Wren Turbines 44 TurboProp Installation And Operating Manual

W

W

W

I

N

S

T

I

N

S

T

I

N

S

T

R

R

R

A

L

A

L

A

L

L

L

L

E

E

E

A

T

A

T

A

T

N

N

N

I

O

I

O

I

O

N

N

N

4

4

T

U

R

B

O

P

R

O

P

4

4

T

U

R

B

O

P

R

4

4

T

U

R

B

O

P

A

N

D

O

P

E

R

A

T

I

N

G

M

A

N

U

A

L

A

N

D

O

P

E

R

A

T

I

N

G

M

A

A

N

D

O

P

E

R

A

T

I

N

G

N

M

A

N

September 2008

U

A

L

U

A

L

Copyright Wren Turbines Ltd

R

O

O

P

P

WREN 44 TurboProp Manual

Congratulations on your purchase of the new miniature Wren 44 TurboProp gas turbine engine.

This manual has been prepared to help you set up and safely operate your engine. If you encounter any

problems then please consult this list first and if you cannot find a solution please get in touch with us. The

engine is simple to prepare and use but certain precautions must be observed for your safety and others

near you – see safety notes.

Included in the manual is a problem checklist to help solve any problems you may encounter in operation.

Please remember, although small and seemingly harmless the engine is definitely not a toy and must be

treated with utmost care and consideration to your own safety and others around you. The manual also

contains sections on the individual components of the installation and operation, refer to these for more

detailed information.

Contents:

3 Introduction

4 Package contents

5 Weights and Measures

6 General description of the two-shaft drive system

9 Detail description of the turboprop unit and ancilliaries

13 Safety issues, do's and don’ts

14 Warranty, service and repair

15 Performance

16 Propeller selection and balancing

17 Fuel consumption/duration

20 Installation Do’s and Don’ts

22 Wiring and Plumbing Schematic

35 Installing the system components

23 Connecting the system components

27 Setting up the ECU

28 ECU Failsafe function

29 Preparing for running

31 Running the unit

36 Starting and running, problem checklist

34 Flying the unit

35 After running

37 Storage

38

Front Cover Pictures - Acknowledgments:

Front page upper – the first 44 Turbo-Prop prototype installed in a Pilatus “Porter” for gliding towing, by kind

permission from Lucien Gerard, Luxemburg.

Front page middle - the 2nd prototype Wren 44 Turbo-Prop installed in a Top Flight “P51 Mustang”, by kind

permission from Lucien Gerard of Luxemburg.

Front page lower left – the first production Wren 44 Turbo-Prop installed in a Graupner “Taxi”. By kind

permission from owner, Barrie King.

Front Page, lower right – Wren 44 Turbo-Prop installed in a YAK88 from ExtremeFlightRC, flown by Jeannot

Behm.

Basic servicing

Wren Turbines Ltd. Unit 19, Century Park Network Centre, Manvers, Rotherham,

South Yorkshire. England.

Tel. 01709 877439. Fax 01709 875935 Email: info@wrenturbines.co.uk

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 2

The new Wren 44 TurboProp

Introduction

This new development from the highly popular Wren 44 Gold thrust engine stable, has been long awaited. It

has built on the success of the Wren 54 Turboprop which has now been on sale in various forms since 2002.

The engine has been the outcome of a long R&D programme primarily concerned with maximising the

performance and minimising the aggravation of installing and operating, allowing the flier to get on with the

business of flying.

We have been careful to keep the weight of the unit down but have not compromised stiffness which has

shown itself to be a major concern for turbo-props. The engine is not modified for use in this application

apart from a small hole drilled in the case to add a lubrication port, enabling the full perfomance to be used

in driving the propeller, producing performance usually described as “awesome” by all those witnessing it.

The gearbox assembly is strongly built to withstand many hours of operation and is designed to be

lubricated with a small fuel take-off from the engine. All this is automatic and the user need do no more than

put fuel into the tank, charge batteries and go fly!

