Page 1

Workrite Sierra HXL™ Crank

Assembly Instructions

for 2-Leg Top Crank models

#1500196 - Rev A

Page 2

Workrite Sierra HXL™ 2-Leg Top Crank Workcenters - Assembly Instructions

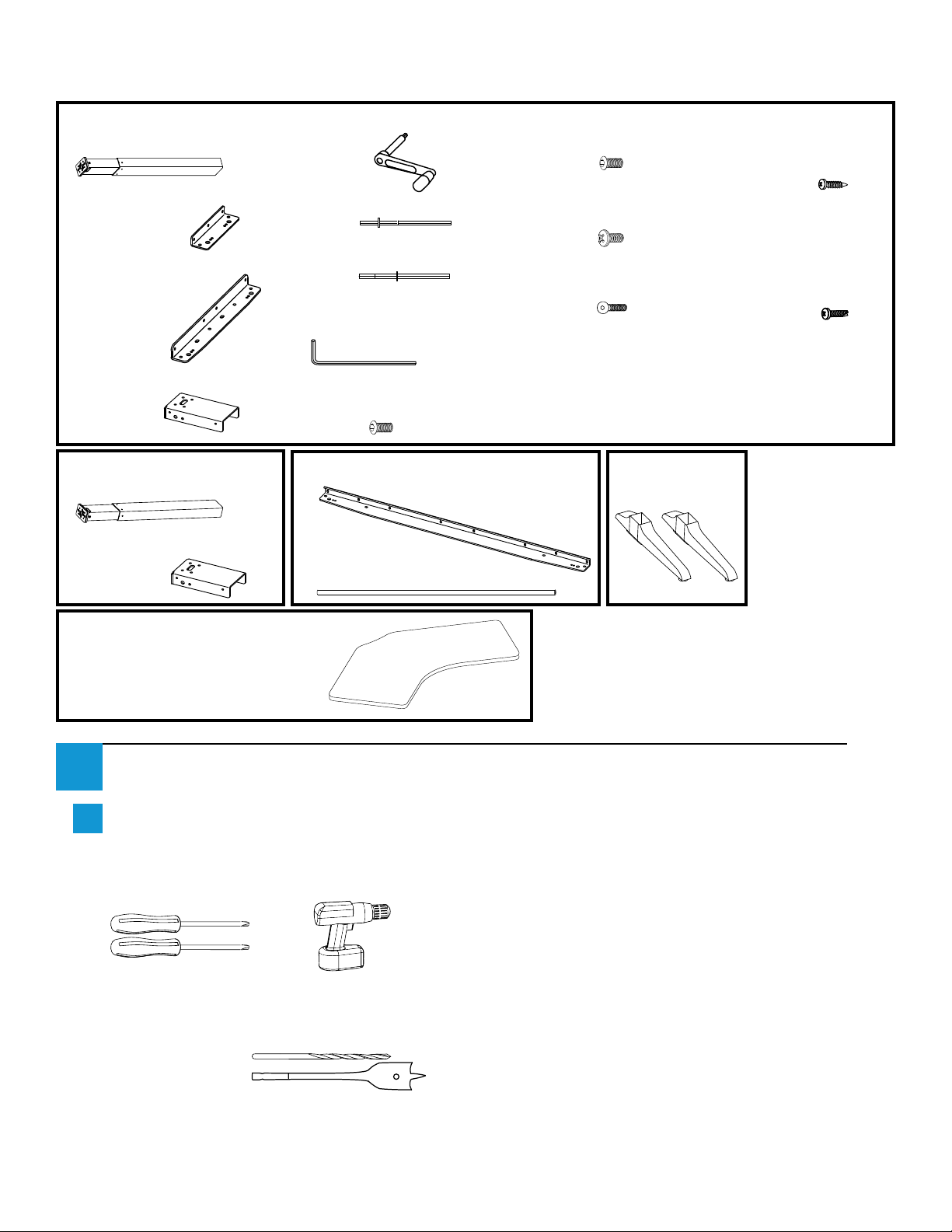

Parts grouped by carton

Leg

A

Qty: 1

Short Bracket

B

Qty: 2

Medium Bracket

C

Qty: 2

Top Leg Bracket

D

Qty: 1

Leg

N

Qty: 1

Top Leg Bracket

O

Qty: 1

Crank Top Handle

E

Qty: 1

Shallow Hex Shaft

F

Qty: 1

Deep Hex Shaft

G

Qty: 1

4 mm Allen Wrench

H

Qty: 1

M6 × 12 mm Button

I

Head Machine Screw

Qty: 8

Long Bracket

P

Qty: 1

Crank Tube

Q

Qty: 1

M6 × 8 mm Button

J

Head Machine Screw

Qty: 12

#12 × ½" Self Tapping

K

Phillips Head Screw

Qty: 1

M6 × 16 mm Flat

L

Head Machine Screw

Qty: 8

R

Feet

Qty: 2

#12 × ¾" Pan

M

Head Laminate

Top Screw

Qty: 32

OR

#10 - 24 × ½"

Self Tapping Pan

Head Silhouette

Top Screw

Qty: 36

Tabletop (size and shape differ

S

for each model)

Qty: 1

Verify that you have all the hardware and tools needed for the assembly

1

Check your cartons against the list above to verify that you have all the parts needed.

a

You will also need the following tools:

#2 tip Phillips screwdriver or drill bit

#3 tip Phillips screwdriver or drill bit

If you do not have a Workrite tabletop

you will also need:

⅛" pilot drill bit

¾" spade drill bit

or

¾

2 of 8 Workrite Ergonomics | 800.959.9675 www.workriteergo.com

Page 3

Workrite Sierra HXL™ 2-Leg Top Crank Workcenters - Assembly Instructions

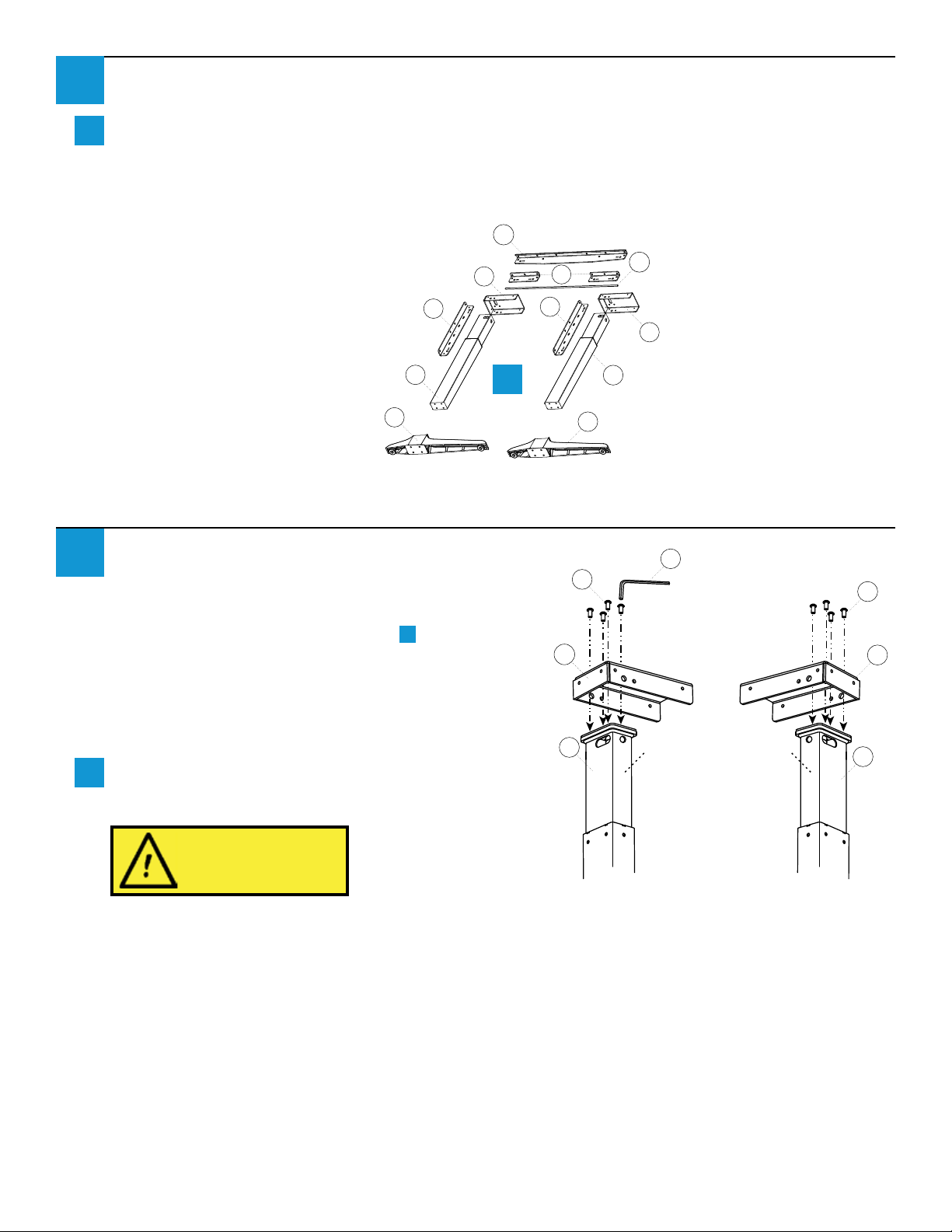

B

...continued

1

Placement of the legs is very important. Take the time now to lay out the Legs (A & N), Leg

b

Brackets (B, C, and P), Crank Tube (Q), and Top Leg Brackets (D & O) on the oor in the proper

location.

Note that the right leg will be on your left and vice versa when the assembly is seen from the back.

P

R

Right Leg

Attach Top Leg Bracket to Legs

2

If you have purchased the HX Spacer Accessory

Kit, refer to instructions provided with that

product. Otherwise, proceed to step a .

Note: Right and Left Legs are interchangeable.

These instructions assume you’ll use the leg from

the main carton as the Right Leg, and the leg

from the Second Leg carton as the Left Leg.

Attach one Top Leg Bracket (D or O) to the top

a

of each Leg (A or N) using M6 × 12 mm Button

Head Screws (I).

O

C

N

b

C

R

Q

D

A

Left Leg

H

I

O

N

Front Front

I

D

A

To avoid stripping the threads,

always insert and make the

rst few turns of the screw BY

HAND with an Allen wrench

(H), ensuring it is in straight.

Left Leg

Workrite Ergonomics | 800.959.9675 www.workriteergo.com 3 of 8

Right Leg

Page 4

