Page 1

KEEP FOR FUTURE REFERENCE

OPERATING

INSTRUCTIONS

INTENDED FOR USE BY SKILLED

PROFESSIONALS • READ AND

UNDERSTAND BEFORE OPERATING

908 W. Main • P.O. Box 368

Laurel, MT USA 59044

800-548-7341 (phone)

406-628-8231 (phone)

406-628-8354 (fax)

www.WPG.com

MANUAL ROTATOR/TILTER,

DC-VOLTAGE

Model numbers: MRT411LDC (shown), MRT49DC,

MRT4HV11DC

Record serial number in blank space above (to locate, see serial

Rev 29.0/10-19 MRT4-DC: #35070i

label on the product).

Page 2

MRT4-DC: #35070 Rev 29.0/10-19ii

Page 3

TABLE OF CONTENTS

SPECIFICATIONS .....................................................................................3

SAFETY...................................................................................................5

OPERATING FEATURES............................................................................6

ASSEMBLY..............................................................................................7

TO CHANGE THE PAD FRAME CONFIGURATION ..................................................9

Installing/Removing Extension Arms and Repositioning Vacuum Pads ............................10

Using Secondary Rotation Stops ....................................................................................... 11

INTENDED USE .....................................................................................12

LOAD CHARACTERISTICS...............................................................................12

OPERATING ENVIRONMENT ..........................................................................13

DISPOSAL OF THE LIFTER .............................................................................13

OPERATION..........................................................................................14

BEFORE USING THE LIFTER...........................................................................14

Taking Safety Precautions .................................................................................................14

Performing Inspections and Tests ..................................................................................... 14

Checking the Battery.........................................................................................................15

TO ATTACH THE PADS TO A LOAD ..................................................................16

Positioning the Lifter on the Load..................................................................................... 16

Sealing the Pads on the Load............................................................................................17

Reading the Vacuum Gauge.............................................................................................. 17

TO LIFT AND MOVE THE LOAD......................................................................18

Interpreting the Warning Light and Optional Warning Buzzer .........................................18

Watching Vacuum Indicators ............................................................................................18

Controlling the Lifter and Load ......................................................................................... 19

In Case of a Power Failure.................................................................................................19

TO ROTATE THE LOAD .................................................................................20

TO TILT THE LOAD ......................................................................................21

TO RELEASE THE PADS FROM THE LOAD .........................................................23

AFTER USING THE LIFTER.............................................................................23

Storing the Lifter............................................................................................................... 23

INSPECTIONS AND TESTS......................................................................25

INSPECTION SCHEDULE ................................................................................25

Rev 29.0/10-19 MRT4-DC: #35070iii

Page 4

TABLE OF CONTENTS

TESTING ...................................................................................................26

Lifter/Load Compatibility Test...........................................................................................26

Operational Tests .............................................................................................................. 27

Vacuum Test......................................................................................................................27

Rated Load Test.................................................................................................................28

MAINTENANCE ....................................................................................29

VACUUM PAD MAINTENANCE.......................................................................29

Pad-to-Load Friction Coefficient .......................................................................................29

Pad Inspection ..................................................................................................................29

Pad Cleaning .....................................................................................................................30

BATT ER Y RECHARGE....................................................................................31

REPLACEMENT PARTS...........................................................................32

LIMITED WARRANTY ............................................................................33

TO OBTAIN REPAIRS OR WARRANTY SERVICE...................................................33

MRT4-DC: #35070 Rev 29.0/10-19iv

Page 5

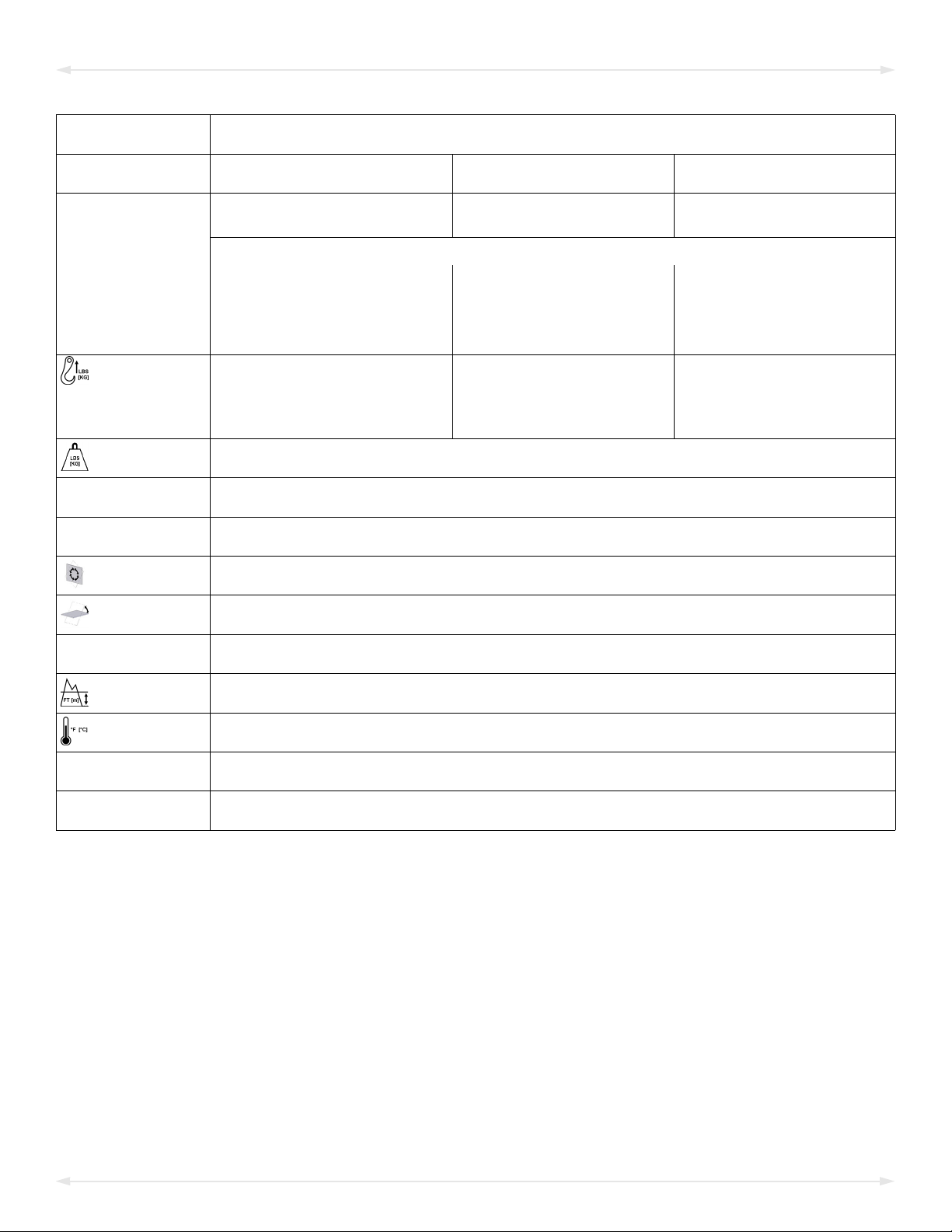

SPECIFICATIONS

Product

Description

Model

Number

Vacuum Pads

(4 each, standard rubber)

