Page 1

UltraMicroPump II

UMP2 Microsyringe Injector and Micro4 Controller

INSTRUCTION MANUAL

Serial No._____________________

071807

World Precision Instruments, Inc.

Page 2

UltraMicroPump II

Contents

Introduction ...................................................................................... 1

Parts List ............................................................................................ 2

Set-up and Operation ........................................................................ 2

Setting Parameters ............................................................................ 6

UltraMicroPump II Operation ........................................................... 13

Defining Other Syringes .................................................................. 14

Computer Control ............................................................................ 18

General Maintenance ...................................................................... 25

Troubleshooting ............................................................................... 25

Specifications .................................................................................. 22

Syringes ........................................................................................... 23

Accessories, Replacement Parts .................................................... 24

References ...................................................................................... 27

Appendix: Nanoliter 2000 / Micro4 Volume Settings ....................... 28

Warranty .......................................................................................... 28

Copyright © 2006 by World Precision Instruments, Inc. All rights reserved. No part of this publication

may be reproduced or translated into any language, in any form, without prior written permission of

World Precision Instruments, Inc.

WORLD PRECISION INSTRUMENTS

31

Page 3

UltraMicroPump II

Introduction

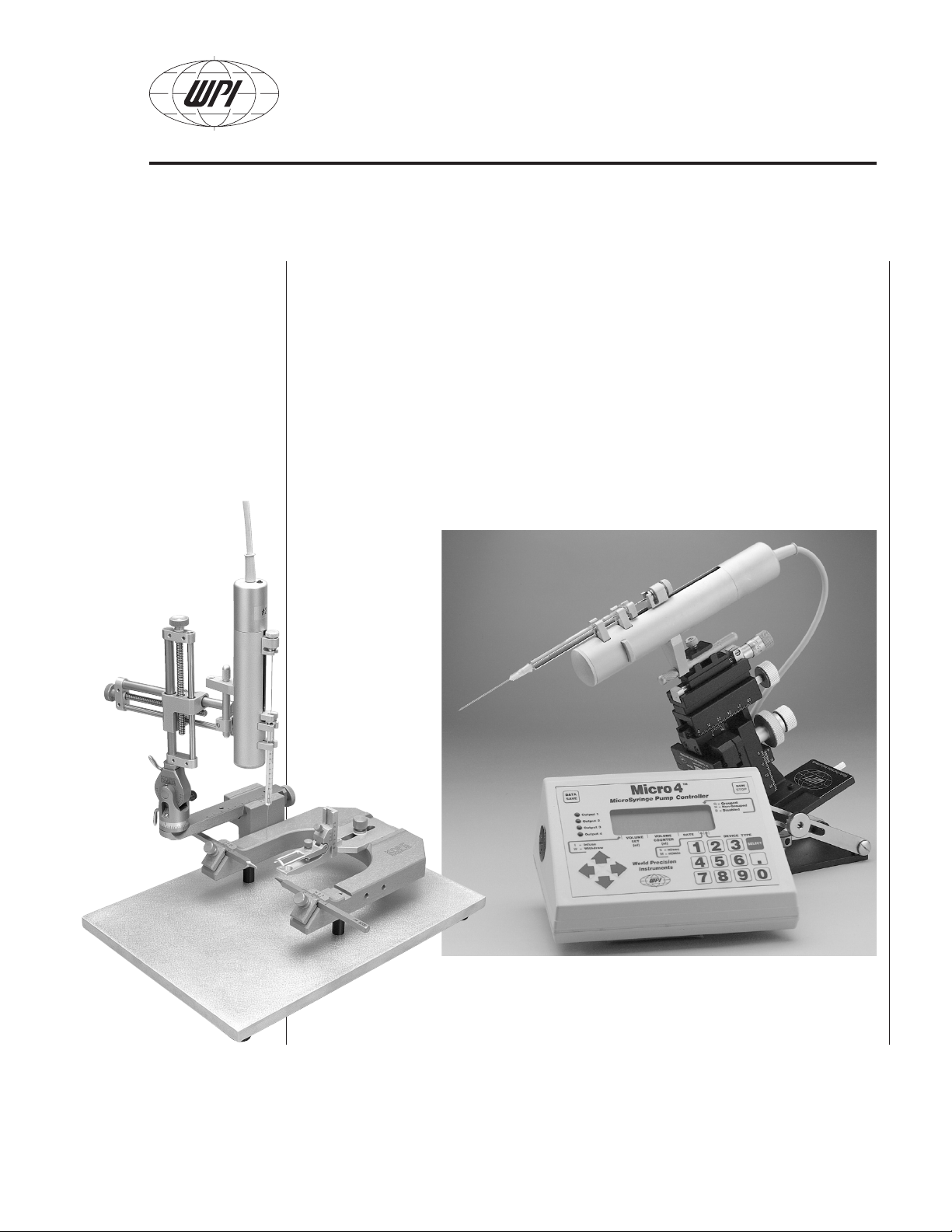

Thank you for purchasing WPI's UltraMicroPump II (UMP2) and the

microprocessor controller, Micro4™ (UMC4). This versatile injector uses

microsyringes to dispense nanoliter sample volumes. Microsyringes are easily

installed by placing the syringe barrel into the UltraMicroPump’s clamps.

UltraMicroPump accepts syringes from 0.5 µL to 250 µL.

UltraMicroPump can be useful for a wide range of applications including

intracellular injection, micro delivery of biochemical agents or dyes, cell

separation, in vitro fertilization, and can be mounted directly onto a stereotaxic

frame or micromanipulator.

WORLD PRECISION INSTRUMENTS

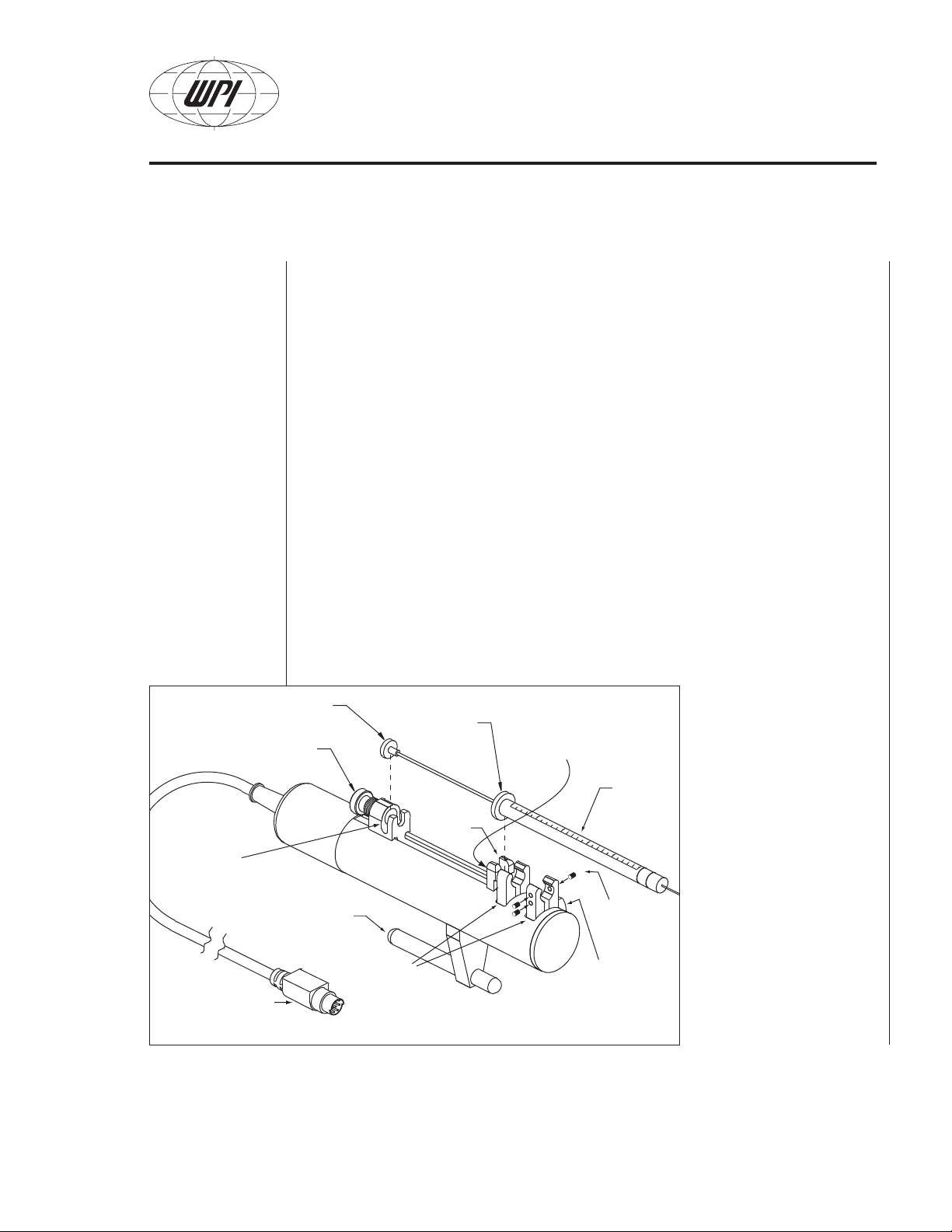

Fig. 1 — UltraMicroPump II and Micro4 controller. The pump above

is mounted on WPI’s M3301 micromanipulator and TB-1 stand (not

included); and syringe with luer µTip (not included). At left, pump is

shown with TAXIC900 stereotaxic frame (not included).

