Wren 5MXTA series, XLCT series, 8MXTA series, 10MXTA series, 20MXTA series Operation And Maintenance Manual

...

OPERATION AND MAINTENANCE MANUAL

IMPORTANT INSTRUCTIONS ON RECEIPT (OPEN PACKAGE INSPECTION)

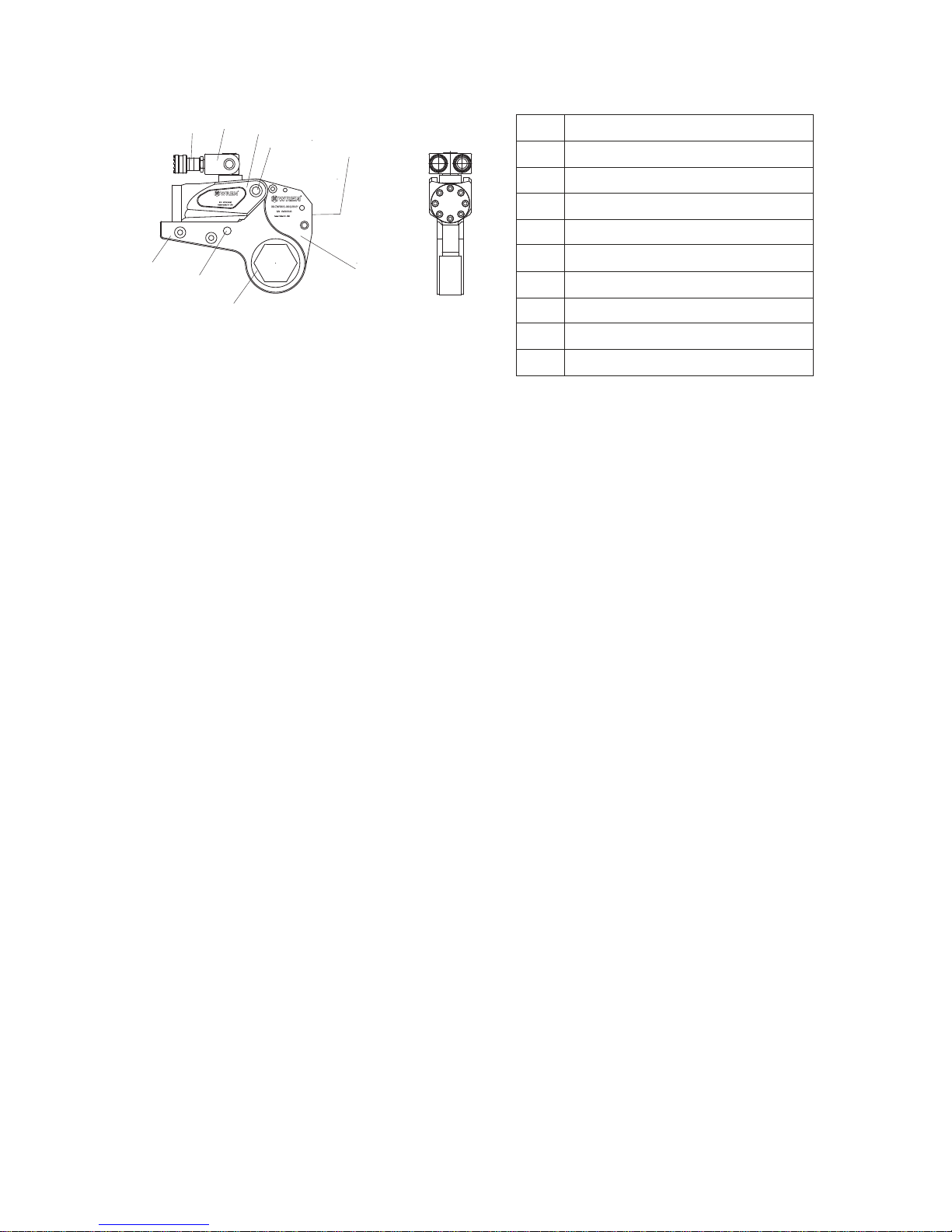

①

②

③

④

⑤

⑥

⑦

ITEM

BODY

360 S° 180° WIVEL JOINT×

QUICK COUPLING

FIXING HOOK

360°SWIVEL REACTION ARM

SQUARE DRIVE

DRIVE RETAINER

NAME

SAFETY FIRST!

The hydraulic tor que wrench is a power tool. Read all the instructions, wa rnings and

cautions before e very operation. Comply with the safety precaution s to avoid personal

injury or equipme nt damage while operating this tool! Neither WREN,n or its distributors

are responsible f or damage to the tool caused by unsafe and/or faulty operatio ns.

Carefully inspe ct all components for shipping damages. If any shippi ng damage is

found, notify the carrier at once. Shipping damage is NOT covered by w arranty.

The carrier is resp onsible for all repairs.

alloy and super high strength alloy steel for increased strength, intensity and durability of the

MXTA series, Square Drive Torque Wrenches:

It is operating man ual of MXTA and XLCT series Torque Wrench, please read carefully

with following in struction, warning and Caution before using Tool.

1

MXTA AND XLCT HYDRAULIC TORQUE WRENCHES

tool. Double acting hydraulic design, Can lock and loosen the bolt connection, widely suitable for

PRODUCTIONS DESCRIPTION

-

QUICK RELEASE ARM

①

②

③

④

⑤

⑥

⑧

⑦

FIG1

large torque bolt and disassembly, High repeatability, a precise design is with accuracy +3%.

-

2

WARNING AND CAUTION

WARNING

WARNING

WARNING

CAUTION

To avoid personal inj uries and/or equipment damage, be sure that every hydraulic

component of the hy draulic torque wrench, hydraulic hose assembly, hydraulic power

To minimize the dange r of injury and damage to equipment: Never use a hydraulic

torque wrench wit hout a hydraulic gauge to indicate the working pressure. The hydra ulic

Immediately rep lace any worn or damaged parts of the tool with genuine WRE N replacement

parts .

Reduce damage to th e hydraulic hose assembly by avoiding sharp bends and kinks when

routing the hydra ulic hose assembly. Using a bent or kinked hydraulic hose assembly wi ll

cause severe back -pressure. Also, sharp bends and kinks will internally damage the hose

leading to premat ure failure. A kinked or damaged hydraulic hose assembly should be

replaced immedi ately.

DO NOT drop heavy obj ects, crush, or drive over the hydraulic hose assembl y. A sharp

impact may cause in ternal damage to the hose wire strands. Applying pressure to a

damaged hose may ca use it to rupture. A crushed hydraulic hose assembly should be

ITEM

NAME

①

②

③

④

⑤

⑥

⑧

⑦

LOW PROFILE CASSETTE

PIN

POWER HEAD

QUICK COUPLING

REACTION ARM

LINK PIN

RATCHET

360° 360 SWIVEL JOINT× °

⑨

360°SWIVEL JOINT

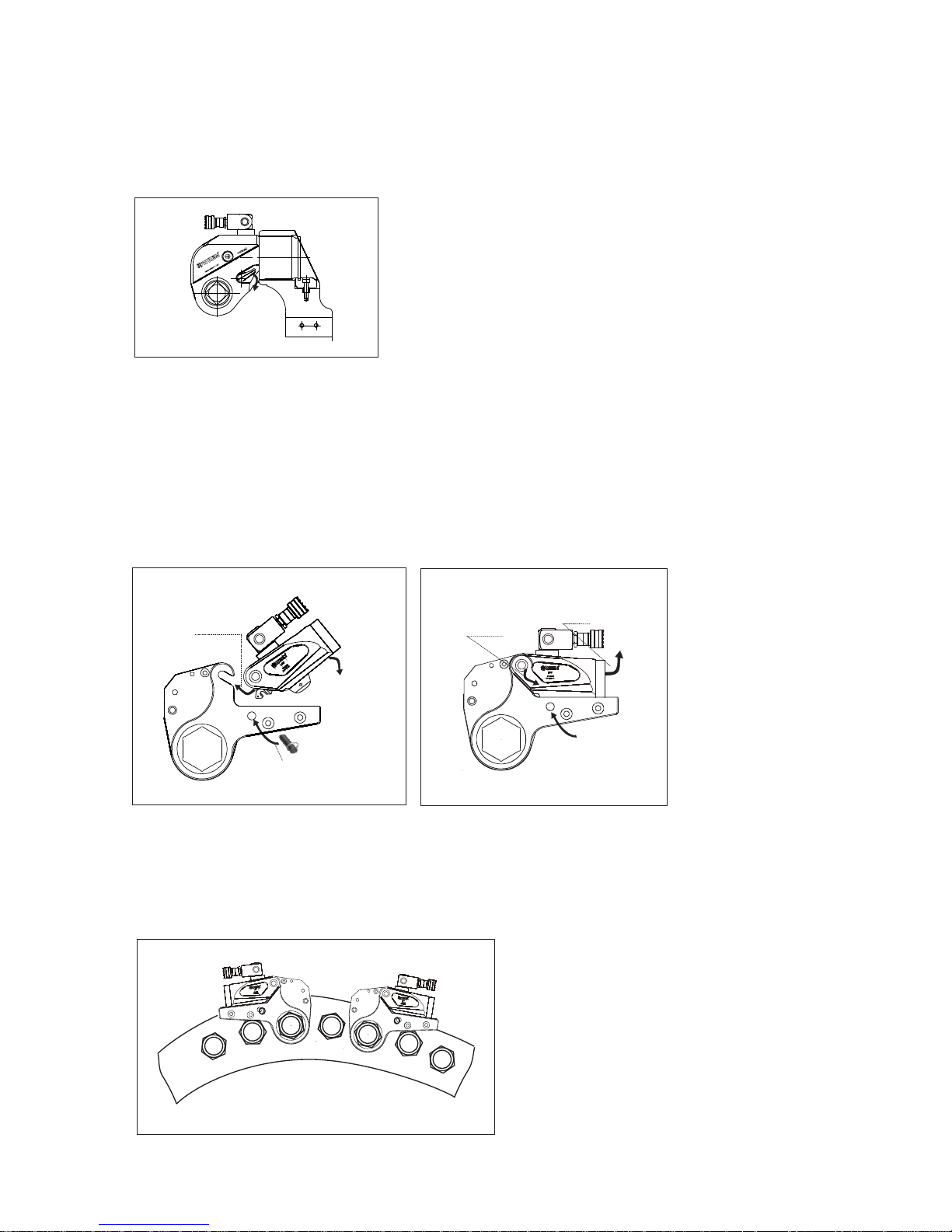

XLCT series,XLCT Porque Wrenches:

SIDE

①

⑤

⑥

⑧

⑦

④

③

②

⑨

SAFETY FIRST!

pack and gauge are ra ted for 10,000 PSI (700kg/cm2) operating pressure .

gauge is a window to sh ow what is happening in the hydraulic system.