Pad Spread

Length ‒ Maximum

Length ‒ Minimum

Width ‒ Maximum

Width ‒ Minimum

Maximum Load

Capacity

Per-Pad

Weight

Power

System

Battery

Capacity

Rotation

Capability

Capability

Product

Options

Operating

Elevation

Operating

Temperatures

Service

ASME Standard

BTH-1

Total

Lifter

Tilt

Life

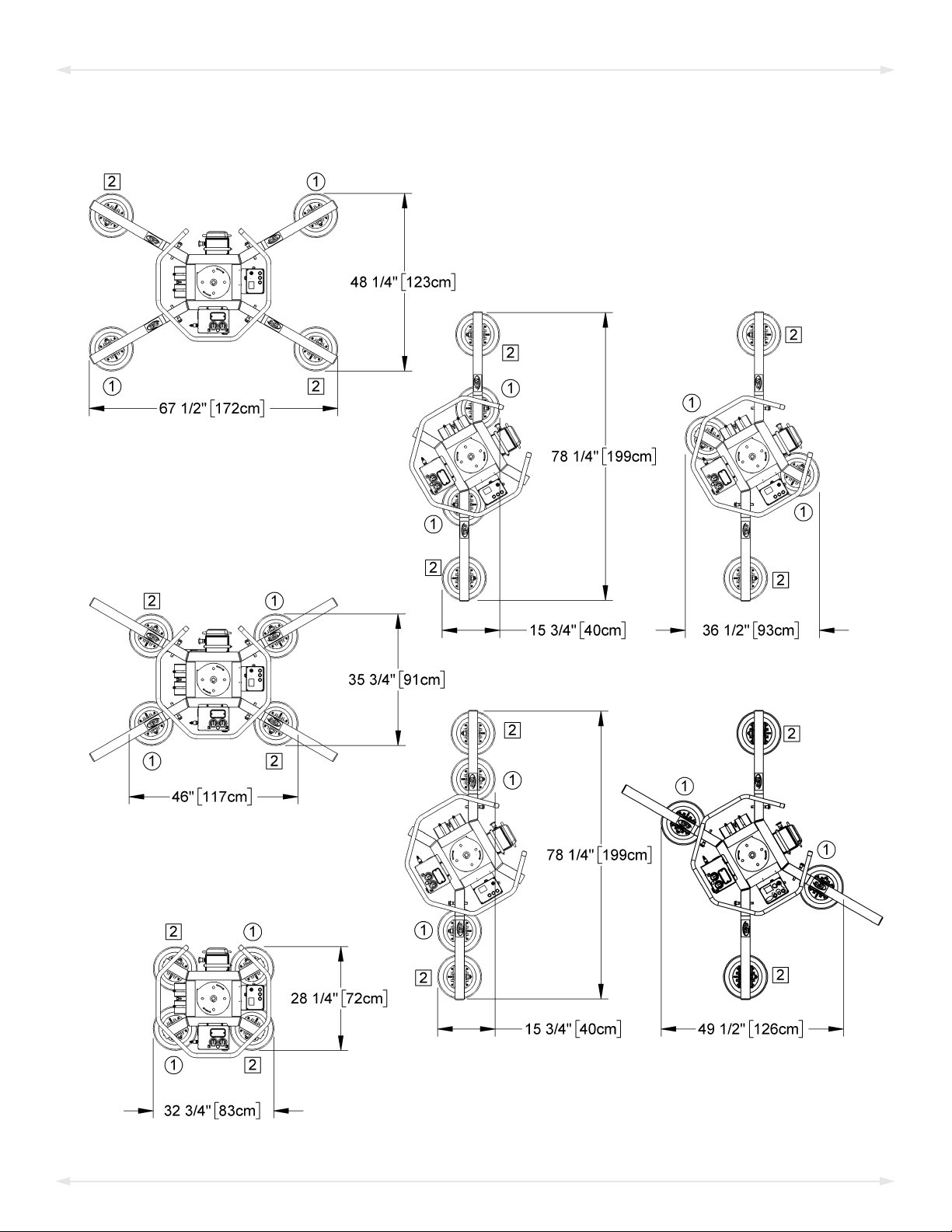

Designed for use with hoisting equipment, MRT4-DC lifters support loads using vacuum and manipulate

loads using manual 360° rotation and manual 90° tilt motions.

MRT49DC MRT4HV11DC MRT411LDC

1

2

9" [23 cm] nom. diameter

(Model VPFS9)

---------------------------- (to outer edges) ----------------------------

10" [25 cm] nom. diameter,

lipped (Model HV11)

11" [28 cm] nom. diameter,

lipped (Model G3370)

75¼" [192 cm] 77¼" [197 cm] 78¼" [199 cm]

29¾" [76 cm] 31¾" [81 cm] 32¾" [83 cm]

46½" [119 cm] 48½" [124 cm] 49½" [126 cm]

12¾" [33 cm] 14¾" [38 cm] 15¾" [40 cm]

3

125 lbs [56.5 kg] 150 lbs [68 kg] 175 lbs [80 kg]

500 lbs [225 kg] 600 lbs [270 kg] 700 lbs [320 kg]

135 lbs [62 kg]

12 volts DC, 3.5 amps

7 amp-hours

Manual, 360°, with latching at each ¼ turn (when required)

Manual, 90°, with automatic locking in vertical position

See separate instructions about options.

Up to 6,000' [1,828 m]

32° — 104° F [0° — 40° C]

20,000 lifting cycles, when used and maintained as intended

4

Design Category "B", Service Class "0" (see www.WPG.com for more information)

1...... Available with other rubber compounds for special purposes (see www.WPG.com).

2...... The illustrations under “T

3...... The Maximum Load Capacity is rated at a vacuum of 16" Hg [-54 kPa] on clean, smooth, nonporous flat surfaces with a friction coefficient of 1. Pad

compound, load rigidity, strength, surface conditions, overhang, angle, center of gravity and temperature can also affect the lifting capacity. A “qualified

person” should evaluate the effective lifting capacity for each use (see definition under “Rated Load Test” on page 28).

4...... Vacuum pads, filter elements and other wear-out items are excluded.

O CHANGE THE PAD FRAME CONFIGURATION” on page 9 show the Pad Spread for all approved pad frame configurations.

!!–CE–!! This symbol appears only when a CE Standard is different from other applicable standards. CE requirements are

mandatory in the European Union, but may be optional elsewhere.

Rev 29.0/10-19 MRT4-DC: #350703

Page 6

SPECIFICATIONS

Note: A standard MRT411LDC is shown.

MRT4-DC: #35070 Rev 29.0/10-194

Page 7

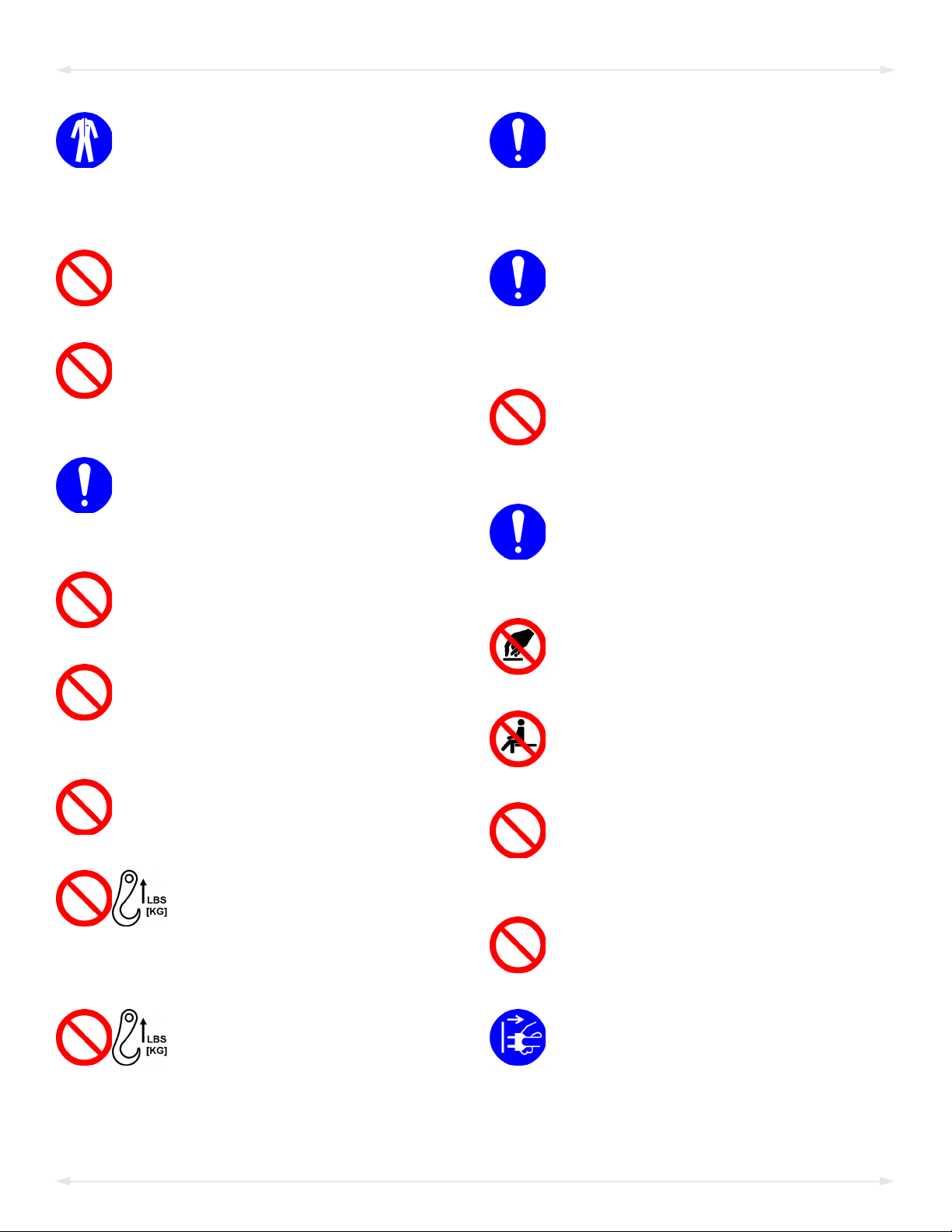

SAFETY

Wear personal protective

equipment that is appropriate for

the load material. Follow trade

association guidelines.

Do not remove or obscure safety

labels.

Do not make any modifications to

the lifter (see “LIMITED

WARRANTY”).

Use the lifter only in an approved

“OPERATING ENVIRONMENT” (see

“INTENDED USE”).