1

Page 4

UltraMicroPump II

Operating parameters for the UltraMicroPump are set with the Micro4. Up to four

pumps may be independently controlled. Operating parameters set by the user are

stored in “non-volatile” memory for instant recall when the unit is powered on.

An optional footswitch can be plugged into an RS232 port on the rear of the

controller for “hands free” start / stop operation. The same port may also be used to

connect the controller to a computer or to some other device for TTL triggering.

Parts List

After unpacking, make certain that there is no visible damage to the instrument.

Check to see that all items are included:

UMP2 UltraMicroPump II

UMC4 Micro4™ Controller, 4-Channel

40300 12-volt Power Supply

Power Cable

Allen key

Instruction Manual

For a list of microsyringes available from WPI, see page 23.

Set-up and Operation

These instructions will help you put the UltraMicroPump to immediate use. We

recommend that you read the entire manual and familiarize yourself with the

various operating procedures of the UltraMicroPump and Micro4.

Mounting the syringe

Syringes may be filled manually before mounting in the UltraMicroPump or filled by

using the fast reverse function (see page 13). Place the plunger button of the filled

syringe into the plunger button holder (leaving the plunger retaining screw loose)

while also placing the syringe collar into the collar stop (see Fig. 2). Take care not

to damage the syringe collar during this installation. Gently tighten the plunger

retaining screw so that the plunger button will not move independently when the

pump is activated (this allows for zero volume error during pump operation).

WORLD PRECISION INSTRUMENTS

2

Page 5

UltraMicroPump II

MOUNTING BAR

COLLAR

STOP

SYRINGE

COLLAR

SET SCREW

(not visible in this view)

PLUNGER

RETAINING

SCREW

PLUNGER BUTTON

PLUNGER

BUTTON

HOLDER

CABLE CONNECTS

TO REAR PANEL OF

MICRO4 CONTROLLER

SYRINGE

CLAMPS

CLAMP

RELEASE

SET

SCREWS

SYRINGE

1

2

3

Axial Needle Alignment

In order to maintain a good syringe needle alignment particularly along the same

axis of the supporting bar, rotate the syringe body while placing in the two clamps

to allow the syringe to seat properly and align along the body of the pump for

minimal slant offset. If the clamp which holds the syringe collar (see “collar stop”

in the drawing below) is too tight or too loose, syringe needle alignment may be off

because of stress.

If the collar stop is too tight to allow the syringe collar to insert easily, then follow

these instructions:

Immediately below and behind the collar stop, in the groove where the long drive

screw is, there is a small Phillips head screw, attached to the collar stop. Loosen

this screw to slightly (about 0.5 to 1 mm) to allow for a thicker collar (see Fig 2).

You may have to grasp the collar stop and wiggle it backwards to move it. Once

the stop is backed out; check and adjust for a tight fit so the syringe body doesn’t

move when placed into the holder. Gently re-tighten the screw in the new position.

Fig. 2 — Initial syringe clamp adjustment — Secure syringe by sequentially

adjusting set screws with supplied Allen key: 1 for horizontal alignment, 2 for

vertical alignment, and 3 to eliminate play.

Note: you may have to retract the plunger button holder to get access to the setscrew.

Mount the pump

The UltraMicroPump can

be mounted directly onto

a stereotaxic frame or a

micromanipulator, using

the mounting bar (see

Fig. 2). The mounting bar

may be unscrewed and

modified by the user, if

necessary.

WORLD PRECISION INSTRUMENTS

3

Page 6

UltraMicroPump II

SWITCH

FOOT

RS232/

+12VDC IN

4

32

POWER ON

1

OFF

OUTPUT

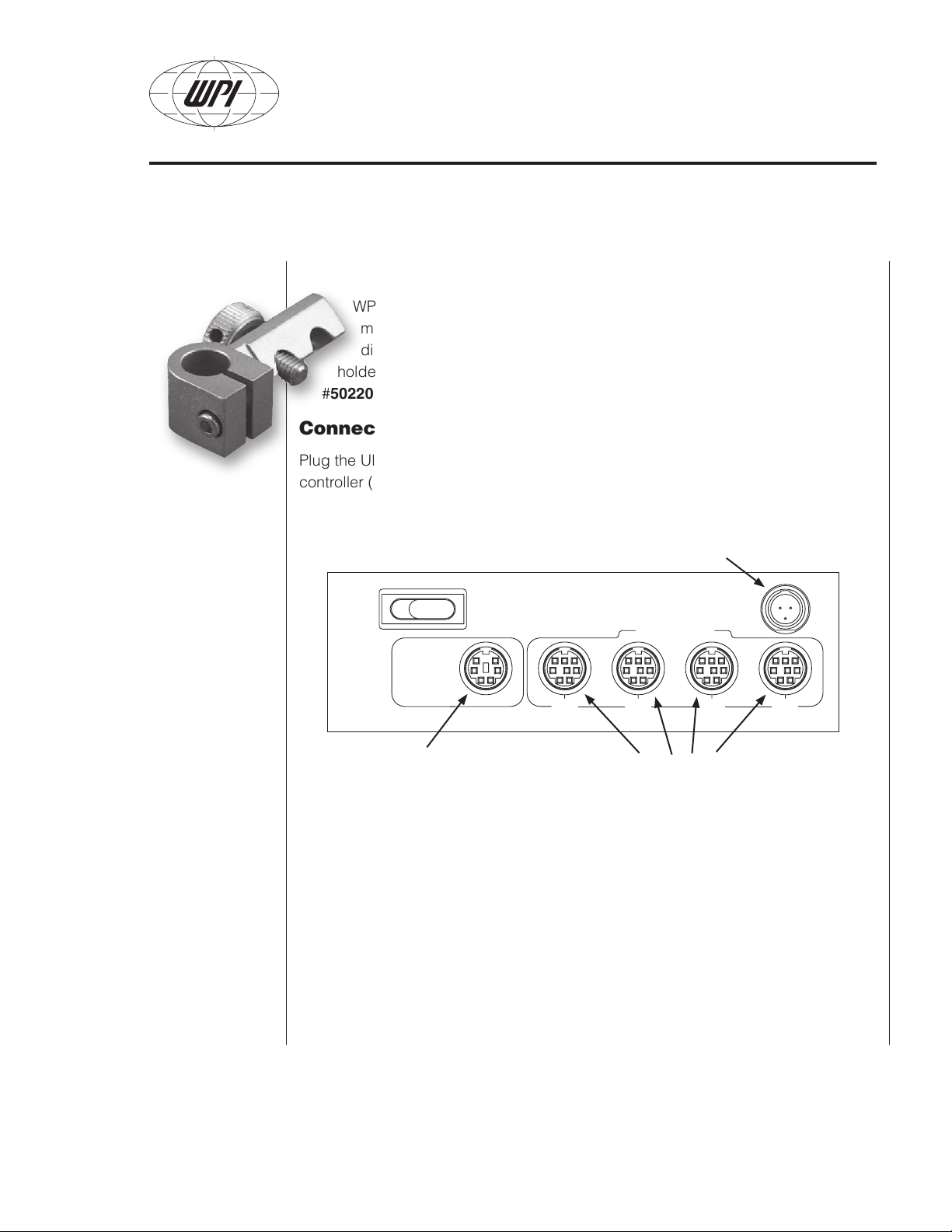

Mounting to Stereotaxic Frames

WPI’s UMP2 fits directly into most standard stereotaxic frames. The UMP2

mounting bar diameter is 7.90 mm (0.311 in.). For example, UMP2 fits

directly into Kopf Standard 900 series frames (in place of 1770 electrode

holder). Stoelting #51681 V-clamp adaptor / probe holder attachment (WPI

#502201, at left) required for use with Stoelting frames.

