Page 1

SAFETY AND OPERATING MANUAL

ORIGINAL INSTRUCTIONS

Mini CirCular Saw wu420

Page 2

2

General power tool safety warnings

Warning: Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric

shock, fire and/or serious injury.

Save all warnings and instruc tions for future reference.

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1

WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

2

ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a residual current device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

3

PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while

you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the

off-position before connecting to power source and/or battery

pack, picking up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all

times. This enables better control of the power tool in unexpected

Page 3

3

situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction

and collection facilities, ensure these are connected and

properly used. Use of dust collection can reduce dust-related

hazards.

f) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier

to control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the

working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result

in a hazardous situation.

4

POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and

off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

5

SERVICE

a) Have your power tool serviced by a qualified repair person

using only identical replacement parts. This will ensure that the

safety of the power tool is maintained.

b) If the replacement of the supply cord is necessary, this has to

be done by the manufacturer or his agent in order to avoid a

safety hazard.

Additional safety rules for your

circular saw

1

Always wear a dust mask, hearing protection and eye protection.

2

Only use saw blades recommended in the specification.

3

Do not use any abrasive wheels.

4

Use only blade diameter(s) in accordance with the markings.

SAFETY WARNINGS FOR ALL SAWS

a) DANGER: Keep hands away from cutting area and the

blade. If both hands are holding the saw, they cannot be cut by the

blade.

Page 4

4

b) Do not reach underneath the workpiece. The guard cannot

protect you from the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece.

Less than a full tooth of the blade teeth should be visible below the

workpiece.

d) Never hold piece being cut in your hands or across your

leg. Secure the workpiece to a stable platform. It is important

to support the work properly to minimize body exposure, blade

binding, or loss of control.

e) Hold power tool by insulated gripping surfaces when

performing an operation where the cutting tool may contact

hidden wiring or its own cord. Contact with a “live” wire will

also make exposed metal parts of the power tool “live” and shock

the operator.

f) When ripping always use a rip fence or straight edge guide.

This improves the accuracy of cut and reduces the chance of blade

binding.

g) Always use blades with correct size and shape (diamond

versus round) of arbor holes. Blades that do not match the

mounting hardware of the saw will run eccentrically, causing loss

of control.

h) Never use damaged or incorrect blade washers or bolt. The

blade washers and bolt were specially designed for your saw, for

optimum performance and safety of operation.

FURTHER SAFET Y INSTRUCTIONS FOR ALL SAWS

KICKBACK CAUSES AND RELATED WARNINGS:

• Kickback is a sudden reaction to a pinched, bound or misaligned

saw blade, causing an uncontrolled saw to lift up and out of the

workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing

down, the blade stalls and the motor reaction drives the unit

rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth

at the back edge of the blade can dig into the top surface of the

wood causing the blade to climb out of the kerf and jump back

toward the operator.

• Kickback is the result of saw misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below.

a) Maintain a firm grip on the saw and position your arm to

resist kickback forces. Position your body to either side of the

blade, but not in line with the blade. Position the hand not

holding the saw well away from the travel path of the saw.

Kickback could cause the saw to jump backwards, but kickback

forces can be controlled by the operator, if proper precautions are

taken.

b) When blade is binding, or when interrupting a cut for any

reason, release the trigger and hold the saw motionless in

the material until the blade comes to a complete stop. Never

attempt to remove the saw from the work or pull the saw

backward while the blade is in motion or kickback may occur.

Investigate and take corrective actions to eliminate the cause of

blade binding.

c) When restarting a saw in the workpiece, center the saw

blade in the kerf and check that saw teeth are not engaged

into the material. If saw blade is binding, it may walk up or

kickback from the workpiece as the saw is restarted.

d) Support large panels to minimize the risk of blade pinching

and kickback. Large panels tend to sag under their own weight.

