than 90 degrees to the centerline of the tread.

Carcass

The tire structure, except tread and sidewall rubber which, when inflated, bears the load.

Chunking

The breaking away of pieces of the tread or sidewall.

Cold inflation pressure

The pressure in the tire before you drive.

Cord

The strands forming the plies in the tire.

Cord separation

The parting of cords from adjacent rubber compounds.

Cracking

Any parting within the tread, sidewall, or inner liner of the tire extending to cord material.

CT

A pneumatic tire with an inverted flange tire and rim system in which the rim is designed with rim flanges

pointed radially inward and the tire is designed to fit on the underside of the rim in a manner that encloses the

rim flanges inside the air cavity of the tire.

Curb weight

The weight of a motor vehicle with standard equipment including the maximum capacity of fuel, oil, and

coolant, and, if so equipped, air conditioning and additional weight optional engine.

Extra load tire

A tire designed to operate at higher loads and at higher inflation pressures than the corresponding standard

tire.

Groove

The space between two adjacent tread ribs.

Gross Axle Weight Rating

The maximum weight that any axle can support, as published on the Certification / VIN label on the front left

side of the trailer. Actual weight determined by weighing each axle on a public scale, with the trailer attached

to the towing vehicle.

Gross Vehicle Weight Rating

The maximum weight of the fully loaded trailer, as published on the Certification / VIN label. Actual weight

determined by weighing trailer on a public scale, without being attached to the towing vehicle.

Hitch Weight

The downward force exerted on the hitch ball by the trailer coupler.

Innerliner

The layer(s) forming the inside surface of a tubeless tire that contains the inflating medium within the tire.

Innerliner separation

The parting of the innerliner from cord material in the carcass.

17

Tire Safety Information

Intended outboard sidewall

The sidewall that contains a white-wall, bears white lettering or bears manufacturer, brand, and/or model name

molding that is higher or deeper than the same molding on the other sidewall of the tire or the outward facing

sidewall of an asymmetrical tire that has a particular side that must always face outward when mounted on a

vehicle.

Light truck (LT) tire

A tire designated by its manufacturer as primarily intended for use on lightweight trucks or multipurpose

passenger vehicles.

Load rating

The maximum load that a tire is rated to carry for a given inflation pressure.

Maximum load rating

The load rating for a tire at the maximum permissible inflation pressure for that tire.

Maximum permissible inflation pressure

The maximum cold inflation pressure to which a tire may be inflated.

Maximum loaded vehicle weight

The sum of curb weight, accessory weight, vehicle capacity weight, and production options weight.

Measuring rim

The rim on which a tire is fitted for physical dimension requirements.

Pin Weight

The downward force applied to the 5

th

wheel or gooseneck ball, by the trailer kingpin or gooseneck coupler.

Non-pneumatic rim

A mechanical device which, when a non-pneumatic tire assembly incorporates a wheel, supports the tire, and

attaches, either integrally or separably, to the wheel center member and upon which the tire is attached.

Non-pneumatic spare tire assembly

A non-pneumatic tire assembly intended for temporary use in place of one of the pneumatic tires and rims that

are fitted to a passenger car in compliance with the requirements of this standard.

Non-pneumatic tire

A mechanical device which transmits, either directly or through a wheel or wheel center member, the vertical

load and tractive forces from the roadway to the vehicle, generates the tractive forces that provide the

directional control of the vehicle and does not rely on the containment of any gas or fluid for providing those

functions.

Non-pneumatic tire assembly

A non-pneumatic tire, alone or in combination with a wheel or wheel center member, which can be mounted on

a vehicle.

Normal occupant weight

This means 68 kilograms (150 lbs.) times the number of occupants specified in the second column of Table I

of 49 CFR 571.110.

Occupant distribution

The distribution of occupants in a vehicle as specified in the third column of Table I of 49 CFR 571.110.

Open splice

Any parting at any junction of tread, sidewall, or innerliner that extends to cord material.

Outer diameter

The overall diameter of an inflated new tire.