Connect the controller

Plug the UltraMicroPump cable into an output socket on the back of the Micro4

controller (see Fig. 3). Up to four pumps may be connected and independently

controlled.

Plug in the 12-volt power

supply.

Fig. 3 — Micro4

rear panel

Footswitch or RS232 cable from

computer plugs into this port.

Plug in the 12-volt power supply and power up

Plug the 12-volt power supply into the rear panel of the Micro4 (see Fig. 3). The

switchable power supply included with this unit automatically senses input line

voltage between 100 and 240 V and converts it to 12 V. Connect the power cord

to the power supply and plug it into an electrical outlet. The power switch is also

located on the rear panel of the Micro4.

Switch the Micro4 on and check that the LCD screen is illuminated.

The hardware setup is now complete. Before operating the UltraMicroPump you

must enter the parameters into the Micro4 controller.

WORLD PRECISION INSTRUMENTS

Connect up to four

UltraMicroPumps.

4

Page 7

UltraMicroPump II

Choosing a Syringe

The syringe should be chosen to inject no less than 5% of the volume of any given

syringe.

Example: A 100 µL syringe may be used for injections on the UMPII to volumes of

5 µL (5000 nL) and higher with high precision and repeatability. Expecting this 100

µL syringe to inject lower than 1 µL may be difficult if the syringe is not calibrated

specifically on the pump. The overall accuracy of the syringe itself is usually no

greater than +/-3% and the syringe internal diameter may deviate from location to

location along the length of the syringe interior.

Choosing the correct syringe for an injection is a very important consideration,

due to accumulated errors of the syringe and the pumping method. For a 1000 nL

injection from a 10 µL (10,000 nL) syringe, the user is asking for a 1/10th the

syringe’s volume value to be injected. Theoretically, based on mathematics without

any consideration to surface tension, heat, pressure, compressibility, silanization,

or air bubbles, the 3% error rate should yield a ± 300 nL variance.

As a rule of thumb, the choice of the syringe should not exceed 1/10th to 1/20th the

stated full volume of the syringe. The Micro4-UMP2 system uses a stepper motor

to move the syringe piston forward to inject the volume. A consideration should

also be made to allow the motor to step forward a good number of steps to prevent

errors in volume injecting.

Example: In the 10 µL case above, a 1-step movement of the motor will inject

a volume of 0.5276 nL. For two steps to occur, a volume of 1.055 nL will be

injected. This may or may not be acceptable as the total error may exceed 1

nL or nearly 0.1%. Also note that two steps is probably not enough resolution to

accurately control the volume; another rule of thumb would be to step no less than

10-100 steps for the entire single injection. Using this 10-step rule, the minimum

acceptable injectable volume from this 10 µL (10,000 nL) syringe would be

0.527.6 nL × 10 or 5.276 nL. Other syringes will give other results, due to the inside

diameter and the volume per step.

WORLD PRECISION INSTRUMENTS

5

Page 8

UltraMicroPump II

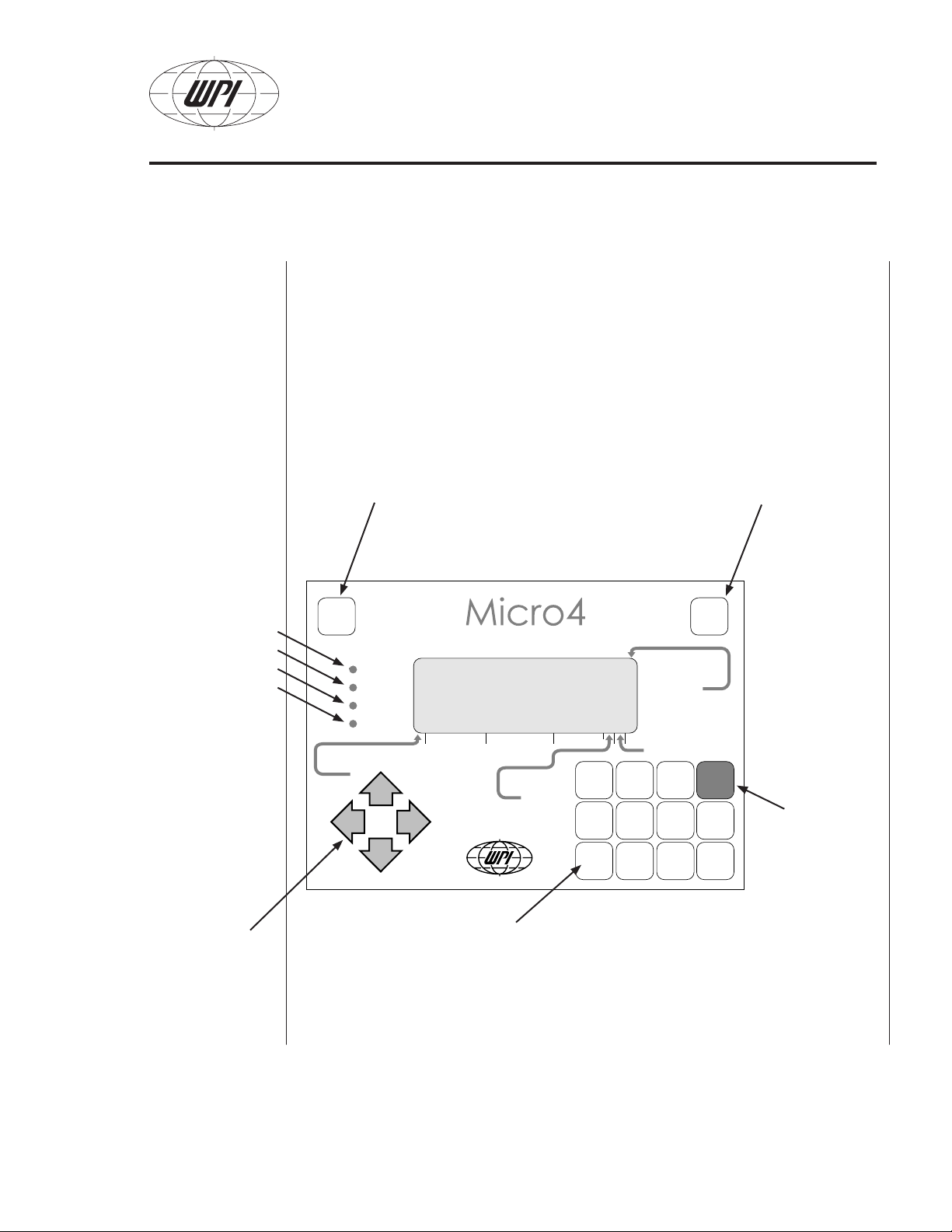

G = Grouped

N = Non-grouped

D = Disabled

World Precision

Instruments

MicroSyringe Pump Controller

Output 1

Output 2

Output 3

Output 4

VOLUME

SET

(nl)

VOLUME

COUNTER

(nl)

