Page 1

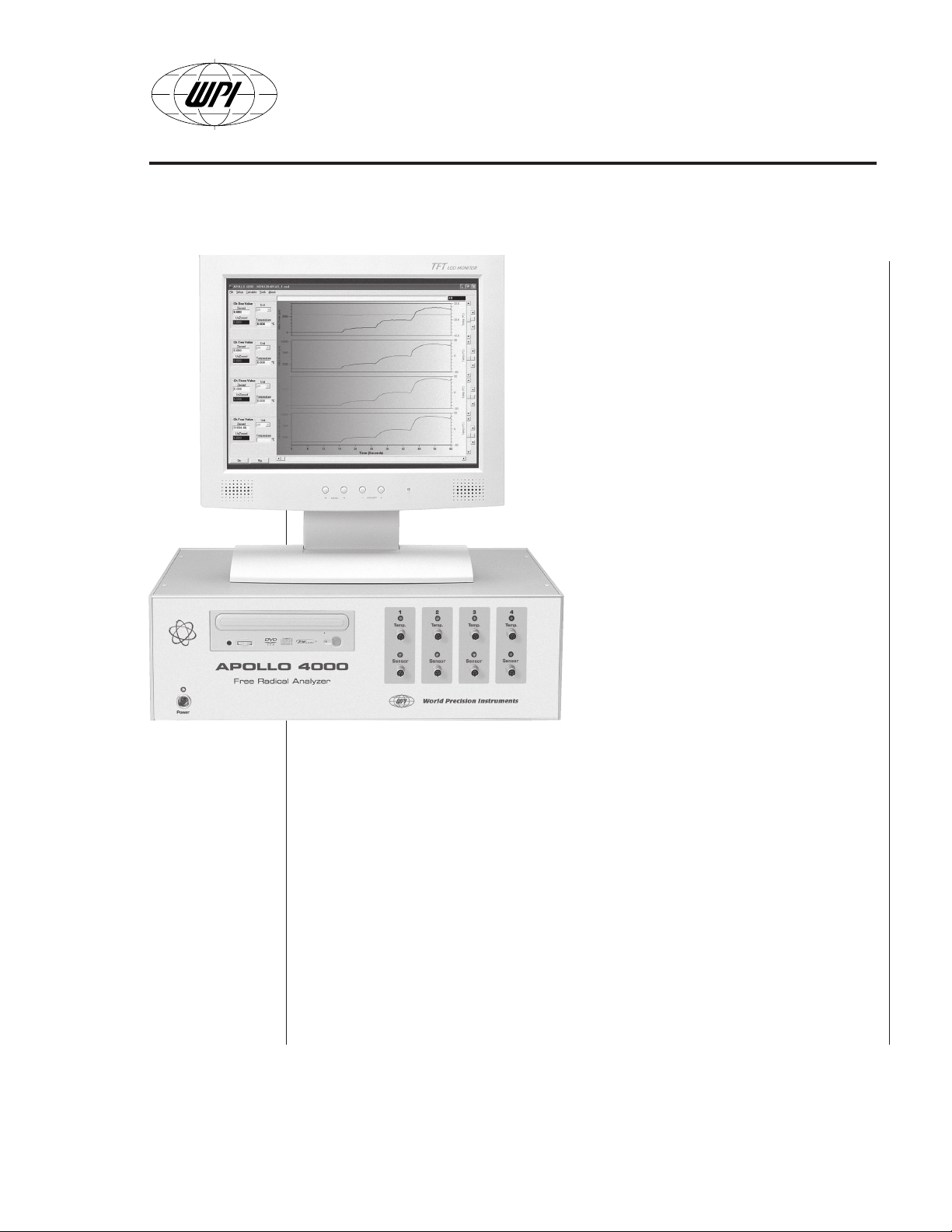

APOLLO 4000

World’s first fully-integrated Free Radical Analyzer

INSTRUCTION MANUAL

Serial No._____________________

APOLLO 4000

WARNING

This instrument must not be connected to a local

network nor to the Internet. Do not attach any

peripheral device other than a USB printer. Any

change to the proprietary hard disk registry in this

device — whether by virus or by normally benign

hardware or software installations — may render the

drive or the Apollo software inoperable, requiring the

instrument’s return to the factory for reformatting.

File corruption or damage to applications or

operating system caused by such use will not be

covered by the Warranty.

www.wpiinc.com

061506

World Precision Instruments

Page 2

Page 3

APOLLO 4000

Contents

INTRODUCTION ............................................................................... A-1

Design Architecture ........................................................................................ A-2

Plug-and-Play Design ..................................................................................... A-2

Free Radical Sensor Technology .................................................................... A-2

Instrument Description ................................................................................... A-3

Unpacking ...................................................................................................... A-5

OPERATING INSTRUCTIONS ...........................................................B-1

Setting up the APOLLO 4000 ......................................................................... B-1

APOLLO.EXE Operating Software .................................................................. B-4

Example of a real signal application ............................................................ B-12

USING THE APOLLO 4000 TO DETECT NITRIC OXIDE ................... C-1

Initial Set-up .................................................................................................... C-1

Calibration of the NO Sensor .......................................................................... C-1

The Calibration Kit .......................................................................................... C-1

Calibration by the chemical generation of NO ............................................... C-2

Calibration of NO sensor by decomposition of SNAP .................................... C-7

Calibration of NO sensor using aqueous standards prepared with NO Gas C-15

Measurement of NO ..................................................................................... C-18

Maintenance of NO Sensors ........................................................................ C-20

USING THE APOLLO 4000 TO DETECT OXYGEN ............................ D-1

Initial Set-up .................................................................................................... D-1

Calibration and Use of Oxygen Sensors ........................................................ D-1

Calibration ...................................................................................................... D-2

Probe Structure and Assembly....................................................................... D-8

USING THE APOLLO 4000 TO DETECT HYDROGEN PEROXIDE..... E-1

Initial Set-up ..................................................................................................... E-1

The structure of the HPO sensor .....................................................................E-1

Calibration of the HPO Sensor ........................................................................ E-2

Calibration Procedure......................................................................................E-2

Interference ..................................................................................................... E-4

Maintenance of HPO Sensors ......................................................................... E-4

TROUBLESHOOTING FOR APOLLO 4000 ........................................ F-1

any language, in any form, without prior written permission of World Precision Instruments, Inc.

Copyright © 2003 by World Precision Instruments, Inc. All rights reserved. No part of this publication may be reproduced or translated into

WORLD PRECISION INSTRUMENTS 3

APPENDIX: BASIC GROUNDING & SHIELDING PRINCIPLES ........ G-1

Page 4

Page 5

INTRODUCTION

The APOLLO 4000 is the end result of an

extensive three-year research and

development program aimed at designing the

most advanced multifunctional free radical

detection system available. Building on

WPI’s worldwide-recognized expertise in

the field of nitric oxide detection and the

success of its popular NO detector (the

ISO-NO series), WPI’s scientists

embarked on an ambitious plan to

develop a state-of-the-art free radical

detection system incorporating the very

latest digital signal processing (DSP) technology.

APOLLO 4000

INTRODUCTION

The APOLLO 4000 is an optically isolated multi-channel electrode-based free

radical analyzer designed specifically for the detection of a variety of redoxreactive species of biomedical importance. The electrochemical (amperometric)

detection principle used is similar to that employed in WPI’s popular nitric oxide

detection system, the ISO-NO Mark II. However, the APOLLO 4000 incorporates

numerous highly advanced design features that enable it to detect a broad range

of redox-reactive species with unsurpassed accuracy and sensitivity. Using WPI’s

extensive range of free radical sensing electrodes the APOLLO 4000 is able to

detect nitric oxide, hydrogen peroxide, s-nitrosothiols and oxygen. On-going

research at WPI is focusing on expanding the range of detectable species.

NO sensors used with ISO-NO Mark II are completely compatible with the APOLLO

4000.

WORLD PRECISION INSTRUMENTS A-1

Page 6

APOLLO 4000

INTRODUCTION

Design Architecture

The APOLLO 4000 is based on an optically isolated 4-channel configuration (a 2-

channel version is also available). This design enables simultaneous real-time

measurement of NO (or other free radicals) to be performed using up to 4 different

electrodes. In addition, each free radical sensing channel also contains an

independent channel for temperature measurement.

APOLLO 4000 incorporates a powerful single board computer and proprietary

software (apollo.exe) that enables real-time display and data-acquisition of

individual channels or any combination of channels. An extensive graphical user

interface (GUI) based on a full color LCD monitor allows complete control and

programming of all detection and data-acquisition parameters to be made using

the standard keyboard and mouse included with the system.

The APOLLO 4000 consists of two functionally independent modules: Front End

Converter (FEC) and User Interface (UI). The FEC is an 8-channel data-acquisition

module based on a 24-bit A-to-D and 16-bit D-to-A conversion driven by a Digital

Signal Processor (DSP). The User Interface is built on a standard PC platform with

Windows 2000® operating system. A standard serial port (RS232) provides the

communication between the FEC and UI. The system is fully compatible with a

standard keyboard and mouse and can be readily interfaced with PC’s, computer

networks, printers, and any device that uses Ethernet Tbase-10/100, USB, Serial

Port or Parallel Port communications.

Plug-and-Play Design

The APOLLO 4000 is designed for use with WPI’s range of free radical sensors.

The user simply plugs the required sensor into any one of the input channels

located on the instruments main front panel and then selects the detection and

acquisition parameters using the integrated software control. Each channel is also

provided with an independent temperature input port that allows real-time

monitoring of temperature using WPI’s appropriate temperature sensors.

Free Radical Sensor Technology

The APOLLO 4000 and its associated free radical sensors can provide fast,

accurate, and stable measurements over a wide range of concentrations in both

aqueous solutions and in gas mixtures. Its features include a rapid response time,

WORLD PRECISION INSTRUMENTSA-2

Page 7

APOLLO 4000

INTRODUCTION

high sensitivity and selectivity, ease of use, and versatility unmatched by any other

similar instrument.

The detection principles are based on the electrochemical (amperometric)

response produced by the various compatible free radical sensors. In summary,

the free radical of interest diffuses through a selective membrane covering the

sensor and is oxidized at the working electrode, resulting in an electrical (redox)

current. The amount of redox current produced is proportional to the free radical

concentration in the sample. All of WPI’s free radical sensors are “combination

electrodes” in which the sensing and reference electrodes have been combined

within a high performance Faraday shield designed to minimize susceptibility to

environmental noise. The Apollo software can be programmed to display either

redox current (

can also be collected via BNC connectors on the rear panel of the instrument.

APOLLO 4000 is fully compatible with WPI’s extensive range of free radical

sensors. Currently this range of sensors includes electrodes for monitoring; nitric

oxide, oxygen and hydrogen peroxide. However, new sensors are currently in

development. For details on the complete list of compatible sensors please see the

latest WPI product catalog, or visit WPI’s website (www.wpiinc.com).

e.g.

, pA) or concentration (

e.g.

, nM). Output from the APOLLO 4000

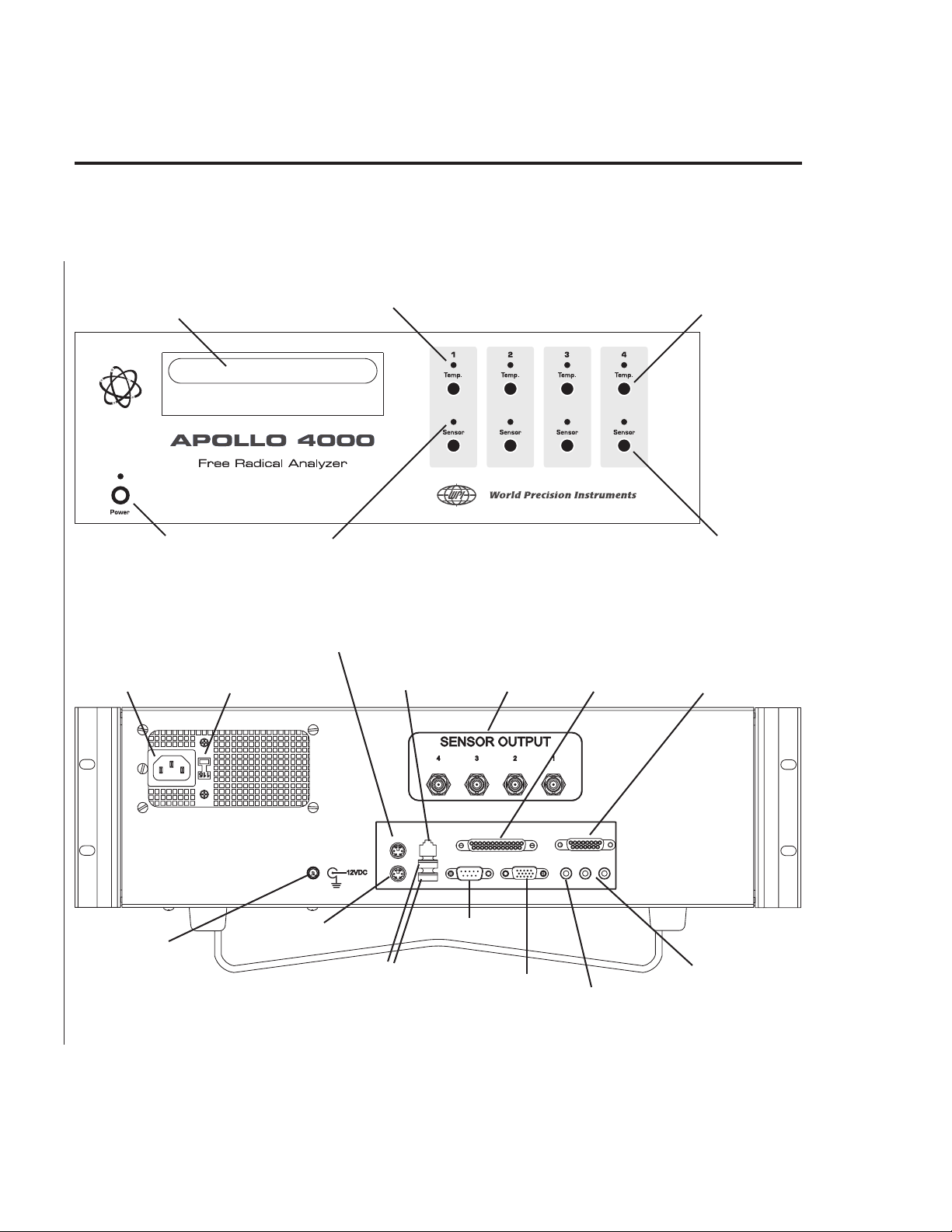

Instrument Description

Parts List

The package should contain the following items:

Part No. Description

APOLLO4000 Free Radical Analyzer

800408 Standard Keyboard

800407 Standard Mouse

800406 17” LCD monitor

35209 Program CD

— Power cables

— Instruction Manual

WORLD PRECISION INSTRUMENTS A-3

Page 8

APOLLO 4000

INTRODUCTION

DVD / CD-RW

Drive

Temperature

LED (red)

Channels

Temperature

Input

}

Power

Mains

Power

Power

Supply for

Monitor

Sensor

(green)

110V/220V

Switch

Keyboard

LED

mouse

Ethernet

USB

Outputs

Serial

Analog

(BNC)

Video

Sensor Input

Parallel Joystick

LR

Audio

Audio

Output

Input

WORLD PRECISION INSTRUMENTSA-4

Page 9

APOLLO 4000

INTRODUCTION

Unpacking

Upon receipt of this product, make a thorough inspection of the contents and check

for possible damage. Missing cartons or obvious damage to cartons should be noted

on the delivery receipt before signing. Concealed loss or damage should be reported at once to the carrier and an inspection requested. Please read the section

entitled “Claims and Returns” on the Warranty page of this manual.

Returns: Do not return any goods to WPI without obtaining prior approval (RMA #

required) and instructions from our Returns Department. Goods returned (unauthorized) by collect freight may be refused. If a return shipment is necessary, use the

original container. If the original container is not available, use a suitable substitute

that is rigid and of adequate size. Wrap the instrument in paper or plastic surrounded

with at least 100 mm (four inches) of shock absorbing material. Please read the section entitled “Claims and Returns” on the Warranty page of this manual.

WORLD PRECISION INSTRUMENTS A-5

Page 10

APOLLO 4000

INTRODUCTION

WORLD PRECISION INSTRUMENTSA-6

Page 11

APOLLO 4000

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

To exploit the APOLLO 4000’s capabilities fully, it is very important that the user be

aware of the general methods for operating the maintaining the instrument. This will

also ensure that the user is able to understand and interpret the readings.

Setting up the APOLLO 4000

1. Place the APOLLO 4000 on a secure, flat surface (

2. Position the LCD display on top of the APOLLO 4000 and connect the

display cable to display output video port located on the rear panel of the

APOLLO 4000 (see A-4).

3. Power the LCD display by connecting one end of the cable from the

provided voltage converter (AC to 12V DC) to the LCD display Power input

receptacle. Connect the other end of the voltage converter to a matching

3-prong grounded wall receptacle and switch on.

4. Connect the power supply cord to the back of the APOLLO 4000 and plug

the other end into a matching 3-prong grounded wall receptacle (see setup diagram below).

NOTE: Ensure that the red voltage selector switch on the rear panel

(next to the power cable receptacle) is set to the correct voltage —

220 or 110.

e.g.

, laboratory bench).

Switching ON the APOLLO 4000

The unit can be turned on by pressing the “Power” pushbutton on the front panel.

After booting up, the system automatically starts the main application software

(APOLLO.exe). If other applications have been used the user can return to

Apollo4000 application by double clicking the “Apollo” icon in the right upper

corner of Windows® desktop.

During the process of booting up no error messages should appear on the screen.

(see Troubleshooting).

Switching OFF the APOLLO 4000

The APOLLO 4000 incorporates a highly advanced single board computer and

WORLD PRECISION INSTRUMENTS B-1

Page 12

APOLLO 4000

OPERATING INSTRUCTIONS

associated electronics. To turn the unit off, it is therefore only necessary to press

the Power button once. It is recommended, however, to close the application

programs

before

computer is not responding it may be necessary to press and hold the Power

button in for 3 seconds before the unit will turn off (see troubleshooting section).

The alternative method for switching the unit off is to position the mouse cusor on

START, click on hold down once, and then choose SHUT DOWN from the pop-up

menu. This method will be familiar to Windows

Precautions for handling sensors

pressing the Power button. In some cases when the embedded

®

users.

The range of free radical sensors offered by WPI vary in their fragility.

However, at

all times the user must exercise caution to avoid damaging the delicate

polymeric membrane covering the end of each sensor.

This membrane

prevents water and dissolved species such as ions and macromolecules from

reaching the electrode surface where they would interfere with normal

measurement and poison the electrode surface. When the sensor membrane

becomes damaged, sample contents are free to react at the electrode surface.

This causes the background current to become very large and/or go off scale

(negative or positive depending on the reacting species). The membrane integrity

of the sensor can always be checked by ascertaining that the current remains low

and stable when the sensor tip is immersed in a 1.0 M saline solution.

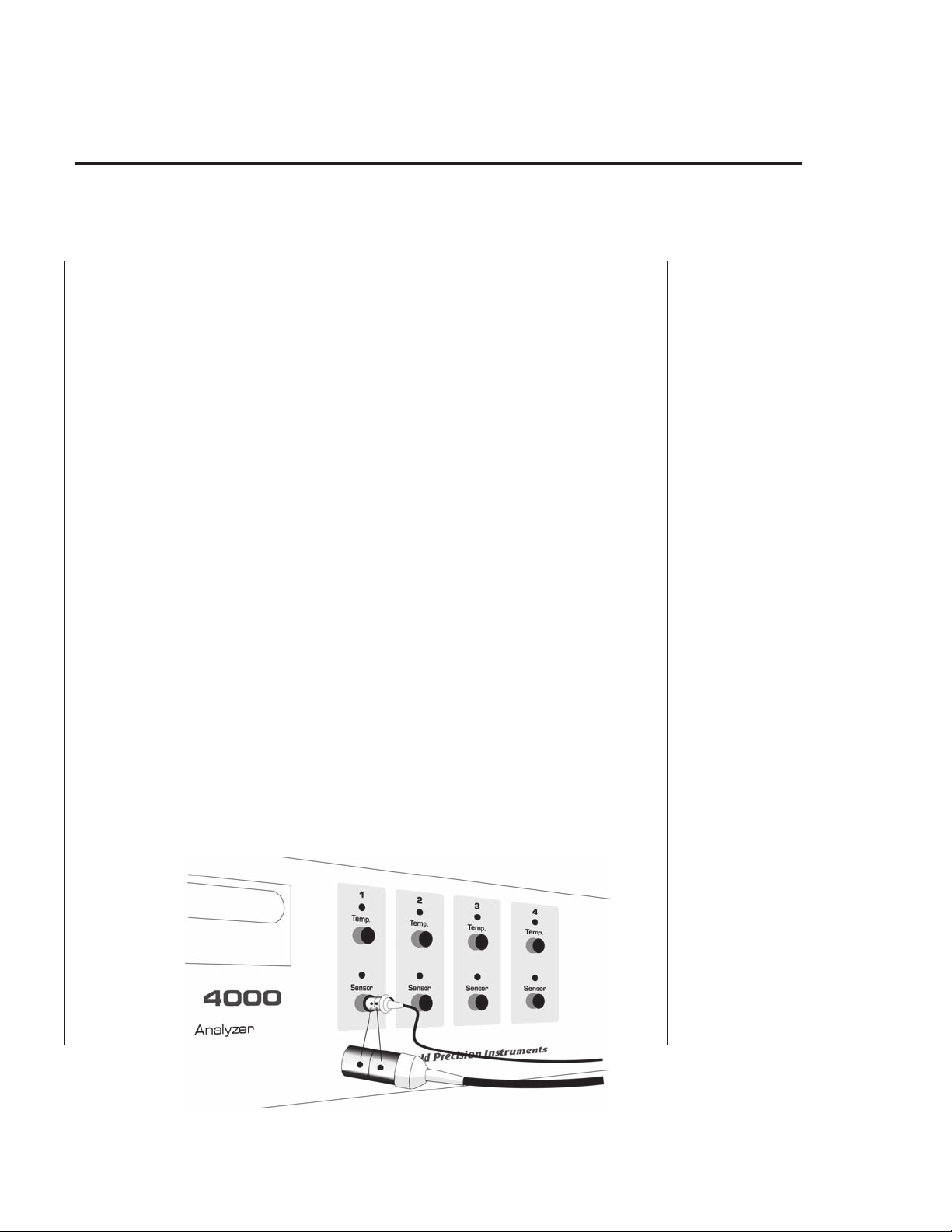

Attaching a sensor to the APOLLO 4000

Each channel on the APOLLO 4000 is equipped with two high quality sensor input

receptacles. The channel marked “Temp” is for use only with a compatible WPI

temperature electrode (

only with one of WPI’s free radical sensors.

e.g.

, ISO-TEMP-2). The channel marked “Sensor” is for use

Fig. B1

attaching a

temperature probe

or sensor to the

APOLLO4000,

align the red dot of

the instrument with

the red dot on the

cable connector.

– When

WORLD PRECISION INSTRUMENTSB-2

Page 13

APOLLO 4000

OPERATING INSTRUCTIONS

NOTE:

The Temp and Sensor inputs are not interchangeable but no damage

to the APOLLO 4000 will occur if a sensor/electrode is accidentally inserted

into the wrong input receptacle.

To connect a sensor, simply line up the red dot on the metal connector attached to

the sensor cable with the red dot on the sensor input receptacle and insert the

cable connector (Fig. B1). An LED (located above each sensor input) will light up

immediately indicating the instrument and sensor are connected and working

correctly. The Temp LED is red. The Sensor LED is green. The following LED

indications will inform the user of the status of the system:

LED CONDITION INDICATION

Temp LED (red)

Steady RED light Electrode is performing normally

No RED light Electrode is not connected or is damaged

Sensor LED (green)

Steady GREEN light Sensor is performing normally within the

user-selected current range

Intermittent blinking GREEN light Sensor current is outside the user-

selected linear range.

No GREEN light ERROR sensor current range too low.

Sensor error or sensor not connected.

NOTE: WPI strongly recommends that APOLLO 4000 be powered

through a Back-UPS unit to avoid system failure during power loss.

It is the responsibility of the user as well to install appropriate antivirus protection software.

WPI will not be liable for any loss of data as a result of power loss or virus-attack to the APOLLO 4000 system.

WORLD PRECISION INSTRUMENTS B-3

Page 14

APOLLO 4000

OPERATING INSTRUCTIONS

APOLLO.EXE Operating Software

The operating software of the APOLLO 4000 is based on a standard Windows

format, hence many of the software control features will already be familiar to the

user.

®

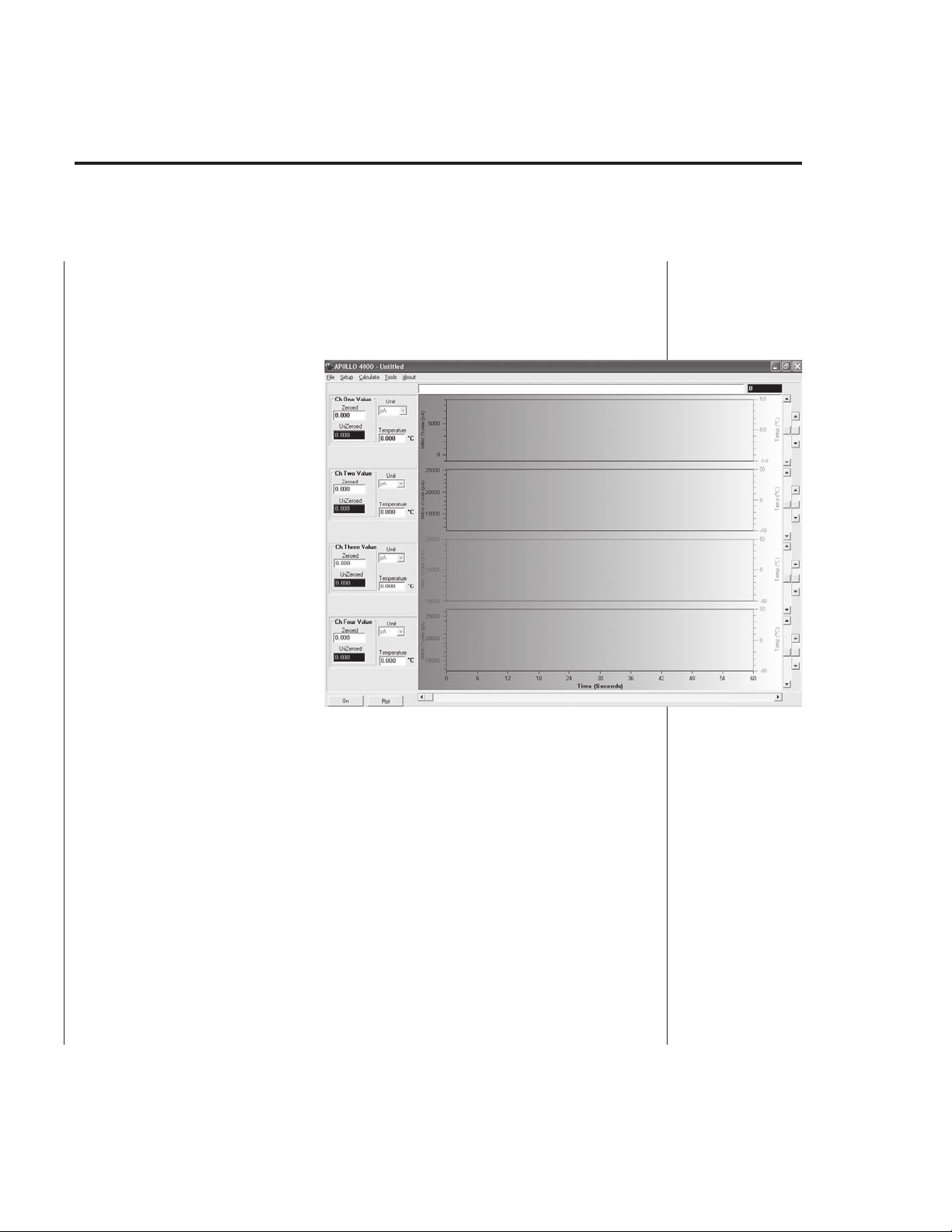

Main Screen

The main working screen is

shown in Fig. B2. The software

automatically recalls the last

settings used, therefore the

appearance of the screen will

depend on how it was last used

immediately before being turned

off.