We have tried hard to produce a compact high power to weight engine capable of filling the gap left by the

noisy medium to large I/C engine, and the existing range of turbo-prop engines now becoming available.

Most of these are really only suited to large aircraft around 2.5 to 3m (8’ to 10’) wingspan, which has

implications for cost, transport and suitability of flying field. There are a large number of airframes already

available in the 2m (6’) size that are attractive for conversion to turbo-prop for the reasons outlined above

and are suited for the average club flier. The low installed weight around 2kg compares well with equivelent

2-cycle engines and helps to keep the wing loading sensible.

Noise is becoming a major concern and the 44 turbo-prop enjoys a remarkably low noise figure, rivalling

electric models in many cases. The noise is predominantly propeller noise and with the smooth application

of torque and total absence of power pulses enables a very low perceived noise level to be achieved.

The Wren 44 Turboprop enjoys the same highly responsive engine as the Wren 44 Gold thrust version so

the absolute minimum throttle lag can be appreciated by those keen on prop hanging and the usual

aerobatics. The small engine size enables the fuel consumption to be described as “stingy” so no need for

lugging a big fuel bottle around.

Importantly, the engine is already well established so you are not buying an unproven design. Parts and

service is readily available and the hundreds of Wren 44 Gold customers across the world will testify to the

longevity and ease of use of this world-beating engine.

Above all - Enjoy!

From all the team at Wren Turbines Ltd

February 2008

Special thanks to:

Lucien Gerard, a good friend and colleague of all at Wren

Turbines, who was the first customer to build a Wren 54

turboprop back in 2002 that still flies in an Embrear Tucano

and encouraged this development from the start.

Lucien supplied aircraft for flight testing the 1st and 2nd Wren

44 turbo-prop prototypes and undertook all the test flying. His

generous help and feedback has greatly assisted and

encouraged us to push this unique development forward into

successful production.

Thank-you.

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 3

The Wren 44 TurboProp package contains the following:

1) Wren 44 TurboProp Engine

2) Fuel pump

3) Autostart ECU (Engine Control Unit)

4) ECU data display terminal

5) ECU Battery (2-cell LiPo)

6) Propane canister valve

7) Fuel solenoid

8) Propane solenoid (with attached adjustable flow control valve)

9) Propane tank and one way valve

10) Brass two-part quick-release propane connector

Lay out the engine and its support equipment on a clean surface and identify all the components.

Weights and Measures

Weights:

Power unit complete with cables 1710g (3-3/4 lbs)

Fuel pump 88g (3oz)

Valves (Propane and Fuel) 65g (2-1/4oz)

ECU (Engine Control Unit) 35g (1-1/4oz)

LiPo battery 7.4v, 1500mAh 80g (2-3/4oz)

All up weight 1978g (4lb 5-3/4oz)

