OWNER’S/

OPERATOR’S

MANUAL

MODEL NO.’s

HPD-16 HSS/P

(S/N 4215 and above)

HPD-22Q HSS/P

(S/N 5501 and above)

HPD-26Q HSS/P

(S/N 1501 and above)

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SI NO LEEINGLES, PIDA AYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

Safety Instructions Assembly & Mounting

Tractor Preparation Maintenance

Operating Instructions Repair Parts

CAUTION

THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE THOROUGHLY UNDERSTOOD

BEFORE ATTEMPTING TO BEGIN ASSEMBLING THIS MACHINE

1. Select an area for assembly that is clean and free of any

debris which might cause persons working on the

assembly to trip.

2. Do not lift heavy parts or assemblies. Use crane, jack,

tackle, fork trucks or other mechanical devices.

3. Preview the assembly instructions in your operator’s

manual before proceeding further.

4. If the assembly instructions call for parts or assemblies to

be blocked up, use only blocking material that is in good

condition and is capable of handling the weight of the

assembly to be blocked. Also insure that the blocking

material is on a clean, dry surface.

5. Never put hands, or any part of body, under blocked up

assemblies if at all possible.

6. After completing assembly, thoroughly inspect the

machine to be sure that all nuts, bolts, hydraulic fittings

or any other fastened assemblies have been thoroughly

tightened.

7. Before operating the machine, thoroughly read the

operation section of your operator’s manual.

8. Before operating, read the maintenance section of your

operator’s manual to be sure that any parts requiring

lubrication, such as gearboxes, are full, to avoid any

possible damage.

9. Before operating equipment – If you have any

questions regarding the proper assembly or

operation, contact your dealer or representative.

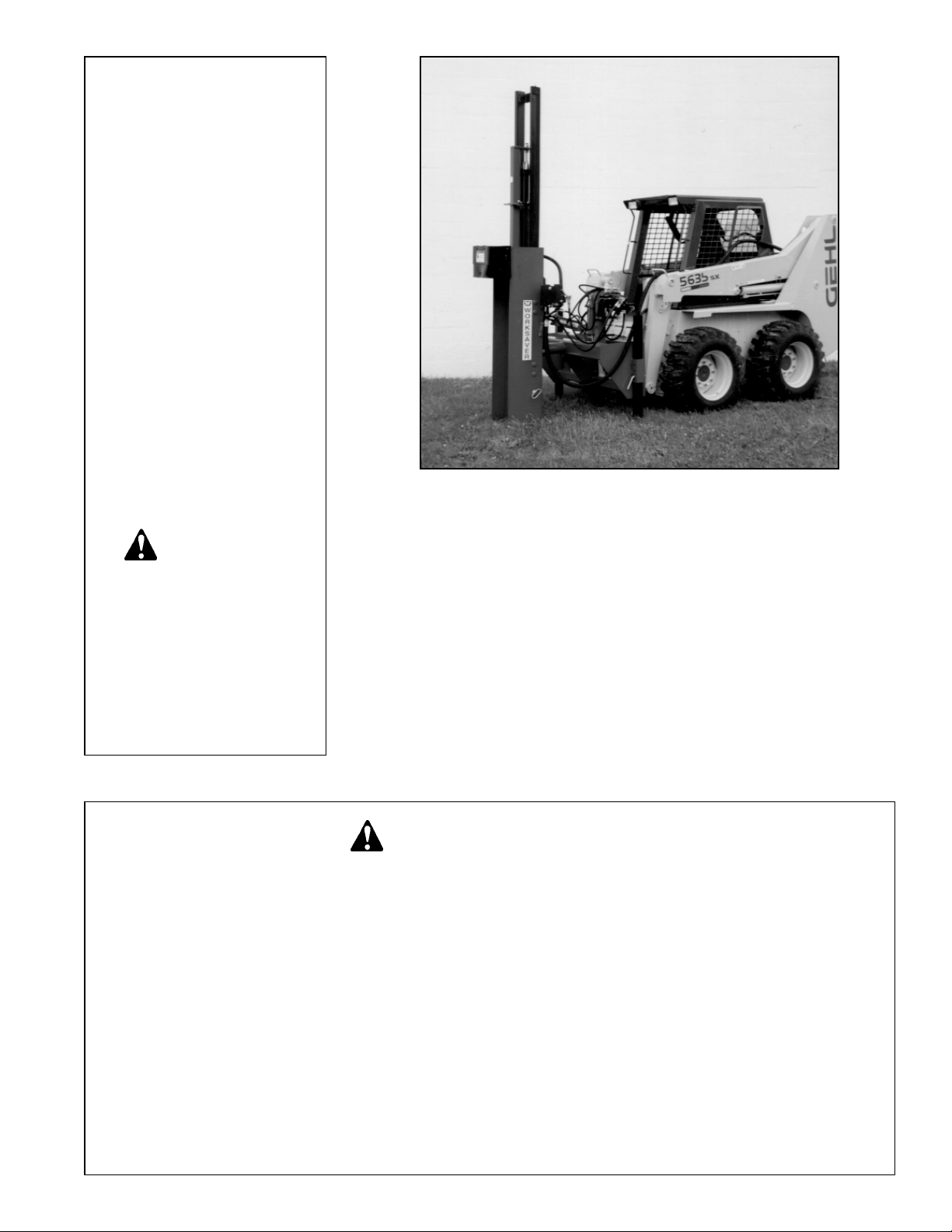

SKID STEER MOUNTED

HYDRAULIC POST DRIVERS

w/ Hydraulic Power Package

1

TABLE OF CONTENTS

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

SAFETY SIGNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

PREPARATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 13-18

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 19-21

SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 21-25

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TROUBLE-SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-27

PARTS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-40

TO THE OWNER:

Read this manual before using your Hydraulic Post Driver. This manual is provided to give you the necessary

operating and maintenance instructions for keeping your Hydraulic Post Driver in top operating condition. Please

read this manual thoroughly. Understand what each control is for and how to use it. Observe all safety signs on

the machine and noted throughout the manual for safe operation of implement. Keep this manual handy for ready

reference.

Like all mechanical products, it will require cleaning and upkeep. Lubricate the Post Driver as specified.

Use only genuine Worksaver, Inc. service parts. Substitute parts will void the warranty and may not meet stan-

dards required for safe and satisfactory operation. Record the model and serial number of your Post Driver here:

Model:________________________________________ Serial Number:_______________________________

RETAIL CUSTOMER’S RESPONSIBILITY

It is the Retail Customer and/or Operator’s responsibility to read the Operator’s Manual, to operate, lubricate, maintain, and store the product in accordance with all instructions and safety procedures. Failure

of the operator to read the Operator’s Manual is a misuse of this equipment.

It is the Retail Customer and/or Operator’s responsibility to inspect the product and to have any part(s)

repaired or replaced when continued operation would cause damage or excessive wear to other parts or

cause a safety hazard.

It is the Retail Customer’s responsibility to deliver the product to the authorized Worksaver Dealer, from

whom he purchased it, for service or replacement of defective parts which are covered by warranty.

Repairs to be submitted for warranty consideration must be made within forty-five (45) days of failure.

It is the Retail Customer’s responsibility for any cost incurred by the Dealer for traveling to or hauling

of the product for the purpose of performing a warranty obligation or inspection.

SI NO LEEINGLES, PIDA AYUDA A

AIGUIEN QUE SI LO LEA PARA QUE

LE TRADUZCA LAS MEDIDAS DE

SEGURIDAD.

STATEMENT

OF POLICY

It is the policy of Worksaver,

Inc. to improve its products where

it is possible and practical to do

so. Worksaver, Inc. reserves the

right to make changes or

improvements in design and construction at any time, without

incurring the obligation to make

these changes on previously

manufactured units.

2

LIMITED WARRANTY

✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯

Worksaver warrants to the original purchaser of any new Hydraulic Post Driver, that the equipment be free from

defects in material and workmanship for a period of twelve (12) months for non-commercial, state, and

municipalities. Use ninety (90) days for commercial use from date of retail sale.

Replacement or repair parts installed in the equipment covered by this warranty are warranted for ninety (90)

days from the date of purchase of such part or to the expiration of the applicable new equipment warranty

period, whichever occurs later.

Such parts shall be provided at no cost to the user during regular working hours. Worksaver reserves the right

to inspect any equipment or parts which are claimed to have been defective in material or workmanship.

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Worksaver’s obligation under this warranty, to the extent allowed by law, is in lieu of all warranties, implied or

expressed, including implied warranties of merchantability and fitness for a particular purpose and any liability for incidental and consequential damages with respect to the sale or use of the items warranted. Such

incidental and consequential damages shall include but not be limited to: transportation charges other than

normal freight charges; cost of installation other than cost approved by Worksaver; duty; taxes; charges for

normal service or adjustments; loss of crops or any other loss of income; rental of substitute equipment,

expenses due to loss, damage, detention or delay in the delivery of equipment or parts resulting from acts

beyond the control of Worksaver.

THIS WARRANTY SHALL NOT APPLY:

1. To vendor items which carry their own warranties, such as hydraulic motors, valves, and hydraulic cylinders.

2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

3. If parts not made or supplied by Worksaver have been used in connection with the unit, if, in sole judgement of Worksaver such use affects its performance, stability, or reliability.

4. If the unit has been altered or repaired outside of an authorized Worksaver dealership in a manner which,

in the sole judgement of Worksaver affects its performance, stability or reliability.