DO NOT exceed the allowable maximum torque of the hydraulic torque wrench.

CAUTION

replaced immedi ately.

Avoid high te mperature exposure to the hydraulic hose assembly.

CAUTION

ALWAYS INSPECT THE HYDRAULIC HOSE ASSEMBLY FOR DAMAGE AND

WEAR PRIOR TO USE.

To avoid personal inj uries, equipment damage and/or warranty invalidation:

DO NOT: Remove the shro ud from the hydraulic torque wrench. Modify any compo nent

of the hydraulic to rque wrench. Adjust the hydraulic torque wrench safe ty relief valve

WARNING

located inside th e swivel couplings.

XLTC

3

CAUTION

CAUTION

The incorrect sys tem connection may cause failure and injury. Before connecting the

hydraulic torqu e wrench and hydraulic hose assembly to the assembled power pack,

make sure the hydra ulic torque wrench swivel couplings, hose couplings and hydraulic

power pack coupli ngs are clean and free of debris.

LOOSE OR DIRTY COUPLERS WILL CAUSE TOOL NOT TO OPERATE PROPERLY

DO NOT use old or damag ed sockets. use the wrong size sockets.

WARNING

Only use a high quali ty socket. The socket must measure up to standard I SO-2725 and

ISO-1174 or DI N3129 and DIN3121 or ASME-B107.2/1995. Never use a chr ome plated

socket.

WARNING

Always use a pin to loc k the socket with the square drive in order to avoid the sock et from

falling off .

PROPER SAFETY ATTIRE

When operating hy draulic equipment, use proper safety equipment an d clothing. Consult

with your company ’s safety representative to obtain this infor mation.

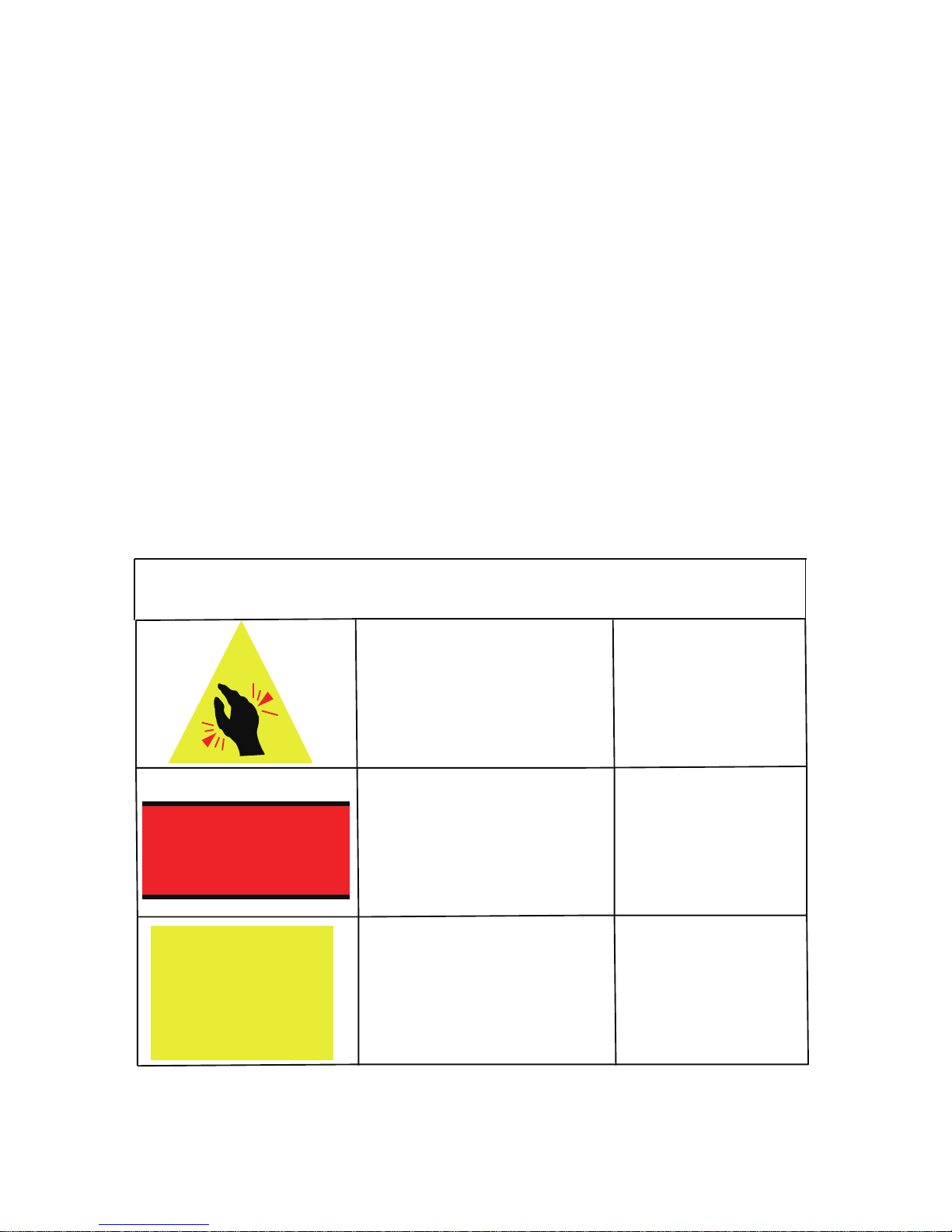

WARNING SIGN

Warni ng signs are shown in the following table

IF DRIVE STICKS OUT RIGHT,

IT'S SET FOR TIGHTEN.

LEFT. IT'S SET FOR LOOSE!

LOCK REACTION

ARM BEFORE

USING TOOL!

warning table

Meaning

Affixed Position

WORK HEAD

REVERSE LEVER

PROHIBIT US ING BY HAND

PRIOR TO USE, FIXED

THE REACTION ARM

REVERSE LEVER

THE SQUARE DRIVE IN

POSITION,LEFT LOOSEN,

RIGHT TIGHTEN

4

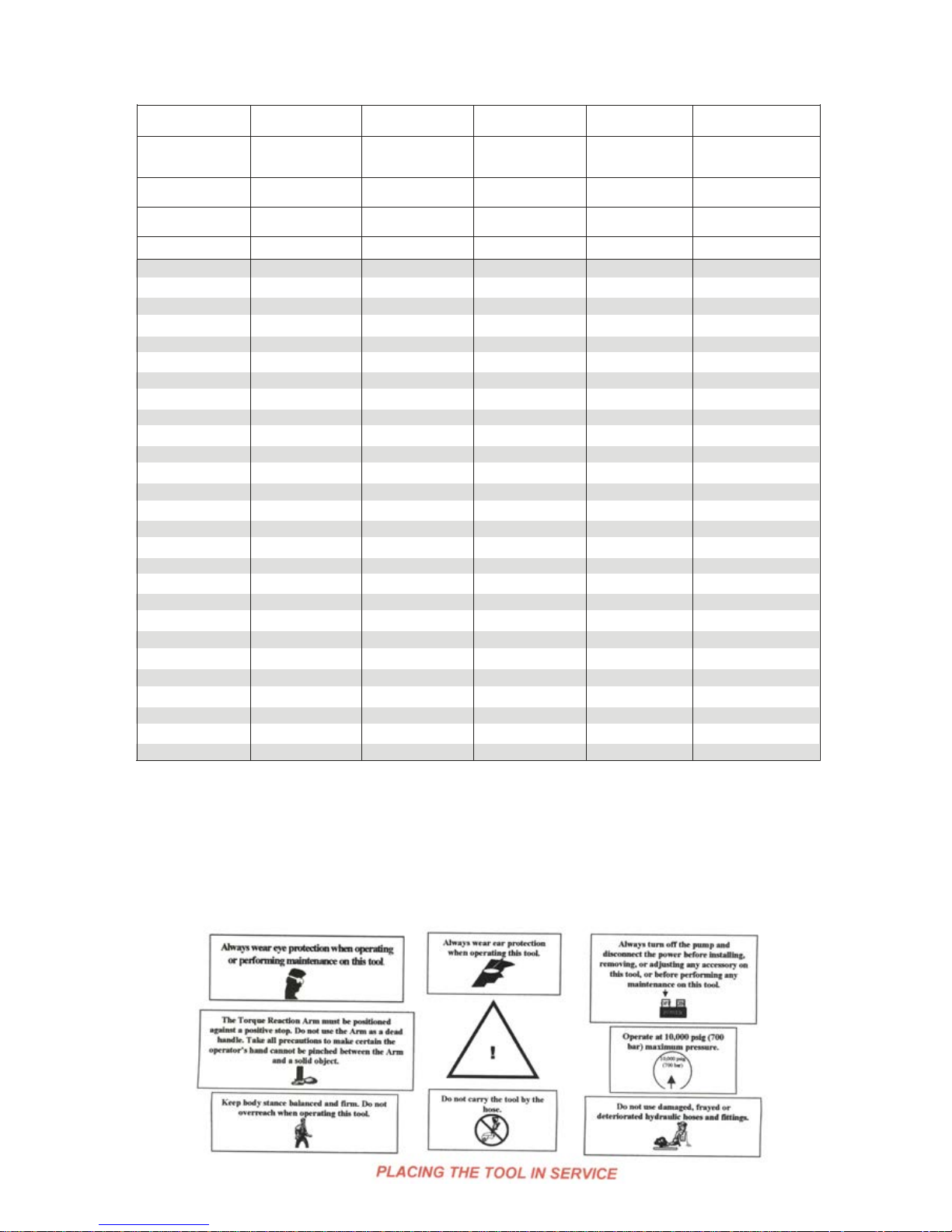

Bolting

REMARKS:

Strength Grade

4.8 6.8 8.8 10.9

Min breaking

strength

392MPa 588MPa 784MPa 941MPa

Material

Q235(SS41) 35(S35C) 35CrMo(SCM3) 42CrMo(SCM4)

Thread

22 7 69 10 98 14 137 17 165

24 10 98 14 137 21 206 25 247

27 14 137 21 206 29 284 35 341

30 18 176 28 296 41 402 58 569

32 23 225 34 333 55 539 78 765

36 32 314 48 470 70 686 100 981

41 45 441 65 637 105 1029 150 1472

46 60 588 90 882 125 1225 200 1962

50 75 735 115 1127 150 1470 210 2060

55 100 980 150 1470 180 1764 250 2453

60 120 1176 180 1764 220 2156 300 2943

65 155 1519 240 2352 280 2744 390 3826

70 180 1764 280 2744 320 3136 450 4415

75 230 2254 350 3430 400 3920 570 5592

80 280 2744 420 4116 480 4704 670 6573

85 360 3528 530 5149 610 5978 860 8437

90 410 4018 610 5978 790 7742 1100 10791

95 510 4998 760 7448 900 8820

100 580 5684 870 8526 1100 10780

105 660 6468 1000 9800 1290 12642

110 750 7350 1100 10780 1500 14701

115 830 8143 1250 12250 1850 18130

120 900 8820 1400 13720 2250 22050

130 1080 10584 1650 16170 2500 24500

145 1400 13720 2050 20090

155 1670 16366 2550 24990

175 2030 19894 3050 29890

mm

1. All recommendat ions above are in accordance with the Germany standar d (DIN).

2.The figures abo ve represent the maximum bolt torque; the recommend ed torque is

12.9

1176MPa

40 GrNiMoA(SNCM)

23 225

36 363

49 480

69 680

93 911

120 1176

180 1764

240 2352

250 2450

300 2940

370 3626

470 4606

550 5390

680 6664

850 8330

1050 10290

1350 13230

14

16

18

20

22

24

27

30

33

36

39

42

45

48

52

56

60

64

68

72

76

80

85

90

100

110

120

M

KGM N.m

KGM N.m KGM N.m KGM N.m

KGM N.m

Torque va lues

Torque va lues

Torque va lues

Torque va lues Torq ue values

FORM 1

BOLTING TIGHTENING FORCE RECOMMENTED CHART

80% of these chart figures.

3.The recommend ed tightening torque is 80% of the chart figure above. Fo r example;

for bolt M52 the strength grade is 8.8 therefore, the tor que is 4704*80% = 3763Nm

4.The recommend ed loosening torque is 150% of the tighting torque. For e xample; the

tightening torq ue is 3763*150%(200%) = 5645(7526) Nm.

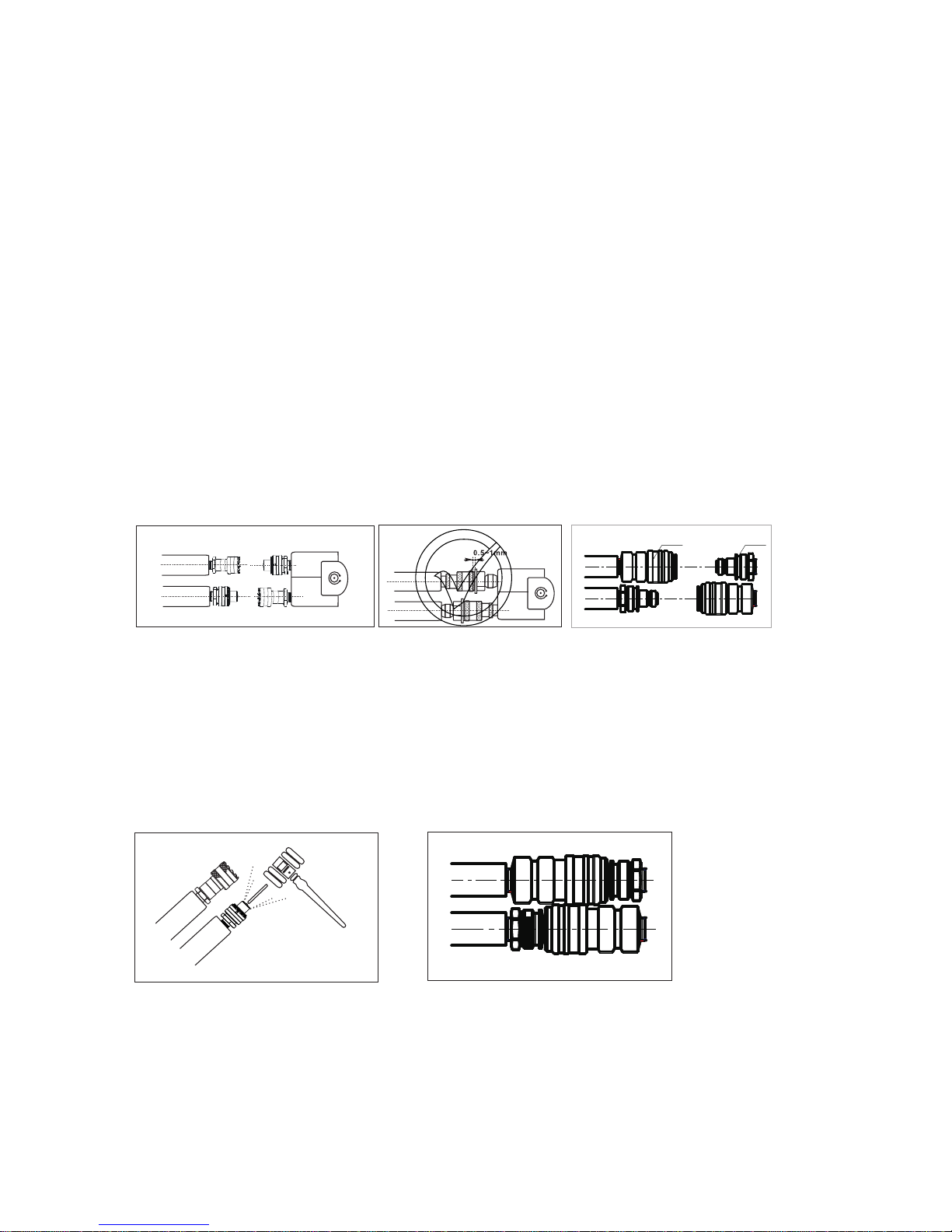

Connect the IBT square drive hydraulic torque wrench and hydraulic power pack with th e

proper twin line hy draulic hose assembly making sure all connections are proper and snug.

If the couplings ar e not properly mated the hydraulic torque wrench may no t operate.

HYDRAULIC TORQUE WRENCH SET UP

OPERATION SECTION

PREPARATION

1. Make certain of the size of the nut or bolt head, material , strength grade and determine

ALWAYS ABIDE BY THE MANUFACTURERS/ENGINEERS PROCEDURES.

2. Determine the to rque value needed and then determine the correspond ing pressure of

3. Inspect the hydraulic torque wrench set. Connect the hydraulic torq ue wrench, hydraulic

hydraulic conne ctions are securely connected. Verify that the hydra ulic hose assembly is

4. Connecting the h ydraulic torque wrench:

The hydraulic tor que wrench and torque wrench power pack are connected b y a 10,000 PSI

the desired torqu e.

the torque wrench p ump. This can be found in the Pressure - Torque Conversion Chart tha t

was provided with t he hydraulic torque wrench.

hose assembly and t he hydraulic power pack in to a hydraulic circuit. Ensu re that all

not kinked, crush ed or damaged.

operation press ure twin line hydraulic hose assembly.

FIG( 3)

FIG( 5)

FIG( 4)

Convex j oin t

Concav e joi nt

FIG(6)

FIG(7)

when in use (completely stuck, according

To connect the hydrau lic hose assembly to the swivel as shown below Insure the c onnectors

are fully engaged a nd screwed snugly together (FIG4) ,do as photo (4) show c an ensure

connection succ essfully.This way can open the check valve,mak e the oil circuit smoothly,

otherwise,the c heck valve will lock under the steel ball without top con nection,as a result

the oil circuit wil l not pass through, the wrench will not operate, Th e reason is that the

connection is fil led with pressure,in order to protect the tool, the top swivel will automatic

drain oil. Right wa y to do correction, please loose the hydraulic hose, ch eck all of the steel

ball inside t he quick coupler, please try to press the steel ball by hand, as nor mal the ball will

be flexible when yo u touch it, if it is hard, you may find a hammer to knock the ball until your

finger can press th e ball(FIG6 ), during relea sing the pressure in the system,please be more

carefully with th e spray oil, to avoid stain your clothes!Perfectly done, You may reconnect

the quick coupler a gain. If you prefer to card set quick coupler, it will be more e asy, ref the

arrow on the couple r, put the male coupler into the female coupler directly.

