Wren Turbines 75 User Manual

W

W

r

r

e

e

n

n

7

7

5

5

New

Miniature Gas Turbine Engine

7.5kg – 16.5lbs thrust

High Performance

Perfect small size, high performance

gas turbine engine for beginners and

expert alike.

Integral FOD screen and high quality

components throughout for long life.

Specifications:

Thrust 75N – 16.5Lbs

Weight – 1030g – 2lb 2oz

Size – 90mm dia x 240mm long (inc

starter)

3-1/2” x 9-1/2” long.

A real quart in a pint pot!!

Introduction to the new Wren 75.

History.

This engine is the latest development in the evolution of gas turbines utilising the same case size as

Wren Turbines’ original Wren54, a 5.4kg (12lbs) thrust engine that broke the mould of ever larger

engines requiring ever larger fuel tanks and ever larger planes.

The Wren 75 “Club” offers the flier a small compact engine with outstanding performance to suit a

wide range of airframes that can be transported in a family car, and at a price to suit the average fliers

budget.

The Wren 75 is built along the lines of the highly successful Wren SuperSport which was the first ultra

high performance turbine commercially produced and has now been in successful continuous

production for six years.

Wren 75 Philosophy

The Wren 75 departs radically from the Wren 54 design in the area of compressor, diffuser and

combustion technology enabling high pressure ratio and high performance to be squeezed into the

same case – just! The latest version of this best selling engine also has a new bearing system

enabling very low rotor resistance for fast pickup and low bearing wear.

Most of the components in the Wren 75 are specially produced for this engine and are not

interchangeable with any of the family of Wren54 derivatives. The ancillaries are however common to

the Wren54 and SuperSport engine and readily available from Wren so you can be sure of regular and

reliable spares backup and Wren Turbines’ legendary service support – you will always get a real

person on the phone at Wren!

With the advantage of extremely low installed weight and small fuel payload requirement the engine

will prove ideal for the club or sports flier looking for reduced wing loadings to fly the typical club circuit

with tight runway space but with agility and response to satisfy the most demanding competition flier.

An exhaust velocity of greater than 800mph gives a breathtaking vertical performance in most slippery

sports airframes and renders the need for the larger engines redundant. Users need to take extra care

in the installation and operation of this engine to ensure their airframe, servos etc are of quality

appropriate to high speed jet flight.

Full Autostart package contents:

Wren 75 gas turbine including integral FOD screen

Fadec Autostart ECU

Hand data terminal for programming and display

Fuel pump

Propane solenoid with flow control valve

Fuel solenoid

3-piece engine mounting strap

2-cell LiPo

Fuel and gas piping

Gas cannister valve and quick coupling

WREN 75 - High Performance Gas Turbine Engine Page 1

Safety notes

A code of practice for operating gas turbines may be accessed from the Gas Turbine Builders

Association (GTBA) website on GTBA.com. The GTBA is the British Model Flying Association (BMFA)

advisory body for model gas turbines.

It is advised always to have a CO2 or similar gas-type fire extinguisher with you when running the

engine – you never know when an emergency will strike and it is best to be prepared. If you need to

extinguish an onboard fire you should point the extinguisher into the front of the engine and not in

through the turbine end.

