....--

~

~

~ORCESTER--.

Highflow

ROOM

FLOOR STANDING COMBINATION BOILER FOR CENTRAL

HEATING

SEALED

AND

MAINS

FANNED

FED

3.5

FLUE

DOMESTIC

RSF

MODEL

HOT

WATER

INSTALLATION AND

SERVICING

INSTRUCTIONS

...__

THESE

_____

IMPORTANT:

INSTRUCTIONS

THIS

THESE

:::.

GC

NUMBER

BOILER OUTPUT

To

Maximum

Minimum

Maximum

APPLIANCE

INSTRUCTIONS

ARE

TO

~

23.4

To

Central Heating

8.8

23.4

IS

BE

LEFT

.rwoRCESTER

41

311

Hot Water

kw

(80,000

kW (30,000

kW (80,000

FOR

USE

APPLY

WITH

Bosch

40

Btu/h)

Btu/h)

Btu/h)

WITH

IN

THE

THE

USER

Group

NATURAL

UK

ONLY

OR

AT

_____

GAS

THE

ONLY

GAS

METER

...

CONTENTS

INSTALLATION

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

Section

1

2

3

4

5

6

7

8

9

9.1

9.2

9.3

10

11

12

13

14

15

16

17

18

19

20

REGULATIONS

General

Siting

Removal

System

Air

Terminal

Air

Connection

Installing

Rear

Vertical

Pre-plumbing

Completion

Sealed

Open

Mains

Electrical

Commissioning

System

Users

Routine

Replacement

Short

Fault

Information

the

Considerations

Supply -Horizontal

Supply -Vertical

Horizontal

Flue

Primary

Vent

Feed

Guidance

Instructions

Cleaning

Parts

Finding

AND

TECHNICAL

Appliance

of

Cabinet

Position -Horizontal

of

the

Systems

of

Primary

Domestic

List

Flue

Primary

Appliance -General

Flue

Outlet

of

the

Appliance

the

Installation

System -Open

System ~ Mains

the

Appliance

and

and

of

Parts

Chart

INSTALLATION REGULATIONS

The

installation

Use)

Regulations,

regulations

the

following

BS

5440:2:1989 and BS 6891.

Safety

Gas

person,

your

The

in

interest, and

manufacturers

of

this

local

and

bye

laws

British

(Installation

accordance

that

notes

appliance

Building

of

the

Standards

and Use)

with

the

of

safety

must

must

be

in

Regulations,

local

water

and

Codes

Regulations

above

regulations. Failure

to

ensure

compliance

not

be taken,

DATA

Flues

Flue

and

Secondary

Hot

Water

Bypass

Inspection

Adjustment

accordance

Building

undertaking.

of

Practice: BS 6798:1987, BS 5449:1:1990,

1984:

in

any

way, as

Vent

Supply

It

with

Vertical

Secondary

Feed

Secondary

(Secondary)

with

the relevant

Standards

It

should

is

the

to

install

the

law.

overriding

Flues

be in

law

that

appliances

System

System

requirements

(Scotland)

accordance

all

gas

statutory

correctly

of

(Consolidation),

with

the relevant

BS

appliances

could

obligations.

the

Gas Safety

5546:1:1990,

are

installed

lead

(Installation

current

lEE

recommendations

BS

5440:1:1990,

by a competent

to

prosecution.

and

wiring

It

is

of

in

TECHNICAL

Table

1

MODE

HEATING

RANGE

DOMESTIC 23.44

HOT WATER

Note:

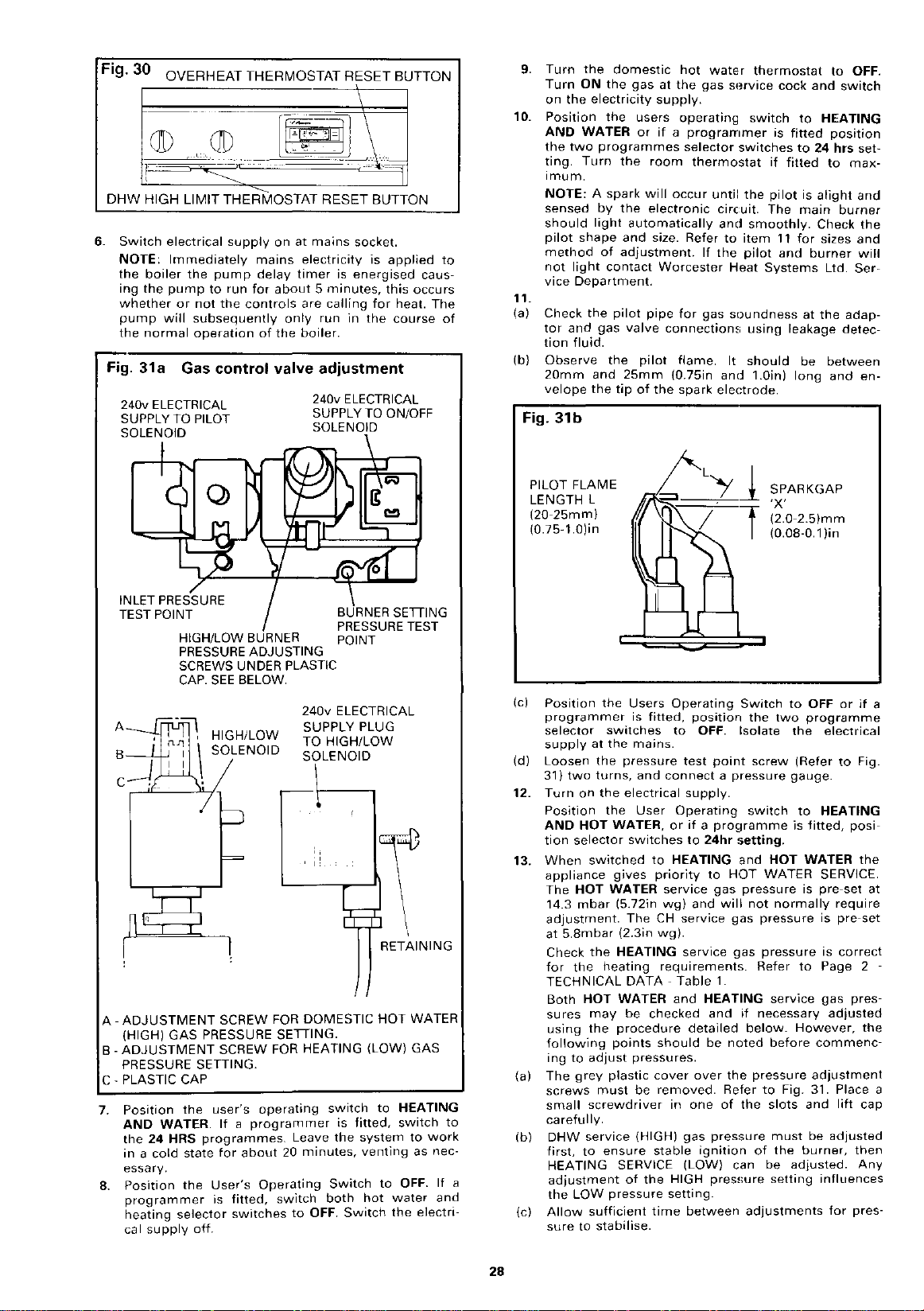

The

pressure

DATA

OUTPUT

kW

8.79

11.0

13.0

15.0 151195) 19.6

17.0

19.0

23.44

test

point

NOTE: THE

HAND

NOMINAL

(Btu/h)

(30000)

(37545) 14.7

1443701

(58020)

(64845) 24.2

(80000) 29.3

(80000) 29.3

is

located

DATA

SIDE.

BOILER RATINGS (10

on

the

PLATE

kW

12.0

17.1

21.9

gas

IS

POSITIONED INSIDE THE APPLIANCE

minutes

INPUT PRESSURE GAS RATE

(Btu/h)

(40955) 2.2

(50170)

(58360) 4.4

(66555) 5.8

(74745)

(82595)

(1

00000)

(1

00000)

valve

(See

fig.

