WSM V1505-CR-TE5 Workshop Manual

WORKSHOP MANUAL

KiSC issued 03, 2022 A

DIESEL ENGINE

V1505-CR-TE5

TO THE READER

KiSC issued 03, 2022 A

This workshop manual provides safety information for service activity, general information such as specifications and

dimensions of the machine, mechanisms and structure descriptions of the machine, and service procedures.

Safety

This section contains safety service descriptions and safety label information.

General

This section contains general instructions, tightening torques, general machine information and special tools.

Maintenance

This section contains information for the recommended oil and general maintenance procedures.

Each section basically consists of mechanism and servicing.

Mechanism

part

Mechanism

or component parts. This part should be comprehended before proceeding with troubleshooting, disassembling,

assembling, and servicing works.

Servicing

Servicing part contains information and procedures for maintenance, troubleshooting and repair works. The reader

should follow these instructions in order to satisfy any servicing work safely, correctly and quickly.

In this WSM, service specifications and service limits are defined as followings.

Service specifications:

Specification which corresponds to new machine's ex-factory. It is based on quality standard, drawings, or actual

measurements conducted by Kubota. This value is used to determine whether there is a problem with the machine in

the event of a troubleshooting. However, it is necessary to consider degradation due to wear, based on the operating

time of the machine, application or maintenance condition.

Service limits:

Service limit is a value corresponding to the recommended performance limit by taking long term-use wear into

account. When the service limit is reached, the machine is required to have proper repair, overhaul or replacement in

order to keep safe and adequate performance.

All of the illustrations, photographs, specifications, and other information in this manual were created based on the

latest model at the time of publication.

The parts names used in this manual are unified into names representing the functions of the parts. Therefore, it does

not necessarily correspond to the names used in other materials (parts list, operators manual etc.) and the name on

the label / identification plates on the product.

Kubota reserves the right to change all information at any time without notice.

contains information and explanations for the structure, functions, and specifications of the machine

© KUBOTA Corporation

January 2020

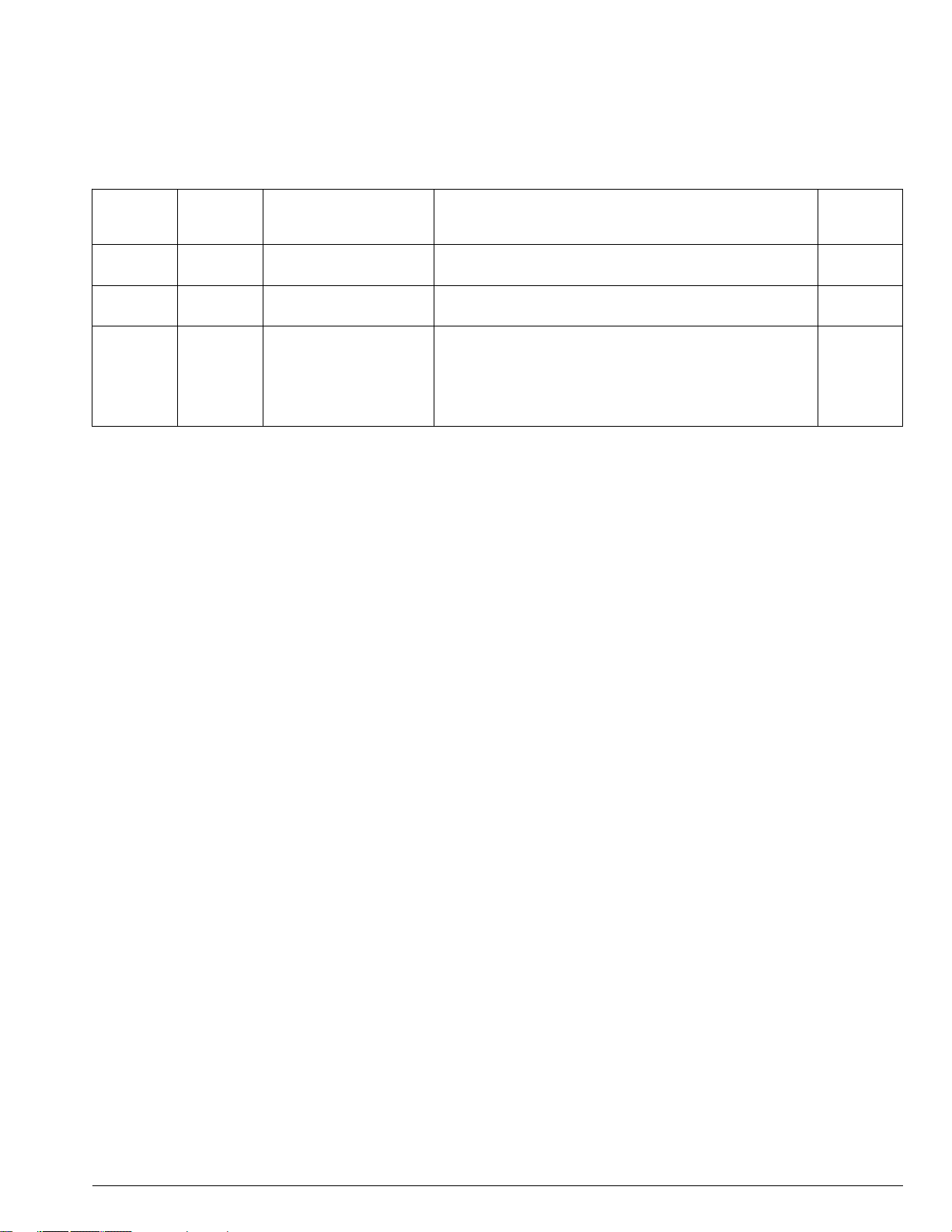

RECORD OF REVISIONS

V1505-CR-TE5

i

KiSC issued 03, 2022 A

Main revised contents and corrective measures are described in a table.

Find the main revised point and corrective measure through the reference page.

Last digit

of the code

No.

1 April 2020 Injector clamp Changed the tightening torque of injector clamp mounting screw.

2 February

3 March 2022 Alternator

Month of

revision

2021

Part name Main revised point and corrective measure

Correcting errors

Compression tester adapter To correct the specification value of the compression adapter. 2-23

Rail

Crankshaft bearing

Cylinder head bolt

Fan belt

Corrected the service specification of regulating voltage at no load

Corrected the description of function of rail assembly

Corrected the dimension value (inch) of crankshaft bearing 1.

Added the description of polished head bolt.

Changed the fan belt tension.

Reference

page

4-93

4-148

.