5. To normal maintenance service and normal replacement items such as gearbox lubricant, hydraulic fluid,

worn blades, or to normal deterioration of such things as belts and exterior finish, due to use or exposure.

6. To expendable or wear items such as slide blocks, bumpers, springs and other items that in the company’s

sole judgement is a wear item.

NO EMPLOYEE OR REPRESENTATIVE OF WORKSAVER IS AUTHORIZED TO CHANGE THIS

WARRANTY IN ANY WAY OR GRANT ANY OTHER WARRANTY UNLESS SUCH CHANGE IS MADE IN

WRITING AND SIGNED BY WORKSAVER’S SERVICE MANAGER, POST OFFICE BOX 100, LITCHFIELD,

ILLINOIS 62056-0100.

✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯ ✯

3

To the Owner/Operator/Dealer

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices.The manufacturer has designed this

implement to be used with all its safety equipment properly attached to minimize the chance of accidents.

BEFORE YOU START!!

Read the safety messages on the implement and shown in your manual.

Observe the rules of safety and common sense!

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT

SAFETY WARNING MESSAGES. CAREFULLY READ EACH

WARNING MESSAGE THAT FOLLOWS. FAILURE TO

UNDERSTAND AND OBEY A SAFETY WARNING, OR

RECOGNIZE A SAFETY HAZARD, COULD RESULT IN AN

INJURY OR DEATH TO YOU OR OTHERS AROUND YOU.

THE OPERATOR IS ULTIMATELY RESPONSIBLE FOR THE

SAFETY OF HIMSELF, AS WELL AS OTHERS, IN THE

OPERATING AREA OF THE TRACTOR AND ATTACHED

EQUIPMENT.

THIS SYMBOL MEANS

– ATTENTION!

– BECOME ALERT!

– YOUR SAFETY IS INVOLVED!

IMPORTANT SAFETY INFORMATION!

Working with equipment can lead to injuries. Read this manual, and the manual for your power unit, before assembly

or operating, to acquaint yourself with the machines. It is the Post Driver owner’s responsibility, if this machine is used

by any person other than yourself, is loaned or rented, to make certain that the operator, prior to operating:

1. Reads and understands the operator’s manuals.

2. Is instructed in safe and proper use.

The use of this equipment is subject to certain hazards which cannot be protected against by mechanical

means or product design. All operators of this equipment must read and understand this entire manual, paying particular attention to safety and operating instructions, prior to using. If there is something in this manual

you do not understand, ask your supervisor, or your dealer, to explain it to you.

Keep all helpers and bystanders twenty-five feet (25’) from an operating driver. Only properly trained people

should operate this machine. It is recommended the power unit be equipped with a Rollover Protection System

(ROPS) and a seat belt that is used. Always engage parking or place transmission in “Park” before dismounting. Never leave equipment unattended with the power unit running.

UNDERSTAND SIGNAL WORDS

Indicates an imminently hazardous situation that, if not avoided, WILL result in

DEATH OR VERY SERIOUS INJURY.

Indicates a imminently hazardous situation that, if not avoided, COULD result in

DEATH OR SERIOUS INJURY.

Indicates a imminently hazardous situation that, if not avoided, MAY result in

MINOR INJURY.

NOTE:

Identifies points of particular interest for more efficient and convenient operation or repair.

If you have questions not answered in this manual or require additional copies or the manual is damaged, please

contact your dealer or the manufacturer directly.

WARNING

DANGER

CAUTION

4

SAFETY INSTRUCTIONS (continued)

Safety of the operator is one of the main concerns in designing and developing a new piece of equipment.

Designers and manufacturers build in as many safety features as possible. However, every year many

accidents occur which could have been avoided by a few seconds of thought and a more careful approach to

handling equipment.You, the operator, can avoid many accidents by observing the following precautions in this

section. To avoid personal injury, study the following precautions and insist those working with you, or for you,

follow them.

In order to provide a better view, certain photographs or illustrations in this manual may show an assembly with

a safety shield removed. However, equipment should never be operated in this condition. Keep all shields in

place. If shield removal becomes necessary for repairs, replace the shield prior to use.

To prevent injury or death, use a power unit equipped with a Roll-Over Protective System (ROPS). Keep foldable ROPS systems in “locked up” position at all times. Keep seat belt fastened.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in question –

DON’T TRY IT.

Do not modify the equipment in any way. Unauthorized modification may impair the function and/or safety and

could affect the life of the equipment.

In addition to the design and configuration of this implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also

to Safety Messages and Operation Instructions in each of the appropriate sections of the power unit and implement manuals. Pay close attention to the Safety Signs affixed to the power unit and the implement.

Replace any CAUTION, WARNING, DANGER or instruction safety sign that is not readable or is missing. Do

not paint over, remove or deface any safety signs or warning signs on your equipment. Observe all safety signs

and practice the instruction on them. Review the safety instructions with all users annually.

Never use alcoholic beverages or drugs which can hinder alertness or coordination while operating this

equipment. Consult your doctor about operating this machine while taking prescription or over the counter

medications.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should be a

responsible adult familiar with farm machinery and trained in this equipment’s operations. Do not allow per-

sons to operate or assemble this unit until they have read this manual and have developed a thorough

understanding of the safety precautions and of how it works.

EQUIPMENT SAFETY GUIDELINES

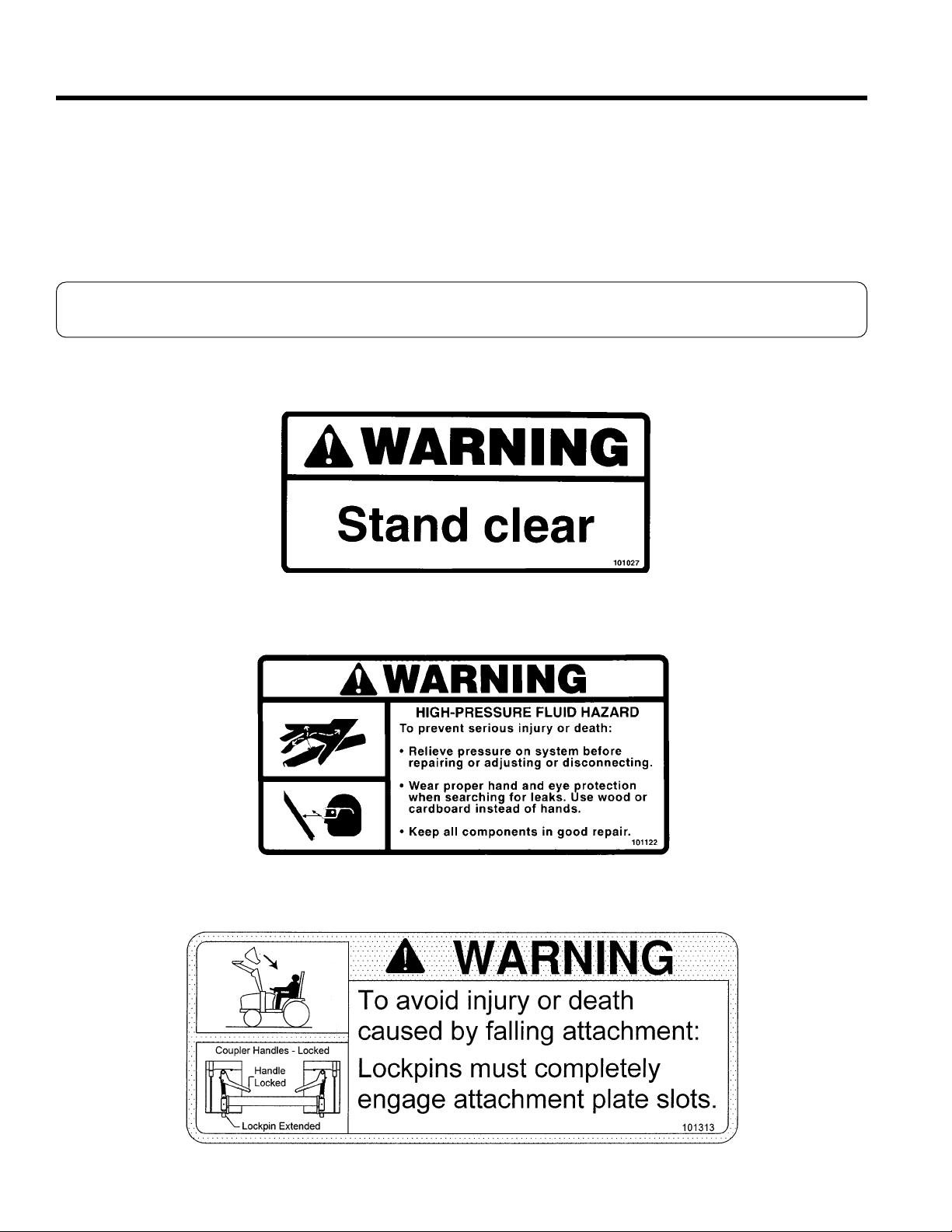

Personal protection equipment including hard hat, safety glasses, safety shoes, and gloves are recommended

during assembly, installation, operation, adjustment, maintaining, repairing, removal, or moving the implement.

Do not allow long hair, loose fitting clothing or jewelry to be around moving parts.

5

SAFETY INSTRUCTIONS (continued)

Never operate the power unit and post driver until you and the operator have read and completely understand

this manual, the power unit operator’s manual, and each of the safety messages found on the safety signs on

the power unit and post driver.

