Wykamol Flitvent Installation And Maintenance Manual

Low Energy Positive Input Ventilation Unit Installation and Maintenance

IMPORTANT NOTES TO INSTALLERS

The FLATVENT range has been curing severe condensation problems for

over 20 years in some of the worst affected properties throughout the world.

Its successful operation depends entirely upon the unit being installed strictly

in accordance with these instructions. We would, therefore, respectfully

suggest that you read through this guide in its entirety before commencing

installation and then go through this guide step by step to ensure a

satisfactory completion.

Whilst the installation of the Flatvent unit may be achieved by a suitable

craftsman, the provision of the electrical supply and the connection of the

unit to the mains must be carried out by a qualified electrician.

The unit has a 5 year warranty starting from the day of delivery and includes

parts and labour for the first year. The remaining 4 years covers parts only.

This warranty is conditional on the following:-

a)

T

ha

t the unit is installed strictly in accordance with this guide.

b) That the unit filters are removed and cleaned or replaced at the

r

ec

ommended in

t

er

vals.

The unit represents a significant financial outlay on the part of the

user/specifier and the unique 5 y

ear war

rant

y is impor

tant t

o them. We make

a point of advising them that the installer is provided with detailed

instructions regarding installation/guarantee registration and therefore has

the r

esponsibility of ensuring that the unit is guaranteed for the user/specifier.

1.0 INST

ALLATION

The unit is designed to take fresh air from outside, clean the air, warm it (if fitted

with heat

er) and discharge it into the central hallway via a system of ducting

supplied by the installer. The dwelling internal air discharge grille is usually

installed at high level in a central location within the hallway, although

discharging the air down the length of the hallway (away from the front door)

should also prove acceptable. Unit performance may be enhanced if an existing

heat source can warm the discharged air eg. by locating the discharge grille

above a radiator.

Before commencing installation decide the best position for the unit and where

the fresh air input air is to come from and be discharged to. The unit can be

installed in many different configurations and is supplied with enough

interchangeable spigots to enable it to be used with either round (100mm) or

rectangular ducting (121mm x 60mm). The unit can be turned through 180o to

any angle if required.

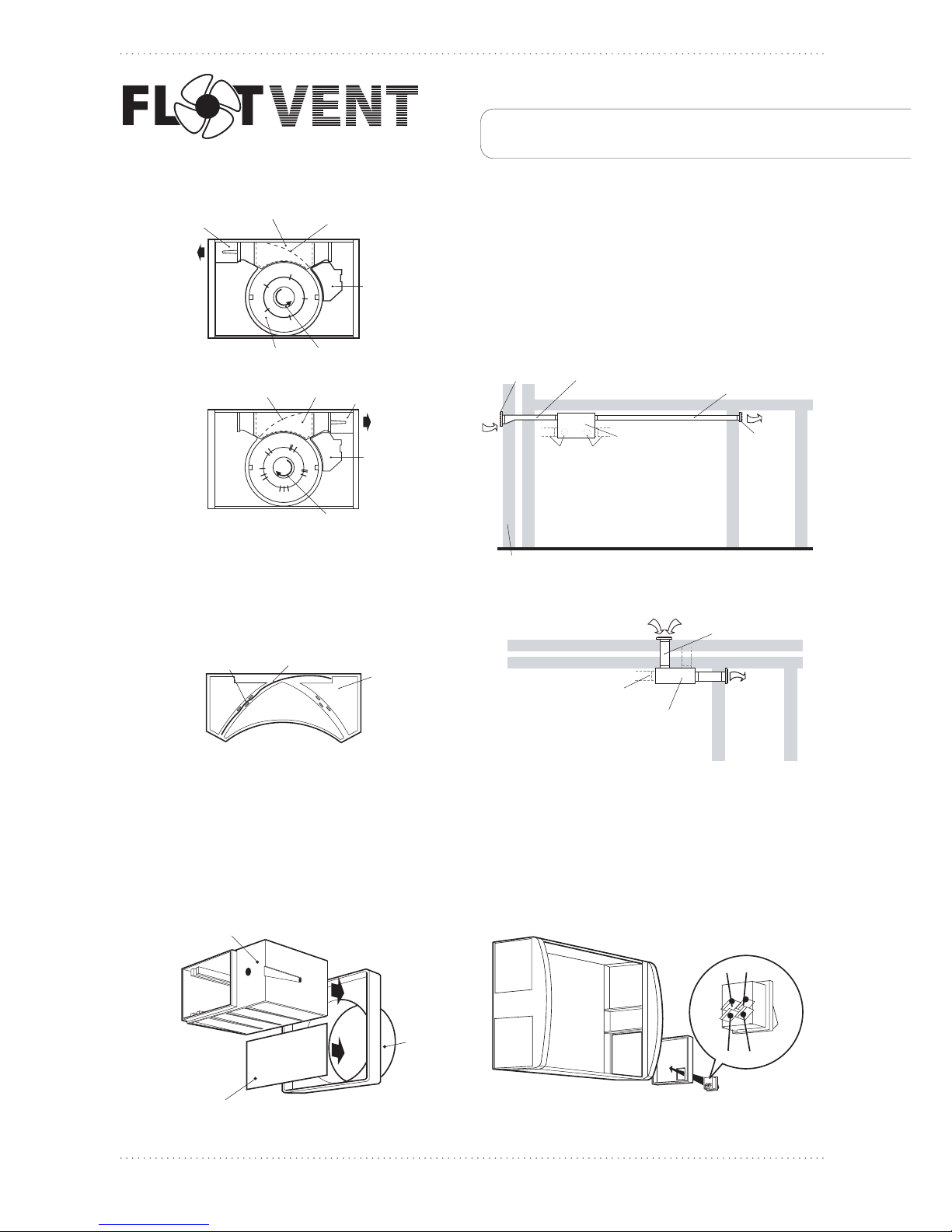

Figure 1. (above) Typical installations show unit with top discharge.