4-103

4-23

4-179

4-93

4-147

4-161

ii

V1505-CR-TE5

KiSC issued 03, 2022 A

CONTENTS

V1505-CR-TE5

iii

KiSC issued 03, 2022 A

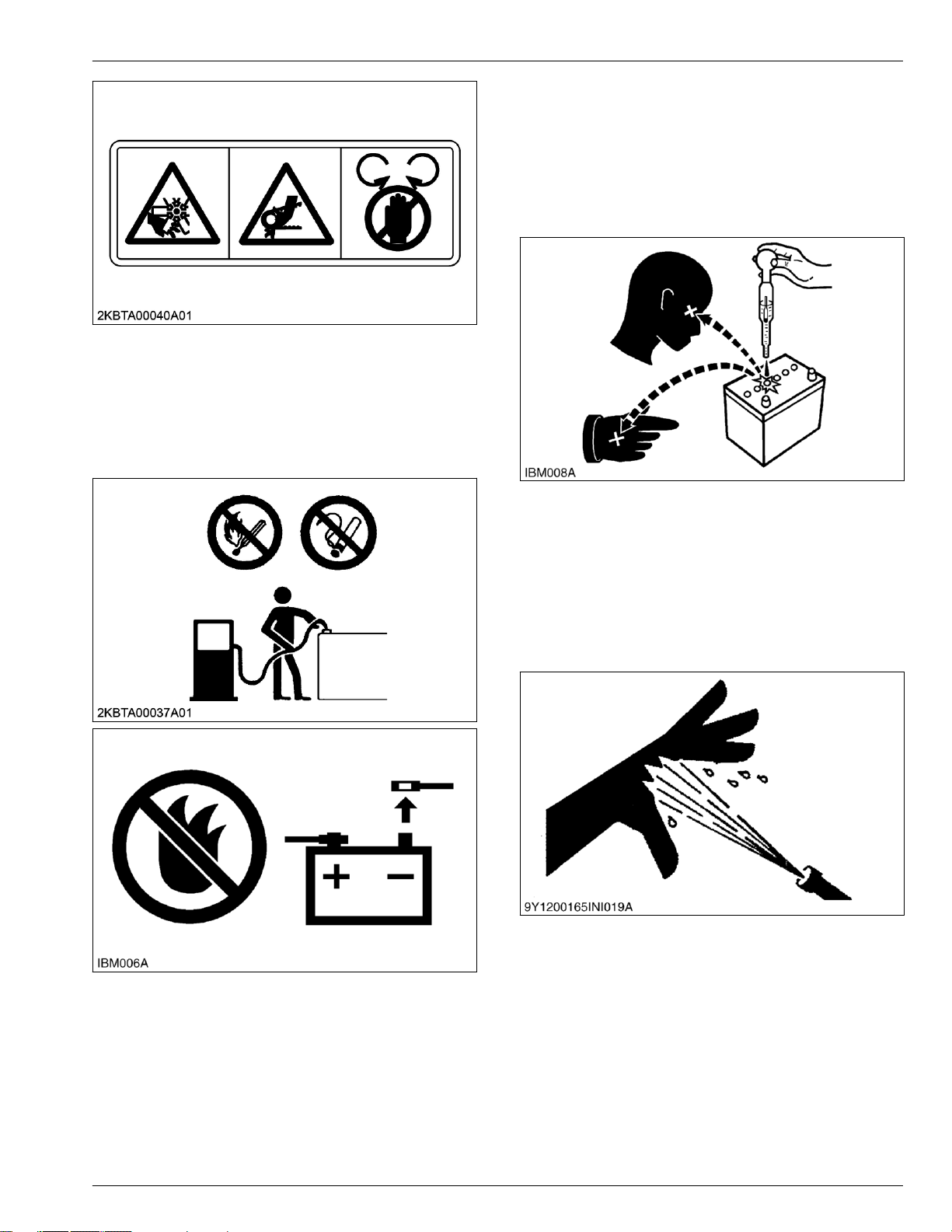

1. SAFETY

SAFETY FIRST

1.

Working precautions.................................................................................................................................1-1

2. Preparing for emergencies .......................................................................................................................1-1

3. Working cautions ...................................................................................................................................... 1-2

4. Starting machine safely ............................................................................................................................1-2

5. Preventing fires......................................................................................................................................... 1-3

6. Preventing acid burns...............................................................................................................................1-3

7. Avoiding high pressure fluid......................................................................................................................1-3

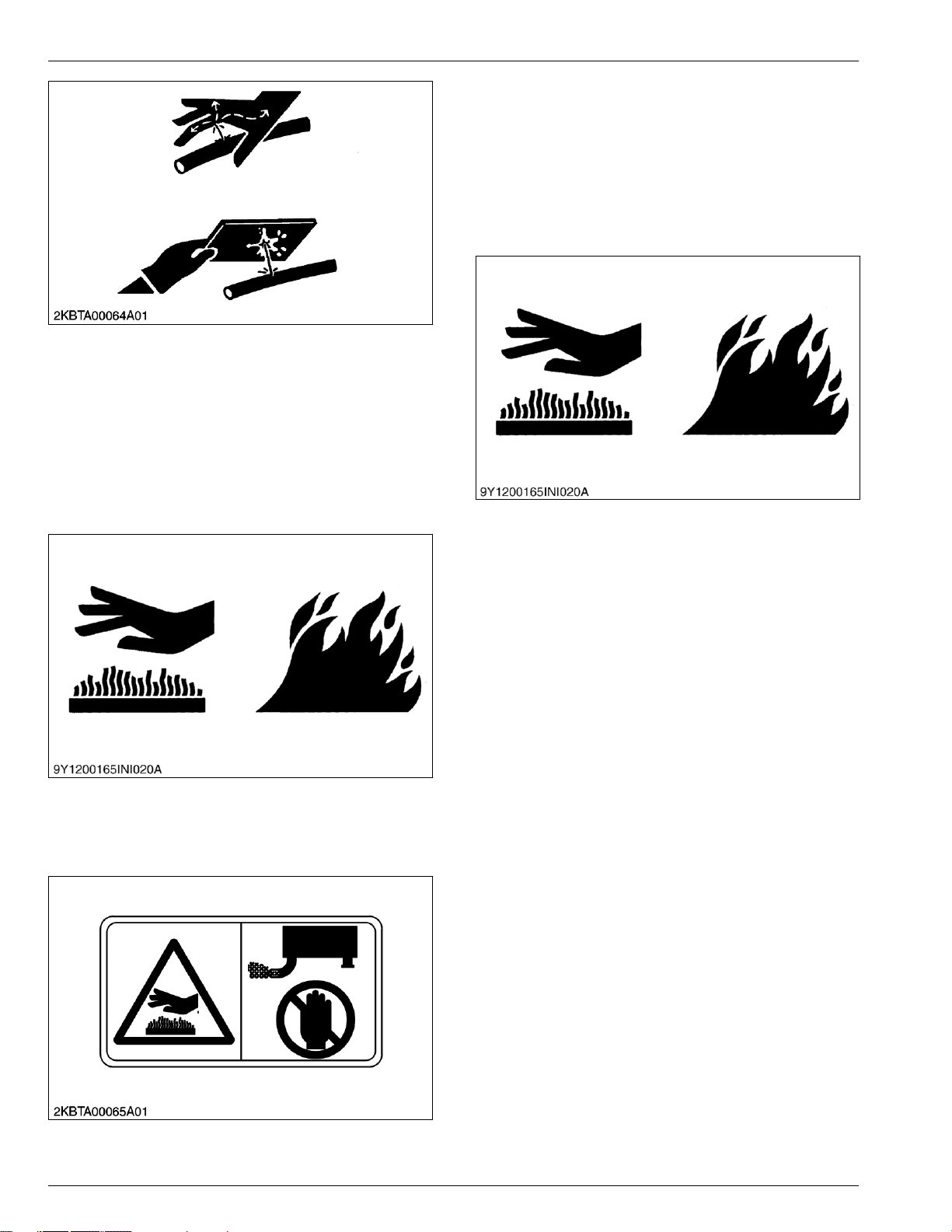

8. Avoiding hot exhaust ................................................................................................................................1-4

9. Cleaning exhaust filter .............................................................................................................................. 1-4

