Wren KLW4000N Series, KLW4000SHNP Series, KLW4100 Series, KLW4000HNP Series, KLW4000A Operation And Maintenance Manual

...

KLW4000

Operation And Maintenance Manual

Of KLW4000 Series Hydraulic Pump

.

1.When using, do not permit any person stand at the oil output in order to avoid personal injury and

equipment damage. Please put the pump far away from the fire.

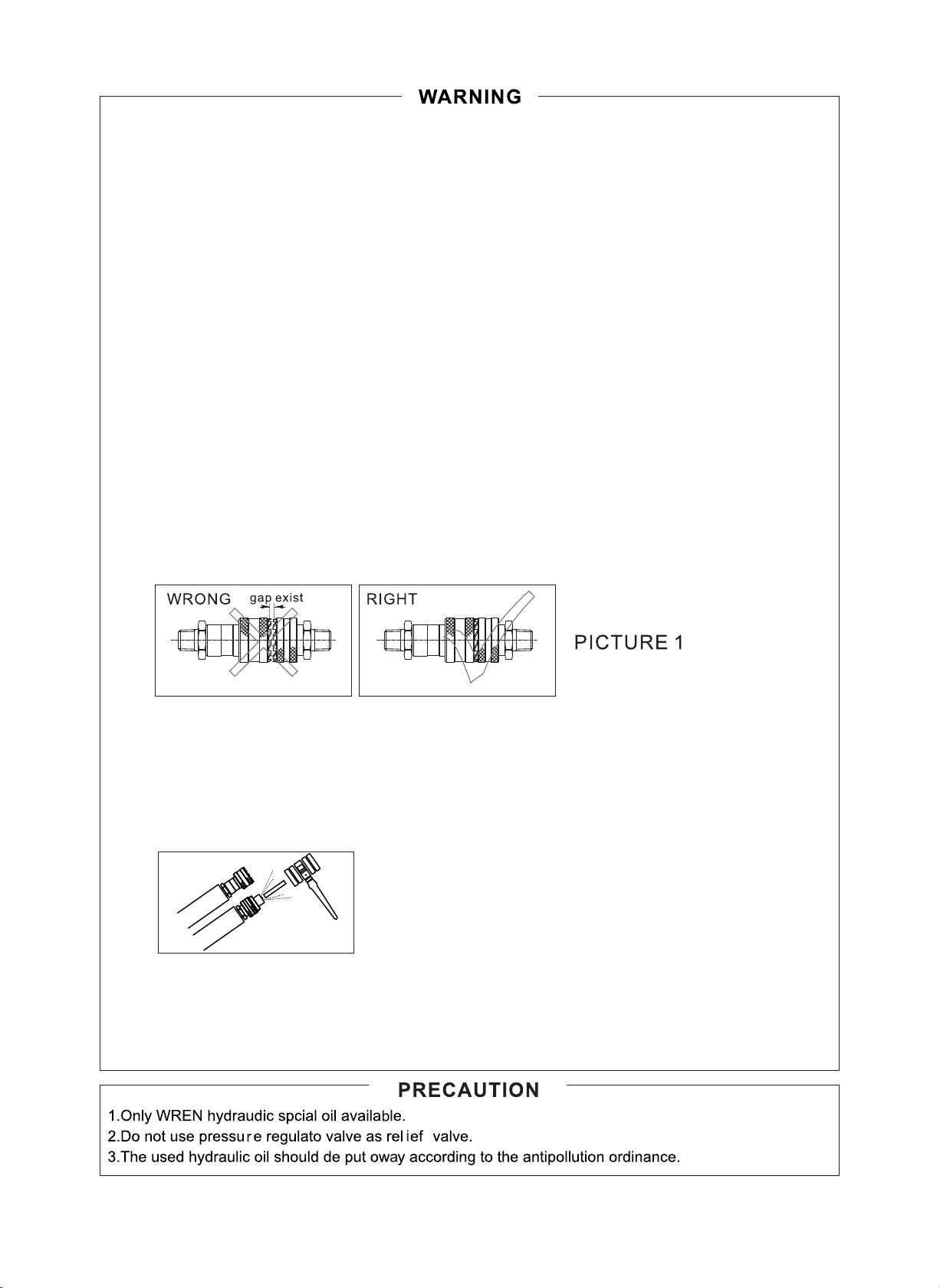

2.Make sure that the hose and quick coupler be connected before building up the pressure in order to

avoid hydraulic fluid spurting out to cause personal injury.

3.The maximum operating pressure of this pump is 70Mpa(10,000Psi),WREN has set up the pressure to

70Mpa before selling this pump. Please do not adjust to a pressure higher than the maximum pressure

whichWREN has not set.