31a).

after

lighting)

BURNER SETTING

(in.

m bar

3.2

7.3

9.1

14.3

14.3

wg)

(0.88)

(1.28) 1.36

(1.76)

(2.32) 1.81

(2.92)

(3.64) 2.25

(5.72)

(5.72)

AT

m

1.11

1.59

2.03

2.72

2.72

THE FRONT LEFT

3

/h

ift'ih

(39.4)

(48.3)

(56.2)

(64.0)

(71.9)

(79.5)

(96.2)

(96.2)

I

2

Table 2

SPECIFICA

nONS

HEATING FLOW

HEATING RETURN

SAFETY VALVE

COLD

FEED

COLD WATER

DOMESTIC

MAINS

IN

WATER OUT

15mm

GAS INLET

HEIGHT

WIDTH

DEPTH

WEIGHT

95kg (2101b)

PRIMARY CAPACITY

*MAXIMUM

*MINIMUM

STATIC HEAD

STATIC HEAD 1000mm (39in)

CIRCULATING PUMP

EXPANSION VESSEL 12

OUTPUT

OUTPUT

CH

DOMESTIC HOT

MAXIMUM

TO

TO

CONTROL

DOMESTIC HOT WATER FLOW RATE

HEATING

MAXIMUM

DOMESTIC HOT WATER 23.4kW (80,000 Btu/h)

THERMOSTAT-

WATER FLOW

MAX.

TEMPERATURE

RATE

(35°C

RISE)

Nominally

Nominally

28mm

28mm

22mm

22mm

COPPER

COPPER

COPPER

COPPER

TUBE

TUBE

TUBE

TUBE

COMPRESSION - SUPPLIED

22mm

22mm

860mm

550mm

600mm

empty-

COPPER

COPPER

TUBE

TUBE

(33.9in)

(21.6inl

(23.6in)

147kg (3241b) full

48 litres (10.6 gal)

25m

(81ft.)

Grundfos

litres

15-60

charged

0.5

bar

23.4kW (80,000 Btu/h)

Nominally

9.6

15

82°C

(180°F)

litres/min + 15%

litres/min

(3.3

gal/min)

(2.1

gal/min)

±15%

*

Appliance

static

heads

are

measured

from

the top

of

the

casing

to

the

highest

point

of

the

Table 3

HORIZONTAL VERTICAL

FLUE

WALL

DETAILS-

OR

See Notes

CEILING-

Below

REAR FLUE PRIMARY FLUE

HOLE DIAMETER FOR AIR DUCT 125mm (Sin)

WALL HOLE DIAMETER FOR SEALING RING 150mm (6in)

MINIMUM FLUE

MAXIMUM FLUE

LENGTHS WITH EXTENSION KIT 1

FLUE

If a flue

FLUE

extension

KIT ONLY

LENGTH-

LENGTH-

is

required

MAY

BE

STANDARD FLUE KIT 100mm (4in)

1

STANDARD FLUE KIT

(See

USED

Section

PER

APPLIANCE. Part No. ZAGAS066

9)

it

may

be

obtained

from

Worcester

OOOmm

001

to 2000mm

(39

to

Heat

73in)

Systems

Table 4

HEATING OUTPUT

kW

8.8

11

13

15

17

19

23.4

Btu/h

(30,000)

(37,500)

(44,350) 4.3

(51,200) 3.8 12.6 14.33

(58,000) 3.3 10.9

(64,800) 2.2 7.2

(80,000)

AVAILABLE PUMP

HEAD

METRES

5.1

4.7 15.5

1.5 5.0

FEET

16.6

14.1

HEADS

MIN. FLOW RATE OPTIMUM

LITRES/MIN.

8.41

10.51

GALUMIN.

1.89

2.36

12.42 2.79

3.22

16.24

18.15

22.35

3.65

4.08

5.02

system

(See

125mm

Fig_s.

24.

(Sin)

1557mm (61.3in)

(39in) 2000mm (73in)

2001

to

3000mm

(79

to

118in)

Ltd. ONE

TEMPERATURE

15°C

between

heating

flow

EXTENSION

RISE

and

return

and

25)

3

1.

GENERAL

IMPORTANT:

to

instal a sealed

ondary

can be

the

(i) Sealed

(ii)

(iii)

FOR FURTHER ADVICE

SYSTEMS

1.

(a)

system

used,

following:

secondary

Open

(Section

Open

feed)

HIGHFLOW

An

exchanger

primary

vented

11)

vented

secondary.

LTD.

induced

INFORMATION

Although

via

i.e.

(Section

3.5 RSF INCORPORATES

primary

the

the

system

and

primary

or

primary

draught

having

the

appliance

water

mains

arrangement

open

1 0)

or

and

and

CONTACT

fan, a

a

maximum

system

supply,

vented

mains

open

low

includes

and

feed

only

one

must

(i.e.

cistern

feed

vented

WORCESTER

thermal

capacity

heat

23.4kW (80000 Btu/h).

(b)

Either a horizontal

flue

system

(c) A

standard

100mm

kit

from

length

A

standard

diverter

The

kit

tween

appliance

2001mm

option).

(d) A

heatbank

(10

gallons)

tioned

to

water

Secondary

through

{e) A

diverter

domestic

(f) A

circulating

(g) A

(h)

(j)

(k)

{I)

2.

multifunctional

tronic

domestic

provides

Boiler

stats

estic

A User/s

or

heating

as an

An

expansion

valve

to

be

An

electronic

ables

utes

after

INSTALLATION

GREAT CARE

NO

FOREIGN

SYSTEM. THIS

APPLIANCE.

3.

NATURAL

The boiler requires 2.72m'/h (96.2ft'/h) of gas. Meter and

supply pipes

in

gas

in tho house.

nominal pressure of 20

equivalent

valve.

should be inspected and tested for soundness and purged

in

accordance with the recommendations of BS 6891.

-to

duct

{4in)

1001

is

available

duct

intended

will

enable

1557 (61.3in)

top

(59in)

having a nominal

inside

heat-exchanger

supply

the

heat

valve

hot

control

hot

automatic

and

hot

providing

hot

water.

Operating

and

optional

and

auto

connected

the

pump

each

GAS

must

addition to the

The

to a pressure of about 18:5-19

The

complete

(rear

order.

kit

to

1000mm

mm

(39in)

as an

kit

for

outlet.

to

3000mm

of

circulating

the

appliance. A copper

exchanger.

to

water

pump.

system

water

water

control

Switch

water. A programmer

extra.

vessel,

air

vent

to

a sealed

pump

to

run

operating

WARNING:

MUST

MATTER

COULD

SUPPLY

be capable of delivering this quantity of

meter

outlet)

for

horizontal

{39in).

to

option).

for

vertical

installation

the

diverter

and

2000mm

(An

is

domestic

direct

the

or

central

HIGH/LOW

to

and

central

ignition.

temperature

for

for

pressure

to

enable

delay

on

for a period

cycle.

BE

TAKEN

IS

CAUSE

demand

outlet governor

mbar

installation,

or

vertical

flue

lengths

(An

2000mm

extension

{118in) is

primary

fitted

boiler

heating

control

central

selection

water

control

LEFT IN THE

from any other appliances

(Bin wg) at the appliance,

extension

{79in)

flues,

complete

within a roof

to

be

installed

(79in)

duct

available

capacity

hot

finned

into

the

hot

water

output

as

gas

valve

individually

heating.

control

heating

of

kit is

gauge,

pressure

the

primary

system.

board

of

TO

ENSURE

DAMAGE

must

mbar

mcluding

about 5 min-

water

required.

The

the

facility

the

of

these

be

one

feed)

secondary

(i.e.

cistern

HEAT

output

fanned

from

duct

maximum

with

space.

above

kit

from

as an

of

45

litres

posi-

water

heatbank.

passes

either

and

elec-

system

thermo-

and

dom-

water

only

available

relief

circuit

which

THAT

WATER

TO

ensure a

at the gas

the

meter,

sec-

of

heat

of

be~

the

to

the

en-

THE

ELECTRICAL SUPPLY

4.

Mains

See

with

continuous.

