WORTHINGTON CS200 Operation & Maintenance Instructions

CS200 Control Systems

LABS and K Series Cryostorage Systems

Operation & Maintenance Instructions

CAUTION - SAFETY FIRST!

• REVIEW AND UNDERSTAND ALL SAFETY PROCEDURES IN THE “HANDLE WITH CARE”

BOOKLET BEFORE ATTEMPTING TO INSTALL, OPERATE OR PERFORM MAINTENANCE

ON THIS LN2 CONTROLLER.

• DO NOT ATTEMPT TO USE OR MAINTAIN ANY LIQUID NITROGEN FREEZER UNTIL YOU

READ AND UNDERSTAND THESE INSTRUCTIONS.

• DO NOT PERMIT UNTRAINED PERSONS TO USE OR MAINTAIN THIS UNIT.

• IF YOU DO NOT FULLY UNDERSTAND THESE INSTRUCTIONS, CONTACT YOUR

SUPPLIER FOR FURTHER INFORMATION.

• BEFORE ATTEMPTING TO OPERATE THIS CONTROLLER WITH ANY WORTHINGTON

INDUSTRIES LABS OR K SERIES UNITS, YOU MUST READ THE SEPARATE OPERATING

AND SAFETY MANUAL PROVIDED WITH THAT UNIT.

Table of Contents

SAFETY PRECAUTIONS .......................................................................5

Liquid Nitrogen (LN2) ............................................................................................. 5

Extreme Cold - Cautionary Statement ....................................................................... 5

Keep Equipment Area Well Ventilated ..................................................................... 5

Liquid Nitrogen System ......................................................................................... 5

Electrical .............................................................................................................. 5

GENERAL INFORMATION ...................................................................6

CS200 Series Control System Specifications ............................................................ 7

DELIVERY AND RETURNS .................................................................. 10

Unpacking and Inspection .................................................................................... 10

Freight Damage Procedures ................................................................................. 10

Repackaging for Shipment .................................................................................. 10

INSTALLATION ................................................................................. 11

Getting Unit into Service ..................................................................................... 11

Electrical ........................................................................................................... 11

Electromagnetic Compatibility (EMC) .................................................................... 11

Power Supply Connection ................................................................................... 12

Validation .......................................................................................................... 12

OPERATION ....................................................................................13

Initial Fill ........................................................................................................... 13

Control Components ........................................................................................... 13

CS200 Controller Display Guide ........................................................................... 14

Operational Theory ............................................................................................. 14

Alarm Conditions ............................................................................................... 15

Lid Switch .......................................................................................................... 16

Solenoid Valve ................................................................................................... 17

Thermocouples ................................................................................................... 17

Power Supply .................................................................................................... 17

Remote Alarm .................................................................................................... 17

Operating Parameters ......................................................................................... 17

Temperature Monitoring ....................................................................................... 18

Liquid Phase Storage ........................................................................................... 18

Maintenance ...................................................................................................... 18

CONTROLLER OPERATION ................................................................20

Introduction ....................................................................................................... 20

Operation Data .................................................................................................. 20

Communications ................................................................................................. 20

Normal Fill Cycle ............................................................................................... 20

Control Setting Adjustments .................................................................................. 20

Temperature .......................................................................................................26

Battery Operation .............................................................................................. 26

LED Status Wheel ............................................................................................... 26

Lid Switch ........................................................................................................... 26

Menu System ..................................................................................................... 27

Factory Defaults ................................................................................................. 29

Troubleshooting ..................................................................................................30

Interconnection Block Diagram .............................................................................. 30

CS200 Control Systems

Table of Contents

Wiring Diagram ..................................................................................................31

Installation & Setup .............................................................................................. 32

External Connector Ratings ................................................................................... 34

LED Status Wheel Flash Patterns ............................................................................ 35

Temperature Thermocouple Select ......................................................................... 35

Temperature Calibration ...................................................................................... 35

Test Temperature System ....................................................................................... 36

Test Level Sensors ................................................................................................ 36

Alarms and Error Conditions ................................................................................ 37

System Alarms .................................................................................................... 37

Test Alarms ........................................................................................................ 37

Logging ............................................................................................................. 37

Display Brightness ............................................................................................... 38

Making Adjustments to the CS200 Series Control System Sensor Assembly ............... 38

Removing/Installing the Solenoid Valve ................................................................. 39

Removing/Installing the Controller 10K/24K Units ................................................. 39

Removing/Installing the Thermocouple .................................................................. 40

Removing/Installing the Sensor Probes .................................................................. 40

Making Adjustments to the Level Settings ............................................................... 40

Removing/Installing the Solenoid Valve ................................................................. 41

REPLACEMENT PARTS ...................................................................... 42

Plumbing Assembly ............................................................................................. 42

Controller Assembly ............................................................................................ 43

TROUBLESHOOTING ........................................................................45

Symptoms ......................................................................................................... 45

Controller Will Not Turn ON ............................................................................... 45

High Liquid Level ................................................................................................ 45

Indicates Low LN2 Supply ..................................................................................... 46

Indicates Open Sensor ......................................................................................... 46

Temperature Reading 10° to 20° Warm ................................................................. 46

Fill Solenoid Cycles On and Off ............................................................................ 47

Solenoid Makes Excessive Humming Noise ............................................................ 47

Lid Open Alarm .................................................................................................. 47

QCF (Quick Chill Feature) Will Not Operate ......................................................... 47

Auto Defog Feature Will Not Operate ..................................................................47

Push Buttons Will Not Respond ............................................................................48

Liquid Level Readout is Incorrect ........................................................................... 48

Power Failure Alarm ........................................................................................... 48

SERVICE AND MAINTENANCE HISTORY LOG ....................................49

APPENDIX ....................................................................................... 50

EN Compliance Tables .........................................................................................50

EC Declaration of Conformity ............................................................................... 54

Warranty ........................................................................................................... 55

Labels ................................................................................................................ 55

CS200 Control Systems

Safety Precautions

Liquid Nitrogen

Nitrogen is an inert, colorless, odorless, and tasteless gas making up four-fifths of the

air you breathe – and can be very dangerous. Air is roughly one-fifth oxygen. Liquid

nitrogen is at a temperature of -196°C (-320°F) under normal atmospheric pressure.

Cryogenic freezers are used in LN2 service only.

Extreme Cold - Cautionary Statement

Accidental contact of liquid nitrogen or cold issuing gas with the skin or eyes may

cause a freezing injury similar to frostbite. Handle the liquid so it won’t splash or

spill. Protect your eyes and cover the skin where the possibility of contact with the

liquid, cold pipes and equipment, or cold gas exists. Safety goggles or a face shield

should be worn when operating this equipment. Insulated gloves that can be easily

removed and long sleeves are recommended for arm protection. Trousers without

cuffs should be worn outside boots or over the shoes to shed spilled liquid.