Do not use a lifter that is damaged,

malfunctioning, or missing parts.

Do not use a lifter if the sealing

edge of any vacuum pad is cut or

otherwise damaged.

Make sure the contact surfaces of

the load and vacuum pads are clean

before attaching the lifter (see

“MAINTENANCE”).

Position the vacuum pads correctly

on the load before lifting (see

“OPERATION: Positioning the Lifter

on the Load”).

Do not lift a load if any vacuum

indicator shows inadequate

vacuum.

Keep unauthorized personnel away

from the lifter, to avoid injury in

case of an unintended load release.

Do not touch the vacuum release

controls during a lift.

Do not allow people to ride on the

lifter or the load.

Do not use a lifter to lift cracked or

broken glass.

Do not exceed the Maximum

Load Capacity or lift loads the

lifter is not designed for (see

“INTENDED USE”).

Do not use a lifter if the

Maximum Load Capacity or

any safety label appears to be

missing or obscured.

Rev 29.0/10-19 MRT4-DC: #350705

Do not lift a load higher than

necessary or leave suspended loads

unattended.

Do not position a loaded or

unloaded lifter over people.

Before servicing a powered lifter,

place the power control in the

inactive position and, when

possible, disconnect the power source.

Page 8

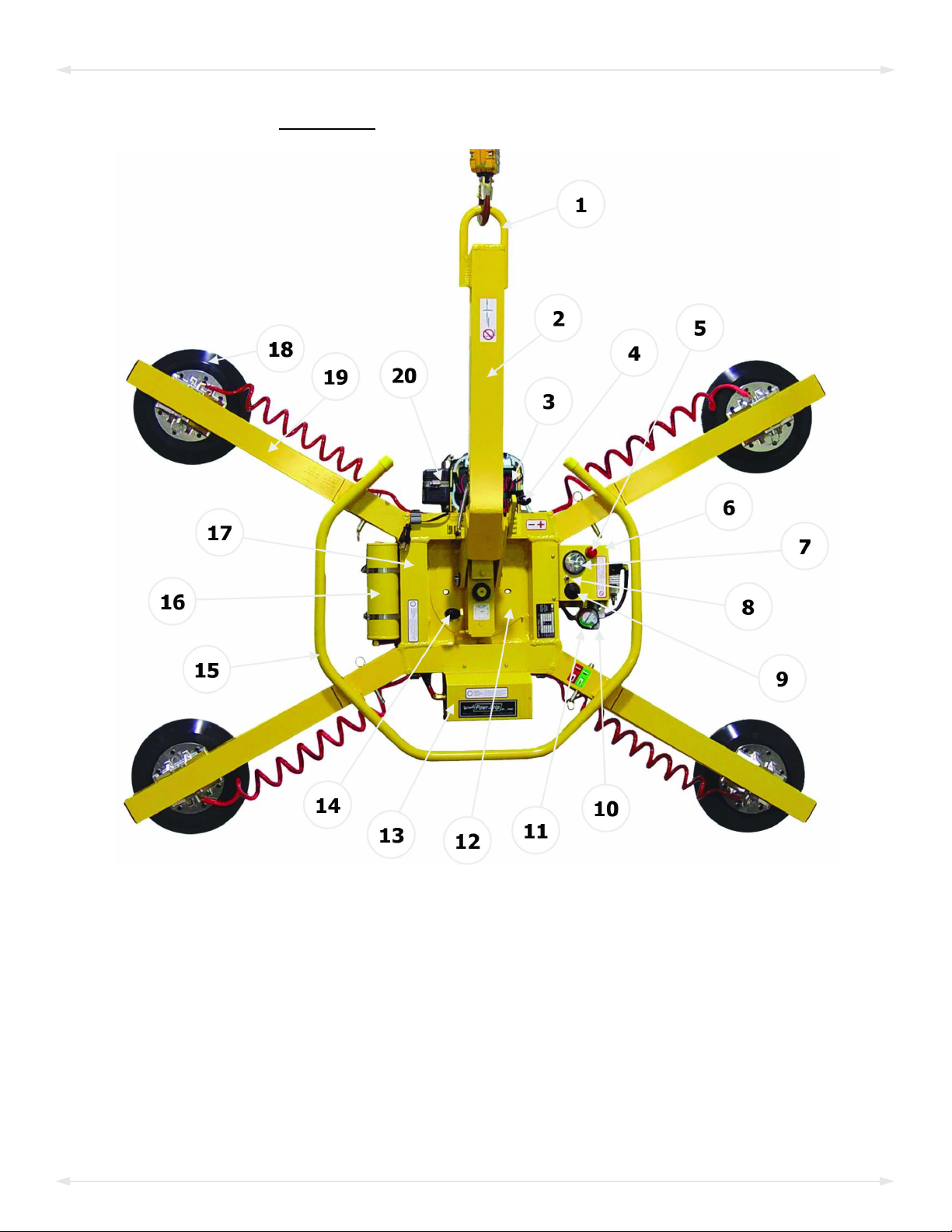

OPERATING FEATURES

Features shown here are underlined on their first appearance in each section following.

1 LIFT POINT 8 BATTERY TEST BUTTON 15 CONTROL HANDLE

2 LIFT BAR 9 LOW VACUUM WARNING BUZZER (optional) 16 VACUUM RESERVE TANK

3 BATTERY 10 VALVE HANDLE 17 PAD FRAME

4 TILT RELEASE LEVER 11 VACUUM GAUGE 18 VACUUM PAD

5 LOW VACUUM WARNING LIGHT 12 ROTATION WEAR PLATE 19 EXTENSION ARM

6 Enclosure with VACUUM SWITCH 13 Cover for VACUUM PUMP 20 BATTERY CHARGER

7 BATTERY GAUGE 14 ROTATION RELEASE LEVER Not shown: INSTRUCTIONS CANISTER

Note: The lifter model MRT411LDC is shown here. Although some of the following photos do not

show this specific lifter, they all illustrate how this kind of lifter functions.

