WURGES HV 6 W Operation Instructions

E

10/99 1/4

vibrationmotors

HV 6 W

Instructions of operation

and

List of spares

Important remark concerning the personal safety of operators

These instructions must be understood by each operator,

who is in charge of the assembly, putting into operation,

maintenance and repair work of vibration motors. The same

applies to supplementary instructions for modified

equipment.

Our vibration motors have been manufactured in

accordance with the latest art. In case of use as provided,

they are sure to operate.

Unauthorized changes with the motors and specific

execution for the client are excluded from the manufactures

guarantee for resulting damage.

It is an implied feature of vibration motors that they

generate destructive forces. In case of improper use, these

destructivforces are apt to cause danger, e.g. the motor or

components thereof can drop uncontrolled after getting

loose from the fastening means. As a precaution, safety

measures must be adopted.

When performing maintenance or repair work, the vibration

motor must be disconnected from the power system.

Putting vibration motors into operation without protective

cover is forbidden, because risk of accident may result.

Instructions for mounting vibration motors

General

Vibration motors must be mounted only on equipment with

plane surfaces, which are resistant to bending. These

surfaces must not be subject to tensions.

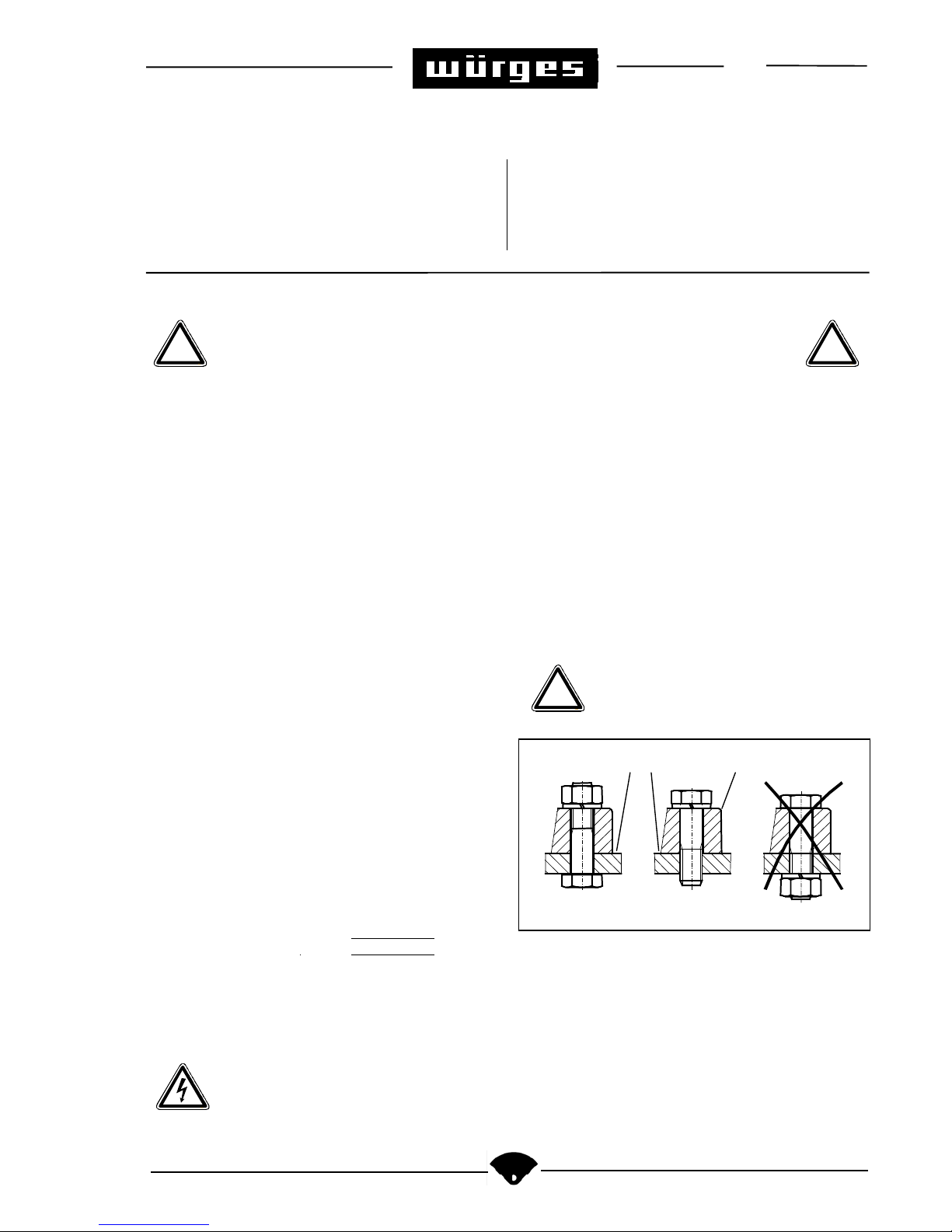

Only screws of grade 8.8 and nuts of grade 6 must be used.

The screws must be secured from slackening, e. g. by spring

washers or the like.

Posterior tightening of screws and nuts

After the first two hours of operation the screws or nuts

must be checked for tight seating. Subsequent inspections

shall be performed once daily. In case of necessity the

screws or nuts must be retightened.

The minimum torques are for: M10 = 55 Nm

M12 = 90 Nm

If the screws have slackened, danger of

breakage of the feet of the vibrator is

impending.

screwplate vibratorfoot

correct correct wrong

Anweisung zum elektrischen Anschluß

Dangerous Voltage!

Non-compliance can cause death, serious

bodily injury or property damage.

General

The power connection must be established only by an

electrician. The voltage and frequency must be that, which

is indicated on the machine plate (230 V , 50/60 Hz). The

vibration motor must be connected only to power supply

which is in agreement with the VDE regulations.

! !

!