Page 5

5

Supports must be placed under the panel on both sides, near the

line of cut and near the edge of the panel.

e) Do not use dull or damaged blades. Unsharpened or

improperly set blades produce narrow kerf causing excessive

friction, blade binding and kickback.

f) Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment shifts

while cutting, it may cause binding and kickback.

g) Use extra caution when making a “plunge cut” into

existing walls or other blind areas. The protruding blade may

cut objects that can cause kickback.

SAFETY INSTRUCTIONS FOR PLUNGE- TYPE SAW

a) Check guard for proper closing before each use. Do not

operate the saw if guard does not move freely and enclose

the blade instantly. Never clamp or tie the guard with the

blade exposed. If saw is accidentally dropped, guard may be bent.

Check to make sure that guard moves freely and does not touch

the blade or any other part, in all angles and depths of cut.

b) Check the operation and condition of the guard return

spring. If the guard and the spring are not operating properly,

they must be serviced before use. Guard may operate sluggishly

due to damaged parts, gummy deposits, or a build-up of debris.

c) Assure that the guide plate of the saw will not shift while

performing the “plunge cut” when the blade bevel setting

is not at 90°. Blade shifting sideways will cause binding and likely

kick back.

d) Always observe that the guard is covering the blade before

placing saw down on bench or floor. An unprotected, coasting

blade will cause the saw to walk backwards, cutting whatever is

in its path. Be aware of the time it takes for the blade to stop after

switch is released.

GENERAL SAFETY WARNINGS FOR YOUR LASER

WARNING: Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in serious

injury.

Save all warnings and instruc tions for future reference.

These lasers do not normally present an optical hazard although

staring at the beam may cause flash blindness.

Do not stare directly at the laser beam. A hazard may exist if you

deliberately stare into the beam, please observe all safety rules as

follows:

1

The laser shall be used and maintained in accordance with the

manufacturer’s instructions.

2

Never aim the beam at any person or an object other than the work

piece.

3

The laser beam shall not be deliberately aimed at another person

and shall be prevented from being directed towards the eye of a

person for longer than 0.25 seconds area.

4

Always ensure the laser beam is aimed at a sturdy work piece

without reflective surfaces, e.g. wood or rough-coated surfaces

are acceptable. Bright shiny reflective sheet steel or similar is not

suitable for laser applications as the reflective surface may direct

the laser beam back at the operator.

5

Do not change the laser device with a different type. The

manufacturer or an authorized agent must carry out repairs.

CAUTION : Use of controls or adjustments other than those

6

specified herein may result in hazardous radiation exposure.

Page 6

6

Symbols

To reduce the risk of injury, user must read instruction

manual.

Warning

Double insulation

Wear eye protection

Wear ear protection

Wear dust mask

Laser radiation

Do not stare into beam

This product has been marked with a symbol relating

to removing electric and electronic waste. This means

that this product shall not be discarded with household

waste but that it shall be returned to a collection

system which conforms to the European Directive

2002/96/CE. It will then be recycled or dismantled in

order to reduce the impact on the environment. Electric

and electronic equipment can be hazardous for the

environment and for human health since they contain

hazardous substances.