MRT4-DC: #35070 Rev 29.0/10-196

Page 9

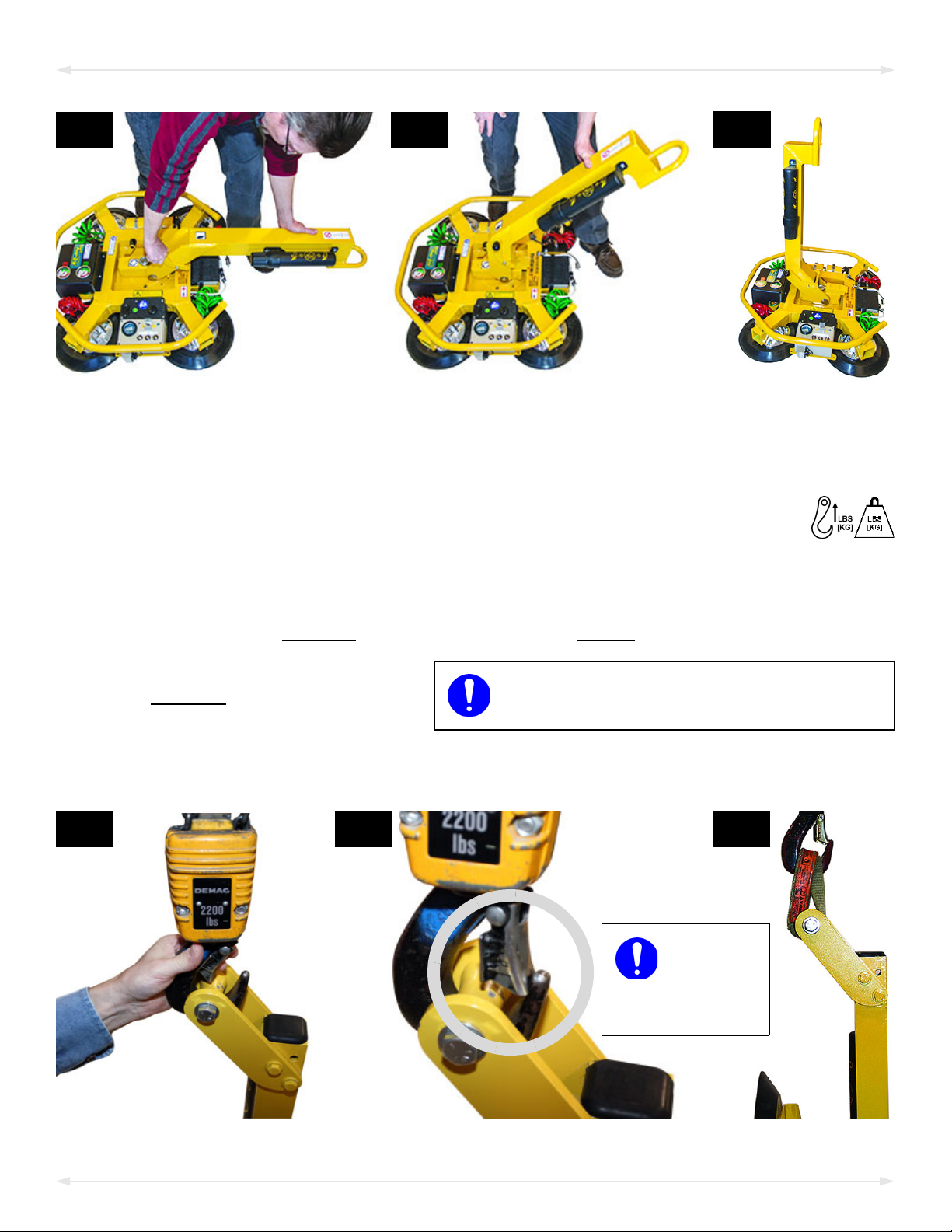

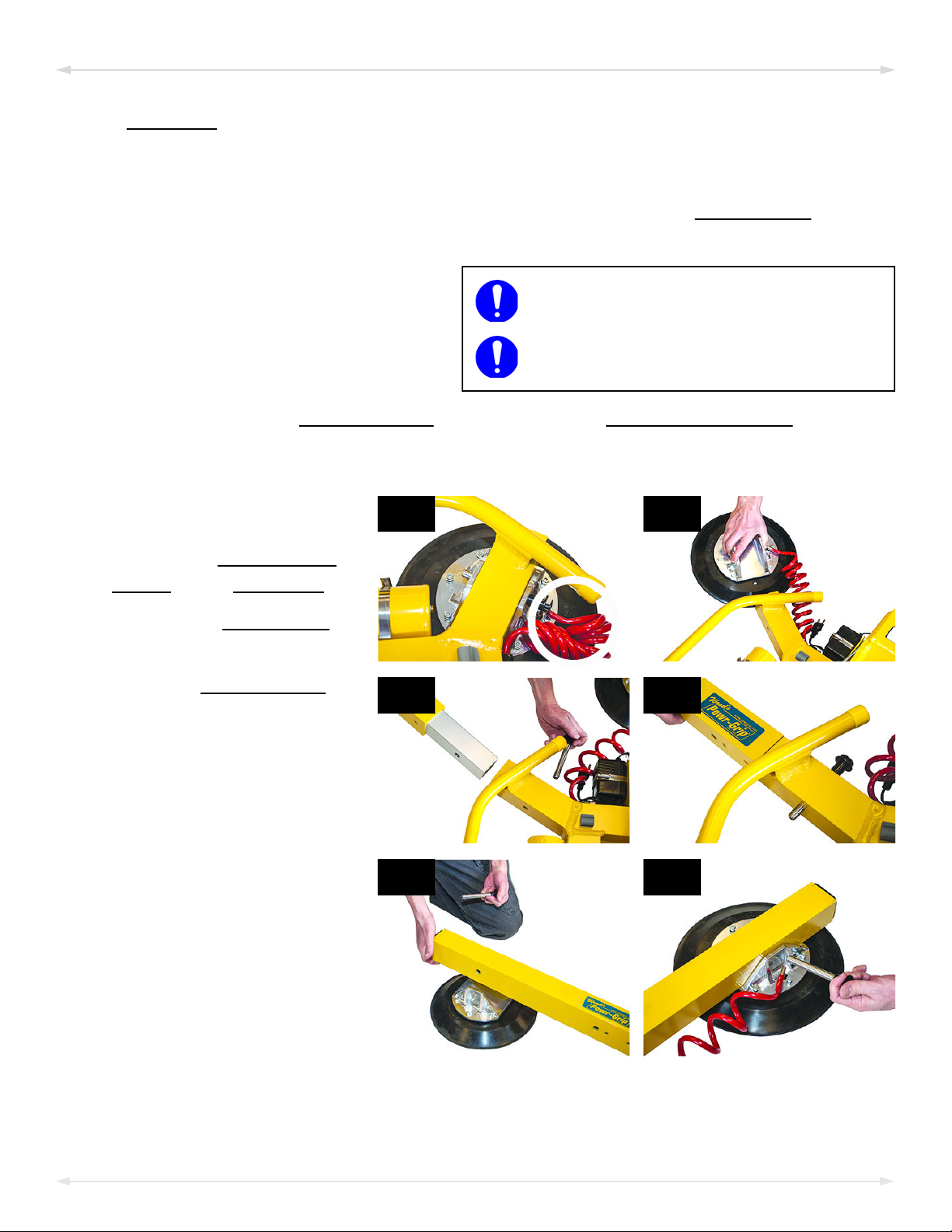

2A 2B

2D 2E

Make

sure hook

has restraining

latch (circled).

2F

Only use rigging rated for Maximum Load

Capacity plus Lifter Weight.

ASSEMBLY

2C

1)

Remove all lifter restraints and save them with the shipping container for future use.

2) Suspend the lifter from appr

Select a crane and/or hoist rated for the Maximum Load Capacity plus the

2.1)

Lifter Weight.

Note: Any lifter use must comply with all statutory or regulatory standards for

ting equipment in your region.

hois

2.2) Disengage any

2.3) Attach the hoisting hook to the

lift point (figs. 2D-E).

rigging (fig. 2F) as needed to

e sure the hook does not

mak

interfere with the load.

tilt locks or latches, and raise the lift bar (figs. 2A-C).

Use

opriate hoisting equipment:

Rev 29.0/10-19 MRT4-DC: #350707

Page 10

3B3A

3C

3D

4A

ASSEMBLY

2.4) Use the hoisting equipment to remove the lifter from the shipping container. Avoid

damaging the

3)

Connect the electrical connectors (figs. 3A-B and

figs. 3C-D).

vacuum pads.

4)

Assemble the pad frame for optimal load support

(see “T

Remove the pad covers (fig. 4A) and save them for future use.

5) Perform tests as required under “T

O CHANGE THE PAD FRAME CONFIGURATION” on page 9).

ESTING” on page 26).

MRT4-DC: #35070 Rev 29.0/10-198

Page 11

ASSEMBLY

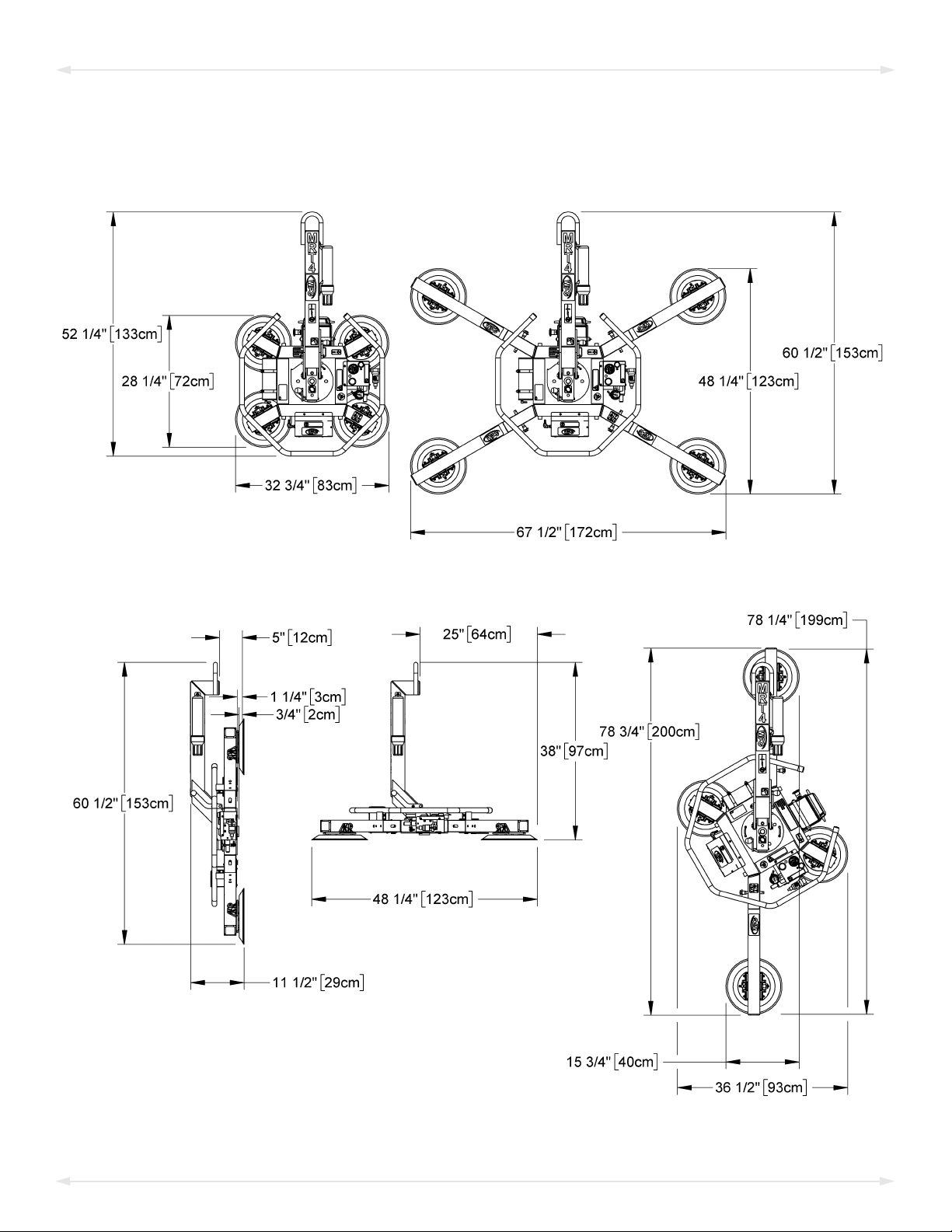

TO CHANGE THE PAD FRAME CONFIGURATION

Rev 29.0/10-19 MRT4-DC: #350709

Page 12

Use only approved pad frame

configurations.