In the example shown, the set-up

is for a four-channel nitric oxide

application with horizonal scale of

6 sec/division and vertical scales

5000 pA/div for channels 1 to 4.

Data for each channel is

displayed on the left of the screen. Each data channel display shows the following

information:

Fig. B2

1. Zeroed — Relative measurement value (includes any zeroing applied to

signal).

2. Unzeroed — Absolute measurement value (

zeroing) often refered as “background signal”.

3. Temp — Temperature measurement in degrees Celsius.

4. Unit — e.g., pA, nM, etc.

Note: If no temperature sensor is connected there will be no value in the temp

window and no trace in the graph.

i.e.

, true value without

WORLD PRECISION INSTRUMENTSB-4

Page 15

APOLLO 4000

OPERATING INSTRUCTIONS

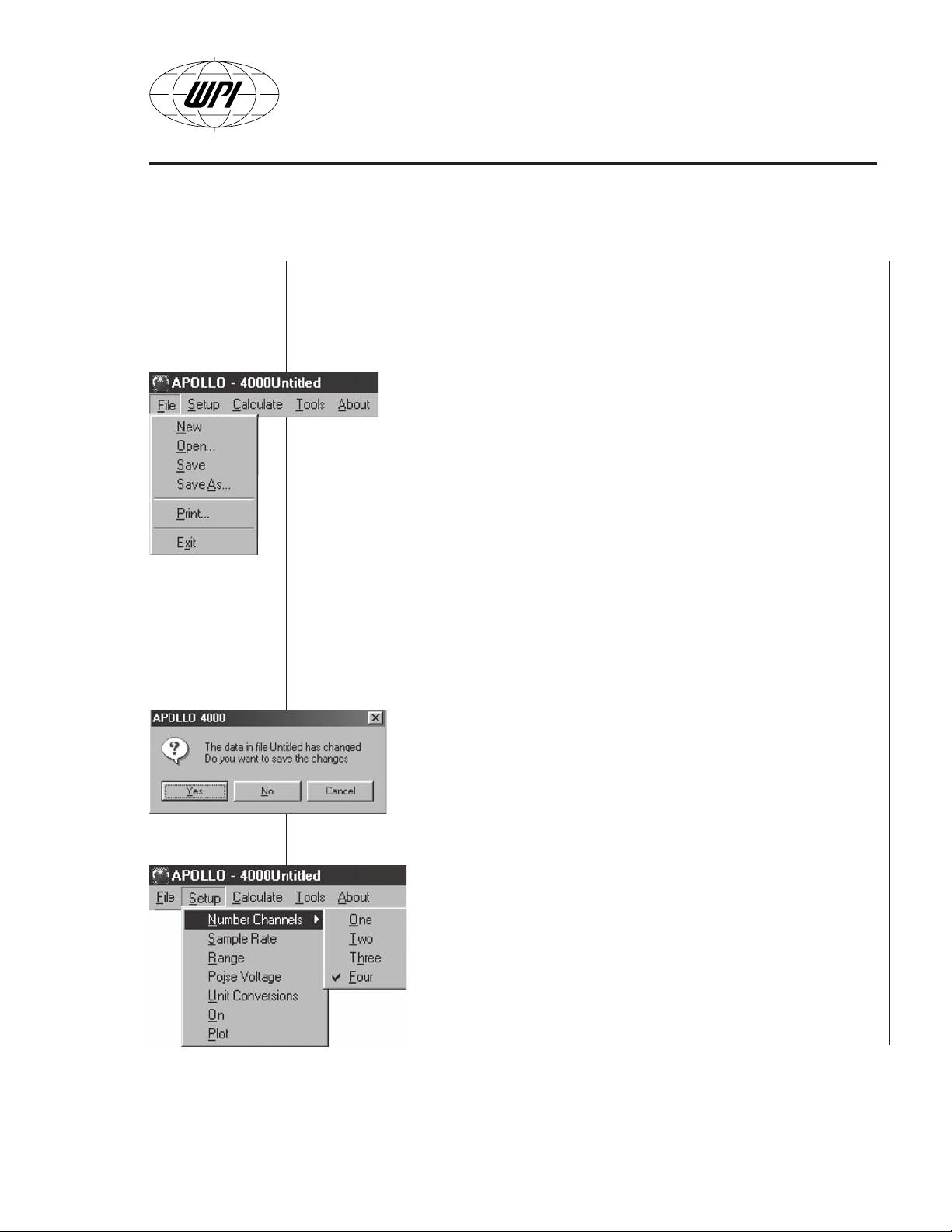

Menu System

The Apollo 4000 software uses standard Windows® controls. Help notes will

therefore automatically appear when the cursor is positioned on any control

function or word.

The following section contains a brief description of the programs

main menu system. However, in most cases a user familiar with

Windows®-based operating programs will be able to operate the

software efficiently with the minimum of instructions.

Fig. B3

File Menu

Fig. B4

—

File Menu

• New

(Fig. B3) consists of typical Windows® commands:

—

starts a new data file

• Open — opens an existing data file

• Save — saves the current experiment with the default name

• Save as — allows the user to chose the name and the path of the saving

data file

• Print — prints the screen to the system default printer

• Exit — exits the program and returns to the Windows® desktop.

The standard message (Fig. B4) appears when it is needed. For a

detailed explanation of the above commands please refer to a

Windows® textbook.

Setup Menu

(Fig. B5) consists of the following menu sub-

commands:

• Number of Channels — Sets the desired number of

displayed channels. When One is selected then only the

Channel 1 is displayed. Select Two Channels and 1 and 2

are displayed. Select Three channels for 1, 2, and 3. Select

Four to display all four channels.

Fig. B5

Setup Menu

WORLD PRECISION INSTRUMENTS B-5

—

Page 16

APOLLO 4000

OPERATING INSTRUCTIONS

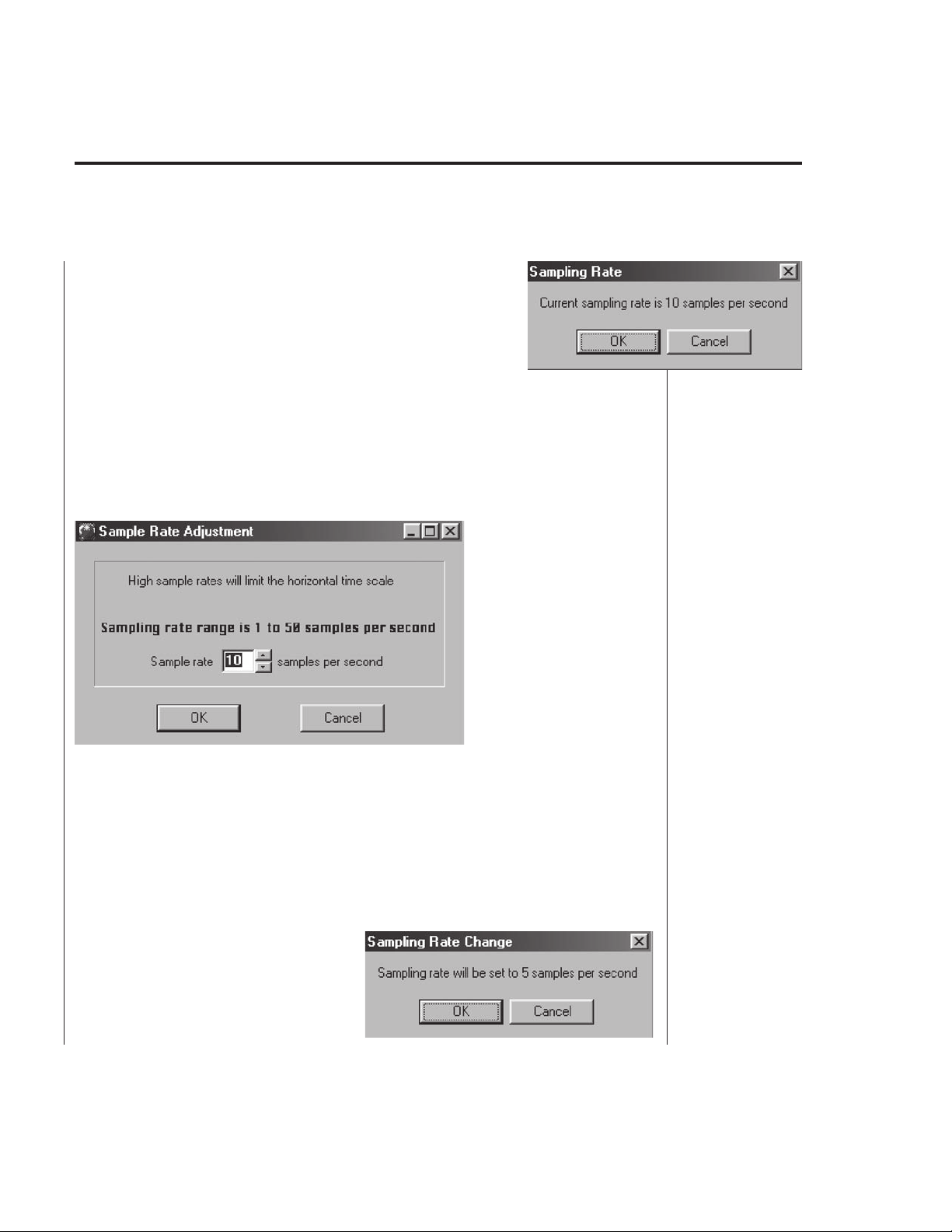

• Sample Rate — Selecting this command triggers the

following sequence of events:

Current sampling rate is indicated (Fig. B6). If this

value is satisfactory, the user can chose Cancel and

continue to work with the current sampling rate.

NOTE: The default sampling rate is 10 samples per second, sufficient

for most applications.

To select a different sampling rate, select OK. The sampling rate change

screen (Fig. B7) will appear following

confirmation screen (Fig. B8).

which may be undesirable. Therefore the user must carefully

sampling rate before the experiment.

50 samples/sec in increments of 5. It is very important for the user to

understand that Windows®-based computers have the limitations of 16,384

pixels per screen and therefore (number of horizontal divisions=10) the

maximum horizontal scale value will be limited to an integer of 1,638.4/

sample rate. After the new sample rate is selected the horizontal scale

factor is set (for clarification) to the absolute maximum value. For instance,

if the sample rate is set to 5

samples/sec the horizontal

scale will be set to 327 sec/div.

The user can reset it to any

lower value (not lower than 1

sec/div).

OK

Sampling rate can be set from 1 to

confirmation by another

The user can cancel the

action and continue to

work with the current

setting. Changing the

sampling rate changes

the data file structure

and it is therefore

necessary to close the

previous file (Fig. B4).

