Wurth Online World COOLIUS 4000 HP, W050200011 User Manual

User’s manual

COOLIUS 4000 HP automatic a/c service unit

Art.-No.W050200011

2154-ENG / Version 02/2014

CONTENTS

Safety precautions ................................................................................................................................................................... 2

Layout drawings ..................................................................................................................................................................... 3

Hydraulic diagram .................................................................................................................................................................. 5

Electric diagram ...................................................................................................................................................................... 6

Legend .................................................................................................................................................................................. 7

1 Introduction to recovery unit COOLIUS-HP ........................................................................................................................ 8

1.1 Technical specifications ................................................................................................................................................ 8

2 Components description and standard equipment .............................................................................................................. 8

2.1 High vacuum pump ..................................................................................................................................................... 8

2.2 Refrigerant charging pump ........................................................................................................................................... 8

2.3 Refrigerant bottle ......................................................................................................................................................... 8

2.4 Distiller/Separator ........................................................................................................................................................ 8

2.5 Compressor ................................................................................................................................................................ 9

2.6 Filters drier .................................................................................................................................................................. 9

2.7 Flexible hoses .............................................................................................................................................................. 9

2.8 Quick coupler valves .................................................................................................................................................... 9

2.9 Printer ......................................................................................................................................................................... 9

2.10 Control module ........................................................................................................................................................... 9

3 Preparing unit COOLIUS-HP for operation ...................................................................................................................... 11

3.1 Checking the vacuum pump oil level ........................................................................................................................... 11

3.2 Turning COOLIUS-HP unit on for the first time ............................................................................................................. 11

3.3 Filling refrigerant into the internal bottle ...................................................................................................................... 12

4 Using unit COOLIUS-HP .............................................................................................................................................. 13

4.1 Refrigerant recovery ................................................................................................................................................... 13

4.2 Vacuum + Vacuum Test ............................................................................................................................................. 14

4.3 Olio / Uv – Refrigerant charge .................................................................................................................................... 14

4.4 Automatic cycle ......................................................................................................................................................... 16

4.5 Flushing .................................................................................................................................................................... 18

4.6 Checking the A/C system operating pressures .............................................................................................................. 19

4.7 Disconnecting the unit from the A/C system ................................................................................................................. 19

4.8 Setting Menu ............................................................................................................................................................. 19

5 Service procedures ...................................................................................................................................................... 21

5.1 Emptying the internal refrigerant bottled ...................................................................................................................... 21

5.2 “Zero” scale check ..................................................................................................................................................... 21

6 Routine maintenance ................................................................................................................................................... 22

6.1 Material for routine maintenance ................................................................................................................................ 22

6.2 Periodic operations .................................................................................................................................................... 22

6.3 Changing the vacuum pump oil .................................................................................................................................. 22

6.4 Replacing the filter drier ............................................................................................................................................. 23

7 Troubleshooting .......................................................................................................................................................... 25

8 Accessories and spare parts .......................................................................................................................................... 26

9 Weight and dimensions ................................................................................................................................................ 26

1 - 32

Safety precautions

This equipment is designed for trained personnel only, who must know the refrigeration

fundamentals, cooling systems, refrigerants and possible damage that pressurized equipment may

cause.

Only use refrigerant R134a. The unit must not be used with a different refrigerant than the one it has

been designed for.

Carefully read the instructions contained in this manual; strict observance of the procedures

described is fundamental to the operator’s safety, the perfect state of the unit and constant

performances as declared.

The unit must always work under the operator’s direct supervision

Before performing any operation, make sure that the hoses used for connections have been

previously evacuated and that they do not contain non-condensable gases.

Avoid skin contact; the low boiling temperature of the refrigerant (about -30°C) can cause freezing.

Avoid breathing refrigerant vapours.

It is recommended to wear suitable protections like safety glasses and gloves; contact with refrigerant

may cause blindness and other personal injuries.

Do not smoke near the unit and do not operate near open flames and hot surfaces; the high

temperatures decompose the refrigerant releasing toxic and caustic substances which are hazardous

for the operator and the environment.

Always make sure that the unit is connected to a suitably protected mains supply provided with an

efficient earth connection.

Before performing maintenance operations or when the unit will not be used for a long period of

time, turn the unit off by turning the main switch to 0 and disconnect the power supply cord;

absolutely follow the sequence of operations.

