Page 1

W&T

Manual

Web-Thermometer

Web-Thermo-Hygrometer

Web-Thermo-Hygrobarometer

Web-Thermometer Relay

Web-Thermometer Air Quality

Typ 10/100BaseT, 12-24V

Modell 57713, 57714, 57715

57716, 57718, 57720

Release 1.03, Mar 2016

Page 2

W&T

© 03/2016 by Wiesemann und Theis GmbH

Microsoft, MS-DOS, Windows, Winsock and Visual Basic

are registered trademarks of the Microsoft Corporation

Subject to errors and changes:

Since we can make mistakes, none of our statements should

be used without checking. Please let us know of any mistakes

or misunderstandings you are aware of, so that we can recognize and eliminate them quickly.

Perform work on and with W&T products only as described

here and only if you have read and understood the manual

fully. Unauthorized use can result in hazards. We are not liable for the consequences of unauthorized use. When in doubt,

check with us or consult your dealer!

Page 3

W&T

Introduction

The W&T Web-Thermometer contains all functions in a box

to measure, store and display your climate data. Moreover,

the numerous alarm functions are available which can be integrated into your own applications or into available systems.

In this manual you find all information which you need for the

installation, configuration and the use of the Web-Thermometer.

Page 4

W&T

Content

Introduction ................................................................... 3

1 Quick-Start/Commissioning ........................................ 7

1.1 Connecting the sensor (#57713, #57714, #57715,

#57718, #57720) ............................................................7

1.2 Connecting the PT100/PT1000 sensor and output confi-

guration (#57616) ...........................................................8

2 Online measurement storage inside the W&T Cloud . 14

2.1 Auto connect ................................................................14

2.2 Create a user account ...................................................14

2.3 Assign data by 4-digit access code in the cloud ............15

2.4 Assign measured data via user account in the device ....15

3.1 Configuring network parameters with WuTility ..... 16

3.1.1 Applications and prerequisites ...................................16

3.2 Assigning the IP using DHCP protocol ................... 19

3.2.1 Manual activation of DHCP .........................................19

3.2.2 System name .............................................................20

3.2.3 Lease time .................................................................20

3.3 Assigning the IP using the ARP command .............. 21

3.4 Assigning the IP using the serial port.................... 23

4 Supply voltage .......................................................... 25

4.1 Power over Ethernet ......................................................25

4.2 External supply .............................................................25

5 Ethernet interface ..................................................... 26

5.1 Link status ....................................................................26

5.2 10/100BaseT on RJ45 ...................................................26

Page 5

5

W&T

6 Connecting the sensor .............................................. 27

6.1 NTC sensor measuring input (#57714) ..........................27

6.2 Pt100/1000 sensor measuring input (#57715) ..............27

6.3 Combined sensor measuring input (#57713, #57720) ..27

7 Configuration Using Web-Based Management ........... 29

7.1 Home ............................................................................29

7.2 Visualization .................................................................30

7.3 Own webpage ...............................................................31

7.4 Login ............................................................................31

8 Basic Settings ............................................................ 33

8.1 Network ........................................................................33

8.2 Sensors .........................................................................34

8.3 Date/Time ....................................................................34

8.4 Language/Infos .............................................................34

8.5 Data storage .................................................................35

8.6 Password ......................................................................35

9 Communication paths ............................................... 36

9.1 Web pages ....................................................................36

9.2 Mail ..............................................................................39

9.3 Cloud............................................................................39

9.4 RSS ...............................................................................39

9.5 SNMP/Syslog .................................................................39

9.6 FTP ...............................................................................40

9.7 Socket access ...............................................................40

10 Alarms/Messages ................................................... 41

11 Diagnosis ................................................................ 43

12 Device information ................................................. 44

13 Maintenance ............................................................ 45

13.1 LED Test .....................................................................45

13.2 Reboot ........................................................................45

13.3 Factory defaults ..........................................................45

13.4 Save configuration ......................................................46

13.5 Restore configuration .................................................46

Page 6

6

W&T

14 Individual request of measurement values ............. 47

14.1 Request via TCP/IP ......................................................47

14.2 Requesting via UDP .....................................................48

14.3 Requesting via SNMP ...................................................49

15 Firmware Update ..................................................... 52

15.1 Where is the latest firmware available? ........................52

15.2 Firmware update over the network under Windows .....52

16 Hardware-Reset to factory defaults ........................ 54

17 Technical data ......................................................... 55

17.1 Technical data for the articles 57714 and 57715 ........55

17.2 Technical data for the articles 57713 and 57720 ........56

17.3 Technical data for the article 57716 ............................57

17.4 Technical data for the article 57718 ............................58

18 Disposal ........................................................................59

Page 7

7

W&T

1 Quick-Start/Commissioning

Just a few steps are required to start up your W&T Web-Thermometer and to make it visible in your network.

Power-over-Ethernet

The Web-Thermometers are designed for use in PoE (Powerover-Ethernet) environments in accordance with IEEE802.3af.

Power is provided by the network infrastructure using the

RJ45 terminal. The devices support both phantom power

using data pairs as well as power feed using the unused wire

pairs s. Power Supply).

!

Use of the Web-Thermometer is also possible in networks

without PoE power supply. In this case simply use an

external power supply attached to the screw terminal as

described in the chapter Power Supply. No additional configurations or settings are necessary.

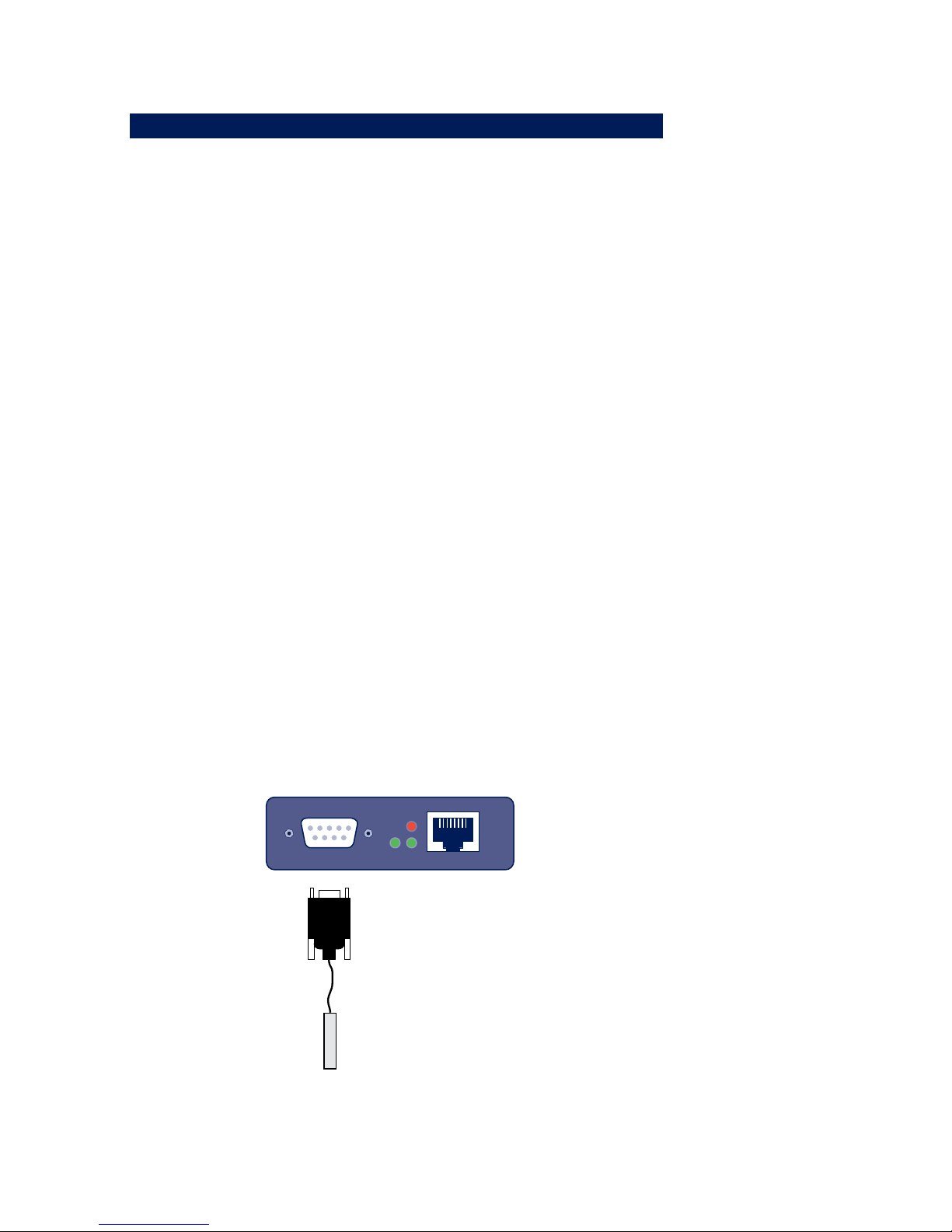

1.1 Connecting the sensor (#57713, #57714, #57715,

#57718, #57720)

Page 8

8

W&T

Plug the sensor included in the scope of delivery into the

9-pin IO terminal on the unit.