FIXING THE UNIT TO THE WALL

The unit has four mounting pads. Mark through these pads when the unit is in

the correct position. Drill and plug wall with suitable fixings. Remove PCB cover

and f

eed the electrical supply cable through the grommet hole (standard

1mm three core lighting cable is recommended) in the rear of the unit screw

unit t

o wall

.

POINTS TO CONSIDER

1.

T

he inlet duc

ting should be k

ept as shor

t as possible t

o a

void

condensation build up on the ducting surface (see figs 5/6).

2.

C

an the dischar

ge g

r

ille be located to take advantage of existing

heat sources?

3.

Find the shortest, most direct route from outside of the unit and then to

the discharge grille using the least number of bends (these bends

incr

ease the air

flow resistance).

4. Note the location of any joists, pipes, electrical cables etc.

5.

Allo

w adequat

e access t

o the fr

ont cover to allow filter cleaning?

6. Refer to the relevant Building and Electrical Regulations.

DATASHEET

W

her

e the sy

st

ems ar

e installed in flats where regulations require the provision of a

protected entrance hall or protected enclosure and the outlet of the systems are

within that enclosure it is necessary to ensure that the safety of the enclosure is not

compromised either in relation to its fire resistance or the entry of smoke. Smoke

detectors must be connected to the fan so that it shuts down if smoke enters the

ductwork. Ductwork must be of steel, with the point of fire penetration stopped, or if

non fir

e-resistant ducting is used, it must be protected in fire-resisting construction

up to the point where it penetrates the wall of the protected entrance hall or

pr

ot

ec

t

ed enclosur

e

.

Where the systems are installed in flats where these regulatory

pr

o

visions do not apply

, good installa

tion practice should be observed; for example

the use of smok

e det

ectors to control the fan, to ensure that occupant safety levels

are not reduced. For more information please refer to the Building Regulations,

Approved Document B (Fire safety) – Volume 1: Dwelling houses (2006 Edition)

IMPORTANT

Rear entry

‘Blank off’ plate

Installation &

Maintenance

Figure 1.

T

ypical installations show

unit with t

op discharge.

Alternative inlet

position

Rear entry

‘Blank off’ plates

FITTING THE DEFLECTOR PLATE

Fit deflector plate into scroll cover as shown below. Once fitted the assembly

can be slotted into the scroll and clipped firmly in place.

TRANSFORMATION PIECE

This should be on the appropriate scroll outlet. The transformation piece

should be fitted into the chosen outlet spigot insert, prior to fitting.

Note: If the round spigot is used as an outlet, the 115 x 55mm clear blanking

plate will need to be fitted (as shown). This plate should be prevented from

movement by the use of silicone sealant.

INLET/OUTLET GRILLE INSTALLATION

I

f a flyscreen is fitted it should be removed from both the internal and

external grille.

Note: When installing the internal grille, the louvres MUST SLANT

UPWARDS to ensure the correct air circulation and the avoidance of

unpleasant downdraughts. The outside wall input grille louvres MUST

SLANT DOWNWARDS.

Standard 100mm dia ducting or 121 x 60mm ducting is used to connect the

Flatvent to the input and discharge grilles.

FIXING ALL NECESSARY DUCTING

A full range of ductwork and ductwork ancillaries are available. Please contact

Flatvent for further details.

2.0 HEATER OPTIONS (ORDER CODE FLAT-HEATER)

The heater kit contains a blank insert with a cut out for the switch. This blank

can be fitted into any appropriate opening. It is important that the switch is

fitted so that the terminals are at the bottom.

SETTING UP THE CORRECT AIRFLOW DIRECTION

Figure 2.

Figure 5. Side input installation.

Figure 6. Rear input installation (view from above).

IMPORTANT

T

he internal grille must not be placed within 1.5m of a smoke alarm.

Input grille

(louvres slant

dow

nwards)

100mm dia/121x60mm

rectangular ducting (note input

side ke

pt as short as possible)

100mm dia/121x60mm rectangular ducting

Out

side wall

Room (typical)

Alternative

spigot positions

Fla

tvent

Discharge

grille (note

louvre

s

slant

upw

ards)

Hallwa

y

(typical)

Deflector plate shown fitted in left hand air discharge (viewed from inside).

Deflector plate

pinched between guide

posts as shown

Deflector plate

shown fitted in

left hand air discharge

Scroll cover

Deflector

plate

position

under

scroll

cover

Transformation

piece

Scroll cover

Scroll cover

Scr

oll

Deflector plate

position under scroll cover

Deflector plate

position under

scr

oll cover

PCB Cover

AIRFLOW

AIRFLOW

Left Hand Discharge

(when viewed from front)

Direction of rotation

(see “S etting the unit”)

Rig

ht Hand Discharge

(when viewed from front)

Dire

ction of rotation

(see “S etting the unit”)

PCB C

over

Tra

nsformation

piec

e

Figure 3.

Transformation

piece

Blanking plate

Outlet

spigot

Figure 4.

Outside wall 100mm dia ducting

Air input

Flatvent

Note alternative

spigot positions

Hallway

(typical)

Air

discharge

Switch terminal connections

Heater

Supply

Note: Switch must be inserted into cut out in the blanking plate

with the terminals to the bottom as shown.

Figure 7.

INSTALLATION AND MAINTENANCE Low Energy Positive Input Ventilation Unit

Loading...

Loading...