Securely position vacuum hoses to

avoid damage during lifter operation.

4A 4B

3B

2A

3A

1A

ASSEMBLY

Various pad frame configurations enable the lifter to match different load dimensions. The

illustrations on the preceding page show all approved configurations. Dimensions show Pad

Spread for a standard MRT411LDC(3) lifter (see “SPECIFICATIONS” on page 3 for other models).

Caution: If the lift

circuits (marked “1” and “2” in the preceding illustrations).

Choose an approved configuration to

1)

maximize support across the load

ace and to minimize load overhang

surf

(see “L

page 12).

2) Install or remove the

er is equipped with a dual vacuum system, position the vacuum pads for the 2

OAD CHARACTERISTICS” on

extension arms and reposition the movable pad mounts as needed.

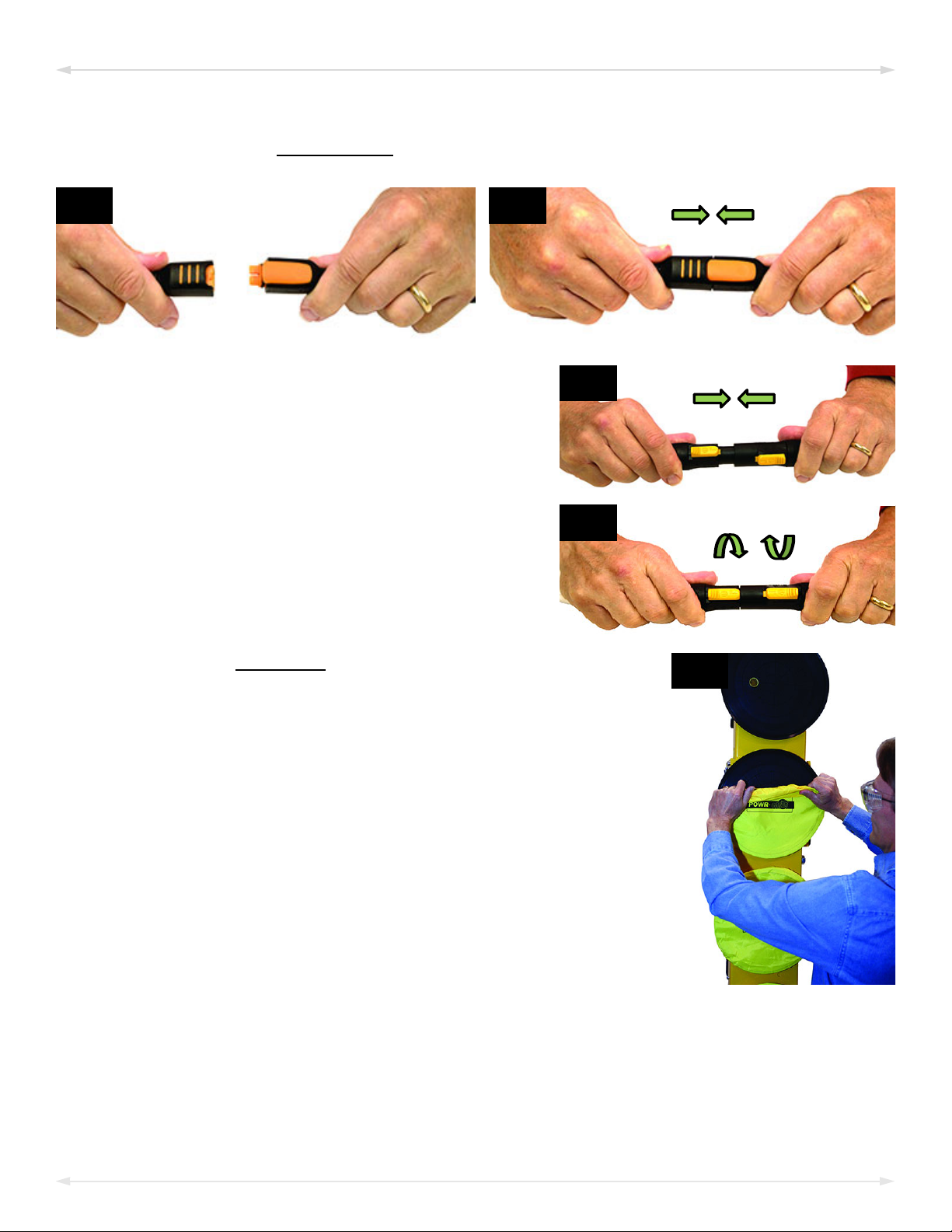

Installing/Removing Extension Arms and Repositioning Vacuum Pads

1)

Remove the cotterless hitch

pin (circled in fig. 1A) that

secur

mount to the pad frame.

2) Remove the

from the pad frame (fig. 2A).

es the

movable pad

vacuum pad

3) Insert the

the pad frame (fig. 3A). Then

insert a cotterless hitch pin

to secure it (fig. 3B).

4) Position the movable pad

moun

(fig. 4A). Then insert a

cotterless hitch pin to secure

it (fig. 4B).

Notes: Repeat or reverse these

teps to configure the pad frame as

s

needed. Store removed

components in a clean, dry

location.

MRT4-DC: #35070 Rev 29.0/10-1910

extension arm into

t on the extension arm

Page 13

1A 1B

1C 1D

ASSEMBLY

Using Secondary Rotation Stops

Align the secondary rotation stops for correct use of the pad frame in long, narrow

configurations:

1) Loosen the 2 screws

2) Rotate the wear plate to align with the sec

3) Tighten the screws secur

Note: Reverse these steps to reali

Rev 29.0/10-19 MRT4-DC: #3507011

that secure the rotation wear plate (fig. 1A).

ondary rotation stops (figs. 1B-C).

ely (circled in fig. 1D).

gn the primary rotation stops.

Page 14

INTENDED USE

Do NOT lift explosives, radioactive

substances or other hazardous materials.

LOAD CHARACTERISTICS

Make sure the vacuum lifter is intended

to handle each load acc

requirements:

ording to these

• The load weight must not e

• The load must be a single piece of r

relatively smooth contact surface.

xceed the Maximum Load Capacity.

elatively nonporous material with a flat and

1, 2

To determine whether the load is too

porous or rough, perform a “Lifter/Load Compatibility Test” on page 26.

• The load's contact surface must be able t

o obtain a friction coefficient of 1 with the lifter's

vacuum pads (see “Pad-to-Load Friction Coefficient” on page 29). Otherwise, the

capacity should be derated appropriately.

• The load's surface temperature must

not exceed the Operating Temperatures.

3

• The load's minimum length and width are determined by the current Pad Spread

(see “SPECIFICATIONS” on page 3).

• The load's ma

• 1" [2.5 cm] is the allowable thickness at Maximum Load Capacity.

ximum length and width are determined by its allowable overhang.

5

Note: Standard vacuum pads can stain or deform load surfaces with light colors or soft

coatings. Test such surfaces for damaging effects before using the lifter on them.

6

4

1..... Although concave vacuum pads can also attach to some curved loads, curvature can reduce lifting capacity. Contact WPG for more information.

2..... A “single piece” of material includes curtainwall assemblies, unitized glazing systems and similar construction units.

3..... Vacuum pads made from a heat-resistant rubber compound can e

authorized dealer for more information.

4..... The allowable overhang is the amount of load material that can extend sideways beyond the vacuum pad without breaking or otherwise being

damaged. This depends on the load material, its thickness, and the angle of handling (if any). Since every material has different physical

properties, the allowable overhang must be evaluated separately for each load type. Contact WPG or an authorized dealer for more

information.

5..... However, the allowable thickness increases as load

6..... Alternative rubber compounds are available for these purposes. C

MRT4-DC: #35070 Rev 29.0/10-1912

weight decreases. Contact WPG for more information.

nable you to lift loads with higher surface temperatures. Contact WPG or an

ontact WPG or an authorized dealer for more information.

Page 15

Never use lifter in dangerous

environments.

Metal particles and similar

environmental contaminates

could result in vacuum pump failure.

Moisture can result in

reduced lifting capacity.