This can interrupt the

current experiment

select the

Fig. B6

Fig. B7

Fig. B8

WORLD PRECISION INSTRUMENTSB-6

Page 17

APOLLO 4000

OPERATING INSTRUCTIONS

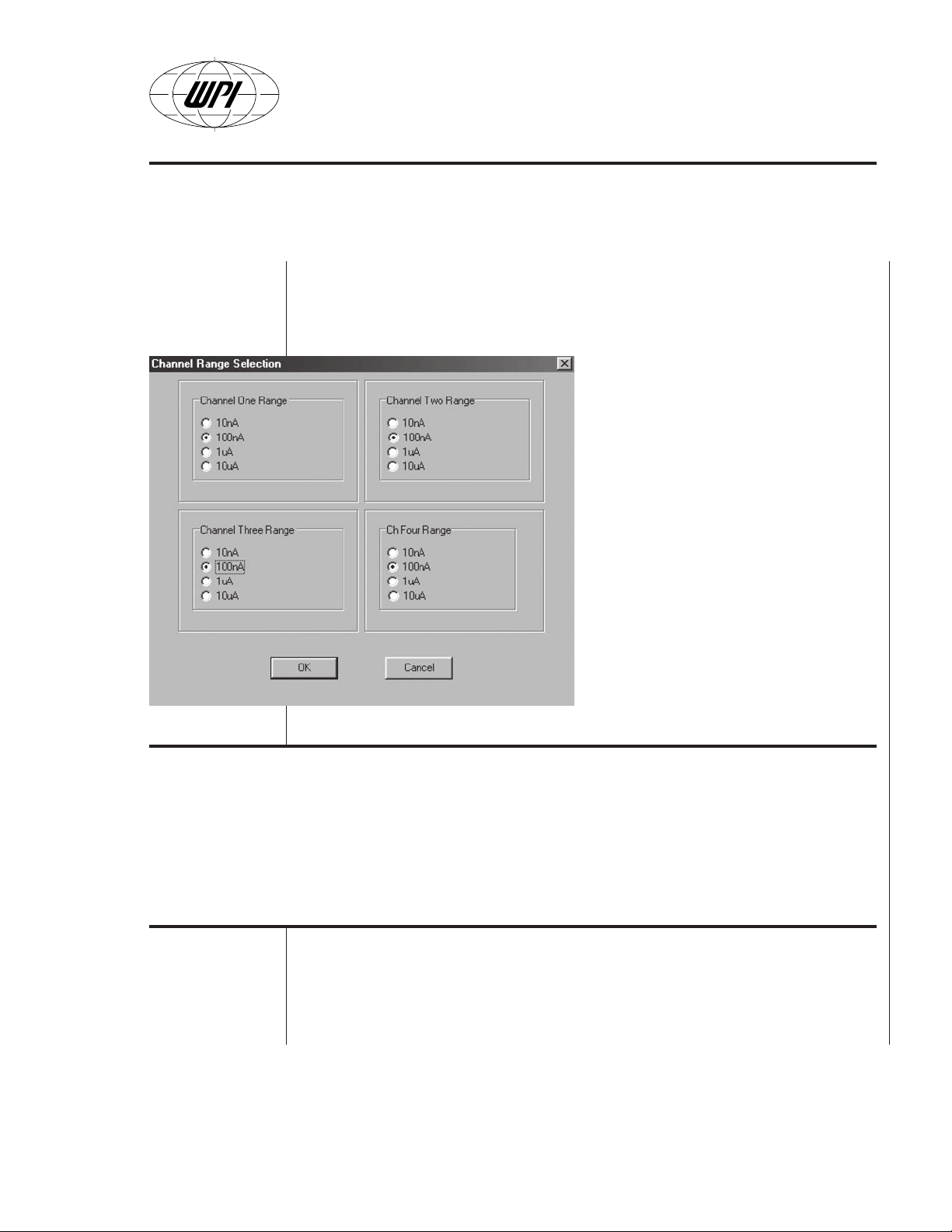

• Range. After selecting this submenu the range control screen appears

(Fig. B9). The user must select a current range for each sensor channel

within the maximum measured/expected value of the experiment. Proper

selection of the measurement range is very important because the

dynamic range of the instrument is

limited to approximately 1,000,000. This

means that the intrinsic background

noise (

i.e.

, “noise floor”) is proportional

to the maximum measured value. For

example:

If 10 nA range is selected, then the

noise floor will be approximately 10 nA

divided by 1,000,000 (

Conversely, if 10 µA range is selected

then the noise floor will be

approximately 10 µA divided by

1,000,000 (

i.e.

, 10 pA).

i.e.

, 10 fA).

If an incorrect range is chosen for any

channel, the Apollo 4000 will indicate

Fig. B9

Green (sensor) LED Indication Remedy

Intermittent blinking Current detected by sensor is too high Select a higher range

for the selected range

No Green Light Current detected by sensor is too low Select a lower range

for the selected range

Steady Green Light Sensor is normal and within the selected range No action required

If the user is satisfied with the current setting he can chose

work as previously.

this as follows:

Cancel

and

WORLD PRECISION INSTRUMENTS B-7

Page 18

APOLLO 4000

OPERATING INSTRUCTIONS

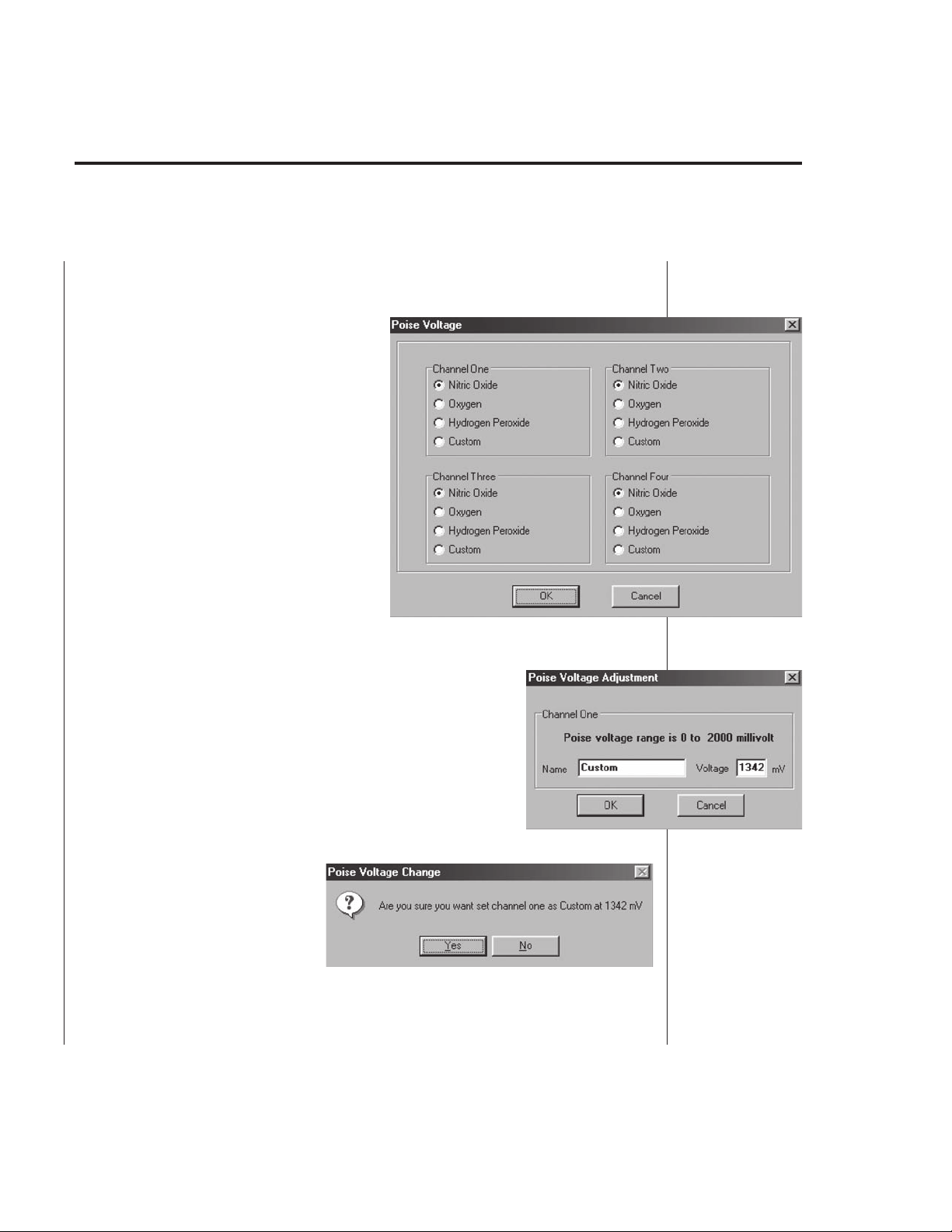

• Poise Voltage. This submenu looks (Fig. B10) and works similarly to the

Range

control. Threre are four choices:

Nitric Oxide —

Automatically configures

the poise voltage (

865 mV) on the selected

channel to measure nitric

oxide.

Oxygen — Automatically

configures the poise

voltage (

the selected channel to

measure oxygen.

Hydrogen Peroxide —

Automatically configures

the poise voltage (

400 mV) on the selected channel to measure

hydrogen peroxide.

i.e.

, 700 mV) on

i.e.

i.e.

,

,

Fig. B10

Custom — Allows the user to manually set

the poise voltage (

(Fig. B11).

Selecting the wrong poise

i.e

., from 0-2000 mV)

voltage will drastically change the results

of an experiment and may render any data

invalid.

confirmation (Fig. B12) prior to changing any

poise voltage.

Hence the program asks for the

Fig. B11

Fig. B12

WORLD PRECISION INSTRUMENTSB-8

Page 19

APOLLO 4000

OPERATING INSTRUCTIONS

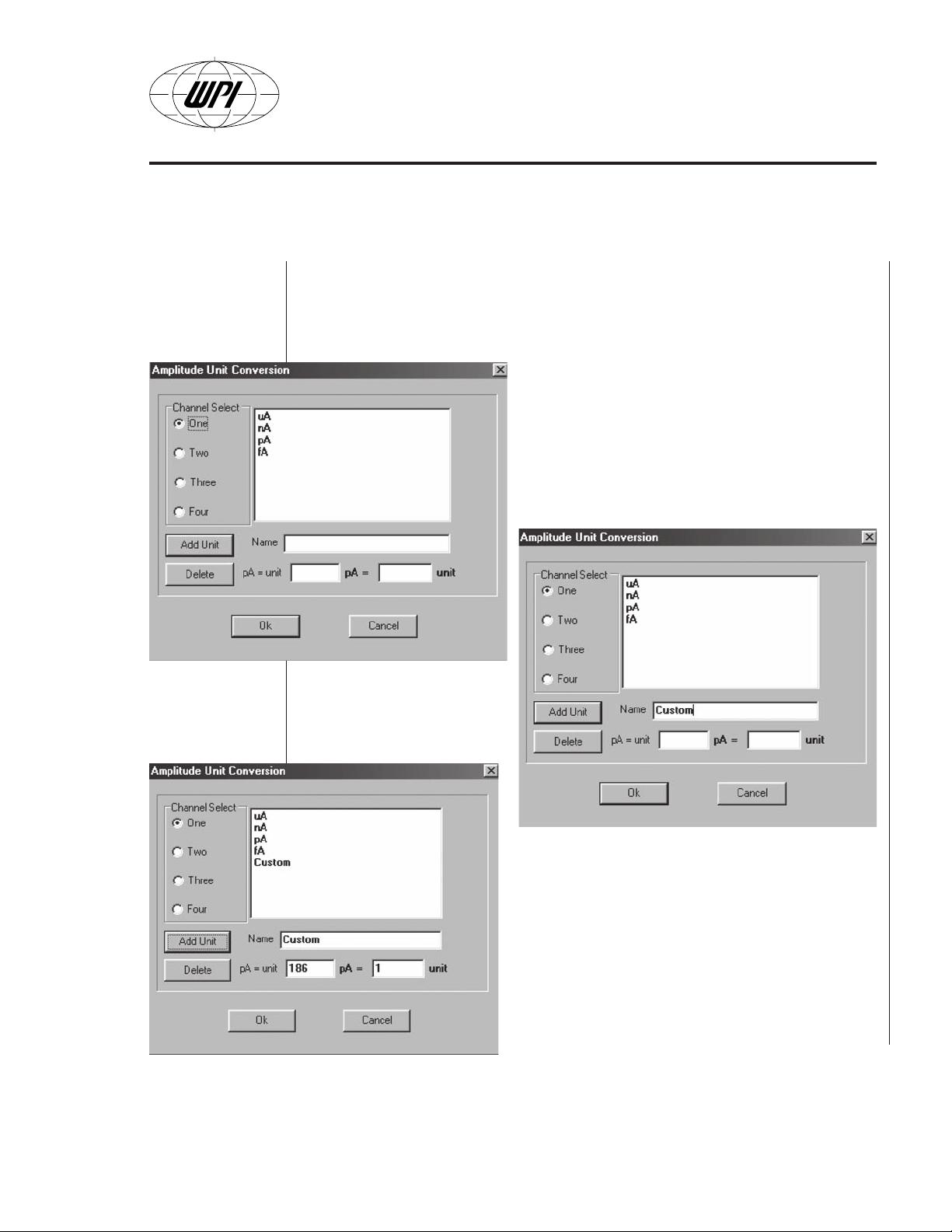

• Unit Conversion. There are four default units of measuring signals: fA,

pA, nA and µA. If a new unit needs to be defined chose the

Conversion

Conversion screen appears (Fig. B13).

submenu in the

Setup

Example: The user defines a new unit called

“Custom” with the conversion ratio 1 unit = 186

pA (Fig.B14). If Add Unit button is selected then

the new unit name appears in the list for the

particular channel (Fig.B15). The user can define

as many custom units as needed as well as

modify the existing custom ones.

control. The Amplitude Unit

Unit

Fig. B13

Fig. B15

Fig. B14

WORLD PRECISION INSTRUMENTS B-9

Page 20

APOLLO 4000

OPERATING INSTRUCTIONS

• On / Off toggle control (also the push button in the

left bottom corner of the screen). This menu starts

and stops the acquisition of data, including writing to

a data file. Before the acquisition starts, the program

notifies the user about the sampling rate and

maximum horizontal scale factor (Fig. B16).