Make sure that all operating and service personnel know that in the event hydraulic fluid penetrates the skin,

it must be surgically removed within a few hours by a physician familiar with this form of injury, or gangrene

may result.

Always use two people or a mechanical lift device to handle heavy, unwieldy components during assembly,

installation, removal, or moving the driver.

Never place any part of your body where it would be in danger if movement should occur during assembly,

installation, operation, maintaining, repairing, removal, or moving the driver.

Before you operate the driver, check over all pins, bolts and connections to be sure all are securely in place.

Replace any damaged or worn parts immediately.

Consult local utility companies (Call 811) to make certain there are no buried gas lines, electrical cables, etc.,

in the work area before beginning operation.

Do not allow anyone who is not familiar with the safety rules and operation instructions to use this Post Driver.

Never allow children to operate or be around this Post Driver.

Clear the work area of objects which might cause operator to trip or fall.

Make sure that all operating and service personnel know that in the event hydraulic fluid penetrates the skin,

it must be surgically removed within a few hours by a doctor familiar with this form of injury, or gangrene may

result.

Ensure post driver is properly mounted, adjusted and in good operating condition.

Personal protection equipment including hard hat, safety glasses, safety shoes, and gloves are recommended

during assembly, installation, operation, adjustment, maintaining, repairing, removal, or moving the implement.

Do not allow long hair, loose fitting clothing or jewelry to be around moving parts.

PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE PERMANENT HEARING LOSS!

Power units

with or without attachments can often be noisy enough to cause permanent, partial hearing loss.

We recommend that you wear hearing protection on a full-time basis if the noise in the Operator’s position

exceeds 80db. Noise over 85db on a long-term basis can cause severe hearing loss. Noise over 90db adjacent to the Operator over a long-term basis may cause permanent, total hearing loss. NOTE: Hearing loss from

loud noise (from tractors, chain saws, radios, and other such sources close to the ear) is cumulative over a lifetime without hope of natural recovery.

PREPARATION

6

SAFETY INSTRUCTIONS (continued)

OPERATIONAL SAFETY

Never operate the power unit and post driver until you have read and completely understand this manual, the

power unit operator’s manual, and each of the safety messages found on the safety signs on the power unit and

post driver.

The use of this equipment is subject to certain hazards which cannot be protected against by mechanical

means or product design. All operators of this equipment must read and understand this entire manual, paying particular attention to safety and operating instructions, prior to using. If there is something in this manual

you do not understand, ask your supervisor, or your dealer, to explain it to you.

Know your controls and how to stop the power unit and engine quickly in an emergency. READ THIS MANUAL

AND THE ONE PROVIDED WITH YOUR POWER UNIT.

Start

power unit

only when properly seated in the operator’s seat. Starting a

power unit

in gear can result in

injury or death. Do not mount or dismount the

power unit

while moving. Mount or dismount the

power unit

only

when the

power unit

and all moving parts are completely stopped.

Do not allow riders on the driver or

power unit

at any time. There is no safe place for any riders.

Do not walk or work under a raised driver ram unless it is securely blocked or held in position. Do not depend

on the tractor hydraulic system to hold the driver ram in place.

Never leave post driver ram in the raised position. Always lower ram to the ground or to the transport position

and install the transport lock pin before transporting or storing.

Do not operate post driver on steep hillsides.When installing posts on uneven or hilly terrain, position the

power

unit

with the post driver uphill. This way if any movement of the

power unit

should occur, it will be away from

the post driver operator.

Never position the post by hand. Always use Post Holder Tool or Post Holder Attachment.

Watch out for low overhead electrical wires and limbs when operating or transporting the post driver. Check

clearance of doorways when entering a building.

Be sure post is cut “SQUARE” on top. Angle cut post can “KICK OUT” of driver and injure the operator.

Install transport lock pin and pin clip before transporting or storing the post driver. NEVER INSERT FINGER

IN TRANSPORT PIN HOLE TO CHECK ALIGNMENT. Finger could be sheared off if driving ram moves.

Keep hands, feet, hair, jewelry, and clothing, away from all moving parts.

Do not operate the Post Driver without all safety shields and guards in place.

7

SAFETY INSTRUCTIONS (continued)

OPERATIONAL SAFETY (continued)

Check that this attachment is securely mounted to the loader. Failure to install lock pins or have the latching

mechanism engage could result in injury or death.

Do not allow children or others to ride on the power unit with an operator. Riders are subject to injury such as

being struck by foreign objects or being thrown off. Riders obstruct the operator’s view resulting in unsafe operation. Never allow anyone to ride on the implement!

For operator safety, always keep load in front of power unit. NEVER position load back over operator. ALWAYS

BE CAREFUL!

Keep alert and watch the rear as well as the front when working with the loader.

Beware of low electrical wires when loader is raised. Serious injury or death can result if contact is made.

Operate loader from operator’s seat only. Remain at controls until operating cycle is complete.

Do not walk or work under a raised driver ram unless it is securely blocked or held in position. Do not depend

on the hydraulic system to hold the driver ram in place.

Never leave post driver ram in the raised position. Always lower ram to the ground or to the transport position

and install the transport lock pin before transporting or storing.

A heavy load can cause instability of the skid steer unit. Use extreme care during travel. Slow down on turns

and watch out for bumps.

Observe safety recommendations in loader instruction manual. Always use care when operating a post driver.

Carry the post driver slowly and as low as possible to the ground. Avoid excessive speed during operation.

Always shut off power unit and shift to “Park” or set brakes when leaving unit. Always lower bucket or

attachment to ground, relieve all hydraulic pressure. Remove key when leaving equipment unattended. Park in

level area.

8

SAFETY INSTRUCTIONS (continued)

Comply with state and local laws governing highway safety and movement of machinery on public roads.

The use of flashing amber lights is acceptable in most localities. However, some localities prohibit their use.

Local laws should be checked for all highway lighting and marking requirements.

When driving the skid steer unit and equipment on the road or highway under 20 mph (32 kph) at night or

during the day, use flashing amber warning lights and a slow moving vehicle (SMV) identification emblem.

Reduce speed on rough roads and surfaces.

Watch out for low overhead electrical wires and limbs when operating or transporting the post driver. Check

clearance of doorways when entering a building.

When maneuvering close to buildings or passing through narrow areas, be sure to allow sufficient clearance

for the skid steer, loader, and post driver. Drive slowly.

Always be sure the implement is in the proper raised position for transport.

Reduce speed when transporting mounted implements to avoid bouncing and momentary loss of steering

control.

Plan your route to avoid heavy traffic.

Always install transport locks, pins or brackets before transporting.

Do not drink and drive!

Watch for traffic when operating near or crossing roadways.

Turn curves or go up or down hills only at a low speed and at a gradual steering angle. Slow down on rough

or uneven surfaces, and loose gravel.

Use extreme care and maintain minimum ground speed when transporting on hillside, over rough ground and

when operating close to ditches or fences. Be careful when turning sharp corners.

Never allow riders on either skid steer or implement. Falling off can kill.

Be a safe and courteous driver. Always yield to oncoming traffic in all situations, including narrow bridges, intersections, etc.

TRANSPORT SAFETY

9

SAFETY INSTRUCTIONS (continued)

MAINTENANCE SAFETY

Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

Before working on this machine, drive to a level area, disengage the PTO, lower implement (or if working

underneath, raise and block securely), shut off the engine, set the brakes, and remove the ignition keys.

Remove hydraulic pressure prior to doing any maintenance. Operate the remote hydraulic control lever in and

out several times to relieve hydraulic pressure.

Be certain all moving parts on attachments have come to a complete stop before attempting to perform

maintenance.

Never work under equipment unless it is blocked securely. Never depend on hydraulic system to keep implement in raised position.

Always use personal protection devices such as eye, hand and hearing protectors, when performing any

service or maintenance.

Keep all persons away from operator control area while performing adjustments, service, or maintenance.

Periodically tighten all bolts, nuts and screws and check that all cotter pins are properly installed to ensure unit

is in a safe condition.

When completing a maintenance or service function, make sure all safety shields and devices are installed

before placing unit in service.

Never use your hands to locate a hydraulic leak on attachments. Use a small piece of cardboard or wood.

Hydraulic fluid escaping under pressure can penetrate the skin.

Openings in the skin and minor cuts are susceptible to infection from hydraulic fluid. If injured by escaping

hydraulic fluid, see a doctor at once. Gangrene and death can result. Without immediate medical treatment,

serious infection and reactions can occur.

Check to ensure all safety signs are installed and in good condition.

Where replacement parts are necessary for periodic maintenance and servicing, genuine factory replacement parts

must be used to restore your equipment to original specifications. The manufacturer will not claim responsibility for use

of unapproved parts and/or accessories and other damages as a result of their use.

If equipment has been altered in any way from original design, the manufacturer does not accept any liability for injury

or warranty.

10

SAFETY INSTRUCTIONS (continued)

Following operation, or when unhooking, stop the power unit, set the brakes, lower ram to lowest position and

engage transport lock pin, shut off the engine, relieve hydraulic pressure and remove the ignition keys.

Store the unit in an area away from human activity.

Do not park equipment where it will be exposed to livestock for long periods of time. Damage and livestock

injury could result.

Do not permit children to play on or around the stored unit.

Make sure all parked machines are on a hard, level surface and engage all safety devices.

If blocking is used, make sure it is solid and secure before leaving area.