RATE

DEVICE TYPE

123

456

789.0

SELECT

DATA

SAVE

RUN

STOP

I=Infuse

W=Withdraw

TM

S=nl/sec

M=nl/min

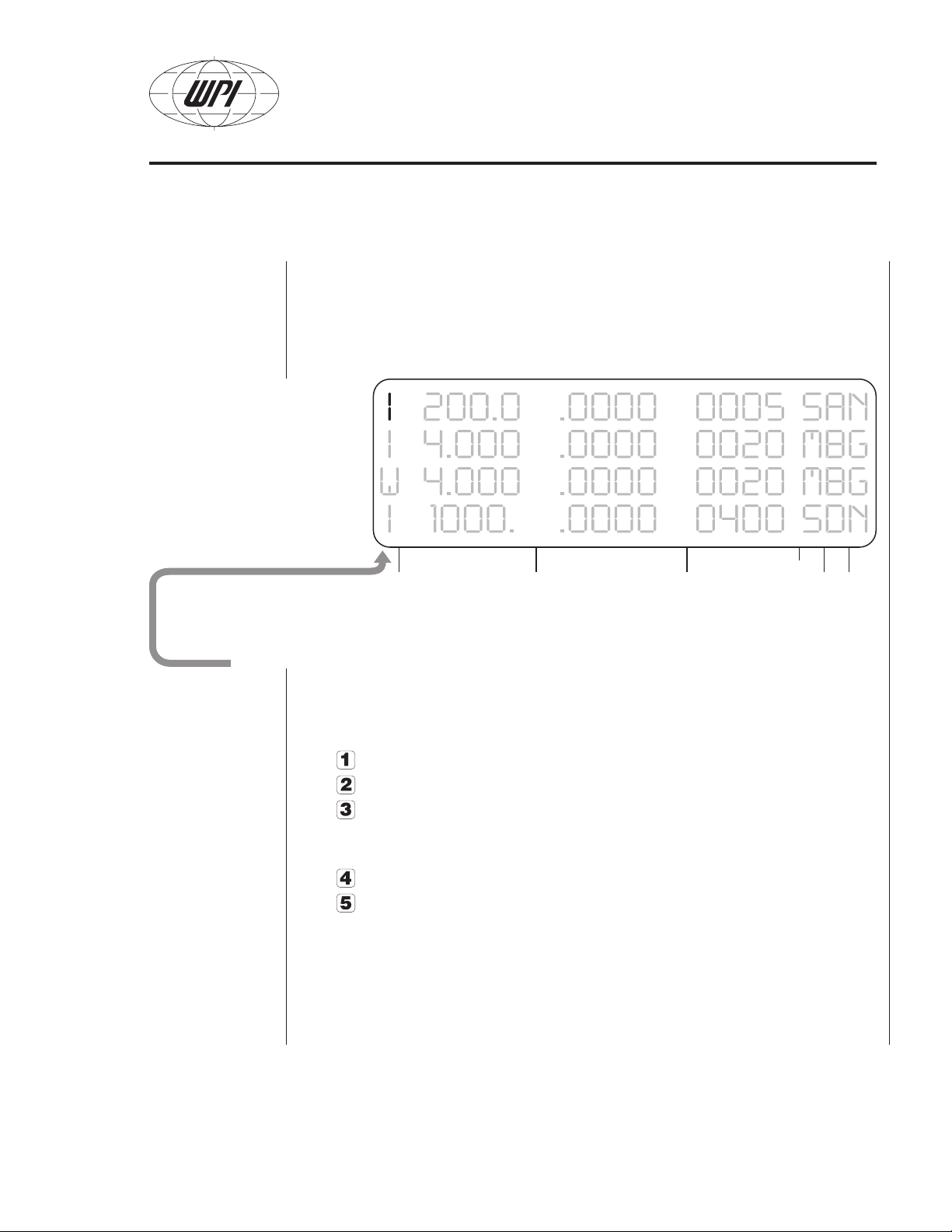

Setting Parameters

Parameters are entered using the membrane keys on the front panel of the Micro4.

The l e f t and r i g h t a r r o w keys move the cursor on the LCD display to the desired

position. The u p and d o w n a r r o w keys select the channel (corresponding to the

output channels on the rear of the instrument). The n u m b e r keys and the s e l e c t

key are used to change parameters.

Fig. 4 — Micro4

front panel

Lights: When a

pump is running,

the corresponding light is on. For

example, the light

next to output 1 will

be on when pump

one is operating.

Arrow keys:

Move the cursor

around the display.

WORLD PRECISION INSTRUMENTS

Data Save: Saves all parameters on LCD display

to memory. Next time the Ultra Microsyringe Pump

controller is turned on, the last paramaters saved will

be displayed.

Numeric keypad: Use these keys to

enter settings for infusion and withdrawal

rates and volumes.

Run/Stop: Starts

and stops the

pump(s).

Select: Toggles

the selected

parameters: Infuse/

Withdraw, Syringe

Size, Rate Units

(nL/sec or nL/min),

and mode (Grouped,

Non-grouped and

Disabled).

6

Page 9

UltraMicroPump II

I = Infuse

W = Withdraw

# = Option

Setting Infuse/Withdraw

The character displayed in the first field indicates the operating mode — I for

Infuse, W for Withdraw. To change modes, use the a r r o w k e y s to position the

cursor in this field, then press s e l e c t .

In addition, the options below may be enabled or disabled when the cursor is in

the Infuse/Withdraw field: position the cursor in the Infuse/Withdraw field and press

the corresponding option number.

Disables audible tone.

Enables audible tone.

Changes the action of r u n /s t o p key or footswitch. When this option is

enabled the pump will operate as long as the r u n /s t o p key or footswitch is

pressed and stop when the r u n /s t o p key or footswitch is released.

Returns r u n /s t o p key or footswitch to normal operation.

Sets Volume per Step for syringe types not already preset in the Micro4’s

memory (see page 14).

WORLD PRECISION INSTRUMENTS

7

Page 10

UltraMicroPump II

VOLUME

SET

(nL)

VOLUME

COUNTER

(nL)

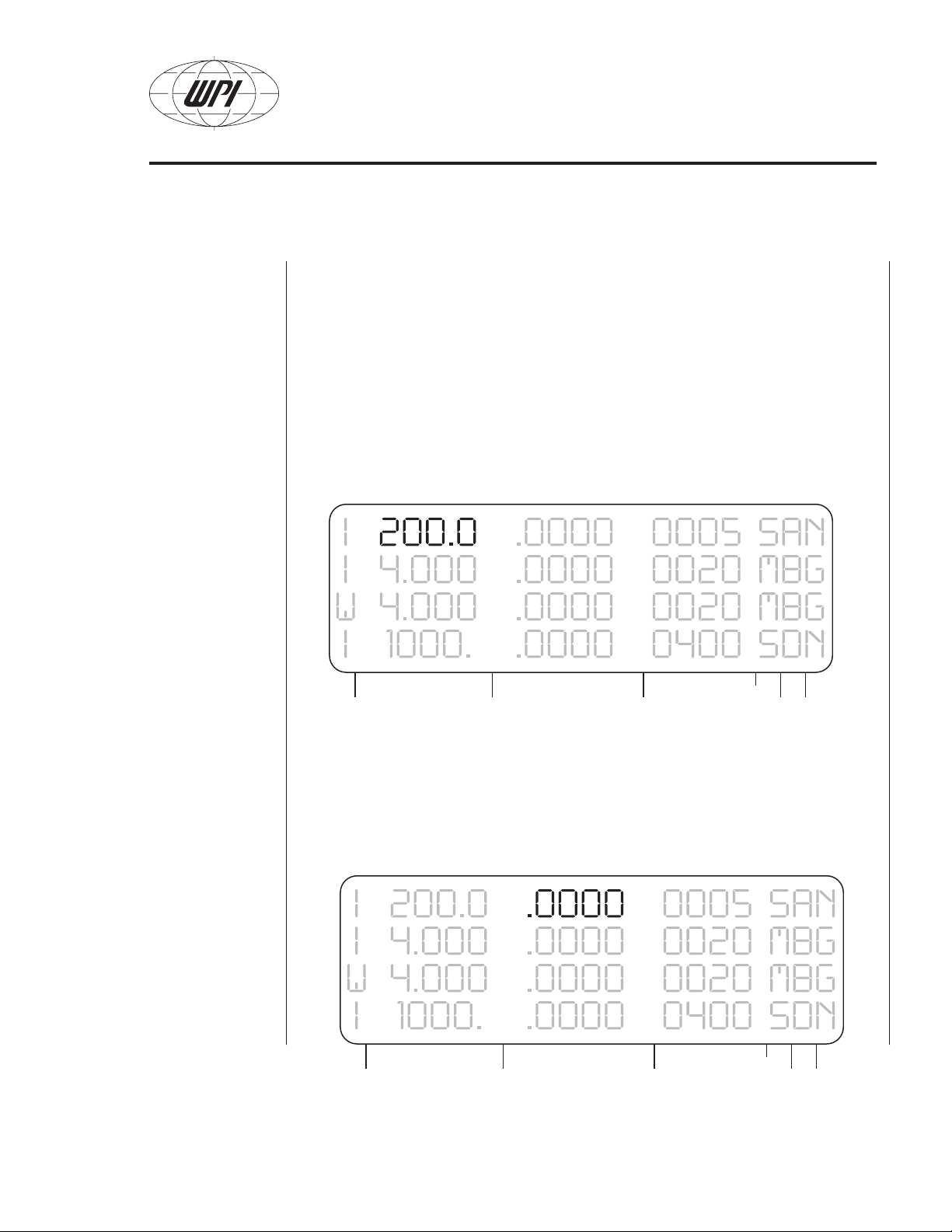

Volume Set

To select the desired volume to be infused or withdrawn, position the cursor in

the volume set field and enter the numbers with the numeric keypad. The values

shown on the LCD display are in nanoliters. (Note: For 10 µL enter “10000”; for

1.0 µL enter “1000.”—including decimal point.)

