WPG MRT411LDC, MRT49DC, MRT4HV11DC Operating Instructions Manual

KEEP FOR FUTURE REFERENCE

OPERATING

INSTRUCTIONS

INTENDED FOR USE BY SKILLED

PROFESSIONALS • READ AND

UNDERSTAND BEFORE OPERATING

908 W. Main • P.O. Box 368

Laurel, MT USA 59044

800-548-7341 (phone)

406-628-8231 (phone)

406-628-8354 (fax)

www.WPG.com

MANUAL ROTATOR/TILTER,

DC-VOLTAGE

Model numbers: MRT411LDC (shown), MRT49DC,

MRT4HV11DC

Record serial number in blank space above (to locate, see serial

Rev 29.0/10-19 MRT4-DC: #35070i

label on the product).

MRT4-DC: #35070 Rev 29.0/10-19ii

TABLE OF CONTENTS

SPECIFICATIONS .....................................................................................3

SAFETY...................................................................................................5

OPERATING FEATURES............................................................................6

ASSEMBLY..............................................................................................7

TO CHANGE THE PAD FRAME CONFIGURATION ..................................................9

Installing/Removing Extension Arms and Repositioning Vacuum Pads ............................10

Using Secondary Rotation Stops ....................................................................................... 11

INTENDED USE .....................................................................................12

LOAD CHARACTERISTICS...............................................................................12

OPERATING ENVIRONMENT ..........................................................................13

DISPOSAL OF THE LIFTER .............................................................................13

OPERATION..........................................................................................14

BEFORE USING THE LIFTER...........................................................................14

Taking Safety Precautions .................................................................................................14

Performing Inspections and Tests ..................................................................................... 14

Checking the Battery.........................................................................................................15

TO ATTACH THE PADS TO A LOAD ..................................................................16

Positioning the Lifter on the Load..................................................................................... 16

Sealing the Pads on the Load............................................................................................17

Reading the Vacuum Gauge.............................................................................................. 17

TO LIFT AND MOVE THE LOAD......................................................................18

Interpreting the Warning Light and Optional Warning Buzzer .........................................18

Watching Vacuum Indicators ............................................................................................18

Controlling the Lifter and Load ......................................................................................... 19

In Case of a Power Failure.................................................................................................19

TO ROTATE THE LOAD .................................................................................20

TO TILT THE LOAD ......................................................................................21

TO RELEASE THE PADS FROM THE LOAD .........................................................23

AFTER USING THE LIFTER.............................................................................23

Storing the Lifter............................................................................................................... 23

INSPECTIONS AND TESTS......................................................................25

INSPECTION SCHEDULE ................................................................................25

Rev 29.0/10-19 MRT4-DC: #35070iii

TABLE OF CONTENTS

TESTING ...................................................................................................26

Lifter/Load Compatibility Test...........................................................................................26

Operational Tests .............................................................................................................. 27

Vacuum Test......................................................................................................................27

Rated Load Test.................................................................................................................28

MAINTENANCE ....................................................................................29

VACUUM PAD MAINTENANCE.......................................................................29

Pad-to-Load Friction Coefficient .......................................................................................29

Pad Inspection ..................................................................................................................29

Pad Cleaning .....................................................................................................................30

