WorkPro WTS 905/DY, WTS 1206/DY, WTS 375/DY, WTS 506/DY, WTS 708/DY Operating Instructions

...

1

USER MANUAL FOR WTS TOWERS

IMPORTANT

Carefully read and understand all points and

aspects of this manual. Lifting loads irresponsibly

can cause lethal accidents. Installation of lifting

systems and proper use are only responsibility of

the user.

It is recommended to attach this manual with the

tower system used.

In case of doubt, consult the technical

department of Work Lifters.

CONTENT

IMPORTANT ............................................................... 1

CONTACT ................................................................... 1

ILLUSTRATION INDEX ................................................ 1

WARNING ICONS ....................................................... 3

ADDITIONAL DOCUMENTS ........................................ 3

RULES AND SAFETY USE ............................................ 4

PARTS IDENTIFICATION ........................................... 10

OPERATING MODES ................................................ 11

MECHANISM MODE ........................................ 11

STRUCTURAL MODE ....................................... 11

HOW TO USE STEP BY STEP ..................................... 12

LINE ARRAY ELEVATION IN MECHANISM MODE...... 12

LINE ARRAY ELEVATION IN STRUCTURE MODE ....... 16

TRUSS SYSTEM ELEVATION IN MECHANISM MODE 21

TRUSS SYSTEM ELEVATION IN STRUCTURE MODE .. 25

USING THE TOWER IN STRUCTURE MODE (WIND

CONDITION) ............................................................. 29

STANDARDS TAKEN INTO ACCOUNT ...................... 30

PLACING THE LOAD ................................................. 31

LOAD CHART ............................................................ 32

GROUND COMPACTION DEGREE ............................ 33

DYNSYS SYSTEM ...................................................... 34

DYNAMIC OVERLAP ................................................. 37

TRANSPORT ............................................................. 38

WITH FORKLIFT ........................................................ 38

WITH TRUCK OR CONTAINER .............................. 39

DGUV V17/18 NORM REGULATION.

Explanation ..................................................... 40

SPECIFICATIONS ...................................................... 41

DECLARATION OF CONFORMITY............................. 42

DGUV MARK ............................................................ 43

CONTACT

Website: www.worklifters.com

E-mail: support@equipson.es

ILLUSTRATION INDEX

Figure 1 ...................................................................... 4

Figure 2 ...................................................................... 4

Figure 3 ...................................................................... 4

Figure 4 ...................................................................... 4

Figure 5 ...................................................................... 5

Figure 6 ...................................................................... 5

Figure 7 ...................................................................... 5

Figure 8 ...................................................................... 5

Figure 9 ...................................................................... 6