Information for Web-Thermometer Air Quality, #57718:

!

The measuring of the VOC value begins after an initialization time of 15 minutes after powering on the device.

In this time a VOC value of 450ppm will be displayed.

1.2 Connecting the PT100/PT1000 sensor and output

configuration (#57616)

The output of the Web-Thermograph Relay is switched internally using a relay contact (normally open). The consumer

is connected to the screw terminals 1 and 2. The maximum

switchable DC or AC voltage is 39V, with a maximum current

flow of 300mA.

The PT100 or PT1000 temperature sensor is connected to

screw terminals 3, 4, 5 and 6, whereby the wires of the same

color must lie adjacent to each other.

Page 9

9

W&T

The incoming line to the PT100 4-wire sensor may be of virtually any practical length.

Connecting a PT100 3-wire sensor:

When connecting a PT100 3-wire sensor the same-color wires

are connected to the terminals marked with the corresponding colors. A jumper to the remaining free terminal is required for the single wire.

Connecting a PT100 2-wire sensor:

When connecting a PT100 2-wire sensor, one wire is brought

to the red terminal and the other to the black terminal. Jumpers must be placed here to the free terminals.

Page 10

10

W&T

1.3 Ethernet connection (#57713, #57714, #57715,

#57716, #57718, #57720)

The Web-Thermometer incorporates an IEEE802.3-compatible

network interface on a shielded RJ45 connector. The pin assignments correspond to an MDI port, so that the connection

to the hub or switch is accomplished using a 1:1 shielded

patch cable.

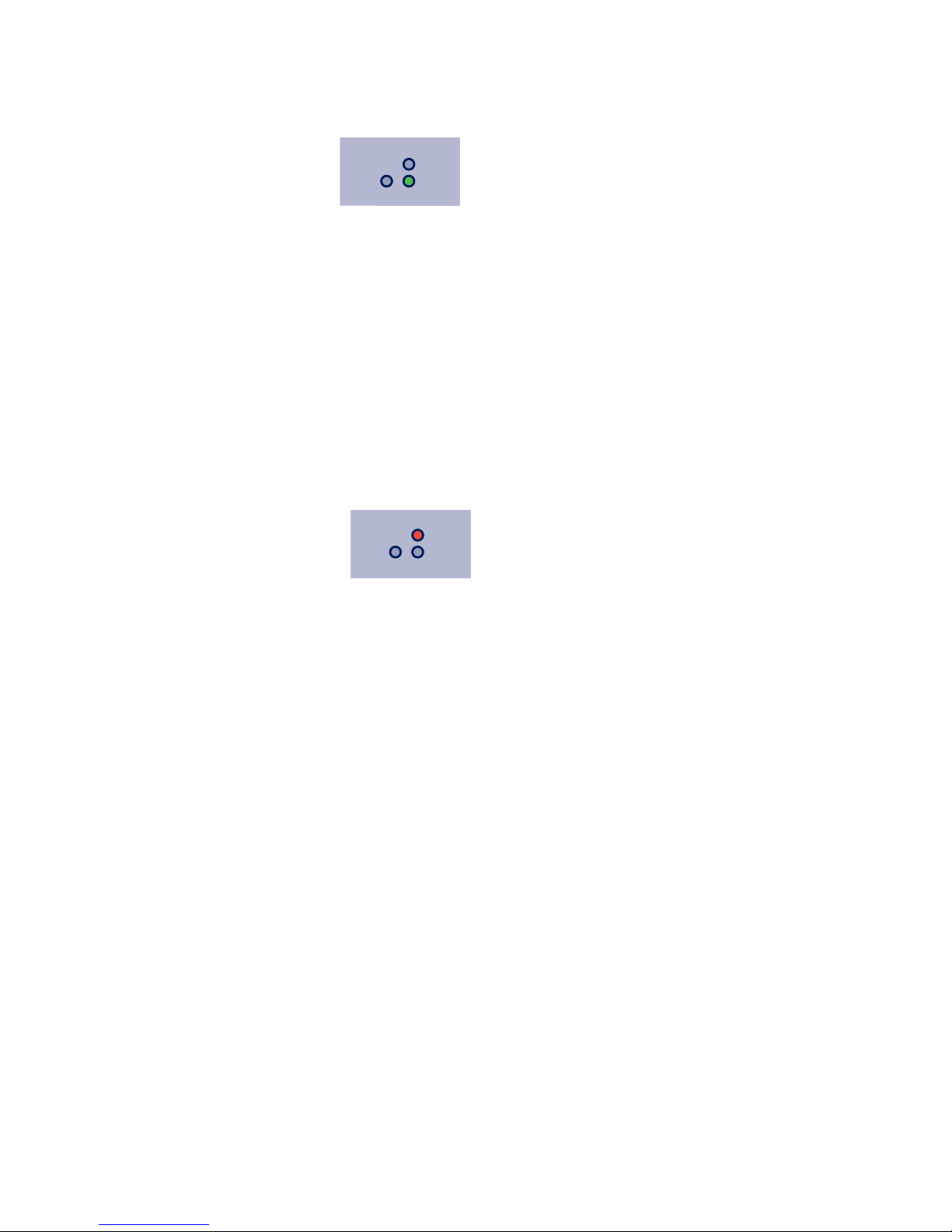

1.4 LED-displays

Power Status

Error

Power-LED

OFF: There is no power present. Check the correct connection of the supply (PoE or the external power supply)

ON: Power is present (PoE or the external power supply).

Page 11

11

W&T

Power Status

Error

Status-LED

Rapid continuous flashing = bootup, no IP

Rapid continuous flashing (approx. 3x/s) indicates that

the device is in the bootup phase and/or has not yet been

assigned an IP address. Please use WuTility for example to

assign the device an IP address.

Slow continuous flashing = connection

Periodic flashing indicates that the port has a valid connection to another network station. After the IP configuration you can open the homepage of the device with a web

browser.

Power Status

Error

Error-LED

The Error-LED shows errors of the device.

All LEDs on = Self-test error

The self-test performed after each start or reset of the

device could not be correctly finished. This error can occur

when you have prematurely broken off a software update

and the full operating software could not be transferred.

The device is no longer capable of being operated in this

condition. Repeat the software update over the network

(see Firmware update), and address the device using its

assigned IP address. If this does not eliminate the error or

should the error occur irrespective of any prior software

update, please return the unit to W&T for service.