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 4

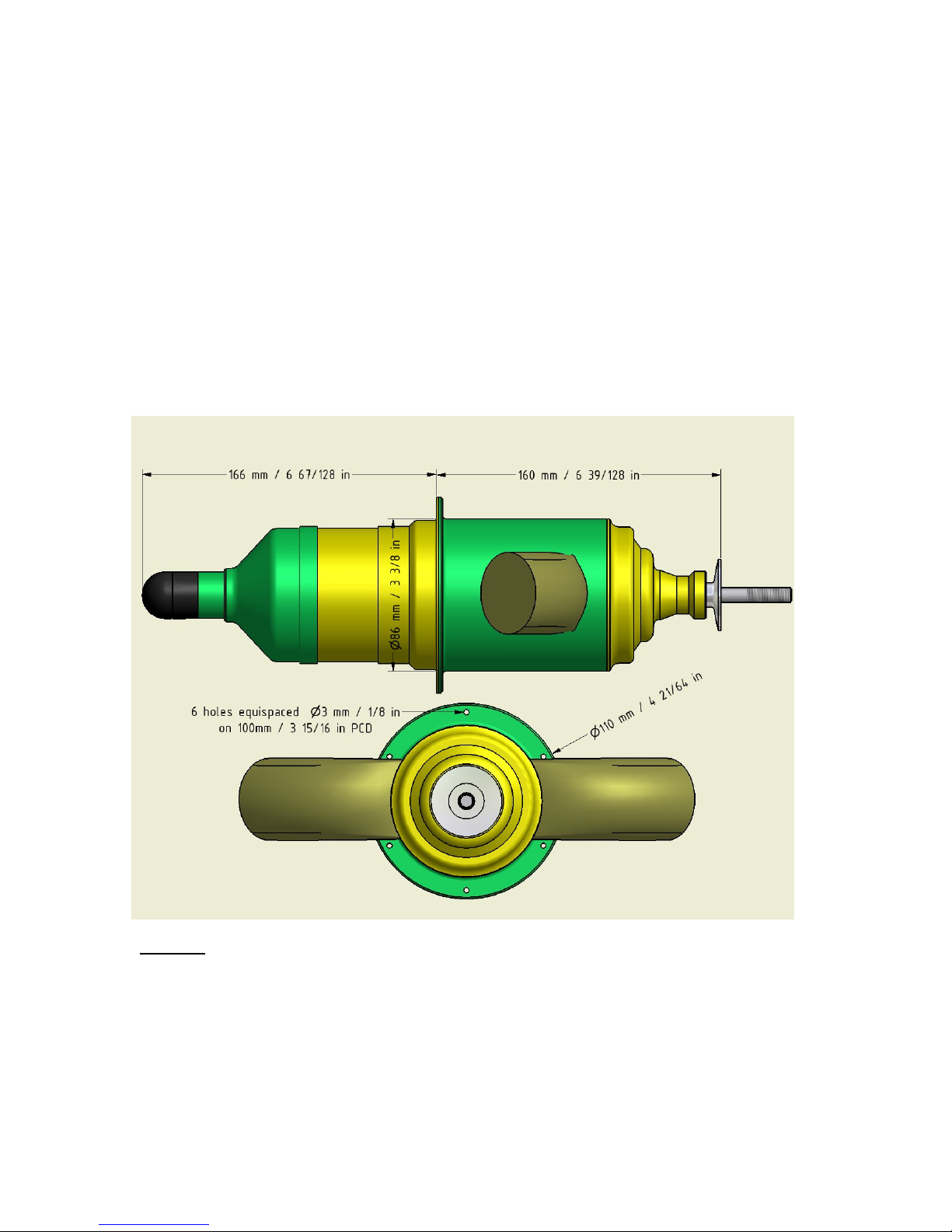

Measurements:

nd

Overall engine length 365mm (14-3/8”)

Overall width across standard exhausts 245mm (9-1/2”)

Engine mounting flange to prop driver 160mm (6-5/16”)

Mounting flange diameter 110mm ( 4-5/16”)

Mounting bolt circle 100mm (3-15/16”)

Mounting bolt M3 (or 4-40 UNC), 6-off, length to suit

Propshaft thread M8 x 1mm pitch

Propshaft length 40mm (1-1/2”)

Max propeller thickness 30mm (1-3/16”)

Prop driver diameter 40mm (1-1/2”)

Prop nut size 12mm A/F

Glowplug JP PowerPlug type F

A couple of templates for making the cutout for the engine mounting are included at the rear of

the manual, to full scale. Simply cut out, stick to the front of the firewall and cut through.

TOP

GlowPlug

The template looks like this (reduced version for show

only):

6 off, Ø3

(1/8")

Viewed from

Propeller end

Ø

8

5

An determined look on the face of Lucien Gerard as he taxis out the 2

prototype turboprop in the Top Flight “P51 Mustang” for handling

checks, ouside Wren Turbines HQ. Nov 2007

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 5

General description of the Wren 44 two-shaft drive system

The Wren 44 TurboProp is the worlds smallest commercial 2-shaft turbo-prop engine. It is

designed for use in miniature aircraft applications in place of an I/C engine. It is generally suited

to aircraft up to 25kg (55lb) in all up weight and will replace I/C engines of around 80cc (4.8cu

inch). The engine runs on standard kerosene and is supplied in full auto-start configuration.