Workrite Sierra HXL™ 2-Leg Top Crank Workcenters - Assembly Instructions

Attach Short and Medium Brackets to Leg Assembly

3

Attach both Short Brackets (B) using M6 × 8 mm Button Head Screws (J). Do not tighten screws

a

completely - allow them to slide left and right in Bracket.

Attach Medium Brackets (C) to sides of Legs using M6 × 8 mm Button Head Screws (H). If you

b

have a 24" deep or less worksurface, use the holes to the rear of the Bracket as shown. For deeper

worksurfaces, use the center holes of the Bracket as shown. Do not tighten screws completely -

allow them to slide left and right in Bracket.

J

J

24" deep

C

C

30" deep

b

J

Front

B

24" deep

C

Front

J

C

b

a

B

J

H

30" deep

J

Attach Long Bracket to Left Leg

4

With legs on their sides, attach

a

Long Bracket (P) to back of Left

Leg Cap using M6 × 8 mm Button

Head Screws (J). The Bracket

should have the lip on top, facing

away from the leg. Do not tighten

screws completely - allow them to

slide left and right in Bracket.

Right Leg

4 of 8 Workrite Ergonomics | 800.959.9675 www.workriteergo.com

Back

Back

Left Leg

H

J

P

Page 5

Workrite Sierra HXL™ 2-Leg Top Crank Workcenters - Assembly Instructions

Attach Legs to Hex Shafts and Crank Tube

5

Turn Leg Assembly upside down.

Right Leg: Insert short end of Deep Hex Shaft (G) into leg. Slide Crank Tube (Q) over Deep Hex

a

Shaft.