• Plot / Analyze toggle control (also the push button in the left bottom corner

of the screen) commands the program to start and stop plotting of the

incoming data to the screen. In the Analyze mode there is a possibility to

measure different parameters of the acquired data defined by Calculate

menu with the cursors. The cursors appear when the pointer device

(mouse) is moved to a certain position and its left button pushed. There are

a total of two cursors. The second cursor appears after the first one when

the pointer device left button is released

.

Fig. B16

Calculate Menu

program can recalculate from the recorded data stream (Fig.B17):

•Value and Delta — The value as well as time parameter of

plotted data is indicated in the appropriate windows (see

Fig. B2) when the pointer device moves. Clicking of the pointer

device left button fixes the first cursor. While the left button is

depressed the first cursor position data is

data of the current cursor position. When the left button is

released the second cursor is fixed and the difference (delta)

between second and first cursors is measured in the approriate amplitude

and time windows.

• Samples, Average, Min, Max modes enable the appropriate figure

measured

minimum or maximum value accordingly.

includes five different self explanatory parameters that the

between

subtracted

the cursors. It is either number of samples, average,

from the

Fig. B17

WORLD PRECISION INSTRUMENTSB-10

Page 21

APOLLO 4000

OPERATING INSTRUCTIONS

Fig. B18

Fig. B19

Fig. B20

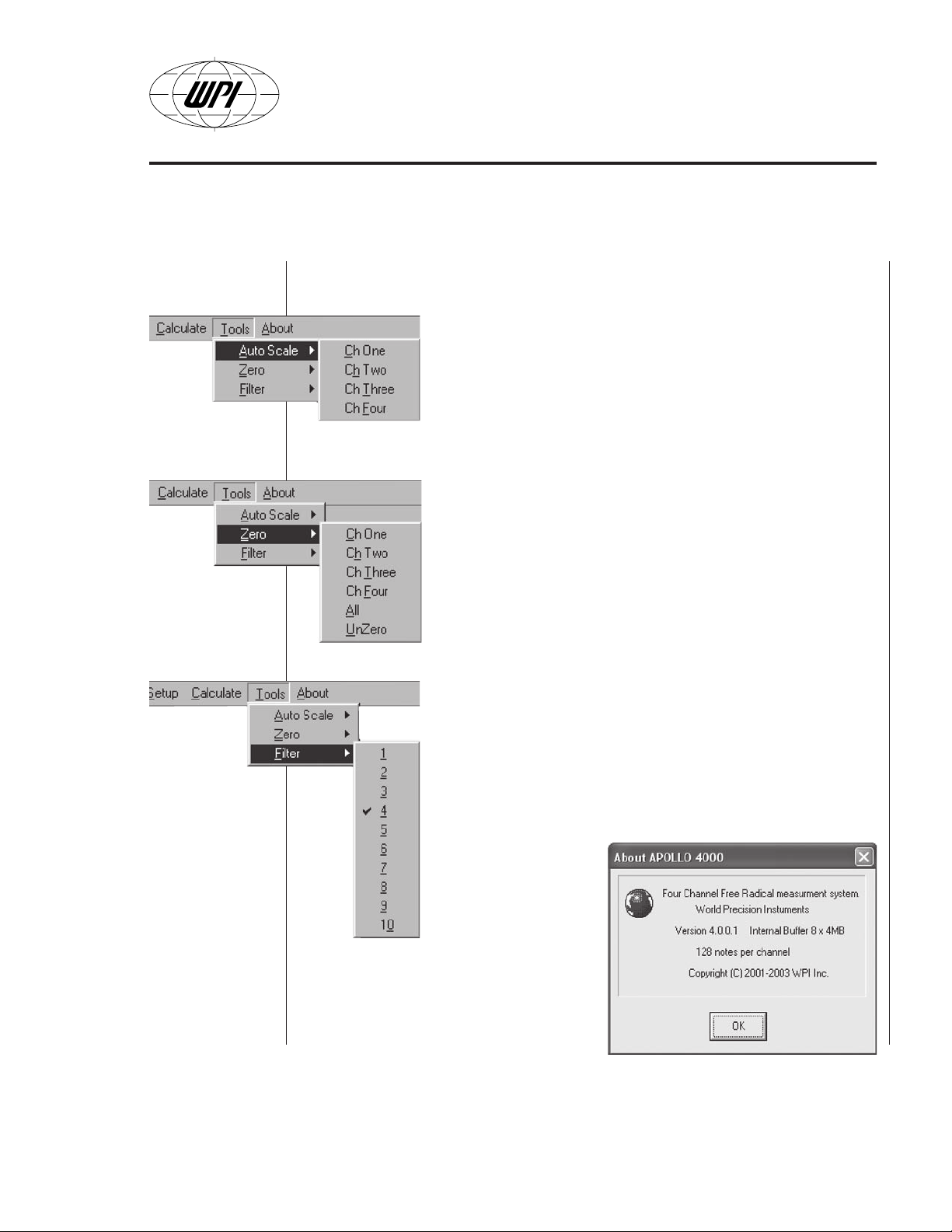

Tools Menu

process.

includes several tools to simplify and improve the acquisition

• Auto Scale. Selecting this option (Fig. B18) allows the user

to quickly find the signal within the plotting windows. This

option moves the vertical zero position and sets vertical

scale to an odd value.

• Zero option subrtacts the current value from the collected

data. The

channel individually, all together or unzero all of previously

“zeroed” channels. The subtracting value is acquired at the

moment of selecting the appropriate action. Zero operation

can be applied as many times as needed. The unzeroed

value is always displayed, too.

• Filter (Fig. B20) applies a moving average digital filter to

the upcoming data. It helps to reduce noise and artifacts if

desirable. Note that the filter does not remove or substitute

data but rather makes the fast transitions of the signal

smoother. There are 10 different orders of filtering from 5

samples averaging (corresponding to filtering level 1) to 50

samples averaging (corresponding to filtering level 10). The

user must select

the most

appropriate filter

for the required

application.

Zero

menu (see Fig. B19) allows to reset each

About Menu

current version of the Apollo 4000 software.

WORLD PRECISION INSTRUMENTS B-11

(Fig. B21) shows the

Fig. B21

Page 22

APOLLO 4000

OPERATING INSTRUCTIONS

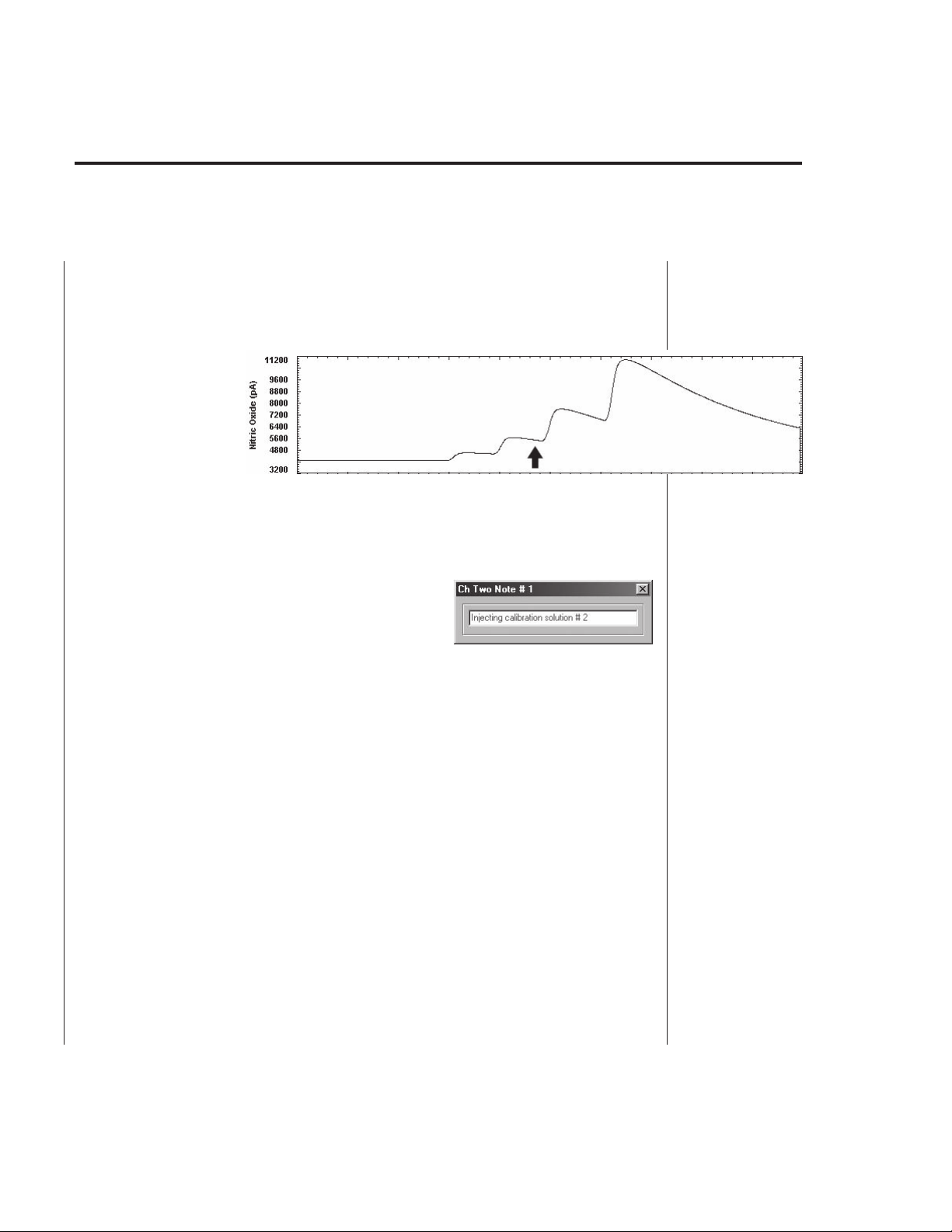

Adding a note: To add a short note to a trace while recording, switch the

operating mode from “PLOT” to “ANALYZE” (see page B-10). The data is still

recorded in the background although the new incoming data is not plotted. Rightclick a point on the trace where you want the Note to be added (see Fig. B22).

This will create a

mark at that place.

Double-click the

created mark. A Note

window will open

where a message of

up to 64 characters can be typed in (see Fig. B23). After the message is entered,

close the window. The mark will remain on the trace and can be double-clicked for

later viewing. Switch to “PLOT” to observe the data as they are being recorded.

To remove a mark from a trace, delete the message from the Note window. When

the Note window is closed, the Note mark will

disappear.

Fig. B22

Fig. B23

WORLD PRECISION INSTRUMENTSB-12

Page 23

OPERATING INSTRUCTIONS

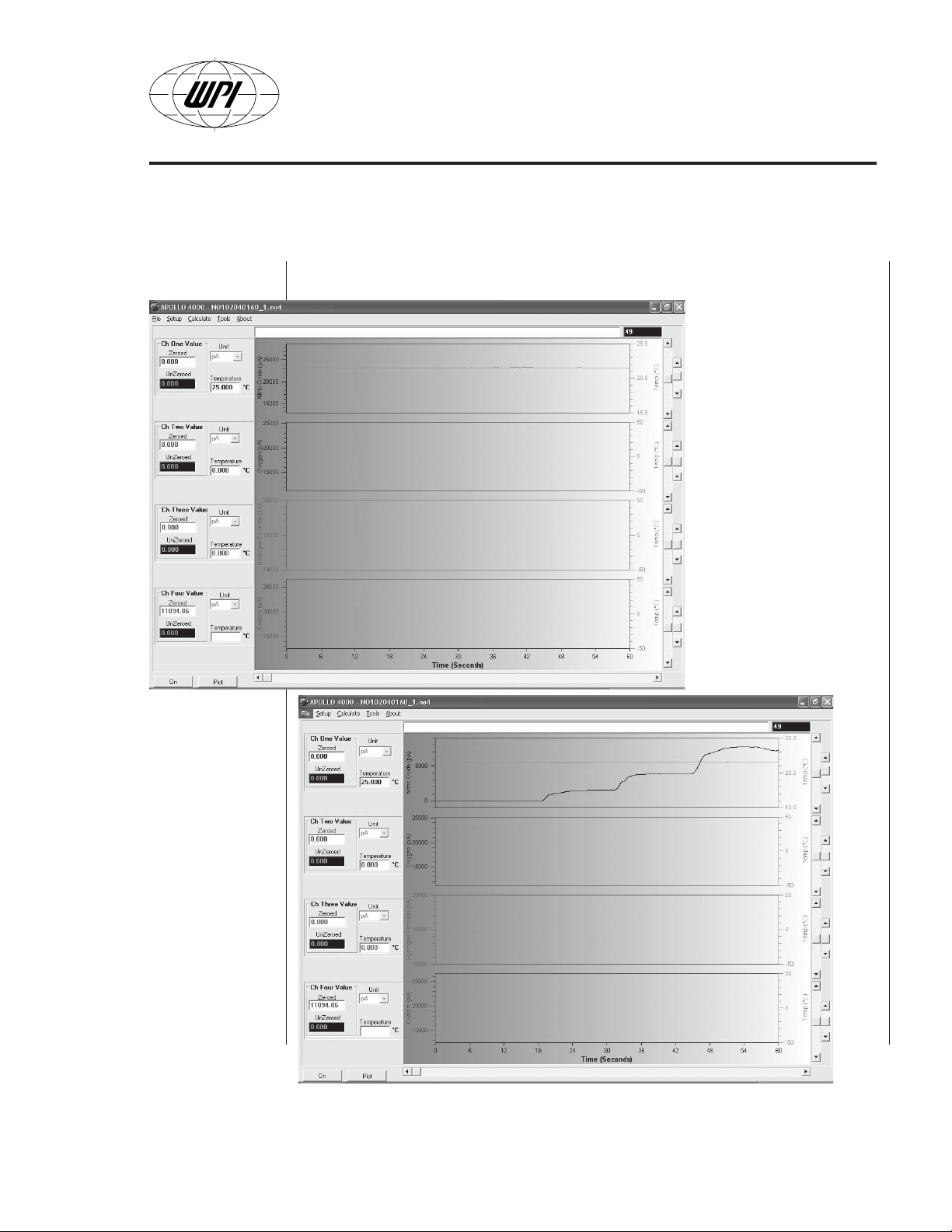

Example of a real signal application

An example file is

loaded in the Apollo

4000 (Fig. B24). Note

the temperature sensor

is also connected to

channel 1 (

line). However, the

sensor signal is not

seen. If we apply

Scale

appears as follows (see

Fig. B25).