INTENDED USE

OPERATING ENVIRONMENT

Make sure the vacuum lifter is intended for use in each work environment, given the following

restrictions:

This lifter is not intended for any environment

•

that is dangerous to the operator or damaging

o the lifter. Avoid environments containing

t

explosives, caustic chemicals and other

dangerous substances.

• The work environment is limited by the Oper

Temperatures.

• The lifter is not designed to be watertight.

use it in rain or other

1, 2

unsuitable conditions.

ating Elevation and Operating

Do not

DISPOSAL OF THE LIFTER

After the Service Life of the vacuum lifter has ended (see “SPECIFICATIONS” on page 3), dispose

of it in compliance with all local codes and applicable regulatory standards.

Note: Special disposal regulations may apply to the

battery.

1..... Although lifter use may be possible at higher elevation, lifting capacity is reduced whenever the lifter is unable to attain vacuum in the green

range on the vacuum gauge. Contact WPG for more information.

2..... Special provisions may allow the lifter to operate outside the specified temperature range. Contact WPG for more information.

Rev 29.0/10-19 MRT4-DC: #3507013

Page 16

OPERATION

Read all directions and safety rules before using

lifter.

Always wear appropriate personal protective

equipment.

Examine air filter regularly

and service when needed.

1A

Make sure warning buzzer can be heard over noise at operator

position.

BEFORE USING THE LIFTER

Determine whether the vacuum lifter is capable of each intended task (see “SPECIFICATIONS”

on page 3 and “INTENDED USE” on page 12). Then complete the f

Taking Safety Precautions

•

Be trained in all industry

and regulatory standards

or lifter operation in your

f

region.

• Follow trade association

ollowing preparations:

guidelines about pr

ecautions needed for each load material.

Performing Inspections and Tests

• Follow the “INSPECTION SCHEDULE” on page 25 and “TESTING” on page 26.

Service the air filter whenever the bowl contains

•

liquid or other contaminates, or the element

ars dirty (see “A

appe

SERVICE MANUAL).

If the lifter has a low vacuum warning buzzer (fig. 1A), make sure it is

•

clearly audible at the maximum dis

the lifter, despite any barriers or obstacles.

IR FILTER MAINTENANCE” in

tance between the operator and

1, 2

1..... Maximum alarm volume is 103 dBA at 2' [60 cm]. If CE Standards apply, consult EN 7731 to make sure the warning buzzer is compliant.

2..... The “Vacuum Test” on page 27 provides a convenient opportunity to check this.

MRT4-DC: #35070 Rev 29.0/10-1914

Page 17

Always check battery energy before

every lift.

OPERATION

Checking the Battery

Use the battery gauge to determine whether the battery needs to be charged (see “BATTE RY

ECHARGE” on page 31).

R

1

Never use the lifter unless battery energy appears in the green range.

• While the

valve handle is in the “attach” position ( / power on), the battery gauge

automatically shows battery energy.

• While the valve handle is in the

“release” position (

use the

battery test button (circled)

to check the battery energy.

/ power off),

3

2

1..... If the pump is running or the battery charger is connected to an AC power source, the reading on the battery gauge will not be accurate.

2..... After the vacuum pump stops running, the battery gauge requires a few moments to stabilize before it shows an accurate energy level.

3..... If the lifter has not been used since the battery was charged, the battery gauge may falsely show a high energy level. This “surface charge”

dissipates after the pump runs for about 1 minute, allowing the gauge to show accurate energy.

Rev 29.0/10-19 MRT4-DC: #3507015

Page 18

1A

2A

Consult the Per-Pad

Load Capacity.

OPERATION

TO ATTACH THE PADS TO A LOAD

Make sure the contact surfaces of the load and vacuum pads are clean (see

“Pad Cleaning” on page 30).

Positioning the Lifter on the Load

1)

Center the pad frame on

the load (fig. 1A).

1

2)

Make sure all vacuum pads

will fit on the load and will

be loaded ev

3) Place the vacuum pads in

contact with the load

surface.

1..... The lifter is designed to handle the maximum load weight when the load’s center of gravity is positioned within 2" [5 cm] of the lifter’s rotation

axis. Uncentered loads may rotate or tilt unexpectedly.

enly (fig. 2A).

MRT4-DC: #35070 Rev 29.0/10-1916

Page 19

1A

Keep valve handle in “attach” position

throughout lift.

1B 1C

OPERATION

Sealing the Pads on the Load

Pull the valve handle outward until it latches (circled

in fig. 1A) in the “attach” position (

The vacuum pump will turn on, the low vacuum

warning light will remain lit and the low vacuum warning buzzer, if present, will sound until the

vacuum pads seal. This is normal.

Press the lifter firmly against the load t

).

o help the pads begin to seal.

1

Reading the Vacuum Gauge

A vacuum gauge shows the current vacuum level in positive inches of Hg and negative kPa:

Green range (>16" Hg [-54 kPa]):

•

Vacuum level is sufficient to lift the

ximum load weight (fig. 1B).

ma

• Re

d range (<16" Hg [-54 kPa]):

Vacuum level is not sufficient to lift

the maximum load weight (fig. 1C).

If it takes more than 5 seconds for the

cuum level to reach 5" Hg [-17 kPa], press

va

on any

Once the pads have sealed, the lifter should be able t

except when used above the maximum Operating Elevation.

vacuum pad that has not yet sealed.

o maintain sufficient vacuum for lifting,

2

If it does not:

• Make sure the

• When necessary, perform the “Vacuum Test” on page 27.

vacuum switch is adjusted correctly (see SERVICE MANUAL).

1..... Although a vacuum pad may become distorted during shipping or storage, this condition should correct itself with continued use.

2..... If the lifter is used above the maximum Operating Elevation (see “SPECIFICATIONS” on page 3), it may not be able to maintain sufficient vacuum

for lifting. Contact WPG for more information.

Rev 29.0/10-19 MRT4-DC: #3507017

Page 20

Lift bar must be vertical to lift

load.

Never lift load unless warning devices turn off, because

this could result in load release and personal injury.

Make sure vacuum indicators remain

completely visible.

1A

Stay clear of any suspended load while

indicators warn of low vacuum.

OPERATION

TO LIFT AND MOVE THE LOAD

Interpreting the Warning Light and Optional Warning Buzzer

When the vacuum

lifter is ready to lift

the Ma

Capacity, the

battery energy.

ximum Load

vacuum pump and the low vacuum warning light turn off temporarily, to conserve

When air leaks into the vacuum system, the vacuum pump turns on and of

warning light) as necessary to maintain sufficient vacuum for lifting.

Note: The low vacuum warning buzzer, if present, turns on and off together with the warning

light.

f (along with the

Watching Vacuum Indicators

Watch the low vacuum warning light and the vacuum

gauge (fig. 1A) throughout the entire lift.

If the warning light turns on and the vacuum gauge

shows a level less than 16" Hg [-54 kPa]:

1) Keep everyone away from a suspended load un

it can be safely lowered to a stable support.

til

2) Stop using the lifter until the cause of the vacuum loss can be identified: Conduct the

“Pad Inspection” on page 29 and perform the “Vacuum Test” on page 27.

3) Correct any faults before resuming nor

MRT4-DC: #35070 Rev 29.0/10-1918

mal operation of the lifter.

Page 21

1A

Stay clear of any suspended

load during power failure.

OPERATION

Controlling the Lifter and Load

When the lifter is ready, use the hoisting equipment to raise

the lifter and load as needed.

Use the

and load in the required position.

Once there is enough clearance, y

required.

control handle (circled in fig. 1A) to keep the lifter

ou may move the load as

In Case of a Power Failure

A vacuum reserve tank helps maintain vacuum temporarily in the event of a battery failure or

electrical system failure. Although the lifter is designed to support the load for at least 5

minutes without power, this depends on many factors, including the “L

page 12 and the condition of the

If a power failure occurs, keep everyone away from a

suspended load until it can be safely lowered to a stable

support. Corr

operation of the lifter.

ect any faults before resuming normal

vacuum pads (see “VACUUM PAD MAINTENANCE” on page 29).

OAD CHARACTERISTICS” on

Rev 29.0/10-19 MRT4-DC: #3507019

Page 22

2A

3A

Make sure load is positioned correctly on

lifter (as previously directed).

Never disengage rotation and tilt latches at

the same time, because this could result in

load damage or personal injury.

Unbalanced loads may rotate unexpectedly

when rotation latch is disengaged.

OPERATION

TO ROTATE THE LOAD

1)

Make sure the load has enough

clearance to rotate without

ontacting anyone or anything.

c

2) Use the

in fig. 2A) to keep the load

under control at all times.

3) Pull the

(fig. 3A) to disengage the

rotation latch, and rotate the load as required.

4) To stop load motion, let go of the rotatio

stop.