10/99 2/4

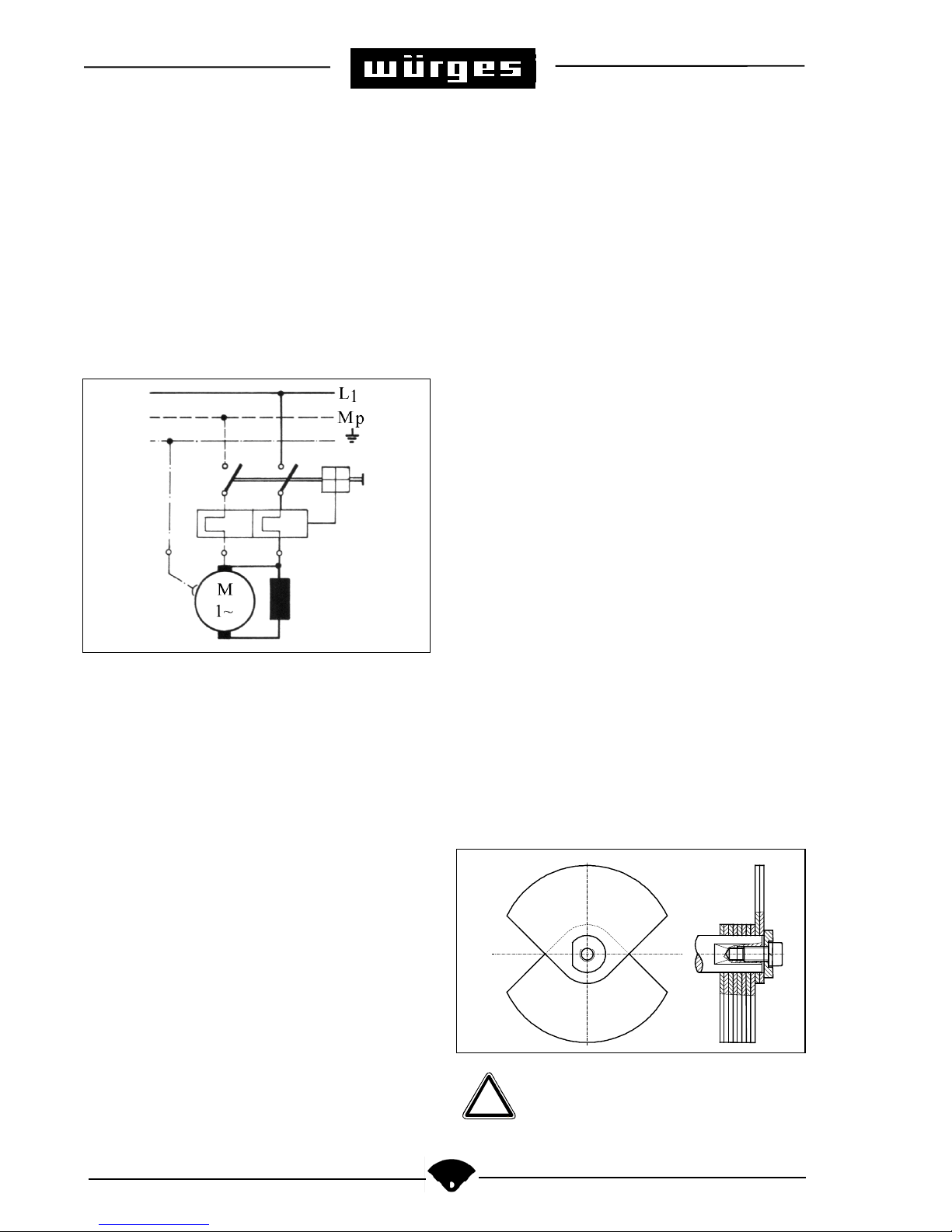

To secure the motor from overload, it must be connected in

series with a terminal circuit breaker (1A).

Power connection

The power connection must be established only by a

flexible cable. We recommend to use the following cable

type: ÖLFLEX 540 P 2,5². Plastic cables are not suitable.

The connection cable must be laid in a manner which

excludes inherent vibrations and any load by traction.

Kunststoffkabel sind ungeeignet.

1. Kabelmantel ca. 8 cm entfernen

2. Den Schutzleiter 1-2 cm Länger belassen als die Adern

der Phasen.

3. Provide the ends of the strands with terminals or

compression cable sockets. Never fasten the terminals

or sockets by soldering, as in default of this the strands

tend to break behind the soldered spots in case of

vibration.

4. Introduce the cable into the the terminal box and

establish the connection as shown in the diagram.

5. When tightening the cap screw of the screw joint, it

must be observed that the cable jacket is still fully

seized by the seal. If this is not observed, the cable is

not firmly clamped, not relieved from traction, and not

waterproof.

6. Close again carefully the terminal box with seal and

screws..

7. The power cable must be fastened firmely shortly

behind the cable gland. This first fastening of the cable

and the motor should by no means be movable against

each other. The cable has to be installed in such a way

that it does not start vibrating itself and that it is not

subject to any tractional forces.

8. When putting the vibration motor into operation the

power input must be examined. Should this be larger