5. OPEN

The

sealed

used

ing

its

taken

6.

CONTROLS

All

controls

in

the

There

thermostat

supply

Section

the

VENTED

appliance

by

not

is

240

13.

appliance

SYSTEM

water

connection.

'Short

is

system.

carefully

to

distort

included

List

provision

to

be

V,

........

The

length

is

rated

supplied

An

removing

See

the

with

of

Parts'

for a room

fitted

50 Hz, 160

of

supply

at a

ready

open

vented

the

safety

Section

pipe.

the

appliance

included

the

appliance.

thermostat

to

watts

temperature

for

11. Care

13.

Thermostatic

system;

this

DRAINAGE

7.

A

drain

primary

vessel

type

to

radiator

however, a suitable

of

control.

cock

is

heat

bank

drain

See

fitted

to

water

valves

Section

in

the

from

can be

by-pass

the

pipe

sealed

the

15.

system

boiler

bank. (Fig. 46)

8.

PACKAGING

The

appliance

arate

package

or

vertical

flue

terminal

flue)

together

materials,

2.

SITING

(Refer also to sections

1. The appliance is floor standing and the

2.

level.

and

The

following

servicing and ventilation:

is

contains

flue

kit. Each kit

(horizontal

with

etc.

THE

despatched

either

includes

flue)

the

necessary

APPLIANCE

5,

6,

7 and 8).

clearances

in

the

must

one

standard

either a balanced

or

diverter

duct

be

(a) Above the appliance: Servicing 450

Ventilation 5 mm (0.2 in.)

(b) In front of the appliance: Servicing 600

(c) Left and right-hand side: Servicing

Ventilation 75

20

Ventilation 20 mm (0.8 in.)

NOTE:

available

tion

3.

4.

NOTE:

building

Gas

Framed

sought

3.

Care

9.

The

chosen

satisfactory

if a horizontal

The

chosen

satisfactory

down

flue

system

If

publication

Housing"

from

REMOVAL

AND

See Fig.

NOTE:

front

panel,

aid

It is

cover,

left

installation.

must

at

either

draught

the

appliance

it

should

the

CABINET

1.

necessary

and

and

right

be

taken

side

for

position

balanced

flue

system

position

secondary

free

to

be used.

be

fitted

"Guide

Ref

local

zone. See

DM2.

Region

is

OF

to

may

be

hand

to

installing

must

flue

must

flue

is

to

be

in

for

Gas

If

FACIA

remove

necessary

side

ensure

the

allow

to

be

allow

terminal

Section

fitted

Installation

in

doubt

British

the

used

the

in a timber

termination.

is

accordance

of

PANEL

the

to

panels

and

adequate

Gas.

cabinet

fused

at 3A.

cable

provided

of

aooc

connection

system

valve

are

in

See

used

is

essential

connecting

and

package. A sep-

work,

floor

left

to

mm

mm

mm

mm

boiler.

provision

See

OR

provision

discharge

8,

with

advice

remove

lower

to

can

and

seal-

should

specified

this

leaflet.

and

frost

Section

in

with

expansion

the

heat

horizontal

(vertical

sealin~1

must

be firm

allow

(18 in.)

(24 in.)

(3 in.)

(0.8 in.)

space

See Sec-

of

Section

of

in

if a vertical

framed

the

British

in

Timber

must

top

cover,

the

facia

grille

a

be

be

the

thE!

for

is

a

6,

a

a

b~3

to

4

Fig. 1

Cabinet -Control

TOP

TOP

COVER

COVER

A

B

Panel

RETAINING LUGS

FIXING BOLT

c FACIA FIXING SCREWS

D DHW AND

MOUNTING

CONTROL PANEL FIXING SCREWS

E

CONTROL PANEL SUPPORT BRACKET

F

AND

LEFT

G

SIDE PANEL BRACKET FIXING SCREWS

H

RIGHT HAND SIDE PANEL FIXING SCREWS

J

K LOWER FRONT GRILL

KICKSTRIP FIXING SCREWS

FRONT COVER {NO FASTENINGS)

L

CH

THERMOSTAT

BRACKET FIXING SCREWS

SCREW

HAND SIDE PANEL FIXING SCREWS

and

Facia Fixing

Screws

A

J,C

c

L

(a)

Remove

the

Remove

pletely

cover.

(b)

Pull

disengage

enough

Undo

(c)

grille

(d) Pull

five

the

it

to

forward

come

programmer,

drawn

in

terminal

the

numbered

halves

removed

(e)

Remove

retaining

two

screw

'J'.

Draw

NOTE:

single

to

strain

4.

(a)

circulating

frost

appliance

bore

The

posidrive

hold

should

SYSTEM

The

thermostat,

or

the

base

and

the

the

See

Fig.

up

the

the

to

disengage

the

five

kick

strip.

off

the

screws

side

the

micro-bore

panels

the

base

until

away

it

forward

heating

of

the

completely.

the

the

M5

slotted

retaining

the

control

panel

be

appliance

pump

will

operate

'C';

rail

14

cabinet

lifting

bolt

cabinet

'B'

front

upwards

top

retaining

cover

and

cover

by

outwards.

by

the

1.

front

edge

of

the

fasteners.

screws

two

thermostat

two

and

three

of

the

it

clears

complete

if

fitted.

enough

positioned

thermostat.

to

17

terminal

two

remaining

top

of

head

the

top

side

panels

panel

screw

'F'. (See Fig. 1).

during

placed

on

Draw

it

at

the

'K'

securing

underneath

control

the

side

with

Support

to

behind

inclusive.

rail,

(Fig. 37)

the

left

screws

of

the

forward

is

supported

installation

the

panel.

the

rear

holding

knobs

the

ends

panel.

panels.

three

gain

The

enabling

posidrive

hand

and

right

and

only

cover

and

position

the

access

and

terminal

Separate

side

CONSIDERATIONS

includes a pump

is

required.

refer

satisfactorily

system.

to

When

Section

fitting a room

13,

on a two

pulling

slackening

front

of

sharply

cover

lift

clear.

the

lower

and

remove

of

the

the

facia,

Pull

the

The

facia

switch

facia

to

to

the

the

facia

screws

panel

single

posidrive

hand

side

lift

out.

in

position

This

is

and

no

and

no

Electrical.

pipe

firmly

com-

the

top

forward

front

the

facia

fixing

facia

will

or

having

the

plug

right

of

rail

the

two

to

be

'C'

and

the

panel

by

intended

undue

other

or

The

small

at

to

to

is

a

""

(b)

5.

1.

2.

Table

5

K

The

heatbank

exchanger

control

the

be

For

thermostat

use, a

heatbank.

this

IT

system

domestic

turned

large

few

period.

IS ESSENTIAL TO FIT A BYPASS TO ALL

contains

which

provides

is

incorporated

hot

off

The

water

when a demand

quantities

should

minutes

be

may

central

a

and

of

set

be

heating

finned

domestic

that

the

central

for

hot

water

at

maximum

required

will

gives

hot

water

remain

copper

hot

to

SYSTEMS.

AIR

SUPPLY

The

room

not

If

the

compartment,

the

cupboard

one

room.

communicate

on

effective

in

require a purpose

appliance

at

low

Both

the

same

areas

which

permanent

or

level,

high

with

required

HORIZONTAL

the

appliance

air

vent.

is

installed

and

to

air

direct

low

same

outside

are

compartment,

either

the

wall

is

in a cupboard

vents

one

at

to

outside

level

room

or

air.

given

in

installed

are

high

air

must

The

Table

5 COOLING AIR REQUIREMENTS

HORIZONTAL

Position

Air

Vents

High

Level

Low

Level

of

AND

VERTICAL FLUE SYSTEMS

Air

from

room

2

264cm

7

)

{41

in

7

264cm

2

(41

in

)

Air direct

from

water.

priority

heating

is

the

and

re-heat

off

FLUE

required

level,

air

vents

both

minimum

5.

outside

132cm

{20.5in

132cm

(20.5in

heat

will

made.

control

after

the

during

does

and

or

to

must

2

2

)

2

7

)

A

to

or

in

a

be

6.