Figure 10 .................................................................... 6

Figure 11 .................................................................... 6

Figure 12 .................................................................... 6

Figure 13 .................................................................... 7

Figure 14 .................................................................... 7

Figure 15 .................................................................... 7

Figure 16 .................................................................... 7

Figure 17 .................................................................... 8

Figure 18 .................................................................... 8

Figure 19 .................................................................... 8

Figure 20 .................................................................... 8

Figure 21 .................................................................... 9

Figure 22 .................................................................... 9

Figure 23 .................................................................... 9

Figure 24. ................................................................. 10

Figure 25 .................................................................. 11

Figure 26 .................................................................. 11

Figure 27 .................................................................. 12

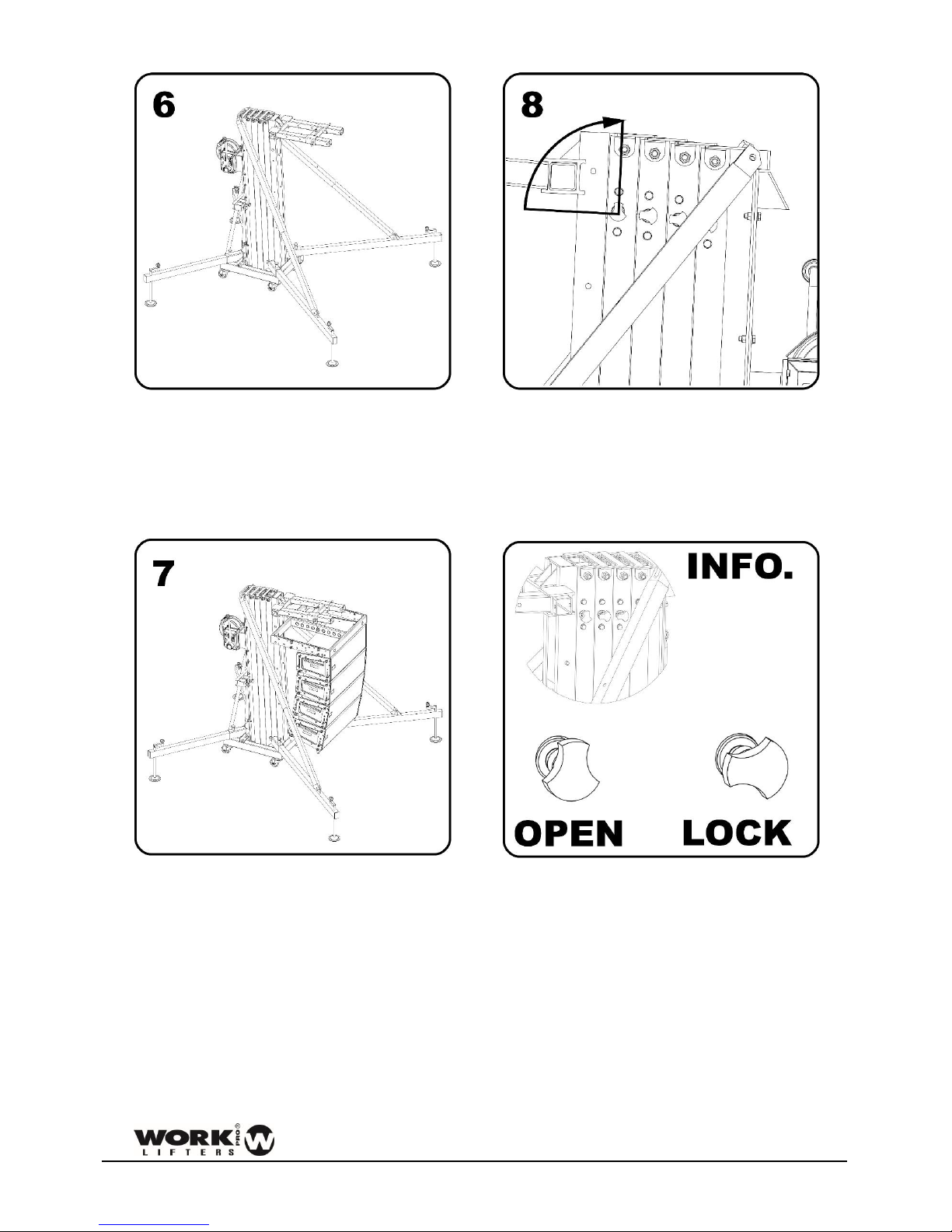

Figure 28 .................................................................. 12

Figure 29 .................................................................. 12

Figure 30 .................................................................. 12

Figure 31 .................................................................. 12

Figure 32 .................................................................. 13

Figure 33 .................................................................. 13

Figure 34 .................................................................. 13

Figure 35 .................................................................. 13

Figure 36 .................................................................. 14

EN

2

USER MANUAL FOR WTS TOWERS

Figure 37 .................................................................. 14

Figure 38 .................................................................. 14

Figure 39 .................................................................. 14

Figure 40 .................................................................. 15

Figure 41 .................................................................. 15

Figure 42 .................................................................. 15

Figure 43 .................................................................. 16

Figure 44 .................................................................. 16

Figure 45 .................................................................. 16

Figure 46 .................................................................. 16

Figure 47 .................................................................. 16

Figure 48 .................................................................. 17

Figure 49 .................................................................. 17

Figure 50 .................................................................. 17

Figure 51 .................................................................. 17

Figure 52 .................................................................. 18

Figure 53 .................................................................. 18

Figure 54 .................................................................. 18

Figure 55 .................................................................. 18

Figure 56 .................................................................. 19

Figure 57 .................................................................. 19

Figure 58 .................................................................. 19

Figure 59 .................................................................. 19

Figure 60 .................................................................. 20

Figure 61 .................................................................. 20

Figure 62 .................................................................. 21

Figure 63 .................................................................. 21

Figure 64 .................................................................. 21

Figure 65 .................................................................. 21

Figure 66 .................................................................. 21

Figure 67 .................................................................. 22

Figure 68 .................................................................. 22

Figure 69 .................................................................. 22

Figure 70 .................................................................. 22

Figure 71 .................................................................. 23

Figure 72 .................................................................. 23

Figure 73 .................................................................. 23

Figure 74 .................................................................. 23

Figure 75 .................................................................. 24

Figure 76 .................................................................. 24

Figure 77 .................................................................. 24

Figure 78 .................................................................. 25

Figure 79 .................................................................. 25

Figure 80 .................................................................. 25

Figure 81 .................................................................. 25

Figure 82 .................................................................. 25

Figure 83 .................................................................. 26

Figure 84 .................................................................. 26

Figure 85 .................................................................. 26

Figure 86 .................................................................. 26

Figure 87 .................................................................. 27

Figure 88 .................................................................. 27

Figure 89 .................................................................. 27

Figure 90 .................................................................. 27

Figure 91 .................................................................. 28

Figure 92 .................................................................. 28

Figure 93 .................................................................. 28

Figure 94 .................................................................. 28

Figure 95 .................................................................. 29

Figure 96 .................................................................. 29

Figure 97 .................................................................. 30

Figure 98 .................................................................. 31

Figure 99 .................................................................. 31

Figure 100 ................................................................ 32

Figure 101 ................................................................ 33

Figure 102 ................................................................ 33

Figure 103 ................................................................ 34

Figure 104 ................................................................ 35

Figure 105 ................................................................ 35

Figure 106 ................................................................ 36

Figure 107 ................................................................ 37

Figure 108 ................................................................ 38

Figure 109 ................................................................ 39

Figure 110 ................................................................ 41

3

USER MANUAL FOR WTS TOWERS

WARNING ICONS

ADDITIONAL DOCUMENTS

Follow this link to download the maintenance

user manual for WTS series.

WTS_Series_MAINTENANCE

Or visit www.worklifters.com

4

USER MANUAL FOR WTS TOWERS

RULES AND SAFETY USE

Figure 1

Keep hands and fingers away from moving parts

of the tower.

Figure 2

Not charge the tower without the stabilizer legs.

Figure 3

Do not lift the tower without proper leveling. To

lift a load, the tower must always be stabilized.

The wheels must not touch the ground.

Figure 4

Place the tower on a stable surface.

If the ground has a low degree of compaction

(earth, gravel, etc..) consult the section of load

data.

5

USER MANUAL FOR WTS TOWERS

Figure 5

Do not use the tower on inclined surfaces that

require pieces to level the tower.

Figure 6

Mount the longest stabilizer legs in the part of

the horns. Safety pins must lock the stabilizers.

Figure 7

Lift the mast in the correct order.

Lift the mast of the tower starting always with

the carriage. The last mast lifted must be the next

to the section where the winch is placed.

Figure 8

Before placing a load, make sure that the load

never exceeds the maximum allowed. Consult

the section of load data.