Keep Equipment Area Well Ventilated

Although nitrogen is non-toxic and non-flammable, it can cause asphyxiation in

a confined area without adequate ventilation. Any atmosphere not containing

enough oxygen for breathing can cause dizziness, unconsciousness, or even death.

Nitrogen, a colorless, odorless, and tasteless gas that cannot be detected by the

human senses, will be inhaled normally as if it were air. One (1) liter of liquid

nitrogen is equivalent to 24.6 scf of nitrogen gas. Without adequate ventilation, the

expanding nitrogen will displace the normal air resulting in death.

Liquid Nitrogen System

The liquid nitrogen supply pressure at the inlet to the freezer should be in the

range of 10 psig (0.7 bar/69 kPa) to 20 psig (1.4 bar/138 kPa) for optimum

performance. Higher operating pressures will increase transfer losses and create

excessive turbulence of the liquid in the freezer, which can generate false signals

to the liquid level controller causing the freezer to under-fill. In “liquid phase”

storage applications, excessive turbulence can cause splashing which could result

in personal injury and/or damage to the freezer. When installing piping or fill hose

assemblies, make certain a suitable safety relief valve is installed in each section

of plumbing between any two isolation points. Trapped liquefied gas will expand

greatly as it warms and may burst hoses or piping causing damage or personal

injury. A relief valve is installed in the freezer plumbing to protect the line between

the customer-supplied shut-off valve and the freezer solenoid valve. Relief valves can

be piped to the outside of the building.

WARNING:

The following safety

precautions are for

your protection. Before

installing, operating,

or maintaining this unit

read and follow all

safety precautions in this

section and in reference

publications. Failure

to observe all safety

precautions can result

in property damage,

personal injury, or

possibly death.

WARNING:

Maintain adequate

ventilation to prevent

asphyxiation hazard

(see Safety Precautions).

Caution:

When installing field

fabricated piping, make

certain a suitable safety

relief valve is installed

in each section of piping

between any two

isolation points.

WARNING:

Inlet pressure should not

exceed 22 psig

(1.5 bar/152 kPa).

Higher pressures could

result in damage to

equipment.

Electrical

• This product is not intended for a life support function.

• This product is intended to be used in hospitals and clinics.

• This product has no Radio Transmitter (Intentional Radiator) functions.

• This product is not intended for electromagnetic shielded rooms only.

WARNING:

Electrical shock can

kill. Do not attempt

any service on these

units without first

disconnecting the

electrical power cord.

CS200 Control Systems

5

General Information

• This product does not intentionally apply RF energy for its function.

• This product does not intentionally receive RF energy for its function.

The liquid level controllers used with these freezers operate from 12 VDC. Disconnect the electrical power cord

from the outlet before attempting any service.

For more detailed information concerning safety precautions and safe practices to be observed when handling

cryogenic liquids consult CGA publication P-12 “Safe Handling of Cryogenic Liquids” available from the

Compressed Gas Association: CGA website: www.cganet.com; CGA customer service +1.703.788.2700; or

email customerservice@cganet.com.

General Information

The CS200 SERIES Control System can monitor and control both the liquid nitrogen level and the vapor

temperature range in the cryostorage unit you have selected. CS200 SERIES Control Systems are designed

to work with Worthington Industries Cryostorage Systems. The features are designed to provide a safe

environment for samples while at the same time tracking all relevant information associated with the freezer.

This control provides a complete historical record of the environment in your unit and therefore, the environment

in which your samples have been stored in this system. This controller features a vacuum fluorescent display.

The addition of a liquid nitrogen supply and inventory control racks for systematic retrieval of stored product

completes the total Cryostorage System.

Worthington Industries Cryostorage Systems are designed for applications where extremely low temperature

storage of biological products is required. They are also appropriate for industrial or other applications where

liquid nitrogen temperatures and high capacity are needed.

Before beginning installation or operation of this CS200 SERIES Control System, make sure that you read and

understand this manual as well as the operating and safety instructions for the cryostorage unit you will be

using with this controller.