BATT ER Y RECHARGE....................................................................................31

REPLACEMENT PARTS...........................................................................32

LIMITED WARRANTY ............................................................................33

TO OBTAIN REPAIRS OR WARRANTY SERVICE...................................................33

MRT4-DC: #35070 Rev 29.0/10-19iv

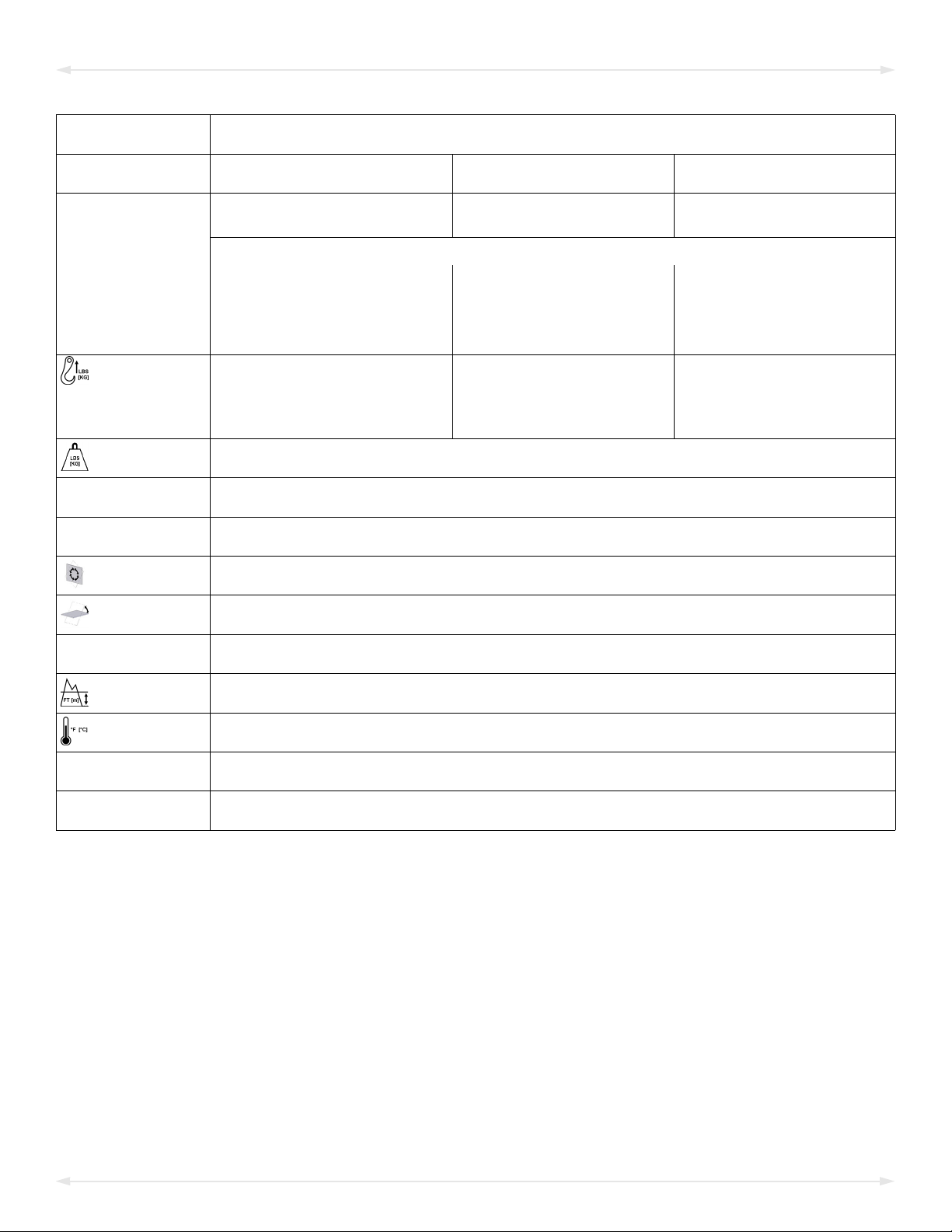

SPECIFICATIONS

Product

Description

Model

Number

Vacuum Pads

(4 each, standard rubber)

Pad Spread

Length ‒ Maximum

Length ‒ Minimum

Width ‒ Maximum

Width ‒ Minimum

Maximum Load

Capacity

Per-Pad

Weight

Power

System

Battery

Capacity

Rotation

Capability

Capability

Product

Options

Operating

Elevation

Operating

Temperatures

Service

ASME Standard

BTH-1

Total

Lifter

Tilt

Life

Designed for use with hoisting equipment, MRT4-DC lifters support loads using vacuum and manipulate

loads using manual 360° rotation and manual 90° tilt motions.

MRT49DC MRT4HV11DC MRT411LDC

1

2

9" [23 cm] nom. diameter

(Model VPFS9)

---------------------------- (to outer edges) ----------------------------

10" [25 cm] nom. diameter,

lipped (Model HV11)

11" [28 cm] nom. diameter,

lipped (Model G3370)

75¼" [192 cm] 77¼" [197 cm] 78¼" [199 cm]

29¾" [76 cm] 31¾" [81 cm] 32¾" [83 cm]

46½" [119 cm] 48½" [124 cm] 49½" [126 cm]

12¾" [33 cm] 14¾" [38 cm] 15¾" [40 cm]

3

125 lbs [56.5 kg] 150 lbs [68 kg] 175 lbs [80 kg]

500 lbs [225 kg] 600 lbs [270 kg] 700 lbs [320 kg]

135 lbs [62 kg]

12 volts DC, 3.5 amps

7 amp-hours

Manual, 360°, with latching at each ¼ turn (when required)

Manual, 90°, with automatic locking in vertical position

See separate instructions about options.

Up to 6,000' [1,828 m]

32° — 104° F [0° — 40° C]

20,000 lifting cycles, when used and maintained as intended

4

Design Category "B", Service Class "0" (see www.WPG.com for more information)

1...... Available with other rubber compounds for special purposes (see www.WPG.com).