Operate the unit only in locations with suitable ventilation and a high number of air changes.

Before disconnecting the unit, make sure that the cycle has been completed and that all valves are

closed in order to avoid release of refrigerant to the atmosphere

Never fill any tank with liquid refrigerant to more than 75% of its maximum capacity.

During operations avoid release of refrigerant to the environment; this precaution is required by

international environmental standards and is essential to avoid difficult leak detection in a refrigerant

polluted environment.

Protect the unit from dripping.

Do not expose the unit to direct sunlight, rain and to the inclemency of the weather.

Do not modify the calibration of safety valve and control systems.

If you recover refrigerant from a cooling system equipped with a water evaporator and/or condenser,

it is necessary to drain water from the evaporator and/or condenser or to keep the circulation pump

running during the entire recovery operation in order to avoid frosting.

Disconnect the unit from the power supply if not used.

General information

Perform a good vacuum cycle before charging refrigerant into the system!

Perform the refrigerant charging phase after having charged oil or UV!

Empty the used oil bottle before starting the recovery phase!

WARNING

If you do not pay attention to the above safety precautions, you could damage the recovery unit and the

car A/C system!

!

2 - 32

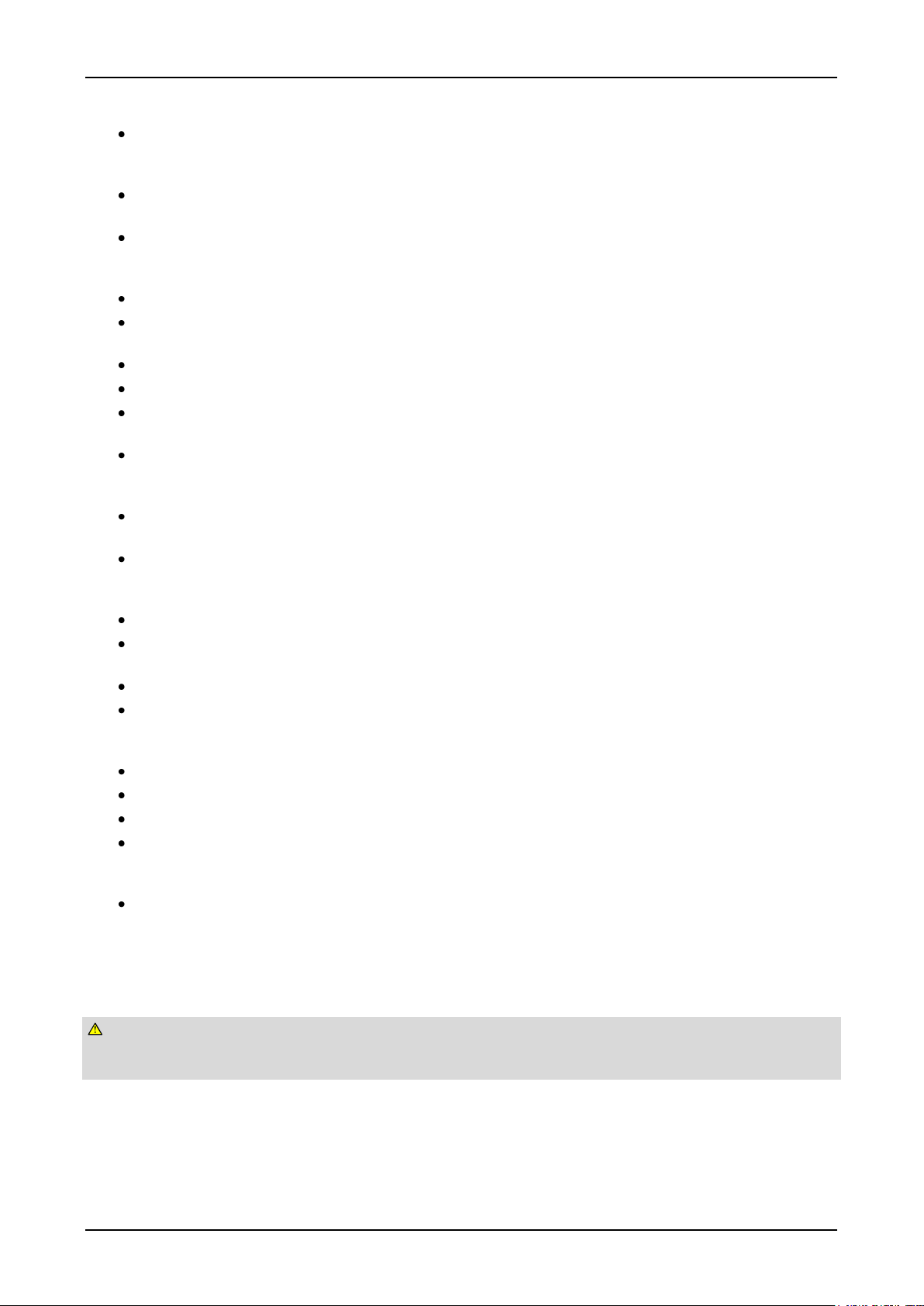

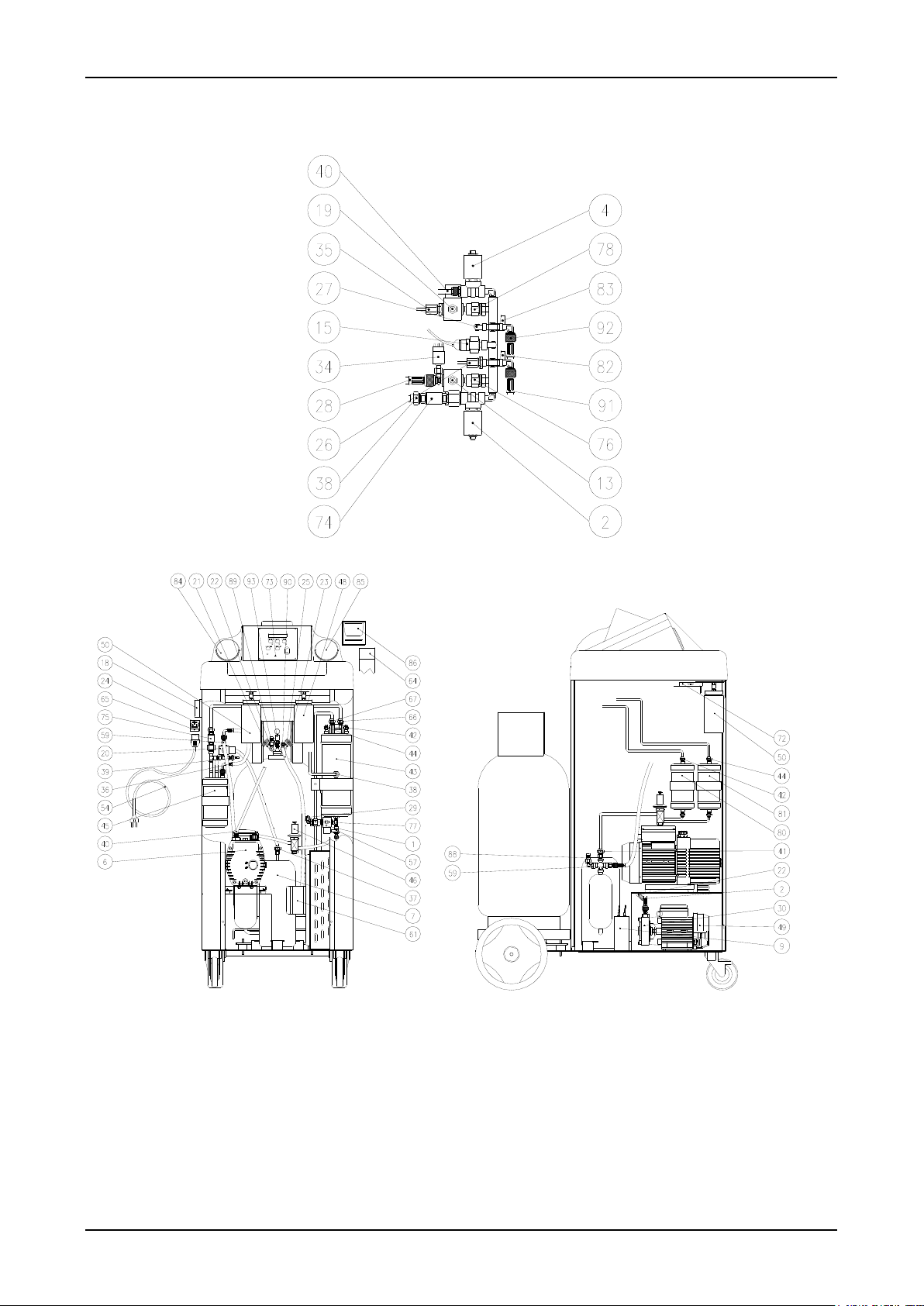

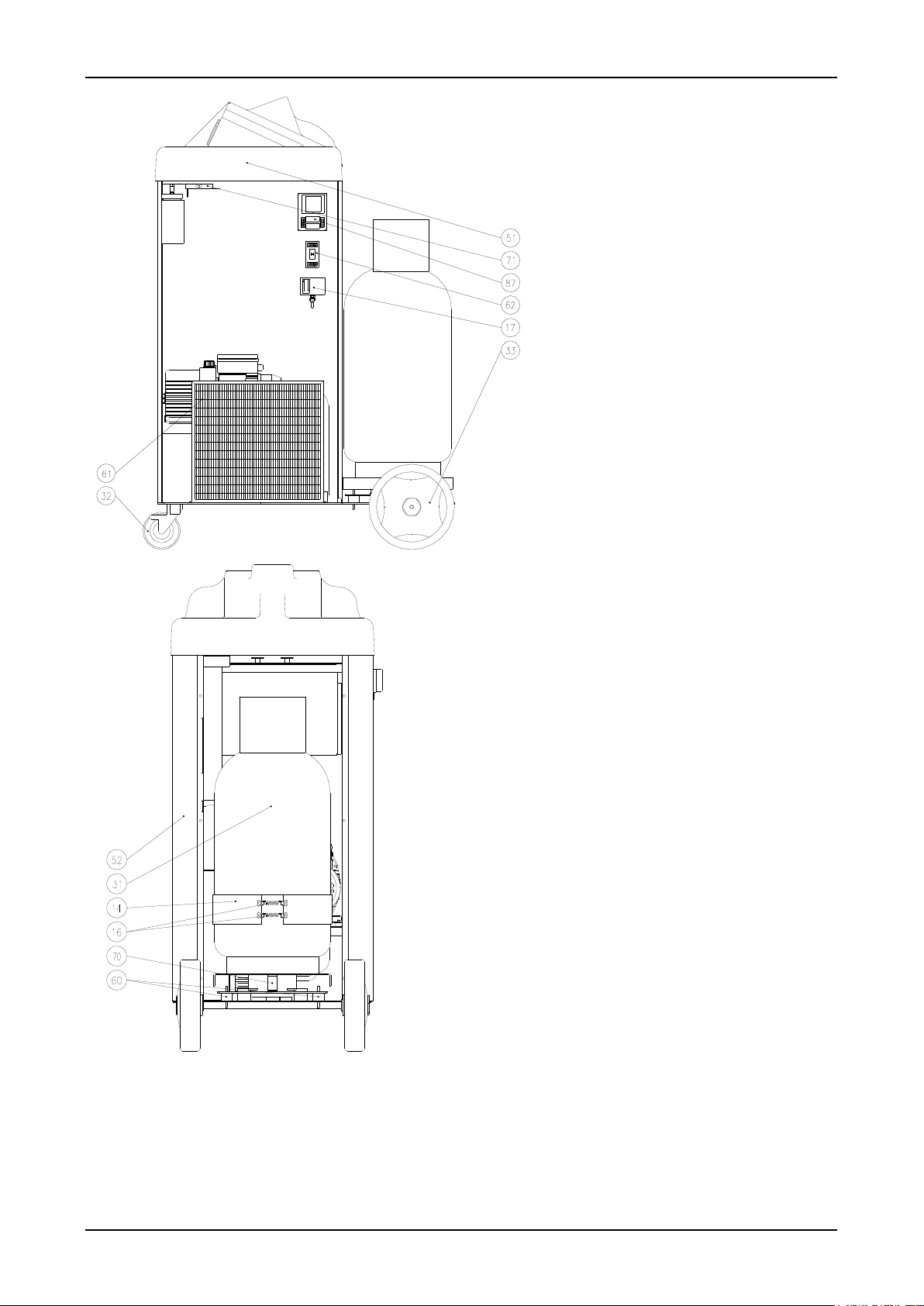

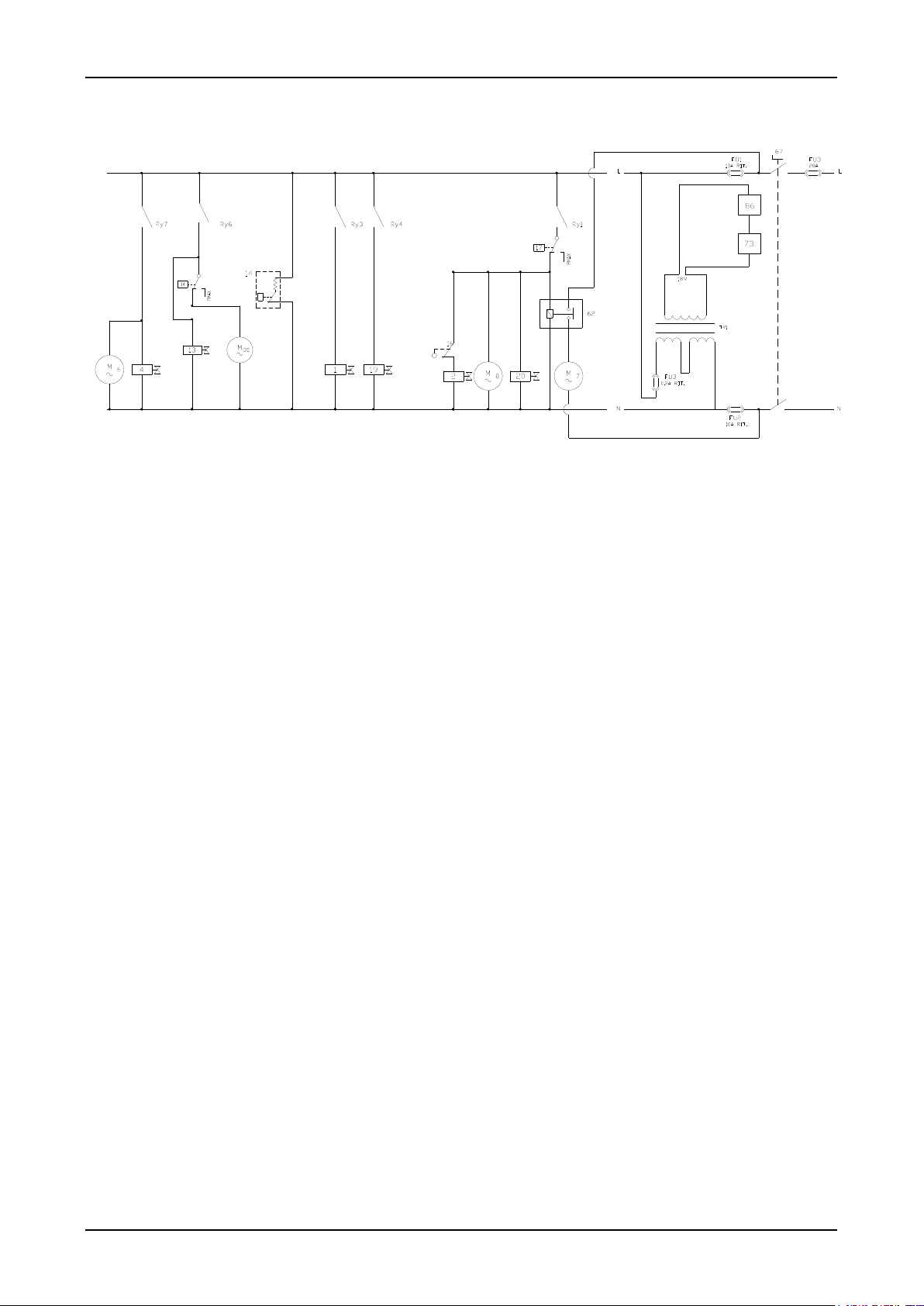

Layout drawings

Picture 1

3 - 32

Picture 2

4 - 32

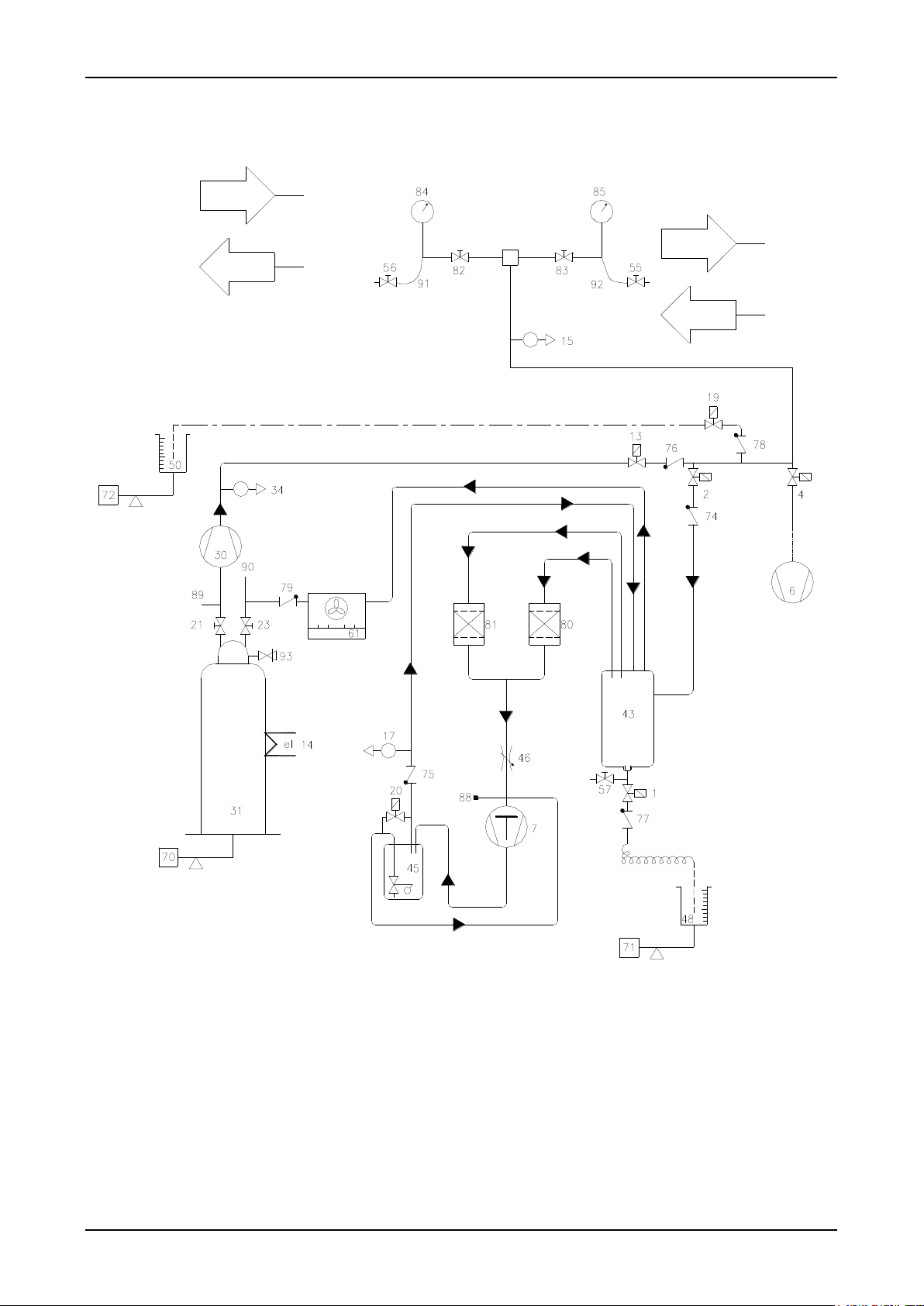

Hydraulic diagram

Picture 3

5 - 32

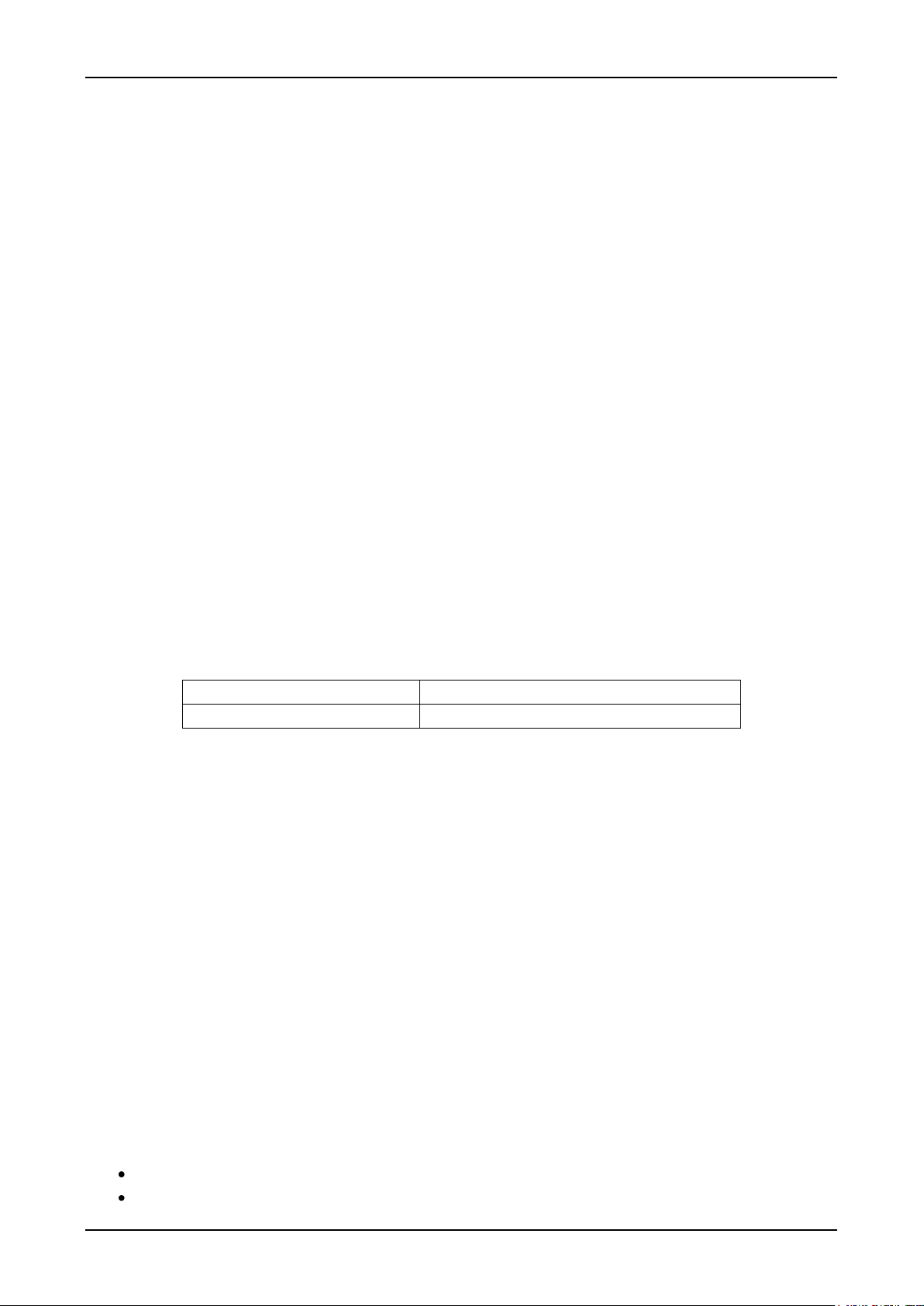

Electric diagram

Picture 4

6 - 32

1

Solenoid valve – oil discharge line

48

Oil discharge bottle

2

Solenoid valve - recovery line

49

Refrigerant charge pump

4

Solenoid valve - vacuum line

50

Oil/UV charging bottle

6

Vacuum pump

51

Plastic cover

7

Compressor

52

Frame

9

Compressor starting condenser

53

Front door

10

Vacuum pump oil filler plug

54

Power cable

11

Vacuum pump sight glass

55

HIGH quick coupler

12

Vacuum pump oil drain plug

56

LOW quick coupler

13

Solenoid valve - refrigerant charging line

57

Manual discharge valve on the distiller

14

Heater belt with thermostat on the bottle

59

Oil return hose to compressor

15

Pressure transducer

60

Vibration damping feet on the scale

16

Spring for heater belt

61

Condenser with fan

17

Safety pressure switch

62

Remote control witch for recovery compressor

18

Main power switch

64

Thermal paper roll

19

Solenoid valve - oil/UV charging line

65

Fuse on outlet (10A)