APOLLO 4000

i.e.

, 25°C

Auto

to the channel 1 it

Fig. B24

Fig. B25

WORLD PRECISION INSTRUMENTS B-13

Page 24

APOLLO 4000

OPERATING INSTRUCTIONS

Fig. B26 demonstrates another option that the software offers: a second plotting

window allows the data in any of the channels to be plotted separately for more

detailed viewing. To enable the second window the user must double click inside

the appropriate channel plot. The second window has a distinctive yellow

background color. Only one second window can be opened at the same time. The

size of the second window can be controlled by regular Windows controls

( ).

There are cursors enabled inside the second window and the appropriate value

and delta measurements displayed. Please note that the trace on the expanded

window is a snapshot of the window you double-clicked and is not updated with

time.

Fig. B26

WORLD PRECISION INSTRUMENTSB-14

Page 25

APOLLO 4000

NITRIC OXIDE DETECTION

USING THE APOLLO 4000 TO DETECT NITRIC OXIDE

Initial Set-up

Attach the nitric oxide sensor to the required sensor input channel on the APOLLO

4000. From the main Setup menu of the software, select the correct poise voltage

“Nitric Oxide” and appropriate Range for the selected channel. The electrode must

now be calibrated.

Calibration of the NO Sensor

Accurate measurements of NO require an accurate calibration. Three calibration

methods are described in this section. The first and most convenient method is based

on a simple chemical reaction which generates known amounts of NO (from NO

This method can only be used with the 2.0 mm sensor (ISO-NOP).

-

2

).

The second method is based on the decomposition of the S-nitrosothiol NO-donor,

SNAP using either Cu(I) as described in Method I or Cu(II) as outlined in Method II,

as a catalyst. The NO liberated from SNAP is used to calibrate the sensor.

The third method involves preparing aqueous solutions of NO standards from saturated

NO solutions.

The Calibration Kit

Perform the calibration using the NO calibration kit (WPI catalog #5435) which consists

of the following items:

Plastic stand with two holes; two glass vials; two silicon septums without holes;

two silicon septums with holes and radial slit; one short needle; one long needle.

The chemicals required for the calibration are not provided.

NOTE: The NO chamber (WPI #NOCHM) can be used as an alternative to the use

of the calibration kit. Designed specifically for use with 2.0 mm electrodes, the

chamber can be adapted to other probes. Calibration temperatures from 4 - 40°C

can be controlled using an external circulating bath.

WORLD PRECISION INSTRUMENTS C-1

Page 26

APOLLO 4000

NITRIC OXIDE DETECTION

Calibration by the chemical generation of NO

(Type of NO sensor that can be calibrated with this method: ISONOP)

This method is recommended for use with the 2.0 mm sensor (ISO-NOP). However,

because it requires the use of strong acid it cannot be used with other NO sensors.

The first step is to prepare the following two solutions:

Solution #1: 0.1 M H

+ 0.1 M KI

2SO4

To make 500 mL of solution requires:

4.9 g of H2SO4 (2.7 mL of concentrated H2SO4 {18.4 M})

8.3 g of KI

Slowly

add the sulfuric acid to about 400 mL of distilled water while stirring. Then

add the KI and mix; finally add distilled water to a final volume of 500 mL.

Solution #2: 50 µM KNO

(or NaNO2)

2

The recommended method for preparing this solution is to purchase an ion

chromatography liquid nitrite standard (NaNO2 or KNO2) which may be diluted as

appropriate. Standard Nitrite is available from WPI, catalog #7357.

Alternatively, crystalline reagent KNO

may be used, but the user should note that

2

KNO2 is extremely hygroscopic and degrades once exposed to atmospheric

moisture. It is therefore recommended that if the crystalline reagent is to be used

that the reagent packaged under argon be purchased (available from Eastman

Kodak Chem #105 7462), and that it be stored in a desiccator. While this will

extend the life of the reagent, it will need to be replaced more frequently than will

the liquid standard. The standard nitrite solution prepared from this compound

should be stored in a gas-tight bottle and refrigerated.

This method of calibration is based on the following reaction:

2KNO2 + 2KI + 2H2SO4 → 2NO + I2 + 2H2O + 2K2SO

4

(1)

where a known amount of KNO2 is added to produce a known amount of NO. The

quantity (and so the concentration) of NO generated can be calculated directly

from the stoichiometry if the concentrations of the reactants are known. Since KI

and H2SO4 are present in great excess the limiting reagent is KNO2. Experiments

WORLD PRECISION INSTRUMENTSC-2

Page 27

APOLLO 4000

NITRIC OXIDE DETECTION

have demonstrated that the nitric oxide generated from this reaction will persist

sufficiently long to calibrate the NO sensor easily and accurately.

Since the reaction goes to completion, the equation above states that the ratio

between KNO

tion will be equal to the amount of KNO

be equal to the diluted concentration of KNO

1. Record the value of the sensor current before removing it from the distilled

water in which the tip has been immersed during storage.

2. Immerse the ISO-NOP sensor tip in a strong saline solution (1 M), and after

waiting a few minutes for the current to stabilize record its value. If the current

Figure 4 —

calibration

setup

and NO is 1:1. Therefore the amount of NO generated in the solu-

2

added. The final concentration of NO will

2

in the solution.

2

Calibration Procedure

is offscale or unstable after

several minutes in solution,

it is likely that the membrane

has been damaged and the

sleeve needs to be

changed (refer to the

section on “Changing the

Membrane Sleeve”).

3. Place a magnetic stirring

bar into one of the glass

vials included in the

calibration kit. Add an

appropriate volume (

10 mL) of solution #1.

e.g.

,

4. Note that the calibration

should be carried out at the

temperature at which the

Fig. C1

calibration setup

—

measurements of NO are to be made. This can be accomplished by placing

the vial and stand in a water bath at the appropriate temperature, and allowing

the temperature of the solution in the bottle to equilibrate with the water bath.

WORLD PRECISION INSTRUMENTS C-3

Page 28

APOLLO 4000

NITRIC OXIDE DETECTION

5. Place the stand (and water bath if appropriate) on the magnetic stirrer, and

turn on the stirrer so that the bar is stirring at a moderate rate.

6. Secure the ISO-NO sensor in an electrode holder or micromanipulator (or use

one of the septums included with the start-up kit). Do not push the sensor

tip through the hole — slide the elctrode through the sliced side

of the septum. Carefully lower the sensor into the vial sealing the opening

with the septum. The sensor tip should be immersed about 2-3 mm into the

solution, and should not be in contact with stir bar. Be very careful when

inserting the sensor not to make contact between the cap and/

or bottom of the jar with the tip of the sensor. This could

damage the membrane of the sensor.

7. Wait until the current on the display becomes stable again before continuing.

This may take several minutes if the sensor has undergone a large temperature

change.

8. If you feel it is necessary to degas solution #1 prior to calibration, this can be

done by inserting one of the long stainless steel needles included with the

calibration kit through the septum so that the tip is in the solution. Attach the

needle through appropriate tubing to a source of pure argon gas (nitrogen

may also be used). Insert one of the short needles included with the kit

through the septum such that the needle tip is clearly exposed (not in the

solution) inside the vial. The small needle allows gas to escape, thereby

avoiding a buildup of pressure. Purge the solution at low pressure (5 psi or

less) for 15 minutes.

9. Once purging is complete and the gas source is turned off, remove the purging

and pressure relief needles.

10. One should allow a few minutes for the temperature to equilibrate with the water

bath again since purging with the gas may have changed the temperature.

11. Once the current has achieved a stable value, record this value.

12. Generally, it is not necessarry to pre-purge the calibration solution, since the NO

decays only very slowly in this solution.

WORLD PRECISION INSTRUMENTSC-4

Page 29

APOLLO 4000

NITRIC OXIDE DETECTION

Creating a Calibration Curve

To create a calibration curve, the user measures the current (pA) generated by the

addition of different amounts of KNO

Once the baseline has been set to zero, generate a known concentration of NO in

the solution by adding a known volume of a the NO standard (solution #2). For

example:

Addition 1:

Add 50 µL of solution #2 to 10 mL of solution #1. Then the amount of NO

produced can be calculated by simple dilution factors, as follows:

to the calibration solution.

2

Fig. C2 —

APOLLO4000

Calibration Output

50 µL of 50 µM KNO

(solution #2) into 10 mL solution #1 = 1:201 dilution.

2

Hence, amount of NO produced = 50 (µM) ÷ 201 = 0.2487 µM = 249 nM.

Likewise:

Addition 2:

100 µL of solution #2 added to the above solution

will produce 493 nM NO (

i.e.,

dilution factor =

1:101.5).

The output from the APOLLO4000 will look similar

to the example shown in Figure C2: here three

sequential additions of KNO2 have been made to

solution #1.

From this output a calibration curve can then be

created by plotting the changes in current (pA)

against the changes in concentration (nM). The

slope of this curve indicates the sensitivity of the

probe.

[NO] nM Response (pA)

00

249 332

493 746

966 1486

WORLD PRECISION INSTRUMENTS C-5

Page 30

APOLLO 4000

NITRIC OXIDE DETECTION

Once the sensitivity of the

probe has been ascertained

(in the above example the

sensitivity was 1.557 pA / nM)

the sensor is ready to use

experimentally.

NO2 and NO3 Determination

ISO-NO Calibration Curve Based on Tabulated Data

1600

1200

800

400

0

0 200 400 600 800 1000

Concentration of NO (nM)

Figure C3 —

APOLLO4000

Calibration Curve

We have recently developed a new reagent-less nitrate-reductor, called the

NITRALYZER™. The Nitralyzer is a very useful tool for researchers currently using

enzymatic conversion of NO3 to NO2. Researchers who use the Greiss method for

NO

determination will also be very interested to learn that using the ISO-NOP (and

2

the titration method for calibration described above) a detection limit for NO

as low

2

of 1 nM is routinely possible. This compares to a detection limit using Greiss

reagent of approximately 1 µM. Hence, the ISO-NOP is several orders of

magnitude more sensitive than the Greiss method. Information on the Nitralyzer is

aavailable from WPI.

WORLD PRECISION INSTRUMENTSC-6

Page 31

APOLLO 4000

NITRIC OXIDE DETECTION

Calibration of NO sensor by decomposition of SNAP

This method can be used to calibrated all NO sensors (see Ref. 1: Zhang,

“Novel Calibration Method for Nitric Oxide Microsensors by Stoichiometrical

Generation of Nitric Oxide from SNAP”

S-nitroso-N-acetyl –D,L-penicillamine (SNAP) is a stable NO containing compound

that can be used for quantitative generation of NO in solution. SNAP decomposes

to NO and a disulfide by product when dissolved in water. However, the rate of

decomposition of the SNAP is very slow. The kinetics controlling the decomposition

of SNAP depends on several parameters including, pH, presence of catalyst,

temperature and light.

In the procedure described here, SNAP is used in combination with a catalyst,

cuprous chloride, to generate known amounts NO in solution, which can then be

used to accurately calibrate various NO-sensors. The protocol does not investigate

all parameters involved in SNAP decomposition neither is it intended to propose a

model by which SNAP is decomposed.

Two methods are described here for the calibration of NO sensors based on

decomposition of SNAP. The first method relies on the use of Cu(I) as a catalyst for

the 100% conversion of SNAP into NO. This method is extremely accurate but

technically more demanding than the second method, which relies on the use of

Cu(II) for the partial but quantifiable conversion of SNAP to NO.

Electroanalysis

, 2000, 12: 6).

et al.

,

Method 1: Calibration by decomposition of a Snitrosothiol compound using Cu(I) as a catalyst

This method of calibration results in the 100% conversion of SNAP to NO. The

amount of NO produced, therefore, is based on the final concentration of SNAP.

CAUTION: The described calibration procedure requires the use of cuprous (I)

chloride, CuCl, where Cu (I) is the active catalyst for the conversion of SNAP to

NO. The calibration curve assumes only the presence of Cu (I) and hence a 100%

conversion efficiency of SNAP to NO (see “A novel method to calibrate nitric oxide

microsensors by stoichiometrical generation of nitric oxide from SNAP”, X. Zhang,

L. Cardosa, M. Broderick, H. Fein, I. R. Davis,

WORLD PRECISION INSTRUMENTS C-7

Electroanalysis

, 2000, 12(6),425-

Page 32

APOLLO 4000

NITRIC OXIDE DETECTION

428). However, in the presence of oxygen

Cu (I) is readily oxidized to Cu (II). This will

happen naturally if the compound is

exposed to air and/or there is inadequate

storage of CuCl. The oxidation product Cu

(II) is much less efficient at catalyzing the

conversion of SNAP to NO, and this would

appear during calibration as an apparent

low sensitivity of the electrode to NO.