Page 12

12

W&T

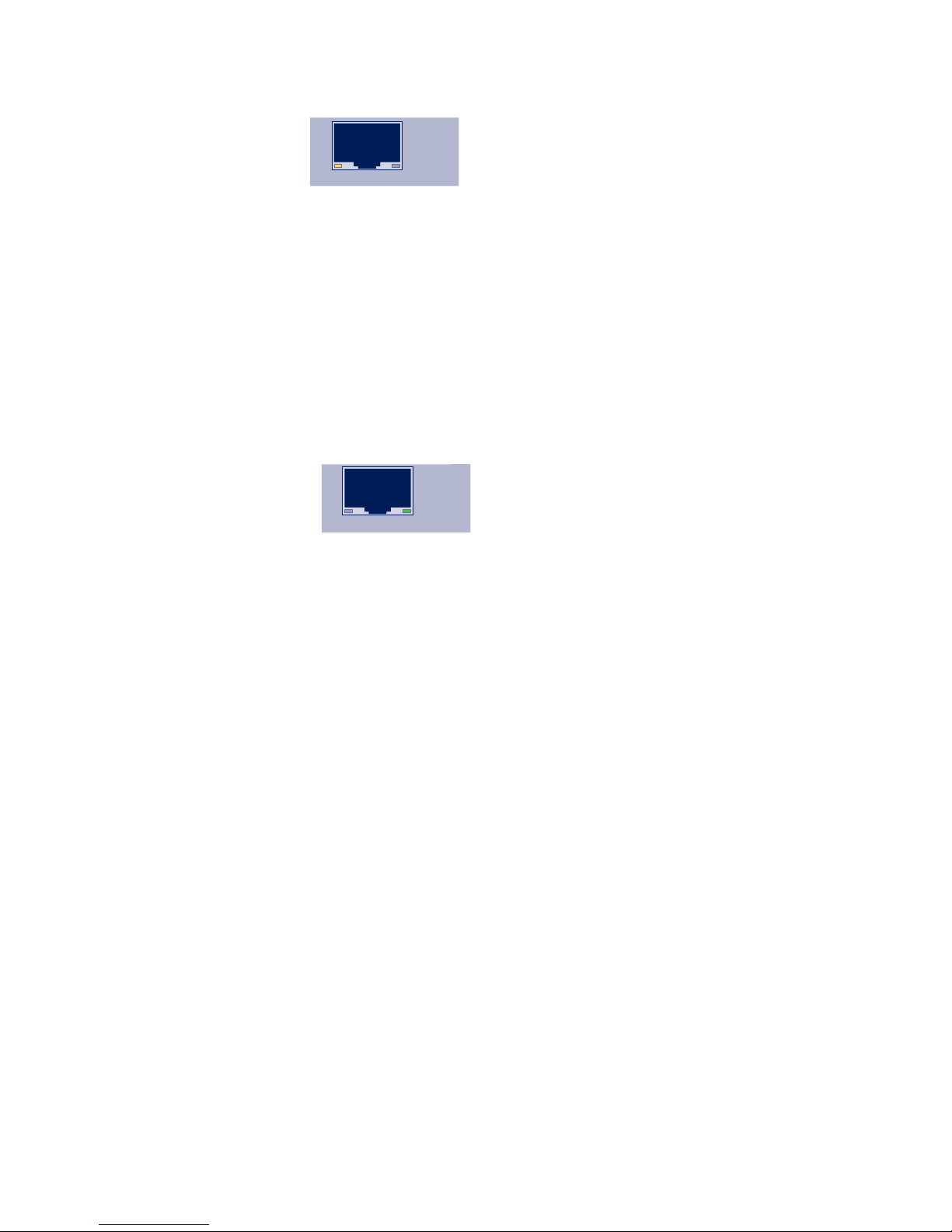

Speed

Link/Activity

Speed (yellow)

OFF: Simultaneous illumination/flashing of the Link/Activity LED means there is a link to a device at a rate of 10

MBit/s (10BaseT).

ON: Simultaneous illumination/flashing of the Link/Activity LED means there is a link to a device at a rate of 100

MBit/s (100BaseT).

Speed

Link/Activity

Link/Activity (green)

OFF: The device is not detecting a Link pulse from a hub

or switch. Check the cable or the hub port.

ON: The device has a valid link to a hub or switch. The

Speed LED indicates the data rate in this case.

Flashing: The device is receiving or sending network pakkets.

Additional LEDs (internal: #57713, #57714, #57715,

#57718, 57720, external: #57716)

■ on error http://xxx.xxx.xxx.xxx/diag -LED: Indicates inter-

nal configuration errors. For troubleshooting, please open

the page http://xxx.xxx.xxx.xxx/diag in the device.

■ system error: Serious hardware error. Attempt to start the

device up again by interrupting supply voltage. If the condition persists, please return the unit for inspection.

!

If the Web-Thermometer has no IP address or

Address 0.0.0.0, the on error and system error LEDs

remain on! The system error LED flashes 3x after a brief

time. The LEDs do not turn off until an IP address has been

Page 13

13

W&T

assigned.

Page 14

14

W&T

2 Online measurement storage inside the W&T Cloud

With the cloud service W&T offers a comprehensive solution

that enables the backup of data in online storage in addition

to the long-term documentation of temperature and humidity

measurement data in the internal data logger. The measurement data will be sent directly from the measuring point to

the cloud, and is available online.

2.1 Auto connect

The cloud functionality is enabled by default on delivery. If

the device receives its network parameters via DHCP, or you

allow the device Internet access by entering the network parameters, it immediately begins the transmission of the collected values in the cloud.

The measuring data is first not assigned to a user account

and will be stored in an enclosed part of the cloud until

further use.

2.2 Create a user account

To personalize the measurement data, first a user account for

the cloud access must be created. To do this, go to the cloud

homepage

http://cloud.wut.de

and click on „create user account“.

After entering your e-mail address and a password you will

get access to the cloud.

Page 15

15

W&T

2.3 Assign data by 4-digit access code in the cloud

Log in with your user account to http://cloud.wut.de and

enter the access code included with the device. The collected

data are now associated with your account and are available

for you immediately.

Alternative:

2.4 Assign measured data via user account in the device

After you have created a cloud user account, open the configuration menu of your device and login as admin user. Navigate to the page

Communication Paths -> Cloud

and enter your user data for the cloud access. After clicking

on the button „Bind“ all measurement data of this device,

from this moment, is stored into your user account.

By clicking on the button „Unbind“ the allocation of the data

from this moment is separated and no further values will be

stored in your account.

Click again on „Bind“ and a new series of measurements is

created in the cloud for your user account that contains all

the unassigned values of the sensor.

!

For further information about the service of the Cloud

functions you find instructions on http://cloud. wut. de

Page 16

16

W&T

3.1 Configuring network parameters with WuTility

WuTility is the central inventorying and management tool for

all W&T network devices. In addition to convenient assigning

of the IP parameters, WuTility also provides quick access to

device configurations, the ability to perform firmware updates, managing configuration profiles, etc.

WuTility can be directly installed from the included product

CD. Current versions are always available on our website at

http://www.wut.de. From there you can navigate using the

menu tree on the left side.

Downloads r Web-Graphr Software-Tools

After extracting the ZIP file you install WuTility by doubleclicking on the file wutility_***.msi. Start WuTility using

Start r All Programs r W&T Software Toolkit r WuTility

3.1.1 Applications and prerequisites

IP assignment using WuTility works regardless of the current

network parameters of the device and the computer used.

This means that even if the device does not have IP parameters consistent with the respective network, WuTility can be

used to overwrite them. Likewise, WuTility can be used to

assign any values not consistent with the network the PC is

located in.

• The PC and device must be located in the same physical

network. This means you cannot assign values through a

router.

• Any firewalls and network security packages installed on

the PC must allow communication between WuTility and

the device based on UDP broadcasts. If necessary these

must be correspondingly configured or temporarily turned

off.

Page 17

17

W&T

• If the device does not have its factory default settings and

there is a system password assigned, this must be known

in order to make changes using WuTility.

Step 1: Start the assignment dialog

WuTility automatically searches the local network for connected W&T network devices and creates an inventory list. This

search process can be repeated manually as often as desired

by clicking on the Scan button:

Within the inventory list you can identify the desired device based on its MAC address. For initial installations its IP

address is 0.0.0.0.

Select the device and click on the IP address button:

Page 18

18

W&T

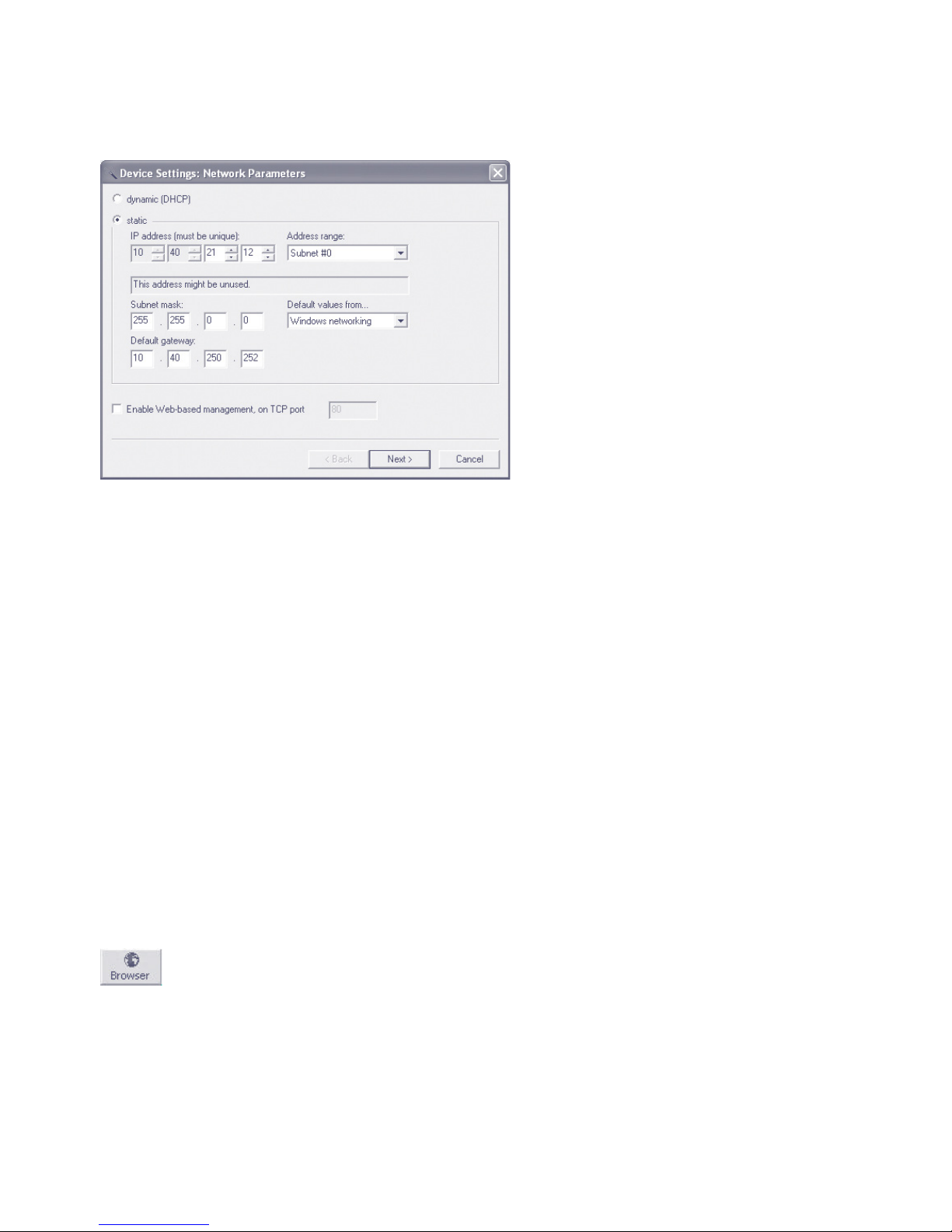

Step 2: Assign the IP parameters

The Static option allows you to assign fixed basic parameters

while simultaneously disabling the DHCP protocol in the device. Enter the desired values for IP address, subnet mask and

gateway address in the corresponding entry fields. The DHCP

option enables DHCP protocol in the device, and operation

with a static IP address is no longer possible (see IP Assign-

ment using DHCP Protocol for detailed information).

Clicking on the Next button assigns the network parameters

to the device. After acknowledging the resulting message, all

the columns in the WuTility device list are filled in with information.

If necessary, the remaining configuration of the device is done

using Web-Based-Management. Click on the Browser button.

Browser:

Additional information can be found in the section Configuration Accesses for the Web-Thermometer.

Page 19

19

W&T

3.2 Assigning the IP using DHCP protocol

DHCP protocol is activated by the factory default settings, so

that in network environments dynamic IP assignment is sufficient for connecting the device to the network. The following

parameters can be assigned using DHCP:

• IP address

• Subnet mask

• Gateway address

• DNS-Server

3.2.1 Manual activation of DHCP

To prevent unintended address assignments or address changes, DHCP protocol is automatically deactivated when using

all other methods for assigning the IP parameters. The following methods are then available for later activation of DHCP.

• Management-Tool WuTility

Select the desired device from the device list and click on

the IP Address button. In the following dialog check the

option DHCP and then click on Next.

• WBM configuration

In the menu branch Basic settings r Network r TCP/IP

Settings you can activate DHCP protocol.

1

A set static IP address is deleted after DHCP is

activated and the associated automatic reset. The device

automatically sets this to 0.0.0.0 and starts sending DHCP

requests.

Page 20

20

W&T

3.2.2 System name

To support any automatic updating of the DNS system by

the DHCP server, the device identifies itself within the DHCP

protocol with its system name. The factory default setting

for this is WEBIO- followed by the last three places of the

Ethernet address. For example the factory set system name of

a device with the Ethernet address 00:c0:3d:01:02:03 is WE-

BIO-010203. The system name of the device can be changed

in the configuration. For additional information refer to the

section Menu: Basic Settings r Language/Infos.

3.2.3 Lease time

The lease time determined and transmitted by the DHCP

server specifies the Time-To-Live of the assigned IP address.

After half the lease time has expired, the device attempts to

extend the time for the assigned DHCP server and up update

the address. If this is not possible by the time the lease time

expires, for example because the DHCP server can no longer

be reached, the device deletes the IP address and starts a new

cyclical search for alternate DHCP servers for the purpose of

assigning a new IP address.

Because of the absent clock, the lease time associated with

the current IP address is no longer available after a reset.

After the restart therefore a corresponding update request is

issued with the original DHCP server. If the latter is not resolvable at this point in time, the device deletes the IP address

and starts a new cyclical search for alternate DHCP servers.

If DHCP is activated, the remaining lease time together with

the current IP address is displayed in the menu item device

Information using the format hh:mm:ss.

Page 21

21

W&T

3.3 Assigning the IP using the ARP command

Requirements

This method can only be used if the device does not already

have an IP address, i.e. the entry is 0.0.0.0. To change an

IP address, use one of the other methods described in this

section or use the configuration menu over web based management. If the device has any other value, this access is

disabled.

When the factory setting is in effect as well as after a manual

changeover from static to DHCP, the method for assigning

the IP described in this section functions only after a delay of

approx. 2 minutes after a reset or after power-up.

This method does not work across networks, e.g. through

routers. This means the PC and device used for assigning

must be connected to the same physical network segment.

Only IP addresses whose Net-ID is identical to that of the assigning computer can be assigned.

1

To avoid unintended changes to the IP address, the

DHCP client of the Com-Server is automatically deactivated when configuring using a static ARP entry.

Step 1

Read off the Ethernet address of the device from the sticker

on the side of the housing.

58xxx [Typ]

EN=00c03d004a05

OK xxxxxx

Ethernet address

Insert a static entry into the ARP table of the computer using

the following command line:

arp -s [IP address] [Etherenet address]

Page 22

22

W&T

E.g. under Windows:

arp -s 172.16.231.10 00-C0-3D-00-12-FF

E.g under UNIX/Linux:

arp -s 172.16.231.10 00:C0:3D:00:12:FF

1

The IP addresses must be without leading zeros in

all Windows environments. Otherwise the entry is incorrectly interpreted by the system and an incorrect IP address

is assigned to the device. In Windows Vista and newer the

prompt cmd.exe necessary for invoking the ARP command

must be started using Administrator rights.

Step 2

Use the following command line to ping the device with the

desired IP address:

ping 10.40.21.12

The device takes the IP address of the first network packet

sent to it as its own and saves it in non-volatile memory. The

ping requests of the PC are then replied.

It is not possible to configure the subnet mask and gateway

address using a static ARP entry. These need to be set in a

separate Telnet configuration session (see section Basic Confi-

guration of the device).

Page 23

23

W&T

3.4 Assigning the IP using the serial port

After a device reset a time window of around 1-2 seconds is

available, during which you can assign a new IP address, subnet mask and gateway address by entering at least 3 „x“.

In contrast to other methods described above, this serial

method functions regardless of whether the device already

has an IP address, a password or not. The procedure can be

repeated as often as desired.

1

To avoid unintended changes to the IP address, the

DHCP client of the device is automatically deactivated

when configuring using the serial port.

Preparations/requirements

First connect the serial port A of the device to a computer. For

a standard PC or laptop, you will need a crossed RS232 cable

where only the pins 2,3, and 5 are connected.

Any serial terminal program can be used for assigning. The

following transmission parameters must be set regardless of

any other settings in the device:

9600 baud, no parity, 8 data bits, 1 Stop bit, no Handshake

Start the serial configuration mode

Reset the device by interrupting the power. While the device

is starting up, use the terminal program to send the letter x

at least three times. The device will then return the prompt

IPno.+<Enter>:.

Assigning the IP settings

Use the usual format (xxx.xxx.xxx.xxx) to enter the IP

address, and end the entry by pressing <Enter>. If the entry was accepted, the acknowledgement is the assigned IP

address. Otherwise you will get a FAIL message followed by

the last current IP address.

Page 24

24

W&T

Together with the IP address, the subnet mask and gateway

address can also be assigned serially. The entry is separated

by commas and follows the IP address. Entering as shown in

the following example will assign IP address 172.17.231.99,

subnet mask 255.255.255.0 and gateway 172.17.231.52 to

the device.

Exampel: Assigning the IP address:

IP no.+<ENTER>: <- Web-Thermometer

172.17.231.99 -> Web-Thermometer

Example: Assigning IP address, Subnet mask and gateway

IP no.+<ENTER>: <- Web-Thermometer

172.17.231.99, 255.255.255.0,172.17.231.1 -> Web-Thermometer

3 Spannungsversorgung

Page 25

25

W&T

4 Supply voltage

The Web-Thermometer can also be operated either using PoE

or from an external power supply.

The current draw can be found in the technical appendix.