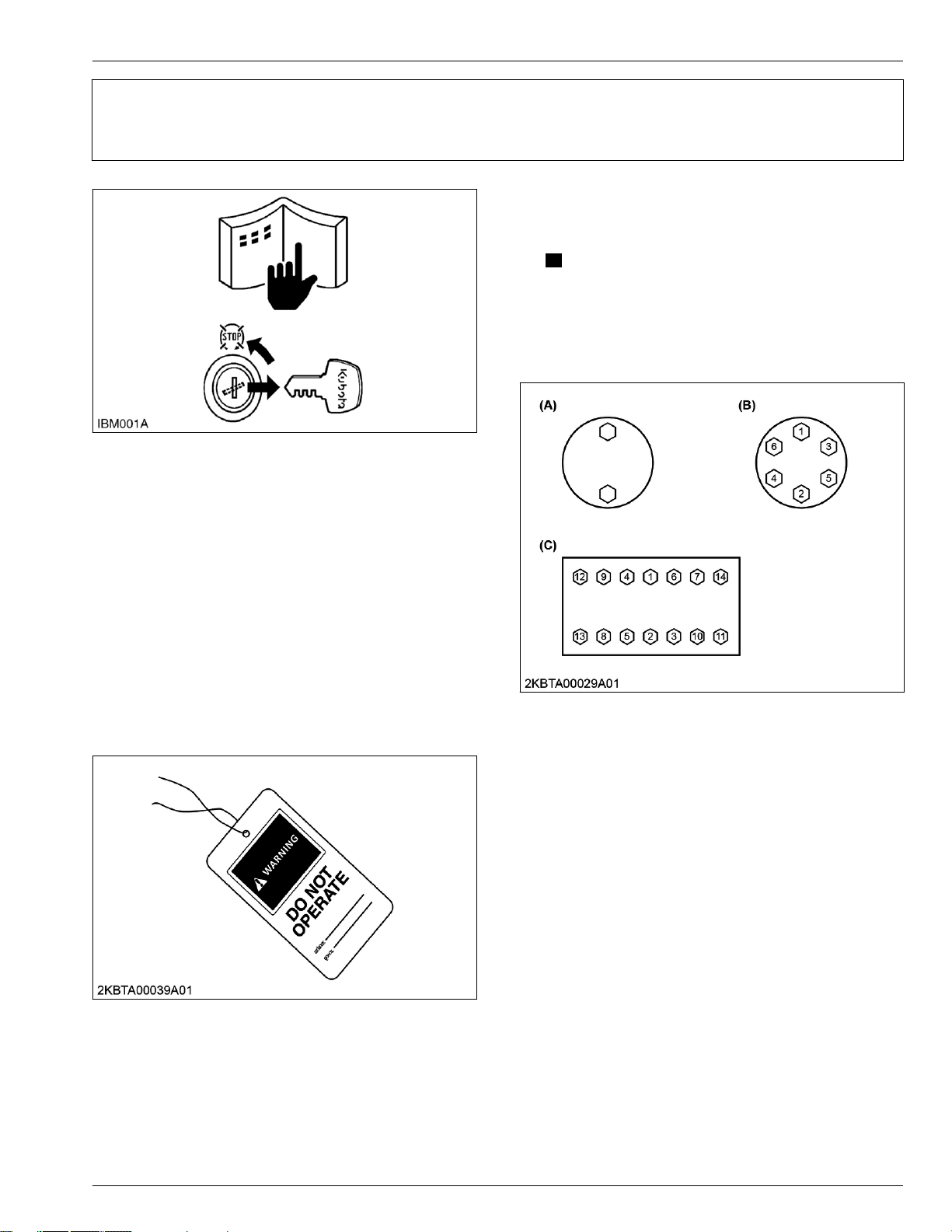

2. GENERAL

GENERAL WORKING PRECAUTIONS ............................................................................................................2-1

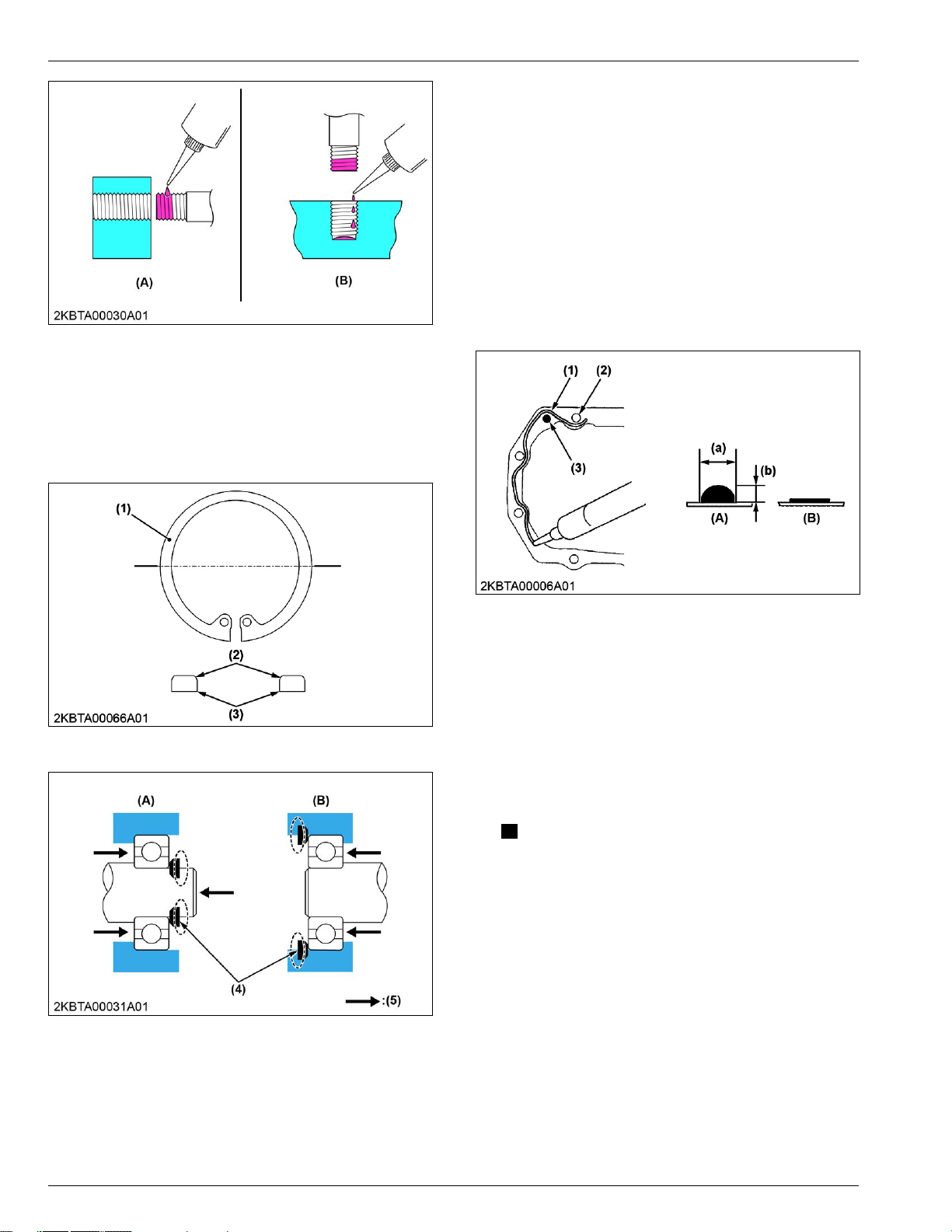

1. Tightening bolts and nuts..........................................................................................................................2-1

2. Applying thread-locking fluid..................................................................................................................... 2-1

3. Installing circlips .......................................................................................................................................2-2

4. Handling liquid gasket ..............................................................................................................................2-2

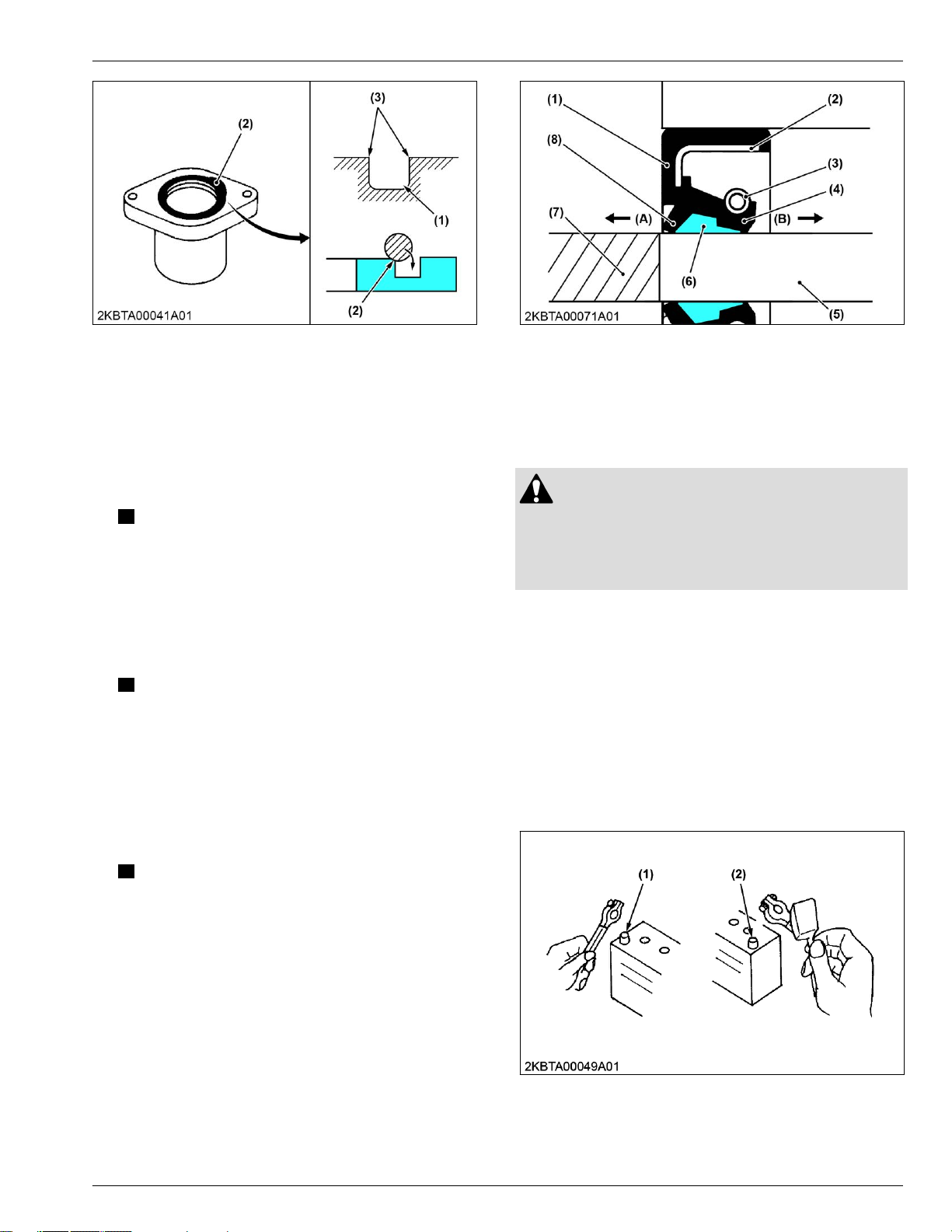

5. Replacing O-rings.....................................................................................................................................2-2