STORAGE SAFETY

Keep safety signs clean and legible at all times.

Replace safety signs that are missing or have become illegible.

Replaced parts that displayed a safety sign should also display the current sign.

Safety signs are available from your Distributor or Dealer Parts Department or the factory.

How to Install Safety Signs:

• Be sure that the installation area is clean and dry.

• Be sure temperature is above 50°F (10°C).

• Decide on the exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the sign over the specified area and carefully press the small portion with the exposed sticky backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the sign in place.

• Small air pockets can be pierced with a pin and smoothed out using the piece of sign backing paper.

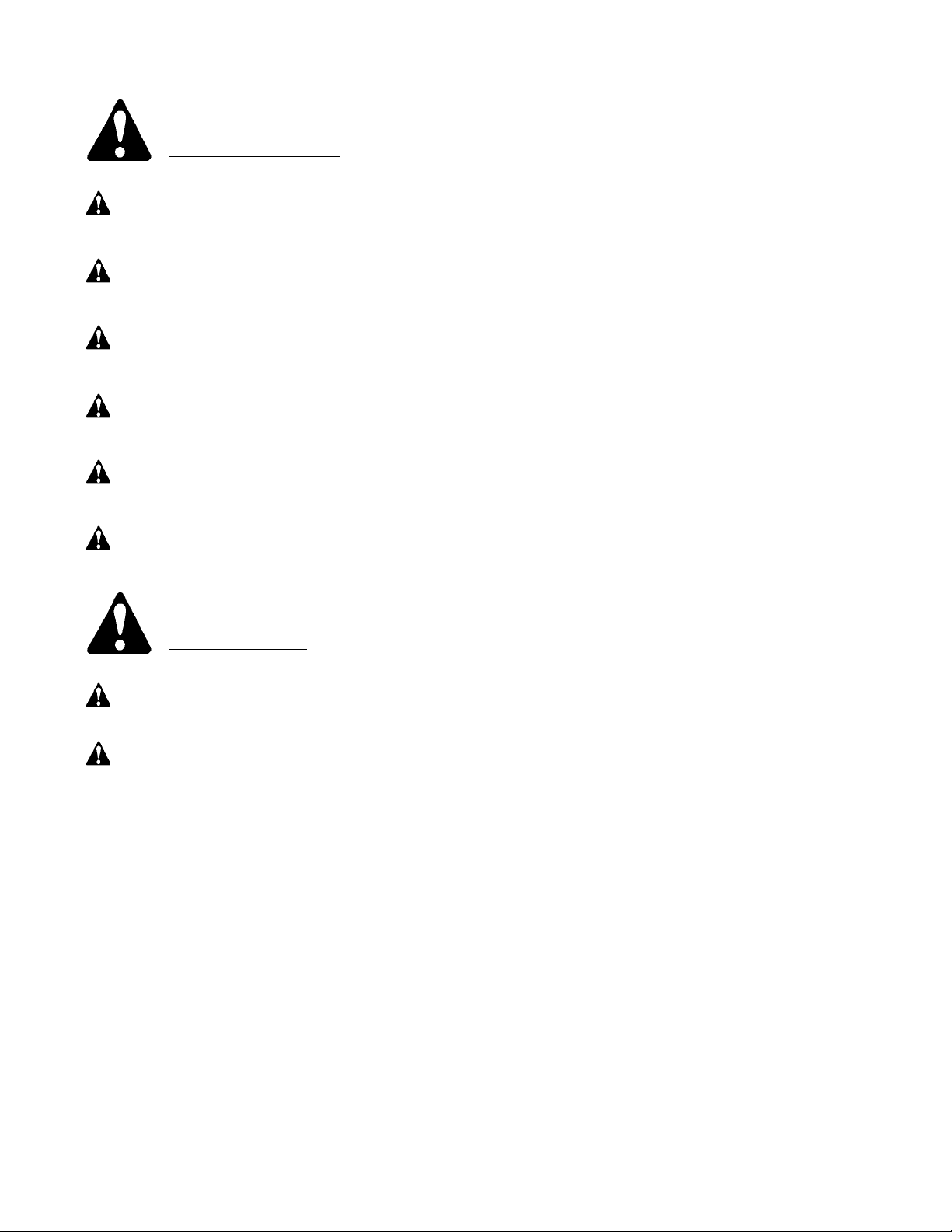

SAFETY SIGNS

11

SAFETY SIGNS

101202

Cylinder Locking Strap - Remove before using Post Driver

BE CAREFUL!

Use a clean, damp cloth to clean safety decals. Avoid spraying to close to decals when using a pressure

washer; high-pressure water can enter through very small scratches or under edges of decals causing them

to peel or come off.

12

SAFETY SIGNS

101358

NOTE: If Safety Sign is

missing or damaged,

replace immediately.

REMEMBER:

If Safety Signs have been damaged, removed, become illegible or parts replaced without Signs, new

Safety Signs must be applied. New Safety Signs are available from your authorized distributor or factory.

13

SKID STEER REQUIREMENTS

AND PREPARATION

Both the manual and hydraulic positioning skid steer

post driver mounts are designed to fit skid steer units

with the “Universal” (Bobcat) style quick-attach loaders.

The model 16, 22Q, and 26Q post drivers vary as to the

size post they can drive and the amount of impact force

they can strike a post with. (Refer to Specifications.)

A larger size skid steer unit is required in relation to the

size of driver used. A general rule is that the skid steer

specified operation lift capacity should be at least 1.25

times the weight of the post driver attachment.

A post driver is equipped with adjustable legs which

should be adjusted to the proper height and have the

weight of the driver on them while driving the post. This

makes the driver a more stable unit and eliminates shock

loads on the skid steer loader.

Be sure that the skid steer unit is in good working order,

particularly the hydraulic system, prior to using the post

driver. Be sure the skid steer hydraulic oil and filter have

been serviced according to the skid steer manufacturer’s

recommendations.

■

Be sure your skid steer and loader is in good

condition. Read all the safety precautions and

make sure all operators are familiar with the safety

rules of operation.

■ Post drivers are tall and visibility of the top of the

post driver may be obstructed by the top of the

skid steer unit operators cab. Always be aware of

low doorways, low limbs, and especially low hanging wires.

A heavy load can cause instability in driving a skid

steer unit. Always drive slowly – especially around

turns. An unstable skid steer unit could steer badly

and possibly tip over, causing damage, injury or even

death.

INSTRUCTIONS

These instructions are for the models HPD-16 HSS/P,

HPD-22Q HSS/P, and HPD-26Q HSS/P skid steer

mounted hydraulic post drivers.

The model 16, 22Q, and 26Q HSS/P post drivers have

a hydraulic motor with a self-contained hydraulic system.

The hydraulic system of the skid steer unit powers the

motor only.

The Models HPD-16 HSS/P has the Quick Change

Cylinder Cap.

The models HPD-16 MSS and HPD-22Q MSS are

manually adjusted post drivers. The manual adjusting

base have two threaded cranks to set the side to side

and front to back positioning of the driving ram.

Models HPD-22Q and HPD-26Q have both the Quick

Change Cap and the new longer lasting Quick Change

spring assemblies.

The models HPD-16 HSS/P, HPD-22Q HSS/P, and

HPD-26Q HSS/P have the driving ram positioning controlled hydraulically. A two spool hydraulic valve controls

the front to back and side to side movement for aligning

to a vertical ram position. A separate single spool valve

controls the raising and lowering of the driving ram.

The hydraulic valve that operates the driving ram is a

convertible valve and is shipped ready for OPEN center

hydraulic systems. Do not change this valve to a closedcenter valve. This convertible feature is only required for

some farm tractor applications.

Post drivers are a tall attachment to your skid steer unit.

Always watch for low clearance problems such as low

tree limbs, doorways, or low hanging wires.

WARNING

CAUTION

PACKAGING

The Post Driver is shipped as bundles.

1. The hydraulic base mount unit, partially pre-plumbed.

2. The driving ram assembly, on a pallet.

3. A hydraulic package for the ram, in a carton.

4. A package for the hydraulic base, in a carton.

5. Post Holder, in a carton.

Please inspect these bundles for any obvious signs of

damage before attempting to assemble the Post Driver.

Unpack all the bundles and lay out the various parts.

14

INSTRUCTIONS (continued)

ASSEMBLY & MOUNTING

The following procedure is recommended for assem-

bling the Skid Steer Mounted Post Driver.

Carefully follow instructions for final assembly.

Before attempting assembly check the following items.

Having all the needed parts and equipment readily at

hand will speed up your assembly task and will make the

job as safe as possible.

• Check for fasteners and pins that were shipped with

the post driver. Some hardware coming from the factory has been installed in the location where it will be

used. If a part or fastener is temporarily removed for

assembly reasons, remember where it goes. Keep the

parts separated.

• Have a fork lift or loader along with chains and safety

stands that are sized for the job ready for the

assembly task.

• Have a minimum of 2 people at hand during assembly.

• Check to see that all nuts are properly tightened.

Refer to the “exploded view” of the skid steer mounted

post driver on pages 25 thru 35 of this manual. Become

familiar with the relationship of the various components

and parts shown.

1. Connect the post driver base mount (manual or

hydraulic) to the “universal” quick-attach plate on

your skid steer loader. Flip the spring loaded latch

pins to the “latch lock” position and check to see they

are properly latched.

