W-W Grinder renegade 250 Owner's Manual

IL

=

GRINDER

INC.

...

INTRODUCTION

w-w

GRINDER

INC.

Mail: P.O.

Box

4029, Wichita, Kansas 67204 •

Dear Customer,

It's a pleasure to have you as an owner

Renegade 250.

The new Renegade 250

yard

beautiful.

250 you can recycle valuable waste

We

handle, a pleasure

manufacturing machines

Renegade

to

last

I think

huge quantities of materials

beauty and productivity of your property.

Again,

that

it will serve y

We

believe you have selected one of the finest units available for personal use.

It

is

a tough built, yeteconomicai Chipper/Shredder/Grinder. With the Renegade

have designed a number of features into the Renegade 250 which makes

250 model meets those objectives superbly and

you

a lifetime.

to

use and convenient

you

will find the Renegade 250 model

we

are very pleased

ou

wen.

Office

and Factory: 2957 N. Mark.et • Telephone (316) 838-4229 • 8CO-835-2127

and

to introduce

is

designed for the person who wants

materials.

to

that

break. shred and grind organic materials and

to

spreadable mulch or compost in a sho

to

have

store. Our business specializes in designing and

is

a tough, efficient machine

you

as an owner

of one

Sincerely,

is

built

of

you

our

to

the capabilities of the

to

keep

their

garden and

it

easy to

other

to

a high sta

rt

products and are confident

wastes. The

ndard

of

that

time, adding

will reduce

quality

to

the

,

I

MANU

FACTURERS OF SHREDDER/

GRINDERS

~R"

Brij

Vice

W· W Grinder Inc.

, POWER SPRAYERS.

~~

~ani

if.f~sident

& General Manager

MAGNETIC

. .

SWEEPERS

w-w

Grinder

Inc.

a period of one (1) year from the date

to purchaser

Commercial use

the purchaser

for replacement under this warranty must

and does not cover misuse, abuse, neglect or damage caused

Al!

are covered under this warranty except as

of

the warranty provisions

The warranty is made

pursuant

va

ry fr

for

motors, engines,

to the laws

om

state to state.

warrants

labor or materials. any

warranty

is

to return the

tires, bearings or other component

of

to

the

origina

l purchaser of this

of

purchase, except when

part

is for a period of ninety (90) days from

part

to

to

these components will

in

addition to and not

the State

of

Kansas. Further, this warranty gives

2957

or parts which shall be determined to

WoW

Grinder Inc., 2957 North Market, Wichita,

be

borne

by

the purchaser. This warranty presumes reasonable

modified

N.

by

be

furnished

in

limitation of the implied warranties of merchantability and fitness for a particular purpose

Market

S1.

WARRANTY

product

that

the

same

used

for

commercial purposes, and agrees to repair or replace at

date

of

purchase. In the event of a defect

by

transporting or accident.

parts

furnished with this product, but not manufactured

the respective manufacturers thereof,

upon

request.

you

specific legal rights and

Wichita, Kansas 67219 Phone 1-800-835-2

is free of defects

be

defective

KS

67219.

whose

in

materials

by

WoW

Grinder Inc. after examination.

or

malfunction

All

transportation costs

care

of the product

names and addresses as well as a copy

you

may also have other rights which

127

or

workmanship

during

on

parts submitted

by

by

WoW

this warranty.

the purchaser

Grinder In

no

for

cost

c.,

WARNING TO

Under California Law. you

are

not permitted

operate an internal combustion engine using hydrocarbon

fuels on any forest covered, brush covered or

covered land; or

on

land covered with grain. hay. or

other flammable agricultural crop without an engine

spark

arrestor

order. The engine

Shredder

internal combustion engine

muffler in continuous effective working

on

/Gr

inder. like most garden equipment. is an

your Renegade 250 Chipper/

that

burns

TABLE OF CONTENTS

Section

Section II. SAFETY INSTRUCTIONS

Section III:

I:

ASSEMBLY & PREPARATION

1.

Inspecting

2.

U ncrating and assembly

3.

Servicing the engine

1.

Precautions before

2. Things

3. Operational safety

to

after

avoid

delivery

............

..............................

...............................

starting

in

operating

...........................

........

............................

. .

.......

4. Safety minded maintenance and storage

5.

Decal safety ..

1.

Features and controls

Shredder/Grinder

2.

3.

Chipper

4.

Power transmission

.........................................

THE

CHIPPERISHREDDERIGRINDER-

HOW

IT

WORKS

.................................

....................................

................................

.................. _ ................

............

..........

.

..............

CALIFORNIA

to

grass

gasoline (a

Page No.

2

2

... 2

3

.........

.

......

.4

.4

.. .4

5

6

7

7

7

OWNER/OPERATORS

hydrocarbon fuel). The Renegade 250

with a

arrestor

muffler; therefore. it

spa

rk

equipped by the purchaser with a

in proper working order. The

attached

that

flammable material.

to

flames

the engine

or

heat

exhaust

from the system will not ignite

Failure

spark

system in such a

of the operator to comply

is

spark

arrestor muffler

arrestor

not equipped

must

must

manner

with this regulation is a misdemeanor under California

Law.

Section

Section

Section VI:

Section VII: PARTS

1

IV: OPERATING INSTRUCTIONS

1.