Page 7

7

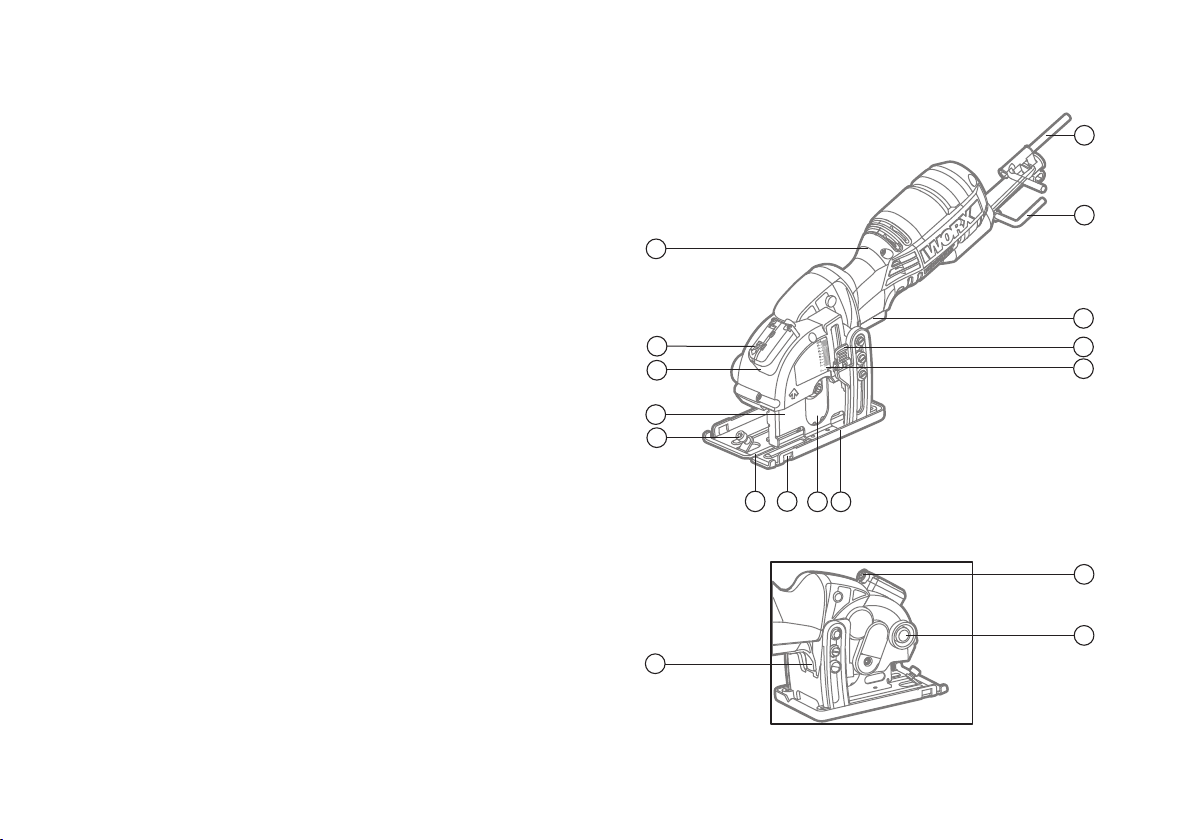

910

11

13

14

15

16

2

23

1

8

12

4

3

7

5

6

Component list

On/ Off Switch

1

Soft Grip Handle

2

Large L Spanner/ Hex KEY

3

Small L Spanner/Hex KEY

4

Laser On -Off Switch

5

Lock Off Switch

6

Dust Extraction Outlet

7

Depth of Cut Adjustment And Lock Lever

8

Base Plate

9

Saw Blade

10

Parallel Guide Fixture

11

Blade Alignment Indicator

12

Parallel Guide Clamping Screw

13

Protective Blade Guard

14

Laser Guide

15

Battery Storage Cover

16

Spindle Clamping Screw ( See Fig. C )

17

Blade Clamping Washer (See Fig. C )

18

Parallel Guide (See Fig. D)

19

Vacuum Adapter ( See Fig. E)

20

21

22

23

Plastic Base Plate Cover (See Fig. F1)

Laser Batteries (Two) (See Fig. J3)

Depth of Cut Indicator

* Not all the accessories illustrated or described are included in

standard delivery.

Page 8

8

Technical data

Vibration Information

Type WU420 (4-designation of machinery, representative of Saw)

•

Voltage 230-240V~50Hz

•

Power input 400W

•

No load speed 3500/min

•

Blade size Ø85mm X 15mm

•

Max cutting depth 27mm

•

Laser battery model no LR44 1.5V

•

Protection class /II

•

Machine weight 1.5kg

Noise and vibration data

A weighted sound pressure LPA: 80dB(A)

•

KPA 3dB(A)

•

A weighted sound power LWA: 91dB(A)

•

KWA 3dB(A)

•

Wear ear protection when sound pressure is over 80dB(A)

•

Vibration total values (triax vector sum) determined according to

•

EN 60745:

Typical weighted

•

vibration

Warning: The vibration emission value during actual use of the

power tool can differ from the declared value depending on the ways

in which the tool is used dependant on the following examples and

other variations on how the tool is used:

How the tool is used and the materials being cut or drilled.

