Page 1

SwingArm–Dual™

Assembly

Instructions

Part no. 1500094 Rev B

Page 2

SwingArm–Dual™ Installation Instructions

Important Safety Instructions

Read and understand all these safety

instructions before using this product.

Do not mount the clamp base or the grommet base on an unstable surface

(any surface that will not hold the base rmly).

For safety reasons, the internal gas-strut of the SwingArm–Dual™ is preadjusted at the factory to the lowest force for the prevention of arm body

recoil during installation.

IMPORTANT SAFETY PRECAUTION:

During installation, beware that the arm body can move suddenly when

attaching or detaching the LCD monitor to the Swing. WHEN CHANGING

THE LCD MONITOR, ALWAYS RE-ADJUST THE GAS STRUT TO THE LOWEST

FORCE SETTING. Without this adjustment, the arm will move suddenly upward when the monitor is removed.

Do not attempt to disassemble, service or modify the product yourself.

Use only a slightly damp cloth to clean the Arm surface. Never use ammable solvents like alcohol, benzene, thinner, etc.

Table of Contents

List of Boxes ................................................................................................. 3

List of Parts .................................................................................................. 3

Step 1: Attach Clamp Base to Work Surface ...................................................... 6

Step 1x: Attach Grommet Base to Work Surface ................................................ 6

Step 2: Attach Monitor Arms to Monitors .......................................................... 7

Step 3: Attach Pivot Base and Arms ................................................................. 8

Step 4: Vertical Movement Adjustment ............................................................. 9

Step 5: Ball-joint Adjustment for Tilt Action ...................................................... 9

Step 6: Final Touches: Cable Management ...................................................... 10

2 Workrite Ergonomics, Inc

Page 3

SwingArm–Dual™ Installation Instructions

List of Boxes

Box # Label Qty

I Desk Clamp 1*

Ix Desk Bolt 1*

II Short Pole 1

III Dual Mount 1

IV Monitor Arm 2

* Note that either Box I or Box Ix will be included, depending on the style of base purchased.