Raise the unit about 21/2ft. from the ground and

lower the adjustable stabilizer legs on each side of

the mounting frame. Pin each leg into position.

Operate the bucket tilt cylinders until the mounting

frame is vertical and then lower until the legs are

supporting the unit.

2.

The hydraulic base mount is shipped with the

hydraulic system partially plumbed and ready to

accept the driving ram assembly. The multi-spool

valve and mounting plate may be detached and shrink

wrapped in place. Simply remove the shrink wrapping,

swing the mounting plate into position and install the

mounting bolts.

3. Prepare the driving ram for attaching to the hydraulic

base mount. To do this, first lower the driving ram to

its lowest transport position. The driving ram is

shipped in the upper transport position for compactness. To lower the ram, pull the transport lock pin,

allow the ram to lower (approximately 10 inches) and

replace the transport lock pin. This should be done

with the Driver laying on the shipping pallet. The ram

is spring loaded downward. Stand clear of the ram

when the pin is removed (see Figure A).

NOTE: This step of repositioning the driving ram is

necessary in order to make the mounting bolts at the

correct height when the unit is stood upright for the

next step.

FIG. A

4. Attach the driving ram assembly to the hydraulic

base mount. A chain hoist or forklift can be used to

stand the driving ram assembly to its normal

(vertical) working position. Take care not to damage

the hydraulic cylinder or carriage when lifting the

unit. Once the ram assembly is upright, remove the

six (6) nuts and lock washers from the mounting

bolts.

Align the mounting bolts with the six (6) holes in

the mounting channel and secure with the nuts and

lock washers.The mounting channel on the hydraulic

base mount will probably have to be positioned by

hand to get the mounting channel and carriage lined

up.

NOTE: The mount is shipped with straps that lock the

hydraulic cylinders. To assemble the unit, it may be

necessary to remove the straps. It is important to reinstall the straps once the unit is assembled.

NOTE: The driving ram assembly will be unstable

until the hydraulic cylinders are filled with oil once all

plumbing is completed.

NOTE: One mounting bolt goes into a blind hole and

does not get a nut and lock washer. Due to trapped

air, it may be necessary to operate the control levers

on the multi-spool valve to position the mounting

channel on the hydraulic base unit. Plastic hose end

caps may have to be removed to allow trapped air in

the hydraulic cylinders to escape. DO NOT

ATTEMPT TO CONNECT THE VALVE TO THE SKID

STEER AND OPERATE IT AT THIS TIME. When

properly mounted, the bottom of the driving ram

should be resting on the same level surface as the

mounting base.

15

INSTRUCTIONS (continued)

ASSEMBLY (continued)

FIG. B

RAM CONTROL VALVE

5. Install the hydraulic package. Refer to Figure B for

correct location and orientation of components.

Some of the hydraulic fittings on the new post drivers

have O-ring type connections.

Do NOT use thread sealant on O-ring fittings.

Connect the 3/4” I.D. x 24” long hose from the control

valve work port to the Post Driver hydraulic cylinder

port.

NOTE: The port and end of the 24” hose has a NPT

(pipe thread) type connection. Use a good grade of

thread sealant at this connection. (Do NOT use

Teflon tape.)

MAKE SURE THAT ALL OPERATING AND SERVICE

PERSONNEL KNOW THAT IN THE EVENT

HYDRAULIC FLUID PENETRATES THE SKIN, IT

MUST BE SURGICALLY REMOVED WITHIN A FEW

HOURS BY A DOCTOR FAMILIAR WITH THIS FORM

OF INJURY, OR GANGRENE MAY RESULT.

WARNING

HYDRAULIC CONNECTIONS

Check all hose and fitting connections. Make sure the

hoses are not twisted or kinked and that they will not be

pinched during operation of the post driver or the skid

steer unit.

MOUNT ASSEMBLY: Connect a 3/8” I.D. x 36” long hose

from the inlet side of the ram control valve to the 90°

elbow (#27) in the 2 spool valve.

Refer to Figure C and assemble the swivel tee (#31)

and the 3/4” to 1/2” reducer bushing (#30) to the 90° outlet

port fitting in the single spool ram control valve. Then

connect a 3/8” I.D. x 36” long hose (#32) from the reducer

bushing to the 90° elbow (#33) that is connected to the

two spool valve.

Connect the 3/4” I.D. x 48” long return line from the bottom of the 3/4” tee (Ref. #31) on the ram control valve to the

hydraulic tank.

Pour 5 gallons of good quality hydraulic oil in the reservoir (this will temporarily fill tank above sight glass).

Operate unit and cycle each hydraulic cylinder to fill with

oil. Then check sight glass and add oil if necessary.

FIG. C

See Figure C for a view of the hoses and fitting to cor-

rectly orient them to the valves.

INSTRUCTIONS (continued)

LUBRICATION

The Post Driver is designed with “SPECIAL” polyethylene

slide blocks for long, trouble-free operation.

• Oil or grease applied to the slide channel will make the

operation smoother and if applied after use will help

keep rust from forming in the channel.

• There are grease fittings on the large side to side pivot

tube. A few shots of grease at the beginning of the

work day is recommended.

• Smear grease over the exposed portion of the plated

hydraulic cylinder rod after use to help prevent pitting

and rust from forming. If Post Driver is going to be

stored outside this is very important.

• The hydraulic control base has a grease fitting on the

large, side to side, pivot tube and one on the lower,

front to rear, pivot pin.

REPLACE

SAFETY SIGNS

IF DAMAGED

OR MISSING.

Keep children away from

danger all day, every day!

ASSEMBLY (continued)

NOTE: Route the hoses to the skid steer so that they

will not be pinched or caught by the movement of the

positioning mount

6. Stand clear of the driving ram assembly and raise the

completely assembled unit approximately 6 inches

with the skid steer loader. The driving ram assembly

will probably lean out of its normal position. Operate

the hydraulic valve so that oil flows from the skid steer

to the multi-spool valve and ram control valve and

returns to the hydraulic reservoir. The skid steer

engine should be operated at an idle until the system

is charged with oil. Remove the two cylinder locking

straps from the positioning cylinders. Now operate the

hydraulic levers on the multi-spool valve. This should

cause the driving ram assembly to pivot, side to side

and front to rear. The cylinders will have to be cycled

several times to remove all the air from the cylinders

and lines. Be sure to check the skid steer hydraulic oil

level after charging the system. Special orifice fittings

have been installed at the hydraulic cylinder ports to

restrict the flow and cause the cylinders to operate in

a slow, smooth manner.

7. Attach the circular (bulls-eye) level as shown in the

parts illustration. Adjust the alignment of the level as

follows: using a 2’ or longer carpenter’s level, adjust

the driving ram with the alignment cranks until the ram

is plumb front to back and side to side. Tilt the top of

the driving ram slightly to the rear to allow for recoil

when the ram drops. Now adjust the valve mounting

bracket and the bubble level bracket so the level bubble is centered in the level circle (see Figure D), then

tighten all bolts.

FIG. D

16

17

PLEASE WORK, DRIVE, PLAY AND LIVE EACH DAY

WITH CARE AND CONCERN FOR YOUR SAFETY

AND THAT OF YOUR FAMILY AND FELLOW CITIZENS.

INSTRUCTIONS (continued)

LUBRICATION

• The Post Driver is designed with “special” polyethylene slide blocks for long trouble-free operation.

• Oil or grease applied to the slide channel will make

the operation smoother and if applied after use will

help keep rust from forming in the channel.

• There are grease fittings on the large side to side pivot

tube and on all the threaded tilt adjustment nuts. A few

shots of grease at the beginning of the work day is

recommended.

• It is recommended to apply grease or oil to the

threaded portion of the tilt adjustment cranks before

storage to help prevent rust from forming.

• Smear grease over the exposed portion of the plated

hydraulic cylinder rod after use to help prevent pitting

and rust from forming. If Post Driver is going to be

stored outside this is very important.

• The hydraulic control base has a grease fitting on the

large, side to side, pivot tube and one on the lower,

front to rear, pivot pin.

POST HOLDER MOUNTING

Refer to page 28 and become familiar with the parts of

the Post Holder and the description of parts.

Locate the two holes in the left side of the support

channel. These holes are directly opposite the valve

mount bracket holes.

Bolt the Post Holder Mount weldment to the support

channel with the two 3/8”x 11/2” hex bolts. (See photo J.)

Assembly the remaining parts of the Post Holder refer-

ring to photo K.

Using the vertical handle on the arm weldment, swing

the Post Holder away from the ram and to the left. The

arm will go over center and remain to the left side of the

post driver.

PHOTO J

PHOTO K

INSTRUCTIONS (continued)

MODELS HSS ATTACHMENT TO

PRIME MOVER

——————————————————

3. Enter the prime mover. Fasten seatbelt, start engine.

Disengage the parking brake.

4. Follow the attaching procedure in the prime mover

owner's manual. Align the attachment mechanism

with the mounting on the post driver, attach to the

prime mover on loader.

5. Engage the parking brake and shut down the prime

mover. Be sure to relieve pressure to the auxiliary

hydraulic lines.

6. Unfasten safety restraints and exit the prime mover.

7. Engage the latching mechanism to secure attachment

to loader. The lockpins must be completely extended

and secured into the retaining slots.

8. Re-enter the prime mover. Fasten seatbelt and restart engine.

1. Position the attachment on a level surface.

2. The quick attach coupler handles should be in the

unlocked position with lock pins retracted, Figure 2.