4.1 Power over Ethernet

In PoE environments (Power-over-Ethernet, IEEE802.3af) power

is provided by the network infrastructure. The device supports both phantom power using data pairs 1/2 and 3/6 as

well as power feed using the unused wire pairs 4/5 and 7/8.

The Web-Thermometer is a device in PoE Power Class 1 (power consumption 0.44 to 3.84W).

4.2 External supply

As an alternative to PoE power supply the device can also be

powered by an external power supply connected to the screw

terminals on the underside of the housing. A half-wave rectifier makes the input reverse polarity protected. AC or DC

power may be used, whereby the following limit values must

be observed:

• AC: 18Vrms (- 10%) - 30Vrms (+10%)

• DC: 12V (-10%) - 48V (+10%)

(before SN 2283238 24V (-10%) - 48V (+10%))

When powering with DC voltage polarity must be observed:

L+M

+12-48V DCGND

Page 26

26

W&T

5 Ethernet interface

The Web-Thermometer incorporates an IEEE 802.3-compatible

network interface.

5.1 Link status

The Link status is indicated on the two LEDs built into the

RJ45 jack.

• Link/Activity (green)

ON indicates a valid link to a hub or switch port. The LED

flashes when there is data traffic.

• Speed (yellow)

ON indicates a 100MBit/s-link (100BaseT). OFF indicates

10MBit/s (10BaseT)

5.2 10/100BaseT on RJ45

The Web-Thermometer has a 10/100BaseT network interface

on a shielded RJ45 connector. The pin assignments shown

below correspond to an MDI interface, so that the connection

to the hub or switch is made using a max. 100m long 1:1

shielded patch cable.

Speed Link/

Activity

1 2 3 4 5 6 7 8

The network connection is galvanically isolated with respect

to the supply voltage as well as the serial interface(s) for at

least 1,5kV

rms

.

Auto Negotiation: 10/100BaseT, Full/Half Duplex

The device is factory set to operate in Auto-Negotiation mode

on the network side. The data transmission speed and duplex

are automatically negotiated with the connected switch/hub

and set accordingly.

Page 27

27

W&T

6 Connecting the sensor

6.1 NTC sensor measuring input (#57714)

The cable of the sensor is not extendable. Please, use exclusively the added sensor.

6.2 Pt100/1000 sensor measuring input (#57715)

Die Zuleitung des Messsensors kann nahezu beliebig verlängert werden. Sofern eine Verlängerung gewünscht ist, wird

empfohlen möglichst gut geschirmte Leitungen zu verwenden

um Störeinflüssen vorzubeugen. Wenn Sie einen alternativen

PT100/PT1000-Messfühler anschließen möchten, oder die Zuleitung verlängern möchten, ist die Steckerbelegung wie folgt:

6.3 Combined sensor measuring input (#57713, #57720)

The provided sensor uses a digital measuring value transfer.

A lengthening is possible up to a total length of 20 m (2 m of

sensor cable + 18 m of lengthening).

We recommend a DB9 plug connector for a connection to the

provided sensor for the lengthening.

we recommend the use of a data cable with the least specification Cat. 5 (shielded) or better and the following pin

allocation:

Page 28

28

W&T

Page 29

29

W&T

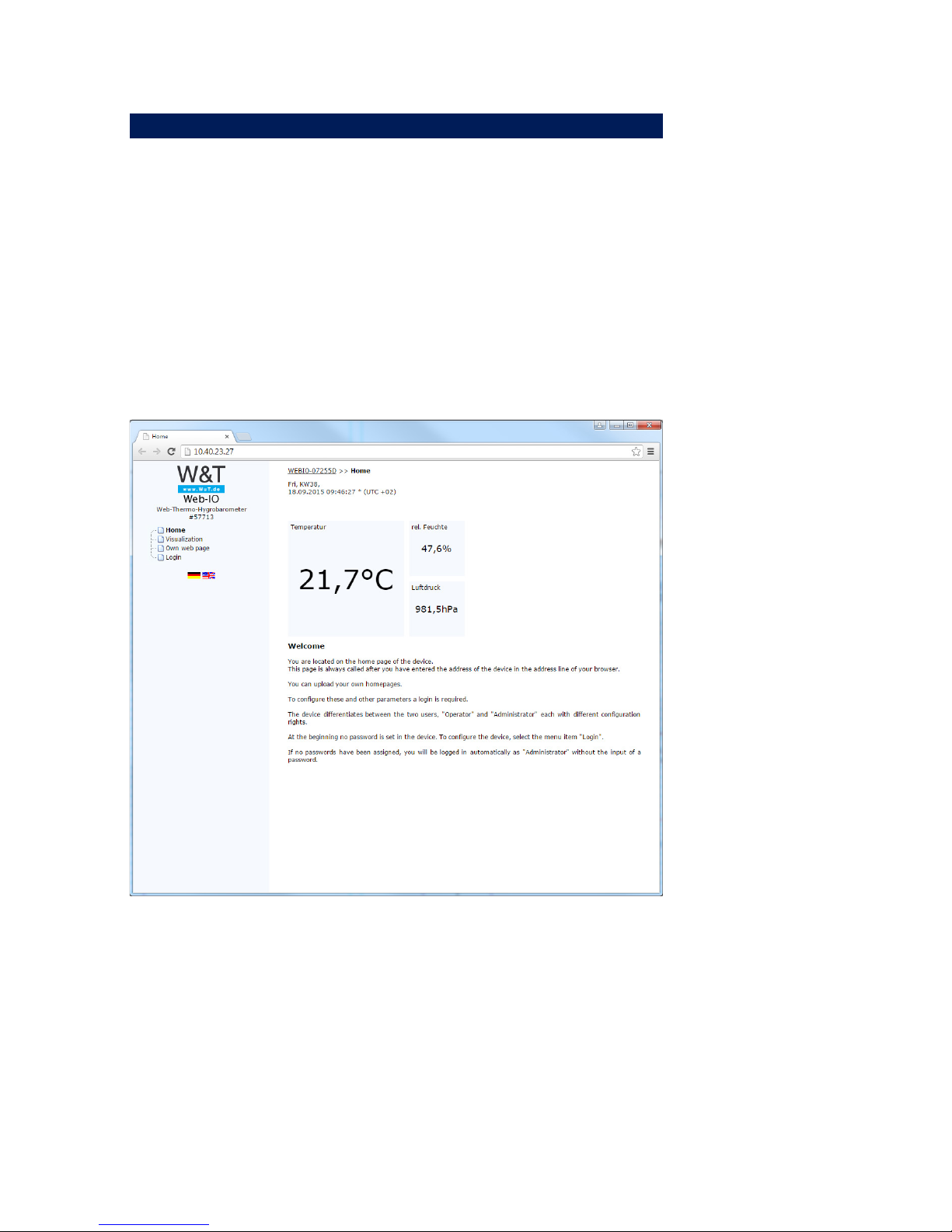

7 Configuration Using Web-Based Management

The remaining configuration is done using the web page of

the device. To open this, enter the assigned IP address in the

address line of your web browser:

http://<IP-adresse>

7.1 Home

The following pages are also available:

Page 30

30

W&T

7.2 Visualization

This page shows you a graphical display of the stored measurement values.

The displayed control elements enable you to adapt this display temporarily, as long as you are on this page. A non-temporary change can be made from the configuration menu (s.

Communication paths >> Web pages).

Page 31

31

W&T

7.3 Own webpage

This page can be individually adjusted or replaced and serves

as an example. Here you are also able to take a look at the

data logger of the device.

7.4 Login

Page 32

32

W&T

The Login dialog gives you access to the device configuration. The device differentiates between an administrator and a

standard user with different access rights.

As shipped the device has no password configured. Select the

administrator or user and click on “Login“.

The menu tree with all the configuration parameters is now

shown.

To get additional information about the respective configuration parameter, click on the Info button on the right border of

the corresponding parameter.

Page 33

33

W&T

8 Basic Settings

This configuration area is where you make all the settings

needed for the various operating modes.

8.1 Network

Here is where you set the network basic parameters. You can

choose between automatic address assignment per DHCP or

manual configuration of the parameters. If you wish to configure communication parameters with names instead of IP

addresses in the further configuration, you can configure additional DNS servers here in addition to any DNS server which

is assigned via DHCP.

Page 34

34

W&T

8.2 Sensors

Here among other things you are able to configure the labels

for the sensors and, for temperature sensors, the units.

If you want to make an adjustment to the sensors, you can

choose between 1-point compensation, whereby a correction

value is added to or subtracted from the measurement value,

or 2-point compensation, in which a straight line is calculated

over the measuring range

8.3 Date/Time

The device time is necessary for obtaining plausible time

stamps for storing the measurement values.