6. Replacing oil seals.................................................................................................................................... 2-3

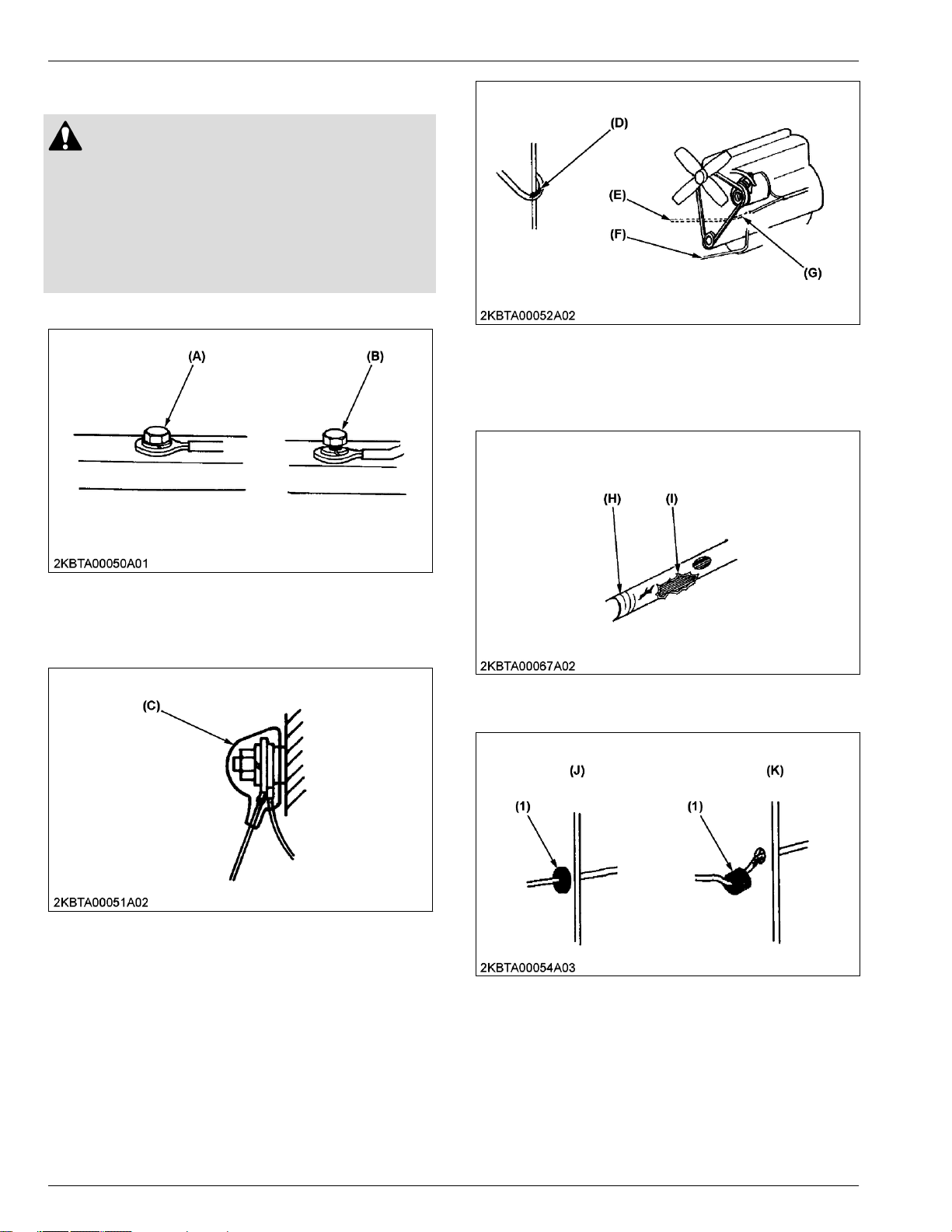

7. Handling the battery .................................................................................................................................2-3

8. Handling wire harness .............................................................................................................................. 2-4

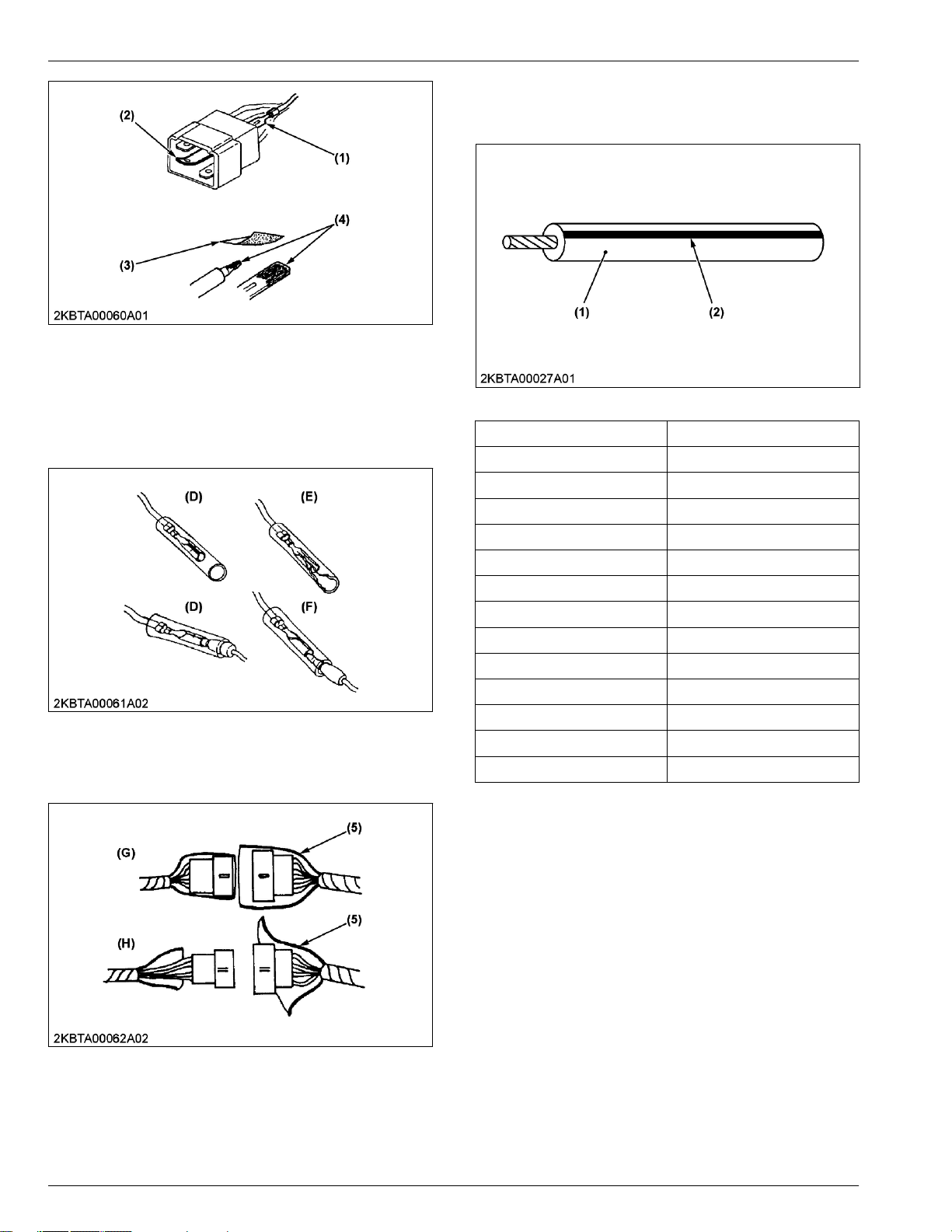

9. Handling fuses..........................................................................................................................................2-5