4.If this pump is used for operating other equipments, make sure the maximum operating pressure of the

equipments will be less than 70Mpa. Please adjust the pressure to which the equipment need, or else the

equipment would be damaged.(Referrence content 5)

5.Make sure the power of the pump is shut off before repairing it.

6.Please shut off the switch before starting power; if the switch is on, the pressure may increase.

7.Make sure the equipment be connected with ground to avoid electric shock.

8.Do not start the pump without oil in tank.

9.Please do not change any part of the pump; if it must be changed, please inform WREN or Wren's agent

for help. Without allowance of WREN or its agent, any refit of it will be out of our warranty Range.

10.Please do not fill the pump reservoir with too much oil, otherwise, the pressure of the reservoir will

increase and the oil will spill over, so the reservoir will be broken and the environment will be polluted.

11.When the pump works,the pressure may be increased with the returning oil.If the oil filler cop is opened

at the moment, this may cause the injury.

12.Make sure the quick coupler is tightened; if the quick coupler is not tightened enough, the equipment

will not work normally; if it is a synchronic system, the problem may cause one or several pieces of

equipment out of order and the quick coupler may be broken and it may cause personal injury or equipment

damage.

13.Make sure to reep the pump in cleaning.

14.Please stand away from the position where the hydraulic oil may be spurt out; hydraulic

oil may penetrate your hand and hurt you.

15.If the hydraulic oil splashed in your eyes, please immediately wash your eyes about 15

minutes with clean water, then you must go to hospital for help right now.