Enter the time manually or use the convenience of the automatic time-of-day compensation using a time server.

Here you can also enable or disable the use of daylight savings time.

8.4 Language/Infos

Here you configure the standard language of the device.

This is automatically used when device pages are opened.

The standard language can be dynamically switched during

operation using the flags below the configuration menu. This

switch is temporary and not saved.

On this page you can change information and device labels

and upload an individual logo, which is displayed above the

configuration menu.

Page 35

35

W&T

8.5 Data storage

Configure at what time interval the measurement data should

be saved in the internal data logger and which sensors should

be included.

!

A change to these settings will clear the entire data

logger and the measurement recording will begin over

again.

In addition, you can download the contents of the data logger

as a CSV file for further processing. On this page you can also

clear the data logger.

8.6 Password

Set up optional password protection for access to the configuration.

You can set a password for an administrator-user and for an

operator-user.

The operator-user has no access rights to system settings for

the device, such as changing network parameters etc.

!

If you assign an administrator password, it must be

stored for IP address changes via WuTility or firmware

updates.

Page 36

36

W&T

9 Communication paths

This device can communicate over various network protocols

and services. Here you configure all the parameters necessary

for this.

9.1 Web pages

This device has three preset pages which can be selected as

the start page.

The default homepage shows you the current values of the

individual sensors, which are updated cyclically.

The visualization page makes it possible to represent the

measurement values graphically.

The user page can be individually designed. To do this it can

Page 37

37

W&T

be downloaded from the device, edited by you and again

uploaded.

To display the measurement values on the user.htm page you

can use the following tags in the source text, which are replaced with the corresponding values when the page is opened:

<w&t_tags=t1>

Shows the current temperature (°C) of the first temperature

sensor. When multiple sensors are used this index is numbered in sequence.

<w&t_tags=h1>

Shows the current relative humidity (%) for models 57713 and

57720.

<w&t_tags=ah>

Shows the current absolute humidity (g/m³) for models 57713

and 57720.

<w&t_tags=pa>

Shows the absolute air pressure (hPa) for model 57713.

<w&t_tags=pNN>

Shows the calculated air pressure (hPa) above sea level for

model 57713 (meteorlogical value).

<w&t_tags=al>

Shows the set altitude of the location of the device for model

57713. (m)

<w&t_tags=time>

Inserts the current time of day.

Background color:

For values shown in tables you use use corresponding background colors depending on the sensor state:

<w&t_tag=bct>

Describes a background color (BGColor), which depends on

the alarm status of the temperature sensor. If a limit has been

Page 38

38

W&T

violated, this color is red. Otherwise the tag does not describe

any explicit color. This tag is necessary for example for showing limit violations in red in the log table. (°C)

<w&t_tag=bch>

Background color for the relative humidity value

<w&t_tag=bcah>

Background color for the absolute humidity value

<w&t_tag=bcrc>

Background color for the current rate of change

<w&t_tags=sensorx>

Inserts the name of sensor x in the page.

<w&t_tags=device_name>

Inserts the assigned device name.

<w&t_tags=device_text>

Inserts the freely configurable, descriptive text for the device.

<w&t_tags=location>

<w&t_tags=contact>

Inserts the respective text blocks which can be configured

under Language/Infos.

This page also provides all the parameters needed for adjusting the visualization.

Page 39

39

W&T

9.2 Mail

The e-mail function allows you to send messages to one or

more e-mail recipients. Here you configure the access parameters for your mail server.

9.3 Cloud

The W&T cloud service is a complete solution which not only

allows long-term documentation of measurement data in the

internal data logger but also makes it possible to save the

data in online storage.

Measurement data are passed directly from the measurement

point to the cloud, where they are then available online.

A user account is required for the W&T cloud. This can be created on the web pages at:

http://cloud.wut.de

9.4 RSS

The device provides an RSS feed which can be subscribed to

by feed readers. Here you configure the necessary channel

settings.

9.5 SNMP/Syslog

Here is where you make the SNMP and syslog basic settings.

The device can be incorporated into your existing automation

system via SNMP or syslog.

Retrieve device and sensor data using corresponding OIDs or

send messages via SNMP trap or syslog.

An MIB is available for direct downloading at

Page 40

40

W&T

http://<ip-address>/mib.zip

9.6 FTP

Measurement data can be stored directly on an FTP server for

archiving and checking. Here you configure the basic settings

for the FTP server.

9.7 Socket access

You can obtain measurement data directly from the device

using a socket access.

In the simplest case you send the command “GET/Single” to

the device to retrieve all the measurement data from the device.

Here you configure the setting for access via HTTP and UDP.

Page 41

41

W&T

10 Alarms/Messages

Messages for limit violations are received as soon as they

occur via e-mail or SNMP trap. Here you select the desired

trigger and configure the desired messaging type. You can

configure up to 12 different messages.

Clicking on the button a new message. Enter

the desired parameters and select the type of messages. After

creating the message using the button

,moni-

toring of the triggering condition is immediately active.

You can find the created message both in the configuration

menu and on the overview page for messages. Here you

are also able to test messages by clicking on the button

. To rescind the trigger condition for the test,

click on

.

The button

deletes the message. This change

becomes effective immediately after a security prompt.

Page 42

42

W&T

To incorporate measurement values into the message texts

the following tags are used which are replaced within the text

by the available values.

Function

comma s

p

elling (##,#) dot spelling (##.#)

<T1> <t1>

Temperature: Displays the

current tem

p

erature.

<H1> <h1>

Humidity: Displays the current

relative humidit

y.

<AH> <ah>

Absolute humidity: Displays

the current absolute humidity.

<RC> <rc>

Rate of change: Displays the

rate of change from the last 5

minutes.

<PA> <pa>

Absolute air pressure: Displays

the current absolute air

p

ressure.

<PN> <pn>

Sea-Level air pressure:

Displays the air pressure

counted back to Mean Sea

Level.

<V> <v>

VOC: Displays the current air

quality value. (#57618)

<O1> <o1>

Output: Shows the current

output state (ON, OFF)

(#57616

)

Alarm active: Shows all alarms

(numbers, komma separatet)

which are currently active.

Alarm sensor number:Shows

all sensors (numbers, komma

separated) which match with

the configured alarm values

per alarm.

Alarm sensor name: see above,

but with sensor names (komma

separated)

Device Name: S hows the

device name.

Displays the actual time and

date as a string.

Year (####): Displays the year.

Month (##): Displays the

month.

Day (##): Displays the day.

Hour (##): Displays the hour.

Minute (##): Displays the

minute.

Second (##): Displays the

second.

W&T tag value

W&T tag date + time

<AA>

<AN>

<AS>

<DN>

<$i>

<$s>

<Z>

<$y>

<$m>

<$d>

<$h>

Page 43

43

W&T

11 Diagnosis

Here you will find all the runtime errors which the device has

generated.

Errors which have occurred but which are no longer current

can be found in the diagnostics archive.

Errors occurring while entering parameters do not appear on

this page, but rather are displayed directly on the parameter.