Syringe Injection Accuracy: Since every syringe in the microliter volume range

has its own unique intricacies, you should verify and calibrate each syringe and log

its characteristics for accurate injections. The Micro4 controller has preset types

of syringes to very accurately move the plunger button of the syringe a precise

distance per injection.

Volume Counter

Real-time display of volume being delivered. When pump is not running, this

number may be changed; when pump is restarted, counter will continue from the

number entered.

WORLD PRECISION INSTRUMENTS

8

Page 11

UltraMicroPump II

RATE

Injections beyond 99,999 nL (5 digits in the volume field)

Example: You want to inject 150,000 nL from a 500 µL liquid tight syringe, but the

volume counter can not accept 150,000 as a number.

1. Take the value 150000 / 500000 = 0.3 or 30% of the syringe volume.

2. Use a syringe TYPE that can accommodate a proportionally reduced number

of the same injection percentage (in this case 50%).

3. Using TYPE H, a 250 µL syringe as the choice a 75,000 nL injection is

equivalent to a 150,000 nL injection in a 500 µL syringe.

4. Multiply times 60 mm for the actual distance travel 0.3 × 60 = 18 mm (60 mm is

the full volume stroke of the syringe).

5. Check: 75,000 / 250,000 = 0.3; 0.3 × 60 mm = 18 mm.

6. Any combination of syringe types and volume choices can be used to displace

a particular length, as long as the volume is noted and the injection speed

does not exceed the rated value nearest that syringe volume. See syringe

tables, page 11.

Rate setting / unit time

To select the rate for infusion or withdrawal, position the cursor in this field and type

in the desired value with the numeric keypad. If the rate entered is too large for

the selected syringe type, the highest possible value will be displayed in this field.

Next, select the rate units.

WORLD PRECISION INSTRUMENTS

9

Page 12

UltraMicroPump II

S = nl/sec

M = nl/min

DEVICE TYPE

Rate Units

Two rate units are available — nanoliters per second and nanoliters per minute.

Position the cursor in this field and use the s e l e c t key to choose either S (nL/sec)

or M (nL/min).

Device (syringe) Type

The volume per step and rate data for eleven microsyringes are already stored in

Micro4’s memory. To specify one of these syringes, position the cursor in this field

and use the s e l e c t key to change the syringe type to a letter (A - L) corresponding to that of the syringe in the table below.

WORLD PRECISION INSTRUMENTS

10

Page 13

UltraMicroPump II

Type

A

B

C**

D

E

F

G

H

I

J

K

L

M

**

Syringe Volume

(Defined for this length)

0.5 µL (54.1 mm)

1.0 µL (54.1 mm)

5 µL (54.1 mm)

10 µL (54.1 mm)

25 µL (60.0 mm) 0.73 1.329 1022

50 µL (60.0 mm) 1.03 2.646 2035

100 µL (60.0 mm) 1.46 5.315 4088

250 µL* (60.0 mm) 2.3 13.191 9999

500 µL* (60.0 mm) 3.26 26.501 9999

1000 µL* (60.0 mm) 4.61 52.995 9999

Nanoliter 2000

10 µL (60 mm) 0.4607 (0.100 Rev H) 0.5293 (0.0249 Rev H) 170

User Defined See page 12

ILS005 (27 mm) 0.4856

†

†

†

†

† †

* Gas-tight syringes are not recommended for UMPII in these volumes; instead, use a liquid-tight

syringe to prevent drive motor damage.

** The ILS005 5 µL syringe must use type M with a 0.5880 nL / step entry. See page 15 for details.

† These are defined as 60 mm in Rev. H firmware.

† † WPI’s Nanoliter 2000, a nanoliter injector for the 2-70 nL range, comes with its own simple controller

but may also be driven by the Micro4. For more information, enquire about WPI # B203XVY.

0.1085 (0.102 REV H) 0.0294 ( 0.026 Rev H) 20

0.1534 (0.145 REVH) 0.0587 (0.052Rev H) 40

0.343 (0.325 REV H) 0.2934 (0.263 Rev H) 202

0.485 (0.46 REV H) 0.5868 (0.528 Rev H) 406

0.48 plunger in 0.50 glass 2.3 nL /step (0.0005” step) 884

ID (mm) nL / step REV J

0.5880 compensates for length as

TYPE M

Max. Rate

nL /sec or

nL /min

Note On Syringe Stroke Length

The delivery of the UMPII is based on 60 mm or 54.1 mm syringes. Please note

which syringe length you are using as a factor of 0.9016 may need to be applied to

Maker Syringe

Hamilton 1700 Series ,10 µL 60 mm

Hamilton 700 Series,10 µL 54.1 mm

SGE 0.5 µL – 10 µL 54.1 mm

ILS 5 µL Luer tip ILS005 28 mm

SGE 25 µL – 500 µL 60 mm

WPI FlexiFil™ 54.1 mm

WPI NanoFil™ 60 mm

WORLD PRECISION INSTRUMENTS

Stroke

Length

Use TYPE

L

D

A,B,C,D

M

E - L

D

L

the volume to be injected in order to have a precise injection.

For the ILS005, use the TYPE

“M” values in the above table.

*Manufacturers have the right to

change this specification at any time.

11

Page 14

UltraMicroPump II

G = Grouped

N = Non-grouped

D = Disabled

(blank)

Grouped/Non-grouped/Disabled

For convenience in operating multiple pumps (whether of identical or various volumes), pumps may be grouped or non-grouped. Pressing the s e l e c t key while the

cursor is in this field will toggle through three operating modes:

Grouped mode: Syringe channels with “G” in this field are started or

stopped when the r u n /s t o p key is pressed while the cursor is located on any

grouped channel.

Non-grouped mode: When the cursor is positioned on a channel that is

not grouped, indicated by the letter “N”, only that channel will start or stop

when the r u n /s t o p key is pressed.

Disabled mode: When a channel is disabled, the line of data is hidden and

the pump will not operate. No changes may be made to this channel while

it is disabled. To re-enable it, move the cursor back to the Group/Nongroup

field and press the s e l e c t key; the previously entered data will be restored.

Saving your settings

Pressing the button will store these values into the controller’s memory for

future use.

WORLD PRECISION INSTRUMENTS

12

Page 15

UltraMicroPump II

UltraMicroPump II Operation

When the pump runs, a series of beeps indicates that the pump is running. At

the end of the program, the controller also beeps. A lamp on the back of the

UltraMicroPump indicates a signal from the controller. As the pump runs, the

counter increments as an indication of the plunger’s motion. Multiple injections can

be achieved by pressing the r u n /s t o p button again after the pump has stopped.

Fast forward

Press and hold the r i g h t a r r o w key then press r u n /s t o p . The syringe

pump will continue running as long as these two keys are depressed or until the

set volume is reached.

Fast reverse

Press and hold the l e f t a r r o w key then press r u n /s t o p . The syringe

pump will continue running as long as these two keys are depressed or until the

set volume is reached..

WORLD PRECISION INSTRUMENTS

13

Page 16

Calculate in Microsoft

Excel — just enter

these formulae into

a spreadsheet,

replacing Volume,

Length, and ID

from your own

measurements.

UltraMicroPump II

Defining Other Syringes

Eleven microsyringes with volumes ranging from 0.5 µL to 1000 µL are already

preset in the Micro4 (syringe types A through L — see table on page 11). A microsyringe with a volume other than those preset may be entered as device type

M. However, the Volume per Step of the type M syringe must be defined for the

Micro4. NOTE: There is only one memory location to define a Type M value for all

four pumps.

First, calculate the Volume per Step using the formula below. Syringe displacement is the distance between 0 and the maximum volume marked on the syringe in

inches. Syringe volume is in nanoliters. ID is in millimeters.

Syringe of known ID

Volume per Step = (ID/2) x (ID/2) x 3.1415926 x 1000 x 0.003175

Syringe of unknown ID

The Inside Diameter (ID) of a syringe can be determined by this formula:

ID = SQRT(Volume/(3.14159 x Length)) x 2

where length is the visible marking on the syringe body (total length in mm) and

Volume is the full volume of the syringe in microliters.

For example, if you have a 60 mm syringe with a

2.5 µL volume, use the formula above to determine

its Volume per Step. Move the cursor to the Volume

Set field of output channel 1 and enter the calculated

value (in this case, 0.1323 nL):

Then use the l e f t a r r o w key to scroll the cursor to the

first position on the LCD display and press . This sets your calculated definition

for your type M syringe into the Micro4’s memory.