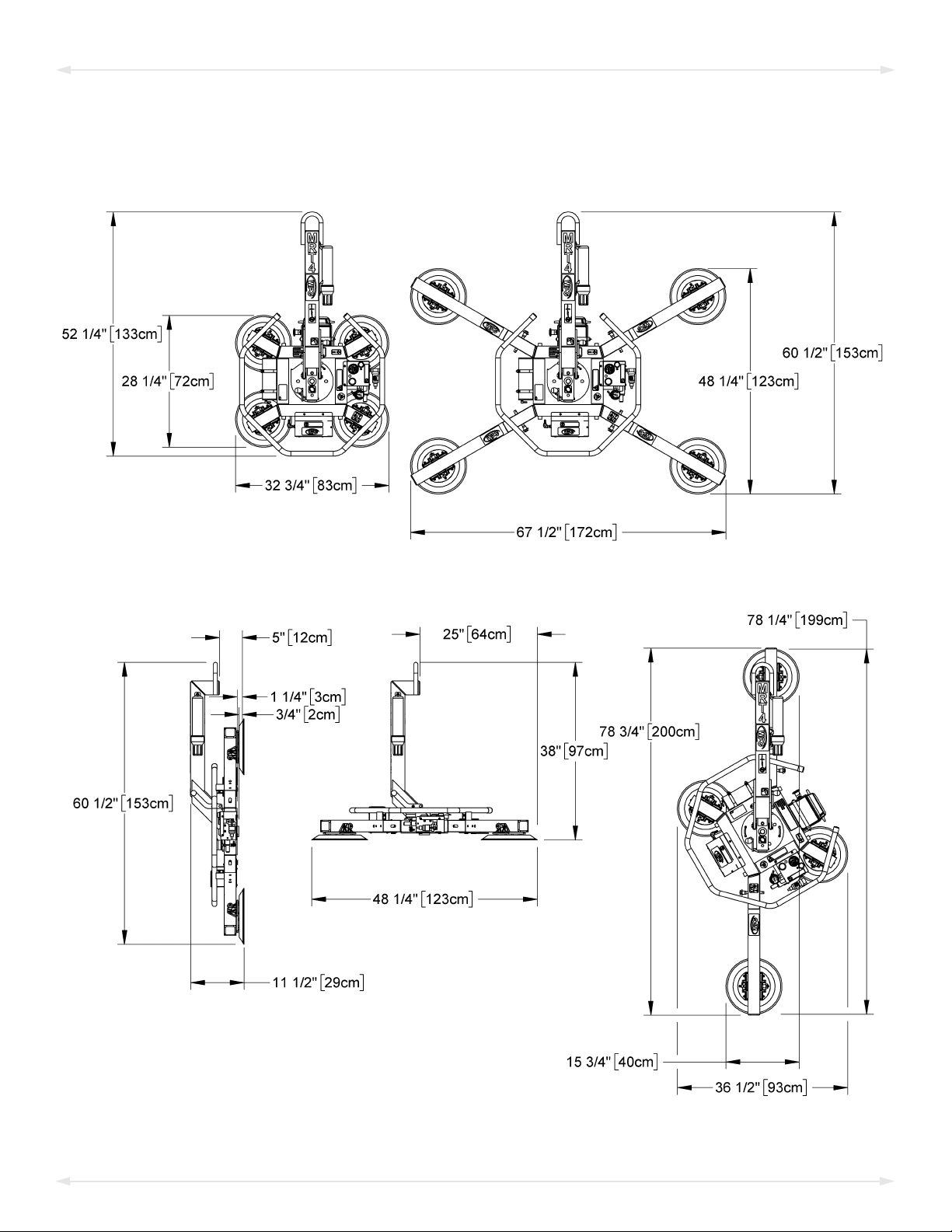

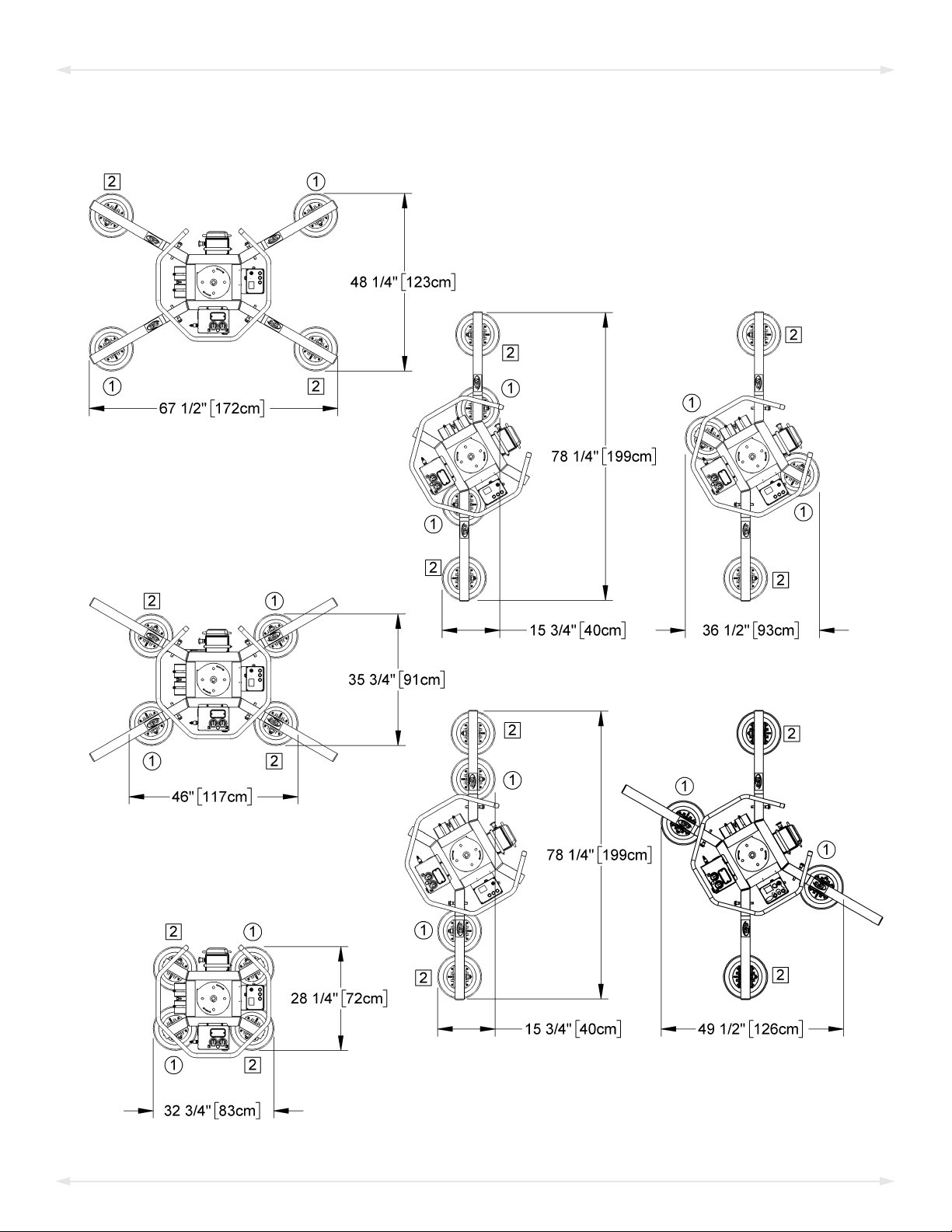

2...... The illustrations under “T

3...... The Maximum Load Capacity is rated at a vacuum of 16" Hg [-54 kPa] on clean, smooth, nonporous flat surfaces with a friction coefficient of 1. Pad

compound, load rigidity, strength, surface conditions, overhang, angle, center of gravity and temperature can also affect the lifting capacity. A “qualified

person” should evaluate the effective lifting capacity for each use (see definition under “Rated Load Test” on page 28).

4...... Vacuum pads, filter elements and other wear-out items are excluded.