The tool being in good condition and well maintained

The use the correct accessory for the tool and ensuring it is sharp and

in good condition.

The tightness of the grip on the handles and if any anti vibration

accessories are used.

And the tool is being used as intended by its design and these

instructions.

This tool may cause hand-arm vibration syndrome if its use is not

adequately managed.

Warning: To be accurate, an estimation of exposure level in

the actual conditions of use should also take account of all parts of

the operating cycle such as the times when the tool is switched off

and when it is running idle but not actually doing the job. This may

significantly reduce the exposure level over the total working period.

Vibration emission value ah =4.24m/s

Uncertainty K = 1.5m/s²

2

Helping to minimise your vibration exposure risk.

Page 9

9

ALWAYS use sharp chisels, drills and blades

Maintain this tool in accordance with these instructions and keep well

lubricated (where appropriate)

If the tool is to be used regularly then invest in anti vibration

accessories.

Avoid using tools in temperatures of 10

Plan your work schedule to spread any high vibration tool use across a

number of days.

o

C or less

Accessories

•

TCT 24T Blade 1

•

Diamond disc 1

•

HSS 44T Blade 1

•

V base 1

•

Parallel Guide 1

•

Vacuum Adaptor 1

•

Plastic base plate cover 1

•

Hex key 2

We recommend that you purchase your accessories from the same

store that sold you the tool. Use good quality accessories marked

with a well-known brand name. Choose the type according to the

work you intend to undertake. Refer to the accessory packaging for

further details. Store personnel can assist you and offer advice.

Page 10

10

Operating instructions

Note: Before using the tool, read the instruction book carefully.

INTENDED USE :

The machine is intended for ripping and cross-cutting wood and other

materials in straight cutting lines, while resting firmly on the work

piece.

Assembly

1

INSTALL /CHANGE THE BLADE

WARNING:

• Before any work on the machine itself, unplug the saw.

• Wear protective gloves when mounting the saw blade.

Danger of injur y when touching the saw blade.

• Only use saw blades that correspond with the

characteristic data given in the operating instructions.

• Do not use grinding discs on this cutting tool under any

circumstances.

1) Insert the small “L” spanner(4 into the center bolt hole on the back

of the spindle assembly.( See Fig. A)

2) Place the large “L” spanner (3) into the blade spindle clamping

screw (17) , while keeping the small “L” spanner in the center bolt

hole on the back of the spindle assembly. Turn the large “L” spanner

clockwise while holding the small “L” spanner stationary. Remove

the screw (17) and the blade clamping washer (18). After the washer

is removed, slide the blade off the spindle and through the blade slot

at the bottom of the saw. (See Fig. B1,B2)

Page 11

11

3) Clean the replacement saw blade and all the clamping parts to be

assembled. Slide the saw blade up through the slot and fit it onto

the inner spindle. Assemble the blade clamping washer (18) and the

spindle clamping screw (17). Use the two spanners to tighten the

spindle clamping screw thoroughly.(See Fig. C)

The steps involved in changing the blade are the same as the steps

used when installing the blade.

NOTE: Remove both spanners after the saw blade is tightly

attached.

WARNING: When mounting, ensure that the cutting direction of

theeth (direction of arrow on saw blade) and the direction-of-rotation

arrow above the blade guard match.

NOTE: Never use a blade that is too thick to allow the blade clamping

washer to engage with the flat side of the spindle.

The table below gives you advice on how to choose correct

blade.

Blade type Cutting material

TCT 24T Wood and aluminum

HSS 44T Thin sheet steel and aluminum, PVC pipe, plastic .

Diamond Concrete, marble, tile , cement backerboard.