Materials suitable for the chipper

2. Materials suitable for the sh

3.

Site selection

4. How

5.

to

How to use the

V:

1.

Engine..

2. Power transmission

A. Clutch

B.

V·Belt

g

..

~~~:r~~::::::

3.

Chipper/Shredder/Grinder

A.

Grinder

B.

Chipper section

C. Hopper

D.

Wheels and axle

..........................

use the chipper

......................

shredder/grinder .........

MAINTENANCE & SERVICE

. . . . .. . . . . . . . . . .. . .

.. , ...............................

........

..................................

..........................

:::::::::::::::

hammers

..............

and shaft

.............. ..

...................

TROVBLESHOOTING

LIST

......................

...................

redder/grinder

.......

..

...............

::::::::::::::

..........................

...................

.................

.

...............

.

........

...................

be

be

Page No.

..........

......

.

........

....

...... ..

..........

..... 16

...

..

.......

. 8

8

... 8

8

9

11

11

11

12

:i~

14

14

15

. 16

17

19

r

I

SECTION

I:

I

""-

I

I

Assembly

A WARNING:

.....

'you have

equipment.

CAUTION: Motor

starting.

STEP

the shippi

If

or the box), phone t he trucking company (carrier)

from whom you purchased your equipment

Info

a claim.

15

a claim

yo

STEP

yo

1. Remove the tie down holding the handle

2. Remove the hold-down

3. The

Item Description Qty.

Owner's Manual.

Engine

Goggles

THMS

Whiz-Nuts 1/4-20.

Allen Wrench 1/4" (For Knife)

Allen Wrench

Lockwasher,

Knife Clearance Gauge

(See Step 3

1:

Inspecting

NOTE:

Inspect your

ng

you find or suspect any

rm

them of

Be

sure

days, The

to

achieve satisfaction.

u need assi

Now

urself with

contai n the following:

for rod retainer pl

sta

2:

Uncrating

that

you have removed the box and

Parts

Manual.. . .. ..................

.................

114-20

and

Do

read