FLUE

HORIZONTAL

TERMINAL

FLUE

POSITION-

IMPORTANT

1.

Flue length. See

tion,

regarding

note

standard

in

Section

flue

1,

General

assembly

and

flue.

2. The flue must be installed in accordance

recommendations

Minimum

flue

siting

terminal:

TERMINAL

A-

Directly

window

brick

B-

Below

drain

pipes

Below

c-

D-

Below

E-

From

vertical

soil

F -

G -

pipes

From

Above

internal

level

H-

From a surface

1-

From a terminal

J -

From

an

(e.g.

KL -

door,

Vertically

the

same

Horizontally

the

same

below

or

gutters,

eaves

balconies

ground,

opening

of

BS

5440:Part

dimensions

for

positioning

POSITION (See Fig.

an

open

other

soil

drain

or

roof

facing a terminal

window)

from a terminal

wall

from a terminal

wall

able

opening,

or

external

facing a terminal

in a car

pipes

car

pipes

or

into

e.g.

or

port

and

corners

balcony

port

dwelling

on

2)

roof

on

1.

the

MIN

air

300mm

75mm

200mm

200mm

75mm

300mm

300mm

600mm

1200mm

1200mm

1500mm

300mm

GENERAL NOTES

1.

The

terminal

bustion

2. In

certain

and

positions

should

3.

If

the

gutter

nium

shield

to

the

(Dimensions 8 and

4.

If a terminal

above a surface

suitable

ive

guard

Limited,

Guard

The

terminal

using

the

corrosion

metrically

and

spaced

imum

5.

The

air

the

boiler

combustible

protection

5440:1

must

products

weather

avoided.

within

of

guard

is

available

vale

guard

three

resistant

positioned

such

must

of

1990,

where

is

at

is

must

Rise,

brackets

the

material.

combustible

sub-section

be

terminal

or

underside

Reference:

between

inlet/products

be

positioned

can

disperse

conditions a terminal

this

fitted

450mm

least

of

the

C in Fig. 2).

fitted

to

which

be

from:

Tonbridge,

GC

393

must

screws.

about

that

end

outlet

not

be

freely

could

within

850mm

of

painted

750mm

less

provided. A terminal

there

of

closer

Detail

long

gutter

than 2 metres

people

Tower

553-

Type

be

securely

provided,

The

guard

the

is a

the

terminal

duct

than

recommendations

material

3.3

such

that

at all

cause a nuisance

of a plastic

eaves, an

should

or

painted

have

access

Flue

1TB.

K2.

fixed

suitable

terminal

gap

of

and

the

50mm

are

Components

must

and

given

TN9

IMPORTANT

It is

absolutely

products

terminal

adjacent

doors,

other

ced

ventilation/air

should

immediately

occur,

cannot

of

combustion

building

sources

the

and

ESSENTIAL

re-enter

the

the

through

of

natural

conditioning.

appliance

problem

to

ensure,

discharging

building

ventilators,

air

infiltration

If

this

MUST

rectified.

or

be

Informa-

extension

with

the

balanced

DISTANCE

(12in)

(3inl

(Sin)

(Bin)

(3in)

(12in)

(12in)

(24in)

(47inl

(47in)

(59in)

(12inl

the

com-

times.

may

steam

alumi-

be

fitted

surface

(78.6in)

then

protect-

Terminal

to

the

wall

plugs

and

be

sym-

assembly

50mm

min-

the

guard.

terminal

(2 in)

on

in BS

in

practice,

from

any

other

windows,

or

for-

eventuality

turned

of

to

the

off

7.

AIR

SUPPLY

1.

The

room

in

appliance

low

level,

Both

high

with

wall

to

required

which

or

the

require a purpose

2.

If

the

compartment,

the

cupboard

one

at

room.

municate

same

areas

REQUIREMENTS,

3.

ALL

installations

designed

direct

THE

air

with

outside

MINIMUM

vents

VENTS WITHIN A ROOF SPACE

4.

The

roof

the

any

space

off

completely

room,

other

cupboard

is

room.

sealed

(a)

appliance

(b)

8.

CONNECTION

SECONDARY

The

components

are

supplied

the

top

ensions

must

be

such

as

A

secondary

diverter.

size

125mm

adaptor

diameter

complete

boiler

shown

positioned

loft

This

will

must

and

flue

in Fig. 3.

insulation.

flue

component

(5in).

need

not

flue

system

up

these

must

If

VERTICAL

the

appliance

air

vent.

is

permanent

installed

compartment,

either

direct

and

low

same

outside

are

room

air.

given

Section

must

in

the

air.

air

level

in

5.

be

roof

vents

one

to

or

The

Table

provided

space,

FLUES

is

installed

in a cupboard

are

at

high

outside

air

vents

must

both

minimum

5,

COOLING AIR

with

communicating

EFFECTIVE AREA REQUIRED

IS

516cm2 (80in

containing

installed

to

and

must

outlet,

such

be

flue

to

be

be

decreased.

must

from:-

Note

that

fitted

will

pipe

fitted,

the

diverter

or

compartment

and

OF

PRIMARY

VERTICAL

including

be

in

to

be

the

installed

accordance

that

the

it

will

not

to

the

accept

flue

BS 4543 is

but

the

The

in

accordance

draught

draught

be

top

nominal

installation

in

FLUES

vertically

with

obstructed

of

pipe

used,

does

required

level,

air

or

must

be

on

effective

purpose

FOR

2

must

which

AND

diverter

above

the

diverter

the

draught

to

BS

then

internal

of

with

not

and

to

com-

the

AIR

).

the

dim-

715

the

BS

or

in

a

be

by

an

5440:1.

The

secondary

ported

at

out

a

of

Table

and

Horizontal

least

in

accordance

propriate

No

part

combustible

7

Max.

secondary

if

set

to

The

flue

sure

that

system

operating

when

NOTE:

openings

within

the

minimised,

of

lengths

The

applicable-

The

user

the

roof

space

space

of

the

compartment -if

A

around

flue

the

exit

runs

and

point

at

which

the

flue

material.

minimum

condensate

flue

6m

(20ft)

recommended

the

conditions.

required

appliance

permanent,

diverter

MUST

MUST

be

which

applicable.

at

least

draught

system

from

bends

and a spillage

with

system

length

CH

does

within

and

NOT

instructed

may

250mm

diverter

must

the

roof

should

BS 5440:1. Fig. 3

to

apply

shall

Max

input

if

set

above

not

form

operates

purpose

the

roof

any

compartment

BECOME BLOCKED.

not

cause

(10in)

with

be

space

ideally

test

the

test.

be

within

secondary

to

maximum

1Om

are

in

the

under

designed

space,

to

store

an

obstruction,

radius

no

obstructions

adequately

water

proofed.

be

avoided,

must

be

carried

shows

25mm

flue

length

CH

(33ft)

intended

secondary

all

approved

ventilation

the

openings

ventilation -if

items

or

shall

be

provided

(Fig. 3).

sup-

but

an

ap-

(1.0in)

input

to

en-

flue

within

in

the

6

Fig. 2 Siting of terminal

Horizontal Flue

A'

j

GJ

~

Dj

~HI'

/

'

-'l

..

'

: .Ji

, , I I

J

, I

I.

F

I

l]

BC~

'

A

~

'

'

\

~J

G

'j

r·E

I

~

F'

,,

L'hl

v .

!

I

/

llF

IK

•

IK

I

Fig. 3 Position of Vertical Primary

TWIN

IS

DRAUGHT

DIVERTER

(5in) SOCKET OUTLET

CLEAR SPACE

RADIUS

DIVERTER WITH

OBSTRUCTIONS

STANDARD

MINIMUM

1557mm

MAXIMUM

2000mm

WITH EXTENSION

KIT

H ~ 3000mm

Flue and Secondary Flue

See also

WALL

RECOMMENDED

WITH

AROUND

(61.3in)

(79in)

MAXIMUM

Fig. 17

SEC. FLUE

125mm-------l-·f"=Y

250mm

NO

FLUE KIT

HEIGHT H

HEIGHT H

HEIGHT

(118in)

-------+

(10in I

TERMINAL

(NOT

SUPPLIED)

.•

~

..