6

USER MANUAL FOR WTS TOWERS

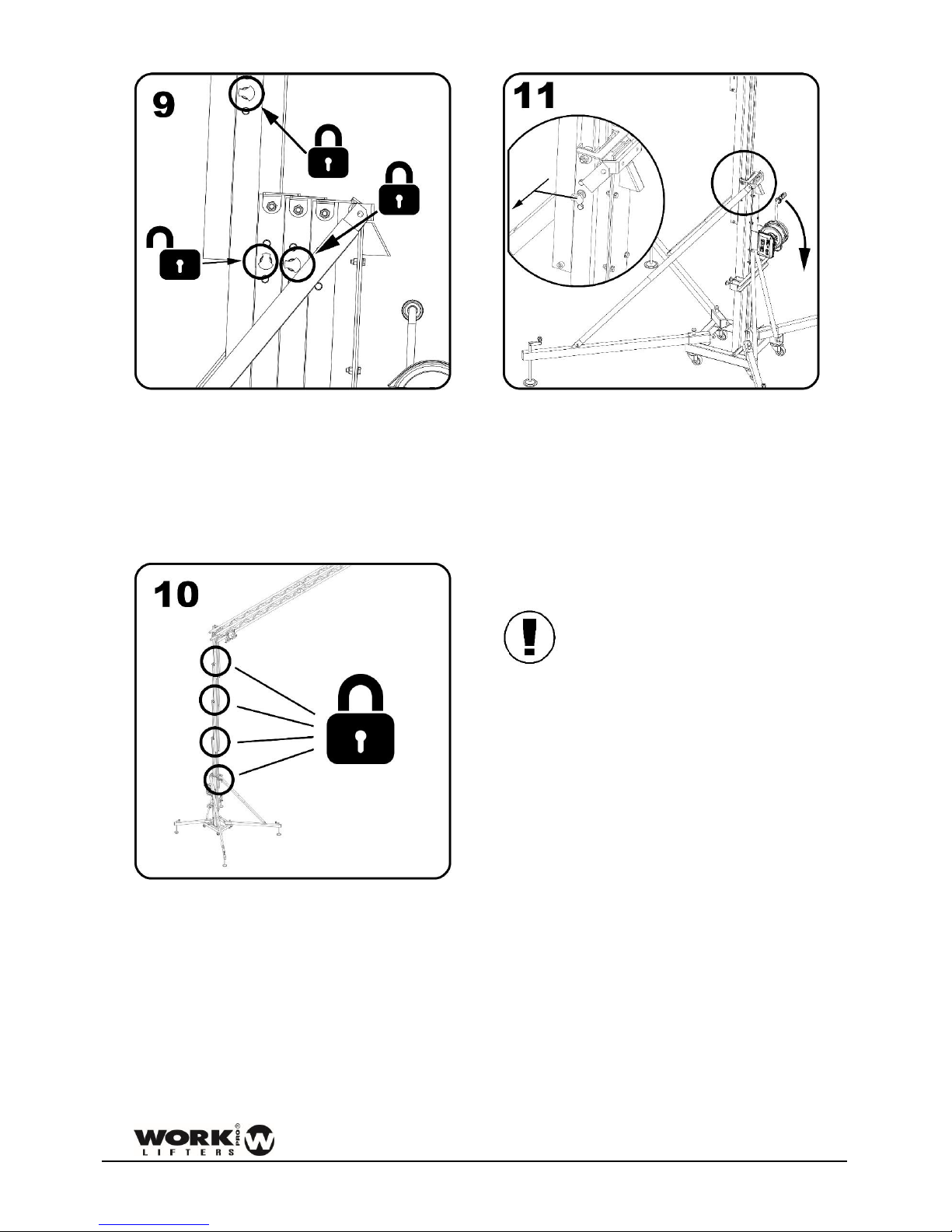

Figure 9

Never move a load without leveling the tower

before.

Figure 10

Do not use ladders on the tower or leaning

against it.

Figure 11

Not grease or lubricate the mechanism of the

winch and the pulleys of the masts.

Figure 12

Not allowed to lift people or animals.

7

USER MANUAL FOR WTS TOWERS

Figure 13

Do not stand under the load. The load must be

secured to the tower in order to prevent that it

cannot fall down.

Figure 14

Verify that the tower is beyond the reach of

power lines.

The tower is not electrically insulated and can

transmit currents of power lines.

On the following table is recommended the

average length between the highest part of the

structure and the power lines.

Voltage

Min. distance

Between phases

Meters

Feet

0 a 230v

1.5

4.92

230v a 400v

2.8

9.19

400v a 50Kv

3.4

11.15

50Kv a 200Kv

4.9

16.08

200Kv a 350Kv

6.5

21.33

350Kv a 500Kv

8.2

26.90

500Kv a 750Kv

11.3

37.07

750Kv a 1000Kv

14.2

46.59

Figure 15

Not use the tower as welding mass.

Figure 16

Not lift a load if there is danger of collision. Take

at least 1.5 meters on any direction to lift the

load safely.

8

USER MANUAL FOR WTS TOWERS

Figure 17

The tower can be used outdoor, only in

structural mode but with the loads

corresponding to mechanism mode (for security

purposes), if the wind speed is low and if it

doesn’t put the installation at risk. The

installation is always under the responsibility of

the owner.

Figure 18

Do not use the tower as a support of banners or

another type of decoration with strong wind that

can destabilize the tower and make it falls.

Figure 19

Prevent that the load do not touch the tower

Figure 20

Do not lift structures that require more than

one tower at different speeds

V1 ≠ V2

No lift

V1 = V2

Ok

9

USER MANUAL FOR WTS TOWERS

Figure 21

The structure must be levelled correctly. If not,

the structure can fall.

Always h1 = h2

Figure 22

Under no circumstances should the tower be

descended if the cable does not have sufficient

tense. The cable should ALWAYS be tensioned in

order to release the safety systems.

Figure 23

Never use structural loads in mechanism mode.

It can result in a dangerous use and can break

internal parts of the tower.

10

USER MANUAL FOR WTS TOWERS

PARTS IDENTIFICATION

Figure 24.