O CHANGE THE PAD FRAME CONFIGURATION” on page 9 show the Pad Spread for all approved pad frame configurations.

!!–CE–!! This symbol appears only when a CE Standard is different from other applicable standards. CE requirements are

mandatory in the European Union, but may be optional elsewhere.

Rev 29.0/10-19 MRT4-DC: #350703

SPECIFICATIONS

Note: A standard MRT411LDC is shown.

MRT4-DC: #35070 Rev 29.0/10-194

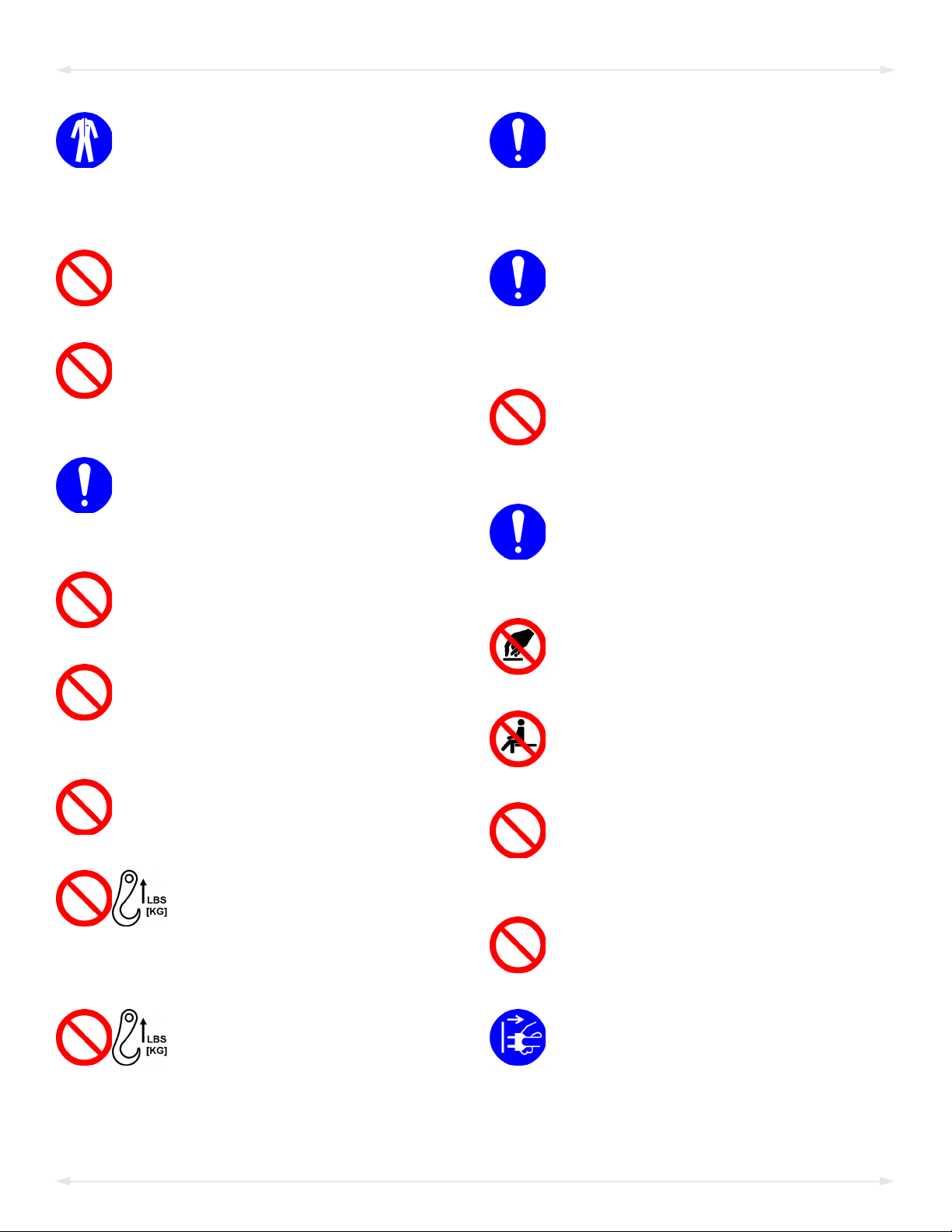

SAFETY

Wear personal protective

equipment that is appropriate for

the load material. Follow trade

association guidelines.