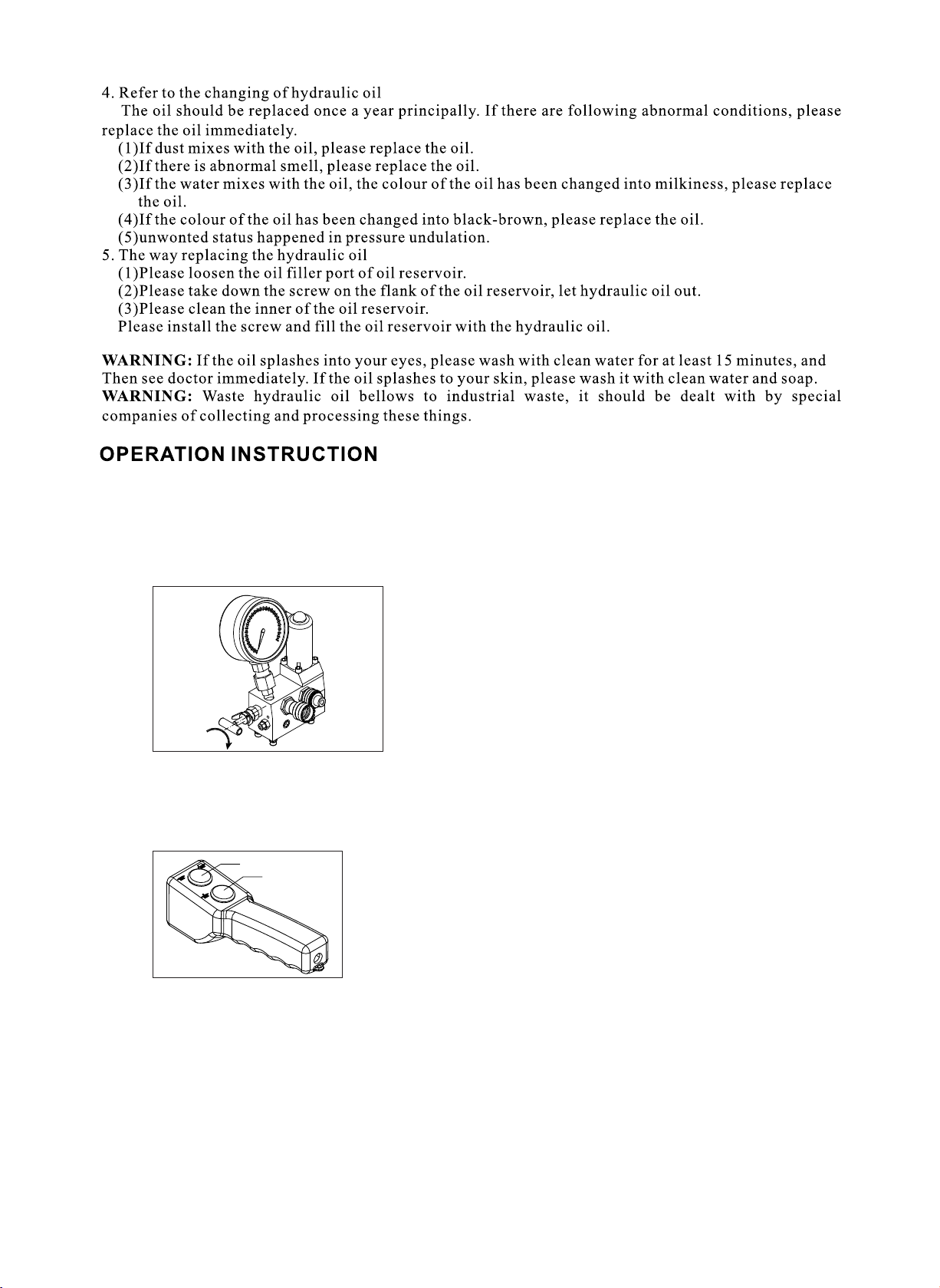

PICTURE 2

16.Please do not touch the pressurized hose; if the hydraulic oil splashed out, it will cause serious

injury.

17.Hydraulic hose is easily spoiled fitting; you inspect the hose with eyes regularly and find no problems,

but the inner side may have crack and small hole; WREN suggests you should change the hose regularly

for smoothing use.When using,try to avoid bending the hose in sudden.

11

1. Oil reservoir: To store hydraulic oil, make sure the reservoir enough oil to keep the pump work

normally.

2.The adjusting pressure regulator: Adjust this valve for setting the working pressure of power pack

(the)max working pressure has been locked before sales, please do not change the locked pressure

at any time.

3. Pressure gauge: it’s effects 0-100Mpa, showing the working pressure of the power pack.

4. Frame for protecting: it is fixed on motor for carrying conveniently.

5. Motor: provide power.

6. Radiator: to exclude the heat, ensure the operating time and life of the pump.

7. Oil level measurer: it can help us know the oil level, when the oil less than the1/3 of total, please

Fill the especial oil for hydraulic tools of WREN.

8. Release oil port: G1/4.

9. Control system: the integrated electric equipment of the pump.

10. Cover plate for oil tank: seal the oil tank and install the parts of power pack.

11. Solenoid valve: Its function is output oil when the pressure is very high, control the flow when

return oil, and soon. It can be set up the maximum pressure and protect system to work normally at the

pressure set up. The threads of oil output port is NPT1/4”.

12. Quick coupler : it’s function is output oil when the pressure is very high, control the flow when

return oil , and so on, it can be set up the maximum pressure and protect system to work normally at

the pressure set up, the threads of oil output port is NPT 1/4”

13. Valve block: control oil driving in and out; make sure the hydraulic system can be worked normally

under the pressure to be set up.