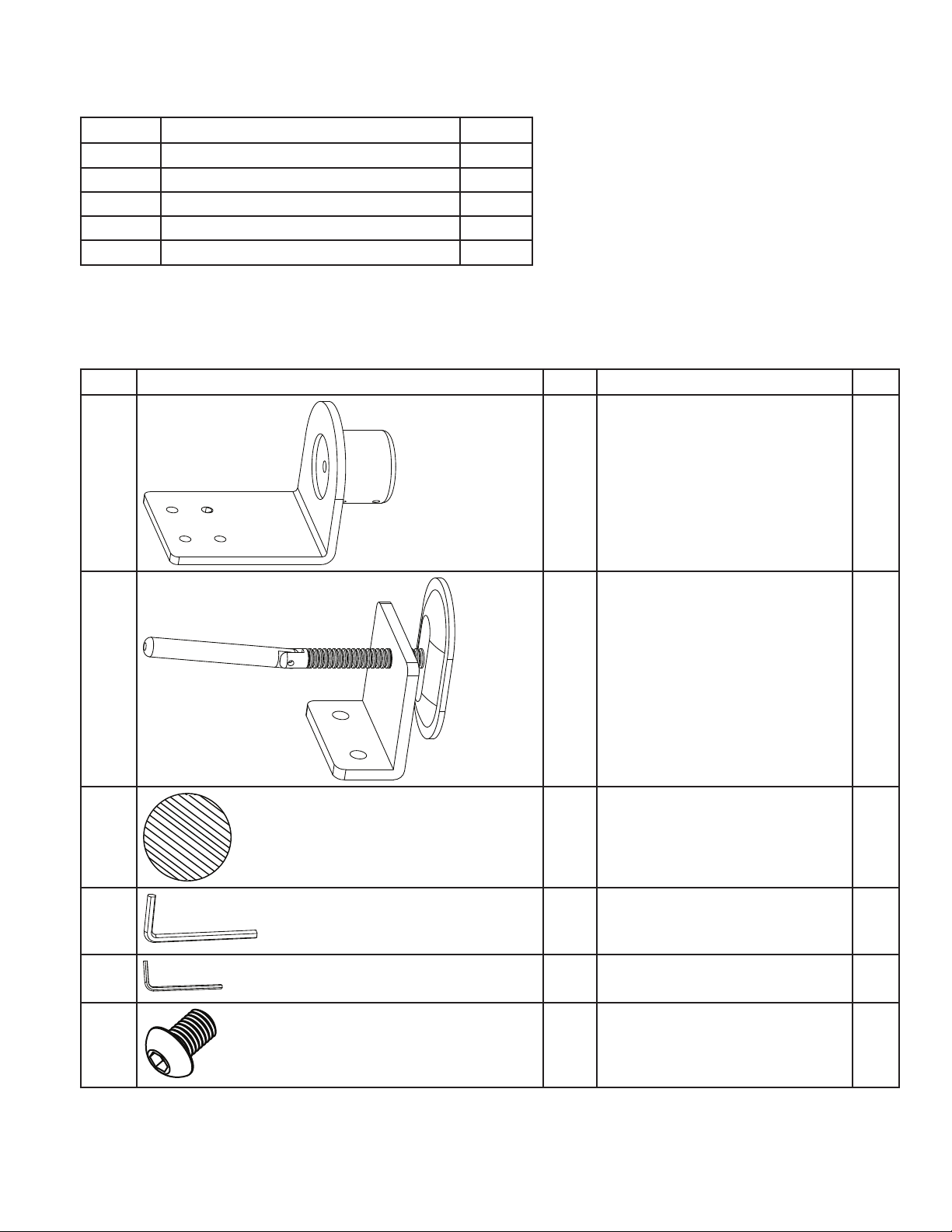

List of Parts

Part Illustration Box Description Qty

I-1 I Clamp Base 1

I-2 I Clamping bracket 1

I-3 I Base cushion 1

I-4 I M5 hex wrench 1

I-5 I M2.5 Hex Wrench 1

I-6 I Button head cap screw M8 X

1.25 X 15mm

2

Workrite Ergonomics, Inc 3

Page 4

SwingArm–Dual™ Installation Instructions

Part Illustration Box Description Qty

Ix-1 Ix Grommet Base 1

Ix-2 Ix U-Bracket 1

Ix-3 Ix M8 X 1.25 X 130mm Thread

Rod

Ix-4 Ix M8 Washer 1

Ix-5 Ix M8 X 1.25 Wing Nut 1

Ix-6 Ix Base cushion 1

Ix-7 Ix M5 hex wrench 1

Ix-8 Ix M2.5 Hex Wrench 1

II-1 II 14” Pole 1

II-2 II Cable manager Velcro® strips 2

1

III-1 III Dual Mount Clamp 1

III-2 III Plastic Spacer 30mm OD,

18.5 mm ID

III-3 III Pivot Pins 55mm 2

III-4 III Button-head Cap Threaded

Bolt M8 X 1.25 X 70mm

III-5 III Set Screws M5 X .8 X 10mm 2

III-6 III M8 Disc Spring Washer 23mm

OD, 8.2 mm ID

III-7 III Flat M8 Washer 16mm OD 2

4 Workrite Ergonomics, Inc

2

2

2

Page 5

SwingArm–Dual™ Installation Instructions

Part Illustration Box Description Qty

IV-1 IV Assembled arm 2*

IV-2 IV End Cap 2*

IV-3 IV Round-head screw M4 X 0.7 X

10mm

IV-4 IV Round-head screw M4 X 0.7 X

6mm

IV-5 IV 75mm Monitor plate 2*

* Quantities for Box IV parts show total from both boxes

8*

8*

Workrite reserves the right to make changes to its products without notice. No liability is assumed

for any misprinting or error in this publication. Copyright 2008. All rights reserved.

Workrite Ergonomics, Inc 5

Page 6

SwingArm–Dual™ Installation Instructions

A

D

C

B

D

A

B

C

Step 1: Attach Clamp Base to Work

Surface

(If you are using the grommet base, please skip to

Step 1x.)

Attach the base cushion (I-3) to the un-A:

derside of the base (I-1).

Attach 14” pole (II-1) to base, securely B:

tighten 4 set screws (already in place).

If there is not enough clearance to t the C:

assembled base between the back of the

work surface and the wall, place the clamp

base on the desk edge before attaching

the clamping bracket (I-2)

from below. Otherwise, attach the clamping bracket

with 2 button-head cap

screws (I-6) before placing

the base on the work surface.

Use the upper set of holes

on the bracket for work surfaces between ½” and 1¼”

thick, and use the lower set

for work surfaces between

1¼” and 2¼” thick.

Step 1x: Attach Grommet Base to Work

Surface

Remove the center hole from the base A:

cushion (Ix-6), then attach it to the underside of the base (Ix-1), aligning the hole

in the base with the hole in the protector.

Thread the M8 Thread Rod (Ix-3) into the

bottom of the base.

Attach 14” pole (II-1) to base, securely B:

tighten 4 set screws (already in place).

Place the base on the C:

work surface, centering it

over a bolting hole from

3/8” to 3” in diameter.