Do not remove or obscure safety

labels.

Do not make any modifications to

the lifter (see “LIMITED

WARRANTY”).

Use the lifter only in an approved

“OPERATING ENVIRONMENT” (see

“INTENDED USE”).

Do not use a lifter that is damaged,

malfunctioning, or missing parts.

Do not use a lifter if the sealing

edge of any vacuum pad is cut or

otherwise damaged.

Make sure the contact surfaces of

the load and vacuum pads are clean

before attaching the lifter (see

“MAINTENANCE”).

Position the vacuum pads correctly

on the load before lifting (see

“OPERATION: Positioning the Lifter

on the Load”).

Do not lift a load if any vacuum

indicator shows inadequate

vacuum.

Keep unauthorized personnel away

from the lifter, to avoid injury in

case of an unintended load release.

Do not touch the vacuum release

controls during a lift.

Do not allow people to ride on the

lifter or the load.

Do not use a lifter to lift cracked or

broken glass.

Do not exceed the Maximum

Load Capacity or lift loads the

lifter is not designed for (see

“INTENDED USE”).

Do not use a lifter if the

Maximum Load Capacity or

any safety label appears to be

missing or obscured.

Rev 29.0/10-19 MRT4-DC: #350705

Do not lift a load higher than

necessary or leave suspended loads

unattended.

Do not position a loaded or

unloaded lifter over people.

Before servicing a powered lifter,

place the power control in the

inactive position and, when

possible, disconnect the power source.

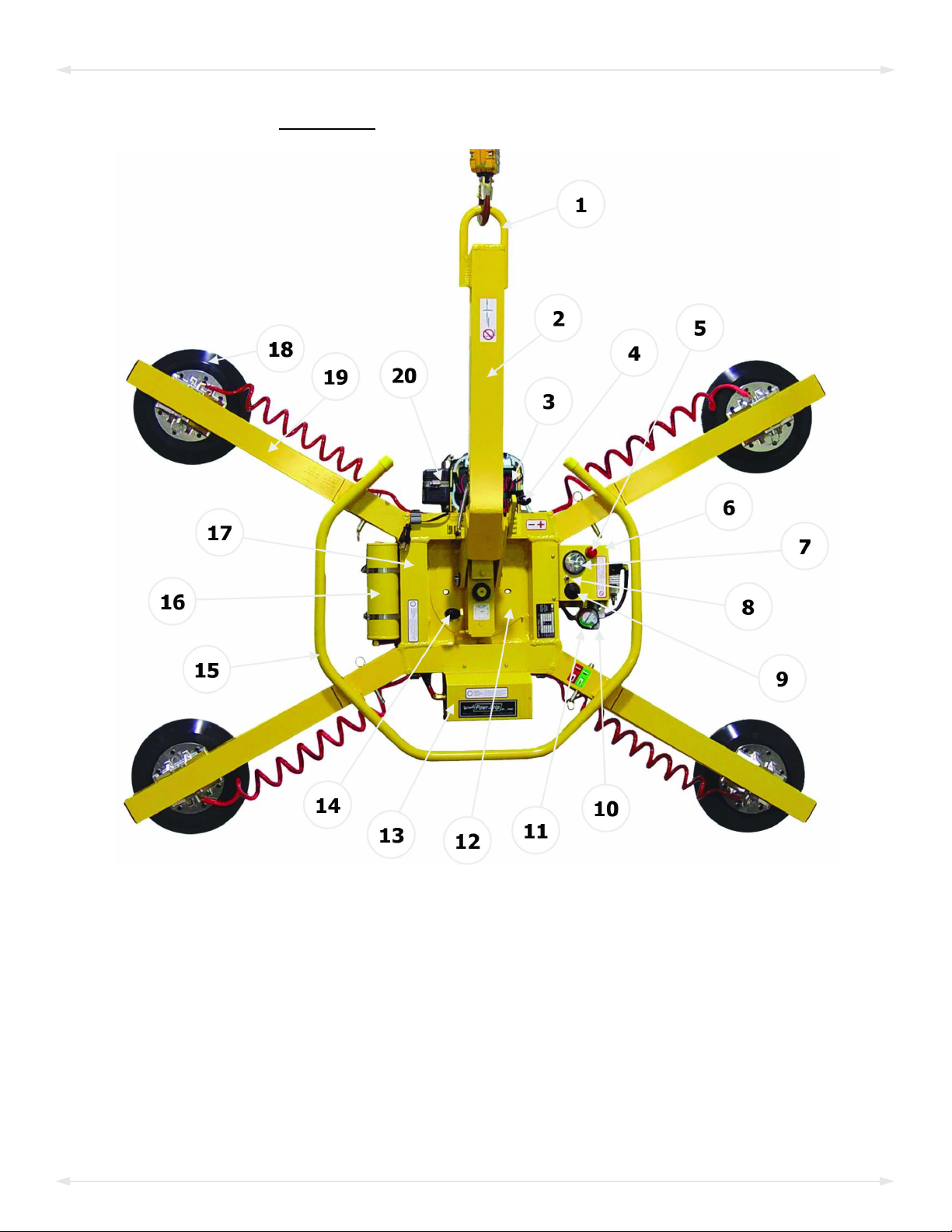

OPERATING FEATURES

Features shown here are underlined on their first appearance in each section following.