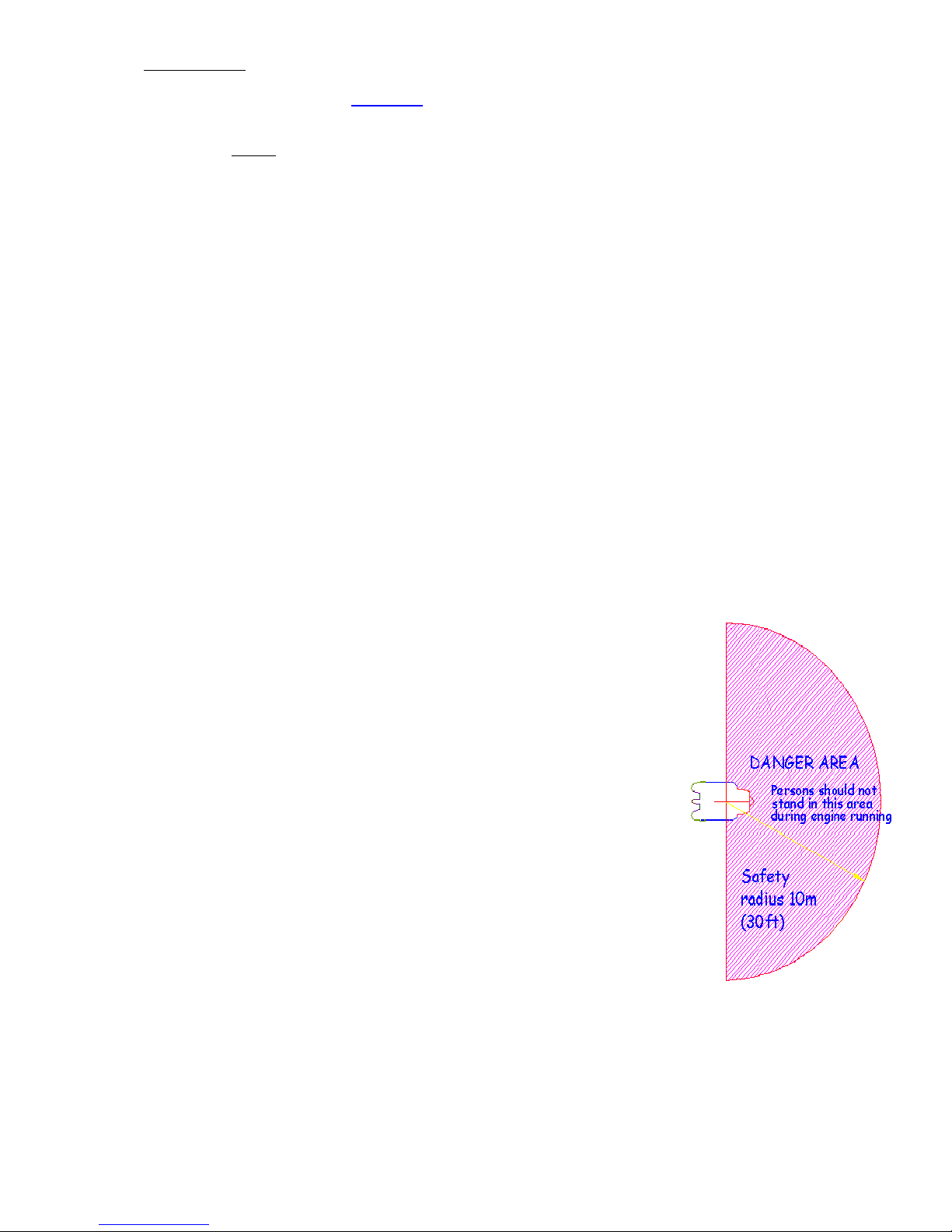

Always ensure, when running a gas turbine that you keep people 10m (30ft) clear of the area to the

side and rear of the engine as you would a propeller engine, as although a broken turbine is extremely

rare it is still technically possible and it is better to be safe.

When running the engine you should stand slightly in front and to one side of the engine, and not to

the side for the reason above.

Always wear ear defenders when running the engine as gas turbines have a high intensity noise level

(around 112db) close to the engine that can impair your hearing in time.

Never try to improve/speed up the starting of the engine by spraying ignition agents into the engine – a

dangerous flashback fire may result and you will in any case never improve the starting this way.

This engine is not a toy and can cause bodily harm to you or others if misused.

It is your responsibility as owner, to ensure safe, careful and considerate operation of your engine at all times, and

in accordance with the manufacturers instructions.

If you sell or give away this engine, please pass these instructions to the new owner.

This engine

thrust is considerable for such a small size and mountings must be sufficient to withstand such forces. Use

appropriate screws and lock-nuts. The engine must not be run held in the hand or clamped in a vice.

This engine is an internal combustion gas turbine engine which generates large quantities

of heat – ensure the mountings and installation are appropriate for operation at these

elevated temperatures.

During operation and for a time afterwards there are parts of the engine which are hot

enough to cause serious burns – do not touch any part of the engine until it has cooled to

room temperature.

Always operate your engine in open air away from confined spaces as the engine exhaust

contains gases which can cause asphyxiation and nuisance from smells.

The exhaust gases are very hot (over 450’C) on leaving the engine and can cause burns to

skin or damage to objects close to it – keep exhausts clear of anything which is affected by

such heat.

This engine must not be used near flammable gases, liquid or materials.

