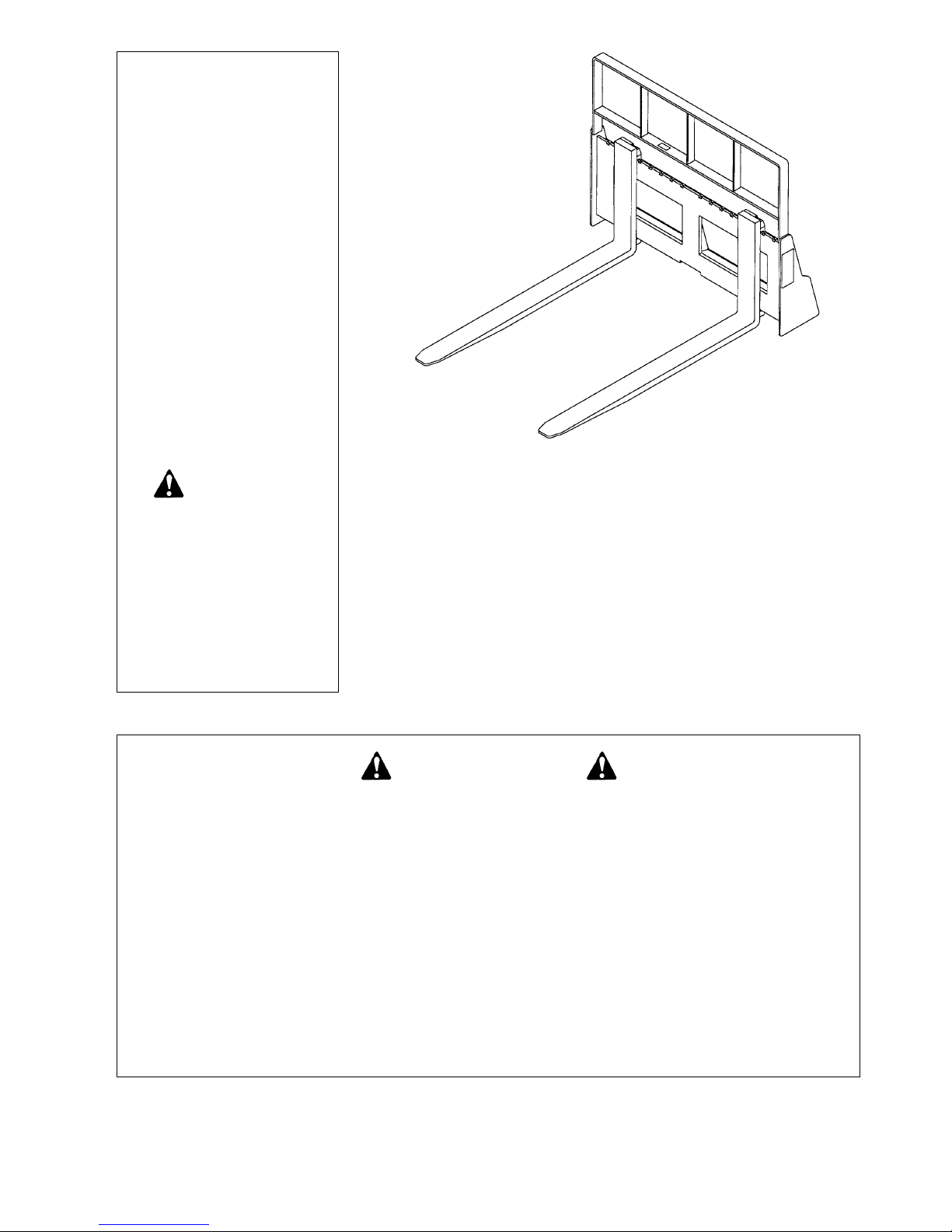

Worksaver SSPF-3748 Owner's/operator's Manual

SKID STEER PALLET FORK

ALSO FOR

SOME TRACTOR FRONT LOADERS

Safety Instructions Assembly & Mounting

Tractor Preparation Maintenance

Operating Instructions Repair Parts

OWNER’S/

OPERATOR’S

MANUAL

MODEL NO.’s

SSPF-3742

SSPF-3748

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SINO LEEINGLES, PIDAAYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

CAUTION

THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE THOROUGHLY UNDERSTOOD

BEFORE ATTEMPTING TO BEGIN ASSEMBLING THIS MACHINE

1. Select an area for assembly that is clean and free of any

debris which might cause persons working on the

assembly to trip.

2. Do not lift heavy parts or assemblies. Use crane, jack,

tackle, fork trucks or other mechanical devices.

3. Preview the assembly instructions in your operator’s

manual before proceeding further.

4. If the assembly instructions call for parts or assemblies to

be blocked up, use only blocking material that is in good

condition and is capable of handling the weight of the

assembly to be blocked. Also insure that the blocking

material is on a clean, dry surface.

5. Never put hands, or any part of body, under blocked up

assemblies if at all possible.