. M .

H

··1-.,+-~

45mm:

(1.8in)

l_

BOTTOM

SOCKET

OF FLUE OUTLET

GENERAL GUIDANCE · SITING OF

VERTICAL

CHIMNEY

PITCH

EXCEEDING 30°

T

CEILING FLUE SEALING PLATE

1;

860mm

(33.9in)

PITCH

EXCEEDING 30° LEVEL

NOTE: A spillage test must be carried out at the

diverter

FLUE

NOT

HERE,

TERMINAL

ON

RIDGE

AT

OR

ABOVE

RIDGE

in

accordance with BS5440:1.

ROOF SPACE VENTILATED

TO

OUTSIDE AIR SECTION 7.3

NOT

Dim. Y 1m

ABOVE ROOF

INTERSECTION

Dim Y

ABOVE ROOF

INTERSECTION

ON

RIDGE

250mm

(3.3ft)

(lOin)

7

9.0

INSTALLING

GENERAL

If a HORIZONTAL

2,

5,

6,

9.1

and

If

a VERTICAL FLUE is

7,

8,

9.2

NOTE:

TO

The

left

A

installation.

then

In

particularly

servicing

pre-plumb

(Fig

tion.

before

whether

tion

A

facilitate

Compression

nections

ing.

1.

2.

3.

4.

MORE

INSTAL

space

hand

description

the

some

5)

to

If

so

assembling

1 (c)

knock-out

Unpack

Unpack

required)

dosed

standard

moved.

Remove

cabinet

The

flue

sealed

quired

To

gain

move

9.3:

and

9.3;

THAN

THE APPLIANCE.

required

side

and

given

If

connections

space

required

circumstances

where

have

been

the

appliance

the

boiler

refer

to

or

not

an

and

Section

panel

vertical

fittings

to

allow

the

appliance.

the

standard

and

check list.

flue

the

as

described

boiler

is

outlet

configuration;

off

with

refer

to

access

the

access

FLUE is

also

to

also

Fig.

ONE PERSON

for

150mm

in

Section

minimum

used,

pipework

Section

the

extension

2.

is

provided

pipe

connections.

may

for

the

check

Ensure

assembly

top

cover

supplied

blanking

Figs 6

to

the

cover.

THE

to

be

be

installed

3.

(6in) at

are

installation

when

clearances

it

may

and

fit

before

9.3

and

system.

kit is

in

be

fitting

flue

kit

the

all

and

and

in

Section

suitable

the

plates.

and

7.

top

Fig.

installed

and

9.3

made

installing

used

contents

cardboard

the

flue

6.

Figs. 2

installation

for

flue

APPLIANCE

refer

4.

refer

MAY

is

50mm

the

right

covers

in a different

be

found

unions

moving

make

Check

required.

the

cabinet

on

of

the

and

flue

flue

front

3.

for a horizontal

vertical

If a vertical

outlet

to

BE

(2in)

hand

one

may

be

the

for

access

necessary

and

stub

it

the

connections

to

Refer

top

all

water

boiler

and

extension

against

packing

extension

panel

outlets

cover,

to

Sections

Sections

2,

REQUIRED

at

the

side.

method

greater.

appliance,

into

determine

flue

to

panel

servic-

the

from

first

of

way

and

to

pipes,

posi-

Sec-

to

con-

kit

(if

en-

in

the

is re-

the

rear

being

is re-

re-

(a)

Remove

plates.

(b) Run a

(c) Fit

working

(d) Fit

NOTE:

THE FLUE

REFER

{EXTENSION

9.1.

1. Take

tions

2.

Determine

boiler

NOTE:

OF

ASSEMBLING

bead

the

rear

the

blanking

push

fully

the

fully

into

THE ACCESS

SYSTEM

TO

SECTION 9.2a

REAR

account

Siting

the

Refer

to

quired

on

diameter.

NOTE:

If a core

is

made

imum

diameter

made

good

9.1a; 9.1b; 9.1c).

ropriate

assembly

Section

9.1a.

9.1b.

9.1

c.

REFER

THE

the

top

air

duct

of

silicone

flue

duct

and

air

plate

and

the

duct

PANEL

IS

FITTED.

top

and

into

tighten

socket

{STANDARD

home

through

rear

air

the

socket

KIT)

Subsection

HORIZONTAL

of

the

appliance.

page 1 and

the

wall.

oversize,

before

the

section

TO

INSTALLATION

THE REQUIRED FLUE

requirements

Fig

Cut a hole

boring

tool

it

must

and

the

the

flue

length

below,

which

procedure.

100mm-1000mm

1001

mm-1200mm

1201

mm-2000mm

SECTION 9.3. COMPLETE THIS PART

and

flue

duct

sealan1

air

tighten

MUST

duct

the

3{a).

around

sockets.

rear

the

duct

blanking

the

BE

flue

clamping

socket

plate,

clamping

REPLACED

FLUE KIT)

FLUE

under

4.

Mark

the

flue

in

the

wall

is

not

be

inner

appliance

Length

AS

used

reduced

by

to

skin

of

the

is

installed

referring

details

the

L

(4in-39.4in)

(39.4in-47.2in)

(47.2in-78.7in)

NECESSARY BEFORE

ARRANGEMENT.

blanking

the

inside

outlet

opening.

push

screw.

OR

Section

position

125mm

and

the

130mm

brickwork

to

the

correct

of

socket,

screw,

it

WHEN

9.2b

2 -

re-

(5in)

hole

max(Sec-

app-

flue/

Fig. 4 Wall

Dimensions

preparation · Rear

mm

(in)

1----

,.-t..""_

.,(---

!.._-----

600 {23.6)

)

--....J---....1

outlet

r-

-,

r~~-

' ' '

~----~

--

- -

-1{~~

)r

5

~

.L~

1:1.

I

I

~

~

TOP AIR

{DEPTH

HOLE

TO ACCEPT REAR AIR

WALL

INCLUDE

FINISH, INSIDE

OR

OUTSIDE

DUCT

18mm

CUT

THROUGH

THICKNESS TO

ANY

SURFACE

SOCKET

{0.7in)

~

REAR AIR

{DEPTH

DIMENSIONS

VARY

ANY

REMOVED

SHEET IS PLACED BETWEEN THE

APPLIANCE

DUCT

18mm

DEPENDING

FLOOR COVERING IS

SOCKET

{0.7in)

ON

AND/OR

AND

FLOOR

PAGE 1

ON

WHETHER

INSULATING

THE FLOOR

LEVEL

INSIDE

PLASTER

MAY

WALL

DUCT

OUTSIDE

RENDERING

IF

APPLIED

8

Fig. 5 Rear View of Boiler Pipework and Flue

Connections

NOTE: ALL DIMENSIONS ARE NOMINAL mm (in)

A CENTRAL

B SAFETY

C GAS INLET (22mm)

DOMESTIC COLD WATER

D

E DOMESTIC HOT WATER OUT (22mm)

F CENTRAL

G VENT AND FEED (22mm)

H REAR FLUE CONNECTION (Centrelines)

HEATING RETURN (28mm)

VALVE (22mm)

HEATING FLOW (28mm)

r

r--·

I

=

-:-·.

---

IN-

R'h ('/,in BSP)

--~

r--:_:

~

~

•

G & B 200mm (7.9in)

D

170mm

(6_7in)

E 135mm

(5.3in)

F 90mm

(3.5~n}

A 60mm (2.4in)

~f

I

I

mn

~-g-~

.£

cr>LOcn~rn

<Drnoc<Jc<J

2.!-~~~'22.

E E E E E

E E E E E

N 0

<r>mro~<D

<Dr-r-roro

:s

lO

o o

Fig. 7 Flue/ Air Duct Socket Clamping Screws

NOTE: A SIMILAR METHOD

IS USED TO CLAMP

AIR DUCT.