Note: Whenever rotation is not required, keep the rot

damage or personal injury.

control handle (circled

rotation release lever

n release lever and guide the load to the next

ation latch engaged, to prevent load

MRT4-DC: #35070 Rev 29.0/10-1920

Page 23

2A

3A

Make sure load is positioned correctly on

lifter (as previously directed).

Never disengage rotation and tilt latches at

the same time, because this could result in

load damage or personal injury.

Unbalanced loads may rotate unexpectedly

when rotation latch is disengaged.

OPERATION

TO TILT THE LOAD

1)

Make sure the load has enough

clearance to tilt without

ntacting anyone or anything.

co

2) Use the

in fig. 2A) to keep the load

under

3) If the

the

disengage the tilt latch.

Note: The pad frame automatically latches when tilt

4) Tilt the load as required.

Note: See “Load Characteristics” on page 12 about allowable load overhang.

control handle (circled

control at all times.

pad frame is latched, pull

tilt release lever (fig. 3A) to

ed t

o the vertical position.

Rev 29.0/10-19 MRT4-DC: #3507021

Page 24

1A

A load with overhang

may force you to release

control handle as

the

the load approaches the

flat position. In this

case, use hand cups

(circled in fig. 1A) or

other appropriate

means to control the

load.

OPERATION

MRT4-DC: #35070 Rev 29.0/10-1922

Page 25

Make sure load is at rest and fully supported

before releasing vacuum pads.

1A

Do not move lifter until pads release completely, because such movement could

result in load damage or personal injury.

OPERATION

TO RELEASE THE PADS FROM THE LOAD

1) Press the lever to release the latch and push the valve

handle inward (fig. 1A) to the “release” position ( ).

2) Before you lift another load, perform the Every-Lift Inspection (see “INSPECTION SCHEDULE”

on page 25).

AFTER USING THE LIFTER

1) Leave the valve handle in the “release” position ( / power off).

2) Charge the

3) Use the hoisting equipment to lower the vacuum lifter gently onto a stable support. Then

detach the hoisting hook from the

Caution: Do not se

4) To transport the lifter, secure it in the or

restraints or equivalent.

battery after each workday as needed (see “BAT TE RY RECHARGE” on page 31).

lift point.

t the lifter on surfaces that could soil or damage vacuum pads.

iginal shipping container with the original

Storing the Lifter

1) 1BUse the pad covers supplied (fig. 1B) to keep the vacuum

pads clean.

1

1..... To maximize battery life, charge it promptly after each use.

Rev 29.0/10-19 MRT4-DC: #3507023

Page 26

3A 3B

3C 3D 3E

OPERATION

!!–CE–!! To prevent the lifter from tipping over on relatively horizontal surfaces, place the

vacuum pads facedown on a clean, smooth, flat surface. Then lower the

support under the

2) Charge the battery completely and repeat every 6 months (see “BATTE RY RECHARGE” on

page 31).

lift point.

lift bar and place a

3) Disconnect the electrical connectors (figs. 3A-B and figs. 3C-E) to prevent battery

discharge.

4) Store the lifter in a clean, dry loc

Avoid storage above 100° F [38° C.]

ation. Store the battery between 32° and 70° F [0-21° C].

MRT4-DC: #35070 Rev 29.0/10-1924

Page 27

INSPECTIONS AND TESTS

INSPECTION SCHEDULE

Perform inspections according to the following frequency schedule. If any fault is found, correct

it and perform the next most frequent inspection before using the vacuum lifter.

Note: If a lifter is used less than 1 day in a 2-week period, perform the Periodic Inspection before using it.

1

Action Every Lift

Examine vacuum pads for contaminates or damage (see

“Pad Inspection” on page 29).

Frequent

(every 20-40 hrs)

Periodic

(every 250-400 hrs)

Examine load surface for contaminates or debris.

Examine controls and indicators for damage.

Check

Battery” on page 15).

battery for adequate charge (see “Checking the

Examine lifter’s structure for damage.

Examine vacuum system for damage (including

pads, fittings and hoses).

Examine

air filter for conditions requiring service (see

“AIR FILTER MAINTENANCE” in SERVICE MANUAL).

vacuum

Perform “Vacuum Test” on page 27.

Check for unusual vibrations or noises while operating lifter.

2

Examine entire lifter for evidence of:

• looseness, excessive wear or excessive corrosion

• deformation, cracks, dents to structural or functional

ponents

com

• cuts in vacuum pads or hoses

• any other hazardous conditions

Inspect entire electrical syste

m for damage, wear or

contamination that could be hazardous, in compliance

with all local codes and regulatory standards.

Caution: Use appropriate cleaning methods for each

electrical part, as specified by codes and standards.

Improper cleaning can damage parts.

1...... The Frequent Inspection is also required whenever the lifter has been out of service for 1 month or more.

2...... The Periodic Inspection is also required whenever the lifter has been out of service for 1 year or more. Keep a written record of all Periodic Inspections. If

necessary, return the lifter to WPG or an authorized dealer for repair (see “LIMITED WARRANTY” on page 33).

Rev 29.0/10-19 MRT4-DC: #3507025

Page 28

Take precautions in case

load should fall during test.

INSPECTIONS AND TESTS

TESTING

Perform the following test to determine whether or not a load surface is too porous or rough:

Lifter/Load Compatibility Test

1

1) Make sure the vacuum generating system is functioning correctly (see “Vacuum Test” on

page 27).

2) Thoroughly clean the load surf

page 30).

2

3) Place the load in the upright position on a stable support.

ace and the vacuum pads (see “Pad Cleaning” on

3

4) Attach the vacuum pads to the load as previously directed.

5) After the

SING THE LIFTER” on page 23).

U

6)

Raise the load a minimal distance, to make sure it

vacuum pump stops running, disconnect the battery connector (see “AFTER

4

is supported by the lifter.

7) Watch each

vacuum gauge: Starting from a

vacuum level of 16" Hg [-54 kPa], the lifter must maintain a vacuum level greater than

5

12" Hg [-41 kPa] for 5 minutes.

If not, lifting this load requires additional precautions

(eg, a load sling). Contact WPG for more information.

8) Lower the load aft

1..... The “Pad-to-Load Friction Coefficient” can affect the outcome of this test (see page 29).

2..... Contaminated loads can cause the vacuum pump to run frequently or continuously. Since excessive pumping quickly reduces battery energy,

clean the load whenever possible.

3..... For Flat Lifters, place the load in the flat position.

4..... Move the valve handle to the “release” position (power

5..... Under CE requirements, the lift

MRT4-DC: #35070 Rev 29.0/10-1926

er 5 minutes or before the vacuum level diminishes to 12" Hg [-41 kPa].

off) before reconnecting the battery.

er must maintain a vacuum level greater than 8" [-27 kPa].

Page 29

Take precautions in case

load should fall during test.

Never use a lifter that has

failed test.

INSPECTIONS AND TESTS

Perform the following tests before placing the lifter in service initially, following any repair,

when directed in the “I

NSPECTION SCHEDULE”, or whenever necessary:

Operational Tests

Test all features and functions of the lifter (see “OPERATING FEATURES” and “OPERATION”).

Vacuum Test

1) Clean the face of each vacuum pad (see “Pad Cleaning” on page 30).

Use a test load with weight equal to the Maximum Load Capacity, a clean, smooth,

2)

nonporous surface and other appropriate “L

OAD CHARACTERISTICS” (see page 12).

3) Attach the lifter to the test load as previously directed. After the vacuum pump stops

running, the vacuum level should appear in the green range on the

see “V

Raise the load a minimal distance and disconnect

4)

the

on page 23).

ACUUM SWITCH ADJUSTMENT” in SERVICE MANUAL).

battery connector (see “AFTER USING THE LIFTER”

2

vacuum gauge (if not,

1

5) Watch the vacuum gauge: The vacuum level should not decrease by more than 4" Hg

[-14 kPa] in 5 minutes.

Lower the load after 5 minutes or whenever a

6)

lifter fails the test, and r

elease the load as

previously directed.

7) Qualified service personnel must correct any f

can be returned to service.

1..... The load surface should have either a flat surface or no more curvature than the lifter is designed for, if any.

2..... Move the valve handle to the “release” position (power off) before reconnecting the battery.

3..... For more information, search for you

r lifter’s Model Number at www.WPG.com and select the “Troubleshooting” link on the product page.

3

ault in the vacuum system before the lifter

Rev 29.0/10-19 MRT4-DC: #3507027

Page 30

Take precautions in case

load should fall during test.

Never use a lifter that has

failed test.

INSPECTIONS AND TESTS

Rated Load Test

The following steps must be performed or supervised by a qualified person:

1

2

1) Use a test load that weights 125% (± 5%) of the Maximum Load Capacity and has

the appropriate “L

2)Attach the

osition the load to produce the gr

3) P

vacuum pads to the load as previously directed.

OAD CHARACTERISTICS” (see page 12).

eatest stress on the lifter consistent with “INTENDED

USE” on page 12.

Raise the load a minimal distance and leave it

4)

suspended for 2 minutes.