5

RIGHT

Fully sc rew ed the q uic k coupler, t o ensure jo int

tooth co mpl etel y.

to the code of the arrow reverse operation)

FOR MXTA SERIES

To remove the square, d isengage the drive retainer assembly by depressin g the center

round button and ge ntly pulling on the square end of the square drive, The square drive

will slide easily o ut.

To insert the square dr ive in the tool(FIG8),place the drive in the desired di rection, engage

drive and bushing s plines, then twist drive and bushing until ratchet sp line can be engaged.

Push drive throug h ratchet. Depress drive retainer button, engage re tainer with drive and

release button to l ock.

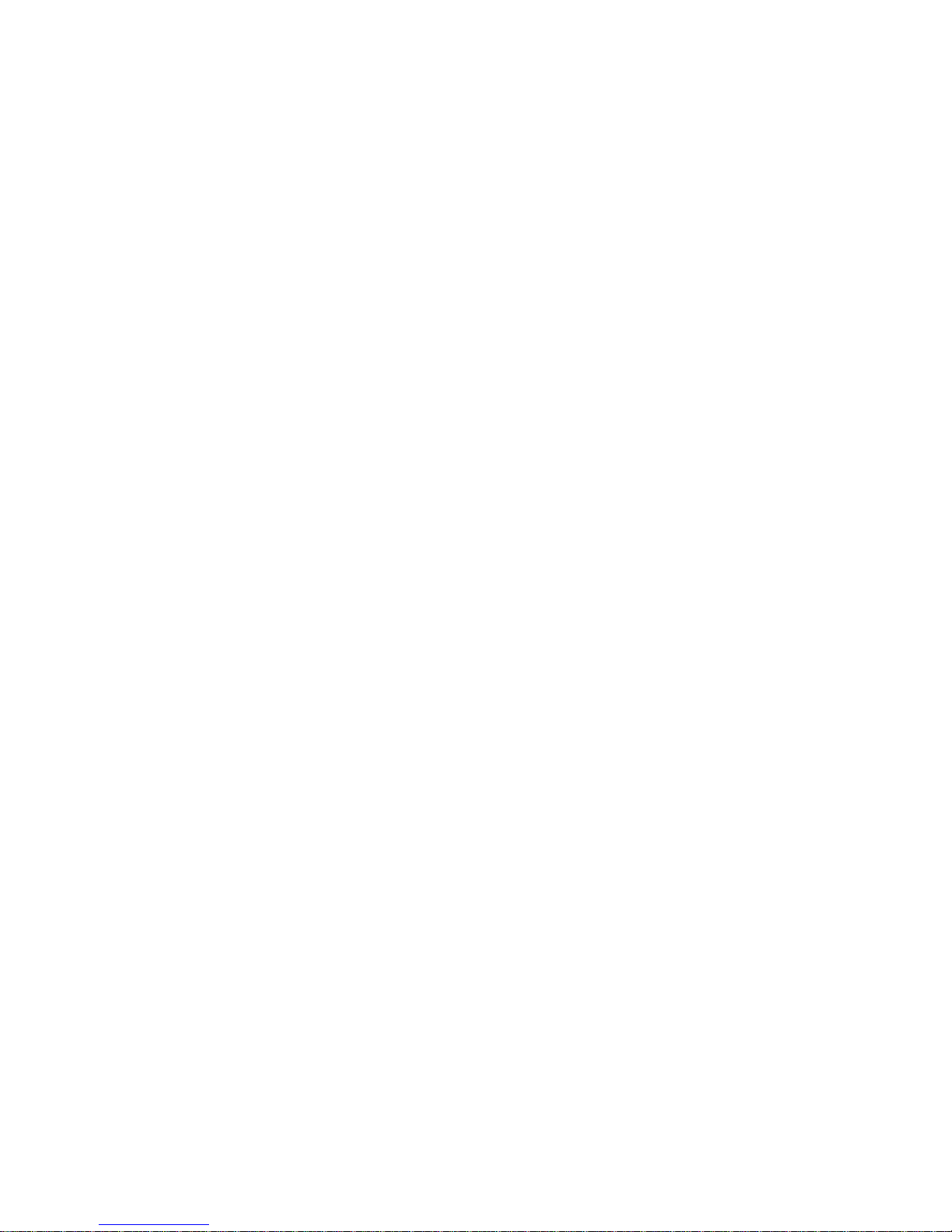

TO SETTING THE SQUARE DRIVE FOR ROTATION:

The position of the square drive when looking at the shroud will determine i f the hydraulic

torque wrench is se t to loosen or tighten. When the square drive extends to the left when

looking at the shro ud, the hydraulic torque wrench is set to loosen. When th e square drive

extends to the righ t, the hydraulic torque wrench is set to tighten.

5. Connecting the h ydraulic pump:

The hydraulic tor que wrench and torque wrench power pack are connected b y a 10,000 PSI

operation press ure twin line hydraulic hose assembly.

IMPORTANT

TO AVOID HYDRAULIC TORQUE WRENCH MALFUNCTION:

DO NOT reverse conn ectors.

When use the hydrau lic hose with quick coupler ,the connection should fo llow from the

hydraulic torqu e wrench advance side to the pump advance side, from the hy draulic torque

wrench retract si de to the pump retract side, Each quick coupler should be i nserted in the

end, then screw the threaded sleeve by hand.

Carefully check w hether the quick coupler is reliable, Carefully che ck the oil in the pump,

no oil shortage ope ration. Please plug the pow er electric power supply.

OPERATING THE HYDRAULIC TORQUE WRENCH

1. Put the wrench to the ground.

2. open the pump powe r switch,start the pump,then press the lock button to confirm the

pump is running nor mally.

3. By pushing the remote control advance button, the rear of the hydraulic torque wrench

will be pushed back u ntil the reaction arm will make contact with the reacti on point.

4. Continue to hold t he advance button as the square drive turns until you hea r an audible

“click” which wil l signify the hydraulic cylinder inside the hydraul ic torque wrench is fully

extended and will n ot turn the socket further. Release button.

5. Continuing to ho ld the remote control advance button, will result in a ra pid buildup of

pressure to the poi nt where the gauge reads what the hydraulic power pack wa s preset to

prior to applying t he hydraulic torque wrench.

IMPORTANT: The reading of full preset pressure after the cylinder is extended DOES

NOT INDICATE that this pressure (torque) is applied to the bolt/nut. It only indicates

that the cylinder is fully extended and cannot turn the socket further, until the tool

automatically resets itself.

6

FIG8

FIG9

Button

Drive Retainer

Square Drive

lossing

tightening

Right is tight.

Left is loose.

6. Releasing the re mote control button will automatically retract th e cylinder. The hydraulic

torque wrench wil l automatically reset itself and the operator will he ar an audible “click”

indicating he can a gain push the remote control button and the square driv e will turn. Each

time the cylinder i s extended and retracted, it is called a cycle. Successive cycles are made

until the tool “stalls” at the preset Torque/PSI with an accuracy of +/- 3%. Repeatability

is +/-1%. Please re peat again and again, make the wrench turn without loading,

observe the wrenc h tightening or loosening, no abnormalities, can be put into the

socket.

IMPORTANT: ALWAYS ATTEMPT ONE FINAL CYCLE TO INSURE THE “STALL” POINT

HAS BEEN REACHED.

REMARKS: When the hydraulic torque wrench not in use,you may turn off the lock

button,if long time no using the wrench,please shut off the motor switch.

ADJUST THE PRESSURE

Setting the press ure on the hydraulic power pack.

To set the pressure on th e pump, follow this procedure.

Loosen the lockin g ring below the “T” handle on the hydraulic power pack’s external pre ssure

regulator. Then, turn the “T” handle counterclockwise until it tu rns freely and easily.

Turn th e hydraulic power pack on. Using the hydraulic power pack remote pendant , push the

advance switch (o r button on the air hydraulic power pack) and hold it.

While holding the h ydraulic power pack in the advance mode, slowly turn th e “T” handle

clockwise and obs erve the hydraulic power pack pressure gauge rise.

NOTE: Always adjust the regulator pressure UP - never down.

When your gauge rea ches the predetermined pressure, stop turning the “ T” handle and let

the gauge settle.

If the pressure continues to rise above the predetermined pressure, re lease the back

pressure slight ly by turning the “T” handle counterclockwise. Then, depress the advance

switch on the remote and slowly bring pressure up to the predetermined pre ssure.

When the pressure i s correct, turn the pump off and tighten the lockin g ring which is under

the “T” handle. This sets the pump pressure, which determines torq ue wrench output.

Once your target pressure is set and locked, cycle the hydraulic power pac k once more to

ensure that your pr essure setting did not change as you tightened the lock ing ring.

THE LOOSENING PROCESS

1. Set the pump to 1000 0 PSI. Change the drive to the loosening mode, assuring t he reaction

2. Press and hold the remote control advance button. Pressure will decrease as the

3. Release the remote control advance button and the cylinder automatically retracts,

4. Repeat this process until the fastener can be removed by hand.

arm abuts squarel y on a solid reaction point.

socket begins to turn. As the cylinder extends fully, you will hear an audible “click”.

at which time you again hear the audible “click”.

NOTE: IF THE BOLT/NUT DOES NOT LOOSEN WITH THE ABOVE PROCEDURES,

IT IS AN INDICATION THAT YOU REQUIRE A LARGER HYDRAULIC TORQUE

WRENCH TO LOOSEN THE BOLT/NUT.

THE TIGHTENING PROCESS

1. hydraulic torq ue wrench setting

Firstly, acc ording to the design requirements set torque,If no de sign torque, please ref the

80% of the recommen ded torque.