Recommended maximum material thickness

Wood 27 mm

Aluminum 3 mm

PVC pipe (radius ) 13 mm

Tile 8 mm

Sheet steel 0. 91mm(20 gauge )

Page 12

12

PARALLEL GUIDE (See Fig. D)

2

The parallel guide is used for making cuts parallel to a work-piece

edge at a chosen distance and can be used from either side of the

base plate (9). Slide the parallel guide (19) arm through the fixture(11)

to achieve the required cutting distance and tighten the clamping

screw (13) with the small “L” spanner to lock into position. Do not

over tighten. The parallel guide enables exact cuts along a workpiece

edge and can also be used for cutting parallel strips.

NOTE: Since the parallel guide clamping screw is spring-loaded, the

operator should take care when unscrewing it completely as to avoid

losing the screw and spring.

SAWDUST REMOVAL (See Fig. E)

3

Your saw includes a vacuum adapter (20) that attaches to the dust

extraction outlet (7) on the saw. This adapter port can be attached to

a vacuum cleaner (sold separately). The use of the vacuum is strongly

recommended as it keeps the work area clean, dramatically increases

cut visibility and reduces airborne dust. It also keeps dust out of the

working elements of the guard.

NOTE:If using the saw without a vacuum attached, in some

circumstances after lengthy operation, dust can accumulate at the

rear of the base and prevent it from reaching full depth. You can

prevent this by occasionally shaking the dust out.

PLASTIC BASE PLATE COVER (See Fig. F1, F2)

4

Your saw includes a plastic base plate cover ( 21). Attach it to your

saw’s base when you are cutting work pieces that have delicate

surfaces (finishes) such as vinyls, plastics, fiberglass, laminate

flooring and tiles that could easily be scratched by the steel base.

Page 13

13

Operation

1

TRIGGER SWITCH (See Fig. G)

The on/off switch is locked off to prevent accidental starting. In order

to turn the machine on, depress and hold the lock off switch (6),

then depress the on/off switch (1) and release the lock off switch.

Your switch is now on. To switch off, just release the on/off switch.

NOTE: When the machine is not in use, the lock off switch rests

against the blade guard in order to block the plunge function and

prevent the blade from being exposed unnecessarily.

2

SET THE BLADE DEPTH

NOTE:The correct choice of cutting depth can improve ease of

cutting and cut quality.

Always use the minimum cut depth that is required for your particular

cut, which should just cut through the material plus a small allowance

e.g. 3 mm.

Excessive cutting depth increases splintering in wood, chipping in tile

and causes severe chatter in sheet steel and aluminum (which can

quickly blunt the blade).

Maximum depth can be used when cutting internal cut-outs in wood

as this reduces the overcutting required.

1) Determine the desired depth according to the thickness of the

material plus a blade allowance of 1/8” (3 mm).

2) Unlock the depth of cut adjustment and lock lever (8 ). ( See Fig. H1)

3) Slide the depth of cut indicator to the desired depth of cut. Lock

down the depth of cut adjustment and lock lever (8). (See Fig. H2)

When plunge or pocket cutting into the middle (or interior) of the

work piece, through the narrow slot, you can easily see the cutting

mark you draw and the location where the blade will plunge into the

Page 14

14

J1

J2

16

J2

22

J1

J2

J3

J4

16

J2

J4

22

J1

J2

J3

J4

J5

J6

16

work piece, based on the blade depth that was selected.

Always practice in a scrap work piece to become familiar with this

cutting operation. The selected depth of cut is now set. When the

saw’s blade is manually lowered, the blade will be below the base at

the selected depth.

The laser is used as a cutting guide and should form a red line on

the material surface that is exactly aligned with the blade alignment

indicator (12).

Press down the laser on/off switch (5) to turn on the laser.

Press down the laser on/off switch again to turn off the laser. (See

Fig. I)

NOTE: Clean the laser generator periodically.

WARNING: Never stare directly into the laser beam and never

point the beam at anybody. The laser beam energy is extremely

harmful to human eyes.

WARNING: When not in use, always turn the laser off to save

the battery capacity.

3

TO REPLACE LASER BATTERIES (See Fig. J1-J6)

The saw comes with laser batteries well assembled. When battery

capacity runs out, replace batteries as follows:

Use 1.5V batteries model LR44, typical to calculators, cameras and

similar small electronics.

