Worldlawn WY36FS481VH, WY48FS481VH Operator's Manual

WY36FS481VH

WY48FS481VH

OPERATORS

MANUAL

WARNING:

DO NOT allow children to operate the

machine. DO NOT allow any adult to operate

the machine without proper instruction.

CAUTION:

Never add fuel to the tank while the engine is

running or hot.

ALWAYS WAIT at least five

minutes before refueling and REFUEL WITH THE

ENGINE OFF. KEEP FUEL AWAY FROM

SPARKS OR FLAMES. WIPE AWAY any fuel

spillage BEFORE starting unit. Never fill the fuel

tank indoors. Wipe up any spilled gasoline.

Gasoline is highly flammable - NO SMOKING.

Your mower is only as safe as the operator! Operator carelessness or error may result

in serious bodily injury. Improper maintenance of the machine may also result in injury.

Please read and follow these instructions on Safe Operation and be certain that anyone

using this mower fully understands and follows these instructions.

1. Familiarize yourself with the controls

and know how to stop this mower.

2. Inspect your work area carefully.

Remove debris from the area to be cut.

Keep all bystanders away from the

mowing area.

3. Avoid contact with moving parts. Keep

hands and feet clear of the mower deck

and all moving parts.

4. Never direct the discharge of material

toward bystanders nor allow anyone

near the machine while in operation.

5. Never tamper with safety devices or

guards. If a guard or safety device is

damaged or removed, replace it before

operating the mower.

6. Handle gasoline carefully: use an

approved gasoline container; fill the fuel

tank to bottom of drop tube with good

quality unleaded gasoline. Operator

must wear proper shoes and clothing,

which may also include safety glasses

and ear protection.

7. Mow only during daylight hours or under

very good artificial light.

8. Do NOT mow in slippery conditions ,

keep a firm grip on the handle bars,

NEVER RUN.

9. The safety shield over the grass

discharge must always be bolted in

place and in the down position unless

the grass catcher back plate is

completely installed.

10. Do NOT leave the operator position

unless the engine has been killed and

blades have stopped.

11. If a solid object has been hit by the

blades, stop the machine and check for

damage. Repair or replace damaged/

broken part(s) prior to restarting the

engine.

12. Do NOT allow anyone to stand or walk

on the grass discharge side of the

mower when the mower is in operation.

13. Do NOT mow close to drop-offs, deep

ditches or other hazards. Mow hillsides

very carefully by mowing across the face

of slopes, not up or down. Do NOT

mow on steep slopes.

14. To avoid burns, DO NOT TOUCH the

engine or muffler immediately after

operation.

1

SPECIFICATIONS

Belt Tension Guide

Belt

Engine to Deck

Right Blade Drive

Engine to Pump

Inch Deflection

1/2”

1/2”

(48”,52”, And 60” only)

1/2”

Hydraulic System

Capacity

(to the top of the tank baffle)

Filter

Oil

A Hi

Worldlawn P/N 423361

gh quality 15W50 synthetic engine oil

Assembly Instructions

1. Remove inner parts box and handle from

crate. Remove outside frame work so

that the mower is setting on the pallet.

2. On a 36" mower, use 3 – 5/16" X 1 3/4"

bolts and 3 – 5/16" whizlocks and bolt the

bumper into place. (On the 48" there are

4 - bumper bolts required.) The

whizlocks should go to the inside of the

deck. When assembling a 48" mower,

make sure that the bumper is flush with

the deck on both ends of the bumper.

3. Using 6 – 3/8" X 1" bolts (3 – used for

each caster) and 6 – 3/8" whizlock nuts,

bolt the casters into place. Position

whizlock nuts to the inside of the deck.

4. Using 2 – 1/4" X 3/4" bolts and 2 – 1/4"

nyloc nuts secure the speed control lever

assembly to the underside of the mount

plate on the lower handle. Connect the

speed control link to the control cam arm

and secure with 1 - 1/4" nyloc nut.