Overall width

18

Tire Safety Information

The linear distance between the exteriors of the sidewalls of an inflated tire, including elevations due to

labeling, decorations, or protective bands or ribs.

Ply

A layer of rubber-coated parallel cords.

Ply separation

A parting of rubber compound between adjacent plies.

Pneumatic tire

A mechanical device made of rubber, chemicals, fabric and steel or other materials, that, when mounted on an

automotive wheel, provides the traction and contains the gas or fluid that sustains the load.

Production options weight

The combined weight of those installed regular production options weighing over 2.3 kilograms (5 lbs.) in

excess of those standard items which they replac e, not previously considered in curb weight or accessory

weight, including heavy duty brakes, ride levelers, roof rack, heavy duty battery, and special trim.

Radial ply tire

A pneumatic tire in which the ply cords that extend to the beads are laid at substantially 90 degrees to the

centerline of the tread.

Recommended inflation pressure

This is the inflation pressure provided by the vehicle manufacturer on the Tire Information label and on the

Certification / VIN tag.

Reinforced tire

A tire designed to operate at higher loads and at higher inflation pressures than the corresponding standard

tire.

Rim

A metal support for a tire or a tire and tube assembly upon which the tire beads are seated.

Rim diameter

This means the nominal diameter of the bead seat.

Rim size designation

This means the rim diameter and width.

Rim type designation

This means the industry of manufacturer’s designation for a rim by style or code.

Rim width

This means the nominal distance between rim flanges.

Section width

The linear distance between the exteriors of the sidewalls of an inflated tire, excluding elevations due to

labeling, decoration, or protective bands.

Sidewall

That portion of a tire between the tread and bead.

Sidewall separation

The parting of the rubber compound from the cord material in the sidewall.

Special Trailer (ST) tire

The "ST" is an indication the tire is for trailer use only.

Test rim

The rim on which a tire is fitted for testing, and may be any rim listed as appropriate for use with that tire.

Tread

19

Tire Safety Information

That portion of a tire that comes into contact with the road.

Tread rib

A tread section running circumferentially around a tire.

Tread separation

Pulling away of the tread from the tire carcass.

Treadwear indicators (TWI)

The projections within the principal grooves designed to give a visual indication of the degrees of wear of the

tread.

Vehicle capacity weight

The rated cargo and luggage load plus 68 kilograms (150 lbs.) times the vehicle’s designated seating capacity.

Vehicle maximum load on the tire

The load on an individual tire that is determined by distributing to each axle its share of the maximum loaded

vehicle weight and dividing by two.

Vehicle normal load on the tire

The load on an individual tire that is determined by distributing to each axle its share of the curb weight,

accessory weight, and normal occupant weight (distributed in accordance with Table I of CRF 4 9 571.110) and

dividing by 2.

Weather side

The surface area of the rim not covered by the inflated tire.

Wheel center member

In the case of a non-pneumatic tire assembly incorporating a wheel, a mechanical device which attaches,

either integrally or separably, to the non-pneumatic rim and provides the connection between the nonpneumatic rim and the vehicle; or, in the case of a non-pneumatic tire assembly not incorporating a wheel, a

mechanical device which attaches, either integrally or separably, to the non-pneumatic tire and provides the

connection between tire and the vehicle.

Wheel-holding fixture

The fixture used to hold the wheel and tire assembly securely during testing.

1.4. TIRE SAFETY - EVERYTHING RIDES ON IT

The National Traffic Safety Administration (NHTSA) has published a brochure (DOT HS 809 361) that

discusses all aspects of Tire Safety, as required by CFR 575.6. This brochure is reproduced in part below. It

can be obtained and downloaded from NHTSA, free of charge, from the following web site:

http://www.nhtsa.dot.gov/cars/rules/TireSafety/ridesonit/tires_index.html

Studies of tire safety show that maintaining proper tire pressure, observing tire and vehicle load limits (not

carrying more weight in your vehicle than your tires or vehicle can safely handle), avoiding road hazards, and

inspecting tires for cuts, slashes, and other irregularities are the most important things you can do to avoid tire

failure, such as tread separation or blowout and flat tires. These actions, along with other care and

maintenance activities, can also:

Improve vehicle handling

Help protect you and others from avoidable breakdowns and accidents

Improve fuel economy

Increase the life of your tires.