CS200 Control Systems

66

General Information

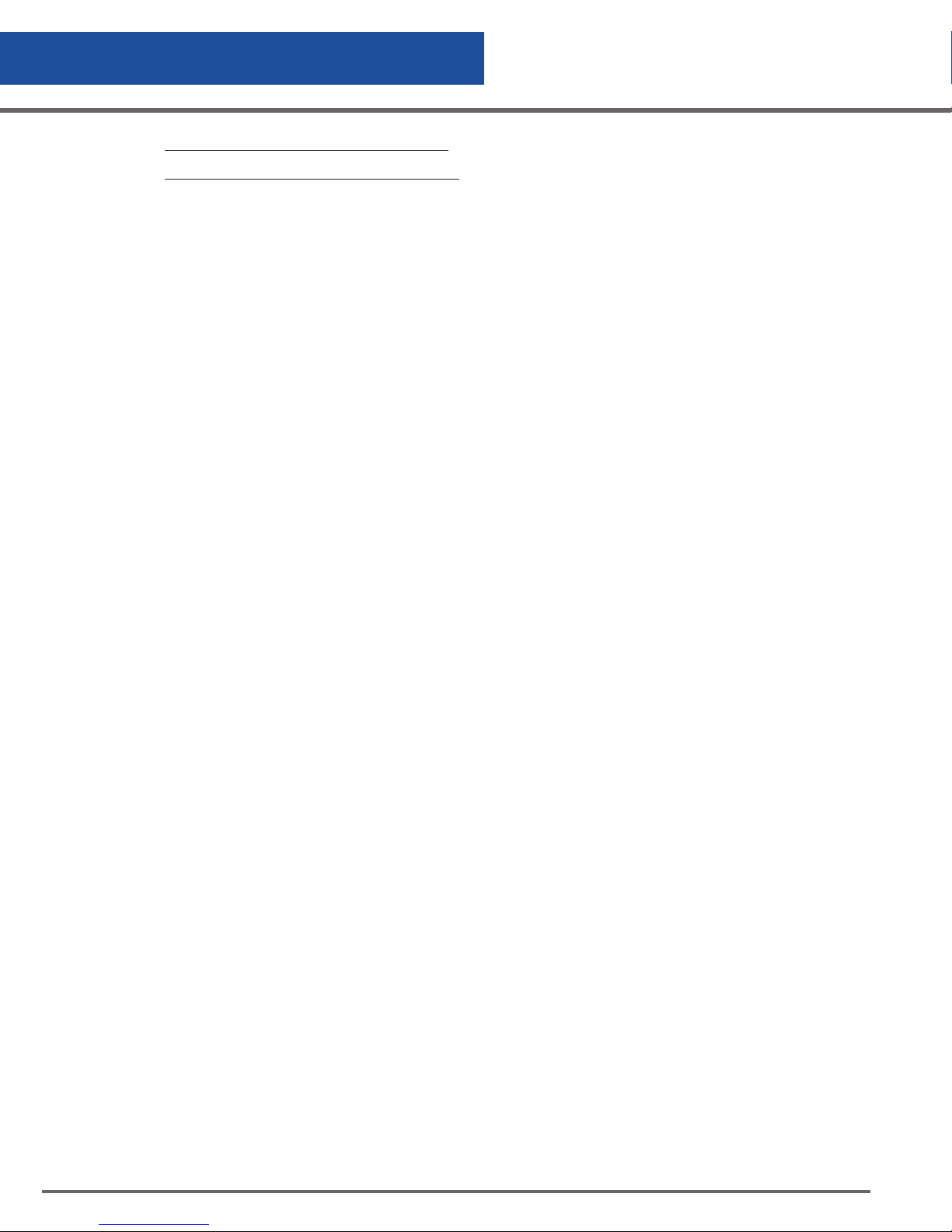

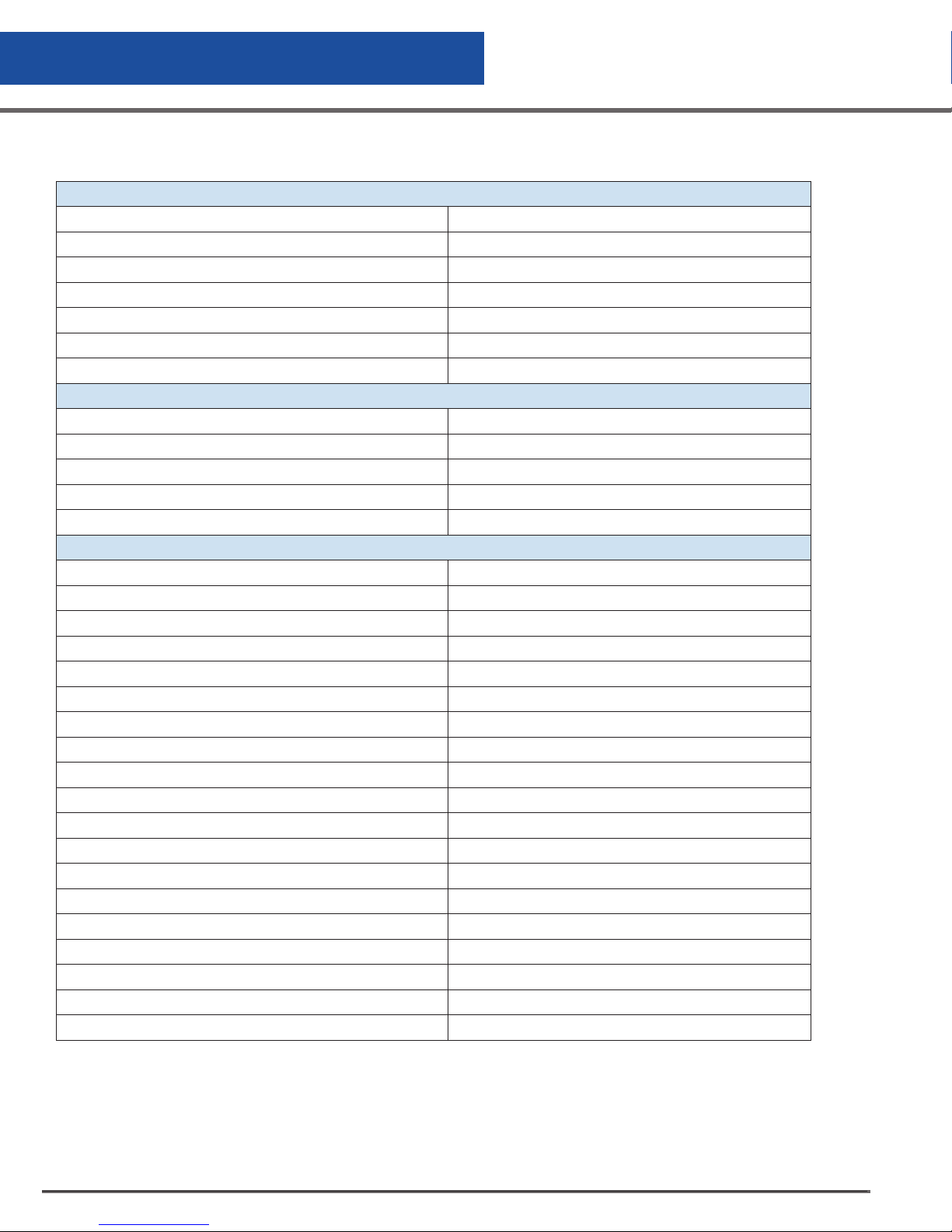

CS200 SERIES Control System Specifications

Specifications

Control Type LN2 Level Control & Temperature Control

Level Measurement

Sensor Type 8-Thermistor Fixed (standard)

Range 8 inch range (8-Thermistor)