oil must be added

.)

after

pallet to see

the

damage and te

to

put

carrier

the

3/8" internal tooth, spare

will let you know how

nce with a shipping problem.

and

manual, proceed as follow

Kit (located in the chipper c

........

x 1

114"

5/32" (For Lock Collar)

ate

Preparation

not operate this

and

understood your manual and

delivery

equipment

that

this

assembly

..................................

........

.

............

...............

.....

while it's still sec

it

arrived

damage

in

brack

..............

(either the eq

ll

uniting

Of

course, let us know if

et

at

•...

•...•...•.

........................

...

them

the fron

.....................

........

. ..

equipment

to

the engine before

in

good condition.

uipment

or dea

right

you

wish to file

to

the

carrier within

to

proceed with

are

familiarizing

s:

to

the

pallet.

tsta

nd.

hut

e)

..

, .......

..........

...

...•......

.

...........

...

..........

..............

.....

..........

until

ured

ler

away.

should

......

.. 1

to

.4

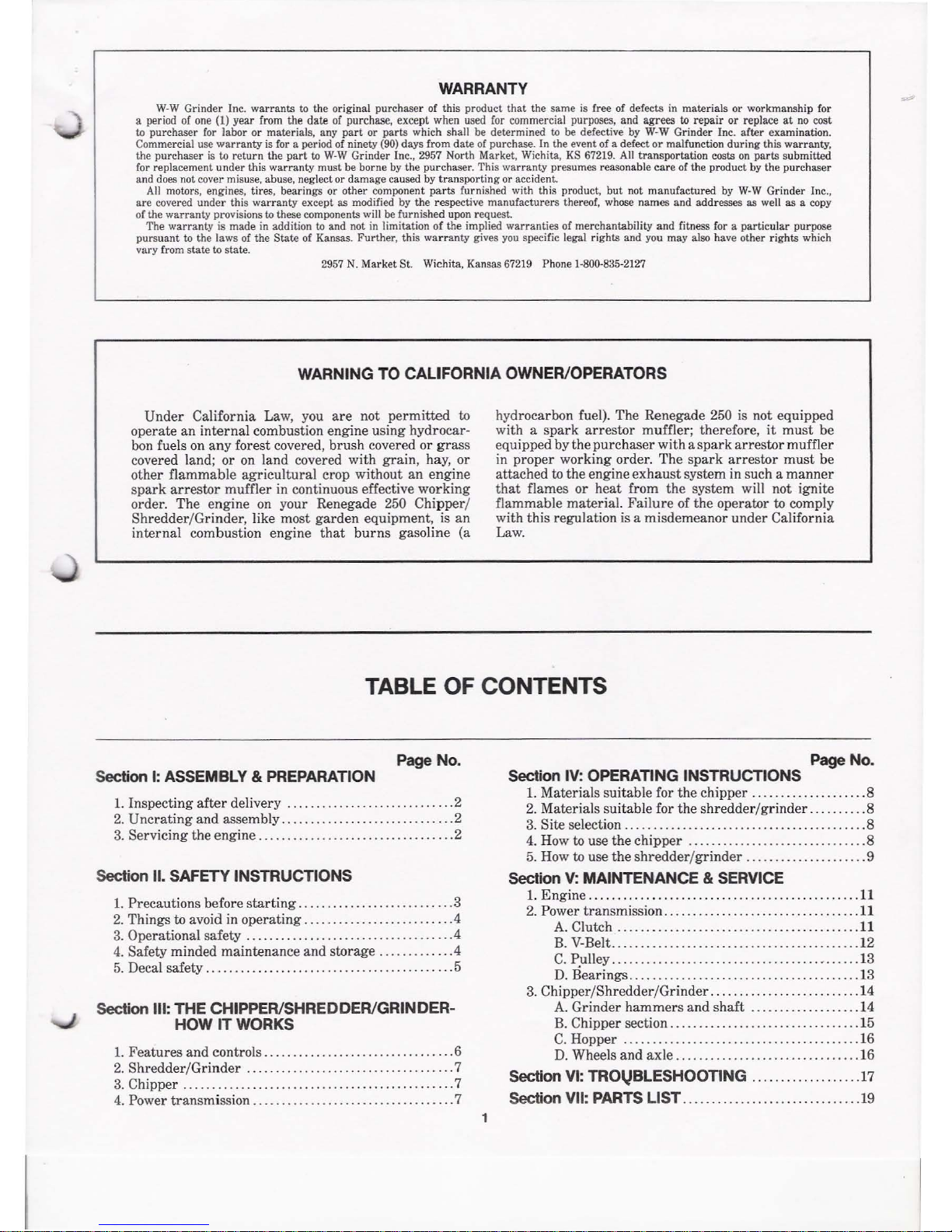

4. Install

screws

a #2 Phillip s screwdriver and a

tighten securely. (See photo L)

(Photo 1)

1

1

1

4

1

1

1

STEP

A

Please refer to your engine operating and maintenance

instruction manual w

package.

engine

orders and warranty service

Section

the handle with the four

(11

/4-20 x 11/4") and the four Whiz-Nuts using

3:

Servicing

WARNING:

wire disconnected before any maintenance or

service procedures are performed.

Your

on your

VoL)

the

engine

Engine

nearest authorized service center

Rene

gad

must

hi

ch was included

e 250 can handle all repairs,

truss

head machine

7/16" wrench,

be off and s

on

your engine. (Refer to

park

in

your literature

and

plug

for

parts,

the

2

"-

•

SECTION

II:

Safety

Instructions

WARNING:

READ THIS MANUAL

Incorrect usage

of

this machine may result