14. Oil filling port: To be used for filling and replacing oil.

2

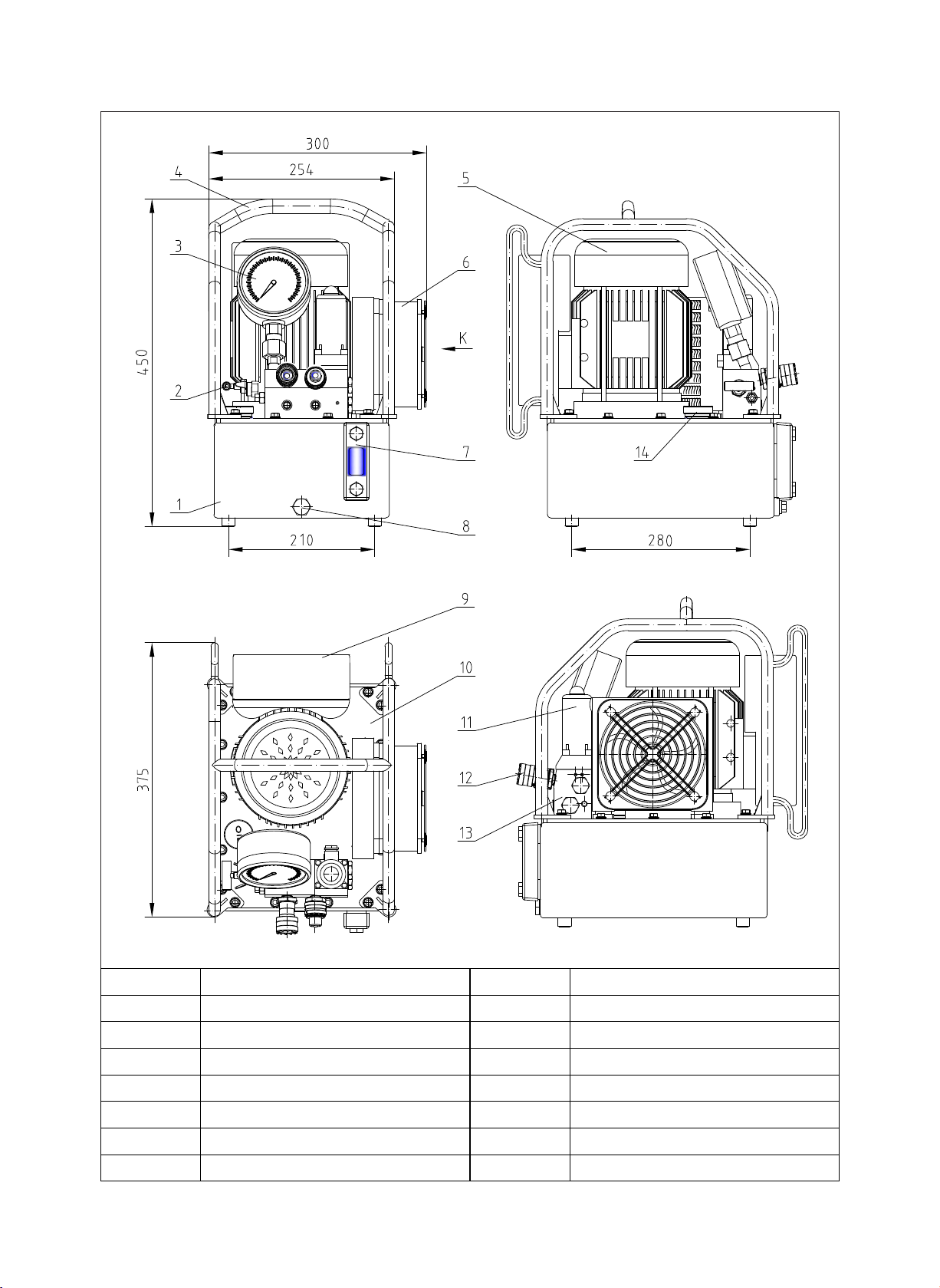

EXTERNAL DIMENSION AND DESCRIPT ION OF PARTS

Item Description Item Description

1 8

2 9

Adjusting pressure regulator

3 10

4 11

5 12

6 13

7 14

Oil reservoir

Pressure gauge

Frame for protecting

Motor

Radiator

Oil lever measurer

3

Release oil port

control system

Cover plate for oil tank

Solenoid valve

Quick Coupler

Valve block

Oil filling port

0.8

7

200-240

/200-240V 60HZ 0.9KW /100-130V 60HZ 0.9KW

27

,And cover on the dust cap.

4

1.Ready:

1.1 KLW4000hydraulic power pump is designed for hydraulic torque wrench. There is a 2-way, 4position solenoid operated direction control valve on the pump, port A is high pressure point, it can

export the oil at the high pressure, and port B is low pressure point which can output the oil at the

low pressure.

1.2 Please loosen the high-pressure valve for adjusting pressure before operating.

Adj ust

pre ssure

2.Adjust the pressure:

2.1 Please connect the power and push the switch at the position of “ON”. Then press the lock

button make the power pack working, then the power pack will output the low-pressure.

2.2 Please press the retract button on the controller and adjust the pressure unit the working

Plessure reach to what you need, and then loosen the retract button on the controller.

Lock butt on

Retra ct b ut to n

3. Operation:

3.1 Please press down the retract button on the controller, the pump output. The high pressure,

torque wrench works;Loosen from the retract button, the pump output the low pressure, the

torque wrench retracts; press down the lock button, the button retracts, the pump stops.

3.2 After operating, please turn off the power. Then press the rubber button on the top of solenoid

operated direction control valve in order to release the pressure in hoses and equipments,then you

can take down the hose and cover the safety cap for the quick couplers.

Attention: First time to use or after service, please try several time to operate without any

loading, this ca eliminate the in system.

