Wren Hudraulic KLW4000 Operation And Maintenance Manual

Operating manual for the KLW4000 Series pump. Please read carefully and follow instructions, warnings and cautions

before use.

Operation and

Maintenance Manual

KLW4000 Series

Electric Hydraulic Pump

Safety Guide

Your Electric Hydraulic Pump requires correct operation and regular inspection as a precaution against direct loss to

personnel and property. Should anything abnormal occur during operation, please turn the pump off, disconnect it from

power supply and consult with your Pacific / WREN agent.

2

1.

Please ensure the power switch is turned off before plugging the pump into a power supply outlet to avoid unexpected activation of the pump.

2. Check that the electric cable and the power supply are in good condition with a good earth connection to avoid possible electric shock. Use

of an earth leakage crcuit breaker is advisable.

3. Always ensure the power supply to the pump is disconnected before carrying out any maintenance and repairs to the unit.

4. Do not make alternations to the pump – if changes are necessary, please inform Pacific / WREN or their agent for assistance. Unauthorised

modifications may void warranty.

5. The maximum hydraulic output pressure of this pump is 70 Mpa (10,000 Psi) and this has been pre-set at the factory and must not be

increased under any circumstances.

6. If this pump is used for operating other equipment, make sure the maximum required operating pressure of the equipment does not exceed

70 Mpa (10,000 Psi). If this requirement is less than 70 Mpa, it may be necessary to reduce the maximum pressure setting to alleviate

equipment damage.

7. Take care not to over-fill the pump reservoir with oil to alleviate the possibility of a pressure increase in the reservoir, spillage and

environmental pollution.

8. Make sure the hose(s) and quick coupler(s) is (are) correctly connected and tightened before building up pressure to avoid hydraulic oil loss,

personal injury and/or equipment malfunction.

9. In the event or an oil leakage, turn the pump off immediately and correct the problem before attempting to operate again.

10. Hydraulic oil leakages can be extremely dangerous and can cause serious injuries which can sometimes be fatal. Always check the complete

system before operating and do not use if there is any doubt about the system’s integrity.

11. In the event of rapid pressure release, the lifting device or the load being operated may drop or spring open etc., depending on the operation

and may cause injuries.

12. Do not operate this equipment in the vicinity of extreme heat or fire.

13. If hydraulic oil comes in contact with your eyes, immediately flush for about 15 minutes with clean water and seek urgent medical attention.

Caution!

Please ensure only ISO grade 32 hydraulic oil is used.

Do not use the pressure regulator valve as a relief valve.

Used hydraulic oil should be carefully stored and / or disposed of in an environmentally acceptable manner.

3

Description

1. The KLW4000 Series electric hydraulic pumps utilise an integrated assembly; consisting of an oil pump, control valve, oil reservoir and

electric motor to provide an independent and complete hydraulic device. It has the advantages of small volume, light weight, simple robust

structure, convenient operation and high work pressure. The pump utilises high and low oil pressure and can provide a larger oil output than

conventional hand pumps. High pressure and low pressure is controlled by an unloading overflow with automatic no-load return to reduce

power consumption and oil pressure is 70 - 700 Bar (10,000 Psi max).

2. Utilises ISO grade 32 wear-resistant hydraulic oil.

3. Working environment temperature; -10 to +80

o

C.

4. Always use appropriate high pressure hoses and quick couplers.

5. This pump is designed for use with hydraulic products of equal pressure - please consult with Pacific / Wren or their agent if in doubt about

an application.