10. Handling connectors...............................................................................................................................2-5

11. Wiring color ............................................................................................................................................. 2-6

12. Dispose fluids correctly........................................................................................................................... 2-6

ENGINE IDENTIFICATION ................................................................................................................................ 2-9

1. Engine model name and engine serial number ........................................................................................ 2-9

2. E5B engine ............................................................................................................................................. 2-10

3. Cylinder number .....................................................................................................................................2-11

MUFFLER FULL ASSEMBLY IDENTIFICATION.............................................................................................2-13

1. Part number and serial number (DPF) ...................................................................................................2-13

INFORMATION ................................................................................................................................................2-15

1. Specifications .........................................................................................................................................2-15

1.1 Specification for V1505-CR-TE5 ..................................................................................................... 2-15

2. Performance curves ...............................................................................................................................2-16

2.1 Performance curve for V1505-CR-TE5 ........................................................................................... 2-16

3. Dimensions.............................................................................................................................................2-17

3.1 Dimensions of V1505-CR-TE5........................................................................................................2-17

4. Wiring diagram .......................................................................................................................................2-18

4.1 Engine intermediate harness (Engine side harness) ......................................................................2-18

4.2 Injector intermediate harness (Engine side harness)......................................................................2-19

4.3 DPF intermediate harness (Engine side harness) ..........................................................................2-19

4.4 System wiring diagram....................................................................................................................2-21

SPECIAL TOOLS............................................................................................................................................. 2-23

1. Diesel engine compression tester ..........................................................................................................2-23

2. Oil pressure tester ..................................................................................................................................2-23

3. Compression tester adapter ...................................................................................................................2-23

4. Small end bushing replacing tool............................................................................................................ 2-25

5. Idle gear bushing replacing tool.............................................................................................................. 2-25

6. Valve guide replacing tool.......................................................................................................................2-26

7. Crankshaft sleeve press fit tool ..............................................................................................................2-27

8. Flywheel stopper ....................................................................................................................................2-27

9. Crankshaft bearing 1 replacing tool........................................................................................................2-28

..................................................................................................................................................1-1

10. Guide pin for suction control valve (SCV)............................................................................................. 2-28

iv

V1505-CR-TE5

KiSC issued 03, 2022 A

1

1. Air gap of the crankshaft position sensor measuring jig

.......................................................................2-29

12. Rotation sensor signal interface unit ....................................................................................................2-30

3. MAINTENANCE

MAINTENANCE CHECK LIST........................................................................................................................... 3-1

CHECK AND MAINTENANCE........................................................................................................................... 3-5

1. Daily check points..................................................................................................................................... 3-5

1.1 Checking engine oil level ..................................................................................................................3-5

1.2 Checking fuel level ............................................................................................................................ 3-5

1.3 Checking coolant level ......................................................................................................................3-6

1.4 Checking fan belt ..............................................................................................................................3-6

2. Check points of initial 50 hours................................................................................................................. 3-8

2.1 Changing engine oil ..........................................................................................................................3-8

2.2 Replacing oil filter cartridge...............................................................................................................3-8

3. Check point of every 50 hours..................................................................................................................3-9

3.1 Checking fuel hoses and clamp bands .............................................................................................3-9

3.2 Checking and draining water separator (Type 1) .............................................................................. 3-9

4. Check points of every 100 hours .............................................................................................................. 3-9

4.1 Checking radiator hose and clamp bands.........................................................................................3-9

4.2 Cleaning air cleaner primary element .............................................................................................3-10

4.3 Adjusting fan belt tension ................................................................................................................ 3-10

4.4 Checking intake air line ................................................................................................................... 3-11

5. Check point of every 250 hours..............................................................................................................3-12

5.1 Changing engine oil ........................................................................................................................3-12

6. Check points of every 400 hours ............................................................................................................ 3-12

6.1 Replacing fuel filter cartridge........................................................................................................... 3-12

6.2 Replacing oil filter cartridge.............................................................................................................3-13

6.3 Cleaning water separator (Type 1).................................................................................................. 3-13

7. Check points of every 500 hours ............................................................................................................ 3-13

7.1 Replacing water separator filter (Type 2) ........................................................................................ 3-13

7.2 Cleaning water jacket and radiator interior...................................................................................... 3-14

7.3 Replacing fan belt ...........................................................................................................................3-15

8. Check point of every 800 hours..............................................................................................................3-16

8.1 Checking valve clearance ...............................................................................................................3-16

9. Check points of every 1500 hours .......................................................................................................... 3-17

9.1 Checking injector (with Diagmaster) ...............................................................................................3-17

9.2 Checking EGR cooler...................................................................................................................... 3-18

9.3 Checking head cover valve ............................................................................................................. 3-19

10. Check points of every 3000 hours ........................................................................................................ 3-19

10.1 Checking turbocharger..................................................................................................................3-19

10.2 Checking EGR system (with Diagmaster).....................................................................................3-20

11. Check points of every 3000 to 6000 hours ...........................................................................................3-21

11.1 Cleaning DPF ................................................................................................................................3-21

11.2 Judging reuse of DPF filter comp before cleaning (Service dealer) ..............................................3-23

11.3 Judging reuse of DPF filter comp after cleaning (Cleaning contractor) ......................................... 3-23

12. Check points of every 1 year ................................................................................................................ 3-24

12.1 Replacing air cleaner element....................................................................................................... 3-24

12.2 Checking DPF differential pressure pipes and hoses ...................................................................3-25

12.3 Checking EGR piping....................................................................................................................3-25

12.4 Checking intake air line ................................................................................................................. 3-25

12.5 Checking exhaust manifold ........................................................................................................... 3-26

12.6 Replacing water hose.................................................................................................................... 3-26

13. Check points of every 2 years ..............................................................................................................3-26

13.1 Replacing fan belt .........................................................................................................................3-26

13.2 Replacing rubber hose of DPF differential pressure sensor..........................................................3-27

13.3 Replacing intake hose (after air flow sensor) and intercooler hose ..............................................3-27

13.4 Replacing EGR cooler hose..........................................................................................................3-27

13.5 Replacing lubricant hose...............................................................................................................3-28

V1505-CR-TE5

v

KiSC issued 03, 2022 A

13.6 Changing radiator coolant

13.7 Replacing radiator hose and clamp bands

.............................................................................................................3-28

....................................................................................3-29

13.8 Replacing fuel hose and clamps ...................................................................................................3-30

13.9 Replacing intake air line ................................................................................................................ 3-30

4. ENGINE

MECHANISM ..................................................................................................................................................... 4-1

1. General (Introduction)............................................................................................................................... 4-1

1.1 Feature of combustion (E-CDIS).......................................................................................................4-1

1.2 Structure of combustion (Center direct injection system (E-CDIS)) .................................................. 4-1

1.3 Flow of combustion (E-CDIS)............................................................................................................ 4-1

1.4 Control of combustion (E-CDIS)........................................................................................................ 4-2

2. Engine body.............................................................................................................................................. 4-3

2.1 Structure of engine body ................................................................................................................... 4-3

2.2 Feature of engine body .....................................................................................................................4-4

2.3 Crankcase ......................................................................................................................................... 4-4

2.3.1 Outline of crankcase ................................................................................................................. 4-4

2.3.2 Structure of crankcase..............................................................................................................4-4

2.3.3 Function of crankcase............................................................................................................... 4-4

2.3.4 Specification of crankcase ........................................................................................................ 4-4

2.4 Cylinder head .................................................................................................................................... 4-4

2.4.1 Outline of cylinder head ............................................................................................................ 4-4

2.4.2 Structure of cylinder head.........................................................................................................4-4

2.4.3 Function of cylinder head.......................................................................................................... 4-4

2.5 Cylinder head cover ..........................................................................................................................4-5

2.5.1 Outline of cylinder head cover ..................................................................................................4-5

2.5.2 Structure of cylinder head cover ............................................................................................... 4-5