in

severe

injury. Personnel operating and maintaining it should

be trained in the proper use, should be

warned

of

dangers

involved, and should read the

manuals

completely and thoroughly before attempting

to

set-

up, operate, adjust

or

service this machine.

SAFETY FIRST!

This is a safety

alert

symbol,

which will be used

to

call your

attention

to

a safety message to

warn you of' possible danger to

your personal safety. When you

see

this symbol it means

you

should

become alert, your personal safety

is involved.

Warnings,

cautions,

notes

In

this manual. Warnings call attention

to

practices

or

procedures which may cause personal injury

or

death. It

is

the

owner's

responsibility

to

see that machine operators

have access

to

adequate instructions about safe operating

a

nd

maintenance procedures. Cautions call attention

to

practices

or

procedures which

may cause damage to your

equipment. Notes give pertinent information that helps

make operation and maintenance more efficient.

Before operating this equipment read all appropriate

manuals, paying partic ular attention to safety precautions

in this manual and

engine

owner/operator's manuals.

11..

WARNING:

Always keep hands and feet out from

.....

under

machine

whenever

engine

is

running.

Always

turn

off and disconnect

spark

plug

wire

before making adjustments

or

servicing equipment.

The W-W Grinder Renegade 250

is

as safe as good design

is capable of

making

it.

Safety

decals

The safety decals should be replaced if they

are

damaged,

co

vered over or otherwise become illegible. See IPL section

of this manual for appropriate

part

numbers.

Additional

safety

precautions

Keep hands, feet and clothing away from moving parts.

Keep hands and feet away from whirling hammer and

chipping blades.

Before servicing hammers or blades or performing

maintenance in chipping/shredding/grinding chamber:

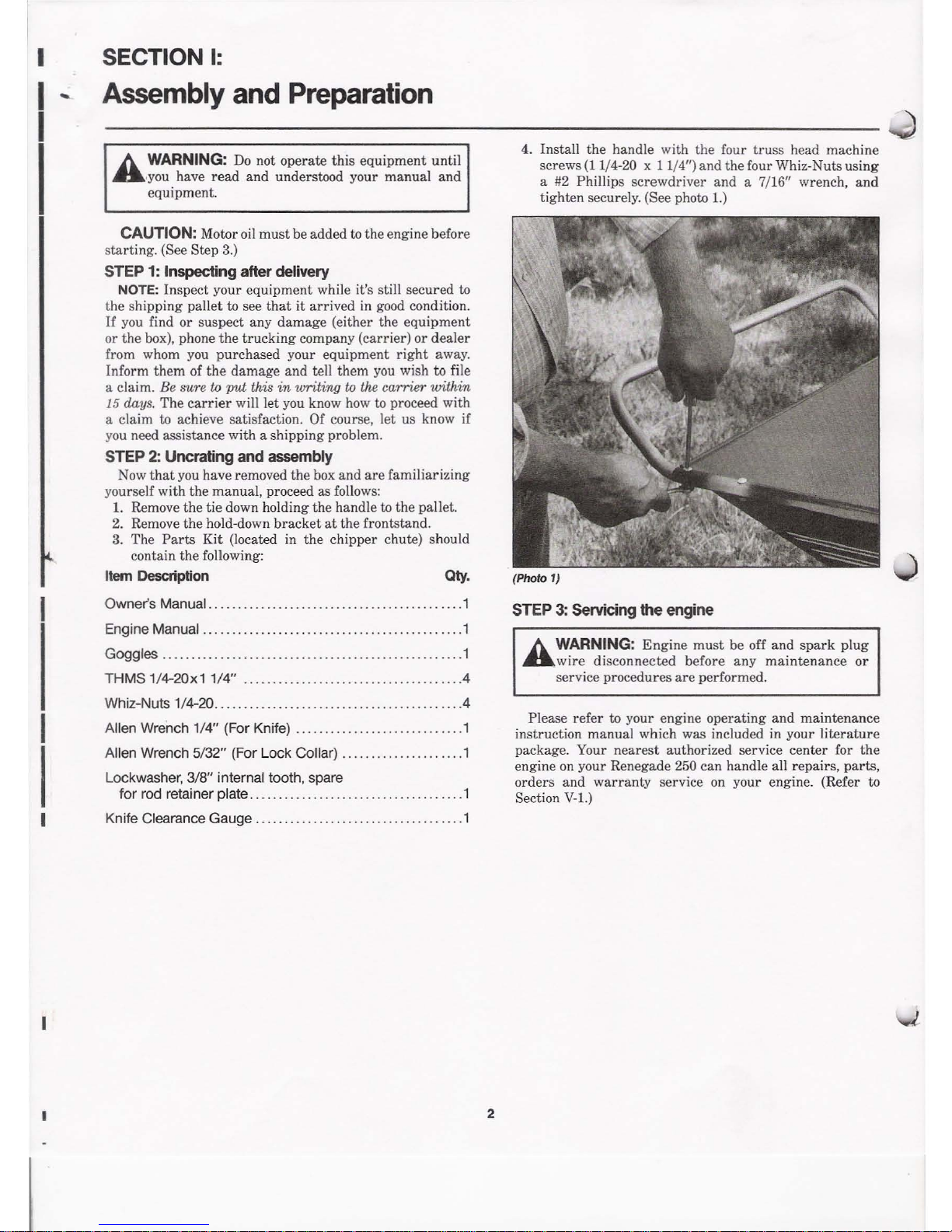

• Engine

must

be off and

spark

plug wire disconnected.

(See photo 2.)

3

(Photo

2)

• Engine stop switch is designed to stop engine when

it

is

engaged with

spark

plug.

Do

not touch

spark

plug

when using stop switch

or

you may receive a shock.

(See illustration A.)

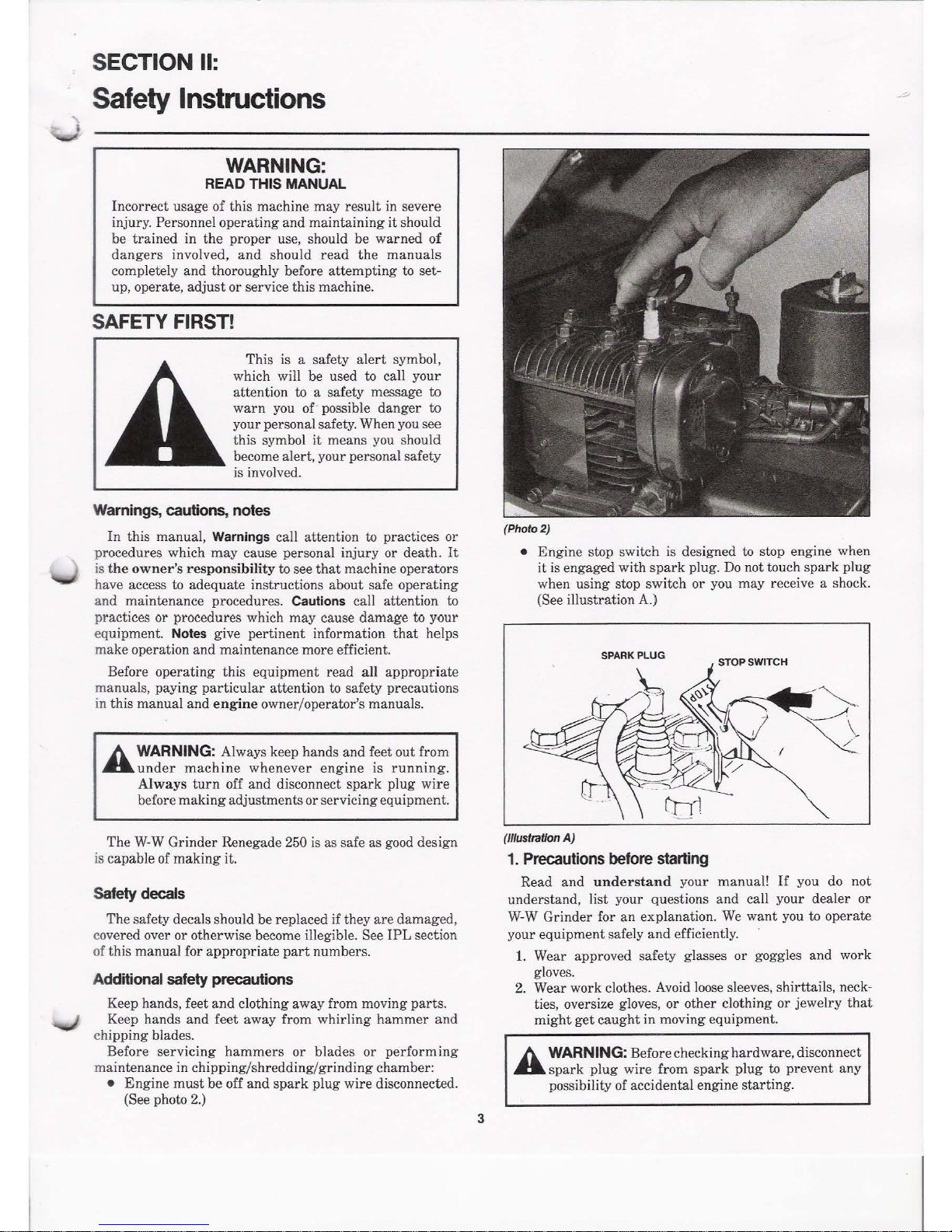

SPARK

PLUG

STOP SWITCH

(illustration

A)

1.

Precautions

before

starting

Read and

understand

your manual!

If

you do not

understand, list your questions and call your dealer or

W

-W

Grinder for an expla nation.

We

want you to operate

your equipment safely and efficiently.

1.

Wear approved safety glasses or goggles and work

gloves.

2. Wear work clothes. Avoid

loo

se sleeves, shirttails, neck-

ties, oversize gloves, or other clothing or jewelry

that

might

get

caught in moving equipment.

A

WARNING:

Before checking hardware, disconnect

~

spark

plug wire from

spark

plug

to

prevent any

possibility of accidental engine

starting

.

SAFETY INSTRUCTIONS

3. Check all fasteners (screws, nuts, bolts, V-belt, wheels,

etc.) and

4. Check

through the

hammers

clear

safet

5.

Move

co

mponents for security.

that

the

cylinder rotates freely by reaching

rubber flap

in

either

direction.

the

chamber

y,

item

number

the unit

to

with a stick and spinning the

If

an obstruction is preSent,

as instructed

under

22.

your work site. (Refer

Operational

to

Section

IV-3.)

2. Thi

ngs

to

avoid

in

operatin

If

you let anyone else operate your machine

you, be

operation of the

6.

7.

8.

sure

they

are

machine.

Do

not allow children

Do

not allow bystanders

are

chipping

Do not

or grinding materials.

put

your face or body in front of

thoroughly instructed

g

to

operate machine.

near

the machine when you

or

work with

to

the

feed openings

the

safe

while operating.

9.

Do

not stand

operat

ing.

10.

