Page 1

Sonoma Series™ — Electric Height Adjustable Workcenters

Sonoma Series™ PREMIUM

Assembly Instructions

for 2 and 3 leg Tables

1450 Technology Lane • Petaluma, CA 94954 • 800-959-9675 • www.workriteergo.com Page 1

1500068 • Rev. C

Page 2

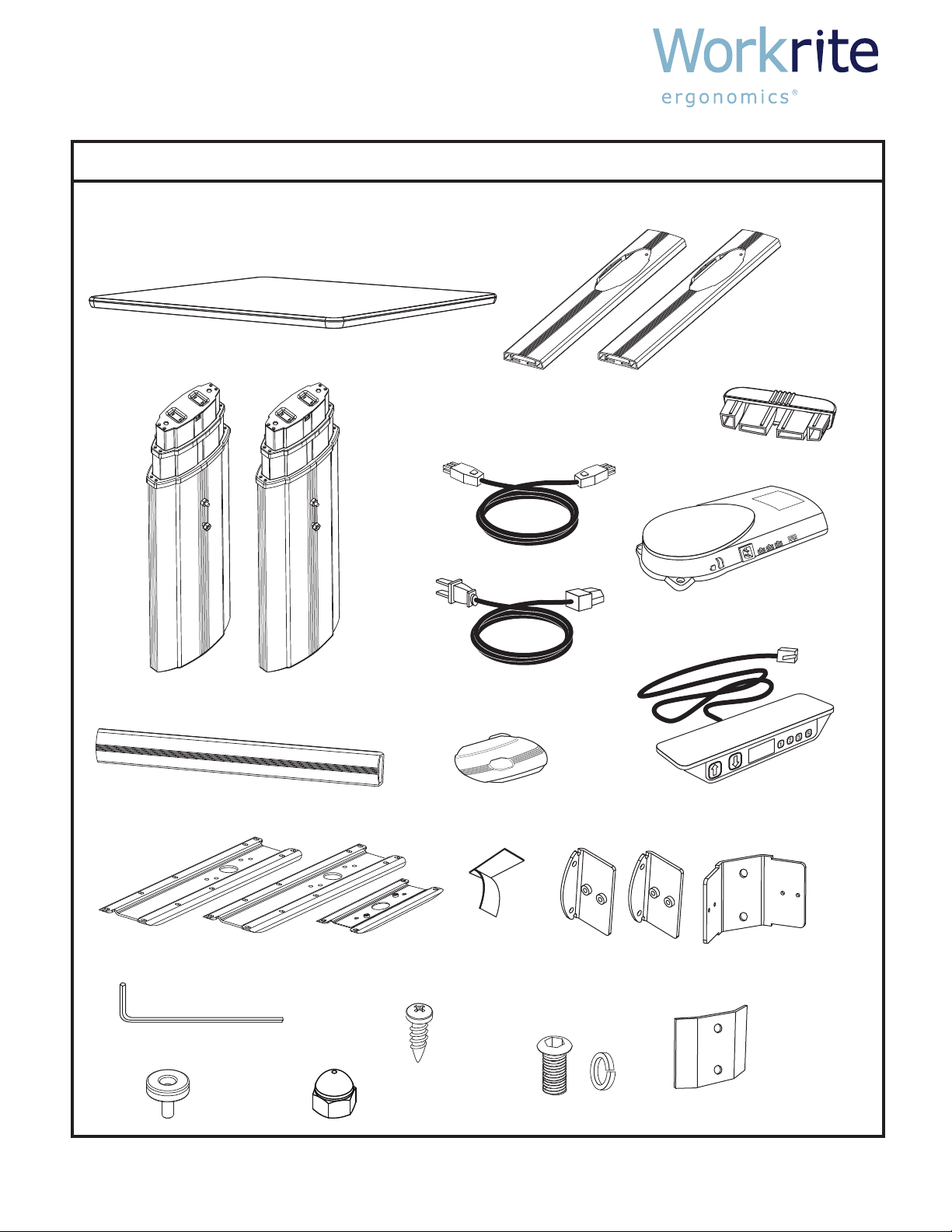

Sonoma Series™ PREMIUM Workcenters

PARTS LISTING

Top (size and shape dier for each model)

If Workrite is not supplying the top, it is installer’s

responsibility to position the base under the worksurface

to provide maximum stability.