Since Cu (I) is readily oxidized to Cu (II)

special precautions must be taken to keep

it in its reduced state prior to any

calibration. It is recommended that CuCl be

stored under inert conditions and if used in solution then the solution must be

degassed with inert gas and absent of all oxygen.

NOTE : If your laboratory is not adequately equipped to satisfy the conditions for

storage and use of CuCl please refer to the following section in the manual which

describes a similar calibration procedure based on the use of copper (II) sulfate

(CuSO4) or cupric (II) chloride CuCl

conversion of SNAP to NO.

Getting Started

in which Cu [II] is the active catalyst for the

2,

Figure C4 —

Responses of an

NO electrode to the

successive

additions of

100 nM SNAP into

CuCl saturated

solution (pH=5.5).

Also shown (inset)

is the resulting

calibration plot.

Prepare the following solutions:

#1—Saturated solution of cuprous chloride: This should be prepared by

adding 150 mg CuCl to 500 mL distilled deoxygenated water. The distilled water

can be deoxygenated by purging with pure nitrogen or argon gas for 15 min. The

saturated CuCl solution will have a concentration of approximately 2.4 mM at room

temperature and should be kept in the dark prior to use.

#2—Standard SNAP solution: Dissolve 5 mg EDTA in 250 mL of HPLC pure

water (HPLC grade, Sigma). Deoxygenate the solution using the method described

above. Add 5.6 mg SNAP to the solution. The Molarity of the SNAP solution ( SNAP

f.w.= 220.3) can then be easily calculated. Since the SNAP solution is very

sensitive to light and temperature it should be stored in the dark and in a

refrigerator until required. (Note: The decomposition of SNAP at low temperature,

WORLD PRECISION INSTRUMENTSC-8

Page 33

APOLLO 4000

NITRIC OXIDE DETECTION

in dark and in absence of trace metal ions proceeds very slowly due to the

presence of chelating reagent, EDTA). The standard SNAP solution can then be

used for many calibrations of NO probes throughout the day. However, since SNAP

will slowly decompose even if stored correctly as described, it is recommended

that a fresh standard stock solution of SNAP is prepared at the beginning of

everyday. This will ensure an accurate calibration of the NO sensor.

The concentration of SNAP

calculated as follows:

Where C is the concentration of SNAP in micromolars, A is the purity of SNAP, W is

weight of SNAP in milligrams and V is the volume of the solution in liters. If SNAP

purity is 98.5%, hence in the above example the concentration of SNAP is:

[C] = [98.5% x 5.6 / (220.3 x 0.25)] x 1000 = 100.1 µM

Note: The purity of SNAP used is extremely important to ensure an accurate

calibration. We recommend the use of high grade SNAP with minimal purity of 98%

or better. SNAP can be purchased from WPI in various amounts.

Calibration Procedure

Within a nitrogen or argon environment, place 10.0 mL of solution #1 (CuCl) in a

20 mL vial (supplied in the calibration kit). Drop a small stirring bar into the

solution, and place the vial on the top of a magnetic stirring plate. Immerse a NO

probe into this solution, and while stirring, allow the background current to decay

and stabilize for 3-5 min. As soon as the background current becomes stable start

recording the data on the APOLLO4000.

Next inject 3 aliquots containing 5 µL, 10 µL and 20 µL sequentially of the SNAP

stock solution (solution #2) into the vial containing cuprous chloride solution.

Depending on the required calibration range (

produced) desired, the volumes of SNAP stock solution could be increased to

produce a greater concentration of NO. It is recommended that calibration range

be kept close to the anticipated experimental concentration of NO.

(and hence NO produced)

[C] = [A•W/(M•V)]1000

i.e.,

the final amount of NO

in the stock solution is

Immediately following the first addition of SNAP into Solution#1 the current (pA) output

from the ISO-NO will be seen to increase rapidly. Within a few seconds the response

WORLD PRECISION INSTRUMENTS C-9

Page 34

APOLLO 4000

NITRIC OXIDE DETECTION

will reach a plateau and the second aliquot of SNAP can then be added. Successive

additions of the remaining aliquots of SNAP can be made in a similar way.

A calibration curve can be constructed by plotting the signal output (pA) vs

concentration (nM) of SNAP. Each addition of SNAP corresponds to equivalent NO

concentration. The response should be very linear from 10 to 1000 nM.

The sensitivity of the NO probe can be established from the gradient of the response

curve. The sensitivity of the ISO-NOP sensor is about 1 pA/nM. Once the slope of the

probe has been determined the value can be entered into the APOLLO4000

software program (see previous section) if the user wishes the observe data in

concentration mode (

Note: Remember that most NO probes are sensitive to temperature changes. It is

therefore recommended that the calibration of a NO sensor is performed at the

experimental temperature.

i.e.

, nM, µM).

Method 2: Calibration by decomposition of SNAP using

Cu(II) as a catalyst

This method of calibration relies on the use of Cu(II) for the partial but quantifiable

conversion of SNAP to NO. This procedure can be used as an alternative to the

previous method in which Cu (I) is the active catalyst for the conversion of SNAP to

NO. In this procedure Cu(II) is substituted as a catalyst for ease-of-handling.

NOTE: Experimentally it has been shown that Cu(II) is less efficient as a catalyst in

the conversion of SNAP to NO (

60%). The accuracy of the calibration may also be reduced (see discussion).

S-Nitriso-N-acetyl-D,L-penicillamine (SNAP) is a stable NO containing compound

that can be used for quantitative generation of NO in solution. SNAP decomposes

to NO and a disulfide byproduct when dissolved in water. However, the rate of

decomposition is very slow. The kinetics of decomposition for this reagent is a

function of several parameters including pH, presence of a catalyst, temperature

and light.

In the procedure described here, SNAP is used in combination with a catalyst,

copper (II) sulfate (CuSO4) or cupric (II) chloride (CuCl2), to generate a known

quantity of NO in solution. Note that this protocol does not investigate the effects of

e.g.,

conversion ratio is reduced to approximately

WORLD PRECISION INSTRUMENTSC-10

Page 35

APOLLO 4000

NITRIC OXIDE DETECTION

all parameters involved in SNAP decomposition nor does it propose a model by

which NO is decomposed. The presented procedure provides an empirical

estimation of the amount of generated NO based on the molarity of a standard

stock solution of SNAP under a controlled set of parameters.

Getting Started

Prepare the following solutions:

Solution #1: Dissolve 5 mg EDTA in 250 mL of water (HPLC grade).

Solution #2: Prepare 250 mL 0.1 M copper (II) sulfate (or cupric (II) chloride) in

distilled water.

Preparing standard SNAP solution:

To prepare the stock solution of SNAP, weigh approximately 5.0 mg +/- 2.0 mg of

SNAP and add it to solution #1. Calculate the Molarity of SNAP solution (SNAP f.w.

= 220.3). Decomposition of SNAP in the stock solution proceeds very slowly due to

the presence of chelating reagent, EDTA. Thus the rate of decomposition is

negligible and the stock solution of SNAP remains relatively stable for at least 5

hours if kept in refrigerator.

Note: The purity of standard reagent, SNAP, is very important for the reported data.

Use high grade SNAP with minimal purity of 95% or better. SNAP can be

purchased from WPI (catalog # SNAP50, SNAP100, SNAP500).

Calibration Procedure

Place 10.0 mL of solution #2 in a 20 mL vial (supplied in the calibration kit). Drop a

small stirring bar into the solution, and place the vial on the top of a magnetic

stirring plate. Immerse a NO probe into this solution, and while stirring, allow the

background current to stabilize for about 3-5 minutes. As soon as the background

current becomes stable start the recording.

Next, sequentially inject three aliquots of SNAP solution, 5 µL, 10 µL, and 20 µL,

into the vial containing copper sulfate solution. The current output will rapidly

increase upon addition of first aliquot and will reach a plateau within a few

seconds. Inject the second aliquot, 10 µL, as soon as the first signal reaches a

plateau. Finally add the third aliquot as the second signal reaches its plateau. If

aliquots are not added promptly when reaching the previous plateau, the signal will

WORLD PRECISION INSTRUMENTS C-11

Page 36

APOLLO 4000

NITRIC OXIDE DETECTION

slowly decline because generated NO is quickly oxidized to nitrite and nitrate

which will not be detected by the probe.

Note: You can change the volume of injected aliquots according to the

concentration of SNAP stock solution. Decrease the volume of aliquot if the

electrode is very sensitive or increase the volume of aliquot if the electrode is less

sensitive.

Because NO sensors can be calibrated in a linear fashion, the magnitude of every

signal should almost double as the volume of SNAP solution added is doubled in

the course of the calibration. Use the recorded data to construct a calibration

curve. The calibration curve can be simply constructed by plotting the signal

output (

every addition of SNAP solution corresponds to a particular NO concentration. This

will be discussed below. After the sensitivity of the NO probe is established, the

APOLLO4000 software can be programmed to display data in either concentration

mode (

e.g.,

in pA) vs. the concentration of SNAP added at that time. Note that

i.e.,

nM, mM) or redox current (

i.e.,

pA, nA).

The standard SNAP solution can be used for the calibration of NO probes

throughout the day. Store the solution in the dark and refrigerate when not in use.

Prepare a fresh stock solution of SNAP in the beginning of every day to ensure

minimal decomposition of SNAP in the stock solution. Concentration of SNAP

decreases to 5-10% of its nominal value after approximately 4-5 hours.

NOTE: Remember that most NO probes are sensitive to changes in temperature.

It is therefore recommended that the calibration of your sensor is performed at

experimental temperature.

WORLD PRECISION INSTRUMENTSC-12

Page 37

APOLLO 4000

NITRIC OXIDE DETECTION

Predicting the level of detectable NO according to the

molar ratio of SNAP in the presence of catalyst

(Method II)

Experiments have shown that SNAP is decomposed instantaneously under the

following set of experimental conditions:

Temperature 25°C

Catalyst solution 0.1M copper sulfate

SNAP WPI, 98% purity. Fresh stock solution with

5 mg/250 mL solution EDTA added.

Copper sulfate is at equilibrium with ambient air (aerobic conditions).

SNAP (RSNO) decomposes to NO and a disulfide byproduct according to the

following equation:

2RSNO → 2NO + RS-SR

Theoretically, the concentration of generated NO should be equal to the final

concentration of SNAP in the copper sulfate solution in the calibration vial if the

decomposition goes to completion and if the generated NO is detected quickly

before it is oxidized to nitrite and nitrate.

However, it is expected that the level of detectable NO will be below the theoretical

value because the copper sulfate solution was at equilibrium with ambient air, and

consequently a portion of the generated NO would have been immediately oxidized

to nitrite and nitrate before it was measured by the NO sensor. In addition, it is

possible that decomposition of SNAP does not go to completion even in the

presence of a catalyst. Results on the kinetics of SNAP decomposition in the

presence of a catalyst in an anaerobic environment are published elsewhere (Zhang

et al.

, “Novel Calibration Method for Nitric Oxide Microsensors by Stoichiometrical

Generation of Nitric Oxide from SNAP”,

Our experimental data indicates a conversion efficiency of SNAP to NO of

approximately 0.6 (

sensor in a solution, which is at equilibrium with ambient air and at the

experimental conditions described above. Hence for each mole of SNAP, 0.6 mole

of NO is liberated under the proposed set of parameters. It is assumed the other

40% of SNAP is either not decomposed or a proportion that is decomposed to NO

i.e.,

60%). This result is only applicable for calibration of a NO

Electroanalysis

, 2000, 12: 6).

WORLD PRECISION INSTRUMENTS C-13

Page 38

APOLLO 4000

NITRIC OXIDE DETECTION

is subsequently oxidized immediately before it is detected by the NO sensor.

Example for creating a calibration curve and related computations

1. SNAP weight = 6.4 mg.

2. SNAP was dissolved in 250 mL solution #1 to obtain the standard stock solution.

3. 20 µL, 40 µL, and 80 µL of SNAP stock were added sequentially into 10 mL of

solution # 2.

4. The current was continuously recorded during the course of the calibration.

5. A standard calibration curve was constructed according to the recorded date.

[SNAP] [NO] = 0.6 X [SNAP] Output Current

232.4 nM 139.4 nM 230 pA

462.0 nM 277.2 nM 488 pA

916.8 nM 550.1 nM 1001 pA

Y = -32.038 + 1.88X

The data from calibration curve indicates that this procedure allows an excellent

linear calibration of NO probes (R2= 1). The accuracy of calibration is

approximately +/- 10% from mean. The source of error arises most probably from

gravimetric measurement of the standard reagent, SNAP. In addition, purity of

SNAP as well as partial oxidation of generated NO in the calibration solution could

contribute to this error. Such a deviation may not be so important when NO is

quantified in biological systems because most often the ability to measure changes

in the basal concentration of NO is more significant than measurement of the

absolute level of NO.

WORLD PRECISION INSTRUMENTSC-14

Page 39

APOLLO 4000

NITRIC OXIDE DETECTION

Calibration of NO sensor using aqueous standards prepared with NO Gas

The following method can be used with all NO sensors.