Left Leg: Insert short end of Shallow Hex Shaft (F) into leg. Slide Crank Tube (Q) over Shallow Hex

Shaft.

F

G

Q

Right Leg Left Leg

Q

Secure Long Bracket

6

Attach Long Bracket to back of right Leg Cap using M6 × 8 mm Button Head Screws (J). Do not

a

tighten screws completely - allow them to slide left and right in Bracket.

Right Leg

J

H

Attach Feet to Leg Assembly

7

L

Attach Foot (R) to left leg with M6 ×16 mm Flat Head

a

Machine Screws screws (L) and tighten securely. Repeat

for right foot.

Workrite Ergonomics | 800.959.9675 www.workriteergo.com 5 of 8

R

Page 6

Workrite Sierra HXL™ 2-Leg Top Crank Workcenters - Assembly Instructions

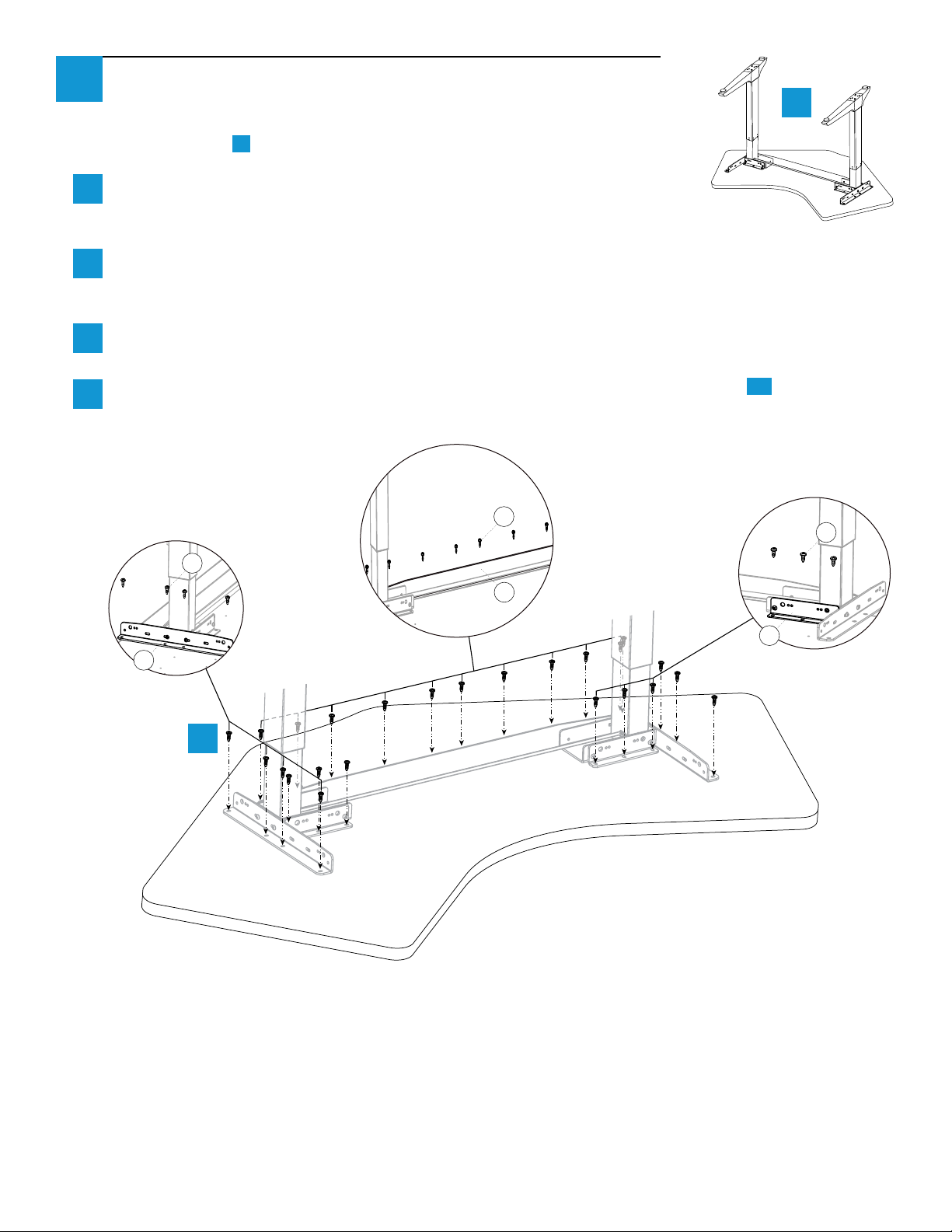

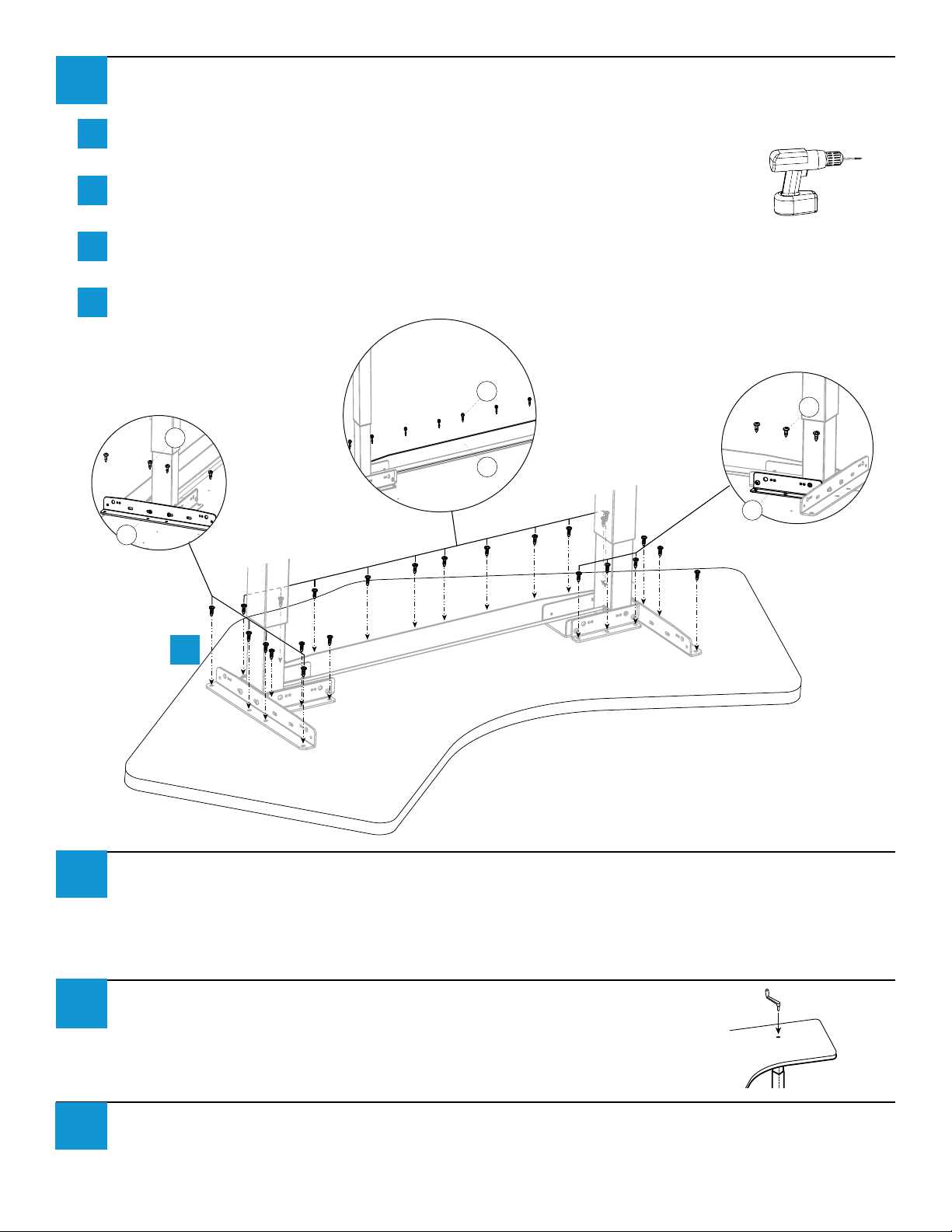

8

Attach Base to Workrite Tabletops

Right Leg

If you have a Base Only Model being attached to a non-Workrite table

top, go to step 9 .