20

Solenoid valve - pressure return to compressor

66

Distiller coil inlet tube

21

Liquid valve on the bottle

67

Distiller coil outlet tube

22

Refrigerant charge hose (bottle-pump)

68

Rear door

23

Vapour valve on the bottle

69

Handle

24

Power outlet (with fuse)

70

Load cell - 100 kg (refrigerant)

25

Condenser / bottle connecting hose

71

Load cell - 5 kg (oil discharge)

26

Capillary hose connecting LOW valve to LP gauge

72

Load cell - 5 kg (oil charge)

27

Capillary hose connecting HIGH valve to HP gauge

73

Control board

28

Refrigerant charge hose (pump-valve block)

74

Check valve - recovery line

29

Oil discharge capillary tube

75

Check valve – compressor delivery line

30

Refrigerant charge pump motor

76

Check valve – refrigerant charging line

31

Complete refrigerant bottle

77

Check valve – oil discharge line

32

Front wheel with brake

78

Check valve – oil charging line

33

Rear wheel Ø 250

79

Check valve - compressor delivery line (condenser)

34

Safety pressure switch on refrigerant charging line

80

Filter drier

35

Oil injection capillary tube

81

Filter drier

36

Hose - pressure return to compressor

82

Manual valve - LOW

37

Compressor/compressor oil separator connecting

hose

83

Manual valve - HIGH

38

Valves assembly - distiller connecting hose

84

LP gauge

39

Safety switch capillary hose

85

HP gauge

40

Vacuum pump hose

86

Printer

41

Compressor suction hose

87

Electric feeder

42

Distiller/filter F1 connecting hose

88

Service connection for compressor evacuation

43

Distiller / separator

89

Bottle service connection

44

Distiller/filter F2 connecting hose

90

Bottle service connection (1/4” SAE)

45

Oil separator – complete compressor

91

LOW flexible hose

46

Flow regulation valve with hoses

92

HIGH flexible hose

47

Handle support

93

Safety valve

Legend

7 - 32

Model

Couplers and connections

COOLIUS-HP

1/4” SAE with quick couplers

1 Introduction to recovery unit COOLIUS-HP

Unit COOLIUS-HP permits quick and efficient recovery of refrigerant from the A/C system, refrigerant

recycling, system evacuation, check for tightness, additive or lubricant injection, the subsequent charge with

refrigerant and measurement of the operating pressures.

Unit COOLIUS-HP permits to control all functions by means of 3 electronic scales (Refrigerant, Discharged

Oil from A/C system, new Oil/Uv), 1 pressure transducers.

1.2 Technical specifications

Refrigerant R134a

Maximum storage capacity 40 kg

Refrigerant supply 4 kg

Maximum recovery rate 1,0 kg/min

Maximum oil capacity 500 g

Oil supply 50 g

Power supply 230/1/50

Power input 1400 W

Storage temperature -10 ÷ +50 °C

Working temperature 0 ÷ 40 °C

Protection degree IP24

Noise level < 70dB (A)

Maximum refrigerant charge The maximum refrigerant quantity available for charging is

calculated by subtracting 4 kg from the weight of the

refrigerant contained in the bottle and indicated on the

display

max kg for charging = kg in bottle - 4 kg

2 Components description and standard equipment

2.1 High vacuum pump

Essential component for extracting from the cooling system the residues of technical gases used for pressing,

ambient air and vapour contained in it as well as water possibly formed through vapour condensation. The

high vacuum pump the unit is equipped with is rotary vane type, lubricated by oil injection.

2.2 Refrigerant charging pump

Rotary gear pump enables to have high refrigerant charging rates

2.3 Refrigerant bottle

Maximum capacity kg 40

Weight of empty bottle kg 22

It is provided with two connections, one of which with tube (liquid refrigerant) and one without tube (vapour

refrigerant), safety valve and heater belt with thermostat. The non condensable gases discharge is controlled

automatically by the software.

2.4 Distiller/Separator

Single body construction, featuring:

Distillation chamber with automatic flow control

Separating chamber for the oil removed from recovery compressor and return

8 - 32

Loading...

Loading...