5

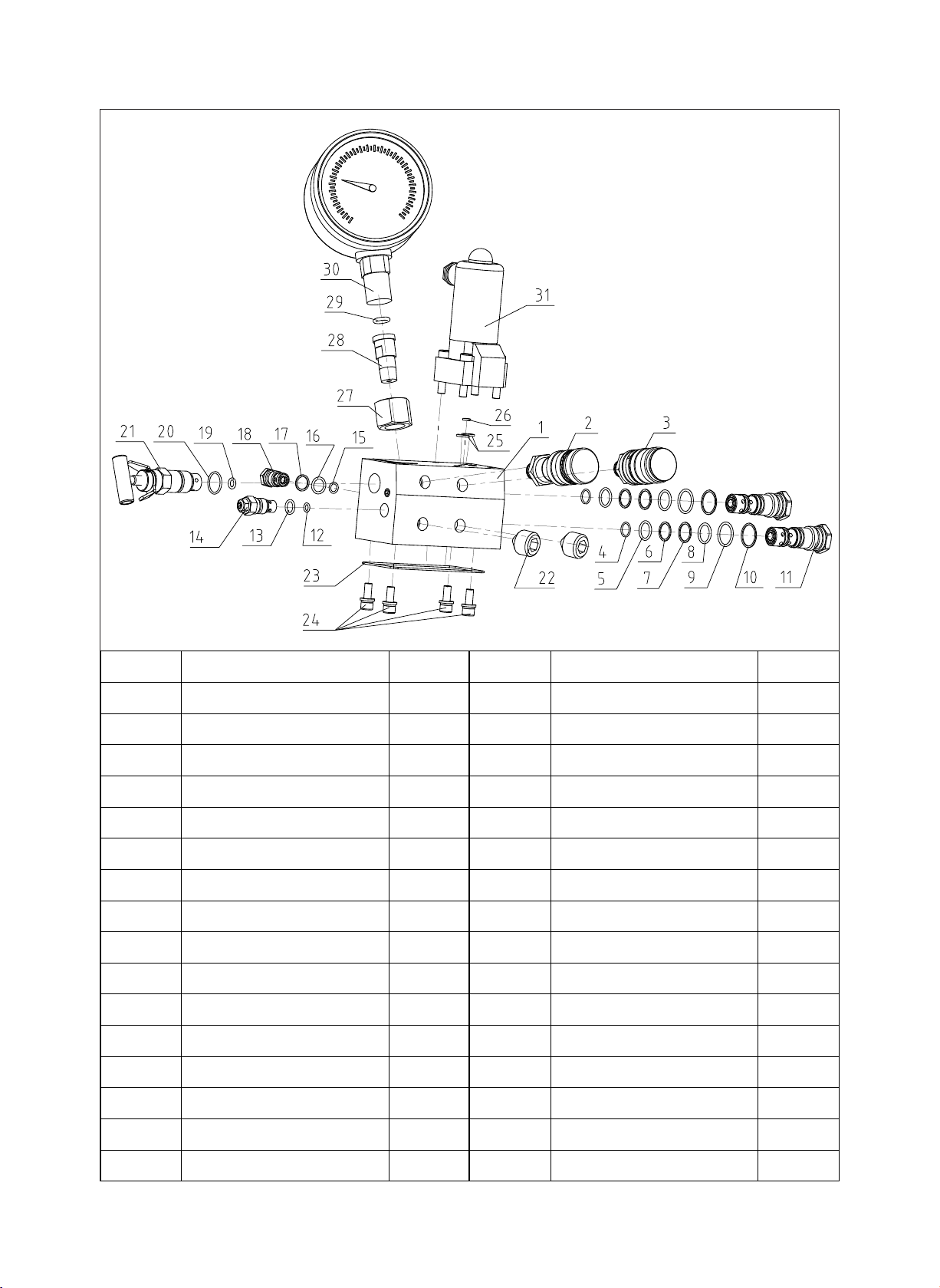

PART LIST FORVALVE SYSTEM

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DESCRIPTION QTY

Valve block

Female coupler

Male coupler

O-ring O-ring

O-ring

Retaining ring

Retaining ring

O-ring

O-ring O-ring

Retaining ring

Reversing valve

O-ring

O-ring O-ring

Adjusting valve

1 17 1

1

1

2

2

2

2

2

2

2

2

1

1

1

ITEM

18

19

20

21

22

23

24

25

26

27

28

29

30

DESCRIPTION QTY

Retaining ring

Unilateralism valve

O-ring

Adjusting valve

Casing screw

O-ring

Screw

O-ring

Connector

Connector

Gauge

1

1

1

1

2

1

4

2

1

1

1

1

1

15

16

O-ring

O-ring

1 31 1

1

6

Solenoid valve

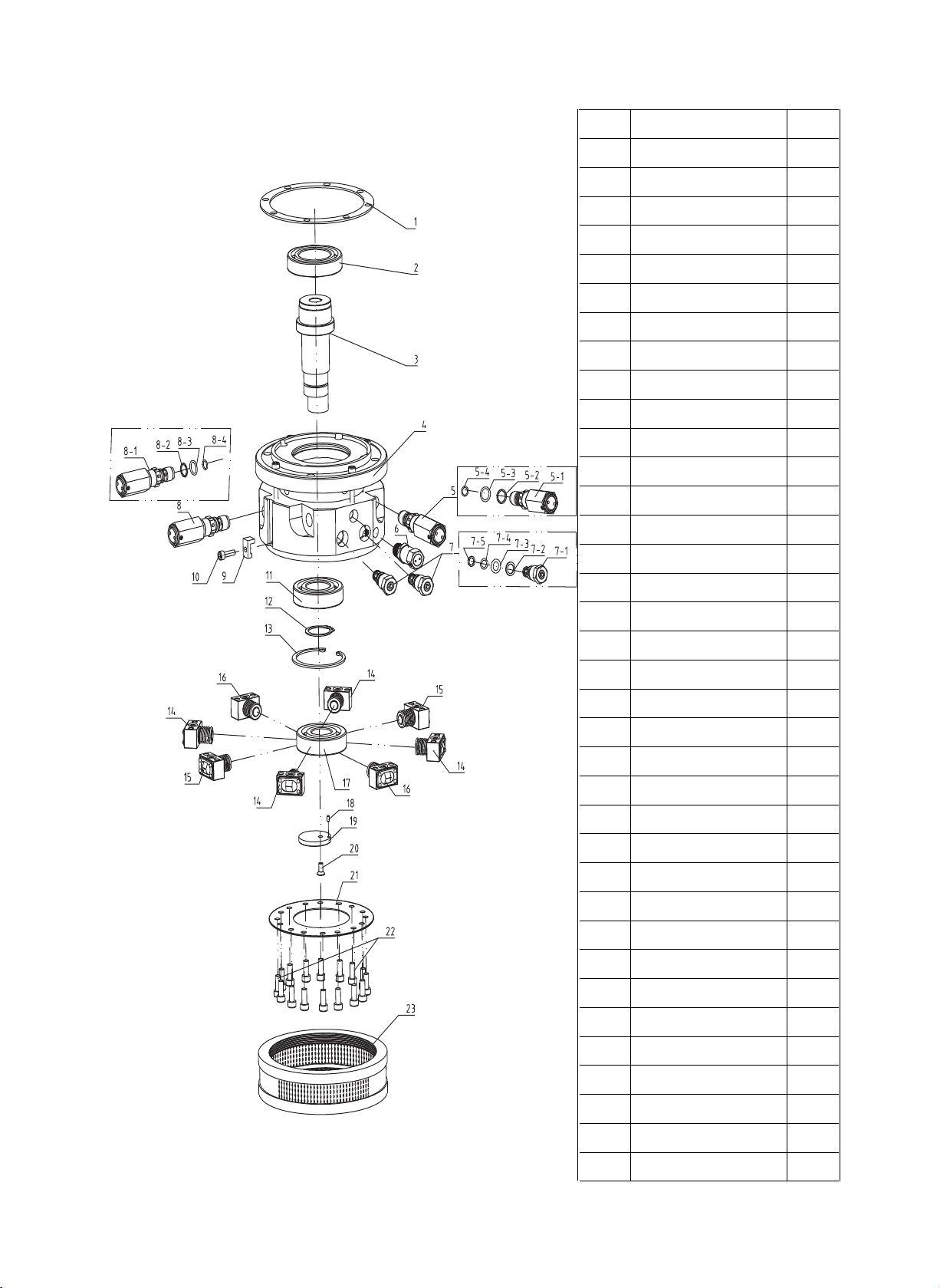

PART LIST FOR PUMP HEAD

ltem

Description

QTY

1

2

3

4

5

5-1

5-2

5-3

5-4

6

7

7-1

7-2

7-3

7-4

7-5

8

Seal gasket

Bearing

Bearing pole

Pump head

Release valve

Relief Valve

Retaining ring

Safety valve

Unilateralism valve

Check Valve

Retaining ring

Retaining ring

Release valve 2

O-ring

O-ring

O-ring

O-ring

1

1

1

1

1

1/set

1/set

1/set

1/set

1

2

1/set

1/set

1/set

1/set

1/set

1

8-1

8-2

8-3

8-4

9

10

11

12

13

14

15

16

17

18

19

20

Relief Valve

Retaining ring

Bearing

Metal Retaining Ring

Piston 1

Piston 2

Piston 3

Bearing

O-ring

O-ring

Clip

Screw

Circle

Pin

Plate

Screw

1/set

1/set

1/set

1/set

1

1

1

1

1

4

2

2

1

1

1

1

Connecting plate

21

22

23

7

Screw

Filter

1

16

1

TROUBLE SHOOTING GUIDE OF HYDRAULIC PUMP

Mal function Reason for caused malfunction Solution

The pump can not be started

The system has no pressure

The system has no pressure

after reinstall the couplers

Leaking in the couplers

The system pressure can

not reach to the rated

pressure

Un-suitable power source

The power is not connected

The coupler is not connected

properly

No oil in the tank Fill oil

Not enough oil

Check if flow control valve, singledirection valve in the system is open

The couplers is not connected in

the properly position

The o-ring, retaining ring worn

out in the couplers

The pressure for high-pressure

leaking valve is adjusted too low

Oil is mixed with water

Ball steel in pressure relief valve

may be broken or the valve seat

may be frayed

Air may be sucked into the system

The leaking valve may be frayed

Confirm if the power meets pump’s

need

Check the power

Re-install

Fill oil

Open the flow control valve to ensure

the system is connected

Uninstall the couplers, check if the steel

roll is elastic with a rod, if it can not move

please knock it with hammer to elimina

te the mist hydraulic oil.