What is a two-shaft system?

The two shaft system means there are two independant shafts running within the unit. The first

shaft is contained within the engine end of the unit and rotates at very high speed (up to

195,000rpm) with just a small compressor wheel and turbine attached at each end. This engine

end of the unit generates a flow of gas at high pressure and volume, and its operation is exactly

as a small gas turbine engine. It fulfills the function of what we call a gas generator. If a nozzle is

attached to the outlet of the engine it imparts a slight squeezing of the gas into a high velocity jet

for producing jet thrust and is the configuration for a thrust engine. For a gas generator version of

the engine, instead of squeezing the gas through a nozzle it is redirected by a vane assembly to

turn a 2nd turbine wheel mounted on the 2nd stage shaft. This is driven round in the gas stream

and this rotation drives the input shaft to the gearbox and onwards to the propeller. This 2nd

turbine is much larger in diameter than the 1st stage and correspondingly runs much slower - up

to only 90,000rpm - still far higher than any 2-stroke or electric motor could achieve, but at a high

torque level. The energy given up by the gas driving the 2nd stage turbine drastically reduces the

speed of the exhaust gas with the result than only a small residual thrust remains from the

exhaust outlets.

What happens if I stall the propeller?

When operating from long grass or in a nose-over situation that causes the propeller to stall, the

gas generator will continue to function normally with little ill-effects. On releasing the propeller

from its stalled form it will spin back up to it's normal running speed. This should be born in mind

when retrieving the model from the long grass or nose-over situation - for you or your helper to

keep well clear of the propeller whenever the gas generator is running.

What sort of gearbox is required?

The modest rpm levels generated by the 2nd stage turbine (by gas turbine standards) enable an

suitable reduction to be contained in a small gearbox, the ratio of which is chosen to suit the

operational needs of the load driven. In the case of the 44 TurboProp the reduction is 9:1 and this

gives a propeller shaft speed range of 6,000-9,000rpm. The 2nd turbine has a wide operating rpm

range and may be slowed with high load or allowed to speed up with low load without upsetting

the 1st stage, therefore the choice of propeller is not at all critical, providing it presents enough

load for the system (see warning below). The main criteria for propeller choice being the type of

plane the unit is fitted to (scale, aerobatic, sports etc).

What are other two shaft examples?

Other Wren applications that use the same 2-shaft system are the Wren 44 Marine variant that

has a 2.3:1 reduction gearbox for an output speed of 25,000-40,000rpm and the Wren 44 Heli

unit with a reduction of 4:1 and output speed range of 12,000-20,000rpm.

WARNING - it is most important that there must always be some load on the output shaft

as otherwise the 2nd stage turbine will be running unrestrained and may easily speed up

beyond it's safe running speed, even when the gas generator is running at only a modest

rpm. This means the unit should never be run without a suitable propeller fitted.

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 6

What is the effect of airspeed on the engine?

Once the aircraft is in the air the propeller rpm will increase as its load reduces with forward

speed. An rpm increase of 10-15% can be expected in the air so always choose a propellor that

keeps the output speed below 9,000rpm. It is this increase in propeller rpm in the air which gives

the turbo-prop powered aircraft a high airspeed capability and shows a definite edge over it's I/C

engine counterpart. I/C engines have a more limited unloaded speed capability, as it can result in

the engine mixture strength "leaning out" which can cause engine damage. By contrast the turboprop will enjoy running cooler as the propeller speed unloads leading to longer life and reduced

loading on critical components.

How is it mounted?