WARNING: Nitric oxide must be handled only in a well-ventilated

area, usually a laboratory fume hood with forced ventilation

U.S. Occupational Safety and Health Administration has set a time-weighted

average maximum NO value as 25 ppm. That is to say that 25 ppm is cited as the

maximum concentration to which workers may be continually exposed. Brief

inhalation of concentrations as low as 200 ppm could produce delayed pulmonary

edema which may be fatal after an asymptomatic period of up to 48 hours after

the initial exposure.

It is therefore critical that the personnel handling

the gas be thoroughly familiar with the Material Safety Data Sheet

(MSDS) and proper handling procedures.

The precautions recommended

by the gas manufacturer must be followed.

. The

Preparing an NO Standard

This method has the advantage of allowing the user to calibrate NO sensors in the

same environment in which the experimental measurements will be made.

However, it has the disadvantages of added cost, inconvenience, and greater

hazard to the user. All of these factors must be taken into consideration. The setup

for preparing a saturated NO aqueous solution is illustrated in Fig. C5.

1. Be certain the fume hood is functioning. See Fig. C5.

2. Make sure that all fittings and connections are secure. The tubing to be used

should not be permeable to NO. We recommend Tygon® tubing if a polymer

tubing is to be used; this is permeable to NO but has the best performance

compared to other polymer tubing of which we are currently aware. Ideally

glass tubing should be used. If Tygon® tubing is used, note that prolonged

exposure to NO affects its properties; therefore it is recommended that the

tubing be inspected frequently and that it be replaced when it appears to be

WORLD PRECISION INSTRUMENTS C-15

Page 40

APOLLO 4000

NITRIC OXIDE DETECTION

*Lecture bottle

of NO (14.2

liters, 98.5%)

obtained from

Aldrich, catalog

#29.556-6;

telephone 800558-9160

brittle. The pressure regulator and tee purge adaptor should be stainless

steel. This is because nitric oxide is a corrosive gas.

3. Prepare 100 mL of a 10 % (by weight) KOH solution and place it in the

sidearm flask as illustrated above. The flask should be sealed with a stopper

through which the tubing passes by means of a Luer fitting to a syringe needle

which extends almost to the bottom of the flask. Tubing is used to connect the

side arm of the flask to the vial containing the water to be equilibrated with

NO. The KOH solution is used to remove other nitrogen oxides from the NO

gas.

4. Place 20 mL of distilled (preferably deionized) water in a small glass vial. Seal

the vial with a stopper and insert through the stopper a long syringe needle

which extends almost to the base of the vial. Connect this syringe needle to

the tubing from the KOH flask as illustrated. Insert an additional shorter

syringe needle which should not extend into the solution. This acts as

a pressure relief during purging.

Figure C5

Setup for preparing

a saturated NO

aqueous solution

must be in a fume

hood with forced

ventilation. Nitric

oxide is highly toxic

and, as illustrated,

escapes into the

atmosphere during

preparation of the

standards.

—

WORLD PRECISION INSTRUMENTSC-16

Page 41

APOLLO 4000

NITRIC OXIDE DETECTION

5. Place the distilled water vial in an ice-water bath. Reducing the temperature

increases the solubility of NO in solution. Thus when the solution is used at

room temperature you will be assured of a saturated NO solution.

6. Purge the system with argon (or nitrogen) gas for a period of 30 minutes at a

moderate flow rate such that the pressure is maintained at a safe level (1-2

psi). When purging it should be observed that gas is indeed bubbling through

the KOH solution as well as the distilled water. After 30 minutes turn off the

argon source, and switch the tee purge valve to the correct position for

purging with NO from the lecture bottle.

7. Purge the system with NO for 5-10 minutes if using a pure source (longer if the

NO source is not pure). Again make sure that gas is bubbling through both

solutions. Warning: NO is now escaping from the pressure relief

needle in the stopper of the distilled water vial. It is imperative

that the fume hood be running at maximum capacity with the

front panel closed (in the down position).

8. After the time in step 7 has elapsed turn off the NO source.

9. Immediately remove the two needles from the distilled water vial.

10. Set the tee purge valve for purging with argon (or nitrogen) gas, and turn on

the argon source. Purge the system for 5-10 minutes at a moderate flow rate.

Gas should be bubbling through the KOH and then escaping from the flask

into the atmosphere. Again be sure that the fume hood is ventilating well.

11. Turn off the argon (or nitrogen) source, and allow the fume hood to continue to

ventilate for 10-15 minutes so as to ensure that all traces of NO gas are

removed from the atmosphere.

12. The solution of distilled water should now be saturated with NO. The

concentration of NO produced by this saturation is dependent upon the

temperature. At 0° C, the concentration is approximately 3.3 mM, and at 20°C

the concentration is approximately 1.91 mM.

13. Dilutions of known concentration can be prepared from this saturated solution

In preparing a dilution, be careful not to unseal the vial, for this

exposes the solution to atmospheric oxygen.

Once the dilutions are prepared, it is a simple matter to calibrate the instrument.

WORLD PRECISION INSTRUMENTS C-17

Page 42

APOLLO 4000

NITRIC OXIDE DETECTION

Measurement of NO

It is impossible to outline in detail how to use NO sensors to measure NO in every

experimental set up the user may encounter. There are, however, some guiding

principles of which the user should be aware to exploit fully the capabilities of the

technology. These are outlined below.

NO Delivery

For any measurement of NO to be made, the NO must reach the sensor surface so

it can react on the surface of the electrode. This point is of particular concern

because in many experiments the lifetime of NO is quite short. This is especially so

in biological systems where compounds such as hemoglobin can reduce the halflife of NO to less than a second. It is therefore very important that the experimental

set up is designed so as to maximize delivery of NO to the sensor. In particular, the

tip of the sensor should be placed as close as possible to the site of release of NO.

Durability and Handling

The user must excercise caution when handling any NO sensor to avoid actions

which could damage the sensor tip. The sensor membrane and membrane coatings are extremely delicate and improper handling will lead to damage.

Environmental Influences

There are two environmental parameters to which NO sensors are quite sensitive:

temperature and electrical interference, both of which are discussed in greater

detail below.

Temperature

Note that the sensitivity of the NO sensor is temperature-dependent. This is due to

the effects of temperature on the partial pressure of NO in either liquid or gas

samples, on the permeability of the membrane or coatings, and on the

conductivities of various circuit components. It is therefore recommended that any

calibration is performed at the same temperature as the experiment.

Electrical Interference

Although nitric oxide monitoring using the Apollo 4000 involves the measurement

of extremely small currents (

e.g.,

less than 1 pA), the intrinsic noise level of the

WORLD PRECISION INSTRUMENTSC-18

Page 43

APOLLO 4000

NITRIC OXIDE DETECTION

Apollo 4000 and NO sensors is sufficiently low so as to provide accurate

measurements of nitric oxide. However various external electrical sources may

couple to the system and produce large extraneous signals in the output record.

The magnitude of this external noise depends on the environment of the laboratory.

If the interference introduced by the electrical signals in the environment is large,

the first step towards eliminating it is to ground and shield the system properly. See

the section on Grounding and Shielding Procedure for the Apollo 4000.

WORLD PRECISION INSTRUMENTS C-19

Page 44

APOLLO 4000

NITRIC OXIDE DETECTION

Maintenance of NO Sensors

The various NO sensors, if well cared for, will require very little maintenance.

Maintenance of the ISO-NOP

When the ISO-NOP sensor is not being used it should be left connected to the

APOLLO 4000 in

tip suspended in distilled water. The basic structure of the ISO-NOP sensor is quite

simple (see Fig. C6). It consists of an internal NO-sensing working/counter

electrode combination. This electrode fits inside a disposable protective stainless

steel sleeve (WPI #5436)

separated from the external environment by a gas permeable polymeric membrane

covering the end of the stainless sleeve. The other end of the sleeve is flanged.

The locking cap is used to attach the sleeve to the probe handle.

ON

position (or to Pre-Polarizer NSA-1, NSA-2 or NSA-3) with the

which must contain fresh electrolyte

(WPI #7325), and is

When the sensor is fully assembled (

i.e.,

with locking cap and sleeve in place) the

internal electrode should be seen to press gently against the polymeric membrane,

which will then be slightly stretched. This ensures that the electrolyte diffusion layer

will be as thin as possible, which is necessary to minimize sensor response time.

Once a membrane is stretched it is permanently deformed and cannot usually be

reused if the sleeve is removed from the electrode. Four additional membrane

sleeves accompany the ISO-NOP in the start-up kit, together with a MicroFil™

electrolyte filling needle (WPI #MF28G67-5) and 1 mL syringe. Additional sleeves

stainless steel

gas permeable

membrane

combination

working / counter

electrode

sleeve

locking cap

probe

handle

connection

to meter

Figure C6

Basic probe

structure of ISONO sensor

—

WORLD PRECISION INSTRUMENTSC-20

Page 45

APOLLO 4000

NITRIC OXIDE DETECTION

can also be purchased separately (WPI #5436). With proper care and by following

the instructions below a membrane sleeve should last more than one month.

Cleaning the Membrane

The membrane sleeve itself requires very little maintenance. The primary concern

is to avoid damage to the membrane and to keep it as clean as possible. After

each use the membrane should be cleaned by suspending the tip in distilled water

for 20-30 minutes to dissolve salts and remove particles, which may have

accumulated on the membrane. If the probe was used in a protein rich solution the

tip should first be soaked in a protease solution for several minutes to remove

protein build-up, and then in distilled water. Enzymatic detergent (

#7363) can also be used. The membrane sleeves can also be sterilized chemically

using an appropriate disinfectant (

matter can be removed by briefly immersing the tip in an acid or base solution (at

times both may be necessary) for 10 seconds. A good indication of a dirty

membrane sleeve is a sluggish response or an unusually low sensitivity. If these

problems are not rectified by the above cleaning procedures then the membrane

sleeve should be replaced.

e.g.,

Cidex, WPI #7364). Accumulated organic

The probe cannot be used in organic

solvents.

e.g.,

Enzol, WPI

Replacing a Membrane Sleeve

All membrane sleeves will eventually have to be replaced by the user. The

procedure for doing so is simple and straightforward.

1. Unscrew the locking cap from the handle.

2. Hold the stainless steel sleeve and remove it with the locking cap from the

internal electrode assembly, being careful not to bend the electrode assembly

when doing so.

3. Rinse the internal electrode with distilled water (particularly the tip) and let it

soak for at least 15 minutes. Be careful not to let water get into the handle. The

current on the ISO-NO meter should go offscale when the electrode is being

rinsed.

4. Gently dry the electrode with a soft tissue (Kimwipes). Be sure to dry

thoroughly the flat surface at the tip of the electrode. After drying the current

should stabilize fairly quickly to a low value (

the electrode is in good working order.

e.g.,

0 - 20 pA). If this occurs then

WORLD PRECISION INSTRUMENTS C-21

Page 46

APOLLO 4000

NITRIC OXIDE DETECTION

5. If the electrode is not clean, repeat steps 3 and 4. If necessary the ISO-NOP

Rejuvenator (WPI #JUV) can be used restore sensitivity of an old electrode

(contact WPI for assistance).

6. Remove the locking cap from the old used sleeve, and gently slide it onto the

new replacement sleeve.

7. Dip the internal electrode 1-2 cm into the electrolyte provided in the ISO-NO

start-up kit, the current should go offscale during this. Using the MicroFil™

nonmetallic syringe needle and 1 mL plastic syringe, supplied, inject

approximately 100 microliters of electrolyte directly into the new sleeve. The

MicroFil supplied should be less than the length of the sleeve, so that it will not

puncture the delicate membrane at the tip of the sleeve during injection. If the

MicroFil is longer than the sleeve it can be cut to the correct length.

8. Slowly and smoothly insert the electrode into the sleeve, and screw the locking

cap into the handle. The electrode should be observed to press gently against

the membrane.

9. The current displayed on the meter at this time will be high or offscale.

10. Suspend the tip of the new assembled probe in distilled water.

11. After 10-15 minutes the current should no longer be offscale and will gradually

decrease with time. It may take several hours for the sensor current to reach a

low stable value, at which time it will be ready for use.

12. The integrity of the new membrane can be determined by immersing the probe

tip into a strong saline solution (1 M). If the current observed, after a few

minutes in the saline solution, increases dramatically or is offscale then the

membrane integrity is not good and a new membrane will have to be fitted.

13. When the ISO-NOP is not being used it should be stored with the tip

suspended in distilled water.

Additional membrane kits (WPI #5436) may be purchased separately.

Maintenance of Nitric Oxide Microsensors

WPI’s Nitric Oxide microsensors are maintenance-free consumable sensors that

are warranted against defect for 30 days from the date of purchase. The following

information should increase the lifetime of the sensor:

WORLD PRECISION INSTRUMENTSC-22

Page 47

APOLLO 4000

NITRIC OXIDE DETECTION

Tip care

The surface of the sensor tip is very sensitive and is covered with a unique layer of

propriety selective membranes. The tip of the sensor should never be handled as

this will damage the membranes and compromise the electrode’s selectivity for

NO. During use the electrode should be held securely, preferably using a micromanipulator or other similar device that permits accurate positioning.

The electrode should be cleaned periodically in distilled water and dried using soft

tissue paper. Organic contamination can be removed using a mild enzymatic

detergent such as ENZOL (WPI part # 7363)

Sterilization

The following methods can be used to sterilize the sensor:

• Ethylene oxide

• Cidex solution (WPI part # 7364)

Storage

NO microsensors should be stored dry in a cool place away from direct sunlight.

They can also be left attached to an ISO-NO Activator (WPI part # NSA-1, NSA-2,