Do

not

operate

11. After towing your machine over uneven

terrain, make sure

in

front of the discharge

on

a paved or gravel surface.

you

have

no

gasoline spill before

area

or

when

rough

starting engine.

12.

Do

not

run

the

engine in an enclosed area, carbon

monoxide fr

poisonous gas, which

om

the engine exhaust is

is

also colorless, odorless

an

ext

remely

tasteless.

13. Do

3.

14. Make

15. Always

not operate with drive belt

Operational

or

operating.

sure

run

safety

the

unit

engine

guard

removed.

is level and stable before

at

full

RPM

while grindi

starting

ng

chipping.

16.

Do

not

put

hands or any other par

inside

openings

17. Keep all safety

an

18.

Do

balance and footing

the

feed hopper,

or

near screen area

guards

(screens and deflectors) in place

d in

goo

d operating conditi

not overreach when feeding material. Keep good

at

all times.

19. When feeding shreddable

grinder

metal, bottles)

20.

If

if the machi

vibration, immediately

the

be

ext

reme ly careful

are

not included.

the cutti ng mechanism strikes a foreign object

ne

starts making

shut

spark plug

wire from

tofthe

body or clothing

chipper

or

chute, discharge

any moving parts.

on.

materia

l in the chipper/

that

foreign objects (rocks,

an

unusual noise

off the engine. Disconnect

the

spark plug

and

take

following steps:

a. Inspect for damage.

h. Check for and tighten any loose parts.

c.

Replace or repair damaged parts.

21.

Do

not allow processed

mater

ial

to

build up

in

discharge area; this may prevent proper discharge

can result in kick-back of

materia

l through

the

opening.

22.

If

the chipper/

engine

cleaning.

23.

Do

not l

debris that could cause engine overheating

to

the

belt.

24.

Do

not

try

and

Use a

et

the

to ad j

grinder

becomes clogged,

disconnect

wood

stick

eng

ine and drive belt

ust

the

shut

off the

the