than the data on the mashine plate, the trouble can be

remedied by reducing the centrifugal force.

9. Now and again it must be checked that there are no

spots which are subject to friction.

Admitted operating temperature

Outside on the housing not higher than 80°C.

This limit may be surpassed by too high a power input, if

the speed which is indicated on the mashine plate is not

reached, with the result that the winding may burn out. The

reason may be too high a centrifugal force for the case

which is existing or a construction of insufficient resistance

to bending. The trouble can be set by reducing the

centrifugal force.

Setting the centrifugal force

Provide that no different centrifugal force had been

indicated in the order sheet, the motor has been set for the

full centrifugal force. In order to be able to change the

centrifugal force both protective covers must be taken off.

Once the protective covers are taken off, the centrifugal

force may be changed as desired. But it must be observed

that the adjustment is the same on both sides.

This is achieved by removing the screws or nuts from the

armature on both sides and by transposing the flywheels by

180°. With this the centrifugal force is reduced by twice the

value of the transposed flywheels. But in the case, the

removed flywheels must be replaced by spacers. (Please

compare the corresponding list of spares).

One flywheel on each side generates a centrifugal forces of

65 daN at 5000 min

-1

.

Nach dem Verstellen müssen gelöste

Schrauben wieder befestigt werden und die

Schutzhauben unbedingt wieder montiert

werden. Ansonsten besteht Unfallgefahr.

!

Loading...

Loading...