The unit is housed within a purpose made containment system which encloses the hot section

components in a three-section aluminium jacket enabling the installation to be limited to a simple

firewall mounting and six bolts and nuts. This firewall provides the essential air separation for gas

generator intake air and the warm air generated by the exhaust unit by placing a solid partition

between them. In normal running the casing will only reach about 100-130'C minimising the

chances of heat damage to the aircraft fuselage. No further stiffening is required or advised for

the unit, this approach enabling the conversion from I/C engine to turbo-prop power to be

accomplished with ease. The mounting supports the engine and gearbox at the approximate

centre of gravity and is built to withstand all normal loads such as might be subjected to the

equivalent I/C engine.

Aren't gas turbine more dangerous than I/C engines?

No. In the unfortunate event of a sudden arrival (or crash) the mounting helps to maintain

containment of all the hot section parts from heat sensitive parts of the airframe and accessories.

Turbine fuel has a high flashpoint which means at normal ambient temperatures it is extremely

difficult to ignite, unlike gasoline or glow fuel which is a low vapour temperature and ignites easily.

With no exposed high temperature components the risk of accidental combustion is greatly

reduced. As starting is undertaken with the operator and observers behind the propeller there is

no possiblility of a sudden power surge allowing the aircraft and propeller to run forward to the

operator such as can happen with I/C engines, with disastrous consequences for fingers and

limbs. The 2nd stage fully encloses the outlet of the gas turbine section affording a high degree of

protection against any component failure due to accidental damage or persistent operation

beyond the normal operational duty cycle.

What's it like to operate?

The power unit itself is operated as a normal miniature gas turbine and possesses all the

standard features of automatic push-button starting and cooling, totally vibration free operation,

very quiet running and exceptional power to weight ratio. The throttle response is of the best in its

class - the small gas generator rotor is small and light allowing very quick spooling to be achieved

safely. Being a very small gas turbine it's fuel consumption has been described as "stingy" - a

typical 10minute flight being easily achieved with a single 1ltr fuel tank, depending on the flying

style. Those fliers used to a 3ltr fuel tank for equivelent flights should find this aspect of operation

a welcome relief.

How does it compare to I/C power?

The exceptional power to weight ratio which is close in performance levels to an 80cc gasoline

engine but weighing in at only 1.71kg (3-3/4 lbs) allows the operator a level of dial-in performance

previously enjoyed by only those operating high performance specialist engines with tuned pipes

etc, with all the attendant noise, extreme vibration and operational issues associated with such

equipement. Scale fliers will really enjoy the smooth and quiet response and operation coupled

with high power reserve to get out of those difficult situations that scale aircraft with fully

articulated surfaces, flaps and fine surface detail, can find themselves in. The high torque ability

of the engine allows it to cope well with a wide range of prop sizes and shapes which will enable

those scale three and four blade props to be a practical reality and further add scale effect.

Almost all aircraft will enjoy an installed power to weight ratio exceeding 1:1 - in many cases

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 7

exceeding 2:1! With a static thrust exceeding 16kg (35lb) the unit should be quite adequate in

power to enable an acceptable flight performance in a plane of 25kg (60lb) or more.

What about flying in noise sensitive areas?

Fliers with noise sensitive flying fields will enjoy the almost silent operation of the unit comparable

to electric flying. Such users are encouraged to make good use of the current crop of quiet

propellors and resist the temptation to zoom around the field like a pylon racer! Sports fliers can

make full use of the highly tractable response and enjoy quelling the myth that turbo-props cannot

prop-hang.

What about smoke?

The engine itself is a clean burning gas turbine that does not produce any smoke in normal

operation. However the gearbox bearings are lubricated with a very small amount of fuel which at

low rpms or throttling down can sometimes be seen as a small puff of smoke, but this is normal.

The minimal oil percentage used in the fuel helps to minimize pollution from unburnt fuel,

although operation of the gas turbine does produce an very distinguishable smell which for many

is the "raison detre" of this type of model flying.

What propellers do you recommend?