spark

plug wire before

to

clear debris.

get

clogged with

or

damage

engine governor setting. The

governor controls the maximum safe operating speed,

and

or

or

or

the

the

and

feed

protecting

the

engine and all moving

parts

from

caused by overs peed.

25. For safe operation do not relocate

machine while it is

26.

Avoid

the possibility of fire

a

hot

or

running engine, allow engine to

running.

or

or

transport

explosion; neVer refuel

refueling.

4.

Safety

27. Make

minded maintenance

sure

the

spark

the

spark

plug, before servicing, inspecting

and stora

ge

plug wire is disconnected f

season storage.

28. Allow

29.

the

eng

ine and chipper/

cool

before mak i

ng

any inspections or adjustments.

Store your machine level and

grinder

outof

the reach of children

and where gasoline vapors will not reach

or

spark. Be sure engine is

cool

before storing.

components to

an

30. Protect the engine from moisture when not in use.

moisture protection is not possible, run

frequently.

31. For

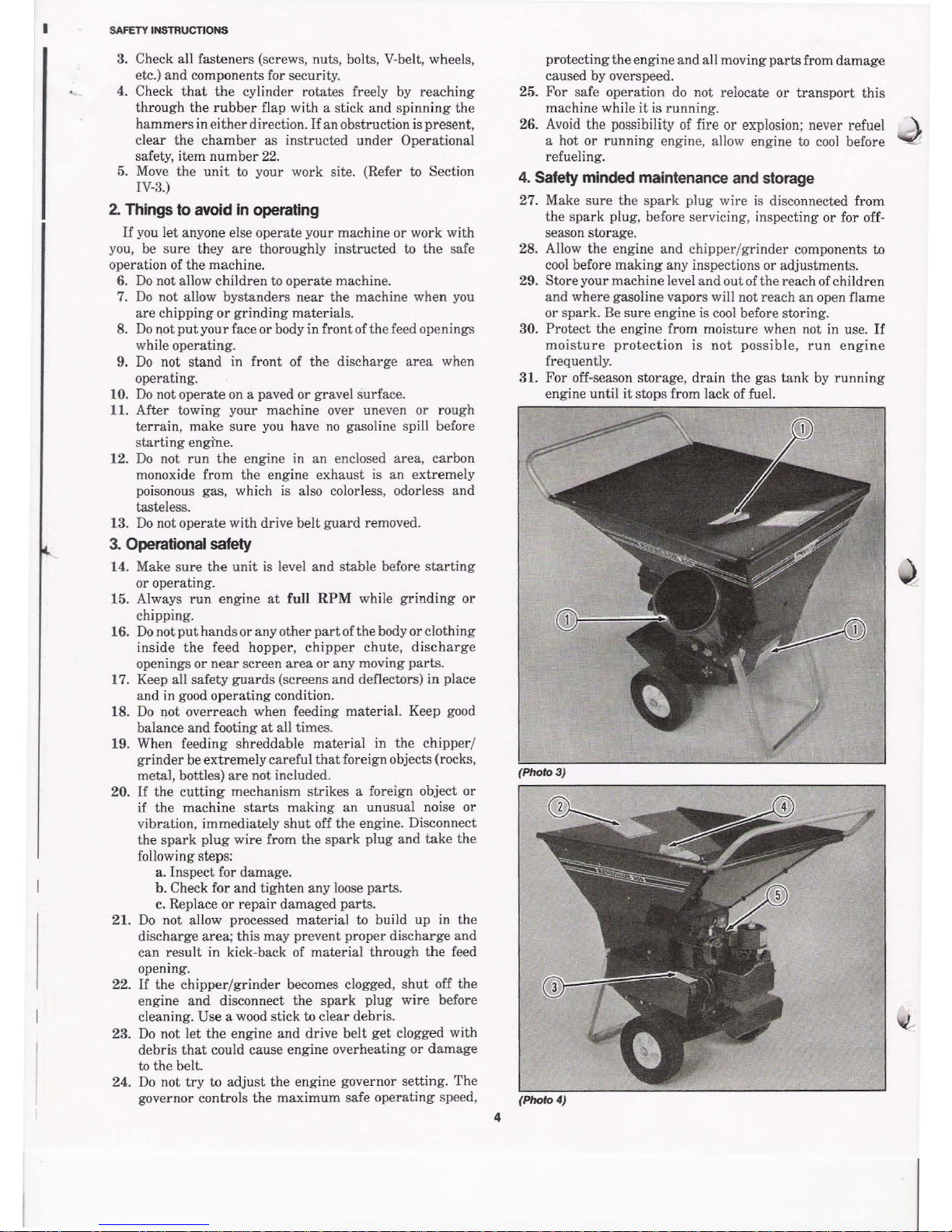

(Photo 3)

(Photo

4

off-season storage,

engine until

4)

drain

the

it

stops from lack of fuel.

gas

tank

damage

this

cool

before

rom

or

for of

open flame

engine

by

runni

ng

If

....

'

~

f-

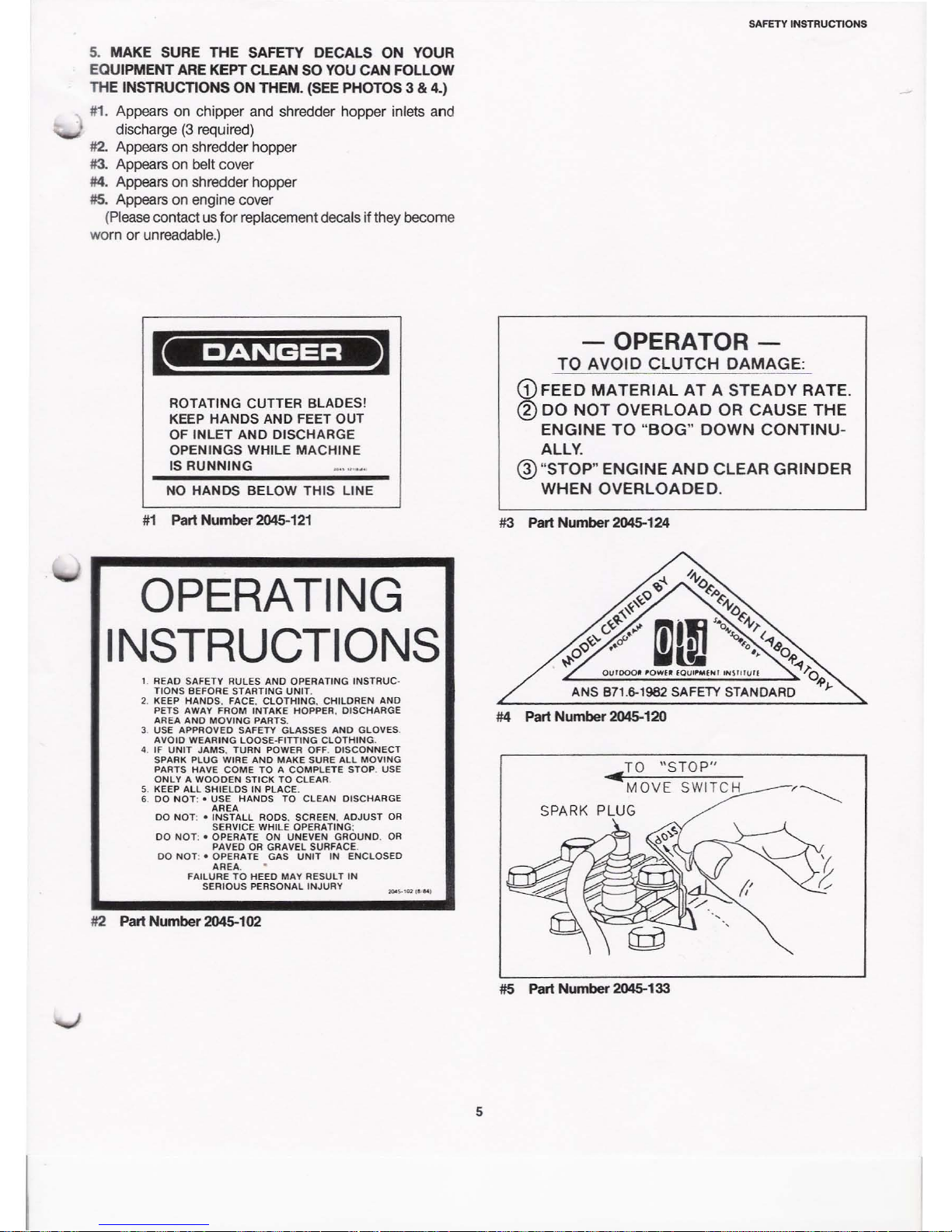

5.

MAKE SURE

EQUIPMENT ARE KEPT CLEAN SO YOU

INSTRUCTIONS

THE

#1.

Appears on chipper and shredder hopper inlets and

discharge

THE

(3

recuired)

SAFETY DECALS

ON

CAN

ON

THEM. (SEE PHOTOS 3 & 4.)

#2. Appears on shredder hopper

#3. Appears on belt cover

#4. Appears on shredder hopper

#5. Appears on engine cover

(Please contact

wo

rn

or

unreadable.)

us

for replacement decals if they become

ROTATING CUTTER BLADES!

KEEP

HANDS

INLET

OF

OPENINGS WHILE

IS

RUNNING

NO HANDS

AND FEET OUT

AND DISCHARGE

MACHINE

BELOW

THIS LINE

YOUR

FOLLOW

-

OPERATOR-

TO

AVOID

G)FEED

®

DO