REAR

ACCESS TO THE SCREW

IS

FROM THE TOP (FIG

VERTICAL AIR DUCT

CLAMPING SCREW

THE

6)

_.----

__

_;;;____ DUCT SOCKET

VERTICAL AIR

[c

Fig. 6 Interchanging Positions of Air Duct/Flue Duct Outlet Blanking Plates

I

~..,

--550mm

H 377mm

{21.6in)--

(14.81n)

___,

-1

APPLY SEALANT

OF

FLUE

REAR

FLUE DUCT

CLAMPING SCREW

AND

REAR

BLANKING PLATE

POSITION

AROUND

AIR DUCT SOCKETS

AIR DUCT

INSIDE

FLUE DUCT HOUSING

REAR

FLUE DUCT BLANKING

PLATE POSITION

tr

I

9

9.1

a BOILER FLUE

NOTE:

1.

Cut

(a)

Measure

(Fig 4, 8

(4.5in)

(b)

Reduce

that

REAR

100mm-1000mm

An

extension

the

air

diameter

one

duct

the

and

the

end

wall

15).

air

OUTLET

of

NOT CUT FROM THIS END

2.

Cut

the

flue

duct

(a)

Take

wall

overall

required.

the

from

to

Figs 6 &

screw

to

be

to

the

duct

only

passed

into

(Fig 8)

flue

{16in)

housing

in

front

the

provided.

the

panel,

rear

flue

rear

air

square

front

of

duct

into

the

clamping

concentrically

the

hole

one

flue

socket

Make

the

with

of

the

and

check

flue

Slide

rolled

as a

3mm

drill

two

No

THAT

from

through

100mm

duct

the

section

the

thickness

length

flue

either

sufficient

pulled

rear

on

wall

should

through

the

duct

prior

of

backing

adhesive

around

of

duct

duct

the

{1.6in) in

through

the

top

screw.

in

end

duct

tighten

sure

within

appliance

the

wall.

terminal

the

stop

guide

supplied.

6 x

BEEN

outside

{4in) is

inside

air

the

duct

(b)

Reduce

cutting

Refer

3.

ping

plate

access

Depending

flue

(a) Be

fixed

housing

(b)

If

the

400mm

duct

tion

4.

Remove

gasket

press

back

Either

(a)

Apply a bead

the

the

position,

in

pane140mm

flue

home

through

duct

itioned

and

or

(b) Push

rear

duct

screw.

centrically

Move

face,

front

hole

5.

Fit

the

holes.

the

duct

the

with

(Fig 10).

6.

RECHECK

QUIRED HAVE

7.

Working

assembly

about

of

flue

over

provided

curately.

ASSEMBLY

(4in-39.4in}

kit

is

NOT

required.

to

length

as

thickness

This

air

duct

duct

the

to

length

of

duct

end.

7.

Slacken

out

flue

thickness

the

socket

or

is

it

may

to

the

inner

Position

backed

the

silicone

socket

socket.

to

the

hole

the

rear

air

duct

the

wall.

of

the

socket.

the

the

back

Allow

the

duct

into

flue

channel.

drill

10mm

ANY

the

the

of

flue

and

follows:-

Land

is

the

overall

required.

'A'

to

L +

duct

has

OF

as

follows:-

Land

add

60mm

to

'C'

to

(Fig 9).

the

to

allow

of

its

socket.

duct

clamping

either:-

relatively

paper

into

terminal

through

STUB

and

wall

from

at

the

be

fixed

moving

wall

from

the

side

rear

flue

sealant

and

Move

wall

face,

in

the

wall.

front

of

wall

and

flue

duct

socket

Make

sure

within

the

flue

duct

Working

the

rear

flue

duct

rear

air

duct

position,

panel

about

the

flue

is

positioned

the

end

Using

Screw

self-tapping

PIPE

face. (Fig 8).

gasket

into

the

the

MADE. (SECTION 9.3).

pass

the

hole. A flue

allowed

terminal

duct

connected

flue

duct

add

28mm

length

28mm

two

(1.1in).

holes

THE DUCT.

51mm

L +

51mm

vertical

air

This

space

outside

of

short

directly

the

boiler

the

firmly

outlet

around

around

the

standing

Position

watl

push

socket.

tighten

the

rear

fully

through

flue

is

socket.

square

40mm

duct

of

the

the

the

holes

flue

assembly

screws

(2.0in).

(2.38in)

air

duct

will

screw.

available

the

e.g.

to

square

as

shown,

against

(Fig 8).

the

the

appliance

face. Pass

the

the

flue

duct

air

duct

home

the

duct

positioned

to

pass

concentrically.

air

air

terminal

diameter

the

rear

the

CONNECTIONS

air

duct

and

expansion

for.

The

engage

have

short

to

been

will

(1.1in).

of

110mm

drilled.

This

(2.0in)

duct

clam-

blanking

facilitate

and

flue

less

the

into

sealing

inside

inside

centrally

the

end

Working

rear

is

socket

into

top

clamping

to

the

(1.6in)

into

duct

duct

up

in

the

together

provided.

terminal

joint

section

and

the

boiler,

cut

Note.

DO

is

flue

by

the

then

duct

than

flue

posi-

then

the

of

of

into

back

the

fully

flue

pos-

the

air

con-

wall

in

the

with

to

air

with

RE-

of

push

ac-

Fig. 8 Rear Flue

Application

FLUE DUCT HOUSING

CLAMPING

,..--------------,\1

SCREW

P~b.R

FLUE

OUTLET

SOCKET

SEALANT

SEALING

GASKET

BLANKING PLATE

REMOVED FROM TOP AIR

DUCT INLET SOCKET

ACCESS PANEL, WITH

SCREW

REAR

AIR DUCT /

FOR

TOP FLUE OUTLET CLAMPING SCREW

CLAMPING SCREW

OUTER

WALL

FACE

POSITION

SEALING GASKET

AROUND

Fig.Ba

REAR

FLUE OUTLET AS SHOWN

OUTER

PLAN VIEW

TOP AIR/FLUE DUCT

CLAMPING SCREWS

BLANKING PLATE "

FITIED

IN TOP FLUE

OUTLET SOCKET

M5

SLOTIED

HEAD FIXING

WALL

SEALING

GASKET

/

,,

"

10

8.

Move

the appliance into its final position. The air

should be pushed fully home into the air duct

duct

socket. The back of the socket should be flush with

the

wall face, compressing the sealing gasket (Fig 8).

Tighten the air duct clamping screw.

Fig. 9 Rear flue application

FOR

WALL

THICKNESSES

100mm

to

1000mm

(4.Q;n

9.

Run

a bead of silicone sealant around the inside of

the top air duct socket. Refit the blanking plate,

pushing

air duct clamping screw.

Note.

with

a

wall

to

39.3;n) USE THE

it

down until it

The

rubber

the

terminal

seai.See Fig.8a

is

REFER

sealing

fitted

to

this

STANDARD

fully home. Tighten the top

TO SECTION 9.3.

ring

only

may

appliance

FLUE KIT

to

be used

provide

IMPORTANT:

ENSURE END

IS

REFER

SQUARE

TO INSTRUCTIONS IN SECTION 9.1a BEFORE CUTTING AIR

AND

FREE

r * OVERALL

110mm

DIAMETER

Fig. 10 Rear flue duct assembly

(4.S;n) [I A

~------------------------~

~*OVERALL

LENGTH~

~--------c--------~~

CUT FLUE DUCT TO REQUIRED LENGTH FROM EITHER END.

ENSURE END

FOR

WALL

IS

SQUARE

THICKNESSES

Air duct - Rear flue application

OF

BURRS.

LENGTH~

Flue duct - Rear flue application

AND

FREE

100mm

L PLUS

OF

to

L PLUS

51mm

BURRS.

1000mm

28mm

(2.0;n)

(4.Q;n

(1.1;n)

to

39.3;n) USE THE

~

0

I

OR

DO

NOT

WITH

60mm

(2.38;n)

DIAMETER

STANDARD

FLUE DUCTS

CUT FROM THE END

TWO

HOLES

FLUE KIT

IMPORTANT:

FLUE DUCT

;..--*OVERALL

3

~

~nT

j

l-

6 x

USING

10mm

* OVERALL

INTO

THE HOLES ALREADY IN THE END

3mm

SUPPLIED.