Way: th e setting torque=(the recommended torque of these c hart figures)×(80%-90%)

For example:the recommended tightening torque is 90% of the chart figure above. For

example; for bolt M 48 the strength grade is 8.8 therefore, the torque is 3920×90% = 3528Nm

2. Pump pressure se tting

According to a desi red torque value and the wrench model to set the pressure o f the pump.

For example 8.8 gra de、M48bolt,the setting torque is 3528N.m, if you prefer to WR-3IBT

wrench,you may fi nd the torque is 3528N. m, the pum p pressur is 54Mpa,so the pump

pressure settin g is 54Mpa.

7

3. Confirm the wren ch is tightening, put the wrench on the nut, perform it until the nut does

not move far.

LOCKED-ON

Should the hydrau lic torque wrench be “locked-on” after the final cycl e, push down the

remote control ad vance button once more (to build pressure) and while ma intaining this

pressure, pull ba ck on the accuracy assurance pawl lever (located on the s ide of the tool).

Release the remot e control advance button, while continuing to push do wn on the accuracy

assurance lever ( this will allow the hydraulic torque wrench to be remov ed easily).

press d own

FIG10

XLCT SERIES

The Ratchet link and the power head assembly and disassembly

Insert the hex ratchet links. The low profile hex ratchet links are in serted and removed from

the power head as fol lows:

The “hook” descri bed by the link’s drive plate is inserted around the fixed pin of the power

head and the link is sw ung down to rest along the base of the power head cylinder. At th is

point, the link pin h oles of the power head and link will align. Insert the link p in to secure.

Pull out the pin, pul l up the power head, and then along the groove direction, d isassembly

the power head and th e ratchet link.

assembl y

disassembly

1. in sert di recti on

2. pr ess to th e end

3. in sert th e pin

1. pu ll out th e

2. ta ke the po wer

3. th e hook gr oove au tomat ic

FIG 11 FIG 12

Direction position

Setting for tightening or loosening the nut:

The position of the tool relative to the nut determines whether the action will tighten or loosen

the nut. The po wer stroke of the piston rod will always turn the hex ratch et toward the shroud.

FIG 13

8

The nut turns clockwise for tightening and counterclockwise for loos ening.

direc tion

com bined p in

hea d up

dow n back, s epara ted fro m

the w rench

lossing

tightening

Low profile hydraulic torque

wrench dire cti on diagram

Preparation Determined the loose(tighten) nut size , select approp riated power head and

ratchet link and re ducer inserts.

CONNECT THE POWER PACK

Use twin hose to Conn ect the high pump pressure outlet(H OR A) with the high pres sure

outlet of hydraul ic wrench,low pressure outlet of the pump to low pressu re outlet of the

hydraulic torqu e wrench。Insert the quick couple sleeve into the end,then s crew tighting

by no space.

Check carefully w hether the twin hose joint connection is reliable, pl ease be sure the oil in

enough.The pump p ower plug power supply.

WARNING No oil short age !

TEST RUN

1. Put the wrench assembly in space, first start to finis h, Check whether the rotating ratchet

normal return or no t, if the rotation is not normal, Mayb e the hook position does not

correspond betw een the power head and ratchet link,open to check.

2. Turn on the pump powe r switch, start the pump, then press the lock button to confirm the

pump is running nor mally.

3. By pushing the rem ote control advance button, the rear of the hydraulic torque wrench

will be pushed back u ntil the reaction arm will make contact with the reacti on point.

4. Continue to hold t he advance button as the cassette turns until you hear an a udible “click”

which will signif y the hydraulic cylinder inside the hydraulic torqu e wrench is fully extended

and will not turn the s ocket further. Release button.

5. Continuing to ho ld the remote control advance button, will result in a ra pid buildup of

pressure to the poi nt where the gauge reads what the hydraulic power pack wa s preset to

prior to applying t he hydraulic torque wrench.

IMPORTANT: The reading of full preset pressure after the cylinder is extended DOES

NOT INDICATE that this pressure (torque) is applied to the bolt/nut. It only indicates

that the cylinder is fully extended and cannot turn the socket further, until the tool

automatically resets itself.

6. Releasing the re mote control button will automatically retract th e cylinder. The hydraulic

torque wrench wil l automatically reset itself and the operator will he ar an audible “click”

indicating he can a gain push the remote control button and the cassette wi ll turn. Each time

the cylinder is ext ended and retracted, it is called a cycle. Successive c ycles are made until

the tool “stalls” at the preset Torque/PSI with an accuracy of +/-3%. Re peatability is +/-1%.

Please repeat aga in and again, make the wrench turn without loading, observe the

wrench tighteni ng or loosening,no abnormalities, can be put int o the nut directly.

IMPORTANT: ALWAYS ATTEMPT ONE FINAL CYCLE TO INSURE THE “STALL” POINT

HAS BEEN REACHED.

REMARKS: When the h ydraulic torque wrench not in use, ,you may turn off the lock button,

if long time no using t he wrench, please shut off the pump motor switch.

9

OPERATION

Setting the press ure on the hydraulic power pack:

To set the pressure on th e pump, follow this procedure:

Loosen the lockin g ring below the “T” handle on the hydraulic power pack ext ernal pressure

regulator. Then, turn the “T” handle counterclockwise until it tu rns freely and easily.

Turn th e hydraulic power pack on. Using the hydraulic power pack remote pendant , push the

advance switch (o r button on the air hydraulic power pack) and hold it.

While holding the hydraulic power pack in the advance mode, slowly turn the “T” handle

clockwise and observe the hydraulic power pack pressure gauge rise.

Note: Always adjust the regulator pressure UP - never down.

When your gauge rea ches the predetermined pressure, stop turning the “ T” handle and

let the gauge settl e.

If the pressure continues to rise above the predetermined pressure, re lease the back

pressure slight ly by turning the “T” handle counterclockwise. Then, depress the advance

switch on the remote and slowly bring pressure up to the predetermined pre ssure.

10

When the pressure i s correct, turn the pump off and tighten the lockin g ring which is under

the “T” handle. This sets the pump pressure, which determines torq ue wrench output.

Once your target pressure is set and locked, cycle the hydraulic power pac k once more to

ensure that your pr essure setting did not change as you tightened the lock ing ring.

THE LOOSENING PROCESS

1. Set the pump to 10000 PSI. Change the drive to the loosening mode, assuring t he reaction

arm abuts squarel y on a solid reaction point.

2. Press and hold the r emote control advance button. Pressure will decre ase as the cassette

begins to turn. As the c ylinder extends fully, you will hear an audible “c lick”.

3. Release the remo te control advance button and the cylinder automati cally retracts, at

which time you agai n hear the audible “click”.

4. Repeat this process until the fastener can be removed by hand.

NOTE: IF THE BOLT/NUT DOES NOT LOOSEN WITH THE ABOVE PROCEDURES, IT IS

AN INDICATION THAT YOU REQUIRE A LARGER HYDRAULIC TORQUE WRENCH TO

LOOSEN THE BOLT/NUT.

THE TIGHTENING PROCESS

1. Draulic torque w rench setting

Firstly, acc ording to the design requirements set torque, If no des ign torque, please ref the

80% of the recommen ded torque.

Way: th e setting torque=(the recommended torque of these c hart figures)×(80%-90%)

For example: The recommended tightening torque is 90% of the chart f igure above. For

example; for bolt M 48 the strength grade is 8.8 therefore, the torque is 3920*90% = 3528Nm

2. Pump pressure se tting

According to a desi red torque value and the wrench model to set the pressure o f the pump.

For example 8.8 gra de、M48 bolt, the sett ing torque is 3528N.m, if you prefer to WR-4LOW

wrench, you may fin d the torque is 3528N.m, the pump pressure is 42Mpa, so the p ump

pressure settin g is 42Mpa.

3.Confirm the wre nch is tightening,put the wrench on the nut,perform i t until the nut does not

move far.

LOCKED-ON

Should the hydrau lic torque wrench be “locked-on” after the final cycl e, push down the

remote control ad vance button once more (to build pressure) and while ma intaining this

pressure, pull ba ck on the accuracy assurance pawl lever (located on the s ide of the tool).

Release the remot e control advance button, while continuing to push do wn on the accuracy

assurance lever ( this will allow the hydraulic torque wrench to be remov ed easily).