1 LIFT POINT 8 BATTERY TEST BUTTON 15 CONTROL HANDLE

2 LIFT BAR 9 LOW VACUUM WARNING BUZZER (optional) 16 VACUUM RESERVE TANK

3 BATTERY 10 VALVE HANDLE 17 PAD FRAME

4 TILT RELEASE LEVER 11 VACUUM GAUGE 18 VACUUM PAD

5 LOW VACUUM WARNING LIGHT 12 ROTATION WEAR PLATE 19 EXTENSION ARM

6 Enclosure with VACUUM SWITCH 13 Cover for VACUUM PUMP 20 BATTERY CHARGER

7 BATTERY GAUGE 14 ROTATION RELEASE LEVER Not shown: INSTRUCTIONS CANISTER

Note: The lifter model MRT411LDC is shown here. Although some of the following photos do not

show this specific lifter, they all illustrate how this kind of lifter functions.

MRT4-DC: #35070 Rev 29.0/10-196

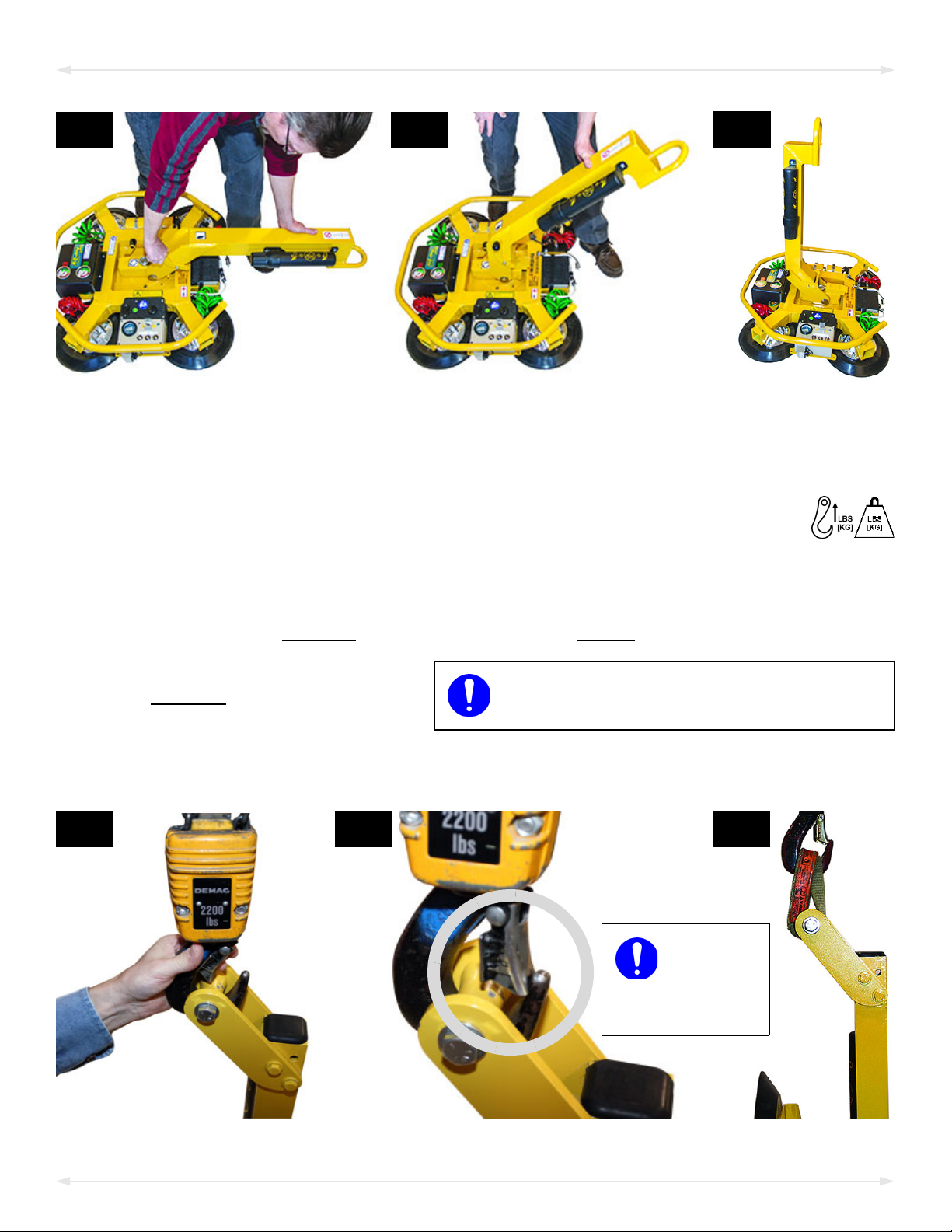

2A 2B

2D 2E

Make

sure hook

has restraining

latch (circled).