2.5.3 Function of cylinder head cover................................................................................................4-5

2.6 Breather ............................................................................................................................................4-6

2.6.1 Outline of breather .................................................................................................................... 4-6

2.6.2 Structure of breather.................................................................................................................4-6

2.6.3 Function of breather.................................................................................................................. 4-6

2.7 Piston ................................................................................................................................................4-6

2.7.1 Outline of piston........................................................................................................................4-6

2.7.2 Structure of piston..................................................................................................................... 4-6

2.7.3 Function of piston .....................................................................................................................4-6

2.7.4 Specification of piston...............................................................................................................4-6

2.8 Piston ring .........................................................................................................................................4-7

2.8.1 Outline of piston ring.................................................................................................................4-7

2.8.2 Structure of piston ring.............................................................................................................. 4-7

2.8.3 Function of piston ring ..............................................................................................................4-7

2.8.4 Specification of piston ring........................................................................................................4-7

2.9 Connecting rod..................................................................................................................................4-7

2.9.1 Outline of connecting rod..........................................................................................................4-7

2.9.2 Structure of connecting rod....................................................................................................... 4-7

2.9.3 Function of connecting rod .......................................................................................................4-7

2.10 Crankshaft.......................................................................................................................................4-8

2.10.1 Outline of crankshaft...............................................................................................................4-8

2.10.2 Structure of crankshaft............................................................................................................ 4-8

2.10.3 Function of crankshaft ............................................................................................................4-8

2.10.4 Specification of crankshaft......................................................................................................4-8

2.11 Main bearing case ...........................................................................................................................4-8

2.11.1 Outline of main bearing case ..................................................................................................4-8

2.11.2 Structure of main bearing case ...............................................................................................4-8

2.11.3 Function of main bearing case ................................................................................................ 4-8

2.12 Flywheel .......................................................................................................................................... 4-9

2.12.1 Outline of flywheel ..................................................................................................................4-9

2.12.2 Structure of flywheel ...............................................................................................................4-9

vi

V1505-CR-TE5

KiSC issued 03, 2022 A

2.12.3 Function of flywheel

2.12.4 Specification of flywheel

................................................................................................................4-9

.........................................................................................................4-9

2.13 Rocker arm assembly .....................................................................................................................4-9

2.13.1 Outline of rocker arm assembly .............................................................................................. 4-9

2.13.2 Structure of rocker arm assembly...........................................................................................4-9

2.13.3 Function of rocker arm assembly............................................................................................ 4-9

2.14 Camshaft.......................................................................................................................................4-10

2.14.1 Outline of camshaft...............................................................................................................4-10

2.14.2 Structure of camshaft............................................................................................................ 4-10

2.14.3 Function of camshaft ............................................................................................................4-10

2.14.4 Specification of camshaft......................................................................................................4-10

2.15 Valve..............................................................................................................................................4-10

2.15.1 Outline of valve ..................................................................................................................... 4-10

2.15.2 Structure of valve..................................................................................................................4-10

2.15.3 Function of valve................................................................................................................... 4-10

2.15.4 Specification of valve ............................................................................................................ 4-10

2.16 Tappet ........................................................................................................................................... 4-11

2.16.1 Outline of tappet ................................................................................................................... 4-11

2.16.2 Structure of tappet ................................................................................................................4-11

2.16.3 Function of tappet ................................................................................................................. 4-11

2.17 Push rod........................................................................................................................................ 4-11

2.17.1 Outline of push rod ............................................................................................................... 4-11

2.17.2 Structure of push rod ............................................................................................................ 4-11

2.17.3 Function of push rod ............................................................................................................. 4-12

2.18 Timing gears..................................................................................................................................4-12

2.18.1 Outline of timing gears..........................................................................................................4-12

2.18.2 Structure of timing gears....................................................................................................... 4-12

2.18.3 Function of timing gears .......................................................................................................4-12

3. Fuel system ............................................................................................................................................4-13

3.1 Structure of common rail system (CRS) engine..............................................................................4-13

3.2 Feature of common rail system (CRS) engine ................................................................................ 4-14

3.3 Flow of common rail system (CRS) engine.....................................................................................4-15

3.4 Control of common rail system (CRS) engine.................................................................................4-17

3.5 Fuel tank .........................................................................................................................................4-17

3.5.1 Outline of fuel tank..................................................................................................................4-17

3.5.2 Structure of fuel tank............................................................................................................... 4-17

3.5.3 Function of fuel tank ...............................................................................................................4-17

3.5.4 Specification of fuel tank.........................................................................................................4-17

3.6 Water separator...............................................................................................................................4-17

3.6.1 Outline of water separator ......................................................................................................4-17

3.6.2 Structure of water separator (Type1)......................................................................................4-17

3.6.3 Structure of water separator (Type2)......................................................................................4-17

3.6.4 Function of water separator .................................................................................................... 4-18

3.6.5 Specification of water separator (Type2) ................................................................................ 4-18

3.7 Electromagnetic fuel feed pump...................................................................................................... 4-18

3.7.1 Outline of electromagnetic fuel feed pump .............................................................................4-18

3.7.2 Structure of electromagnetic fuel feed pump .......................................................................... 4-18

3.7.3 Function of electromagnetic fuel feed pump...........................................................................4-18

3.7.4 Specification of electromagnetic fuel feed pump ....................................................................4-18

3.8 Fuel filter .........................................................................................................................................4-19

3.8.1 Outline of fuel filter..................................................................................................................4-19

3.8.2 Structure of fuel filter............................................................................................................... 4-19

3.8.3 Function of fuel filter ...............................................................................................................4-19

3.8.4 Specification of fuel filter.........................................................................................................4-19

3.9 Supply pump ...................................................................................................................................4-19

3.9.1 Outline of supply pump ........................................................................................................... 4-19

3.9.2 Structure of supply pump........................................................................................................4-19

3.9.3 Function of supply pump......................................................................................................... 4-21

V1505-CR-TE5

vii

KiSC issued 03, 2022 A

3.9.4 Specification of supply pump

3.10 Injection pipe

.................................................................................................................................4-23

..................................................................................................4-23

3.10.1 Outline of injection pipe ........................................................................................................4-23

3.10.2 Structure of injection pipe .....................................................................................................4-23

3.10.3 Function of injection pipe ...................................................................................................... 4-23

3.11 Rail assembly ................................................................................................................................4-23

3.11.1 Outline of rail assembly.........................................................................................................4-23

3.11.2 Structure of rail assembly...................................................................................................... 4-23

3.11.3 Function of rail assembly ......................................................................................................4-23

3.11.4 Specification of rail assembly................................................................................................4-24

3.12 Injector ..........................................................................................................................................4-24

3.12.1 Outline of injector..................................................................................................................4-24

3.12.2 Structure of injector............................................................................................................... 4-24

3.12.3 Function of injector ...............................................................................................................4-26

3.12.4 Specification of injector.........................................................................................................4-28

3.13 Overflow pipe ................................................................................................................................4-28

3.13.1 Outline of overflow pipe ........................................................................................................4-28

3.13.2 Structure of overflow pipe ..................................................................................................... 4-28

3.13.3 Function of overflow pipe......................................................................................................4-28

3.14 Check valve................................................................................................................................... 4-28

3.14.1 Outline of check valve........................................................................................................... 4-28

3.14.2 Structure of check valve .......................................................................................................4-28

3.14.3 Function of check valve ........................................................................................................4-28

3.15 Fuel cooler ....................................................................................................................................4-28

3.15.1 Outline of fuel cooler.............................................................................................................4-28

3.15.2 Structure of fuel cooler.......................................................................................................... 4-29

3.15.3 Function of fuel cooler ..........................................................................................................4-29

3.16 Engine ECU ..................................................................................................................................4-29

3.16.1 Outline of engine ECU .......................................................................................................... 4-29

3.16.2 Structure of engine ECU.......................................................................................................4-29

3.16.3 Function of engine ECU........................................................................................................ 4-29

3.16.4 Specification of engine ECU ................................................................................................. 4-29

3.17 Crankshaft position sensor............................................................................................................ 4-30

3.17.1 Outline of crankshaft position sensor.................................................................................... 4-30

3.17.2 Structure of crankshaft position sensor ................................................................................4-30

3.17.3 Function of crankshaft position sensor .................................................................................4-30

3.17.4 Specification of crankshaft position sensor........................................................................... 4-30