Redundancy Multiple discrete points

Temperature Measurement Sensor Type

Type T Thermocouple

Accuracy

Resolution

Number of channels

Temperature Display Units

Electrical

Input Voltage 100-240 VAC

Input Current (max) 1.75 A

Input Current (continuous) .5 A

Power Consumption (max) 21 W

Power Consumption (continuous) 6 W

Input Frequency 50/60 Hz

Output 12 VD C

Control Input Voltage 12 VD C

Power cord Available for all countries

Battery

Rating 12 Volt, 18Ah

Type AGM Sealed Non-Spillable

Short Protection Installed PCB with thermal fuse

Battery Cover Vinyl

Solenoid Valve

Input Voltage 12 VD C

Input Current .96 amps

Communications

Protocol CryoWire Secure™

Number of Communication Ports 3

1o or 1.5% of reading

.1oC

2

o

C, F, K, R

CS200 Control Systems

7

General Information

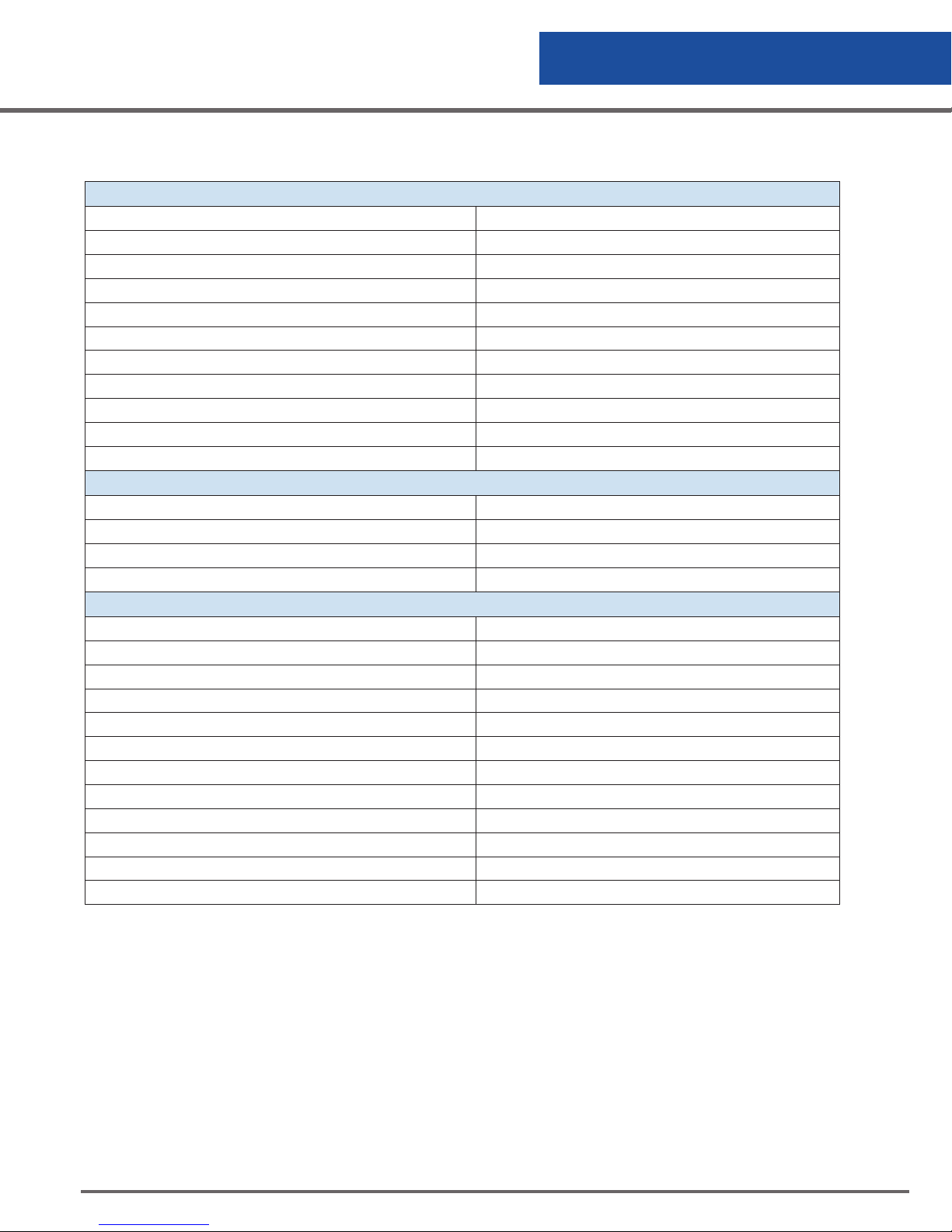

CS200 SERIES Control System Specifications (cont’d)

User Interface

Display Type Vacuum Fluorescent Display (VFD)

Buttons 11

Level, Temperature and Alarm Information VFD

“At a Glance” status LED status wheel

Filling 1 LED

Menu Access 1 LED

Language English and German

Control Tests

Power Up Self-Test Control system check

Thermistor Status Yes

Battery voltage Yes

Control voltages Yes

Temperature circuit Yes

Alarms

Low Level Alarm Always enabled

High Level Alarm Always enabled

Sensor Error Alarm Always enabled

High Temperature Alarm (T/C #1, T/C #2) Programmable

Low Temperature Alarm (T/C#1, T/C#2 ) Programmable

Thermocouple Calibration Alarm Always enabled

Thermocouple Open Alarm Always enabled

Power Failure (Remote only) Always enabled

Low LN2 Supply Alarm Programmable

Battery Mode Warning Always enabled

Lid Open Too Long Alarm Programmable

Valve Stuck Open Alarm Programmable

Unauthorized Access Warning Programmable

LN2 Use Warning Programmable

Low Battery Voltage Always enabled

Audible Alarm Always enabled

Audible Alarm Re-trigger Programmable

Visual Alarm Indicator Always enabled

Remote Alarm Delay Programmable

CS200 Control Systems

8

General Information

CS200 SERIES Control System Specifications (cont’d)

Buttons

Power Turns power on/off

Fill/Defog Open Valve

Stop Close Valve

Menu Access Menu

Mute Silence audible

Enter Save a setting or select a menu choice

Back/Exit Leave a setting unchanged or back out of menu.

Up arrow Scroll the menu system or increase a value

Down arrow Scroll the menu system or decrease a value

Left arrow Scroll horizontal menu

Right arrow Scroll horizontal menu

Data Collection

Temperature Yes

Level Yes

Alarms Yes

Memory 4 Mb

Dimensions

Display Width 9.5” (241 mm)

Display Height 2.0” (50.8 mm)

Display Depth 1.31” (33.3 mm)

Display Weight .625 lbs (.28 kg)

Main Control Width 8.875” (225.4 mm)

Main Control Height 6.688” (169.9 mm)

Main Control Depth 1” (25.4 mm)

Main Control Weight 1.0 lbs (.45 kg)

Battery Width 7.25” (184.2 mm)

Battery Height 6.375” (161.9 mm)

Battery Depth 3.25” (82.6 mm)

Battery Weight 12.4 lbs (5.6 kg)

NOTE: Above measurements are for LABS; CS200 controllers are integrated into all K Series models.

CS200 Control Systems

9

Delivery & Returns

Unpacking and Inspection

Inspect shipping containers for external damage. All claims for damage (apparent or concealed) or partial loss

of shipment must be made in writing within ten (10) days from receipt of goods. If damage or loss is apparent,

please notify the appropriate parties as indicated below:

Domestic LTL Shipments – The customer should notify and file the appropriate damage claims with the

carrier. All products are shipped Ex Works.

Domestic UPS Shipments – Any damage should be noted and reported to shipper upon delivery, and

Worthington Industries must also be notified. Confirm with Worthington Industries Customer Service the filing

procedures for any UPS damage claims.