Page 44

44

W&T

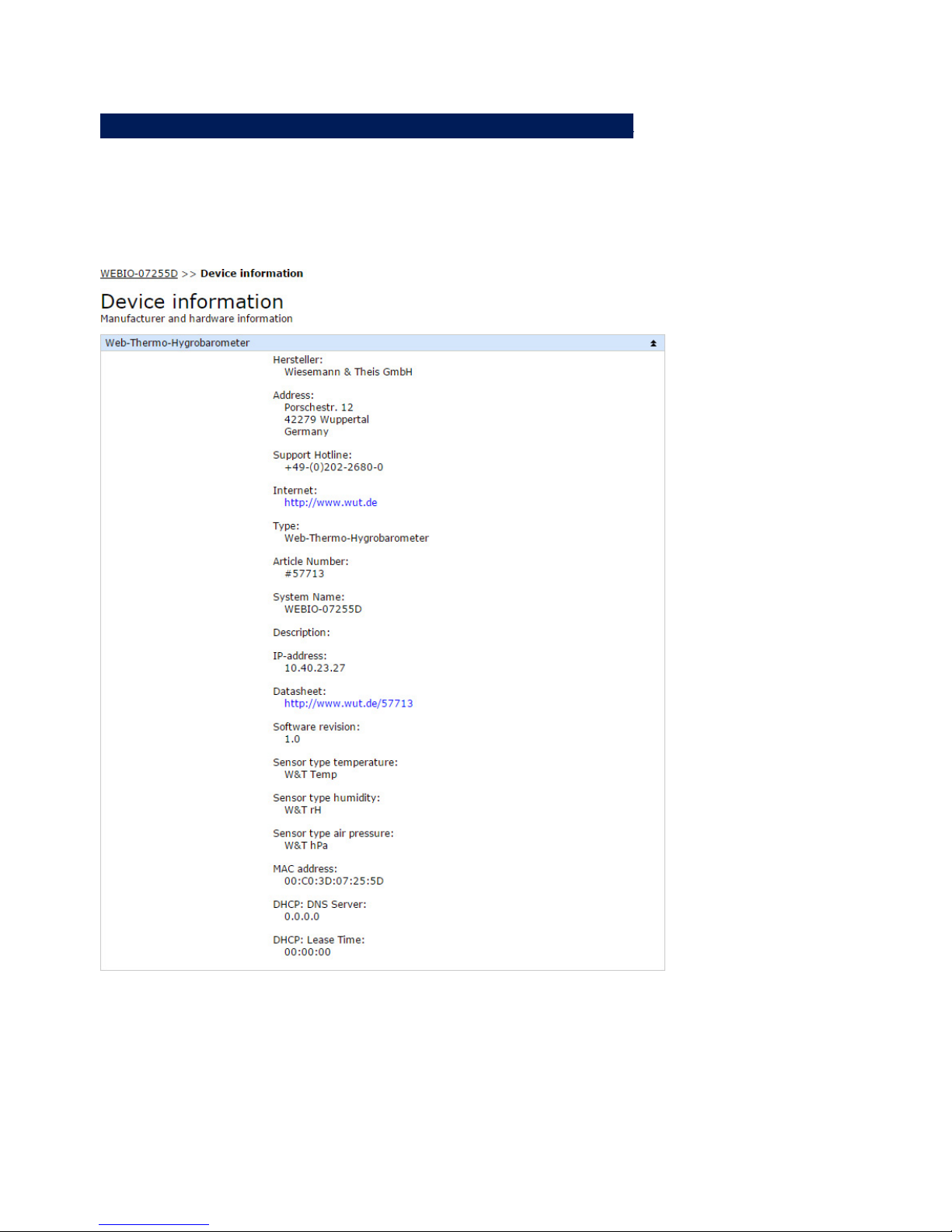

12 Device information

Here you find descriptive information about your device and

manufacturer’s descriptions. The contents of this information

can be changed in the basic settings under Language/Infos.

Page 45

45

W&T

13 Maintenance

13.1 LED Test

After clicking on this button both the internal LEDs of the device come on for 2 seconds. This serves to identify the device.

13.2 Reboot

Restarts the device and resets all network connections.

13.3 Factory defaults

The device is reset to the factory default settings. All configuration parameters and passwords are cleared. After a reset

you must start over with IP address assignment.

Page 46

46

W&T

13.4 Save configuration

Clicking on the Download button downloads a file containing

the entire device configuration. This can be edited in a text

editor.

13.5 Restore configuration

Select a configuration file and upload it to the device. After

a restart all the configuration parameters are applied by the

device

Page 47

47

W&T

14 Individual request of measurement values

14.1 Request via TCP/IP

It is possible to manually request the current measurement

values in CSV format (comma-separated data) through a sokket connection. This function is used for requesting individual

data without using the web interface.

To do this, send the following string to Port 80:

GET /Thermo.csv

This expression can also include additional parameters which

determine the contents:

start=ttmmjjjjThhmmss

Start-date and –time for the measurement data to be loaded

end=ttmmjjjjThhmmss

End-date and –time for the measurement data to be loaded

DTb=x&

Output interval, where x =

1 -> 15 Sek.

2 -> 30 Sek.

3 -> 1 Min.

4 -> 5 Min.

5 -> 15 Min.

6 -> 60 Min.

The expression must begin with “?” after the file name, where

the individual variables are separated by a “&”.

Page 48

48

W&T

Example:

http://<ip-adresse>/thermo.csv?start=01012010T123000&end=30032010T200000&DTb=3&

The above expression generates a CSV file which contains

the measurement data from 01.01.2010, 12:30 p.m. until

03.30.2010, 8:00 p.m. in 1 minute intervals.

To request the individual current measurement value, send:

GET /Single1

for the 1st measuring channel

GET /Single2

for the 2nd measuring channel, etc.

To receive an output for all measuring channels, send:

GET /Single

without Index.

14.2 Requesting via UDP

Open a UDP connection to the IP address of the device or

to the Net-ID as a broadcast and Port 42279 (preset can be

changed).

Then send one of the above GET /Single expressions to the

device and the device will return the measurement values on

the port you are using.

i

When using multiple devices it may make sense to also

have the name and IP address of the device included

with broadcast messages. To do this, select “Enable GET

Header” under “Communication paths >> Socket access”.

Page 49

49

W&T

14.3 Requesting via SNMP

The sensors can be queried directly using SNMP instructions.

The paths of the different model variations are:

#57713 Web-Thermo-Hygrobarometer:

1.3.6.1.4.1.5040.1.2.37....

#57714Web-Thermometer NTC:

1.3.6.1.4.1.5040.1.2.38....

#57715 Web-Thermometer Pt100/Pt1000:

1.3.6.1.4.1.5040.1.2.39....

#57716 Web-Thermometer Relay:

1.3.6.1.4.1.5040.1.2.40....

#57718 Web-Thermometer Air Quality:

1.3.6.1.4.1.5040.1.2.41....

#57720 Web-Thermo-Hygrometer

1.3.6.1.4.1.5040.1.2.42....

Access the sensors through the following path:

<IP-Adresse> 1.3.6.1.4.1.5040.1.2.X.1.3.1.1.1 = First channel

with a decimal point with comma separation

<IP-Adresse> 1.3.6.1.4.1.5040.1.2.X.1.4.1.1.1 = First channel

as three place integer value, without comma separation

<IP-Adresse> 1.3.6.1.4.1.5040.1.2.X.1.8.1.1.1 = First channel

with one decimal place with decimal point separation

Page 50

50

W&T

The last index describes the channel number you are

querying.

!

For querying indicate the configured SNMP read or read/

write community.

An MIB for incorporating into management applications is

available for downloading on the datasheet page of the device

on the W&T homepage http://www.wut.de or in the device

itself at http://<ip-address>/mib.zip.

If you wish to change device settings via SNMP (IP address,

subnet mask, etc.) you must first start a session on the device

using your SNMP manager.

Entering the administrator password in the variable

wtWebGraphThermoBaroSessCntrlPassword

opens a session. By reading the variable

wtWebGraphThermoBaroSessCntrlConfigMode

you can check whether the session was successfully opened.

1 = Session opened, device is in configuration mode.

0 = Opening of the session failed. Check whether an incor-

rect password was entered.

After successfully opening the session, you can make any

desired configuration changes using the variables defined in

the private MIB.

After configuration is finished, close the session by writing

the variables

wtWebGraphThermoBaroSessCntrlLogout

wtWebGraphThermoBaroSessCntrlLogout =

Page 51

51

W&T

1 All changes are saved

2 Quit without saving

If while a session is open no SNMP communication takes place

for a period of 5 minutes, the device itself will close the session and all changes are discarded.

1

Opening an SNMP session has priority over an HTTP

login. This means: A user with operator or administrator rights loses his browser access as soon as an

SNMP session is opened.

The description of the individual SNMP variables, OIDs etc.

can be found in the private MIB.

Page 52

52

W&T

15 Firmware Update

The operating software for the Web-Thermometer is being

continuously improved. The following section describes the

procedure for uploading new firmware.

. Where is the latest firmware available?

. Firmware update under Windows

15.1 Where is the latest firmware available?

The most current firmware including the available update

tools and a revision list are published on our website at the

following address: http://www.wut.de

Please first write down the 5-digit model number located on

the Web-Thermometer before downloading. From the homepage you can then reach the product overview sorted by

article numbers, which takes you directly to the datasheet for

the device. Here you follow the link to the current version of

the firmware.

15.2 Firmware update over the network under Windows

Prerequisite is a PC running Windows XP/Vista/7/8/8.1/10

with a network connection and activated TCP/IP stack. The

update process requires two files which are as noted above

are available for downloading on the homepage at http://

www.wut.de:

· The executable WuTility tool for sending the firmware to the

Web-Thermometer

· The file with the new firmware for sending to the device.

No special preparation of the Web-Thermometer is necessary

for the firmware update.

Page 53

53

W&T

The WuTility tool used for the update detects all WuT devices

located in your network and is for the most part self-explanatory. If any questions arise, please use the associated documentation or go to online help.

!

Do not intentionally interrupt the update process by disconnecting power or pressing the Reset button if one is

present. The Web-Thermometer will be inoperable after

an incomplete update

Never mix files with different version numbers in file names.

This will cause the device to become inoperable.