FIG 14

press d own

direc tion

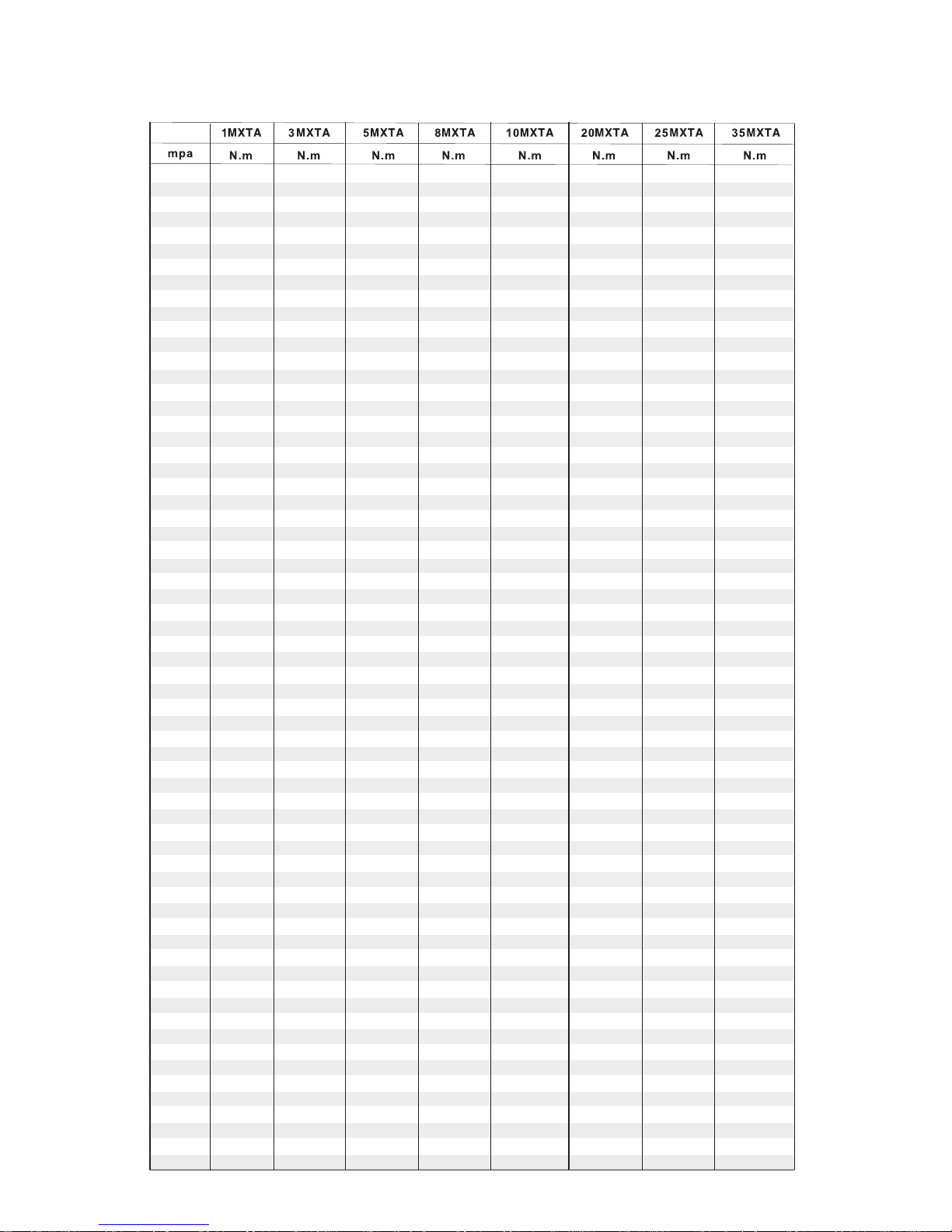

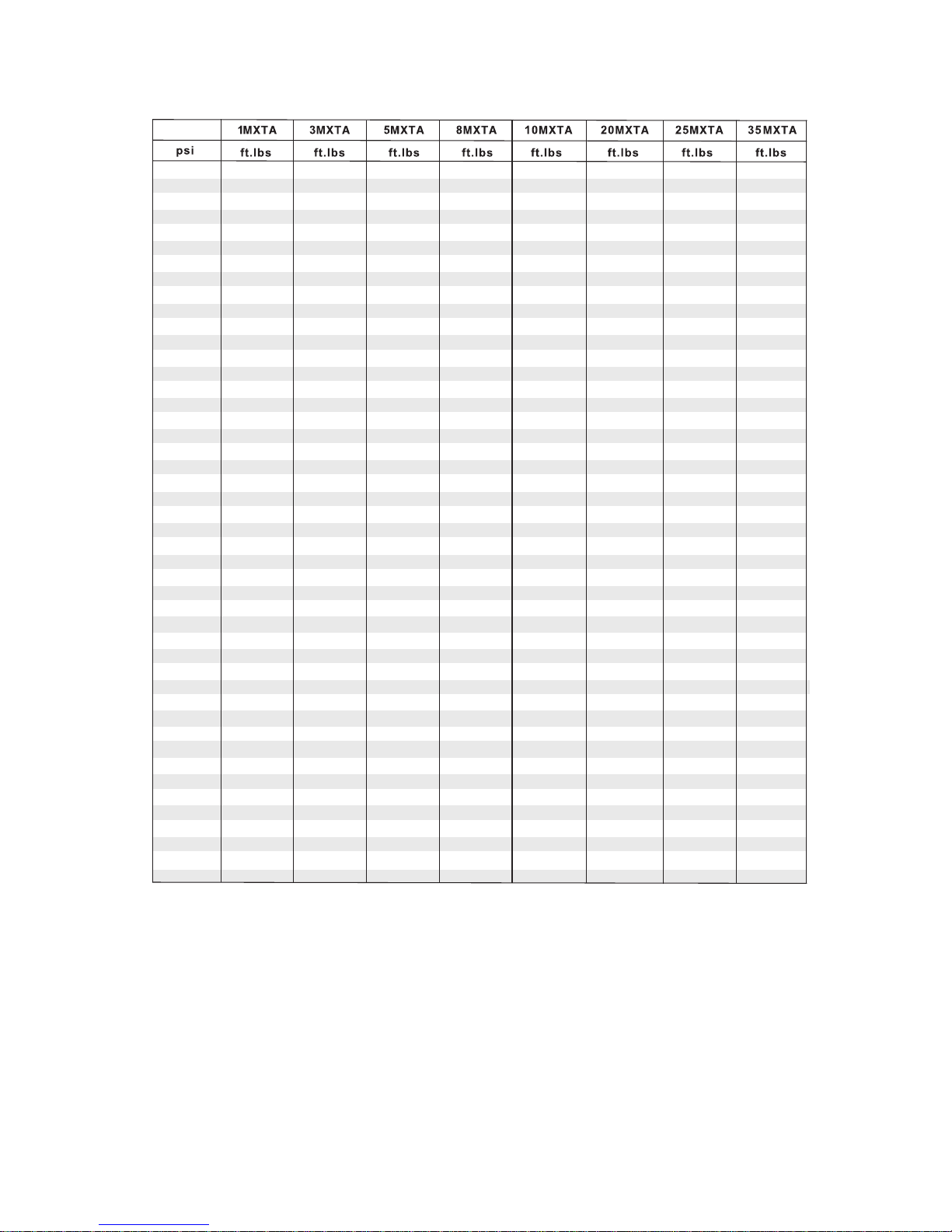

MXTA SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

FORM 2

11

Model

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

7

8

9

183

209

236

262

288

314

341

367

393

419

446

472

498

524

551

577

603

629

656

682

708

734

761

787

813

839

866

892

918

944

971

997

1023

1049

1076

1102

1128

1154

1181

1207

1233

1259

1286

1312

1338

1364

1391

1417

1443

1469

1496

1522

1548

1574

1601

1627

1653

1679

1706

1732

1758

1784

1811

1837

1031

1096

1160

1225

1289

1353

1418

1482

1547

1611

1676

1740

1805

1869

1934

1998

2063

2127

2191

2256

2320

2385

2449

2514

2578

2643

2707

2772

2836

2900

2965

3029

3094

3158

3223

3287

3352

3416

3481

3545

3610

3674

3738

3803

3867

3932

3996

4061

4125

4190

4254

4319

4383

4448

4512

451

515

580

644

709

773

838

902

967

1075

1182

1290

1397

1505

1612

1720

1828

1935

2043

2150

2258

2365

2473

2580

2688

2796

2903

3011

3118

3226

3333

3441

3548

3656

3764

3871

3979

4086

4194

4301

4409

4516

4624

4732

4839

4947

5054

5162

5269

5377

5484

5592

5700

5807

5915

6022

6130

6237

6345

6452

6560

6668

6775

6883

6990

7098

7205

7313

7420

7528

752

860

967

1078

1232

1386

1540

1694

1848

2002

2156

2310

2464

2618

2772

2926

3080

3234

3388

3542

3696

3850

4004

4158

4312

4466

4620

4774

4928

5082

5236

5390

5544

5698

5852

6006

6160

6314

6468

6622

6776

6930

7084

7238

7392

7546

7700

7854

8008

8162

8316

8470

8624

8778

8932

9086

9240

9394

9548

9702

9856

10010

10164

10318

10472

10626

10780

1551

1773

1994

2216

2438

2659

2881

3103

3324

3546

3768

3989

4211

4433

4654

4876

5098

5319

5541

5763

5984

6206

6428

6649

6871

7093

7314

7536

7758

7979

8201

8423

8644

8866

9088

9309

9531

9753

9974

10196

10418

10639

10861

11083

11304

11526

11748

11969

12191

12413

12634

12856

13078

13299

13521

13743

13964

14186

14408

14629

14851

15073

15294

15516

10284

10665

11046

11427

11808

12189

12570

12951

13332

13713

14094

14475

14855

15236

15617

15998

16379

16760

17141

17522

17903

18284

18665

19046

19427

19807

20188

20569

20950

21331

21712

22093

22474

22855

23236

23617

23998

24378

24759

25140

25521

25902

26283

26664

2666

3047

3428

3809

4190

4571

4952

5332

5713

6094

6475

6856

7237

7618

7999

8380

8761

9142

9523

9903

3472

3968

4464

4960

5456

5952

6448

6945

7441

7937

8433

8929

9425

9921

10417

10913

11409

11905

12401

12898

13394

13890

14386

14882

15378

15874

16370

16866

17362

17858

18354

18850

19347

19843

20339

20835

21331

21827

22323

22819

23315

23811

24307

24803

25299

25796

26292

26788

27284

27780

28276

28772

29268

29764

30260

30756

31252

31749

32245

32741

33237

33733

34229

34725

10428

11123

11818

12514

13209

13904

14599

15295

15990

16685

17380

18076

18771

19466

20161

20856

21552

22247

22942

23637

24333

25028

25723

26418

27114

27809

28504

29199

29895

30590

31285

31980

32676

33371

34066

34761

35456

36152

36847

37542

38237

38933

39628

40323

41018

41714

42409

43104

43799

44495

45190

45885

46580

47276

47971

48666

4866

5561

6256

6952

7647

8342

9037

9733

MXTA SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

FORM 3

12

Model

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

4400

4600

4800

5000

5200

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

7400

7600

7800

8000

8200

8400

8600

8800

9000

9200

9400

9600

9800

10000

134

161

188

215

242

268

295

322

349

376

403

430

457

483

510

537

564

591

618

645

672

698

725

752

779

806

833

860

887

914

940

967

994

1021

1048

1075

1102

1129

1155

1182

1209

1236

1263

1290

1317

1344

328

394

459

525

590

656

721

787

852

918

984

1049

1115

1180

1246

1311

1377

1443

1508

1574

1639

1705

1770

1836

1901

1967

2033

2098

2164

2229

2295

2360

2426

2491

2557

2623

2688

2754

2819

2885

2950

3016

3082

3147

3213

3278

547

656

766

875

985

1094

1203

1313

1422

1532

1641

1750

1860

1969

2079

2188

2297

2407

2516

2626

2735

2844

2954

3063

3173

3282

3391

3501

3610

3720

3829

3938

4048

4157

4267

4376

4485

4595

4704

4814

4923

5032

5142

5251

5361

5470

1096

1253

1409

1566

1723

1879

2036

2193

2349

2506

2662

2819

2976

3132

3289

3446

3602

3759

3915

4072

4229

4385

4542

4699