6. Please do not use the electric hydraulic pump near flames.

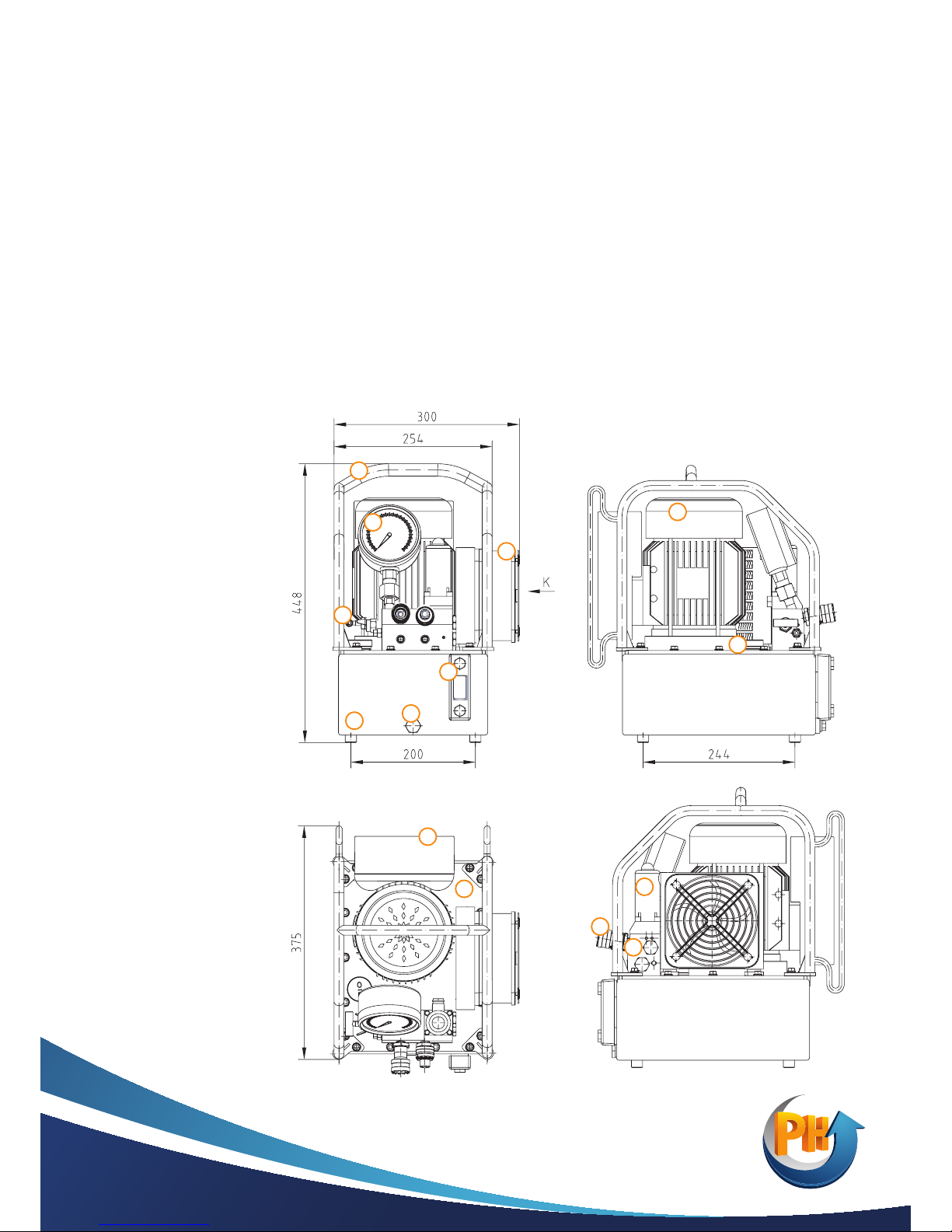

•

Oil reservoir

•

Adjustable pressure regulator

•

Pressure gauge

•

Protection frame

•

Motor

•

Radiator

•

Oil level measure

•

Oil port release

•

Control system

•

Cover plate for oil tank

•

Solenoid valve

•

Quick coupler

•

Valve block

•

Oil port

1

2

3

4

9

10

11

12

14

13

6

7

8

5

Parts for KLW4000 Series Pump

3

4

2

1

10

12

13

14

11

6

7

9

8

5

4

Description of Parts

•

Oil reservoir; contains the oil.

•

Adjustable pressure regulator; regulates the high pressure + or – to the set up pressure to the attached equipment.

•

Pressure gauge; ranges from 0-100 Mpa.

•

Protection frame; protects pump assembly and can be used for carry frame for ease of transportation.

•

Motor; electric 240 v 50 Hz motor (415 v 3 phase POA).

•

Radiator; to dissipate heat ensuring longer operating time and life of the pump.

•

Oil level measure; sight glass indicating the current oil level, when the level is below 1/3rd of the reservoir storage capacity, oil must be added.

•

Oil port release; port on base of Tank for removal of used oil.

•

Control system; Pendant or lever control (part of the integrated control system).

•

Cover plate; air tight sealing for the oil reservoir.

•

Solenoid valve; electrically operated with optional manual pressure release.

•

Quick coupler; for ease of attachment for both tools and hoses.

•

Valve Block; integral part of the hydraulic flow configuration

•

Oil port; includes breather cap which has a pre-filter to prevent access of dirt into the tank.

Characteristics

1. The KLW4000 is a three stage pump. The pressure relief valve is assembled in the high pressure port; the flow of 0.8 L/M is under high pressure,

the flow of 1.6 L/M is under middle pressure and the flow of 7 L/M is under low pressure.

2. Maximum operating pressure: 70 Mpa.

3. Flow: three stage, can simultaneously use up to four torque wrenches.

4. Electric motor: 240 v 50 Hz.

5. Working temperature range: -10 ~ 80

o

C.

6. Reservoir dimension: 310 x 240 x 130mm.

7. Weight of pump excluding oil: 27 kg.

8. ISO grade 32 hydraulic oil.

1

2

3

4

9

10

11

12

14

13

6

7

8

5

Warning!

Do not attempt to operate without oil.

Always keep the unit and coupling clean and free from contamination.

Never open the tank while the pump is in operation since serious injury can occur.

5

Maintenance and Inspection

Pre-oPeration checks

1. Check if all connections are clean, secure and tight.

2. Check oil / fluid levels in the reservoir.

3. Check if the gauge is in good condition.

4. Check if all hoses are safe to use.

oPeration checks

1. Operate the pump and controls to test their function and if they are in working order.

2. Monitor the pump during the test operation for the following:

- Leaks

- Abnormal noises

- Excess vibration

- Valve condition

- Pendant or lever condition

- High temperature

3. If any abnormalities occur during testing, discontinue use and contact your Pacific / WREN agent.

after oPeration checks / maintenance

1. Check if the pump is turned off and isolated.

2. Clean the pump and remove any contamination.

3. Check the fluid levels and replenish if necessary.

changing the hydraulic oil

The oil should be replaced once a year. However, if there any of the following abnormalities occur, please replace the oil immediately.

1. If oil is contaminated in any way with dust / dirt etc.

2. If an abnormal smell occurs.

3. If the oil mixes with water and the colour of the oil has changed to milkiness.

4. If the colour of the oil has changed to black - brown.

rePlacing hydraulic oil

1. Loosen the oil filter port of the oil reservoir.

2. Remove the drain plug / screw at the front of the oil reservoir to drain the oil.

3. Clean the oil filter and reservoir.

4. Install the drain plug / screw and fill the oil reservoir with new oil as per recommendation.

Warning!

If the oil comes into contact with the eyes, please wash for at least 15 minutes with clean water and seek immediate medical assistance.

If the oil comes into contact with the skin, please wash with water and soap.

Used hydraulic oil is considered industrial waste; it should be disposed of in an environmentally friendly controlled manner.

Loading...

Loading...