1

Support stabilizer legs carrier

11

Steel carrier

2

Steel cable

12

Base wheel

3

Top boost reinforcement

13

Pin horn

4

Red knob mast security system

14

Frontal leg

5

Strut reinforcement mast support

15

Steel carrier

6

Winch

16

Leveler screw

7

Tower mast

17

Leveler brace

8

Steel reinforcement strut

18

Leveler knob

9

Red knob base security system

19

Forks

10

Tower base

20

Leg carrier knob

11

USER MANUAL FOR WTS TOWERS

OPERATING MODES

MECHANISM MODE

This mode involves lifting the load with the help of the winch. That is, the load is placed in the tower once

leveled and placed with all its masts in transport position. Then, the load is raised by using the included

hand winch.

Figure 25

STRUCTURAL MODE

This mode involves lifting the load with the help of a manual or electric hoist. That is, the tower is used as

a structure that is all locked to the required working height. Once the tower is raised to this desired height,

the load must be raised with the hoist.

Figure 26

12

USER MANUAL FOR WTS TOWERS

HOW TO USE STEP BY STEP

LINE ARRAY ELEVATION IN

MECHANISM MODE

Figure 27

Fix and secure the stabilizer legs to the base.

Figure 28

Turn the forks and adjust to the desired width.

Ensure it with the pins.

Figure 29

WTS towers have the option of changing the

position of the carriage. Therefore, depending on

the use, the load can be raised from different

heights. The carriage can be rotated to obtain the

required height.

WTS A B C D E 256

435

695

1105

1315

1505

375

435

695

1105

1315

1505

Dimensions in mm.

Figure 30

WTS A B C D E 256

17,13

27,36

43,5

51,77

59,25

375

17,13

27,36

43,5

51,77

59,25

Dimensions in inches.

Figure 31

13

USER MANUAL FOR WTS TOWERS

Figure 32

Place the reinforcement bars and fix them with

its pins to the frontal legs.

Figure 33

Place the tower in its working position and level

until the bubble level is centered. Wheels should

not get in contact with the ground.

Calculate the load to be lifted with the tower.

An example of basic load calculation is attached.

ITEM

WEIGHT

(kg)

QUANTITY

TOTAL

(kg)

Line array

accessory

5,5 1 5,5

Bumper

35 1 35

Loudspeakers

28 4 112

Cables

20 1 20 172,5

Figure 34

In this example we have obtained a weight of

172,5 kg.

With that load, see what position the load should

have on the forks of the tower. Take into account

that the inclination of the loudspeakers and the

bumper should not lean against any part of the

tower.

Figure 35

Choose the WTS tower model. Check for the

value immediately above the load you need.

With this value, take the farthest position to

which the accessory for flying must be placed. It

is recommended that this position is always as

close to the carriage as possible.

14

USER MANUAL FOR WTS TOWERS

Figure 36

Place the accessory in the calculated position.

Block it making sure that the screws are inserted

into the hole of the fork position.

Figure 37

Join the line array equipment to the tower.

Figure 38

Unlock the mast safety system. Operate the

winch handle to raise the load.

Figure 39

15

USER MANUAL FOR WTS TOWERS

Figure 40

When the section reaches its limit, lock with the

security system and unlock the following security

system to lift the next mast. Do the same

operation until you reach the required height.

Figure 41

All security systems must be in locked position.

Slack the cable of the winch so that the system

can stabilize correctly.

Figure 42

To descend the load: Tense the cable and unlock

the first security system. Turn the winch while

keeping the safety system unlocked with your

other hand. If the safety system is not operated

with one hand, the tower will lower until it is

locked.

WARNING! If the tower is attempted

to go down without tension in the

cable and any of the safety systems are

activated, a dangerous situation will occur

because the load will descend very abruptly,

being able to destabilize the whole installation

and incurring in a serious accident.

Once the load is descended, block all sections

and follow steps 4 to 1 (in that order).

16

USER MANUAL FOR WTS TOWERS

LINE ARRAY ELEVATION IN

STRUCTURAL MODE

Figure 43

Fix and secure the stabilizer legs to the base.

Figure 44

Turn the forks and adjust to the desired width.

Ensure it with the pins.

Figure 45

WTS towers have the option of changing the

position of the carriage. Therefore, depending on

the use, the load can be raised from different

heights. The carriage can be rotated to obtain the

required height.

WTS A B C D E 256

435

695

1105

1315

1505

375

435

695

1105

1315

1505

Dimensions in mm.

Figure 46

WTS A B C D E 256

17,13

27,36

43,5

51,77

59,25

375

17,13

27,36

43,5

51,77

59,25

Dimensions in inches.

Figure 47

17

USER MANUAL FOR WTS TOWERS

Figure 48

Place the reinforcement bars and fix them with

its pins to the frontal legs.

Figure 49

Place the tower in its working position and level

until the bubble level is centered. Wheels should

not get in contact with the ground

Calculate the load to be lifted with the tower. An

example of basic load calculation is attached.

ITEM

WEIGHT

(kg)

QUANTITY

TOTAL

(kg)

Line array

accessory

5,5 1 5,5

Bumper

35 1 35

Loudspeakers

28 6 168

Cables

30 1 30 238,5

Figure 50

In this example we have obtained a weight of

238,5 kg.

With that load, see what position the load should

have on the forks of the tower. Take into account

that the inclination of the loudspeakers and the

bumper should not lean against any part of the

tower.

Figure 51

Choose the WTS tower model. Check for the

value immediately above the load you need.

With this value, take the exact position to which

the accessory for flying must be placed.

18

USER MANUAL FOR WTS TOWERS

Figure 52

Place the accessory in the calculated position.

Figure 53

Hung the hoist on the tower support. The hoist

must have a path equal to or greater than the

maximum height of the tower.

Figure 54

Unlock the mast safety system. Operate the

handle of the winch to raise the load.