Turbine fuel is poisonous to living beings. Keep it away from the mouth and eyes and from

contact with skin. Always store it in a marked container out of reach to children.

Turbine fuel has a relatively high flash-point but in certain circumstances can be highly

flammable. Keep it away from heat and sources of combustion.

The starting gas is highly flammable and must be used with extreme care. Maintain canister and fittings in good

leak-proof condition. Protect from sunlight and prevent exposure to temperatures exceeding 50’C. Keep out of

reach of children. Discard used canisters in a safe place and do not puncture or incinerate, even when empty.

Avoid deliberate inhalation.

must

only be run firmly attached to a secure and sturdy engine test stand or model installation. The

WREN 75 - High Performance Gas Turbine Engine Page 2

Ensure gas only is supplied the engine, liquid gas must not be allowed to pass into the system. Gas supply must be

disconnected until ready for immediate use. Gas is heavier than air and can fill a model if allowed to leak unchecked,

and become a potential explosion hazard.

Turbine oil can be are hazardous to health and must not be allowed to come into contact with skin, mouth, eyes or

through ingestion, accidental or otherwise. Take care when decanting and ensure any spillage is wiped away

immediately and clean any affected area with warm soapy water.. Wash hands and any affected part immediately

after any contact.

Turbine oil can discolour or affect certain paint finishes as may be used. Take precautions to prevent spillage .

Do not discard or allow any spillage to run into drains.

If removing the glow-plug to test it, keep fingers or bare skin away from possible burn from the glowing element – use

a metal tool or appropriate insulation.

As operator, it is your responsibility to ensure any spectators (especially small children) or helpers are kept well away

from the engine whilst it is operating. The safest position to operate the engine is directly in front. The area inline and to

the rear of the turbine is the most dangerous area and you must keep well clear of this.

Keep all spectators away from the side and rear of the engine to a distance of at least 10mtrs (30ft) radius, as shown. If

operating from a pit area take special care as safety distances are often difficult to maintain.

Keep all helpers close by and brief them fully on their duties before starting the engine. One helper can carry out the

role of fireman. Ensure they are aware of what to do in event of emergency and where to position the extinguisher if

required.

Do not attempt to alter the starting characteristics of the engine by spraying ignition agents into the

intake, as might be used for gasoline and diesel engines. A dangerous fire and flashback may result.

Specifications:

Max thrust 7.5kg (16.5lbs) nominal @ 160,000rpm.

Idle speed 45,000rpm

Pressure Ratio 3:1

Fuel consumption 260ml/min @ full power @ 15’C.

Weight engine only 1030gms

Weight ancillaries ex. ECU battery 260gms.

Setting Up.

A 2-cell LiPo battery pack is supplied with the engine. Charge the pack prior to use. A larger capacity

pack can be substituted if required. Before connecting up, ensure the charger is one specified for use

with LiPo batteries and is set to the correct charge rate.

Fuel.

The engine is designed to run on Jet A or Jet A1 kerosine. Paraffin such as is available at hardware or

DIY stores or at filling stations from the pump is a suitable alternatively where available.

Oil.

To this fuel must be added 5% oil, ie a mixture of around 20:1 fuel to oil. Suitable oils are turbine oils

such as Mobil JetOil, Aeroshell 500 or Exxon 2380. Alternatively, good quality 2-stroke motor cycle oil

such as Castrol Power 1 TTS (Halfords) may be used.

When decanting fuel, take precautions to ensure no solid particles or water droplets are carried over

into your fuel tank – use an effective filter system. Note that jet fuels and oils should not be allowed to

come into skin contact so wear suitable gloves and take extra care when handling.

If you are new to turbines it is a good idea to set the engine up on a simple test-stand and to get used

to starting and running the engine before installing in a model. A three-piece mounting strap is

supplied and this should be attached to a pair of timber battens screwed to a base-board. The two

straps must fit securely on the engine to prevent the casing sliding. The various components can be

temporarily secured to the baseboard, be especially careful not to allow any cables or pipes to run

close to the engine intake where they might be sucked against the fod screen.

The mounting must be properly secured as the thrust from this small engine is considerable and users

are asked to use “belt and braces” in mounting to avoid any possibility of the stand being pushed over

WREN 75 - High Performance Gas Turbine Engine Page 3

Loading...

Loading...