An important question. In all cases, we recommend only wooden props as in the even of a nose-

over in a taildragger aircraft, the prop will break and not damage the engine. Similarly, in the

event of an undercarriage failure where the u/c will not extend and a belly landing is required, a

prop strike is inevitable and a strong carbon prop will not bend enough to protect the engine and

can cause serious damage to the propshaft. Wooden props are available in sufficient styles and

shapes to cover most needs although users should satisfy themselves in the case of three or

more blade props, that the hub fixing is adequate enough for the power of this engine.

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 8

Detail description of the Wren 44 two-shaft drive system

Gas Generator

The gas generator used in the system is the well proven

Wren 44 GOLD engine which has the standard Wren FOD

guard fitted – this is no place for a tea strainer. A lubrication

port in the outer casing has been added and this connects

through a stainless tube to the gearbox. Other than the lube

outlet there are no other changes to the engine and the full

throughput has been utilised to generate shaft power.

This TurboProp engine has been fully run and tested

It is important to stress the unit has been fully tested with all the components supplied with it

before it left the factory at Wren Turbines Ltd. There should be no need to make adjustments

other than setting the radio to the ecu. Please refrain from jumping in and changing things just

because you or a friend have another Wren 44. The settings match the components used and

may not be the same as you are used to.

Hot Section

A specially designed and manufactured miniature

interstage and guide vane assembly, cast from high

temperature stainless steel is bolted to the engine.

A purpose made 66mm power turbine – not just

taken from a thrust engine, is cast in Inconel 713c

and is fitted and running on a fully hardened and

ground shaft in a pair of preloaded high speed

ceramic angular contact bearings. The shaft tunnel

they run in is made from low expansion stainless

steel.

These components define what is called the hot

section. Nothing has been left to chance.

Gearbox

The front of the turbine shaft is contoured with a hardened and ground gear profile and supplies

the shaft power into a specially design high speed planetary gearbox. This heavy duty assembly

utilising fully ballraced support shafts and the planet carrier has been ground and bored as an

assembly to retain great strength and accuracy.

The housings are

anodised to resist

corrosion and maintain

their lustre. The gears

are fully hardened and

are able to run with

long life using just a

small amount of engine

fuel bled off the gas generator fuel system. To keep the flow

to a low level the oil percentage is maintained at 5% to

ensure satisfactory lubrication.

The lubrication reaches the gearbox by a small pipe in the gearbox front wall and is fed from a

special fitting mounted on the engine. The gearbox is designed to retain much of the lubrication

and only release what is surplus via the power turbine bearing.

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 9

The Mounting

The gearbox housing incorporates a Wren Turbines’ innovation – a fully integral mounting

system. This specially designed housing answers two of the criticisms of turbo-props – that of

their generally awkward mounting arrangement for gearbox and engine, and the amount of heat

they generate within the airframe.

Our unique new system is machined from solid aircraft

grade aluminium and carefully anodised to retain its

corrosion resistant qualities and durability of finish. It

provides a secure and rigid connection between the

firewall and gearbox and provides full support to the gas

generator at its C of G. This eliminates the danger of

distorting the hot section between the engine and

gearbox when individually clamping engine and

gearbox to different sections of the airframe. The Wren

system also allows a very simple mounting for the

engine – just align the supplied template (at the back of

this manual), and cut out the shape, drill the six mount

holes and bolt onto a firewall like a 2-cycle engine. This

also allows for the simple offsetting of the thrust line by

simply building it into the firewall at the point of construction, as recommended or included for the

I/C installation.

The mounting has a further advantage – it envelopes the hot section and exhaust sections and

holds in the heat which would normally be released to the interior of the aircraft. Such heat

release can cause heat damage to paint finishes cowl materials, or make it difficult for the engine

to get an adequate supply of essential cool air for the engine to run on. We think the system is so

good that some day all turbo-props will look like this.