Move the battery storage cover (16) in the direction the arrow (on the

cover) points. Then lift the battery storage cover (See Fig. J1, J2).

You can see one end of a cord. To remove the batteries, just slowly

pull the end of the cord. The two batteries will be taken out along

with the cord ( See Fig. J3).

To fit new batteries, adjust the position of the cord and insert two

batteries in place. Make sure two batteries are pressed on the cord

(See Fig. J4, J5).

Page 15

15

J2

J4

J6

22

J1

J2

J3

J4

J5

J6

K

L

J2

J4

J6

L

22

J3

J4

J5

J6

K

L

M

N

Restore the cover ( See Fig. J6).

NOTE: Pay attention that “+/-” of the batteries are the same as the

illustration on the machine.

4

CUTTING GUIDE (See Fig. K)

The blade alignment indicator (12) in the front of the base plate is

used as a cutting guide. Always guide it along the cutting mark made

on the workpiece for accurate cutting.

NOTE: It is best to carry out a trial cut.

Function

MAKING CROSS CUTS AND RIP CUTS (See Fig. L, M)

1

WARNING: To avoid sudden kick-back, never start a stationary

blade while it is in contact with the work piece.

Always start the saw and allow it to reach full speed before

commencing to plunge.

The blade teeth are exposed during this operation so proceed with

extreme caution.

a) A LWAYS use your saw with your hands positioned correctly.

WARNING: Always maintain proper control of the saw to make

sawing safer and easier. Loss of control of the saw could cause an

accident resulting in possible serious injury.

b) When making cross or rip cuts, align your line of cut with the

center of the “V” (blade alignment indicator), located on the front of

the saw’s base (See Fig. L).

c) Since the thickness of blades vary, make a trial cut in scrap material

along your cut mark to determine how much, if any, you should offset

the blade from the cut mark to allow for the blade thickness to get an

accurate cut.

Page 16

16

J4

J6

L

N

MAKING RIP CUTS (See Fig. M)

Always use a guide when making long rip cuts with your saw. You

can use any suitable straight edge clamped to the work or the parallel

guide that is included with your saw.

POCKET CUTTING (SOFT MATERIALS ONLY) (See Fig. N)

2

This operation requires much skill with a saw and must only be

carried out by a qualified person.

Clearly mark the area to be cut. Set the depth of cut on the saw (See

Fig. H1). Tilt the saw over the marked area with the front edge of the

base plate resting on the work surface and the back edge lifted above

the work surface. The cutting guide should be aligned with the line

you have marked on your workpiece. With the saw still in the tilted

position, apply pressure to the base plate so that the saw blade is

fully exposed through the blade slot in the base plate (according to

the depth of cut you have set). Ensure the blade is not touching but

is close to the work surface. Hold the saw firmly while applying the

least amount of pressure as possible on base plate. To avoid kickback,

you should hold the tool firmly before switching on the saw. switch

the saw on, wait for it to reach full speed, and gently guide the blade

down into the material but maintain a pivoting force on the front edge

of the base. Watch your cutting line by carefully looking through the

front end of the blade slot.

DO NOT bind the blade in the cut; push the saw blade forward at a

rate where the blade is not laboring.

When the cut is complete, release the trigger safety release

and switch and let the blade come to a complete stop. DO NOT

REMOVE the saw and blade from the workpiece while the blade is

moving. This could damage your cut (kerf), cause kickback and loss

of control, resulting in injury.

Page 17

17

Working hints for your circular

saw

If your Versacut becomes too hot, please run your VersacutTM no

load for 2-3 minutes to cool the motor. Avoid prolonged usage under

strenuous cutting loads.

Protect saw blades against impact and shock. Excessive feed

significantly reduces the performance capability of the machine and

reduces the service life of the saw blade. Sawing performance and

cutting quality depend essentially on the condition and the tooth

count of the saw blade. Therefore, use only sharp saw blades that are

suited for the material to be worked.