9

1

FIT FLUE

STOP CHANNEL.

TERMINAL

SCREWS

TERMINAL

WITH THE

No

REFER

TO

INSTRUCTION IN SECTION

A FLUE DUCT EXPANSION

100mm

PROVIDING THE AIR

ACCURATELY CUT

TWO

No.6

SELF

FLUE

AIR DUCT

x 1Dmm

TAPPING SCREWS

9.1

a BEFORE

(4;n) OVERLAP IS

TO

\

LENGTH~

LENGTH~

END OF AIR DUCT. SLIDE THE FLUE

DRILL SUPPLIED. SECURE THE

L PLUS

L PLUS

51mm

28mm

(2.0;nl--

(1.1;n)

TERMINAL

OF

THE AIR DUCT, DRILL THROUGH THE FLUE

ASSEMBLY

ROLLED STOP

CHANNEL

INTO

THE AIR

TOGETHER WITH THE

ASSEMBLY

JOINT

OF

ALLOWED

AND

FLUE DUCTS

THE REQUIRED LENGTH.

DUCT

APPROXIMATELY

FOR

ARE

FLUE

TERMINAL

UP

TO

THE ROLLED

TWO

SELF TAPPING

11

9.1

b BOILER

REAR

1001mm ~ 1200mm

NOTE:

1.

(a)

(b)

{c)

(d)

(e)

2.

3.

(a)

(b)

(c)

(d)

(e)

(f) Refer

NOTE:

passed

(9.1

access

duct

section

4.

Use

Cut

the

Measure

This

is

air

duct

Reduce

900mm

(Fig. 11)

Fully

engage

into

the

Reduce

cutting

overall

Using

'8'

as

the

drill

a

smear

previously

and

secure

(F1gs

11

Slide

the

'A',

to

Using

drill

through

supplied.

No.6 x 10mm

Cut

and

Take

the

is

the

duct

required.

Reduce

900mm

Fully

engage

expanded

Reduce

cutting

length.

Using

'D'

as a

the

drill

a

smear

engaged

with

two

clamping

ing

plate

ilitate

Run a

the

rear

If

the

through

b.4

and

is

insufficient

work

is

Remove

gasket

press

back

panel,

Apply a bead

the

flue

Move

face,

standing

wall.

Position

front

of

wall

and

duct

socket.

tighten

the

flue

rear

air

the

standard

air

duct

the

wall

the

overall

required.

the

length

{35.4in).

the

expanded

the

length

from

the

length

the

two

a

guide,

supplied.

of

silicone

engaged

with

& 12).

flue

the

rolled

the

holes

Secure

self-tapping

assemble

wall

thickness

overall

the

length

(35.4in)

end

the

length

from

the

(Fig. 11).

the

two

guide,

supplied.

of

silicone

end

of

self-tapping

to

Figs 6

screw

to

be

access

bead

of

air

duct

fully

the

9.1 b.6)

piecemeal,

added.

the

backing

provided.

the

adhesive

around

duct

and

the

appliance

the

wall

push

Working

the

rear

duct

duct

socket

FLUE

flue

to

length

thickness

length

of

Cut

surplus

end

end

of

end

WITHOUT

(Fig.11)

holes

in

drill

two

Disengage

sealant

end

two

terminal

stop

channel.

at

the

the

flue

tt1e

the

flue

depth

of

of

by

cutting

either

end

of

flue

duct

of

the

plain

holes

in

drill

two

Disengage

sealant

flue

duct

screws

and

7.

sufficient

pulled

to

the

rear

silicone

socket.

assembled

hole

in

there

it

may

passing

paper

Position

backed

the

of

silicone

air

duct

into

centrally

the

back

face. Pass

the

end

through

flue

dtJCt

is

positioned

and

ASSEMBLY

(39.5in-

kit

and

extension

as

follows:

L.

and add

of

110mm

the

extension

from

of

air

duct

of

air

duct

'B'

the

standard

holes

the

expanded

3mm

diameter

the

air

around

of

air

self-tapping

into

end

terminal

assembly

Land

60mm

the

end,

the

Slacken

out

MUST

rear

fully

the

duct

the

of

air

screws.

duct

as

add

(2.38in)

standard

from

either

of

flue

'D'

(Fig. 11).

extension

to

expanded

3mm

diameter

the

around

'C'.

Reassemble

supplied

to

allow

of

its

flue

duct

sealant

flue

and

the

wall

be

be

possible

it

through

from

the

gasket

side

flue

sealant

sockets.

position,

in

front

panel

about

the

home

the

clamping

concentrically

hole

open

duct

with

the

flue

the

socket.

round

as

sufficient

outlet

around

flue

in

47.2in)

28mm

(4.5in)

air

plain

'A'

(without

(Fig. 11)

air

to

end

ducts

the

outside

'A'.

screws

end

'A'

the

together

{Figs.

follows:

51mm

diameter

flue

end.

duct

flue

required

end

ducts

the

(Figs.

vertical

the

air

clamping

the

air

ducts

described

to

the

the

square

as

firmly

(Fig. 8).

square

of

the

40mm

duct

into

top

air

screw.

the

wall.

flue

kit.

(1.1in).

diameter

duct

'B'

end

ONLY.

holes)

duct

'A'

the

required

of

air

holes

using

and

apply

of

Reassemble

supplied.

of

air

as a

guide,

3mm

with

11

& 12).

(2.0in);

duct

'C'

(Fig. 11).

'C'

into

duct

'D'

overall

of

flue

holes

using

and

apply

previously

and

secure

11

& 12).

air

duct

duct

blank-

This

will

screw.

inside

are

to

below

access.

assemble

hole

as

sealing

shown,

against

the

inside

to

the

hole

in

(1.6}

through

the

rear

duct

socket

Make

within

to

by

duct

the

duct

drill

two

This

flue

to

the

by

duct

fac-

of

be

the

each

then

the

of

wall

the

in

the

flue

sure

the

5.

RECHECK

REQUIRED HAVE BEEN

6.

Working

assembly

about

of

flue

over

provided

accurately.

7.

Move

duct

socket.

the

wall

8.

Run a bead

the

pushing

air

duct

100mm

duct

the

the

should

The

face.

top

it

clamping

THAT

from

through

inside

section

the

appliance

be

back

Tighten

of

air

duct

down

ANY

outside

the

(4in)

the

of

flue

air

and

pushed

of

silicone

socket.

until

screw.

STUB

MADE.

pass

hole. A flue

is

allowed

terminal

duct

flue

into

its

fully

the

socket

the

air

sealant

it

is

fully

PIPE

(SECTION 9.3)

the

air

duct

expansion

for.

The

will

engage

connected

ducts

final

position.

home

should

duct

clamping

around

Refit

the

home.

CONNECTIONS

and

terminal

joint

short

section

and

the

the

flush

push

boiiE!r,

been

The

air

screw.

inside

plate

the

to

have

into

be

the

blanking

Tighten

of

cut

air

duct

with

of

top

REFER TO SECTION 9.3

9.1

c BOILER

FLUE

ASSEMBL

V

REAR

1201mm-

NOTE:

kit.

1.

(a)

{b)

Use

Cut

the

Measure

This

is

air

duct

Do

not

the

air

the

the

required.

reduce

(Fig. 13).

(c)

Fully

engage

into

the

expanded

(d)

Reduce

cutting

overall

Using

(e)

'B'

the

a

previously

and

supplied.

Slide

2.

'A',

Using

drill

supplied.

No.6 x 10mm

Cut

3.

(a)

Do

as a

drill

smear

secure

the

to

through

and

not

the

from

length.

the

guide,

supplied.

of

the

the

assemble

reduce

{Fig. 13)

(b) Take

(c)

If

(d)

(e)

the

Fully

engage

expanded

Reduce

cutting

length,

tained.