Ancillaries

ECU (Engine Control Unit)

Data display terminal

RPM pickup (mounted in engine)

Temperature Probe (mounted on engine)

Fuel pump

Propane valve and flow restrictor

Fuel valve

Ecu battery

Propane tank

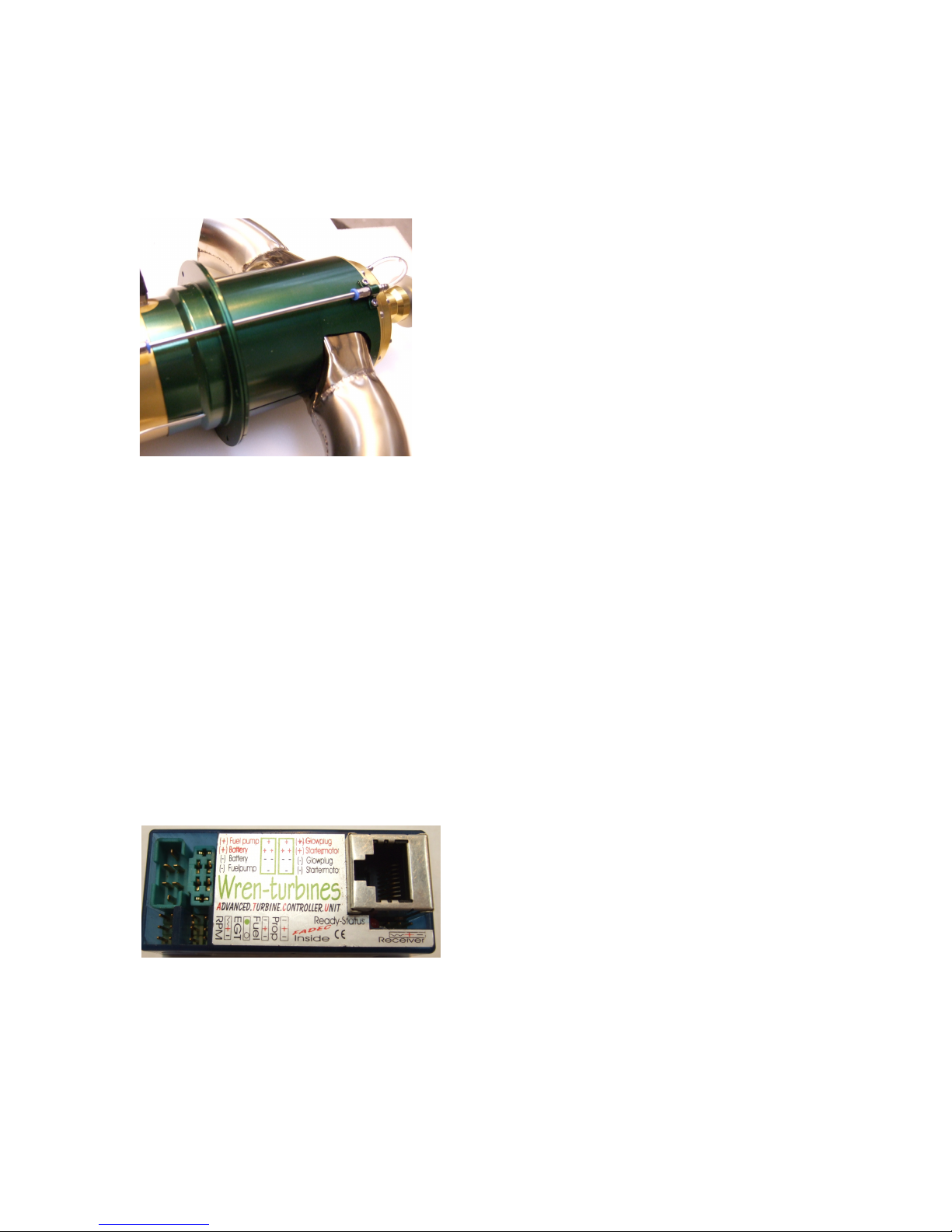

ECU (Engine Control Unit)

The ECU and ancillaries are identical to the thrust engine

variant and use similar programmed settings. It is

important however, that users do not change settings

from those set without refering back to Wren Turbines.