3.18 Camshaft position sensor.............................................................................................................. 4-31

3.18.1 Outline of camshaft position sensor...................................................................................... 4-31

3.18.2 Structure of camshaft position sensor ..................................................................................4-31

3.18.3 Function of camshaft position sensor ...................................................................................4-31

3.18.4 Specification of camshaft position sensor............................................................................. 4-31

3.19 Coolant temperature sensor.......................................................................................................... 4-32

3.19.1 Outline of coolant temperature sensor.................................................................................. 4-32

3.19.2 Structure of coolant temperature sensor ..............................................................................4-32

3.19.3 Function of coolant temperature sensor ...............................................................................4-32

3.19.4 Specification of coolant temperature sensor......................................................................... 4-32

3.20 TMAP sensor ................................................................................................................................4-33

3.20.1 Outline of TMAP sensor........................................................................................................ 4-33

3.20.2 Structure of TMAP sensor ....................................................................................................4-33

3.20.3 Function of TMAP sensor .....................................................................................................4-33

3.20.4 Specification of TMAP sensor............................................................................................... 4-33

3.21 Atmosphere pressure sensor ........................................................................................................ 4-34

3.21.1 Outline of atmosphere pressure sensor................................................................................ 4-34

3.21.2 Structure of atmosphere pressure sensor ............................................................................4-34

3.21.3 Function of atmosphere pressure sensor .............................................................................4-34

4. Intake and exhaust system.....................................................................................................................4-35

4.1 Structure of intake and exhaust system .......................................................................................... 4-35

viii

V1505-CR-TE5

KiSC issued 03, 2022 A

4.2 Feature of intake and exhaust system

4.3 Flow of intake and exhaust system

............................................................................................4-36

.................................................................................................4-37

4.4 Control of intake and exhaust system ............................................................................................. 4-39

4.5 Pre-cleaner...................................................................................................................................... 4-39

4.5.1 Outline of pre-cleaner .............................................................................................................4-39

4.5.2 Structure of pre-cleaner .......................................................................................................... 4-39

4.5.3 Function of pre-cleaner...........................................................................................................4-39

4.5.4 Specification of pre-cleaner ....................................................................................................4-39

4.6 Air cleaner ....................................................................................................................................... 4-39

4.6.1 Outline of air cleaner............................................................................................................... 4-39

4.6.2 Structure of air cleaner ...........................................................................................................4-39

4.6.3 Function of air cleaner ............................................................................................................4-39

4.6.4 Specification of air cleaner...................................................................................................... 4-39

4.7 Turbocharger................................................................................................................................... 4-39

4.7.1 Outline of turbocharger ........................................................................................................... 4-39

4.7.2 Structure of turbocharger........................................................................................................4-40

4.7.3 Function of turbocharger......................................................................................................... 4-40

4.7.4 Specification of turbocharger .................................................................................................. 4-40

4.8 Intake air heater ..............................................................................................................................4-40

4.8.1 Outline of intake air heater...................................................................................................... 4-40

4.8.2 Structure of intake air heater ..................................................................................................4-40

4.8.3 Function of intake air heater ...................................................................................................4-40

4.8.4 Specification of intake air heater............................................................................................. 4-40

4.9 Intake manifold................................................................................................................................4-41

4.9.1 Outline of intake manifold .......................................................................................................4-41

4.9.2 Structure of intake manifold .................................................................................................... 4-41

4.9.3 Function of intake manifold.....................................................................................................4-41

4.10 Exhaust manifold........................................................................................................................... 4-41

4.10.1 Outline of exhaust manifold ..................................................................................................4-41

4.10.2 Structure of exhaust manifold ............................................................................................... 4-41

4.10.3 Function of exhaust manifold................................................................................................4-41

5. Exhaust gas recirculation (EGR) system................................................................................................4-42

5.1 Structure of EGR system ................................................................................................................4-42

5.2 Feature of EGR system................................................................................................................... 4-43

5.3 Flow of EGR system........................................................................................................................4-44

5.4 Control of EGR system ...................................................................................................................4-46

5.5 EGR cooler...................................................................................................................................... 4-46

5.5.1 Outline of EGR cooler.............................................................................................................4-46

5.5.2 Structure of EGR cooler.......................................................................................................... 4-46

5.5.3 Function of EGR cooler ..........................................................................................................4-46

5.5.4 Specification of EGR cooler....................................................................................................4-46

5.6 EGR valve ....................................................................................................................................... 4-46

5.6.1 Outline of EGR valve ..............................................................................................................4-46

5.6.2 Structure of EGR valve ........................................................................................................... 4-47

5.6.3 Function of EGR valve............................................................................................................4-49

5.6.4 Specification of EGR valve .....................................................................................................4-49

5.7 Reed valve ......................................................................................................................................4-49

5.7.1 Outline of reed valve...............................................................................................................4-49

5.7.2 Structure of reed valve............................................................................................................ 4-49

5.7.3 Function of reed valve ............................................................................................................4-49

6. Lubricating system.................................................................................................................................. 4-50

6.1 Structure of lubricating system........................................................................................................4-50

6.2 Feature of lubricating system .......................................................................................................... 4-51

6.3 Flow of lubricating system...............................................................................................................4-52

6.4 Oil pan.............................................................................................................................................4-54

6.4.1 Outline of oil pan.....................................................................................................................4-54

6.4.2 Structure of oil pan.................................................................................................................. 4-54

6.4.3 Function of oil pan ..................................................................................................................4-54

V1505-CR-TE5

ix

KiSC issued 03, 2022 A

6.4.4 Specification of oil pan

6.5 Oil strainer

.......................................................................................................................................4-54

............................................................................................................4-54

6.5.1 Outline of oil strainer...............................................................................................................4-54

6.5.2 Structure of oil strainer............................................................................................................ 4-54

6.5.3 Function of oil strainer ............................................................................................................4-54

6.5.4 Specification of oil strainer......................................................................................................4-54

6.6 Oil pump..........................................................................................................................................4-55

6.6.1 Outline of oil pump..................................................................................................................4-55

6.6.2 Structure of oil pump............................................................................................................... 4-55

6.6.3 Function of oil pump ...............................................................................................................4-55

6.6.4 Specification of oil pump.........................................................................................................4-55

6.7 Relief valve...................................................................................................................................... 4-56

6.7.1 Outline of relief valve ..............................................................................................................4-56

6.7.2 Structure of relief valve ........................................................................................................... 4-56

6.7.3 Function of relief valve............................................................................................................4-56

6.8 Oil filter ............................................................................................................................................ 4-56

6.8.1 Outline of oil filter .................................................................................................................... 4-56

6.8.2 Structure of oil filter.................................................................................................................4-56

6.8.3 Function of oil filter.................................................................................................................. 4-56

6.8.4 Specification of oil filter ........................................................................................................... 4-57

6.9 Oil cooler ......................................................................................................................................... 4-57

6.9.1 Outline of oil cooler ................................................................................................................. 4-57

6.9.2 Structure of oil cooler..............................................................................................................4-57

6.9.3 Function of oil cooler............................................................................................................... 4-57

6.9.4 Specification of oil cooler ........................................................................................................ 4-57

6.10 Oil pressure switch........................................................................................................................4-58

6.10.1 Outline of oil pressure switch................................................................................................4-58

6.10.2 Structure of oil pressure switch............................................................................................. 4-58

6.10.3 Function of oil pressure switch .............................................................................................4-58

6.10.4 Specification of oil pressure switch.......................................................................................4-58

7. Cooling system ....................................................................................................................................... 4-59

7.1 Structure of cooling system.............................................................................................................4-59

7.2 Feature of cooling system ............................................................................................................... 4-60

7.3 Flow of cooling system....................................................................................................................4-60

7.4 Control of cooling system................................................................................................................4-60

7.5 Water pump..................................................................................................................................... 4-60

7.5.1 Outline of water pump............................................................................................................. 4-60

7.5.2 Structure of water pump .........................................................................................................4-60

7.5.3 Function of water pump ..........................................................................................................4-60

7.6 Thermostat ...................................................................................................................................... 4-60

7.6.1 Outline of thermostat ..............................................................................................................4-60

7.6.2 Structure of thermostat ...........................................................................................................4-61

7.6.3 Function of thermostat ............................................................................................................ 4-61

7.6.4 Specification of thermostat .....................................................................................................4-61

7.7 Radiator........................................................................................................................................... 4-61