Figure 55

19

USER MANUAL FOR WTS TOWERS

Figure 56

When the section reaches its end of path, lock

with the safety system and unlock the next safety

system to raise the next mast. Perform the same

operation until you reach the required height.

Figure 57

All security systems must be in locked position.

Slacken the cable of the winch so that the system

can stabilize correctly.

Figure 58

Raise the load with the hoist to the required

height.

Figure 59

Take into account the space of the hoist. This

dimension causes that the maximum height of

the tower to be reduced.

20

USER MANUAL FOR WTS TOWERS

Figure 60

To descend the load: Descend the load with the

hoist until it is just above the ground. The load

should never be descended with the tower

winch.

Figure 61

To descend the tower: Tense the cable and

unlock the first security system. Turn the winch

while keeping the safety system unlocked with

your other hand. If the safety system is not

operated with one hand, the tower will descend

until it is locked.

WARNING! If the tower is attempted

to go down without tension in the

cable and any of the safety systems

are activated, a dangerous situation will occur

because the load will descend very abruptly,

being able to destabilize the whole installation

and incurring in a serious accident.

Once the load is descended, block all sections

and follow steps 4 to 1 (in that order).

21

USER MANUAL FOR WTS TOWERS

TRUSS SYSTEM ELEVATION IN

MECHANISM MODE

Figure 62

Fix and secure the stabilizer legs to the base.

Figure 63

Turn the forks and adjust to the desired width.

Ensure it with the pins.

Figure 64

WTS towers have the option to change the

position of the carriage. Therefore, depending on

the use, the load can be raised from different

heights. The carriage can be rotated to obtain the

required height.

WTS A B C D E 256

435

695

1105

1315

1505

375

435

695

1105

1315

1505

Dimensions in mm.

Figure 65

WTS A B C D E 256

17,13

27,36

43,5

51,77

59,25

375

17,13

27,36

43,5

51,77

59,25

Dimensions in inches.

Figure 66

In case of using the tower in its positions A and

B: Raise the load until reaching the position C and

then follow steps from 3 onwards.

22

USER MANUAL FOR WTS TOWERS

Figure 67

Place the reinforcement bars and fix them with

its pins to frontal legs.

Figure 68

Place the tower in its working position and level

until the bubble level is centered. Wheels should

not get in contact with the ground

Calculate the load to be lifted with the tower. An

example of basic load calculation is attached.

ITEM

WEIGHT

(kg)

QUANTITY

TOTAL

(kg)

Truss

accessory

0,75 2 1,5

Complete

truss system

53,3

0,5

26,65

Loads

368

0,5

184

Cables

38

0,5

19 231,15

Figure 69

In this example we have a weight of 231,15 kg.

With that load, check what position the load

should have on the tower fork. Take into account

that the truss is supported by two points of the

fork. To find out which is the largest load, take

the farthest position from the base of the fork.

Figure 70

Choose the WTS tower model. Check for the

value immediately above the load you need.

With this value, take the exact position to which

the accessory for fixing the truss must be placed.

23

USER MANUAL FOR WTS TOWERS

Figure 71

Place the accessory in the calculated position.

Figure 72

Join the truss system to the tower.

Figure 73

Unlock the mast safety system. Operate the

winch handle to raise the load.

Figure 74

24

USER MANUAL FOR WTS TOWERS

Figure 75

When the section reaches its end of path, lock

with the safety system and unlock the next safety

system to raise the next mast. Perform the same

operation until you reach the required height.

Figure 76

All safety systems must be in their locked

position. Slack the cable from the winch so that

the system is seated.

WARNING! The rate of rise and descend should

be similar. If the structure rises or descends

faster at one end, a destabilization of the entire

facility can occur, causing a serious accident.

Figure 77

To descend the load: Tense the cable and unlock

the first security system. Turn the winch while

keeping the safety system unlocked with your

other hand. If the safety system is not operated

with one hand, the tower will descend until it is

locked.

WARNING! If the tower is attempted

to go down without tension in the

cable and any of the safety systems

are activated, a dangerous situation will occur

because the load will descend very abruptly,

being able to destabilize the whole installation

and incurring in a serious accident.

Once the load is descended, block all sections

and follow steps 4 to 1.

25

USER MANUAL FOR WTS TOWERS

TRUSS SYSTEM ELEVATION IN

STRUCTURAL MODE

Figure 78

Fix and secure the stabilizer legs to the base.

Figure 79

Turn the forks and adjust to the desired width.

Ensure it with the pins.

Figure 80

WTS towers have the option to change the

position of the carriage. Therefore, depending on

the use, the load can be raised from different

heights. The carriage can be rotated to obtain the

required height.

WTS A B C D E 256

435

695

1105

1315

1505

375

435

695

1105

1315

1505

Dimensions in mm.

Figure 81

WTS A B C D E 256

17,13

27,36

43,5

51,77

59,25

375

17,13

27,36

43,5

51,77

59,25

Dimensions in inches.

Figure 82

26

USER MANUAL FOR WTS TOWERS

Figure 83

Place the reinforcement bars and fix them with

its pins to the frontal legs.

Figure 84

Place the tower in its working position and level

until the bubble level is centered. Wheels

should not get in contact with the ground.

Calculate the load to be lifted with the tower. An

example of basic load calculation is attached.

ITEM

WEIGHT

(kg)

QUANTITY

TOTAL

(kg)

Truss

accessory

0,75 2 1,5

Complete

truss system

53,3

0,5

26,65

Loads

368

0,5

184

Cables

38

0,5

19 231,15

Figure 85

In this example we have a weight of 231.15 kg.

With that load, see what position the load should

have on the tower fork. Take in account that the

truss is supported by two points of the fork. To

find out which is the largest load, take the

position farthest from the base of the fork.

Figure 86

Choose the WTS tower model. Check for the

value immediately above the load you need.

With this value, take the exact position to which

the accessory for fixing the truss must be placed.