ENGINE

MATERIAL

NOT

OVERLOAD

TO

ALLY.

@ "

STOP"ENGINEAND

WHEN

OVERLOADED.

CLUTCH

AT A STEADY

"BOG"

DOWN

SAFETY

INSTRUCTIONS

DAMAGE:

RATE.

OR CAUSE THE

CONTINU-

CLEAR GRINDER

#1

Part Number 2045-121

OPERATING

INSTRUCTIONS

1 REAO SAFETY RULES

TION

S BEFORE

2. KEEP

HANDS

PETS AWAY

AREA

3. USE APPROVED SAFETY GLASSES

AVOID

4.

IF

UNIT

SPARK

PARTS HAVE

ONLY A WOODEN

5.

KEEP

6

DO

DO

DO

DO

FROM

AND

MOVING

WEARING

JAMS. TURN

PLUG

ALL

SHIELDS

NOT

: •

USE

AREA

NOT

: •

INSTALL

SERVICe WHILE OPERATING:

NOT

: • OPERATE ON UNEVEN

PAVED OR GRAVEL SURFACE.

NOT

: . OPERATE

AREA. •

FAILUAE

SERIOUS PERSONAL INJURY

#2 Part Number 2045-102

AND

STARTING

. FACE.

WIRE

COME

HANDS

TO

UNIT

CLOTHING. CHILDREN

INTAKE

PARTS

.

LOOSE-FITTING

POWER

AND

MAKE

TO A COMPLETE

STICK

TO

IN

PLACE

TO

RODS. SCREEN ,

GAS

HEED MAY RESULT IN

OPERATING

HOPPER.

CLEAR.

.

CLEAN

UNIT

INSTRUC-

.

DISCHARGE

AND

CLOTHING

OFF. DISCONNECT

SURE

ALL

STOP

DISCHARGE

ADJUST

GROUND.

IN

ENCLOSED

AND

GLOVES

.

MOVING

. USE

.

OR

OR

»O

<j..'"241&*)

#3 Part Number 2045-124

#4 Part Number 2045-120

TO

·M

OVE SWITC

SPARK

PLUG

"ST

OP"

H

#5 Part Number 2045-133

5

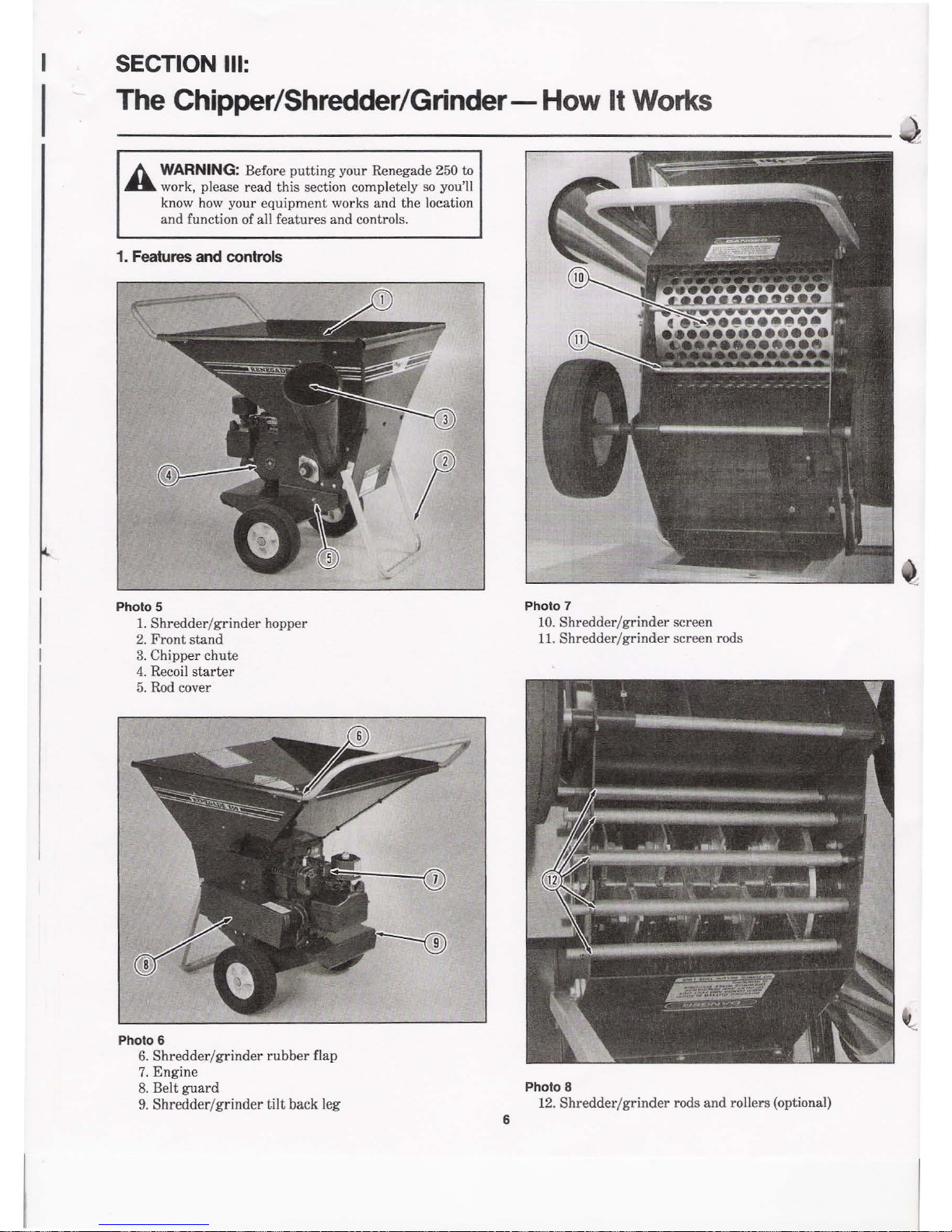

SECTION III:

The ChipperlShredder/Grinder-How It Works

WARNING: Before putting your Renegade 250

A

work, please read this section completely so you'll

know

how

you

r equipment works

and function of all features and controls.

1.

Features

Photo 5

1.

2.

3.

4.

5.

and

controls

Shredder/gr

Front

Chipper chute

Recoil

Rod

cover

inder hopper

stand

starter

and

to

the location

!

Photo 7

10.

Shredder/grinder

11.

Shredder/grinderscreen

screen

rods

Photo 6

6.

Shredder/grinder

7.

Engine

8.

Belt

guard

9.

Shredder/grinder

rubber

flap

tilt back leg

6

Photo 8

12.

Shredder/grinder

rods and rollers (optional)

Loading...

Loading...