2F

Only use rigging rated for Maximum Load

Capacity plus Lifter Weight.

ASSEMBLY

2C

1)

Remove all lifter restraints and save them with the shipping container for future use.

2) Suspend the lifter from appr

Select a crane and/or hoist rated for the Maximum Load Capacity plus the

2.1)

Lifter Weight.

Note: Any lifter use must comply with all statutory or regulatory standards for

ting equipment in your region.

hois

2.2) Disengage any

2.3) Attach the hoisting hook to the

lift point (figs. 2D-E).

rigging (fig. 2F) as needed to

e sure the hook does not

mak

interfere with the load.

tilt locks or latches, and raise the lift bar (figs. 2A-C).

Use

opriate hoisting equipment:

Rev 29.0/10-19 MRT4-DC: #350707

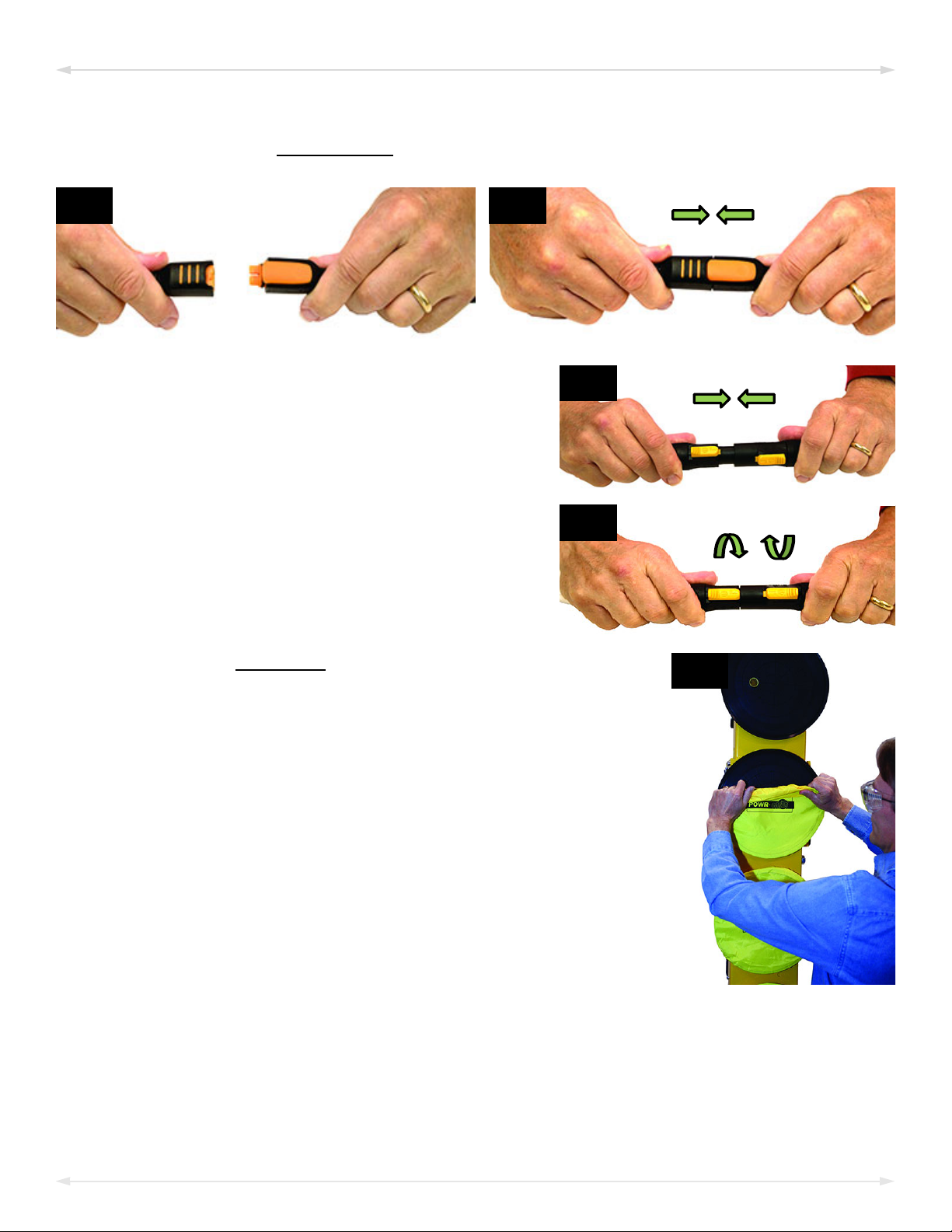

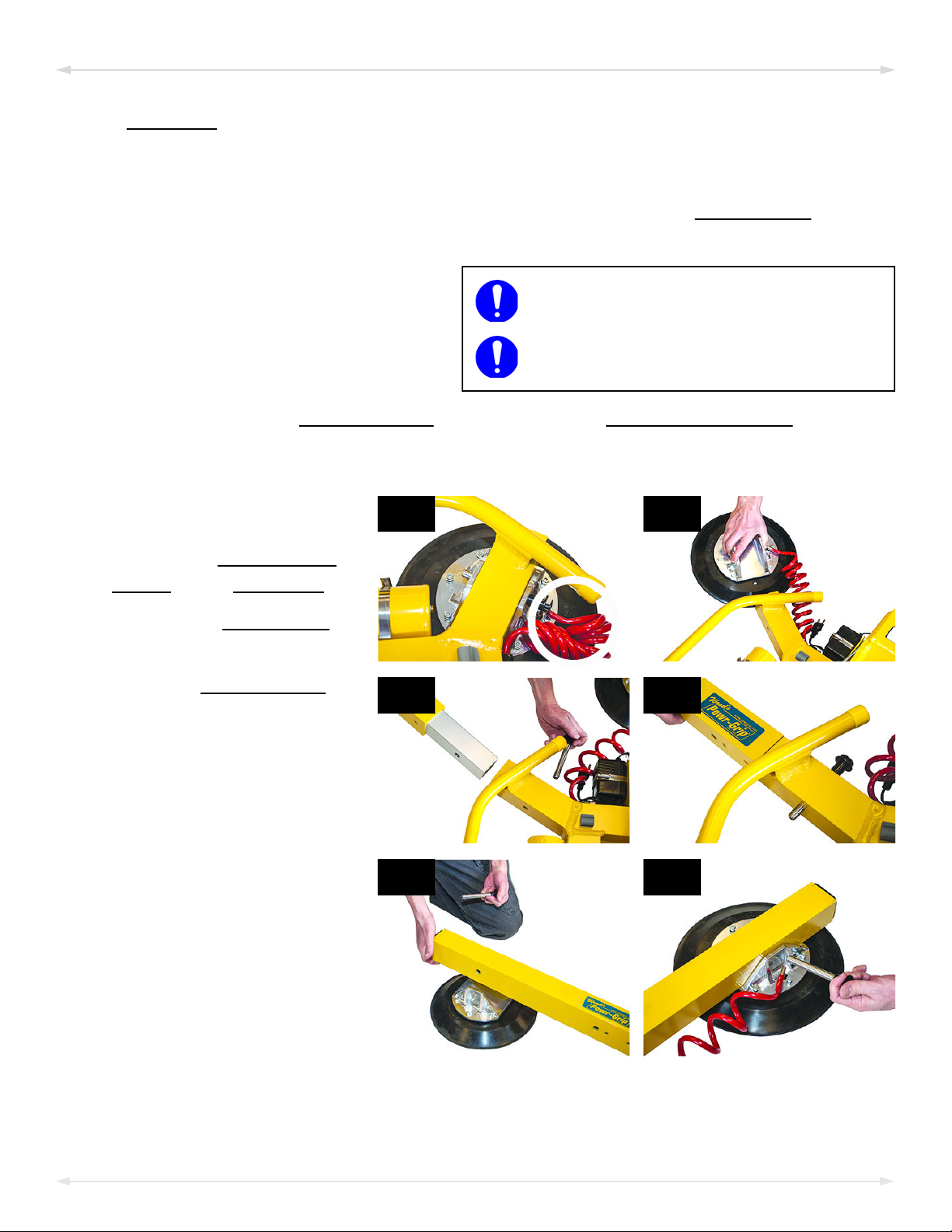

3B3A

3C

3D

4A

ASSEMBLY

2.4) Use the hoisting equipment to remove the lifter from the shipping container. Avoid

damaging the

3)

Connect the electrical connectors (figs. 3A-B and

figs. 3C-D).

vacuum pads.

4)

Assemble the pad frame for optimal load support

(see “T

Remove the pad covers (fig. 4A) and save them for future use.

5) Perform tests as required under “T

O CHANGE THE PAD FRAME CONFIGURATION” on page 9).

ESTING” on page 26).

MRT4-DC: #35070 Rev 29.0/10-198

ASSEMBLY

TO CHANGE THE PAD FRAME CONFIGURATION

Rev 29.0/10-19 MRT4-DC: #350709

Use only approved pad frame

configurations.

Securely position vacuum hoses to