27

USER MANUAL FOR WTS TOWERS

Figure 87

Place the accessory in the calculated position.

Figure 88

Join the truss system to the tower.

Figure 89

Unlock the mast safety system. Operate the

winch handle to raise the load.

Figure 90

28

USER MANUAL FOR WTS TOWERS

Figure 91

When the section reaches its end of path, lock

with the safety system and unlock the next safety

system to raise the next mast. Perform the same

operation until you reach the required height.

Figure 92

Figure 93

All safety systems must be in their locked

position. Slack the cable from the winch so that

the system is seated.

WARNING! The rate of rise and

descend should be similar. If the

structure rises or descend faster at

one end, a destabilization of the entire facility

can occur, causing a serious accident.

Figure 94

To descend the load: Tense the cable and unlock

the first security system. Turn the winch while

keeping the safety system unlocked with your

other hand. If the safety system is not operated

29

USER MANUAL FOR WTS TOWERS

with one hand, the tower will descend until it is

locked.

Once the load is descended, block all sections

and follow steps 4 to 1 (in that order).

Figure 95

Figure 96

WARNING! If the tower is attempted

to go down without tension in the

cable and any of the safety systems

are activated, a dangerous situation will occur

because the load will descend very abruptly,

being able to destabilize the whole installation

and incurring in a serious accident.

USING THE TOWER IN

STRUCTURAL MODE (WIND

CONDITION)

The towers used in the structural mode form a

column type system that can withstand higher

loads than the mechanism mode.

In order to be able to use the towers outdoors

and subjected to bursts of wind, you should

contact an engineer in the area or our technical

department to study the case

In outdoor use many factors must be taken into

account, the most important are:

- Wind gusts

- Total exposed area

- Working height

- Angle of the braces

- Weights and distance to the tower

- Rigging of all joints

- Etc …

As an operating guide, the towers involved in this

manual can be used outdoors as long as they are

in structural mode and the maximum loads are

those of the mechanism mode.

This is because the loads transmitted by the

winds are transmitted vertically from the tower

to the ground, adding an overload that depends

on several factors. This overload is added to the

maximum load of the tower.

If it is not calculated in each specific case of use,

it is possible to take as base the data contained

in the load chart (figure 100) operating the

tower as mechanism for security purposes.

30

USER MANUAL FOR WTS TOWERS

STANDARDS TAKEN INTO ACCOUNT

Figure 97

31

USER MANUAL FOR WTS TOWERS

PLACING THE LOAD

1. Determine the position where the load will be placed and consult the tower capacity. Never

exceed it.

2. The “X” distance between the load is taken from the carriage to the end of the horns.

3. When possible, place the load as close to the carriage as possible. This prolongs the life of the

tower.

TOWER

X in P1

(mm / inch)

X in P2

(mm / inch)

X in P3

(mm / inch)

X in P4

(mm / inch)

X in P5

(mm / inch)

WTS 1206/DY

WTS 905/DY

WTS 708/DY

85

270

450

635

820

3.34

10.63

17.72

25

32.33

WTS 506/DY

100

260

425

580 3.93

10.23

16.73

22.83

WTS 375/DY

WTS 256/DY

95

225

355

485

3.74

8.85

13.97

19.1

Figure 98

Detail of the position of all points of load.

Figure 99

Detail of load positions.

32

USER MANUAL FOR WTS TOWERS

LOAD CHART

The maximum loads supported by each tower model, for its maximum working height, can be consulted

below:

USING THE TOWER AS MECHANISM.

The tower behaves like a machine when lifting a load making use of the winch as a lifting element. In this

case all the parts of the tower behave like a mechanism that uses pulleys, cables and guides to be able to

execute the elevation of a load at a certain height.

USING THE TOWER AS STRUCTURE.

The tower behaves like a structure when all the sections are blocked in such a way that the cable is without

tension. In this case the locking system together with the profiles, base and legs act as a support column

from which loads can be hung using some support elements such as manual or electric hoists.

WTS

UNIT

AS MECHANISM

AS STRUCTURE

P1

P2

P3

P4

P5

P1

P2

P3

P4

P5

905

lbs

992

970

926

895

1984

1653

1433

1336

kg

450

440

420

406 900

750

650

606

1206

lbs

1213

1168

1146

1124

1080

2646

2425

2094

1808

1543

kg

550

530

520

510

490

1200

1100

950

820

700

708

lbs

992

970

948

926

882

1543

1367

1213

1047

882

kg

450

440

430

420

400

700

620

550

475

400

506

lbs

1124

882

772

661

1124

882

772

661

kg

510

400

350

300 510

400

350

300

256

lbs

551

482

419

353 573

482

419

353

kg

250

220

190

160 260

220

190

160

375

lbs

772

639

529

507 838

705

573

507

kg

350

290

240

230 380

320

260

230

Figure 100

33

USER MANUAL FOR WTS TOWERS

GROUND COMPACTION DEGREE

Surfaces such as hard ground or gravel can vary in strength depending on the relative humidity. This

relative humidity varies throughout the day, so the resistance of the ground to absorb the stress of the

tower loaded also varies. Positioning a tower in these conditions can result in the ground falling under the

tower supports, being able to cause a serious accident.

Figure 101

Detail of plates place. Support must be centered with respect to the plate.

To avoid this, it is advisable to put bases in the support, to facilitate uniform distribution on the ground,

expanding the contact surface of each support. The following table lists the minimum area of these

surfaces.

WTS TOWER

MODEL

Side length of the plate in meters, and kg/m2 that can

support the ground.