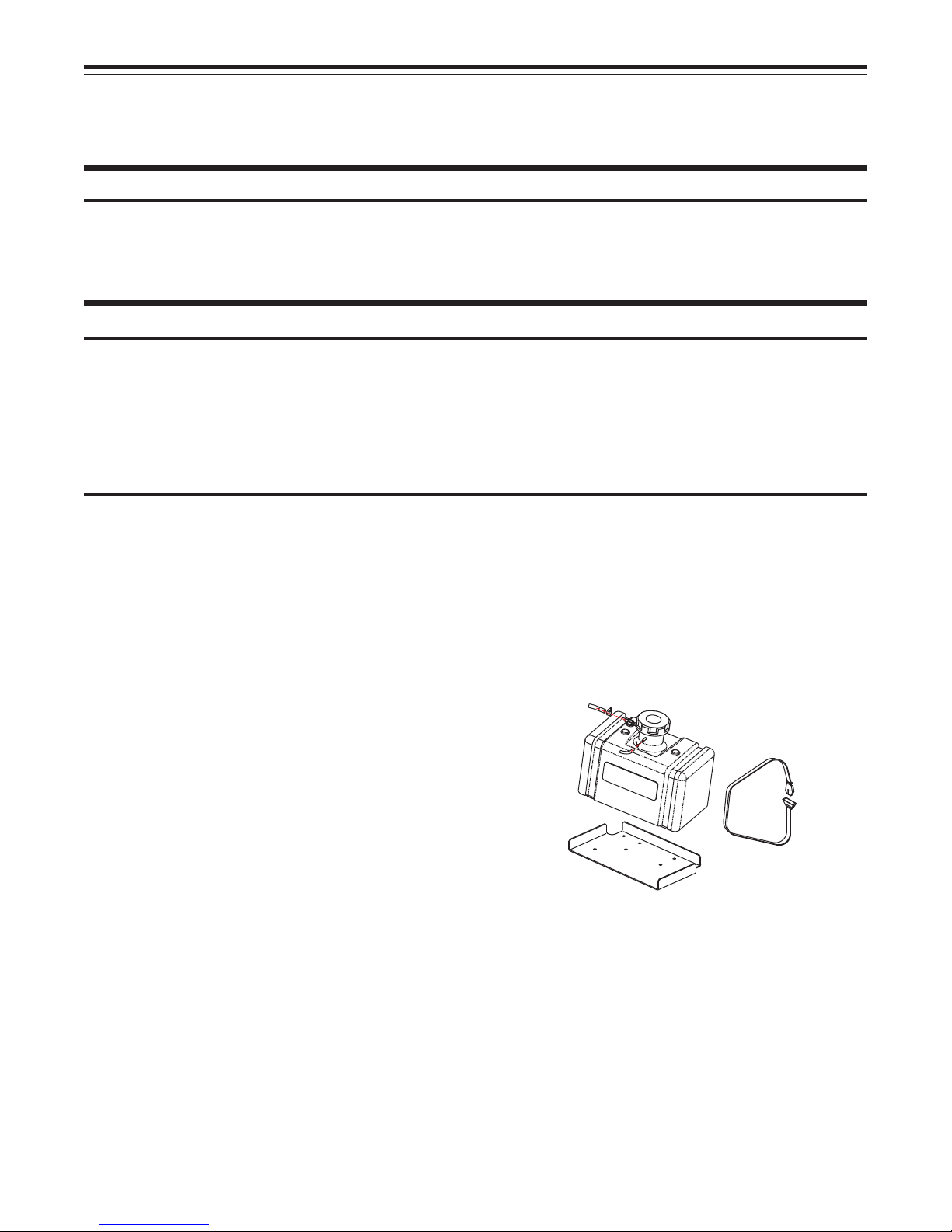

5. Mount the gas tank using the 2 – nylon

hold down straps, pulling tension on the

buckles until secure. Attach fuel line on

tank to fuel filter on engine. Attach vapor

recovery line on engine to vent barb on

fill neck. Secure all connections with

hose clamps.

6. Using the remaining 3/8" X 1" bolts and

the 4 – 3/8" nyloc nuts, bolt the upper

handle into position. (Remember that

there are 3 – height settings for the

How to Adjust

Turnbuckle at Idler

Threaded Rod

Fixed idler with Slot

3 quarts

Fig. 1

2

Assembly Instructions

handle for operator comfort.) Route the

wiring harness along the handle, plugging it

into the blade control switch, o.p.c. and

speed control switch located under the

speed control plate. There is not a specific

color code for hooking up the harness. Run

the throttle cable around the left hand side

of the engine to the throttle plate, Place the

throttle in the full speed detent, with the

throttle wire hooked in the speed control

arm on the engine throttle plate, pull on the

conduit until the speed control arm is at

maximum speed, tighten conduit clamp.

7. At this point, you are ready to oil and fuel

the engine. With that being done, take

the unit and raise the rear wheels off the

ground so that they may free wheel.

Block the unit up securely so that you

may run the engine with no danger of it

falling from the stand. With the speed

control in the neutral position, start the

engine and run it at 3/4 to full throttle.