WORLD PRECISION INSTRUMENTS

14

Page 17

UltraMicroPump II

Note that this does not yet affect the action of any channel since M has not been

selected as the device type for any channel. Before proceeding, move the cursor back to the Volume Set field and re-enter the correct volume for the syringe on

output channel 1 (which may be any type — not necessarily type M).

Special Syringe Considerations ILS005

The UMPII-Micro4 was designed around 60 mm or 54.1mm syringes. The full

injection of a 5 µL syringe is expected to be a 60 mm movement. In the case of this

ILS special 5 µL glass luer tip syringe this length is 27 mm for an injection of 5 µL.

There are two solutions:

Solution 1. Using Type “C” (the 54.1 mm 5 µL syringe), Multiply the volume

to be injected by 27/54.1 or (0.4990).

Example. A 2500 nL injection using type C should be entered into the micro4

as 2500 × 0.4990 or 1247.5 nL. this value can be further calibrated see page

17 for details.

Solution 2. Using Type M, divide the Type C nL/step number by 0.4990.

Example: The standard 54.1 mm syringe has a value of 0.2934 nL/step on

a 5 µL syringe. The ILS005 has a 27mm stroke for this same full volume.

0.2934 / 0.4990 = 0.5880 is the nL / step value to enter following the Type

M instructions on this page. (0.5880 is also verified by the formulas on the

previous page.)

After defining your syringe in Micro4’s memory, move the cursor to the Device Type

field of the output channel to which that pump is connected and press s e l e c t until

M appears.

Any number of channels may use type M syringes, but

since a single definition for type M is stored in Micro4 all

M devices must be identical. (That is, you cannot use

two non-standard types, such as 2.5 µL and 0.25 µL.)

The minimum delivered volume depends on the syringe

size and is listed in the syringe type table under Volume

per Step. The actual volume delivered is divisible by the volume per step. For

example, using a syringe with a Volume per Step of 1 nL, actual delivered volume

for the given set volume is listed below.

WORLD PRECISION INSTRUMENTS

15

Page 18

UltraMicroPump II

Volume Set Actual volume delivered

0-0.9999 nL 0

1 nL-1.999 nL 1 nL

2 nL-2.999 nL 2 nL

and so on...

Using Teflon Tipped syringes

Carefully remove the plunger and its Teflon tip by drawing it out of the syringe

barrel.

1. Before inserting the plunger tip into the syringe, pre-wet the Teflon plunger tip

and the syringe body interior with water.

2. Use care in inserting the plunger into the syringe as the plunger rod may be

easily bent.

3. Carefully place the plunger tip into the syringe and gently work the tip down

into the body of the syringe using a thumb and forefinger to grasp and push

small lengths of the plunger rod into the syringe. Repeat this procedure until the

plunger tip is near the zero mark of the syringe.

4. Draw additional water into the syringe and slowly work the plunger up and down

until the plunger tip is cold formed into the syringe and the stiffness goes away.

The stiffness of the new plunger tip may require you to move the rod in small

increments until the tip is formed enough to actuate by the rods full length.

Wet Autoclaving Syringes

Typically the answer to autoclaving any Teflon syringe is no, since the adhesives

and the Teflon seal will eventually breakdown or swell from the heat and pressures

involved. The most practical method of sterilizing is either gas or liquid chemical

sterilization, but both require meticulous removal of the sterilizing agents prior to use.

If you are willing to replace the syringe after a few uses then most syringes will

stand up to a few cycles of wet autoclaving. The Teflon tipped plunger should be

removed for this operation. Careful examination of any glued components and the

Teflon tip integrity is required before reuse of an autoclaved syringe. If the Teflon tip

cannot be replaced into the syringe body easily then the plunger (tip) and perhaps

the syringe requires replacement due to infusion of water. Autoclaving will usually

void the warranty on Teflon tipped syringes.

WORLD PRECISION INSTRUMENTS

16

Page 19

UltraMicroPump II

Calibration

Every syringe should be calibrated on the pump that it is being used with.

This gives the user two things, verification of the error involved in the injection and

the confidence that injection is correct. Micro volume syringes are rated at 1% to

3% of the full-scale volume. So for a 10 µL syringe injecting 10 µL there will be a

maximum error of ± 0.3 µL if the injection takes place along the markings on the

syringe barrel. When used in a specialized syringe pump like the UMPII, this same

syringe is now defined by a fixed length and moved by a precision stepper motor.

This can offer a very high degree of precision and repeatability. This same 3% error

10 µL syringe can now be calibrated to deliver a reduced error of ± 0.5% tolerance

or better.

Two methods of calibration

Calculate in Microsoft

Excel — just enter

these formulae into

a spreadsheet,

replacing Volume,

Length, and ID

from your own

measurements.

Volumetric diameter measurement

Using a microscope and a calibrated reticle or stage micrometer, inject an

amount of water into a hydrated oil droplet, measure the sphere and use

Volume = ((Diam/2) × (Diam/2) × (Diam/2) × 3.1415926 × (4/3) × 1000))

to determine the volume in nanoliters. (Diameter in mm.)

Analytical Balance

Use an analytical balance to weigh the mass of the injected volume. (Pure

water is 1 gm = 1 mL at 4 degrees C.) Tables for other temperatures are

easily obtained.

Calibration on the Pump

Method 1: Multiply the ratio of the injected volume by the actual volume and

adjust the volume injected accordingly.

Method 2 : Use the TYPE M syringe and enter the new nl/sec number after

recalculation.

Note: It may be necessary with some syringes to verify injections at different

locations along the length of the syringe barrel as there can be variations along the

inside length of the glass barrel.

WORLD PRECISION INSTRUMENTS

17

Page 20

UltraMicroPump II

Computer Control

RS232 commands are used to control the Micro4 via the serial port of a PC or

Macintosh computer.

RS232 Commands

All commands are case sensitive. The settings for the RS232 port are baud rate

9600, 8 data bits, 1 start bit, 1 stop bit. Microsoft HyperTerminal setting: Flow control must be set to NONE.

Numbers and decimal points are indicated below by the “#” symbol.

V######; Sets the delivered volume. Number must have a decimal point and

terminate with “;” (semicolon) — see page 19.

C######; Sets the volume counter. Number must have a decimal point and

terminate with “;” (semicolon) — see page 19.

R####; Sets the delivery rate. Number must have a decimal point and

terminate with “;” (semicolon) — see page 19.

I Infuse mode.

W Withdraw mode.

G Go — Starts the syringe pump.

H Halt — Stops the syringe pump.

S Sets the rate units to nanoliters/second.

M Sets the rate units to nanoliters/minute.

L#; Line number — sets the syringe number on display (Micro4 only).

N Not Grouped mode.

P Grouped mode.

D Disabled mode.

Tx Syringe Type. The letter indicating syringe type follows the T. For

example, to select syringe type “A” the command is “TA”.

RS232 Query Commands

All query commands begin with a question mark. Below is a list of the query

commands.

?V Returns the set volume.

?C Returns the volume counter

?R Returns the delivery rate

WORLD PRECISION INSTRUMENTS

18

Page 21

UltraMicroPump II

?M Returns a G for grouped mode, N for nongrouped mode, and D for

disabled mode.

?S Returns the letter of the syringe type.

?D Returns the syringe pump direction: I=infuse, W=Withdraw.

?U Returns the rate units: S=nL/second, M=nL/minute.

?G Returns a R if pump is running, S if pump is stopped.

TROUBLESHOOTING RS232 Commands

The correct format in relation with a specific command sent is as follows:

There is no set sequence to follow when issuing commands, but for logical

programming purposes, follow the following sequence: L1;IV100.0;C0.0;R200.0;ST

FN

Note there are no spaces, line feeds or enters (carriage returns). The CR does not

interfere.

The V, R and C parameters require a “.” (decimal point) and the character “;”

(semi-colon) to be entered.

You should immediately see a response on the UMC4 display from each entry as it

is entered.

The cursor channel indicator (the L#; command) must be on the pump channel

that is being run. If the cursor is elsewhere, then the command will not function on

other channels unless the grouping is turned on (G last column).

Format of the V volume command

The character field of V is a maximum of five numerals; a 6th character can be the

period (.) There is no requirement for a zero to the right of the decimal point. One

could enter V12345.; and see the result echo by typing ?V and getting 12345 on

the display. The channel selected will show 12345 on the UMC4 display as soon as

the “;” character is typed.