Placement of the legs is very important. Lay out the leg assembly in

a

the proper location. Note that the Right Leg will be on your left and

vice versa when the assembly is upside down.

Align Base to the pre-drilled holes in top. Install #12 × ¾" Pan Head Wood Screws (M) into the

b

Short Brackets (B), Medium Brackets (C) , and Long Bracket (P). DO NOT FULLY TIGHTEN

SCREWS!

Tighten all of the M6 × 8 mm Button Head Screws (J) that were installed in steps 3 & 4 on the base

c

to the brackets.

Now tighten all of the #12 × ¾" Pan Head Screws (M) into the top. Go to Step 11 .

d

6-10 screws

per Long Bracket

4 screws per

Medium Bracket

M

a

3 screws per

Short Bracket

M

Left Leg

M

P

C

Right Leg

Left Leg

B

b

6 of 8 Workrite Ergonomics | 800.959.9675 www.workriteergo.com

Page 7

Workrite Sierra HXL™ 2-Leg Top Crank Workcenters - Assembly Instructions

Half the leg depth

Base-Only Models & Other Tabletops: Position and Drill Hole for Top Crank

9

Position the leg assembly on the face-down table top. Center the assembly on the table so that

a

neither of the side legs overlap the edge. Measure carefully to ensure that your table will be

positioned correctly as detailed below before drilling.

Mark ¾" hole for crank handle: Trace around outside of leg bracket before removing leg assembly.

Measure from front left corner of leg bracket as shown, then mark hole placement. The hole should

be directly under the center of the leg.

Use the ⅛" drill bit to drill from the bottom of the worksurface completely through the

b

worksurface. DO NOT USE ¾" bit. Drill from bottom to avoid damaging top surface.

a

Center of leg

1⅜"

Trace

Half the leg width

Turn the worksurface over to the top nish

c

side and use the ¾" spade drill bit to nish

drilling the hole from the top down, to ¾"

diameter, using the ⅛" hole as a guide.

1⅞"

Trace

b

1⅞"

1⅜"

Top of

worksurface

¾

c

Flip table back and reposition leg assembly.

d

Drill pilot holes and insert screws for two

positioning holes rst being sure to center the

leg over the crank handle hole. TAKE EXTRA

CARE TO NOT DRILL THROUGH TOP!

Use the other screw holes to mark the

location of the remaining holes for each leg.

Workrite Ergonomics | 800.959.9675 www.workriteergo.com 7 of 8

d

Bottom of

worksurface

Page 8

10

a

b

c

d

Base-Only Models & Other Tabletops (continued): Attach Base

Drill 1⁄8" × ¾" deep pilot holes through all of the bracket holes. TAKE EXTRA CARE TO NOT DRILL

THROUGH TOP!

Install #12 × ¾" Phillips Head Wood Screws (M) into the Short Brackets (B) ,

Medium Brackets (C), and Long Bracket (P). DO NOT FULLY TIGHTEN SCREWS!

Tighten all of the M6 × 8 mm Button Head Screws (J) that were installed in steps 3 & 4 on the base

to the brackets.

Now tighten all of the #12 × ¾" Pan Pan Head Screws (M) into the top.

4 screws per

Medium Bracket

M

C

b

Right Leg

6-10 screws

per Long Bracket

M

P

3 screws per

Short Bracket

M

Left Leg

B

11

12

13

Conrm All Screws are Tightened and Flip Table Over

Tighten all screws in frame assembly and tighten all screws connecting frame to worksurface. Flip

table over.

Install Crank Handle

Insert Crank Handle into hole in worksurface over the right leg so that

it engages the gearbox. Turn Handle to raise or lower table.

Adjust Leveling Guides

If necessary, adjust leveling guides on table feet to level the worksurface.

Loading...

Loading...