International Shipments – Any damage and/or claims are to be filed with the carrier. Insurance agent(s)

and Customs should also be notified.

In all cases, Worthington Industries should be notified so we can assist if needed in filing

damage claims.

Open the shipping containers; a packing list is included with the system to simplify checking that all

components, cables, accessories, and manuals were received. Please use the packing list to check off each

item as the system is unpacked. Inspect for damage. Be sure to inventory all components supplied before

discarding any shipping materials. If there is damage to the system during transit, be sure to file proper claims

promptly. Please advise Worthington Industries of such filings. In case of parts or accessory shortages, advise

Worthington Industries immediately. Worthington Industries cannot be responsible for any missing parts unless

notified within 10 days of shipment.

Freight Damage Procedures

Any freight damage claims are your responsibility. Cryostorage Systems are delivered to your

carrier from Worthington Industries’ dock in new condition; when you receive our product

you may expect it to be in that same condition. For your own protection, take time to visually inspect

each shipment in the presence of the carrier’s agent before you accept delivery. If any damage is observed,

make an appropriate notation on the freight bill. Then, ask the driver to sign the notation before you receive the

equipment. You should decline to accept containers that show damage which might affect serviceability.

Repackaging for Shipment

If it is necessary to return any part of the system for repair or replacement, a Material Return Authorization

(MRA) number must be obtained from an authorized factory representative before returning the equipment

to our service department. Contact your distributor for return authorization. When returning equipment for

service, the following information must be provided before obtaining an MRA:

1. System model and serial number, and controller model and serial number.

2. User’s name, company, address, and phone number

3. Malfunction symptoms

If possible, the original packing material should be retained for reshipment. If not available, consult

Worthington Industries for shipping and packing instructions. It is the responsibility of the customer to assure

that the goods are adequately packaged for return to the factory. All freezers returned to Worthington Industries

must be clean and decontaminated before return.

CS200 Control Systems

10

Installation

Getting Unit into Service

Your Cryostorage System comes with complete instructions for how you should

remove the unit from the crate and put it into service. Read both this manual and

your Cryostorage System’s manual before beginning any installation. Make sure to

follow any required procedures and safety guidelines when you are connecting your

Liquid Nitrogen source.

The CS200 SERIES Control System is designed to be operated at normal room

temperatures 15° C to 27° C (60° F to 80° F) at a relative humidity level below

50%. The humidity level should be maintained such that the electronics are not

exposed to condensation.

The Worthington Industries Cryostorage freezer should be positioned such that the

all sides of the unit are easily accessible and the user can easily connect/disconnect

the power cord from the wall socket.

Proper ventilation MUST BE adequate to sustain life for those working with or

maintaining this equipment.

Electrical

The liquid level controllers used with these freezers operate at 12 VDC. The external

power supply has a 120 VAC (50/60 Hz) primary. Disconnect the electrical power

cord from the wall outlet before attempting any service.

Electromagnetic Compatibility (EMC)

Although this equipment conforms to the intent of the 2004/108/EC EMC Directive,

all medical equipment may produce electromagnetic interference or be susceptible

to electromagnetic interference. The following are guidance and manufacturer’s

declarations regarding EMC for the CS200 SERIES Control System.

WARNING:

Electrical shock can

kill. Do not attempt

any service on these

units without first

disconnecting the

electrical power

cord.

The CS200 SERIES Control System needs special precautions regarding EMC

and needs to be installed and put into service according to the EMC information

provided in the following pages.

Portable and Mobile RF communications equipment can affect the performance of

the CS200 SERIES Control System. Please use the guidelines and recommendations

specified in the EN Compliance tables found on pages 50-54.

Other equipment or systems can produce electromagnetic emissions and therefore

can interfere with the functionality of the CS200 SERIES Control System. Care

should be used when operating the CS200 SERIES Control System adjacent to or

stacked with other equipment. If adjacent or stacked use is necessary, the CS200

SERIES Control System should initially be observed to verify normal operation in the

configuration in which it will be used.

The electrical cables, external power supplies and accessories listed or referenced

in this manual have been shown to comply with the test requirements listed in the

EN Compliance tables found on pages 50-54. Care should be taken to use only

manufacturer-recommended cables, power supplies and electrical accessories with

the C200S SERIES Control System. If a third-party supplier offers cables, external

WARNING:

Maintain adequate

ventilation

to prevent

asphyxiation

hazard (see Safety

Precautions).

WARNING:

If the fill fails to

stop for any reason,

quickly close the

liquid supply

valve to prevent

overfilling until the

the problem can be

determined.

CS200 Control Systems

11

Installation

WARNING:

This equipment

is intended for

use by healthcare

professionals. As

with all electrical

medical equipment,

this equipment

may cause radio

interference or

may disrupt the

operation of nearby

equipment. It may

be necessary to

take mitigation

measures such

as re-orienting

or relocating the

CS200 SERIES

Control System unit

or shielding the

location.

power supplies and electrical accessories for use with the CS200 SERIES Control

System and they are not listed or referenced in this manual, it is the responsibility of

that third-party supplier to determine compliance with the standards and tests in the

EN Compliance tables found on pages 50–54.

The use of electrical cables and accessories other than those specified in this manual

or referenced documents may result in increased electromagnetic emissions from the

CS200 SERIES Control System or decreased electromagnetic immunity of the CS200

SERIES Control System.

Power Supply Connection

Connect the power supply to your Cryostorage System and then plug the power

supply into a surge-protected wall outlet.

Validation

Some organizations require that equipment be validated periodically. If information

is needed on the proper techniques to validate this equipment, please contact your

supplier.

CS200 Control Systems

1212

Operation

These instructions are for operators experienced with cryogenic equipment. Before operating the system,

become familiar with the safety precautions in this manual and in reference publications. Make certain all

applicable provisions set forth in the Installation Section have been followed before placing a system in

operation. Study this manual thoroughly. Know the location and function of all system components.

Initial Fill

The Cryostorage System, using the CS200 SERIES Controller, comes preset from the factory. The liquid nitrogen

supply pressure at the inlet to the freezer should be in the range of 10 psig (0.7 bar/69 kPa) to 22 psig

(1.5 bar/152 kPa) for optimum performance. Higher operating pressures will increase transfer losses and

create excessive turbulence of the liquid in the freezer which can generate false signals to the liquid level

controller causing the freezer to under fill. In “liquid phase” storage applications, excessive turbulence can

cause splashing which could result in personal injury.