Format of the R rate command

The character field of R is a maximum of four numerals; a 5th character can be the

decimal point (.). You cannot override the maximum number for the syringe type.

Example: Type A is a 0.5 µL syringe and has a maximum rate of 20 nL/sec. Typing

in a greater number will still give you the maximum rate of 20 nL/sec.

WORLD PRECISION INSTRUMENTS

19

Page 22

UltraMicroPump II

Format of the C counter command

The character field of C is a maximum of five numerals; a 6th character can be the

decimal point (.).

This field should be entered as C0.0; to begin with as this is the counter that

determines how much more the sryinge needs to move before it stops. Note:

Resetting this field to 0; may be required in certain conditions.

The Micro4 Controller echos the follwing if issued the preceeding command

V123.4; will give 123.40

V12.34; will give 12.340

V12.; will give 12.000

C1234; = 12340

C1234.; = 1234.0

R100.0; = 0020. (TYPE A rate restriction)

R1000.; = 1000. (Using type F, 2035 maximum rate)

R1000.1; = 1000.

V120; will yield 12000. since the decimal point was not entered.

Display not showing programmed values

If the volume and the rate cannot immediately be seen on the Micro4 display, this

could be due to the Grouping being turned off; the programmed units display

comes up immediately on acceptace of the “;” transmission.

The first item to test is the line number command and see that the cursor moves to

the line and blinks.

When the final character “;” is entered then the display will change, if it does not,

then apply a hard reset. (Power off then on and try again). All the parameters need

to be entered for the pump to act accordingly; blank fields are unknowns (most

likely a previously stored condition).

Non-grouped Dispensing

The pump channel where cursor is blinking is the only active program line that

WORLD PRECISION INSTRUMENTS

20

Page 23

UltraMicroPump II

1

2

3

4

5

6

will activate. The way to run multiple lines is to run them grouped or run them

by separate commands after the line number is changed to that channel. The

channels in this latter case are completely independent from each other (nongrouped).

Incorrect Volume Dispensed

The amount of volume actually dispensed was what was programmed in on a prior

programmed instance. To correct this, reset the counter, specify the C parameter

as “C0.0;” with the Volume and Rate on a separate command line, just before

issuing the G (go) command.

RS232 Cable Pinouts

To control the Micro4 by computer, the RS232 cable must be configured as shown

here:

Mini-DIN connector

on rear panel of

Micro4 controller

Micro4 cable with 9pin connector is WPI

#40500.

Signal Micro4

Mini-DIN

Ground 1 5 7

UMC Data IN 2 3 2

UMC Data OUT 5 2 3

Run/ Stop 4 - -

+5V pull up 6 - -

9-Pin

D-sub

25-Pin

D-sub

Footswitch Connections

Since the footswitch produces Run and Stop signals by connecting +5 volts (from

pin 4) to pin 6, this port may also be used for TTL signals from other sources.

WORLD PRECISION INSTRUMENTS

21

Page 24

UltraMicroPump II

General Maintenance

UltraMicroPump requires minimal maintenance; regular laboratory cleaning will

keep this instrument in optimum operating condition.

Do not apply solvents or oils to any part of the UltraMicroPump.

This instrument is not autoclavable.

Do not disassemble—there are no serviceable parts inside either the UMPII or the

Micro 4 controller.

Always hold UltraMicroPump by the main body or mounting bar. Do not swing or

carry the UltraMicroPump by its cable.

Storage:

Store the UMPII in a sealed plastic zip bag to prevent dust from accumulating on

the drive screw. Excessive dust can cause jams and inadvertent stops.

Use of gas-tight syringes on the UMPII is not recommended for syringes above

250 µL as this can damage the motor. Please use liquid-tight syringes for

applications that require volumes greater than 250 µL.

Troubleshooting

Problem: The instrument motor makes noise but the plunger button does not travel.

Check: Look for a loose connector at the rear of the Micro4, make sure the UMPII

plug is firmly seated. The gray plastic plug should be a flush fit with the connector

on the controller. Verify that the pins in the connector are not damaged.

Check: Test the pump in another channel, with the same program parameters.

Instrument Overtravel

If the plunger button has traveled to the extreme edge of the pump and has

jammed, try the following procedure to free the plunger button:

Place the pump so that the syringe would be pointing to the right (no syringe

should be in the pump). Program the Micro4 to Syringe style F (or larger to H),

program in about 2000 to 5000 nL in the volume and program in a rate of 2000 or

greater (there are internal limits). Press and hold the Right or left arrow key for the

WORLD PRECISION INSTRUMENTS

22

Page 25

UltraMicroPump II

direction you want the plunger holder to move in and quickly tap the RUN/STOP

key a couple of times to unwind the tension on the drive screw and move the

plunger holder away from the end of its travel. If the holder cannot be moved away

from the stop end easily by this method, then contact techsupport@wpiinc.com

for assistance. The pump may have to be returned for mechanical disassembly to

correct this.

Stalling

The UMP2 may stall for a number of reasons. The most likely cause is that the

pump motor cannot push the syringe plunger for the following reasons:

1. More than 400 g is required to push the syringe plunger. The syringe should not

be a gas-tight (i.e., Teflon-sealed) piston greater than 250 microliters in volume;

this syringe type requires more force than the motor can push. If you require a

large volume syringe (over 250 µL), please use a liquid-tight plunger.

2. Needle blockage. The micropipette or the needle might be blocked by a

tissue mass in or outside of the needle, or the needle tip may be too small for the

programmed injection. Check for normal operation of the pump in air with and

without the syringe attached. Too high a delivery rate through a too small tip can

cause tissue damage and overtax the pump.

3. Syringe misalignment. The syringe must be axially aligned to the UMP2 body

in the clevises and the syringe plunger button must be centered in its holder to

properly inject along the length of the syringe. A small misalignment of the syringe

plunger can cause pulsating waves in the injection and an incorrect amount of

delivery.

4. Mechanical damage. If the UMP2 plunger carrier is loose (a condition which

can be caused by overtravel), the pump must be returned to WPI for repair.

WORLD PRECISION INSTRUMENTS

23

Page 26

UltraMicroPump II

Specifications

UltraMicroPump II

Total Number of Steps (end to end) ....... 20,000 (63 mm travel)

Minimum Dispensing Volume ................. 0.58 nL/step

Linear Motion .......................................... 3.175 µ/step

Plunger Position Error ............................. < 0.5%

Pump Force ............................................ 400 g

Syringe Diameters .................................. 5.5 mm to 9.0 mm

Maximum Step Rate ............................... 700 steps/sec (depending on syringe)

Weight .................................................... 325 grams (11.4 oz.)

Size ......................................................... Ø 32 mm x 190 mm (Ø 1.3 in. x 7.5 in.)

Power Requirements .............................. 12 VDC 2 amps, provided by Micro4

Micro4 Controller

Power Requirements .............................. 12 V (1.6 A)

Dimensions ............................................. 12.7 x 15.2 x 8.9 cm (5 x 6 x 3.5 in.)

Power Requirements .............................. 12 VDC from auto-switchable power

................................................................ supply (100-240 VAC input)

WORLD PRECISION INSTRUMENTS

24

Page 27

UltraMicroPump II

Syringes

UltraMicroPump II is designed to be used with glass syringes having barrel

diameters from 5.5 mm to 9 mm. WPI stocks the following syringes (with

replaceable beveled needles):

SGE0005RN* 0.5 µL 23 gauge (0.63 mm) 70 mm long (S) †

SGE001RN* 1.0 µL 26 gauge (0.47 mm) 70 mm long cone (S) †

*The capacity of the above syringes is so small that the entire sample is contained

within the needle. The plunger extends to the tip of the needle, displacing the full

sample during injection — giving the syringe zero dead volume.