This booklet presents a comprehensive overview of tire safety, including information on the following topics:

Basic tire maintenance

Uniform Tire Quality Grading System

Fundamental characteristics of tires

20

Tire Safety Information

Tire safety tips.

Use this information to make tire safety a regular part of your vehicle maintenance routine. Recognize that the

time you spend is minimal compared with the inconvenience and safety consequences of a flat tire or other tire

failure.

1.5. SAFETY FIRST–BASIC TIRE MAINTENANCE

Properly maintained tires improve the steering, stopping, traction, and load -carrying capability of your vehicle.

Underinflated tires and overloaded vehicles are a major cause of tire failure. Therefore, as mentioned above,

to avoid flat tires and other types of tire failure, you should maintain proper tire pressure, observe tire and

vehicle load limits, avoid road hazards, and regularly inspect your tires.

1.5.1. F

INDING YOUR VEHICLE'S RECOMMENDED TIRE PRESSURE AND LOAD LIMITS

Tire information placards and vehicle certification labels contain information on tires and load limits. These

labels indicate the vehicle manufacturer's information including:

Recommended tire size

Recommended tire inflation pressure

Vehicle capacity weight (VCW–the maximum occupant and cargo weight a vehicle is designed to carry)

Front and rear gross axle weight ratings (GAWR– the maximum weight the axle systems are designed to

carry).

Both placards and certification labels are permanently attached to the trailer near the left front.

1.5.2. U

NDERSTANDING TIRE PRESSURE AND LOAD LIMITS

Tire inflation pressure is the level of air in the tire that provides it with load-carrying capacity and affects the

overall performance of the vehicle. The tire inflation pressure is a number that indicates the amount of air

pressure– measured in pounds per square inch (psi)–a tire requires to be properly inflated. (You will also find

this number on the vehicle information placard express ed in kilopascals (kpa), which is the metric measure

used internationally.)

Manufacturers of passenger vehicles and light trucks determine this number based on the vehicle's design

load limit, that is, the greatest amount of weight a vehicle can safely carry and the vehicle's tire size. The

proper tire pressure for your vehicle is referred to as the "recommended cold inflation pressure." (As you will

read below, it is difficult to obtain the recommended tire pressure if your tires are not cold.)

Because tires are designed to be used on more than one type of vehicle, tire manufacturers list the "maximum

permissible inflation pressure" on the tire sidewall. This number is the greatest amount of air pressure that

should ever be put in the tire under normal driving conditions.

1.5.3. C

HECKING TIRE PRESSURE

It is important to check your vehicle's tire pressure at least once a month for the following reasons:

Most tires may naturally lose air over time.

Tires can lose air suddenly if you drive over a pothole or other object or if you strike the curb when

parking.

With radial tires, it is usually not possible to determine underinflation by visual inspection.

For convenience, purchase a tire pressure gauge to keep in your vehicle. Gauges can be purchased at tire

dealerships, auto supply stores, and other retail outlets.

The recommended tire inflation pressure that vehicle manufacturers provide reflects the proper psi when a tire

is cold. The term cold does not relate to the outside temperature. Rather, a cold tire is one that has not been

driven on for at least three hours. When you drive, your tires get warmer, causing the air pressure within them

to increase. Therefore, to get an accurate tire pressure reading, you must measure tire pressure when the tires

are cold or compensate for the extra pressure in warm tires.

21

Tire Safety Information

1.5.4. STEPS FOR MAINTAINING PROPER TIRE PRESSURE

Step 1: Locate the recommended tire pressure on the vehicle's tire information placard, certification

label, or in the owner's manual.

Step 2: Record the tire pressure of all tires.