5) Once the t

est is complete

d, lower the load for

release as previously directed.

Inspect the lifter for any stress damage, and

6)

repair or replace components as necessary to

successfully pass the t

est.

epare a written report of the tes

7) Pr

t and keep it on file.

1..... An equivalent simulation may also be used. Contact WPG for more information.

2..... A “qualified person” has successfully demonstrated the ability to solve problems relating to the subject matter and work, either by possessing a

recognized degree in an applicable field or a certificate of professional standing, or by possessing extensive knowledge, training and experience.

MRT4-DC: #35070 Rev 29.0/10-1928

Page 31

MAINTENANCE

Replace any pad that has damaged

sealing edges.

1A

Notes: Refer to SERVICE MANUAL #36110 when applicable. See final section for wiring

diagrams.

VACUUM PAD MAINTENANCE

Pad-to-Load Friction Coefficient

The friction coefficient represents the lifter's ability to resist load slippage.1 The

Maximum Load Capacity is based on a friction c

oefficient of 1, as determined by testing

of clean, new, standard rubber

used under any other conditions, a qualified person must first determine the effective lifting

capacity.

Long-term exposure to heat, chemicals or UV light can reduce the friction coefficient of vacuum

pads. Replace pads every 2 years or more often, when necessary.

2

vacuum pads on clean, dry, regular glass. If the lifter is

Pad Inspection

Inspect each vacuum pad (fig. 1A) according to

the “I

correct the following faults before using the

lifter (see “REPLACEMENT PARTS”, when

applicable):

NSPECTION SCHEDULE” on page 25 and

• Contaminates on the face (1) or sealing

es (2).

edg

• Filter screen (3) missing from face.

• Nicks, cuts or abrasions in sealing edg

es.

• Wear, stiffness or glaze.

1..... Not applicable to Flat Lifters.

2..... A “qualified person” has successfully demonstrated the ability to solve problems relating to the subject matter and work, either by possessing a

recognized degree in an applicable field or a certificate of professional standing, or by possessing extensive knowledge, training and experience.

Rev 29.0/10-19 MRT4-DC: #3507029

Page 32

Pad Cleaning

1A

Never use harsh chemicals on

vacuum pad.

Never use rubber conditioners on

vacuum pad.

1)

Regularly clean the face of each

vacuum pad (fig. 1A), using soapy

water or other mild cleansers to

remove oil, dust and other

contaminates.

Solvents, petroleum-based products

(including kerosene, gasoline and

diesel fuel) or other harsh chemicals

can damage vacuum pads.

MAINTENANCE

Many rubber conditioners can leave a

hazardous film on vacuum pads.

2) Prevent liquid from entering the v

face.

3) Wipe the pad face clean, using a clean spong

4) Allow the pad to dry completely before using the lifter.

acuum system through the suction hole on the pad

e or lint-free cloth to apply the cleanser.

1

1..... A brush with bristles that do not harm rubber can help remove contaminates clinging to sealing edges. If these cleaning methods are not

successful, contact WPG or an authorized dealer for assistance.

MRT4-DC: #35070 Rev 29.0/10-1930

Page 33

Make sure power source has ground fault circuit

interrupter.

MAINTENANCE

BATTERY RECHARGE

Charge the battery whenever the battery gauge shows reduced energy. Caution: Make sure

valve handle is in “release” position ( / power off).

Identify the input voltage

marked on the

charger, and plug it in to an

appropriate power source.

The power lamp (Ф) turns on when the charger is functioning. Consult the six-stage display to

determine the charging status. The battery can be used after stage 3 and is fully charged at

stage 5.

Normally, the battery should take no more than 8 hours to charge completely.

the following faults:

Power lamp (Ф) flashes:

•

Charger is not

nnected to battery;

co

reconnect charger (see

“ASSEMBLY” on page 8).

• Error lamp (!) turns on

immedia

battery

tely: Battery

1

2

If not, check for

leads connected to

wrong poles; reverse

battery leads.

• Charging stops at stage

1 or 4, and err

(!) turns on: Battery is

no longer functioning; replace battery (see “REPLACEMENT PARTS” on page 32).

Before you return the lifter to service, r

1..... Any external power supply must conform to all applicable local codes. This lifter is not intended for use while the charger is connected to AC

power.

2..... The charger automatically reduces the charging rate when the battery is fully charged.

Rev 29.0/10-19 MRT4-DC: #3507031

or lamp

echeck the battery as previously directed.

Page 34

REPLACEMENT PARTS

Stock No. Description Qty.

65441 Vacuum Hose ‒ 0

65440 Vacuum Hose ‒ 0

65014 Pad Spring ‒ W

65010 Pad Spring ‒

64716 Battery Charger ‒ 0.8

64715 Battery Charger ‒ 0.8

64714 Battery Charger ‒ 0.8

64664 Battery ‒ 12 V

64283 Bulb ‒ 13

59086NC Battery Connector ‒ Twin

59028 Movable Pad Mount ‒ 2-1/

54390NC Power Lead 1

53120 Pad Fitting ‒ Elbow

53114 Hose Fitting ‒ Co

49646T Vacuum Pad ‒ Model

49605T Vacuum Pad ‒ Model

49506TA Vacuum Pad ‒ Model

49180 End Plug ‒ 3"

49150 End Plug ‒ 2-1

36110 Service Manual — 12V DC, — 1 SFCM — Single Vacuum System

29353 Pad Cover 4

15792 Tilt or Rotation Release Lever Knob 2

15632 Pad Filter Screen ‒ Sm

15630 Pad Filter Screen ‒ Large (for

13532 Cotterless Hitch Pin ‒

10900 Shoulder Bolt ‒ So

V ‒ Bayonet (for low vacuum warning light) 1

.245" ID x 3/8" OD x 48" Length ‒ Coiled 4

.245" ID x 3/8" OD *

ave Type (for HV11 pad) 4

Coil Type (for VPFS9 & G3370 pads) 4

Amp ‒ 240 V AC ‒ Australian Type 1

Amp ‒ 240 V AC 1

Amp ‒ 100 / 120 V AC 1

DC ‒ 7 Amp-Hours 1

Lead 1

2" Tubing Size 4

‒ 3/64" ID 4

upler ‒ 1/4" Barb 4

G3370 / 11" [28 cm] Diameter ‒ Lipped 4

HV11 / 10" [25 cm] Diameter ‒ Lipped 4

VPFS9 / 9" [23 cm] Diameter 4

x 3" x 1/4" Tubing Size 1

/2" x 2-1/2" x 1/4" Tubing Size 4

— Manual Valve 1

all (for VPFS9 pad) 4

G3370 & HV11 pads) 4

1/2" x 3-3/8" 8

cket Head ‒ 5/16" x 1/2" x 1/4-20 Thread (for mounting pads) 24

*Length as required; vacuum hose is sold by the foot (approx. 30.5 cm).

See SERVICE MANUAL #36110 for additional parts.

ERVICE ONLY WITH IDENTICAL REPLACEMENT PARTS,

S

AVAIL ABLE AT WPG.COM OR THROUGH AN AUTHORIZED WPG DEALER

MRT4-DC: #35070 Rev 29.0/10-1932

Page 35

LIMITED WARRANTY

Wood's Powr-Grip Co., Inc.

908 West Main St.

Laurel, MT 59044 USA

406-628-8231 (phone)

800-548-7341 (phone)

406-628-8354 (fax)

Wood's Powr-Grip® (WPG) products are carefully constructed, thoroughly inspected at various

stages of production, and individually tested. They are warranted to be free from defects in

workmanship and materials for a period of one year from the date of purchase.

If a problem develops during the warranty period, f

warranty service. If inspection shows that the problem is due to defective workmanship or

materials, WPG will repair the product without charge.

Warranty does not apply when ...

• modifications have been made to the pr

• rubber portions have been cut or scr

• repairs are required due to abnormal w

• the product has been damag

If a problem is not covered under warranty, WPG will notif

repair. If the customer agrees to pay all repair costs and to receive the repaired product on a

C.O.D. basis, WPG then will proceed with repairs.

ed, misused or neglected.

ollow the instructions below to obtain

oduct after leaving the factory

atched during use;

ear and tear, and/or;

y the customer of costs prior to

TO OBTAIN REPAIRS OR WARRANTY SERVICE

For purchases in North America:

Contact the WPG Technical Service Department. When f

complete product – prepaid – along with your name, address and phone number to the street

address listed at the bottom of this page. WPG may be reached by phone or fax numbers listed

below.

For purchases in all other loc

Contact your dealer or the WPG T

reached by phone or fax numbers listed below.

alities:

echnical Service Department for assistance. WPG may be

actory service is required, ship the

Rev 29.0/10-19 MRT4-DC: #3507033

Page 36

MRT4-DC: #35070 Rev 29.0/10-1934

Page 37

Rev 29.0/10-19 MRT4-DC: #3507035

Page 38

MRT4-DC: #35070 Rev 29.0/10-1936

Loading...

Loading...