Control Components

CS200 Series Control System Components

The CS200 SERIES Control System for the Worthington Industries Cryostorage freezer consists of the following

components:

• Main Control Module

• VFD (Vacuum Florescent Display) Module

• Shielded Display Cable

• Wiring Harness Assembly

• Power Supply

• Thermocouple Assembly (Optional Second Thermocouple)

• Sensor Assembly

• Cryogenic Solenoid Valve

• Remote Alarm Plug

• Lid Switch Assembly

• 12 Volt, 18aH battery

• Solenoid Valve Assembly with Freezeguard

• Strainer

The CS200 Series Control System is assembled onto the freezer at the factory and completely tested. Refer to

the Quick Start Guide for freezer set-up. Start operation of the control system by plugging the power cord into

the wall outlet. Press and hold the POWER button for 2 seconds. The CS200 Series Control System will go

through a short startup routine and then start operation. Refer to Figure 2.0 CS200 Controller Display for a

description of the controller’s navigation buttons.

CS200 Control Systems

13

Operation

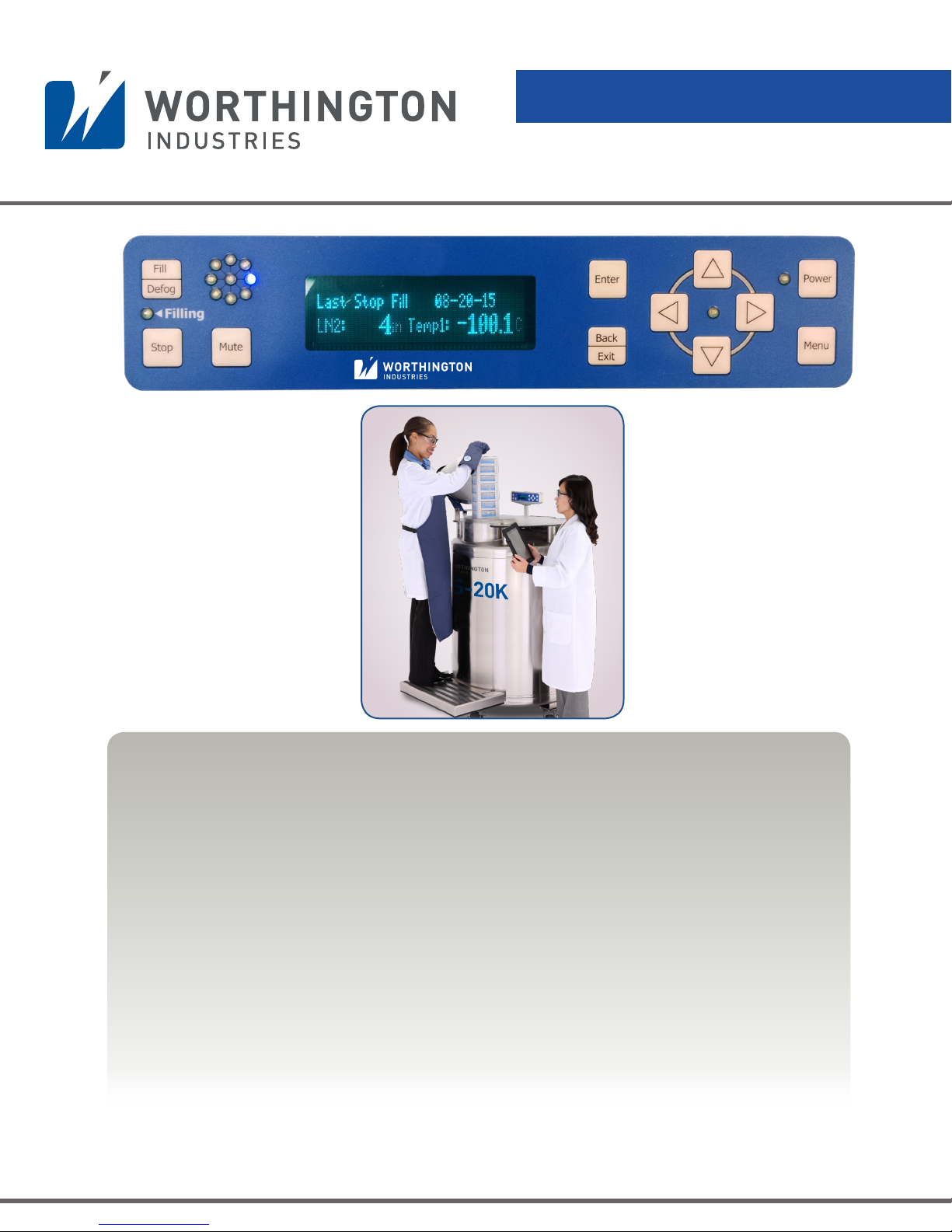

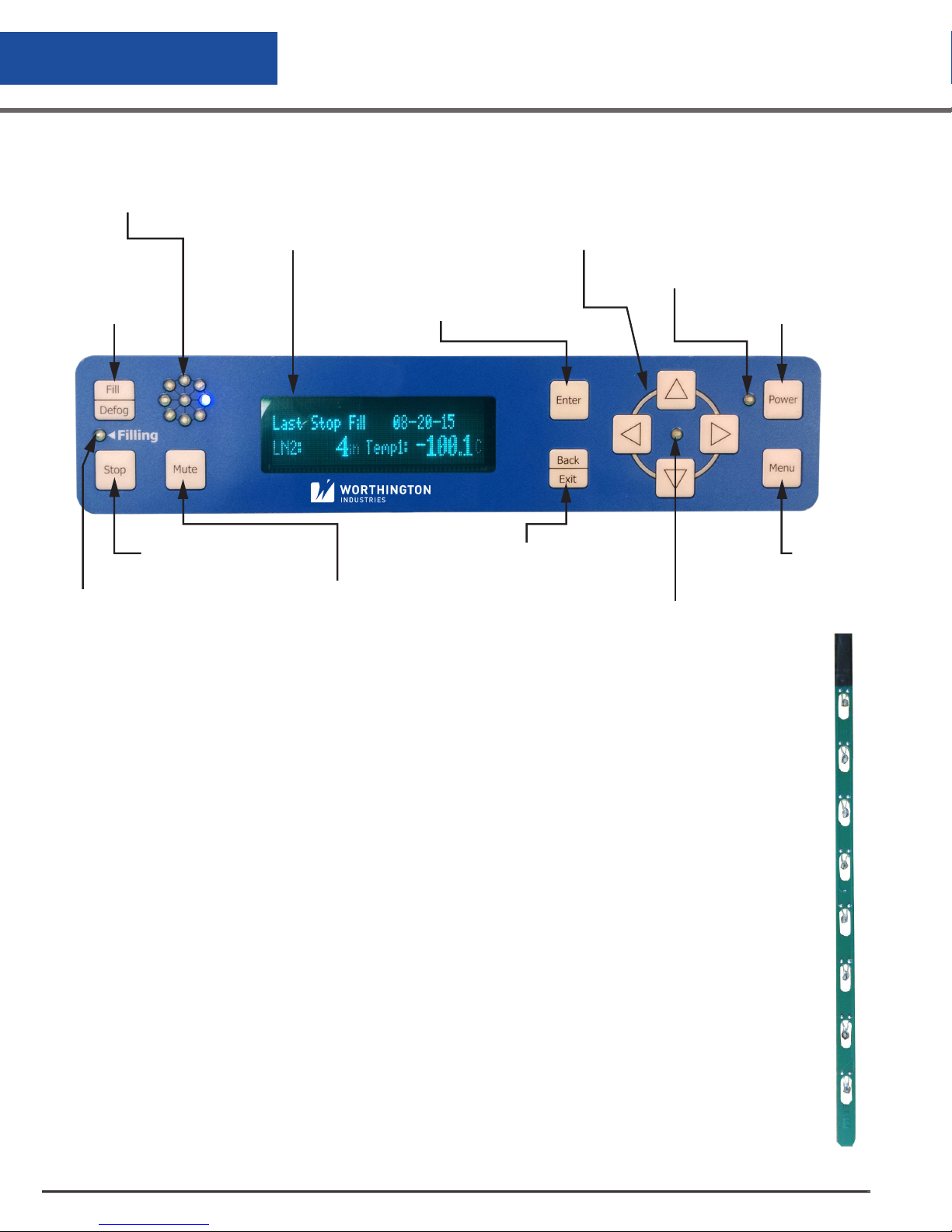

CS200 Controller Display Guide

Status Wheel

VFD Graphics Display

shows information about

the freezer

Fill button

usend to open

the valve

Enter Button “selects”

a menu choice or setting

Stop Button used

to close the valve

Mutes the

Valve Indicator lights

audible alarm

if the valve is open

Figure 1.0 CS200 Controller Display

Directional Buttons

Increment/decrement values or

allow movement through the system

Power Indicator

Back Button

moves out of the

menu system or

leaves current set-

Menu Indicator

ting unchanged

Power On/Off