Improper attachment of the post driver could result

in injury or death. Do not operate this product until

you have positive indication that the attachment is

securely mounted.

Attachment coupler handles must always be

rotated to LOCK POSITION to prevent coupler latch

from disengaging and attachment from falling off.

Figure 2. Quick Attach Coupler Handles - Unlocked

Figure 3. Attachment Coupler Handles - Locked

9. Carefully raise the loader and cycle the rollback/tilt

cylinders to check clearances and to ensure that the

attachment is securely mounted.

REMOVING THE POST DRIVER

1. If possible, find a level solid location to place the

attachment. This makes it easier to disconnect and

re-connect later on.

2. Lower the attachment to the ground.

3. Engage the parking brake and shut down the prime

mover. Be sure to relieve pressure to the auxiliary

hydraulic lines.

4. Unfasten safety restraints and exit prime mover.

5. Disengage attachment-locking mechanism (mechanical type).

6. Enter prime mover, fasten safety restraints and start

the prime mover.

7. Disengage attachment-locking mechanism (hydraulic

type).

8. Disengage the parking brake, and back away from

the attachment.

WARNING

WARNING

18

19

BEFORE YOU START

Review the assembly instructions to be sure the Driver

is properly assembled and plumbed correctly for your

skid steer hydraulic system. Be sure the skid steer unit’s

hydraulic oil and filter have been serviced according to

the skid steer units manufacturer’s recommendations

before using the Post Driver.

OPERATING INSTRUCTIONS

PRE-OPERATION CHECKLIST

(OWNER/OPERATOR RESPONSIBILITY)

____ Review and follow safety rules and safety signs on

pages 3 through 12.

____ Check that Post Driver is properly and securely

attached to skid steer loader.

____ Lubricate all grease fitting locations.

____ Check that all hardware is properly installed.

____ Check that no one enters the area of machine

operation. Always keep bystanders at a safe distance from the post driver.

____ Know your controls and how to stop skid steer,

engine and PTO quickly in an emergency. READ

THIS MANUAL AND THE ONE PROVIDED WITH

YOUR SKID STEER.

____ To avoid accident or injury, do not allow anyone to

operate this equipment without proper instructions.

Any person who operates this equipment must be

instructed in and be capable of the safe operation

of the skid steer, post driver and all controls.

Beware of low electrical wires when loader is

raised. Serious injury or death can result if contact is

made.

OPERATION

Observe all operating and safety instructions in this

manual and those on the Post Driver before using

this machine.

1. Position the skid steer for driving a post.

2. On the skid steer mount with adjustable legs, adjust

the legs so that when the driver is at the desired

height, the legs will be on the ground supporting the

weight of the driver. Always lower loader so weight of

loader and driver is on the legs.

3. Set the skid steer brakes. Raise the ram slightly and

remove the transport pin.

4. Align the driving ram vertically by use of the “bulls-eye”

bubble level and the multi-spool hydraulic valve

handles.

5. Raise the driving ram by lifting up on the control valve

handle. NOTE: Do not allow the ram to continually

hit the urethane bumpers at the top of the carriage. Tractors with high volume hydraulic pumps

will cause the ram to raise very fast. If the ram

raises too fast, turn the up stroke limit screw into the

valve body to limit the amount of handle movement

(see Figure E). Tighten the lock nut to keep the limit

screw in position. Raise the ram so that it is 18” to 24”

above the top of the post. The tractor hydraulic control

valve should be tied in the “ON” position so the Driver

is controlled solely by the Post Driver control valve.

6. Place the post within the driving ram. The back of the

post should be against the web of the I-Beam and

centered between the flanges. Stabilize the post using

the special “Post Holder Tool” provided.

FIG. E

DANGER

20

NEVER hold the post with your hand. Always use

the post holder or the special STEEL T-POST Holder

when driving steel T-posts. Order part #814490.

OPERATING INSTRUCTIONS (continued)

Improper use of loaders can result in serious injury or

death to the skid steer operator.

For optimum stability, visibility and safety:

• Carry the post driver slowly and low to the ground.

• Operate the loader controls smoothly, avoiding jerky

operation.

• When driving posts on a slope, always have the post

driver facing uphill.

• Only use a skid steer equipped with a ROPS cab or

roll-over protective structure.

• Use particular care when working on inclines and hillsides.

• Avoid holes, ditches, and obstructions which may

cause skid steer loader to tip.

• Never allow anyone to walk or work under a raised

loader.

• Be sure that people, livestock, or pets are not standing near the machine while operating.

• Make sure there are no buried utilities in work area

(call 811).

DRIVE POSTS SAFELY

7. Stand at a 45° angle to the post – not directly in front

of the post. Be sure all bystanders are at a safe distance from the Post Driver.

8. Drop the driving ram by pushing “Full Down” on the

control valve handle.

9. Repeat raising and dropping the driving ram until the

post is to the desired depth. Be sure the ram slide

blocks are not “BOTTOMING OUT” on the urethane

bumpers. Likewise, do not raise the ram to its

extreme up position with each stroke.The ram should

normally be raised 18” to 24” above the top of the

post. Once the post is deep enough to be stable, it is

no longer necessary to hold the post with the “POST

HOLDER TOOL.” Stand back and “DRIVE” the post.

10. In dry or light rocky conditions, cutting a point on the

post may be beneficial. The point should be centered

on the post to prevent the post veering to one side.

11. When driving steel “T” posts do not raise the ram as

you would for wood posts. Usually, raising the ram 4”

to 6” is enough for steel “T” post. Too much impact on

steel “T” post can cause the post to buckle or bend.

12. Re-engage the transport lock pin when finished with

the job.

When traveling on public roads, whether at night or

during the day, use accessory light and devices for

adequate warnings to operators of other vehicles.

Comply with all federal, state and local laws.

Install the two cylinder locking straps on the hydraulic

positioning cylinders before transporting long distances.

Carry load low.

Check visibility. If visibility is impaired, reduce speed or

consider other means of transport.

Allow for additional length of loader on tractor while

turning.

Select a safe ground travel speed when transporting

from one area to another. When traveling on roadways,

transport in such a way that faster moving vehicles may

pass you safely.

When traveling over rough or hilly terrain or when mak-

ing turns, slow down and use extra care.

Read all the safety warnings in the front of the manual.

TRANSPORTING

OPERATION (continued)

CAUTION

CAUTION

21

STORING THE POST DRIVER

Following operation, or when disconnecting the post

driver, stop the skid steer unit, set the brakes, lower the

loader, lower the driver ram to it’s lowest position and

engage the transport lock pin. Install the two locking

straps on the angle cylinders and make sure the

adjustable legs are positioned correctly.

Shut off the engine and remove the ignition key.

Lower the ram to the lowest position and engage the

transport lock pin. This position will have the hydraulic

cylinder rod fully retracted into the cylinder and will be

self-protecting.

Make sure driver will be located on a solid surface and

in a location away from children, animals, or traffic area.

Inside storage is preferred to prevent deterioration of the

springs, hoses, etc. For safety, the Driver should be

securely blocked for stability.

To store the skid steer mount with adjustable legs,

locate the transport locking pin into the higher hole

location in the ram and then adjust legs to same height.

Smear grease over the exposed portion of the plated

hydraulic cylinder rod to prevent pitting and rust from

forming.

It is recommended to apply grease or oil to any exposed

portion of the tilt cylinders or threaded cranks to help

prevent rust from forming.

Thoroughly clean the grease zerks before servicing. Dirt

mixed with lubricant will rapidly wear parts and destroy

bearings. Keep it clean. Lubricate all grease fittings prior

to storage.

MAINTENANCE AND

ADJUSTMENTS

Before servicing the machine, engage the parking

brake or place the transmission in “Park,” shut off the

skid steer and remove the key. Relieve all hydraulic

pressure in lines.

Do not get under machine to make measurements

or adjustments without securely blocking implement

first.

• Serious injury or death may result from disengaging the attachment when the attachment is in an

unstable position. Place the attachment in a stable

position before disengaging.

• Hoses for the attachment must be disconnected

before the quick attach is disengaged. Pulling the

attachment with the hoses could result in damage to

the prime mover or the attachment.

If the machine is used in heavy duty conditions, the

maintenance operations must be carried out more

frequently.

Thoroughly clean the grease zerks before servicing. Dirt

mixed with lubricant will rapidly wear parts and destroy

bearings. Keep it clean.

Check the pins at the ends of the loader arms. Make

sure they are locked in place with the linchpins.

Periodically check all bolts to make sure they are tight

(except those that are supposed to be loose).

Check hydraulic hoses. Make sure they are not chafed

or pinched. Replace any damaged hose.

Check hydraulic hoses and fittings for leaks. Repair any

leaks immediately. Never use your hand to check for a

hydraulic leak when system is under pressure.

Replace any worn or damaged parts immediately. Do

not use post driver attachment with any damaged parts.

Make certain the safety and instruction decals are

attached to the Post Driver. If they are lost, damaged, or

painted over, order replacements.

Do not work under a raised loader unless it is

securely blocked or held in position. Do not depend

on the hydraulic system to hold loader and attachment in place.

OWNER SERVICE

WARNING

WARNING

WARNING

SERVICE INSTRUCTIONS (continued)

FIG. G

VALVE CONVERSION INSTRUCTIONS

The conversion plug for making the control valve compatible with closed-center hydraulic systems is shipped in

the hardware box (see Figure F). DO NOT USE.