Using

the

as a

guide,

drill

supplied.

smear

of

ged

end

the

two

wall

the

from

after

(Fig.13)

silicone

of

self

2000mm

standard

duct

to

length

wall

thickness l and add

overall

two

silicone

engaged

(Figs. 13 & 14)

flue

rolled

holes

Secure

end

two

flue

length

(Figs. 4, 8

the

length

the

end

end

length

length

drill

tapping

of

the

end

(Fig. 13)

holes

drill

Disengage

sealant

with

terminal

stop

at

the

the

flue

the

self-tapping

the

the

length

thickness

either

of

flue

of

the

plain

engagement

holes

two

Disengage

sealant

duct

screws

in

two

end

the

channel.

assembly

flue

end

duct

in

3mm

'C'.

(4:,.3in-

flue

kit

as

follows:

of

110mm

and

of

the

of

air

duct

of

air

duct

the

standard

without

the

expanded

3mrn

the

around

of

air

two

into

the

end

o1'

terminal

screws.

duct

of

the

Land

of

'D'.

the

ex':ension

end,

until

of

the

expanded

diameter

the

around

Reassemble

supplied.

78.7in)

and

the

(4.5in)

16)

extension

'A'

(without

'B'.

air

holes

to

diameter

air

ducts

the

duct

'A'.

self-tapping

open

air

duct

with

together

(Figs. 13 & 14)

as

follows:

standard

add

51mm

flue

duct

(Fig. 13)

flue

the

required

the

two

holes

flue

ducts

the

previously

and

(Figs

extension

28mm

diameter

air

duct

the

end

of

holes

and

outside

Reassemble

end

of

'A'

as a

the

3mm

with

flue

(2.0in).

'C'

duct

ducts,

end

of

using

and

secure

13 & 14)

flue

(1.1in).

duct

'B'.

holes)

'A'

by

required

air

duct

using

apply

of

the

screws

air

duct

guide,

drill

the

two

duct

'C'.

into

the

'D'

by

overall

is

ob-

duct

'D'

the

apply

enga-

with

a

12

(f) Refer to Figs. 6 and

clamping screw sufficient to

ing plate to be

facilitate access to the rear flue duct clam

Fig.

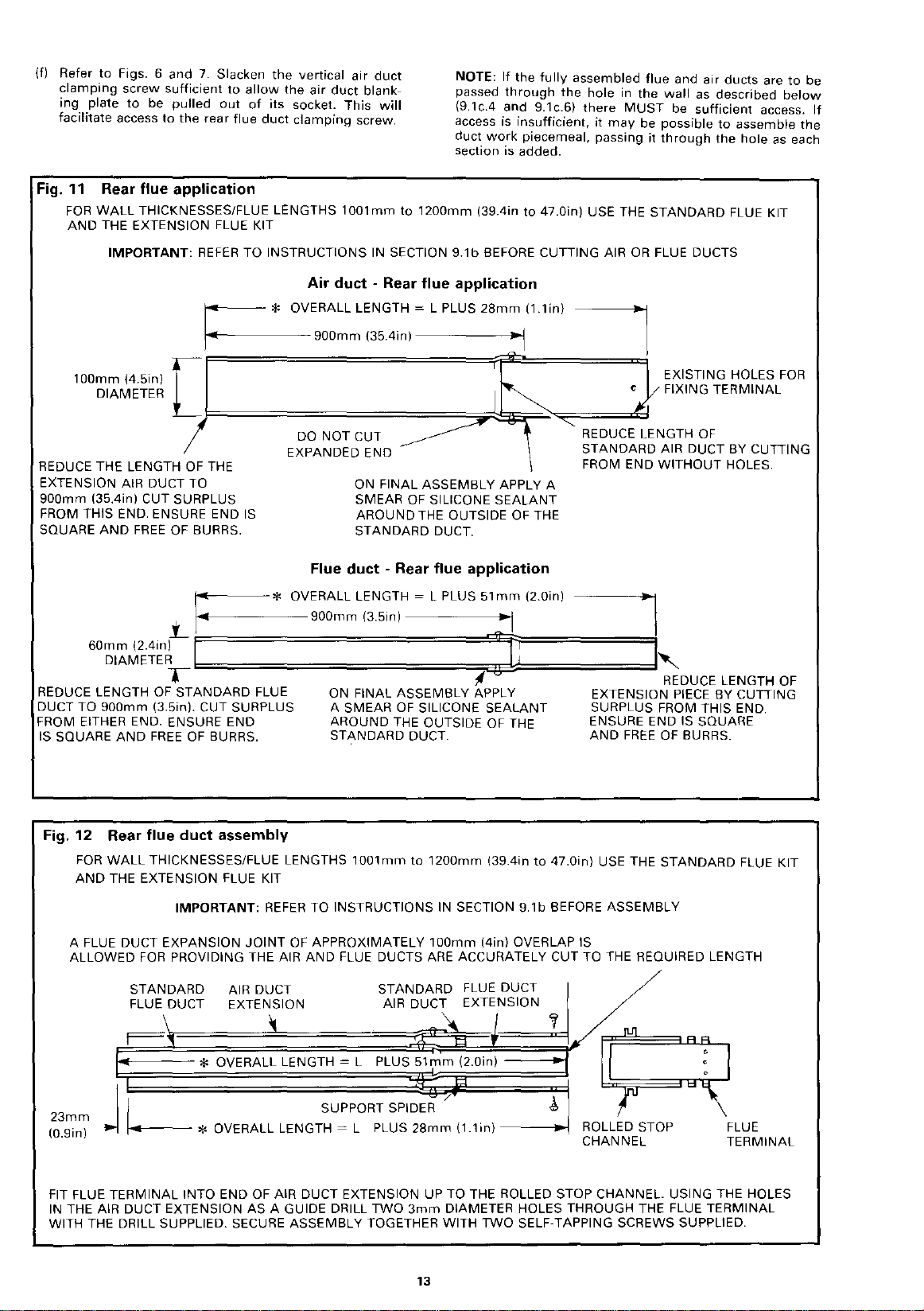

11

Rear flue application

FOR

WALL

AND

THICKNESSES/FLUE LENGTHS

THE EXTENSION FLUE KIT

7.

Slacken the vertical air duct

pulled out of its socket. This will

allow

the air duct blank-

pin~

screw.

1001mm

to

1200mm

NOTE:

If the fully assembled flue and air ducts are to be

passed through the

(9.1c.4 and 9.1c.6) there

access

is

duct work piecemeal, passing

section

is

(39.4in

insufficient, it

added.

to

47.0in)

hole

in

MUST

may

USE THE

the wall

be possible to assemble the

it

as

described

be sufficient access. If

through the hole

STANDARD

as

FLUE KIT

below

each

IMPORTANT:

REFER

TO

o---

l-·-t-------900mm

r:

100mm

(4.5in)

DIAMETER

[

f============"jrj!;/~~r2~==~/

/

REDUCE THE LENGTH OF THE

EXTENSION AIR DUCT TO

900mm

FROM THIS

SQUARE

REDUCE LENGTH OF

DUCT

FROM EITHER END. ENSURE END

IS SQUARE

(35.4in) CUT SURPLUS

END. ENSURE END

AND

FREE

OF BURRS.

~~:------*

.i_

i-o[-l-------900mm

60mm

(2.4in) I 1

DIAMETER

TO

900mm

AND

6::;:;:;:;:;:;:;============~~~=====;=====;=dl'.~

T

STANDARD

(3.5in). CUT SURPLUS A SMEAR

FREE

OF BURRS.

IS

INSTRUCTIONS IN SECTION

Air duct - Rear flue application

* OVERALL

DO

EXPANDED END

LENGTH~

(35.4in)-----~

NOT

CUT -

ON FINAL

SMEAR OF SILICONE

AROUND

STANDARD

Flue duct - Rear flue application

OVERALL

FLUE ON FINAL

LENGTH~

(3.5in) I

ASSEMBLY

AROUND

STANDARD

OF

THE OUTSIDE OF THE ENSURE END IS SQUARE

DUCT.

9.1

b BEFORE CUTTING AIR

L PLUS

28mm

(1.1in)

....,._1

~

ASSEMBLY

THE OUTSIDE OF THE

DUCT.

L PLUS

SILICONE

APPLY A

SEALANT

51mm

(2.0in)

~~

APPLY EXTENSION

SEALANT