4855

5012

5168

5325

5482

5638

5795

5951

6108

6265

6421

6578

6735

6891

7048

7204

7361

7518

7674

7831

783

940

1127

1352

1578

1803

2029

2254

2480

2705

2931

3156

3381

3607

3832

4058

4283

4509

4734

4959

5185

5410

5636

5861

6087

6312

6538

6763

6988

7214

7439

7665

7890

8116

8341

8567

8792

9017

9243

9468

9694

9919

10145

10370

10595

10821

11046

11272

1937

2324

2712

3099

3487

3874

4261

4649

5036

5424

5811

6198

6586

6973

7361

7748

8135

8523

8910

9298

9685

10072

10460

10847

11235

11622

12009

12397

12784

13172

13559

13946

14334

14721

15109

15496

15883

16271

16658

17046

17433

17820

18208

18595

18983

19370

2523

3028

3532

4037

4541

5046

5550

6055

6559

7064

7568

8073

8577

9082

9586

10091

10595

11100

11604

12109

12613

13118

13622

14127

14631

15136

15641

16145

16650

17154

17659

18163

18668

19172

19677

20181

20686

21190

21695

22199

22704

23208

23713

24217

24722

25226

3535

4242

4949

5656

6363

7070

7777

8485

9192

9899

10606

11313

12020

12727

13434

14141

14848

15555

16262

16970

17677

18384

19091

19798

20505

21212

21919

22626

23333

24040

24747

25454

26162

26869

27576

28283

28990

29697

30404

31111

31818

32525

33232

33939

34647

35354

13

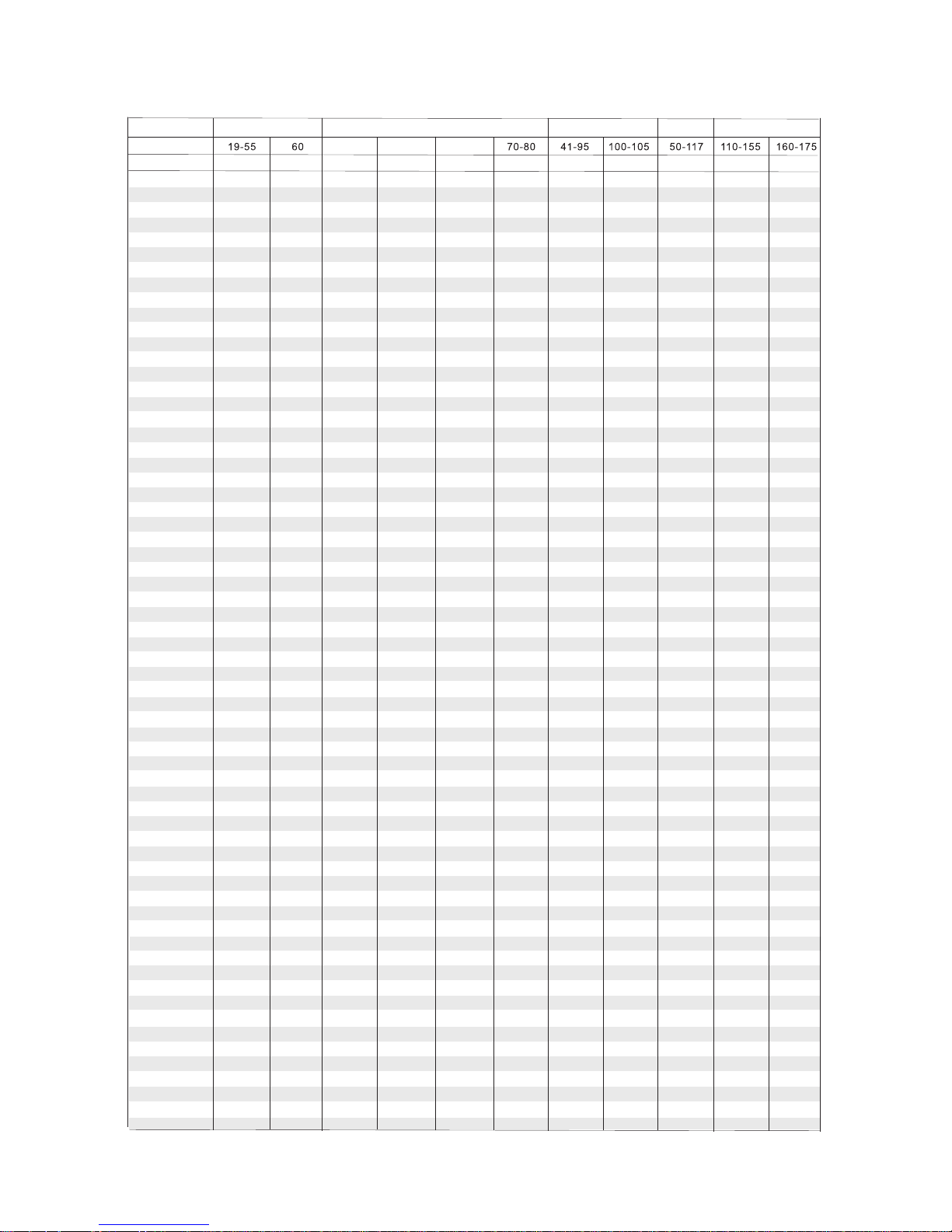

XLCT SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

FORM 4

2XLCT

30XLCT

14XLCT

8XLCT4XLCT

Model

Bolt Siz e Ran ge

34-36

41

46-65

Mpa

N.m

N.m

N.m

N.m N.m

N.m

N.m

N.m

N.m

N.m

N.m

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

7

8

9

232

265

299

332

365

398

432

465

498

531

565

598

631

665

698

731

764

798

831

864

897

931

964

997

1030

1064

1097

1130

1164

1197

1230

1263

1297

1330

1363

1396

1430

1463

1496

1530

1563

1596

1629

1663

1696

1729

1762

1796

1829

1862

1895

1929

1962

1995

2029

2062

2095

2128

2162

2195

2228

2261

2295

2328

241

275

310

344

379

413

448

482

517

551

586

620

655

689

724

758

793

827

862

896

931

965

1000

1034

1069

1103

1138

1172

1207

1241

1276

1310

1345

1379

1414

1448

1483

1517

1552

1586

1621

1655

1690

1724

1759

1793

1828

1862

1897

1931

1966

2000

2035

2069

2104

2138

2173

2207

2242

2276

2311

2345

2380

2414

585

669

752

836

920

1003

1087

1171

1255

1338

1422

1506

1589

1673

1757

1840

1924

2008

2092

2175

2259

2343

2426

2510

585

669

752

836

920

1003

1087

1171

1255

1338

1422

1506

1589

1673

1757

1840

1924

2008

2092

2175

2259

2343

2426

2510

2594

2677

2761

2845

2929

3012

3096

3180

3263

3347

3431

3514

3598

3682

3766

3849

3933

4017

4100

4184

4268

4351

4435

4519

4603

4686

4770

4854

4937

5021

1003

1087

1171

1255

1338

1422

1506

1589

1673

1757

1840

1924

2008

2092

2175

2259

2343

2426

2510

2594

2677

2761

2845

2929

3012

3096

3180

3263

3347

3431

3514

3598

3682

3766

3849

3933

4017

4100

4184

4268

4351

4435

4519

4603

4686

4770

4854

4937

5021

5105

5188

5272

5356

5440

5523

5607

5691

5774

5858

585

669

752

836

920

647

739

832

924

1017

1109

1202

1294

1387

1479

1572

1664

1757

1849

1942

2034

2127

2219

2312

2404

2497

2589

2682

2774

2867

2959

3052

3144

3237

3329

3422

3514

3607

3699

3792

3884

3977

4069

4162

4254

4347

4439

4532

4624

4717

4809

4902

4994

5087

5179

5272

5364

5457

5549

5642

5734

5827

5919

6012

6104

6197

6289

6382

6474

1094

1250

1407

1563

1719

1876

2032

2188

2344

2501

2657

2813

2970

3126

3282

3439

3595

3751

3907

4064

4220

4376

4533

4689

4845

5002

5158

5314

5470

5627

5783

5939

6096

6252

6408

6565

6721

6877

7033

7190

7346

7502

7659

7815

7971

8128

8284

8440

8596

8753

8909

9065

9222

9378

9534

9691

9847

10003

10159

10316

10472

10628

10785

10941

10092

10260

10428

10597

10765

10933

11101

11269

11438

11606

11774

1177

1345

1513

1682

1850

2018

2186

2354

2523

2691

2859

3027

3195

3364

3532

3700

3868

4037

4205

4373

4541

4709

4878

5046

5214

5382

5550

5719

5887

6055

6223

6391

6560

6728

6896

7064

7232

7401

7569

7737

7905

8073

8242

8410

8578

8746

8914

9083

9251

9419

9587

9756

9924

1852

2117

2381

2646

2910

3175

3440

3704

3969

4233

4498

4762

5027

5292

5556

5821

6085

6350

6615

6879

7144

7408

7673

7938

8202

8467

8731

8996

9260

9525

9790

10054

10319

10583

10848

11113

11377

11642

11906

12171

12435

12700

12965

13229

13494

13758

14023

14288

14552

14817