FIG. F

NOT USED

ON HSS/P

MODELS

MAINTENANCE AND

ADJUSTMENTS

(continued)

RAM CONTROL HYDRAULIC VALVE

The hydraulic ram control valve supplied with the Post

Driver is “convertible” to accommodate both open-center

and closed-center hydraulic systems.The control valve is

shipped “ready” for open-center hydraulic systems.

NOTE: HSS/P Models require the valve to have the

open center plug.

HYDRAULIC CYLINDER BASE ADJUSTMENT – HPD-16

Due to the design of the Driver carriage, it is necessary

for both the base and rod end of the hydraulic cylinder to

have a slight amount of freedom. This adjustment should

only be necessary if the hydraulic cylinder is removed for

servicing (see Figure G).

The “Special 7/8” Nut” (Part #815205) has the correct

amount of freedom designed in. No adjustment is

required at the rod end of the cylinder rod.

NOTE: These instructions

are for the HPD-16 Models

only.

DISASSEMBLY – CARRIAGE AND RAM ASSEMBLY

1. Lay the driving ram assembly face down on the floor

or on a solid workbench.

2. Remove the transport lock pin. This will allow the ram

carriage to move up, thereby relieving the spring tension. Disconnect the upper spring bracket.

3. Remove the lock nut from the top of the cylinder rod

using a 115/16” wrench and a 11/2” wrench on the step

nut and push the rod back into the cylinder.

4. Now remove the hex nuts (or bolts for Models HPD22Q and HPD-26Q) holding the transport lock pin

bracket in place. Slide the carriage down and remove

the hydraulic cylinder and springs as a unit from the

lower end.

5. The carriage can now be removed from the upper end

of the ram assembly.

HYDRAULIC CYLINDER DISASSEMBLY

1. Refer to the exploded view of your model post hole

driver and become familiar with the parts and how

they are assembled.

2. It is NOT necessary to remove the complete hydraulic

cylinder to change any of the internal cylinder parts.

These parts can be changed from the top of the cylinder. (See following section on replacing the seal).

NOTE: If you need to replace the rod or rod guide, it

may be easier to remove the complete cylinder. This

will allow you to place the cylinder in a vise to remove

the lower part of the cap (gland) from the cylinder

tube.

NOTE: The lower hydraulic cylinder mounting bolts have

stamploc hex nuts (

3

/8” on HPD-16). DO NOT use regular

hex nuts in place of these nuts.They need to be stamploc

nuts. Also, on reassembly, there are instructions on the

proper adjustment of these bolts. See the section on

Hydraulic Cylinder Base and Rod End Adjustment.

(Figure G). (HPD-16 Models only.)

22

23

SERVICE INSTRUCTIONS (continued)

PHOTO L PHOTO M

PHOTO P PHOTO Q

MAINTENANCE AND

ADJUSTMENTS

(continued)

3. Remove the hydraulic cylinder from the carriage.

4. Remove the special 7/8" step nut from the cylinder

rod. Use a 1 1/2" wrench on the step nut and a 5/8"

wrench on the rod flats at the top of the rod.

5. Place the base end of the hydraulic cylinder in a vise,

support the upper end of the cylinder and remove the

aluminum cap assembly.

6. Carefully slide the aluminum cap assembly off the

upper end of the cylinder rod.

7. Pull the rod from the cylinder tube.

8. Remove the nut from the lower end of the cylinder

rod. The rod must be protected with leather, cardboard, or wood blocks and placed in a vise to remove

the nut. Remove the rod guide.

9. NOTE: It is advisable to install a new rod guide and

seal when rebuilding the cylinder. Inspect the cylinder

rod for pits and/or rust and replace if necessary.

CAP SEAL REPLACEMENT

Tools required:

2 1/8" wrench or 18" crescent wrench

Seal pick or small flat blade screwdriver

1 1/2" wrench or 12" crescent wrench

1 5/16" wrench or 12" crescent wrench

5/8" wrench or 12" crescent wrench

Anti-seize thread compound

The procedure for changing the seal is as follows:

1. The driver must be connected to the tractor/skid steer

for stability. The tractor engine turned off.

2. Lock the driver in the upper lock position by inserting

the transport lock pin through the bottom hole of the

driver ram (Photo L).

3. Remove the top lock nut from the rod using the

1 5/16" wrench and the 1 1/2" wrench on the step nut

(Photo M).

4. Lower the cylinder with the valve (Photo N).

5. Remove the step nut from the cylinder rod using the

1 1/2" wrench and the 5/8" wrench on the rod flats

(Photo 0).

6. Unscrew the top of the cap from the bottom of the cap

(Photo P). (2 1/8" wrench or 18" crescent wrench.)

7. Remove the old seal with a flat blade screw driver or

seal pick.

8. Install the new seal over the rod and start one edge

into the cap.

9. Carefully using a flat blade screw driver, gently work

the seal into the bottom of the cap (Photo Q).

10. Reinstall the top of the cap using approx. 50 FT/LB

of torque.

11. Never use any type of thread sealant on the threads

between the top cap and bottom gland of the cap and

seal assembly. This will destroy the aluminum

threads when trying to remove. Thread sealant is

only needed on the bottom threads of the cap (gland)

to the cylinder tube weldment.

12. Reapply anti seize on threads of rod.

13. Reinstall step nut to bottom of threads on rod.

14. Pull cylinder rod up to the driver mount plate and

reinstall top nut to approx. 80 FT/LB of torque.

15. The driver is now ready to drive posts.

PHOTO N PHOTO O

24

SERVICE INSTRUCTIONS (continued)

MAINTENANCE AND

ADJUSTMENTS

(continued)

SPRING REPLACEMENT – MODELS 16 ONLY

1. Lower the driving ram so the springs are in their

relaxed position. Remove the upper spring bracket

from the square tube by removing the 3/8” bolt.

2. Remove the upper spring clip from the spring bracket

by rotating the clip and sliding it out the keyhole slot.

3. Insert a screwdriver in the spring clip and screw it out

of the spring coils. The spring can be removed from

the lower spring clip by rotating the spring.

4. Install the plastic stabilizing pipe inside the springs

prior to installing the spring

clips. Install new spring clips by

inserting a screwdriver in the

end coil and screwing the clip

onto the first two coils (see

Figure H). Use a large pair of

adjustable (water pump) pliers

and close the ends of the clips

to retain them on the spring.

5. To replace the springs, it is necessary to remove the

top spring anchor (#814408) and to remove the two

lower bolts that hold the lower end of the main

hydraulic cylinder. Removing these bolts will allow the

removal of the lower spring bracket (#814430 on

HPD-16).

NOTE: The lower hydraulic cylinder mounting bolts have

stamploc hex nuts (3/8” on HPD-16). DO NOT use regular

hex nuts in place of these nuts.They need to be stamploc

nuts. Also, on reassembly, there are instructions on the

proper adjustment of these bolts. See the section on

Hydraulic Cylinder Base Adjustment. (Figure G).

FIG. H

QUICK-CHANGE SPRING REPLACEMENT –

HPD-22Q and 26Q MODELS

The Models HPD-22Q and HPD-26Q have the new

longer lasting springs with the new Quick Change spring

assembly mounting.

The following procedure will instruct how to replace the

spring assemblies.

1. Lower the driving ram so the springs are in their

relaxed position. Remove the nut on top of the upper

spring bracket on the threaded rod of the spring

assemly to be replaced.

2. On the top rear of the driving ram are two tabs weld-

ed to the ram I-beam. Raise the driving ram until the

holes in these tabs are slightly above the top of the

two vertical brace bars on the back of the carriage.

Slide the transport lock pin through the two welded

tabs. The transport pin will be just above the two ver-

tical brace bars.This will prevent any accidental down-

ward movement of the driving ram.

3. Using a ratchet with a 3/4” socket, loosen the 1/2” bolt

connecting the spring assembly to the spring mount

plate that is welded on the hydraulic ram cylinder.

NOTE: Just loosen this bolt so the spring assembly

can slide out of the slotted mount plate.

4. Once the bottom of the spring assembly is free from

the slotted mount plate, the spring assembly can be

removed from the post driver thru the top of the driv-

ing ram.

5. To install new spring assemblies, just reverse the

above proceedure.

SKID STEER POST DRIVER SPECIFICATIONS

Skid Steer should have SAE Operating Load Rating

at least 1.25 times weight of post driver.

DRIVER MOUNT MODEL

DRIVER MODEL

Maximum Post Size . . . . . . . . . . . . . . . . . . . . . . . . . .

Impact at Full Stroke . . . . . . . . . . . . . . . . . . . . . . . . . .

Impact at Half Stroke . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Skid Steer Size . . . . . . . . . . . . . . . . . . . . . .

Recommended Minimum SAE Operating

Load Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Hydraulics Recommended . . . . . . . . . . . . .

Ram Lift Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Range (above ground) . . . . . . . . . . . . . . . .

Tilt Adjustment – front/back . . . . . . . . . . . . . . . . . . . .

Tilt Adjustment – side/side . . . . . . . . . . . . . . . . . . . . .

No. of Cylinder(s)/Size . . . . . . . . . . . . . . . . . . . . . . . .

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HSS/P (Hydraulic Adjust)

1,300 1,500 1,800

15 gpm 15 gpm

1,058 lb.

1,215 lb. 1,451 lb.

2” x 56”

50” to 116”

2” x 68”

50” to 128”

17° each way from vertical

20° each way from vertical

Two 3” x 6”

32,000 lb.