The Web-Thermometer automatically detects when the transfer of the new operating software is complete and then performs an automatic reset.

Page 54

54

W&T

16 Hardware-Reset to factory defaults

A reset of the device to its factory defaults can be done via

hardware. For this purpose the device has a jumper on the

board. For normal operation this jumper must be out. To set

the factory defaults, proceed as follows:

• Power off the device and open the enclosure

• Close the jumper and reconnect the supply voltage. An

internal self-test will be performed during which messages

will be issued on serial port. The Fail messages in the lines

Port A: and TP Test: can be ignored.

• The self-test will be finished in approx. 20s, at which point

the factory defaults are active.

• Turn off the device, open the jumper and close up the

housing again.

1

Resetting the non-volatile memory results in a loss

of all the settings which are different from the factory

defaults, including the IP address, passwords and all measured values.

Page 55

55

W&T

17 Technical data

17.1 Technical data for the articles 57714 and 57715

Prod. No. 57714, 57715

Network: 10/100BaseT autosensin

g

Supply voltage:

Power-over-Ethernet or

12-48V DC (+/-10%) or

18Veff-30Veff AC (+/-10%) via screw

terminal

Measuring unit (57714)

Sensor: NTC 10k

Measuring range: -45°C...75°C

Resolution: 1/10°C

Measuring error: ±0,3°C, ±5,1%

Storage frequency: 15, 30 sec, 1, 5, 15, 60 min

Memory depth (4MB): min. 16 weeks, max. 20 years

Deviation of the internal clock: max. 1 min. / Month

M

easuring unit (57715)

Sensor: Pt100, Pt1000 connection, 2-, 3- or 4-conductor

Measuring range:

W&T sensor: -50°C...180°C

PT100/PT1000 measuring input: -200°C...650°C

Resolution: 1/10°C

Measuring error: ±0,3°C, ±0,2%

Storage frequency: 15, 30 sec, 1, 5, 15, 60 min

Memory depth (4MB): min. 16 weeks, max. 20 years

Deviation of the internal clock: max. 1 min. / Month

Power supply

typ. 62mA @24VDC, 80mA @20VAC,

max. 70mA @24VDC, 40mA @48VDC

PoE Class 1 (0,44 - 3,84W

)

Emergency access: serial port RS232, 9600 baud, 8 data bits, 1 stopbit,

no

p

arity

Housin

g

: Compact plastic housing, 105 x 75 x 22mm (lxwxh)

Wei

g

ht: approx. 200

g

Ambient storage temperature: -40..+70°C

Ambient operating temperature: non-row mounting:

0 .. +60°C

row mountin

g

:

0 ..+50°C

Current consumption:

Page 56

56

W&T

17.2 Technical data for the articles 57713 and 57720

Prod. No. 57713, 57720

Thermo-Hygro Probe: I2C connection

Air

p

ressure probe: SPI connection (57713 only)

Network: 10/100BaseT autosensin

g

Supply voltage:

Power-over-Ethernet or

12-48V DC (+/-10%) or

18Veff-30Veff AC (+/-10%) via screw

terminal

M

easuring unit

Measuring range: -40°C...85°C, 0..100% rF, 10-1100 hPa (57713 only)

Resolution: 1/10 °C, 1/10% rF, 0.1 hPa

Measurin

g

error: Temperature:

t

yp

. @ 25°C ±0.3°C

max. @ -40..85°C ±1.5°C

Relative humidity:

t

yp

. @ -20..60°C (normal range) ±1.8%rH (10-90%rH)

max. @ -20..60°C (normal ran

g

e) ±4%rH (0-100%rH)

temporary @ -40..85°C (max range) +3%rH after 60h

O

p

eration outside normal range

Lon

g

-term stability typ. <0.5%rH / year

Atmos

p

heric pressure (57713 only):

t

yp

. @ 25°C ±0.8hPa (750..1100hPa)

max. @ 25°C ±2.5hPa (750..1100hPa)

max. @ -40..85°C: ±3.5hPa (300..1100hPa)

Lon

g

-term stability: typ. -1hPa / year

Stora

g

e frequency: 15, 30 sec, 1, 5, 15, 60 min

Memory depth (4MB): min. 7 weeks, max. 20 years (57713)

min. 12 weeks

,

max. 20 years (57720

)

Deviation of the internal clock: max. 1 min. / Month

Power suppl

y

typ. 62mA @24VDC, 80mA @20VAC,

max. 70mA @24VDC, 40mA @48VDC

PoE Class 1 (0,44 - 3,84W)

Emergency access: serial port RS232, 9600 baud, 8 data bits, 1 stopbit,

no parity

Housin

g

: Compact plastic housing, 105 x 75 x 22mm (lxwxh)

Wei

g

ht: approx. 200

g

Ambient storage temperature: -40..+70°C

Ambient operating temperature: non-row mounting:

0 .. +60°C

row mountin

g

:

0 ..+50°C

Current consumption:

Page 57

57

W&T

17.3 Technical data for the article 57716

Prod. No.

57716

Thermo-Probe:

Pt100/Pt1000-Connection via screw terminal

Network: 10/100BaseT autosensin

g

Supply voltage:

Power-over-Ethernet or

12-48V DC (+/-10%) or

18Veff-30Veff AC (+/-10%) via screw

terminal

M

easurin

g

unit

Sensor: Pt100/Pt1000-Connection, 2-,3- or 4-wire

W&T Sensor: -50°C...180°C

PT100/PT1000-In

p

ut: -200°C...650°

C

Resolution:

1/10°C

Measurin

g

error:

Measurin

g

unit:

±0,3°C, ±0,2

%

PT100/1000 Sensor Class A:

±0,15°C, ±0,2

%

Storage frequency:

15, 30 sek, 1, 5, 15, 60 min

Memory depth (4MB): min. 16 weeks, max. 20

y

ears

Deviation of the internal clock: max. 1 min. / month

Semiconductor-Relaiy-Output

Digital output: 1

p

otential-free semiconductor-rela

y

max. switching current: typ. 300mA AC/DC (peak 500mA)

max. switching voltage: 39V AC/DV

max. power consumption: 11,7W AC/DC

Power supply

typ. 62mA @24VDC, 80mA @20VAC,

max. 70mA @24VDC, 40mA @48VDC

PoE Class 1 (0,44 - 3,84W)

Housin

g

: Plastic compact housing, 105x75x22mm

Wei

g

ht: approx. 200

g

Ambient storage temperature: -40..+70°C

Ambient operating temperature: non-row mounting:

0 .. +60°C

row mounting:

0.. +50°C

Measuring range:

Current consumption:

Page 58

58

W&T

17.4 Technical data for the article 57718

Prod. No.57718

Thermo-H

yg

ro Probe:

I2C connection

VOC probe:

I2C connection

Network:

10/100BaseT autosensin

g

Supply voltage:

Power-over-Ethernet or

12-48V DC (+/-10%) or

18Veff-30Veff AC (+/-10%) via screw

terminal

Measurin

g

unit

Measuring range:

0°C...50°C, 5..95% rF, 450-2000ppm VOC/CO2Equivalent

Resolution: 1/10 °C, 1/10% rH

VOC sensor, detected substances: Alcohols

Aldehydes

aliphatic hydrocarbons

Amines

Aromatic hydrocarbons

CO, CH4, LPG

Ketones

Or

g

anic acids

Measuring error:

Temperature:

typ. @ 25°C ±0.3°C

max. @ 0..50°C ±1.2°

C

Relative humidity:

typ. @ 25°C ±3%rH

max. @ 0..50°C ±7%rH (0-100%rH

)

Long-term stability typ. <0.5%rH / year

Stora

g

e frequency:

15, 30 sek, 1, 5, 15, 60 min

Memory depth (4MB):

min. 7 weeks, max. 20 years

Deviation of the internal clock: max. 1 min. / month

Power su

pply

typ. 62mA @24VDC, 80mA @20VAC,

max. 70mA @24VDC, 40mA @48VDC

PoE Class 1 (0,44 - 3,84W)

Housin

g

:

Plastic compact housin

g

, 105x75x22mm

Wei

g

ht:

approx. 200

g

Ambient storage temperature:

-25+50°C

Ambient operating temperature: non-row mounting:

0 .. +60°C

row mountin

g

:

0 ..+50°C

Current consumption:

Page 59

59

W&T

18 Disposal

This device contains a non-rechargeable lithium button battery type BR (lithium carbon monofluoride) for retaining the

time even when the device is turned off. This battery must

be disposed of after its useful life has expired. Take it to an

official collection site for recycling.

First disconnect all cables from the device and open the device.

The button battery is located on the circuit board. Remove it

from its holder and take it to a recycler.

Loading...

Loading...