Choice of blades: 24 teeth for general work, approx. 40 teeth for finer

cuts, more than 40 teeth for very fine cuts into delicate surfaces,

diamond for tile, cement board, etc.

Maintenance

Remove the plug from the socket before carrying out any

adjustment, servicing or maintenance.

Keep tools sharp and clean for better and safer performance. Follow

instructions for lubricating and changing accessories. Inspect tool

cords periodically and if damaged, have repaired by authorized

service facility. Your power tool requires no additional lubrication or

maintenance. There are no user serviceable parts in your power tool.

Never use water or chemical cleaners to clean your power tool. Wipe

clean with a dry cloth. Always store your power tool in a dry place.

Keep the motor ventilation slots clean. Keep all working controls free

of dust.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in order

to avoid a hazard.

Periodically clear dust and chips from guard and base to ensure

proper performance.

Page 18

18

Troubleshooting

Environmental protection

Symptom Possible Causes Possible Solution

Tool will not start

when operating the

on/ off switch.

Cutting depth is less

than that is set.

Blade spins or slips

Blade will not cut a

straight line.

Blade kicks back

when beginning a cut

Power cord not

plugged in.

Power cord is

broken.

Carbon brush has

worn down

Sawdust

accumulated at

the rear of the

base.

Blade is not tightly

engaged with the

spindle.

Blade is dull.

Blade is not

mounted properly.

Saw is not being

guided properly.

Blade is not

spinning fast

enough

Check to make sure

power cord is connected

well into a working outlet.

Unplug the power

cord. Replace it using a

qualified maintenance

person.

Replace the carbon

brush using a qualified

maintenance person.

Shake out sawdust.

Consider connecting

a vacuum for dust

collection.

Remove the blade,

and reassembled it as

described in INSTALL /

CHANGE THE BLADE

section.

Mount a new, sharp

blade on the saw.

Check that blade is

properly mounted.

Use an edge guide.

Allow the saw blade to

reach full speed prior to

beginning a cut

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your local authorities or retailer for recycling advice.

Page 19

19

Connect

Blue to N

(neutral)

Outer sleeve

firmly clamped

Cable grip

Brown L (live)

13 Amp fuse approved

to BS1362

Plug replacement

(UK & Ireland only)

If you need to replace the fitted plug then follow the instructions

below.

IMPORTANT

The wires in the mains lead are colored in accordance with the

following code:

BLUE =NEUTR AL BROWN = LIVE

As the colors of the wires in the mains lead of this appliance may not

correspond with the colored markings identifying the terminals in

your plug, proceed as follows. The wire which is colored blue must

be connected to the terminal which is marked with N. The wire which

is colored brown must be connected to the terminal which is marked

with L.

NOTE: If a moulded plug is fitted and has to be removed take great

care in disposing of the plug and severed cable, it must be destroyed

to prevent engaging into a socket.

WARNING!

Never connect live

or neutral wires to

the earth terminal

of the plug. Only

fit an approved

13ABS1363/A plug

and the correct

rated fuse.

Page 20

EC DECLARATION OF

CONFORMITY

We,

Positec Power Tools (Europe) Ltd, PO Box 152,

Leeds, LS10 9DS, UK

Declare that the product,

Description WORX Mini circular saw

Typ e WU420 (4-designation of machinery, representative of Saw)

Function Cutting various materials with a rotating toothed blade

Complies with the following Directives,

•

EC Machiner y Directive 2006/42/EC

•

EC Electromagnetic Compatibility Directive 2004/108/EC

Standards conform to

EN 55014-1 EN 55014-2 EN 61000-3-2

EN 61000-3-3 EN 60745-1 EN 60745-2-5

The person authorized to compile the technical file,

Name Russell Nicholson

Address Positec Power Tools (Europe)Ltd, PO Box 152, Leeds,

LS10 9DS, UK

2012/08/08

Leo Yue

POSITEC Qualit y Manager

20

Page 21

Page 22

Page 23

Page 24

2PSC15APK11002A0

Copyright © 2012, Positec. All Rights Reserved.

Loading...

Loading...