avoid damage during lifter operation.

4A 4B

3B

2A

3A

1A

ASSEMBLY

Various pad frame configurations enable the lifter to match different load dimensions. The

illustrations on the preceding page show all approved configurations. Dimensions show Pad

Spread for a standard MRT411LDC(3) lifter (see “SPECIFICATIONS” on page 3 for other models).

Caution: If the lift

circuits (marked “1” and “2” in the preceding illustrations).

Choose an approved configuration to

1)

maximize support across the load

ace and to minimize load overhang

surf

(see “L

page 12).

2) Install or remove the

er is equipped with a dual vacuum system, position the vacuum pads for the 2

OAD CHARACTERISTICS” on

extension arms and reposition the movable pad mounts as needed.

Installing/Removing Extension Arms and Repositioning Vacuum Pads

1)

Remove the cotterless hitch

pin (circled in fig. 1A) that

secur

mount to the pad frame.

2) Remove the

from the pad frame (fig. 2A).

es the

movable pad

vacuum pad

3) Insert the

the pad frame (fig. 3A). Then

insert a cotterless hitch pin

to secure it (fig. 3B).

4) Position the movable pad

moun

(fig. 4A). Then insert a

cotterless hitch pin to secure

it (fig. 4B).

Notes: Repeat or reverse these

teps to configure the pad frame as

s

needed. Store removed

components in a clean, dry

location.

MRT4-DC: #35070 Rev 29.0/10-1910

extension arm into

t on the extension arm

Loading...

Loading...