Enter/Exit

menu system

Operational Theory

The CS200 SERIES Control System automatically maintains the Liquid Nitrogen (LN2) level

and monitors temperature in the Cryostorage freezer. Operational conditions are monitored

and any alarm is triggered if necessary. Operations data is stored in memory on the control

board.

The CS200 CONTROL SYSTEM uses thermistors to measure the LN2 level within the vessel.

A thermistor is a thermal resistor and its resistance changes as the temperature changes.

When a thermistor is submerged in LN2, its resistance will be significantly greater than its

resistance at room temperature. The control can detect this resistance change and determine

the level of the LN2 within the freezer. The CS CONTROL SYSTEM is designed to work with

an 8-thermistor assembly. There are four thermistors that can be selected to maintain the LN2

level. These selected thermistors correspond to Low Alarm, Start Fill, Stop Fill and High Alarm.

When the LN2 level drops below the Start Fill thermistor, the control opens the solenoid valve

allowing LN2 to enter the vessel. This continues until the Stop Fill thermistor is submerged in

LN2 at which point the solenoid valve is closed, preventing the flow of additional LN2 into the

vessel. The Low Alarm, Start Fill, Stop Fill and High Alarm settings can all be changed by the

user through the menu system.

High Level

High Level A

Low Level

Low Level A

Alarm

Alarm

#8

#7

#6

#5Stop Fill

#4

#3Start Fill

#2

#1

CS200 Control Systems

14

Figure 2.0 Factory Default Settings Shown

Operation

The LN2 level is indicated on the display and is determined by the number of

thermistors submerged in LN2 according to the table below:

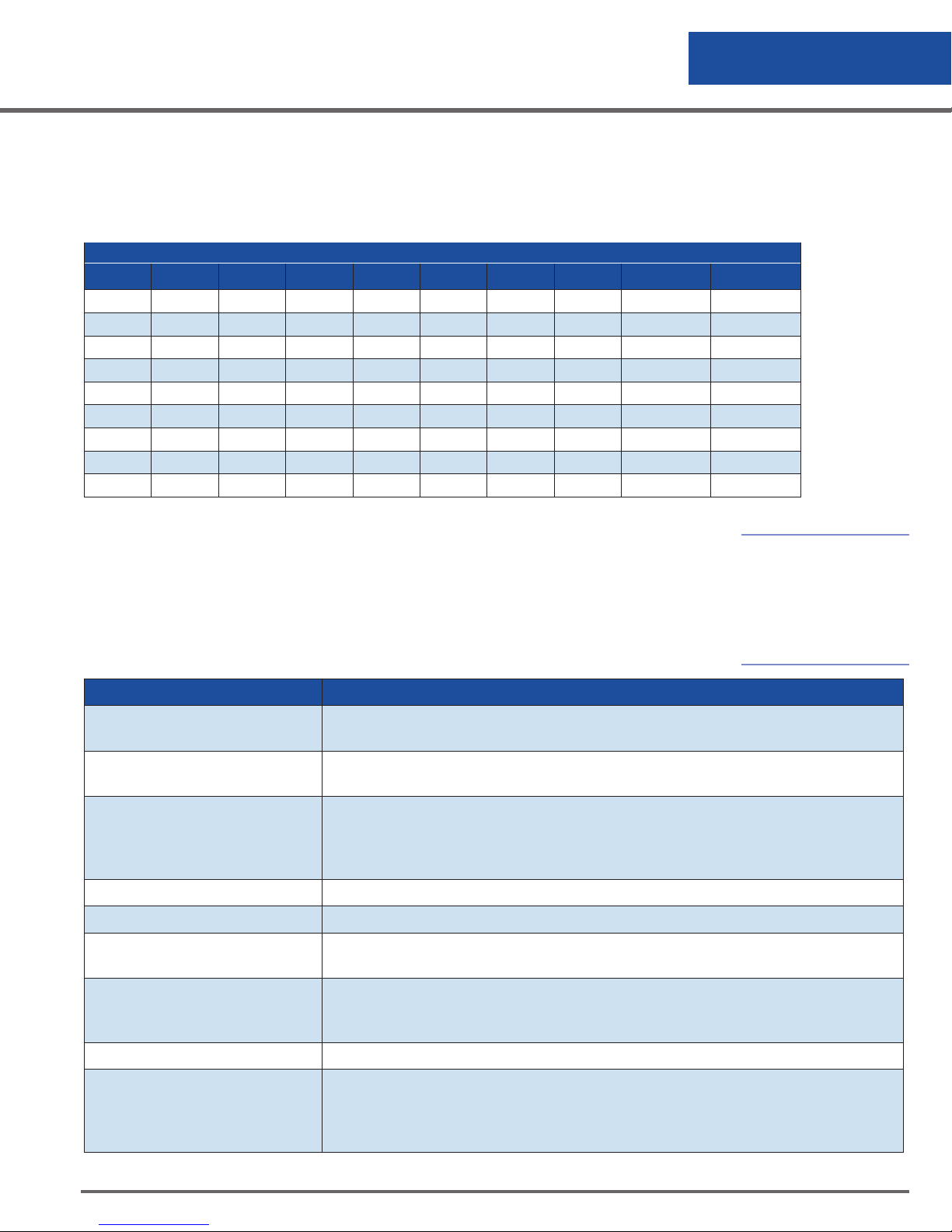

Table 1.0 8-Thermistor Sensor (G=GAS, L=LIQUID)

8-THERMISTOR SENSOR

#1 #2 #3 #4 #5 #6 #7 #8 OFFSET DISPLAY

G G G G G G G G 0 0

L G G G G G G G 0 1

L L G G G G G G 0 2

L L L G G G G G 0 3

L L L L G G G G 0 4

L L L L L G G G 0 5

L L L L L L G G 0 6

L L L L L L L G 0 7

L L L L L L L L 0 8

NOTE - Offset value for LABS94K only = 3.0 in (126 mm).

Alarm Conditions

The CS200 SERIES Control System monitors a number of conditions and provides an

alarm if a problem is detected. The alarms are listed below:

Table 2.0 Alarm Conditions

Note: Please see

description of

the offset. Level

displayed may vary

depending on the

offset setting.

Alarm Problem Detected

Low Level Alarm

High Level Alarm

Sensor Error Alarm

High Temperature Alarm The temperature detected is warmer than the high temperature alarm setting.

Low Temperature Alarm The temperature detected is colder than the low temperature alarm setting.

Thermocouple Calibration

Alarm

Thermocouple Open Alarm

LN2 level is too low. The low level alarm thermistor on the sensor assembly is not

submerged in LN2.

LN2 level is too high. The high level alarm thermistor on the sensor assembly is

submerged in LN2.

A problem exists with the level sensor assembly. The control detects an open sensor

circuit meaning that the sensor is unplugged or the sensor assembly has been

damaged. A Sensor Error will be represented by an “O” within the Thermistor Status

menu.

The calibration data is incorrect.

A problem exists with the temperature sensor (thermocouple). The control detects an

open circuit meaning that the sensor is unplugged or the sensor assembly has been

damaged.

Power Failure No Power.

Low LN2 Supply Alarm

A problem may exist with the LN2 supply connected to the freezer. This alarm occurs

if the freezer does not fill within the designated amount of time as determined by the

setting on the control. This may occur for a number of reasons including an empty

supply cylinder, low pressure in the supply cylinder or a closed shut off valve.

CS200 Control Systems

15

Operation

Alarm Problem Detected

Lid Open Too Long Alarm

Valve Stuck Open Alarm The solenoid valve is stuck open.

Unauthorized Access Warning The lid has been opened and an incorrect identification has been entered.

LN2 Usage Warning The consumption of LN2 has increased and should be checked.

Low Battery Voltage The voltage on the battery is low.

The lid has been opened for a period which is longer than the designated alarm

setting.

Audible Alarm Retrigger

Remote Alarm Relay

Operating in Battery Mode Alarm

Warning

The audible alarm is retriggered if error conditions still exist when the retrigger timer

expires. The retrigger time can be adjusted by the user.

The control provides a relay to provide an external signal that an alarm condition

has occurred. The remote alarm timer can be set through the menu system. This

setting determines the amount of time an error must be active before the relay is

triggered.

The power from the power supply has been disrupted and the control system is operating on battery power.

All alarms include the following:

• The flashing status wheel flashes to signal an error condition

• An audible tone sounds

• The error detected is displayed and scrolled on the screen

• The remote alarm relay changes state to provide a dry contact output signal

Lid Switch

The Lid Switch (Figure 4.0 and 4.1) is attached to the hinge and determines whether or not the lid is open on

the freezer. This also allows the control to determine whether to activate the Auto Defog, Quick Chill or Lid

Alarm features.

CS200 Control Systems

16

Lid Switch

Figure 3.1 K Series Lid SwitchFigure 3.0 LABS Lid Switch

Operation

Solenoid Valve

These units are designed to work with 12 VDC solenoid valve (see Figures 17.0, 17.1, and 17.2 Plumbing

Assemblies on page 42).

Thermocouples

Type T thermocouples monitor the temperature in the freezer. The user may choose to use NONE, 1 or 2

thermocouples with this control at any time. (The unit comes complete with one Thermocouple)

Power Supply

A 12 VDC power supply is supplied for the CS200 SERIES Control System. This system is supplied with a

universal power supply that accepts 100/240 VAC (50/60 Hz). UL approval for the system as a whole is not

required since the control operates on low voltage. If your power source differs, or is subject to disruption or

line surges due to other equipment on line, consult your Worthington Industries representative.

Remote Alarm

If an error condition occurs after a user defined period of time, a remote alarm can be initiated. This is

accomplished by connecting a remote device to the remote alarm jack on the rear electrical panel. The 3-pin

jack on the back of the unit provides continuity between pin #2 (common) and pin #3 in the normal condition.

Continuity between pin #1 and pin #2 is provided in an error condition.

Remote Alarm Connector

Figure 4.0 Remote Alarm Plug Connection

Operating Parameters

When materials are immersed in LN2, they will assume the temperature of the liquid (-196°C/-320°F). When

material is stored in the vapor phase over the liquid, the liquid nitrogen vapor is still a very cold refrigerant,

but the freezer’s interior temperature increases as product is stored higher above the liquid. This temperature

differential is not significant for many biological storage applications, and is affected by the amount of product

stored in the freezer, the type, size and material of the inventory control system, and the liquid level in the unit.

The liquid level in the freezer is determined by the position of the of the Thermistor Assembly in the sensor tube.

These sensors are set at installation to maintain a specific liquid level. A filling cycle is initiated when the level

falls below the Start Fill sensor and is completed when the Stop Fill sensor is reached. This filling cycle repeats

when the level fall below the Start Fill sensor. Sensor Probe assignments may be changed on the controller

CS200 Control Systems

17

Loading...

Loading...