Leg Assemblies (2 or 3)

Top Brackets (2 or 3)

Foot caps (4 or 6)

Control Box

Control Panel with

2 attachment screws

Cables (2 or 3)

Power Cord

Crossbar (1 or 2)

Crossbar Brackets (2 or 3)

Crossbar Bracket for

center leg if a three

leg table

Stiening Brackets (2)

For two leg tables

only

Leveling Glides (4 or 6)

Feet (2 or 3)

5/32” Allen Wrench

3/4” Button Head

machine screws (12 or 20)

and lock washers (12 or 20)

Wood screws (24 or 28)

Top Bracket for center

leg if a three leg table

Velro Cable Strap

(1 per leg)

Cable Spool &

#8 x1” wood screw

(1 per leg)

NOTE: The quantities listed vary depending

on whether it is a two or three leg table

Nuts and

lock washers

are already

threaded

onto studs

Acorn Nuts (2)

For three leg tables only

1450 Technology Lane • Petaluma, CA 94954 • 800-959-9675 • www.workriteergo.com Page 2

1500068 • Rev. C

Page 3

Sonoma Series™ PREMIUM Workcenters

ASSEMBLY INSTRUCTIONS

Remove and discard Phillips

head transit screws from

sheet metal plates at both

ends of leg assembly.

Attach Top Bracket to

smallest end of each

leg assembly using

3/4” button head

machine screws.

This end is up and

attaches to the underside

of the worksurface.

Note: if table has three

legs, the center leg uses

the short Top Bracket.

Remove nuts and

lock washers from leg

studs. If 2-leg table, Slide

Stiffening Bracket onto

studs, slide Crossbar Bracket

onto studs and reinstall nuts

(no lock washers). Note how

the flange orients to the leg.

Note: if table has three

legs, the center leg uses

the double flange Crossbar

Bracket. The two Acorn nuts

should be used with this bracket.

Insert Foot Caps into

ends of foot. Screw in

Leveling Glides. Slide foot

onto Leg Assembly and

attach with button head

machine screws. Note that

the longest end of the foot

extends to the front

edge of the worksurface.

STEP 1

STEP 3

STEP 2

Place assembled legs onto the underside of the

worksurface in their approximate location. Note

that mounting holes have been pre-drilled to match

the top bracket.

STEP 4

OPEN ALL PACKAGES AND VERIFY THAT YOU HAVE ALL THE HARDWARE AS INDICATED IN THE PARTS LISTING.

To assemble you will need a #3 tip Philips screwdriver and a 7/16" wrench or socket.

Note: if table has three

legs, the center leg uses

the short Foot.

Left Leg

Right Leg

Front

Front

Front

Stiffening Bracket

(2-Leg tables only)

1450 Technology Lane • Petaluma, CA 94954 • 800-959-9675 • www.workriteergo.com Page 3

1500068 • Rev. C

Page 4

Sonoma Series™ PREMIUM Workcenters

ASSEMBLY INSTRUCTIONS

Slide Crossbar onto Crossbar Brackets and attach

with two machine screws to each bracket.

Attach Top Brackets to underside of the worksurface.

Note: do not fully tighten screws. Screw cable

spools to underside of worksurface. Note that the

attachment locations are marked with labels.

Attach Control Box and Control Panel to the underside of the

worksurface. Mounting holes are provided. Plug leg cables into

control box. NOTE: There are three 6-pin female connectors

on the control box. On a 2-leg table, connect the leg cables

to the middle and furthest to the right connectors from the

power cable. To insure that cables t tight to the underside of

worksurface, wrap excess cable length around spools as required.

Plug leg cables into plugs extending from

legs. Wrap Control panel cable

around spool as required and plug

into Control Box. Use velcro

straps to take up remaining

slack in cables.

If you are assembling a three leg table, note that

the middle leg is oriented at a 45˚ angle. The side

with the double ange Crossbar Bracket faces the

front edge of the table.

STEP 5

STEP 6 STEP 7

3 LEG

Control Box uses 3/4”

screws for attachment

Control Panel uses #8 x

5/8”

screws for attachment

1450 Technology Lane • Petaluma, CA 94954 • 800-959-9675 • www.workriteergo.com Page 4

1500068 • Rev. C

Page 5

Sonoma Series™ PREMIUM Workcenters

ASSEMBLY INSTRUCTIONS

Flip table over and adjust leveling glides so that the

table does not wobble. Run table up and down one

time and then tighten all top bracket screws.

STEP 8 STEP 9

It may be necessary to adjust the display height

readout. The low height will vary depending on the

ooring surface and adjusted height of the leveling

glides. To obtain an accurate readout, lower the table to

its lowest position and measure from the oor to the top

of the worksurface.

Change the display by pressing and holding the

“S” button, hit the UP or DOWN button until the

display shows the correct height.

1450 Technology Lane • Petaluma, CA 94954 • 800-959-9675 • www.workriteergo.com Page 5

1500068 • Rev. C

Loading...

Loading...