16,000 lb.

80,000 lb.

40,000 lb.

110,000 lb.

55,000 lb.

5” x 9’

8

3

/4” x 10’

11” x 10’

16 22Q 26Q

25

TROUBLE-SHOOTING GUIDE

PROBLEM POSSIBLE CAUSE POSSIBLE REMEDY

DRIVER DOES NOT

DRIVE A POST

1. Quick-connect couplers not properly connected.

2. The ram may be binding in the carriage.

3. Carriage springs may be disconnected or

broken.

4. Ground may be too dry or hard.

5. Post may be encountering a rock.

6. Remote hydraulic connection fittings not

compatible.

Hydraulic motor on post driver is designed to

turn in only one direction. Reverse hydraulic control lever or switch hoses.

Carriage slide blocks may need lubrication or

replacement.

Check springs and replace.

Pointing the post may help. Otherwise, wait for

rain.

Relocate post 6-8 inches and try again. Pointing

post may help in light, rocky soil.

Check for proper fitting.

DRIVING RAM WILL

NOT RAISE OR RAISES SLOWLY

1. Hydraulic valve may be improperly

plumbed.

2. Post driver control valve handle “UP” limit

screw may need adjustment.

3. Carriage may be binding.

4. Hydraulic cylinder rod guide (piston) may

be excessively worn.

5. Skid steer hydraulic system may not be

supplying rated pressure (usually 1500 to

2250 PSI).

6. Worn, damaged, insufficient, or inadequate

pump on skid steer.

7. Hydraulic valve on post driver may be

leaking.

8. Carriage may be bent due to hitting overhead object.

9. Insufficient oil in system.

10.Hose ends not completely engaged.

11.Air in hydraulic lines.

12.Skid steer engine rpm too low.

See assembly instructions.

See Figure E page 19.

Check for broken springs, worn slide blocks or

other obstructions.

Replace rod guide.

Consult your dealer.

Repair or replace hydraulic pump.

Repair or replace valve.

Straighten or replace carriage assembly.

Service the hydraulic reservoir.

Check hose coupling and engage properly.

Cycle auxiliary hydraulic system serveral times to

remove air from lines.

Increase engine speed.

26

TROUBLE-SHOOTING GUIDE (continued)

PROBLEM POSSIBLE CAUSE POSSIBLE REMEDY

POST VEERS OFF AT

AN ANGLE WHILE

BEING DRIVEN

1. Top of post is not cut “square,” causing the

post to drive at an angle.

2. Bottom of post is cut at an angle or post is

pointed off-center.

3. Post driver mount may not be properly

latched on skid steer loader.

4. Adjustable legs on mount are not setting

firmly on the ground.

5. Skid steer has moved slightly while driving

post.

6. Post may have encountered a rock or large

root.

7. Ground may be too dry or hard.

Re-cut top of post “square.”

Re-cut bottom of post.

Check lock pins.

Re-adjust legs.

Always set brakes and use extra care on slopes.

Post may have to be relocated.

Point post or may have to wait until it rains.

HYDRAULIC OIL

OVERHEATS

1. Oil level low.

2. Dirty filters.

3. Reservoir of power unit too small.

4. Oil or oil filter on post driver may be dirty.

Check oil level in power unit and driver reservoir.

Change oil and filters in power unit per manufacturer’s recommendations.

Allow time for oil to cool down.

Change oil and filter.

HYDRAULIC HOSE

FAILURE

1. Hose being pinched.

2. Hoses are worn or frayed.

3. Hydraulic relief pressure on power unit too

high.

Reroute hose and fasten out of harms way.

Replace hose.

Adjust relief pressure (if possible) or change

power unit.

27

TROUBLE-SHOOTING GUIDE (continued)

PROBLEM POSSIBLE CAUSE POSSIBLE REMEDY

DRIVER RAM RAISES

VERY FAST AND HITS

TOP URETHANE

BUMPERS

1. Post driver control valve “UP” limit screw

needs adjusting.

2. Skid steer model has high volume

hydraulic oil pump.

3. Operator continuously raising ram to the

full height.

Adjust limit screw (see page 19).

Set throttle at lower speed to reduce volume of

oil or if necessary, install an orifice in line to

reduce volume of oil.

Only raise ram 18-20 inches to achieve full hitting force. Retrain operator.

SPRING AND/OR

SPRING CLIP BREAKAGE

1. Operator is continuously raising the ram to

the full height.

2. Springs are cold.

3. Springs and clips are a wear item on post

drivers. It is expected that these parts will

have to be replaced depending on length

of use and when being subjected to “hard

driving” conditions.

It is only necessary to raise the ram 18-20 inches to achieve full hitting force. Retrain operator.

In colder temperatures, it will help to “warm-up”

or “season” the springs by first only raising the

ram 6-8 inches, then 12-16 inches, then normal

hitting height. This allows the spring steel to

warm-up and not be subjected to full stretch

when cold.

DRIVER HAS EXCESSIVE MOVEMENT OR

BOUNCE

1. Top of post is not cut “square,” causing the

driver to veer off at an angle.

2. Post driver mount may not be properly

latched on skid steer loader.

3. Skid steer loader is not all the way down.

4. Adjustable legs on mount are not setting

firmly on the ground.

5. Springs may be disconnected or broken.

6. Ground may be too dry or hard.

7. Post may be encountering a rock.

8. Driver ram may be improperly angled.

9. Skid steer may not be large enough to

handle driver.

Re-cut top of post “square.”

Check lock pins.

Lower loader.

Lower loader or adjust legs.

Check and repair or replace.

Pointing the post may help. You may have to wait

until it rains if ground is extremely hard and dry.

Relocate post 6-8 inches and try again. Pointing

post may help in light, rocky soil.

If top of ram is angled away from post, ram will

veer off post. Re-adjust ram angle.

Use larger, heavier skid steer.

28

POST HOLDER ATTACHMENT

PARTS DRAWING & LIST

29

HPD-16

PARTS DRAWING

HPD-16

Effective with S/N 4215

30

HPD-16 PARTS LIST

31

HPD-22Q

PARTS DRAWING

HPD-22Q

Effective with S/N 5501

32

HPD-22Q PARTS LIST

33

HPD-26Q

PARTS DRAWING

HPD-26Q

Effective with S/N 1501

34

HPD-26Q PARTS LIST

35

HYDRAULIC ADJUSTMENT SKID STEER MOUNT

PARTS DRAWING

36

HYDRAULIC ADJUSTMENT SKID STEER MOUNT

PARTS LIST

37

HYDRAULIC POWER PACKAGE PARTS DRAWING

(Skid Steer Application)

38

HYDRAULIC POWER PACKAGE PARTS LIST

(Skid Steer Application)

39

HYDRAULIC CONTROL VALVE AND

MOUNTING BRACKET PARTS DRAWING

40

HYDRAULIC CONTROL VALVE AND

MOUNTING BRACKET PARTS LIST

SKID STEER MOUNTED

HYDRAULIC POST DRIVERS

with

Quick ChangeTMSystem

and Hydraulic Power Package

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFORMATION:

1. PART NUMBER

2. PART DESCRIPTION

3. MODEL NUMBER

4. NAME OF ITEM

OWNER’S/

OPERATOR’S

MANUAL

MODEL NO.’s

HPD-16

(S/N 4215 and above)

HPD-22Q

(S/N 5501 and above)

HPD-26Q

(S/N 1501 and above)

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SI NO LEEINGLES, PIDA AYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

MAY 2014

WS-PH019-OG

WORKSAVER, INC.

P.O. BOX 100 LITCHFIELD, IL 62056-0100 (217) 324-5973

WEB: http:// www.worksaver.com E-MAIL: sales@worksaver.com

MAKE EVERY DAY

A HOLIDAY FROM ACCIDENTS

• Machinery should be operated only by those who are

responsible and are authorized to do so.

• Stop the engine, lower all equipment, lock the brakes,

and remove the ignition key before dismounting from the

tractor.

• Never stand between tractor and implement while tractor

is being backed to hitch.

• Loose fitting clothing should not be worn, to avoid catch-

ing on various parts.

• Detach implement in area where children normally do not

play.

• When performing adjustments or maintenance on an

implement, first lower it to the ground or block it securely

at a workable height.

• Only a qualified operator should be permitted on tractor

when in operation; no riders allowed.

• Make certain everyone is in the clear before starting

tractor or raising or lowering equipment.

•

Operate the tractor and implement only while seated in

the driver’s seat.

•

Reduce speed when transporting mounted implements

to avoid bouncing and momentary loss of steering

control.

• A heavy load can cause instability of the tractor. Use

extreme care during road travel. Slow down on turns and

watch out for bumps. Tractor may need front counterweights to counter-balance the weight of the implement.

• Reduce speed on hillsides or curves so there is no

danger of tipping.

• Avoid driving too close to the edge of ditches or creeks.

• Do not transport implement on public roads without

reflectors and slow moving vehicle emblem in daylight

and with approved warning lights at night and other

periods of poor visibility.

• Due to the width of some implements, use extra caution

on highways, farm roads, and when approaching gates.

• Always be sure the implement is in the proper position for

transport.

• Keep alert and watch the front as well as the rear when

working with the implement.

SAFETY REQUIREMENTS

AVOID ACCIDENTS BY FOLLOWING ALL OF THE SAFETY REQUIREMENTS LISTED BELOW.

Loading...

Loading...