6. After completing assembly, thoroughly inspect the

machine to be sure that all nuts, bolts, hydraulic fittings

or any other fastened assemblies have been thoroughly

tightened.

7. Before operating the machine, thoroughly read the

operation section of your operator’s manual.

8. Before operating, read the maintenance section of your

operator’s manual to be sure that any parts requiring

lubrication, such as gearboxes, are full, to avoid any

possible damage.

9. Before operating equipment – If you have any

questions regarding the proper assembly or

operation, contact your dealer or representative.

2

LIMITED WARRANTY

Worksaver warrants to the original purchaser of any new Pallet Fork (Models SSPF-3742 and SSPF-3748),

that the equipment be free from defects in material and workmanship for a period of six (6) months for noncommercial, state, and municipalities. Use sixty (60) days for commercial use from date of retail sale.

Replacement or repair parts installed in the equipment covered by this warranty are warranted for sixty (60)

days from the date of purchase of such part or to the expiration of the applicable new equipment warranty

period, whichever occurs later.

Such parts shall be provided at no cost to the user during regular working hours. Worksaver reserves the right

to inspect any equipment or parts which are claimed to have been defective in material or workmanship.

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Worksaver’s obligation under this warranty, to the extent allowed by law, is in lieu of all warranties, implied or

expressed, including implied warranties of merchantability and fitness for a particular purpose and any liability

for incidental and consequential damages with respect to the sale or use of the items warranted. Such

incidental and consequential damages shall include but not be limited to: transportation charges other than

normal freight charges; cost of installation other than cost approved by Worksaver; duty; taxes; charges for

normal service or adjustments; loss of crops or any other loss of income; rental of substitute equipment,

expenses due to loss, damage, detention or delay in the delivery of equipment or parts resulting from acts

beyond the control of Worksaver.

THIS WARRANTY SHALL NOT APPLY:

1. To vendor items which carry their own warranties, such as hydraulic cylinders, tires, and tubes.

2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

3. If parts not made or supplied by Worksaver have been used in connection with the unit, if, in sole judgement of Worksaver such use affects its performance, stability, or reliability.

4. If the unit has been altered or repaired outside of an authorized Worksaver dealership in a manner which,

in the sole judgement of Worksaver affects its performance, stability or reliability.

5. To normal maintenance service and normal replacement items such as gearbox lubricant, hydraulic fluid,

worn blades, or to normal deterioration of such things as belts and exterior finish, due to use or exposure.

6. To expendable or wear items such as teeth, chains, sprockets, belts, springs and other items that in the

company’s sole judgement is a wear item.

NO EMPLOYEE OR REPRESENTATIVE OF WORKSAVER IS AUTHORIZED TO CHANGE THIS WARRANTY IN

ANY WAYOR GRANTANY OTHER WARRANTY UNLESS SUCH CHANGE IS MADE IN WRITING AND SIGNED

BY WORKSAVER’S SERVICE MANAGER, POST OFFICE BOX 100, LITCHFIELD, ILLINOIS 62056-0100.

4

SAFETY INSTRUCTIONS (continued)INSTRUCTIONS (continued)

Safety of the operator is one of the main concerns in designing and developing a new piece of equipment.

Designers and manufacturers build in as many safety features as possible. However, every year many

accidents occur which could have been avoided by a few seconds of thought and a more careful approach to

handling equipment. You, the operator, can avoid many accidents by observing the following precautions in

this section. To avoid personal injury, study the following precautions and insist those working with you, or for

you, follow them.

In order to provide a better view, certain photographs or illustrations in this manual may show an assembly

with a safety shield removed. However, equipment should never be operated in this condition. Keep all shields

in place. If shield removal becomes necessary for repairs, replace the shield prior to use.

To prevent injury or death, use a tractor equipped with a Roll-Over Protective System (ROPS). Do not paint

over, remove or deface any safety signs or warning signs on your equipment. Observe all safety signs and

practice the instruction on them.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in question -

DON’T TRY IT.

Do not modify the equipment in any way . Unauthorized modification may impair the function and/or safety and

could affect the life of the equipment.

In addition to the design and configuration of this implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also

to Safety Messages and Operation Instructions in each of the appropriate sections of the Tractor, Skid Steer,

and Implement Manuals. Pay close attention to the Safety Signs affixed to the Tractor, Skid Steer, and the

Implement.

Replace any CAUTION, WARNING, DANGER or instruction safety sign that is not readable or is missing.

Location of such safety signs is indicated in this booklet.

Never use alcoholic beverages or drugs which can hinder alertness or coordination while operating this

equipment. Consult your doctor about operating this machine while taking prescription medications.

Review the safety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should be a

responsible adult familiar with farm machinery and trained in this equipment’s operations. Do not allow per-

sons to operate or assemble this unit until they have read this manual and have developed a thorough

understanding of the safety precautions and of how it works.

EQUIPMENT SAFETY GUIDELINES

Loading...

Loading...