Step 3: If the tire pressure is too high in any of the tires, slowly release air by gently pressing on the

tire valve stem with the edge of your tire gauge until you get to the correct pressure.

Step 4: If the tire pressure is too low, note the difference between the measured tire pressure and the

correct tire pressure. These "missing" pounds of pressure are what you will need to add.

Step 5: At a service station, add the missing pounds of air pressure to each tire that is underinflated.

Step 6: Check all the tires to make sure they have the same air pressure (except in cases in which the

front and rear tires are supposed to have different amounts of pressure).

If you have been driving your vehicle and think that a tire is underinflated, fill it to the recommended cold

inflation pressure indicated on your vehicle's tire information placard or certification label. While your tire may

still be slightly underinflated due to the extra pounds of pressure in the warm tire, it is safer to drive with air

pressure that is slightly lower than the vehicle manufacturer's recommended cold inflation pressure than to

drive with a significantly underinflated tire. Since this is a temporary fix, don't forget to recheck and adjust the

tire's pressure when you can obtain a cold reading.

1.5.5. T

IRE SIZE

To maintain tire safety, purchase new tires that are the same size as the vehicle's original tires or another size

recommended by the manufacturer. Look at the tire information placard, the owner's manual, or the sidewall of

the tire you are replacing to find this information. If you have any doubt about the correct size to choose,

consult with the tire dealer.

1.5.6. T

IRE TREAD

The tire tread provides the gripping action and traction that prevent your vehicle from slipping or sliding,

especially when the road is wet or icy. In general, tires are not safe and should be replaced when the tread is

worn down to 1/16 of an inch. Tires have built-in treadwear indicators that let you know when it is time to

replace your tires. These indicators are raised sections spaced intermittently in the bottom of the tread

grooves. When they appear "even" with the outside of the tread, it is time to replace your tires. Another method

for checking tread depth is to place a penny in the tread with Lincoln's head upside down and facing you. If

you can see the top of Lincoln's head, you are ready for new tires.

1.5.7. T

IRE BALANCE AND WHEEL ALIGN MENT

To avoid vibration or shaking of the vehicle when a tire rotates, the tire must be properly balanced. This

balance is achieved by positioning weights on the wheel to counterbalance heavy spots on the wheel-and-tire

assembly. A wheel alignment adjusts the angles of the wheels so that they are positioned correctly relative to

the vehicle's frame. This adjustment maximizes the life of your tires. These adjustments require special

equipment and should be performed by a qualified technician.

1.5.8. T

IRE REPAIR

The proper repair of a punctured tire requires a plug for the hole and a patch for the area inside the tire that

surrounds the puncture hole. Punctures through the tread can be repaired if they are not too large, but

punctures to the sidewall should not be repaired. Tires must be removed from the rim to be properly inspected

before being plugged and patched.

1.5.9. T

IRE FUNDAMENTALS

Federal law requires tire manufacturers to place standardized information on the sidewall of all tires. This

information identifies and describes the fundamental characteristics of the tire and also provides a tire

identification number for safety standard certification and in case of a rec all.

22

1.5.9.1. Information on Passenger Vehicle Tires

Please r efer to the diagram below .

Tire Safety Information

P

The "P" indicates the tire is for passenger vehicles.

Next number

This three-digit number gives the width in millimeters of the tire from sidewall edge to sidewall edge. In

general, the larger the number, the wider the tire.

Next number

This two-digit number, known as the aspect ratio, gives the tire's ratio of height to width. Numbers of 70 or

lower indicate a short sidewall for improved steering response and better overall handling on dry pavement.

R

The "R" stands for radial. Radial ply construction of tires has been the industry standard for the past 20 years.

Next number

This two-digit number is the wheel or rim diameter in inches. If you change your wheel size, you will have to

purchase new tires to match the new wheel diameter.

Next number

This two- or three-digit number is the tire's load index. It is a measurement of how much weight each tire can

support. You may find this information in your owner's manual. If not, contact a local tire dealer. Note: You may

not find this information on all tires because it is not required by law.