Replace the couplers

Please check the gauge, adjust it to

rated value

Replace the oil, please

Replace them,please

Repeat operating the system with no

load for several times to eliminate air

Replace it, please

There is a strong noise

when the power pack is

operated

When using under static

pressure, the pressure

reduces slowly

High-pressure flux is not

enough

High-pressure leaking valve may

not be tightened

The o-ring for high-pressure leaking

valve may be broken

There may be some inclusion into

the oil

The bearing may be broken

Air may be mixed into this power

pack

The seal is out of control,please

check all the seal

Piston or spring may be broken

Leaking may be happened at

brushfire position

Oil lever may be too low

High-pressure system may not

eliminate the oil fully

Too low oil temperature may make

lead to suck oil difficultly

Oil temperature may be too high

that cause the damage of pump

Tighten it, please

Replace it, please

Wash the power pack valve and

replace oil

Replace it, please

Exhaust the air from the system

Replace the seal

Change them, please

Tighten the couplers and replace

the seals

Fill the oil,please

Please try several times without load

before using

Control the temperature at -10℃ to

60℃ ,please

If so, the power pack need to be

replaced with new one

8

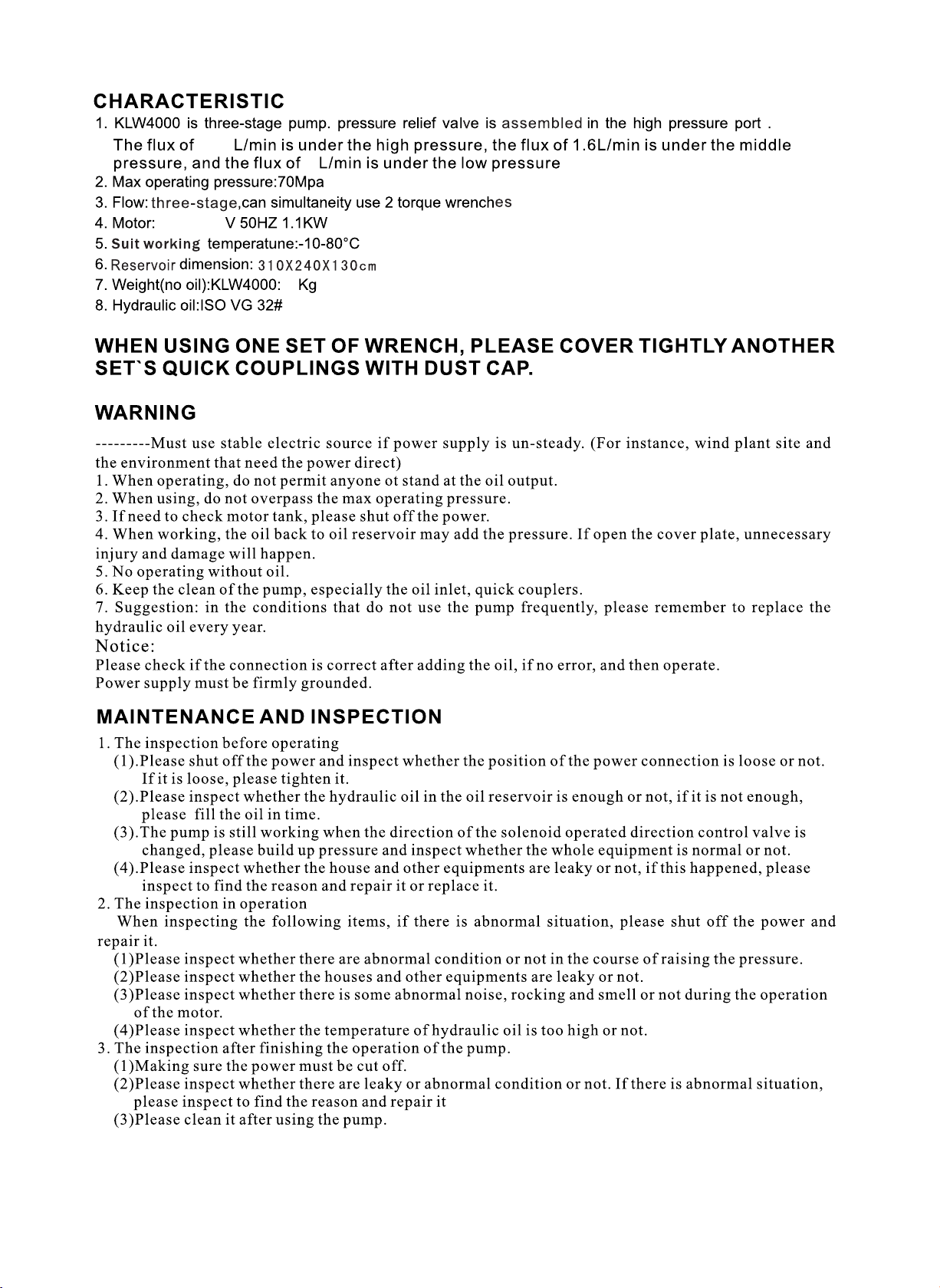

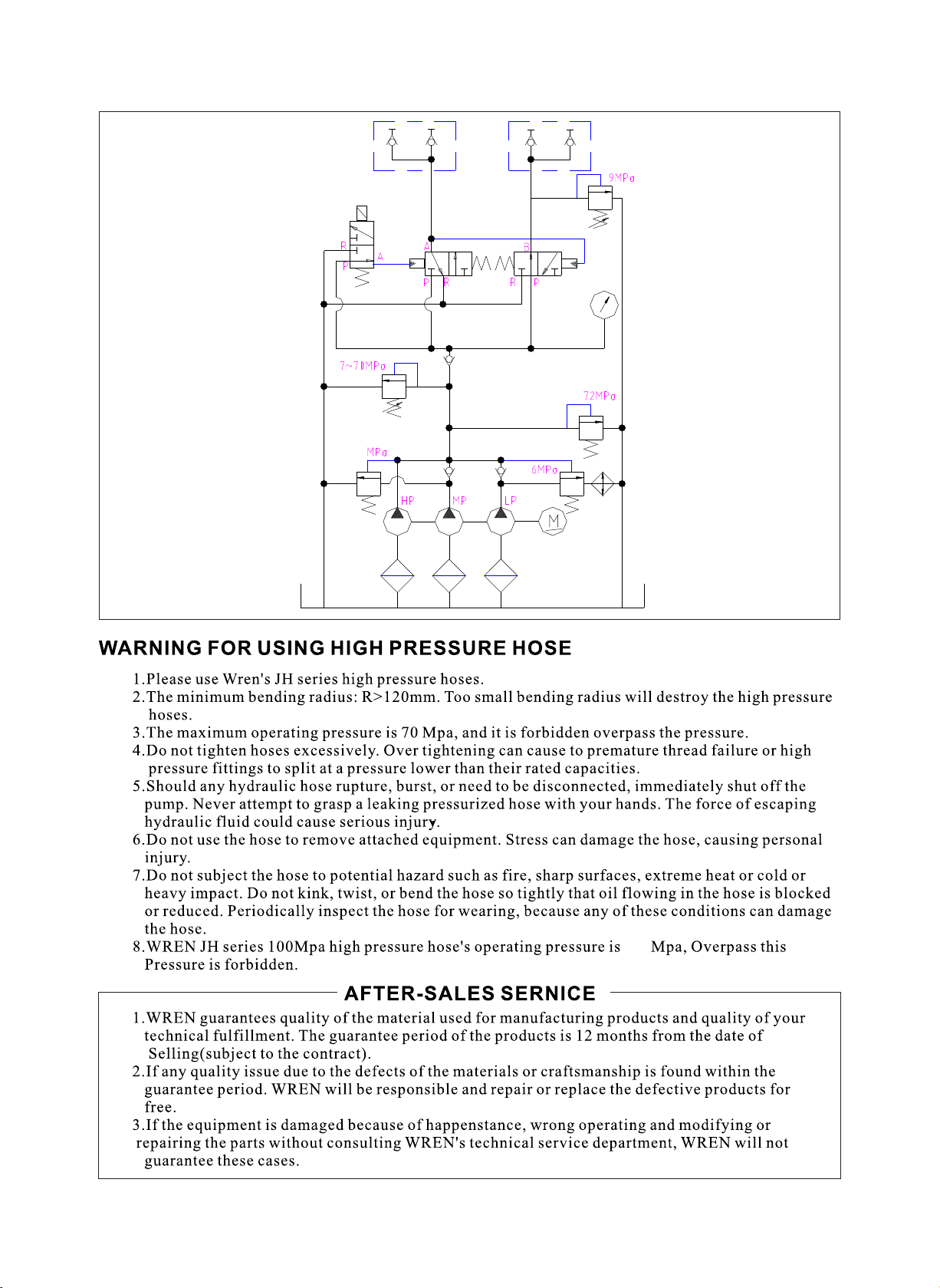

HYDRAULIC PRINCIPLE

24~26

70

9

Loading...

Loading...