SGE005RN 5.0 µL 23 gauge (0.63 mm) 70 mm long (S) †

SGE010RNS 10 µL 26 ga. 50mm needle (S)†

SGE025RN 25 µL 25 ga. 50mm needle (S)†

SGE050RN 50 µL Glass Microsyringe, 25 ga. needle (S)†

SGE100RN 100 µL Glass Microsyringe, 25 ga. needle (S)†

Replacement needles

RN0005 For Syringe SGE0005RN, 23 ga. (0.63 mm) 70 mm long

RN001 For Syringe SGE001RN, 26 ga. (0.47 mm cone) 70 mm long

RN010 For Syringe SGE010RN, 26 ga. (0.63 mm) 50 mm long, 5-pack

RN025 For Syringe SGE025RN, 25 ga. (0.63 mm) 50 mm long, 5-pack

RN025 For Syringe SGE050RN, 25 ga. (0.63 mm) 50 mm long, 5-pack

RN025 For Syringe SGE100RN, 25 ga. (0.63 mm) 50 mm long, 5-pack

Syringes with luer fitting (no needle)

ILS005LT 5 µL Gas tight Microsyringe, Glass Luer Fitting (I)†

ILS010LT 10 µL Gas tight Microsyringe, Luer Fitting (I)†

ILS025LT 25 µL Gas tight Microsyringe, Luer Fitting (I)†

SGE050TLL 50 µL Gas tight Microsyringe, Teflon Luer Lock Fitting (S)†

SGE100TLL 100 µL Gas tight Microsyringe, Teflon Luer Lock Fitting (S)†

SGE250TLL 250 µL Gas tight Microsyringe, Teflon Luer Lock Fitting (S)†

Use of Gas tight Syringes above 250 µL on the UMPII is not recommended, Please

use Liquid tight syringes for applications that require volumes greater than 250 µL

† Hamilton is a trademark of Hamilton Co., SGE is a trademark of Scientific Glass

Engineering., ILS is a trademark of Innovative Labor Systeme

WORLD PRECISION INSTRUMENTS

25

Page 28

UltraMicroPump II

Accessories

15867 Foot switch for Micro4

40500 RS232 cable for Micro4

UMP2 UltraMicroPump II

300033 Adaptor for Micro4 to Nanoliter 2000

B203MC4 Nanoliter 2000 and Micro4 controller

B203XVY Nanoliter 2000 Injector (USA 110V power adapter included)

Replacement parts

65134 Mounting Bar

65085 Mounting Bar Locking Nut

65015 Collar Stop Nut

For special connections:

6-pin Miniature DIN plug (Digi-Key # CP-20600-ND) Not available from WPI.

WORLD PRECISION INSTRUMENTS

26

Page 29

UltraMicroPump II

References

S.B. Mazzone, D.P. Geraghty “Respiratory actions of tachykinins in the nucleus of

the solitary tract: effect of neonatal capsaicin pretreatment” (2000) British Journal

of Pharmacology 129:6 pp1132-1139.

B.L. Davidson, C.S. Stein, J.A. Heth, I. Martins, R.M. Kotin, T.A. Derksen,

J. Zabner, A. Ghodsi, J.A. Chiorini “Recombinant adeno-associated virus type 2,

4, and 5 vectors: Transduct ion of variant cell types and regions in the mammalian

central nervous system” (2000) Proceedings of the National Academy of Sciences

of the United States of America 97:7 pp3428-3432.

A.I. Brooks, et al. “Reproduciable and Efficient Murine CNS Gene Delivery Using

a Microprocessor Controlled Injector” (1998) Journal of Neuroscience Methods 80

pp 137-147.

WORLD PRECISION INSTRUMENTS

27

Page 30

UltraMicroPump II

APPENDIX: Nanoliter 2000 / Micro4

Volume Settings

When using the Micro4 to control injections with the Nanoliter 2000, take care

when entering the injection volume. The Nanoliter 2000 injector’s volume per step

is based on the movement of the plunger wire inside a pulled glass pipette. This

plunger moves 0.0005" (12.7 µ) for each step of the motor. The volume of 2.3

nanoliters per step is based on the inside diameter of a 0.5 mm pipette and the

12.7 µ movement of the plunger wire.

Setting the correct volume on the Micro4

Since the volume per step is 2.3 nanoliters, the volume to be entered on the Micro4

touch panel must be a multiple of 2.3.

Example: You wish to inject 100 nanoliters. The setting on the Micro4 panel will be

calculated as 100/2.3 or 43.47 steps. The motor can only step in whole numbers,

so the volume must be adjusted, up or down, to the nearest whole step value.

Increasing to 44 steps times 2.3 gives a volume of 101.2 nL; decreasing to 43

steps times 2.3 gives a volume of 98.9 nL. One of these two volumes should be

used to insure a proper injection. Leaving the value on the Micro4 at 100 nL will

result in 98.9 nL being injected.

Difficulty can arise when the volume value is half or more of the next 2.3 nL step.

For example, setting the Micro4 for an injection of 10 nL will result in an actual

injection of 9.2 nL, produced by 4 whole steps of the injector; 5 whole steps

would result in 11.5 nL. Entering a value of 11.0 nL in the controller, however, will

generate a spurious value in the Micro4 display — 10.35 nL — but the actual

injection will still be only 9.2 nL. To avoid this error, enter only multiples of 2.3 nL

when calculating required volumes.

WORLD PRECISION INSTRUMENTS

28

Page 31

UltraMicroPump II

Warranty

WPI (World Precision Instruments, Inc.) warrants to the original purchaser that this equipment, including its

components and parts, shall be free from defects in material and workmanship for a period of one year* from

the date of receipt. WPI’s obligation under this warranty shall be limited to repair or replacement, at WPI’s

option, of the equipment or defective components or parts upon receipt thereof f.o.b. WPI, Sarasota, Florida

U.S.A. Return of a repaired instrument shall be f.o.b. Sarasota.

The above warranty is contingent upon normal usage and does not cover products which have been

modified without WPI’s approval or which have been subjected to unusual physical or electrical stress or on

which the original identification marks have been removed or altered. The above warranty will not apply if

adjustment, repair or parts replacement is required because of accident, neglect, misuse, failure of electric

power, air conditioning, humidity control, or causes other than normal and ordinary usage.

To the extent that any of its equipment is furnished by a manufacturer other than WPI, the foregoing warranty

shall be applicable only to the extent of the warranty furnished by such other manufacturer. This warranty will

not apply to appearance terms, such as knobs, handles, dials or the like.

WPI makes no warranty of any kind, express or implied or statutory, including without limitation any

warranties of merchantability and/or fitness for a particular purpose. WPI shall not be liable for any damages,

whether direct, indirect, special or consequential arising from a failure of this product to operate in the manner

desired by the user. WPI shall not be liable for any damage to data or property that may be caused directly or

indirectly by use of this product.

* Electrodes,

batteries and other

consumable parts are

warranted for 30 days

only from the date on

which the customer

receives these items.

Claims and Returns

• Inspect all shipments upon receipt. Missing cartons or obvious damage to cartons should be noted on

the delivery receipt before signing. Concealed loss or damage should be reported at once to the carrier and

an inspection requested. All claims for shortage or damage must be made within 10 days after receipt of

shipment. Claims for lost shipments must be made within 30 days of invoice or other notification of shipment.

Please save damaged or pilfered cartons until claim settles. In some instances, photographic documentation

may be required. Some items are time sensitive; WPI assumes no extended warranty or any liability for use

beyond the date specified on the container.

• WPI cannot be held responsible for items damaged in shipment en route to us. Please enclose

merchandise in its original shipping container to avoid damage from handling. We recommend that you insure

merchandise when shipping. The customer is responsible for paying shipping expenses including adequate

insurance on all items returned.

• Do not return any goods to WPI without obtaining prior approval and instructions (RMA#) from our returns

department. Goods returned unauthorized or by collect freight may be refused. The RMA# must be clearly

displayed on the outside of the box, or the package will not be accepted. Please contact the RMA department

for a request form.

• Goods returned for repair must be reasonably clean and free of hazardous materials.

• A handling fee is charged for goods returned for exchange or credit. This fee may add up to 25% of the

sale price depending on the condition of the item. Goods ordered in error are also subject to the handling fee.

• Equipment which was built as a special order cannot be returned.

• Always refer to the RMA# when contacting WPI to obtain a status of your returned item.

• For any other issues regarding a claim or return, please contact the RMA department

Warning: This equipment is not designed or intended for use on humans.

World Precision Instruments, Inc.

International Trade Center, 175 Sarasota Center Blvd., Sarasota FL 34240-9258

Tel: 941-371-1003 • Fax: 941-377-5428 • E-mail: sales@wpiinc.com

UK: Astonbury Farm Business Centre • Aston, Stevenage, Hertfordshire SG2 7EG • Tel: 01438-880025 • Fax: 01438-880026 • E-mail: wpiuk@wpi-europe.com

WORLD PRECISION INSTRUMENTS

Germany: Liegnitzer Str. 15, D-10999 Berlin • Tel: 030-6188845 • Fax: 030-6188670 • E-mail: wpide@wpi-europe.com

29

Page 32

Loading...

Loading...