Position the U-Bracket D:

(Ix-2) and Small Washer (Ix-4) onto the M8

Thread Rod and secure

the bracket by tightening

the Wing Nut (Ix-5).

Proceed to step 2.E:

Tighten the clamping bracket D:

until it is rmly clamped to

the work surface.

Skip to step 2.E:

6 Workrite Ergonomics, Inc

Page 7

SwingArm–Dual™ Installation Instructions

Step 2: Attach Monitor Arms to Monitors

Place monitor carefully on a clean, at surface, face down.A:

Attach the monitor arm (IV-1) to the back of the monitor with four screws, using a Phillips-B:

head screwdriver (not included). Use the mounting screws provided by your monitor manufacturer if available. Otherwise, use the screws provided that best ts your monitor (IV-4 or

IV-5).

If the mounting area on your monitor is smaller than the 100mm VESA connecting plate

and is recessed, remove the plate and replace it with the smaller 75mm plate (IV-6). Then

attach the plate to the back of the monitor.

Repeat A & B for the second monitor.C:

Workrite Ergonomics, Inc 7

Page 8

SwingArm–Dual™ Installation Instructions

C

A

B

D

E

F

Step 3: Attach Pivot Base and Arms

Place the pivot pins (III-3) and the large plastic spacers (III-2) onto the dual mount clamp (III-1).A:

Place the dual mount clamp assembly onto the pole with the ratchet handle facing the back. Posi-B:

tion the mount so that the top of it is approximately 7” from the desk for a 15” monitor, 8” for a 17”

monitor or 9” for a 19” monitor. Tighten the dual mount using the ratcheting handle. Pull the handle

out to release and rotate to allow for additional turns to tighten.

Attach one assembled monitor arm to the dual mount clamp. Position the arm horizontally and test C:

the height range to be sure it is correct for your monitor. If not, remove the arm and move the dual

mount clamp accordingly. Then replace the arm. Attach the second arm to the dual mount clamp.

NOTE: Remove the monitor arms before adjusting the clamp height to avoid scratching

the nish of the pole

Secure the monitor arms by placing the small at washer (III-7) on the 70mm threaded bolt (III-4), D:

followed by the larger disc spring washer (III-6), with the concave side facing away from the bolt

head (down), and then placing the bolt with the washers into the hole on the end of the monitor

arm, tightening with the M5 hex wrench. Tighten to a light friction so that the arm can turn, but not

too loosely.

Install and tighten the set screws in the dual mount with the M2.5 hex wrench to lock the 70mm E:

bolts.

Press the end caps onto the ends of the monitor arms, covering the 70mm bolts.F:

8 Workrite Ergonomics, Inc

Page 9

SwingArm–Dual™ Installation Instructions

C

A

D

B

Adjustment screw

90°

A

Your SwingArm—Dual is now installed and it is

time for the nal adjustments. If your monitor is

too light or too heavy for the factory-set tension,

the arm will raise or lower too easily (or even on

its own). If this is the case, you need to adjust the

vertical movement.

Step 4: Vertical Movement Adjustment

Set the monitor arm at a 90° angle and lo-A:

cate the adjustment screw on the top of the

arm joint.

If the arm tends to rise, turn the adjustment B:

screw clockwise using the M5 hex wrench,

decreasing tension until the arm reaches a

stable, balanced adjustment.

If the arm tends to drop, turn the adjust-C:

ment screw counterclockwise using the M5

hex wrench, increasing tension until the arm

reaches a stable, balanced adjustment. With

too much tension on the arm, the arm will

tend to rise.

To prevent damage to the arm, remove the D:

hex wrench after adjustment.

Step 5: Ball-joint Adjustment for Tilt

Action

If the monitor is too tight or too loose A:

on the ball-joint, adjust the tension by

turning the four screws closest to the

ball one quarter turn each*, clockwise to tighten or counterclockwise to

loosen.

Repeat as necessary. B:

* It is important to turn them in very

small increments and turn each of the

four screws the same amount until

the desired tension is achieved.

Workrite Ergonomics, Inc 9

Page 10

SwingArm–Dual™ Installation Instructions

Strip

Strip

Step 6: Final Touches: Cable Management

Thread the monitor cable through the plastic A:

sleeve mounted on the lower side of the monitor arm, taking care to leave enough slack in

the cable for full monitor movement on both

sides of the sleeve.

Secure attached hook and loop strips around B:

monitor cables, again leaving enough slack at

both ends of the arm for full movement of the

arms.

Attach the monitor cables to the pole and C:

secure with the Velcro® straps, again leaving

enough slack between the extension arm and

the pole for full movement of the arm.

10 Workrite Ergonomics, Inc

Loading...

Loading...