150 kg/m2

250 kg/m2

350 kg/m2

WTS 905/DY

1,4 1 0,9

WTS 1206/DY

1,5

1,2

1

WTS 708/DY

1,3 1 0,8

WTS 506/DY

1,1

0,8

0,7

WTS 256/DY

0,8

0,6

0,5

WTS 375/DY

0,9

0,7

0,6

Figure 102

34

USER MANUAL FOR WTS TOWERS

DYNSYS SYSTEM

The lifters that incorporate the DYNSYS system are named as WTS xxx DY:

- WTS 256 DY - WTS 375 DY - WTS 506 DY - WTS 905 DY - WTS 708 DY - WTS 1206 DY

EXPLANATION

DYNSYS system is a solution for the control of the maximum load in lifting systems.

DYNSYS limits the maximum load of the tower avoiding raising a higher load than the specified when the

tower is used as mechanism. For more information about the maximum load, consult the load chart.

In case of raising a load higher than the maximum, DYNSYS detects the increase in load and prevents it

from being raised, allowing only the descent of the load.

DYNSYS system works as a preventive maintenance element. In case the tower has some internal damage

and forces the system to operate in a forced manner, DYNSYS system will limit its use, preventing that the

internal components (cable, pulleys, profiles, etc. ...) may deteriorate further. If this happens, contact the

technical department or your nearest distributor.

The system allows the disassembly of the crank, thus allowing the blocking of the tower. In this way it is

avoided that personnel outside the installation can manipulate the tower by raising or lowering it. Only

the two Allen screws should be removed.

Figure 103

The system has several elements working in a coordinated manner. On the one hand, the most external

aluminum profile has a special machining to house the safety pin, and the iron carriage has the mechanics

of overload detection and a status marker.

Finally, the original handle of the winch is replaced by a specific one for the DYNSYS system.

35

USER MANUAL FOR WTS TOWERS

OPERATING

NORMAL OPERATION, WITHOUT OVERLOAD

Figure 104

Under these conditions, the tower raises the coupled load and no vertical displacement occurs in the

carriage (1) so that the inner spring (2) does not compress and the safety pin (3) does not act. The winch

handle allows the user to raise or lower the load with ease and the window of the status marker (4) shows

the color GREEN.

Figure 105

36

USER MANUAL FOR WTS TOWERS

OPERATION WITH OVERLOAD

In the event that the tower has to raise a load higher than the one marked in features, the tower would

enter overload mode. Under these conditions, the following occurs:

Figure 106

- There is a more pronounced vertical displacement in the iron carriage (1).

- The internal spring (2) shrinks due to this additional pressure.

- The safety pin (3) is released from its resting position and entered the first free hole found in the

aluminum profile, blocking the tower and preventing any attempt to raise the load.

- In the same way, the own characteristics of the exclusive DYNSYS handle prevents to force the winch.

- The status dial window (4) shows the RED color of overload.

To get out of this state of overload, it is necessary to lower the load and adjust it to the weight supported

by the tower.

To do this, pull the safety pin (3) to release it and, keeping it, turn the hand winch handle to lower the

load. Throughout this process, the spring (2), will be relaxed by reducing the pressure exerted on it and

the iron car will go back to the initial position. At the end of the descent of the load, you can release the

safety pin that will remain in its resting position.

37

USER MANUAL FOR WTS TOWERS

DYNAMIC OVERLAP

Thanks to the continuous development of new solutions for the lifting towers, Work Lifters has developed

and patented an innovative solution that increases the resistance of the towers and reduces their

deflection. Dynamic Overlap makes that each tower section overlaps with the previous one at different

distances, as with trees in nature. This means that all efforts are concentrated in the same way in all the

sections of the tower. Thanks to this, the tower can withstand greater efforts with less deflection.

Figure 107

38

USER MANUAL FOR WTS TOWERS

TRANSPORT

To transport the towers:

- Check that the legs are firmly attached to the tower in their transport position and cannot be

released.

- Check that the forks are securely fastened with the pins and cannot be removed.

- Check that the carriage is securely fastened with the car brake system.

- Check that all sections are blocked.

WITH FORKLIFT

To transport the towers with a mechanism type forklift, the AWS 100 accessory is necessary. Follow the

instructions of the machine operator transport manual. Consider the height of what is transported. Avoid

sudden turns and braking.

Figure 108

Detail of transport with forklift.

39

USER MANUAL FOR WTS TOWERS

WITH TRUCK OR CONTAINER

To transport the tower by truck or container always tie the tower by two points. Use ratchets not less than

1000 kg of force for the WTS 506, 256 and 375 models. Use ratchets no less than 2000 kg of force for the

WTS 905, 1206 and 708 models.

Place ratchets so that the tower cannot move by inertia in curves or sudden braking.

Figure 109

Detail tower place and shape holding.

40

USER MANUAL FOR WTS TOWERS

DGUV V17/18 NORM REGULATION. Explanation

DGUV V17/18 is a norm that regulates the stage and production elements in the entertainment industry.

Lifting equipment and rigging are part of this norm and cover structures and other technical elements.

Adopt DGUV V17/18 is totally voluntary (except in Germany) but its adoption is required by insurance

companies and indeed is becoming a norm in the industry

The application of this norm on lifter towers is vital because, in theaters, stages, etc.., are used to move

loads above artists, technical staff, etc... and in some cases, above viewers, representing a potential risk

of fall.

NORM DGUV V17/18. Fields of application

This standard is oriented in two ways:

On the one hand, lifting towers adopt designs and materials to achieve a high degree of safety in quantities

such as supported load, equilibrium, resistance to friction, etc.

Thus, WORK lifter towers DGUV V17/18 certified assure the user that they have passed strict controls

during design, choice of materials or load checks and effort.

On the other hand, in order to achieve an optimal performance with these units, it is recommended, apart

from a responsible use of the unit, (meeting basic norms such as obey the maximum load or balance), a

periodic maintenance, which must be carried out by expert technicians, checking the condition of the steel

cable and winch, the functioning of the security pins and the folding/unfolding of all sections.

All the above tests are only mandatory in those countries with specific regulations on the matter, applied

through regulations or laws. As manufacturers, we recommend passing all tests in order to prevent

damage and ensure proper operation of P.A. lift systems.