15081

15346

15611

15875

16140

16404

16669

16933

17198

17463

17727

17992

18256

18521

4188

4786

5385

5983

6581

7180

7778

8376

8975

9573

10171

10769

11368

11966

12564

13163

13761

14359

14958

15556

16154

16753

17351

17949

18548

19146

19744

20343

20941

21539

22138

22736

23334

23932

24531

25129

25727

26326

26924

27522

28121

28719

29317

29916

30514

31112

31711

32309

32907

33506

34104

34702

35301

35899

36497

37095

37694

38292

38890

39489

40087

40685

41284

41882

4459

5096

5733

6370

7007

7644

8281

8918

9555

10192

10829

11467

12104

12741

13378

14015

14652

15289

15926

16563

17200

17837

18474

19111

19748

20385

21022

21659

22296

22933

23570

24207

24845

25482

26119

26756

27393

28030

28667

29304

29941

30578

31215

31852

32489

33126

33763

34400

35037

35674

36311

36948

37585

38223

38860

39497

40134

40771

41408

42045

42682

43319

43956

44593

14

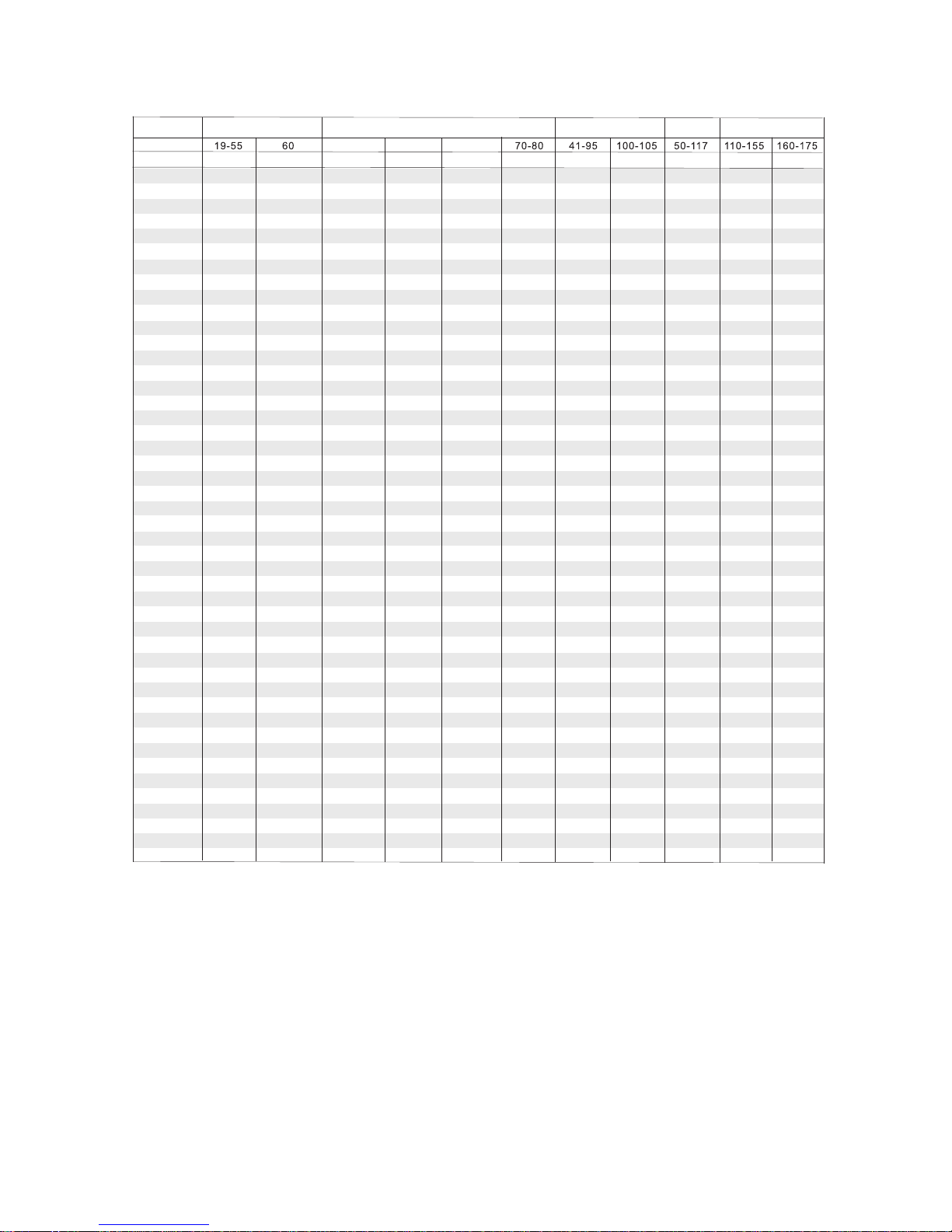

XLCT SERIES HYDRAULIC TORQUE WRENCH PRESSURE-TORQUE CHART

FORM 4

Model

Bolt Siz e Ran ge

34-36

41

46-65

ft.lbs

psi

ft.lbs ft.lbs

ft.lbsft.lbs ft. lbs ft.lbsft.lbs ft.lbs

ft.lbsft. lbs

2XLCT

4XLCT

8XLCT

14XLCT

30XLCT

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

4400

4600

4800

5000

5200

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

7400

7600

7800

8000

8200

8400

8600

8800

9000

9200

9400

9600

9800

10000

169

203

237

270

304

338

372

406

440

473

507

541

575

609

642

676

710

744

778

812

845

879

913

947

981

1015

1048

1082

1116

1150

1184

1217

1251

1285

1319

1353

1387

1420

1454

1488

1522

1556

1589

1623

1657

1691

1017

1052

1087

1122

1157

1192

1227

1262

1298

1333

1368

1403

1438

1473

1508

1543

1578

1613

1648

1683

1719

1754

175

210

245

280

315

350

385

421

456

491

526

561

596

631

666

701

736

771

806

842

877

912

947

982

426

511

596

681

766

852

937

1022

1107

1192

1277

1362

1447

1533

1618

1703

1788

1873

426

511

596

681

766

852

937

1022

1107

1192

1277

1362

1447

1533

1618

1703

1788

1873

1958

2043

2128

2214

2299

2384

2469

2554

2639

2724

2809

2894

2980

3065

3150

3235

3320

3405

3490

3575

3661

426

511

596

681

766

852

937

1022

1107

1192

1277

1362

1447

1533

1618

1703

1788

1873

1958

2043

2128

2214

2299

2384

2469

2554

2639

2724

2809

2894

2980

3065

3150

3235

3320

3405

3490

3575

3661

3746

3831

3916

4001

4086

4171

4256

470

564

658

752

846

940

1034

1128

1222

1317

1411

1505

1599

1693

1787

1881

1975

2069

2163

2257

2351

2445

2539

2633

2727

2822

2916

3010

3104

3198

3292

3386

3480

3574

3668

3762

3856

3950

4044

4138

4232

4326

4421

4515

4609

4703

795

954

1113

1272

1431

1590

1749

1908

2067

2226

2385

2544

2703

2861

3020

3179

3338

3497

3656

3815

3974

4133

4292

4451

4610

4769

4928

5087

5246

5405

5564

5723

5882

6041

6200

6359

6518

6677

6835

6994

7153

7312

7471

7630

7789

7948

855

1026

1197

1368

1539

1710

1881

2052

2223

2395

2566

2737

2908

3079

3250

3421

3592

3763

3934

4105

4276

4447

4618

4789

4960

5132

5303

5474

5645

5816

5987

6158

6329

6500

6671

6842

7013

7184

7355

7526

7697

7868

8040

8211

8382

8553

1346

1615

1884

2153

2422

2692

2961

3230

3499

3768

4037

4306

4575

4844

5113

5383

5652

5921

6190

6459

6728

6997

7266

7535

7804

8074

8343

8612

8881

9150

9419

9688

9957

10226

10495

10765

11034

11303

11572

11841

12110

12379

12648

12917

13186

13456

3043

3652

4260

4869

5477

6086

6694

7303

7911

8520

9128

9737

10345

10954

11562

12171

12779

13388

13996

14605

15213

15822

16430

17039

17647

18256

18865

19473

20082

20690

21299

21907

22516

23124

23733

24341

24950

25558

26167

26775

27384

27992

28601

29209

29818

30426

3240

3888

4536

5184

5832

6480

7127

7775

8423

9071

9719

10367

11015

11663

12311

12959

13606

14254

14902

15550

16198

16846

17494

18142

18790

19438

20085

20733

21381

22029

22677

23325

23973

24621

25269

25917

26564

27212

27860

28508

29156

29804

30452

31100

31748

32396

15

1MXTA、 3 、5 、8 10 20 25 35 SERIESMXTA MXTA MXTA、 MXTA、 MXTA、 MXTA、 MXTA

INSTRUC TION:

3. #1 Body asse mbly and 5-1# pist on assembly are no t detachable parts.

2. Quick coup ler C1 assembly an d C2 assembly are optional pa rts, own interch ange ability.

MXTA SERIES DRAWING AND PARTS LIST

1. Swivel B1 an d B2 are optional pa rts, own interch ange ability.

Loading...

Loading...