Using a 5/16" wrench adjust the speed

control link, to set the right hand wheel to

neutral no matter what the left hand

wheel does. With that accomplished,

lock the lock nuts into place on speed

control link. If the left hand wheel is not

neutralized use a 1/2" wrench, to break

the lock nut loose on the pump link and

adjust the rod end to neutral the left hand

wheel. After accomplishing neutral, shut

the engine off and remove the support

blocks from under the machine. With the

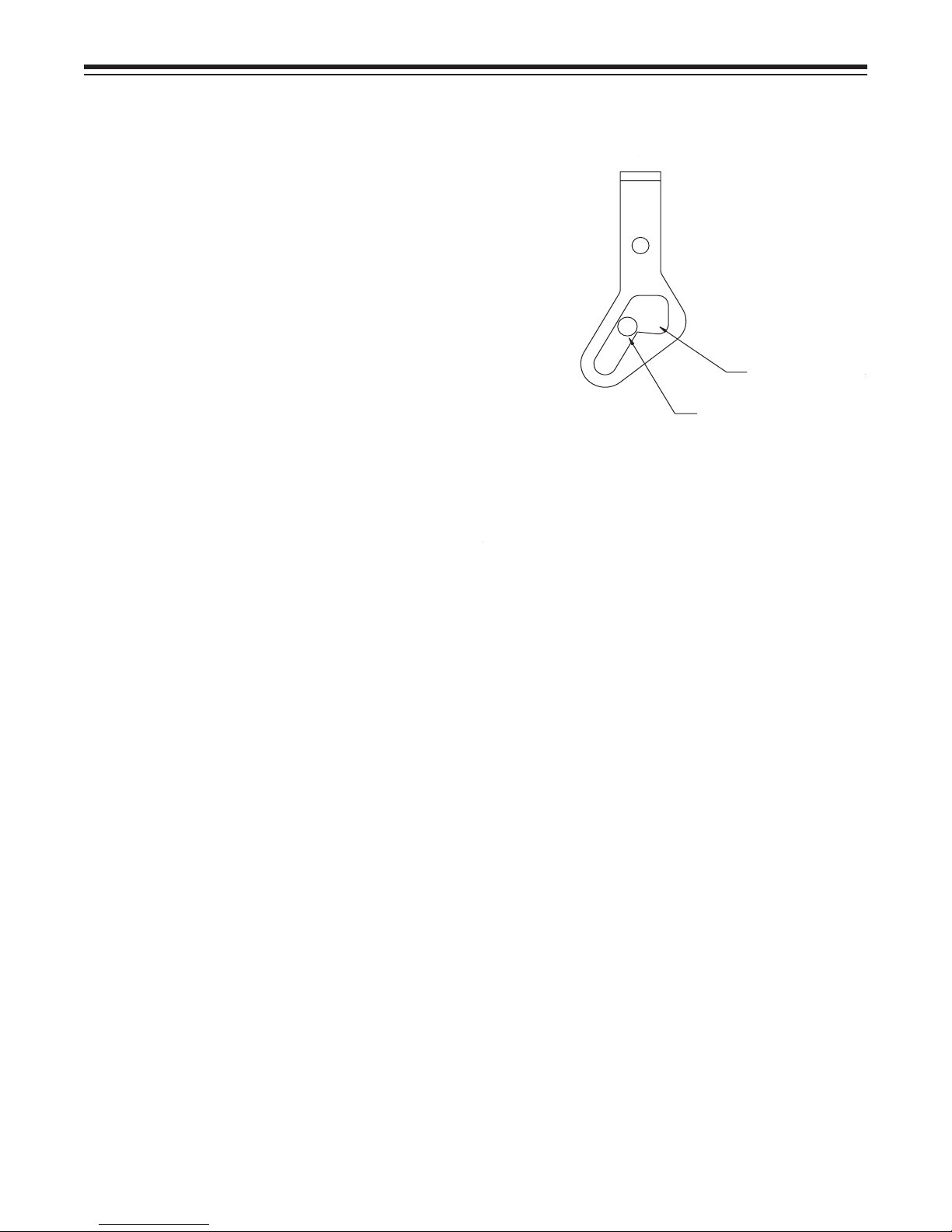

engine shut down, take the drive rods

and bolt them onto the main control shaft

using the 5/16" nyloc nuts provided.

Adjust the length of the rod so that the

pins in the drive levers are just a little

under center of the neutral lock on the

thumb lock. (See fig.)

8. You are ready for your test run to set the

full speed tracking. Remember to check

the air pressure in the tires. Rear wheels

Hydro Drive Thumblock

should be set at 12 psi, front casters to

20 psi. Run unit at full throttle and set

control lever to the full speed setting.

The test run should be made on some

type of hard surface with the ground

being fairly level. If the machine pulls

one way in full speed, adjust the slow

side stop bolt up to speed up the slow

motor. If there is not enough adjustment

to speed up the slow motor, you may

have to lengthen the stop bolt on the fast

side. Run that machine at an

intermediate speed. If you have a

tracking problem after full speed tracking

is set, the adjustment is in the pump arm

rod end. This is remedied by adjusting

the length of the pump arm. Brake the

lock nut loose on the pump arm and

remove the bolt from the rod end that

attaches it to the link. To increase the

pump speed, shorten the pump arm. To

decrease the speed, lengthen the pump

arm. Usually about two full turns on the

pump arm rod end to speed up or slow

down is adequate. (See fig.3)

Neutral Lock

Drive-Rod

Fig. 2

3

Loading...

Loading...