41

USER MANUAL FOR WTS TOWERS

SPECIFICATIONS

WTS Model

256

375

506

905

708

1206

Folded height

1,60 m 1,60 m 1,93 m 1,66 m 2,00 m 2,00

m

5,25

ft

5,25

ft

6,33

ft

5,45

ft

6,56

ft

6,56

ft

Base width

0,56 m 0,56 m 0,58

m

0,585

m

0,705 m 0,585

m

1,84

ft

1,84

ft

1,90

ft

1,92

ft

2,31

ft

1,92

ft

Base length

0,44 m 0,44 m 0,52 m 0,58 m 0,58 m 0,58

m

1,44

ft

1,44

ft

1,71

ft

1,90

ft

1,90

ft

1,90

ft

Maximum height

6,26 m 5,09 m 6,08 m 5,20 m 8,13 m 6,00

m

20,54

ft

16,70

ft

19,95

ft

17,06

ft

26,67

ft

19,69

ft

Minimum fork height

0,43 m 0,43 m 0,33 m 0,41 m 0,41 m 0,41

m

1,41

ft

1,41

ft

1,08

ft

1,35

ft

1,35

ft

1,35

ft

Unfolded diameter

2,65 m 2,65 m 2,71 m 2,80 m 3,47 m 3,40

m

8,69

ft

8,69

ft

8,89

ft

9,19

ft

11,38

ft

11,15

ft

Frontal side width

1,88 m 1,88 m 2,11 m 2,13 m 2,15 m 2,15

m

6,17

ft

6,17

ft

6,92

ft

6,99

ft

7,05

ft

7,05

ft

Rear side width

1,60 m 1,60 m 1,55 m 1,90 m 2,55 m 2,55

m

5,25

ft

5,25

ft

5,09

ft

6,23

ft

8,37

ft

8,37

ft

Fork length

0,50 m 0,50 m 0,61 m 0,65 m 0,86 m 0,86

m

1,64

ft

1,64

ft

2,00

ft

2,13

ft

2,82

ft

2,82

ft

Number of profiles

5 4 4 4 6 4

Minimum load capacity

25

Kg

25

Kg

25

Kg

25

Kg

25

Kg

25

Kg

55,12

Lb

55,12

Lb

55,12

Lb

55,12

Lb

55,12

Lb

55,12

Lb

Max.load as mechanism

250

Kg

350

Kg

510

Kg

450

Kg

450

Kg

550

Kg

551,16

Lb

771,62

Lb

1124,36

Lb

992,08

Lb

992,08

Lb

1212,54

Lb

Max. load as structure

260

Kg

380

Kg

510

Kg

900

Kg

700

Kg

1200

Kg

573,20

Lb

837,76

Lb

1124,36

Lb

1984,16

Lb

1543,24

Lb

2645,55

Lb

Net weight

109,50

Kg

90,50

Kg

152

Kg

202

Kg

272

Kg

230,50

Kg

241,41

Lb

199,52

Lb

335,10

Lb

445,33

Lb

599,66

Lb

508,17

Lb

Winch

900

Kg

900

Kg

900

Kg

1200

Kg

1200

Kg

1200

Kg

1984,2

Lb

1984,2

Lb

1984,2

Lb

2645,5

Lb

2645,5

Lb

2645,5

Lb

Cable diameter

6

mm2 6 mm2 6 mm2 7 mm2 7 mm2 7 mm2

Noise emissions

70

dB

70

dB

71

dB

73

dB

73

dB

73

dB

Figure 110

42

USER MANUAL FOR WTS TOWERS

DECLARATION OF CONFORMITY

The tower lifters described complies with all the specific requirements of Directive 2006/42 /EC of the

European Parliament and of the Council of 17 May 2006 on the Machinery Directive.

The tower lifters described meet all the specific requirements in DIN56950: 1/3. If the DYNSYS system is

installed in the tower.

The tower lifters described meet all the specific requirements in DGUV V17/18

Manufacturer:

EQUIPSON, S.A.

Person responsible of the technical data:

José Vila Ortiz

Address:

Avda. El Saler, 14 Pol. Industrial

L’Alteró. 46460 SILLA – Valencia

(Spain)

Description:

Frontal load lifter

MODEL WTS 905 – WTS 905 DY

MODEL WTS 1206 – WTS 1206 DY

MODEL WTS 708 – WTS 708 DY

MODEL WTS 506 – WTS 506 DY

MODEL WTS 256 – WTS 256 DY

MODEL WTS 375 – WTS 375 DY

MAX. LOAD: 900 kg

MAX. LOAD: 1200 kg

MAX. LOAD: 700 kg

MAX. LOAD: 510 kg

MAX. LOAD: 260 kg

MAX. LOAD: 380 kg

Jose Vila Ortiz, July 2016

43

USER MANUAL FOR WTS TOWERS

DGUV MARK

NUMERO DE SERIE:

SERIAL NUMBER:

LAUFENDE NUMMER:

Primer test en fábrica

First test in factory.

Erstprüfung im Werk.

Fecha/Date/Datum

Testado por/Tested by/Prüfer

Examen a los cuatro años.

Four years test

UVV Prüfung (alle 4Jahre)

Fecha/Date/Datum

Testado por/Tested by/Prüfer

44

USER MANUAL FOR WTS TOWERS

Examen anual a partir

del cuarto año.

Annual test after the

fourth year.

UVV Jährlicher Test nach

dem vierten Jahr.

Fecha/Date/Datum

Testado por/Tested by/Prüfer

Fecha/Date/Datum

Testado por/Tested by/Prüfer

Fecha/Date/Datum

Testado por/Tested by/Prüfer

Fecha/Date/Datum

Testado por/Tested by/Prüfer

45

USER MANUAL FOR WTS TOWERS

46

USER MANUAL FOR WTS TOWERS

Loading...

Loading...