7.7.1 Outline of radiator ...................................................................................................................4-61

7.7.2 Structure of radiator ................................................................................................................ 4-62

7.7.3 Function of radiator.................................................................................................................4-62

7.7.4 Specification of radiator ..........................................................................................................4-62

7.8 Radiator cap....................................................................................................................................4-62

7.8.1 Outline of radiator cap ............................................................................................................4-62

7.8.2 Structure of radiator cap .........................................................................................................4-62

7.8.3 Function of radiator cap .......................................................................................................... 4-62

7.8.4 Specification of radiator cap ...................................................................................................4-63

7.9 Cooling fan ...................................................................................................................................... 4-63

7.9.1 Outline of cooling fan .............................................................................................................. 4-63

7.9.2 Structure of cooling fan...........................................................................................................4-63

7.9.3 Function of cooling fan............................................................................................................ 4-63

x

V1505-CR-TE5

KiSC issued 03, 2022 A

7.9.4 Specification of cooling fan

7.10 Reserve tank

.................................................................................................................................4-64

.....................................................................................................4-63

7.10.1 Outline of reserve tank.......................................................................................................... 4-64

7.10.2 Structure of reserve tank ......................................................................................................4-64

7.10.3 Function of reserve tank .......................................................................................................4-64

7.11 Fan belt..........................................................................................................................................4-64

7.11.1 Outline of fan belt .................................................................................................................. 4-64

7.11.2 Structure of fan belt...............................................................................................................4-64

7.11.3 Function of fan belt................................................................................................................4-64

8. Electrical system..................................................................................................................................... 4-65

8.1 Structure of electrical system .......................................................................................................... 4-65

8.2 Feature of electrical system ............................................................................................................4-66

8.3 Flow of electrical system ................................................................................................................. 4-67

8.4 Control of electrical system ............................................................................................................. 4-69

8.5 Battery.............................................................................................................................................4-69

8.5.1 Outline of battery ....................................................................................................................4-69

8.5.2 Structure of battery .................................................................................................................4-69

8.5.3 Function of battery .................................................................................................................. 4-69

8.5.4 Specification of battery ...........................................................................................................4-69

8.6 Key switch ....................................................................................................................................... 4-69

8.6.1 Outline of key switch...............................................................................................................4-69

8.6.2 Structure of key switch............................................................................................................ 4-69

8.6.3 Function of key switch ............................................................................................................4-70

8.6.4 Specification of key switch......................................................................................................4-70

8.7 Starter (Gear reduction type) ..........................................................................................................4-70

8.7.1 Outline of starter (gear reduction type) ................................................................................... 4-70

8.7.2 Structure of starter (gear reduction type)................................................................................4-70

8.7.3 Function of starter (gear reduction type)................................................................................. 4-70

8.7.4 Specification of starter (Gear reduction type) .........................................................................4-71

8.8 Starter (Planetary gear reduction type) ........................................................................................... 4-72

8.8.1 Outline of starter (planetary gear reduction type) ...................................................................4-72

8.8.2 Structure of starter (planetary gear reduction type) ................................................................ 4-72

8.8.3 Function of starter (planetary gear reduction type).................................................................4-72

8.8.4 Specification of starter (planetary gear reduction type) ..........................................................4-72

8.9 Alternator......................................................................................................................................... 4-72

8.9.1 Outline of alternator ................................................................................................................4-72

8.9.2 Structure of alternator ............................................................................................................. 4-72

8.9.3 Function of alternator..............................................................................................................4-72

8.9.4 Specification of alternator .......................................................................................................4-73

9. Aftertreatment system ............................................................................................................................4-73

9.1 Structure of diesel particulate filter (DPF) system...........................................................................4-73

9.2 Feature of diesel particulate filter (DPF) system ............................................................................. 4-74

9.3 Flow of diesel particulate filter (DPF) system..................................................................................4-74

9.4 Control of diesel particulate filter (DPF) system..............................................................................4-75

9.5 Diesel oxidation catalyst (DOC) ......................................................................................................4-77

9.5.1 Outline of diesel oxidation catalyst (DOC) .............................................................................. 4-77

9.5.2 Structure of diesel oxidation catalyst (DOC)...........................................................................4-77

9.5.3 Function of diesel oxidation catalyst (DOC)............................................................................ 4-77

9.6 Diesel particulate filter (DPF) ..........................................................................................................4-77

9.6.1 Outline of diesel particulate filter (DPF) .................................................................................. 4-77

9.6.2 Structure of diesel particulate filter (DPF)...............................................................................4-77

9.6.3 Function of diesel particulate filter (DPF)................................................................................ 4-78

9.7 Air flow sensor................................................................................................................................. 4-78

9.7.1 Outline of air flow sensor ........................................................................................................4-78

9.7.2 Structure of air flow sensor ..................................................................................................... 4-78

9.7.3 Function of air flow sensor......................................................................................................4-78

9.7.4 Specification of air flow sensor ...............................................................................................4-79

9.8 Exhaust gas temperature sensor ....................................................................................................4-79

V1505-CR-TE5

xi

KiSC issued 03, 2022 A

9.8.1 Outline of exhaust gas temperature sensor

9.8.2 Structure of exhaust gas temperature sensor

............................................................................4-79

.........................................................................4-79

9.8.3 Function of exhaust gas temperature sensor .........................................................................4-79

9.8.4 Specification of exhaust gas temperature sensor...................................................................4-80

9.9 DPF differential pressure sensor..................................................................................................... 4-80

9.9.1 Outline of DPF differential pressure sensor............................................................................4-80

9.9.2 Structure of DPF differential pressure sensor......................................................................... 4-80

9.9.3 Function of DPF differential pressure sensor..........................................................................4-81

9.9.4 Specification of differential pressure sensor ........................................................................... 4-81

9.10 Intake throttle valve ....................................................................................................................... 4-81

9.10.1 Outline of intake throttle valve ..............................................................................................4-81

9.10.2 Structure of intake throttle valve ...........................................................................................4-81

9.10.3 Function of intake throttle valve ............................................................................................ 4-82

9.10.4 Specification of intake throttle valve .....................................................................................4-82

SERVICING .....................................................................................................................................................4-83

1. Troubleshooting......................................................................................................................................4-83

1.1 Troubleshooting for V1505-CR-TE5................................................................................................ 4-83

2. Servicing specifications ..........................................................................................................................4-87

2.1 Servicing specification for engine.................................................................................................... 4-87

3. Tightening torques..................................................................................................................................4-93

3.1 Tightening torques of screws, bolts and nuts for general use.........................................................4-93

3.2 Tightening torques of screws, bolts and nuts for special use.......................................................... 4-93

4. Checking and adjusting ..........................................................................................................................4-95

4.1 Checking compression pressure of cylinder ...................................................................................4-95

4.2 Adjusting valve clearance ...............................................................................................................4-95

4.3 Checking engine oil pressure..........................................................................................................4-96

4.4 Checking fan belt tension................................................................................................................4-97

4.5 Checking fan belt damage and wear............................................................................................... 4-98

4.6 Checking radiator cap air leakage................................................................................................... 4-98

4.7 Checking radiator water leakage..................................................................................................... 4-99

4.8 Checking opening temperature of thermostat valve........................................................................ 4-99

4.9 Checking battery voltage............................................................................................................... 4-100

4.10 Checking battery specific gravity................................................................................................. 4-100

4.11 Checking starter motor ................................................................................................................4-101

4.12 Checking magnetic switch of starter ...........................................................................................4-102

4.13 Checking magnetic switch continuity ..........................................................................................4-103

4.14 Checking alternator on unit .........................................................................................................4-103

4.15 Checking intake air heater ..........................................................................................................4-104

4.16 Checking exhaust gas leakage of turbocharger turbine side ......................................................4-104

4.17 Checking air leakage of turbocharger compressor side..............................................................4-104

4.18 Checking radial clearance of turbocharger .................................................................................4-105

4.19 Checking injector......................................................................................................................... 4-105

4.20 Checking suction control valve (SCV).........................................................................................4-105

4.21 Checking TMAP sensor ..............................................................................................................4-106

4.22 Checking crankshaft position sensor ..........................................................................................4-106

4.23 Checking camshaft position sensor ............................................................................................4-107

4.24 Checking coolant temperature sensor ........................................................................................4-107

4.25 Checking EGR system ................................................................................................................ 4-107