The ECU is the well proven Digitech type supplied by

Gaspar Espiell and which the engine, fuel pump and ecu

battery plugs into. It controls the engine through its

starting, running and cooling down phases. A signal lead from your receiver connects to the ecu and

provides the throttle commands to the engine from the receiver throttle channel and next to it is the larger

socket for plugging in the Data terminal (see below). The ECU unit has a printed label which shows where all

the engine accessories are plugged in; “RPM” - rpm pickup (the servo-type lead coming out of the cowl of

the engine), “EGT” - temp’ probe, “Fuel” - fuel valve, “Prop” - propane valve. To orientate these servo-type

leads, the “-“ refers to the brown wire. There are various timers that are used to keep track of running hours

– see the detail section on setting the ecu.

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 10

Data Terminal

The ecu is accessed from the outside world by a port with a telephone style

socket connector and a hand-held unit called the Data Terminal.

This terminal is primarily a display for the engine but is also used to input

settings from buttons on its front panel. The terminal’s functions are

described in more detail later.

RPM Pickup

Mounted on the front of the engine, under the FOD screen is a hall-type

magnetic rpm sensor. It picks up a signal from a small magnet fitted into

the compressor nut one the end of the shaft of the engine. The signal

terminates in a servo-type plug which plugs into the rpm input on the

ECU.

The pickup is sensitive to stray magnetic and electrical noise so be careful

about routing cables close to it. The starter and glow plug cables are

tightly twisted to reduce their stray signal for this reason – do not untwist

them.

Temperature probe. The temperature probe is a standard

miniature industrial thermocouple which is positioned in the

interstage casting via the engine bulkead and senses the

exhaust temperature of the engine and feeds this

information back to the ECU.

Temperature information is used to detect sufficient pre-heating at the engine start phase and correct

operation during normal running. On shutdown, the temp’ probe indicates to the ECU when the engine has

cooled sufficiently during the cool-down phase. It is secured on the front of the engine and connects to the

ECU via a small servo-type plug with a special green cable. It is attached to the engine and should not be

moved from this position.

Fuel Pump. The fuel pump is one of two special

gear type pumps especially made for the Wren 44

and turbo-prop. They have very small gears to allow

a wide range of control for the engine and must not

be substituted for anything else. Almost all other

turbine fuel pumps are much too large and are

therefore not suitable for this application and result in

loss of control on this engine. Be very careful whenever disconnecting or connecting it

to ensure there are no small slices of pipe left at the inlet or outlet.

When people say that “cleanliness is next to godliness” they are referring to small turbine fuel pumps. Treat

this component with total reverence and keep it spotless. Always carefully blank off the pipes with clean

blanks, when moving it about. The smallest particle can spoil the operation of this pump so only allow clean

fully filtered fuel into it. Connect to a fuel tank by a single direct pipe with no connectors, fuelling valves,

stoppers etc between it and the fuel pickup. The pickup should be a quality felt type clunk or propietry pickup

with fine filtering qualities.

ALWAYS carefully filter the fuel going into the tank, don’t rely on the pickup to stop particles getting in. If a

tank gets badly contaminated then discard it – this engine is far too costly to risk a dirty tank. Be careful also

to ensure any tank vents cannot suck grit into the tank. A filter on the air vent is not going too far to keep the

fuel pump in tip-top condition.

Propane Valve

This valve is a specially made brass body valve used to switch the propane gas on and off

during the start phase. It has an “in” and “out” (marked by an arrow). The valve is powered

by the propane outlet on the ECU and care should be taken to ensure it is plugged into the

correct ECU socket. The valve coil is rated at 5v and may be tested with a 5v supply where

a solid click can be heard. If it malfunctions the valve is not user serviceable and must be

replaced. It is identical to the fuel valve in construction. Note – the “F” on the side of the

valve base indicates the direction of “Flow” and not “Fuel”.

Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 11

Loading...

Loading...