M+S

The "M+S" or "M/S" indicates that the tire has some mud and snow capability. Most radial tires have these

markings; hence, they have some mud and snow capability.

Speed Rating

The speed rating denotes the speed at which a tire is designed to be driven for extended periods of time. The

ratings range from 99 miles per hour (mph) to 186 mph. These ratings are listed below. Note: You may not find

this information on all tires because it is not required by law.

23

Tire Safety Information

Letter Rating

Speed Rating

Q

99 mph

R

106 mph

S

112 mph

T

118 mph

U

124 mph

H

130 mph

V

149 mph

W

168* mph

Y

186* mph

Tire Safety Information

* For tires with a maximum speed capability over 149 mph, tire manufacturers sometimes use the letters ZR.

For those with a maximum speed capability over 186 mph, tire manufacturers always use the letters ZR.

U.S. DOT Tire Identification Number

This begins with the letters "DOT" and indicates that the tire meets all federal standards. The next two

numbers or letters are the plant code where it was manufactured, and the last four numbers represent the

week and year the tire was built. For example, the numbers 3197 means the 31st week of 1997. The other

numbers are marketing codes used at the manufacturer's discretion. This information is used to contact

consumers if a tire defect requires a recall.

Tire Ply Composition and Materials Used

The number of plies indicates the number of layers of rubber-coated fabric in the tire. In general, the greater

the number of plies, the more weight a tire can support. Tire manufacturers also must indicate the materials in

the tire, which include steel, nylon, polyester, and others.

Maximum Load Rating

This number indicates the maximum load in kilograms and pounds that can be carried by the tire.

Maximum Permissible Inflation Pressure

This number is the greatest amount of air pressure that should ever be put in the tire under normal driving

conditions.

1.5.9.2. UTQGS Information

Treadwear Number

This number indicates the tire's wear rate. The higher the treadwear number is, the longer it should take for th e

tread to wear down. For example, a tire graded 400 should last twice as long as a tire graded 200.

Traction Letter

This letter indicates a tire's ability to stop on wet pavement. A higher graded tire should allow you to stop your

car on wet roads in a shorter distance than a tire with a lower grade. Traction is graded from highest to lowest

as "AA","A", "B", and "C".

Temperature Letter

This letter indicates a tire's resistance to heat. The temperature grade is for a tire that is inflated properly and

not overloaded. Excessive speed, underinflation or excessive loading, either separately or in combination, can

cause heat build-up and possible tire failure. From highest to lowest, a tire's resistance to heat is graded as

"A", "B", or "C".

24

1.5.9.3. Additional Information on Light Truck Tires

Please refer to the following diagram.

Tire Safety Information

Tires for light trucks have other markings besides those found on the sidewalls of passenger tires.

LT

The "LT" indicates the tire is for light trucks or trailers.

ST

An "ST" is an indication the tire is for trailer use only.

Max. Load Dual kg (lbs) at kPa (psi) Cold

This information indicates the maximum load and tire pressure when the tire is used as a dual, that is,

when four tires are put on each rear axle (a total of six or more tires on the vehicle).

Max. Load Single kg (lbs) at kPa (psi) Cold

This information indicates the maximum load and tire pressure when the tire is used as a single.

Load Range

This information identifies the tire's load -carrying capabilities and its inflation limits.

1.6. TIRE SAFETY TIPS

Preventing Tire Damage

Slow down if you have to go over a pothole or other object in the road.

Do not run over curbs or other foreign objects in the roadway, and try not to strike the curb when

parking.

Tire Safety Checklist

Check tire pressure regularly (at least once a month), including the spare.

Inspect tires for uneven wear patterns on the tread, cracks, foreign objects, or other signs of wear or

trauma.

Remove bits of glass and foreign objects wedged in the tread.

Make sure your tire valves have valve caps.

Check tire pressure before going on a long trip.

Do not overload your vehicle. Check the Tire Information and Loading Placard or User’s Manual for the

maximum recommended load for the vehicle.

25

Notes

Notes

26

Loading...

Loading...