Page 1

COPYRIGHT © 1995 BY WOODSTOCK INTERNATIONAL, INC., REG.# TX 3 360-515

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

PRINTED IN TAIWAN

REPRINTED FEBRUARY 1999

P.O. Box 2309

Bellingham, WA 98227

ROUTER TABLE

ITEM W2000

OPERATING MANUAL

®

Page 2

W2000 Rebel

®

– 1

TABLE OF CONTENTS

I. INTRODUCTION ..................................................................................................................................2

A. SAFETY INSTRUCTIONS FOR ALL TOOLS ............................................................................2

B. ADDITIONAL SAFETY RULES FOR THE REBEL

®

................................................................3

C. COMMENTARY ............................................................................................................................4

D. UNPACKING ..................................................................................................................................5

E. PIECE INVENTORY ......................................................................................................................5

II. ASSEMBLY ............................................................................................................................................6

A. STAND ............................................................................................................................................6

B. FENCE ............................................................................................................................................7

C. SAFETY GUARD ..........................................................................................................................8

D. MITER GAUGE ..............................................................................................................................9

E. ELECTRICAL SWITCH (OPTIONAL) ........................................................................................9

F. MOUNTING THE ROUTER ..........................................................................................................9

G. WIRING THE ROUTER ..............................................................................................................10

III. ADJUSTMENTS ..................................................................................................................................11

A. ROUTER TABLE INSERT ..........................................................................................................11

B. FENCE ADJUSTMENT................................................................................................................12

C. SAFETY GUARD ........................................................................................................................13

D. MITER GAUGE ............................................................................................................................14

IV. OPERATIONS ......................................................................................................................................15

A. SITE PLANNING..........................................................................................................................15

B. WORKING HEIGHT ....................................................................................................................15

C. SAFETY ........................................................................................................................................16

D. GENERAL OPERATIONS ..........................................................................................................16

E. STRAIGHT EDGE SHAPING......................................................................................................17

F. MITER GAUGE WORK ..............................................................................................................17

G. FREEHAND WORK ....................................................................................................................18

H. USING STOP BLOCKS................................................................................................................20

V. MAINTENANCE ..................................................................................................................................21

VI. PARTS BREAKDOWN........................................................................................................................22

VII. PARTS LIST..........................................................................................................................................23

VIII. WARRANTY AND RETURNS ..........................................................................................................24

Page 3

2– W2000 Rebel

®

For Your Own Safety, Read Instructions Before Using The Rebel

®

A. Safety Instructions For All Tools

These safety rules cannot cover every situation in a workshop. Consider your individual workshop conditions

when setting up or operating any machine.

• Always wear eye protection

• Always feed against the rotation of the cutter

• Use overhead guard when fence is not in place

• Keep fingers away from rotating cutters

• Do not use awkward hand positions

7. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should be kept

a safe distance away from your work area.

8. MAKE WORKSHOP CHILD-PROOF with

padlocks, master switches, or by removing

starter keys.

9. DO NOT FORCE TOOL. Tools work better

and more safely when they are allowed to work

at their own speed.

10. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, or jewelry that

might get caught in moving parts. Non-slip

footwear should be worn. Wear a hat or other

protective head wear if your hair is long.

11. NEVER STAND OR LEAN ON TOOL.

12. USE SAFETY GLASSES AND EAR PROTECTION. Also use a DUST MASK if the cut-

ting operation is dusty.

1. KNOW YOUR POWER TOOL. Read the

owner’s manual carefully. Learn the tool’s

applications and limitations, as well as its particular hazards.

2. KEEP ALL GUARDS IN PLACE and in

working order.

3. GROUND ALL POWER TOOLS. If an

adapter is used to accommodate a two-prong

receptacle, the adapter plug must be attached

to a known ground. Never remove the grounding prong.

4. REMOVE ADJUSTING KEYS AND

WRENCHES. Make it a habit to check that

keys and adjusting wrenches are removed from

the machine before turning it on.

5. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

6. AVOID DANGEROUS ENVIRONMENTS.

Do not use power tools in damp or wet locations or expose them to rain. Keep your work

area well lighted.

I. Introduction

Page 4

W2000 Rebel

®

– 3

B. Additional Safety Rules For The Rebel

®

18. NEVER LEAVE THE TOOL RUNNING

UNATTENDED - TURN POWER OFF. Do

not leave the tool until it comes to a full stop.

19. DO NOT OPERATE THE TOOL IF USING

DRUGS, ALCOHOL, OR MEDICATION.

20. DO NOT WORK IN HASTE or operate

machine if you are mentally or physically

fatigued.

21. IF THERE IS SOMETHING YOU DO NOT

KNOW OR UNDERSTAND, DO NOT

OPERATE MACHINE! Ask for help first.

Confusion is dangerous.

22. BAD HABITS ARE DANGEROUS. Review

all safety procedures often.

13. DO NOT OVERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS IN TOP CONDITION.

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

15. DISCONNECT TOOLS FROM POWER

before servicing and when changing accessories,

such as blades, bits, and cutters.

16. AVOID ACCIDENTAL STARTING. Make

sure the switch is in the “OFF” position before

plugging in the cord.

17. CHECK DAMAGED PARTS. Do not operate

the machine until you are certain it is in perfect

running condition.

1. Always feed against the rotation of the cutter.

For most routers and bits, the direction of feed

is from right to left as you face The Rebel

®

.

2. Always cut the end grain first before putting an

edge all the way around any stock such as a

table top or raised panel to guard against grain

tear-out as the workpiece clears the bit.

3. Use quality material. Wood that is cupped,

warped, bent or split will not machine properly and can present many safety hazards. Do not

shape or rout material that contains loose or

unsound knots.

4. The router collet must be securely tightened

against the router bit. A loose router bit can

cause serious injury. Periodically check to see

if the router bit is held securely in the collet.

5. Always use the safety guard and incorporate

feather boards, hold downs or other safety

devices when using your router table.

6. When shaping end grain there is a greater tendency for kick-back. Hold the workpiece firmly using clamps, jigs or fixtures and feed evenly.

7. Wear ANSI approved safety equipment such as

eye, face, ear and respiratory protection.

8. Use sharp router bits. The old adage is true: A

sharp tool is a safe tool.

9. Plan your work. Figure your steps out before

you start cutting

10. Do not shape material that is too small to be

safely processed without a jig or fixture to hold

the piece

11. Make sure that all fasteners used in assembly

have not vibrated loose.

12. A starting pin or starting block must be used

when shaping irregular workpieces.

The following are important safety considerations when using The Rebel®.

Page 5

4– W2000 Rebel

®

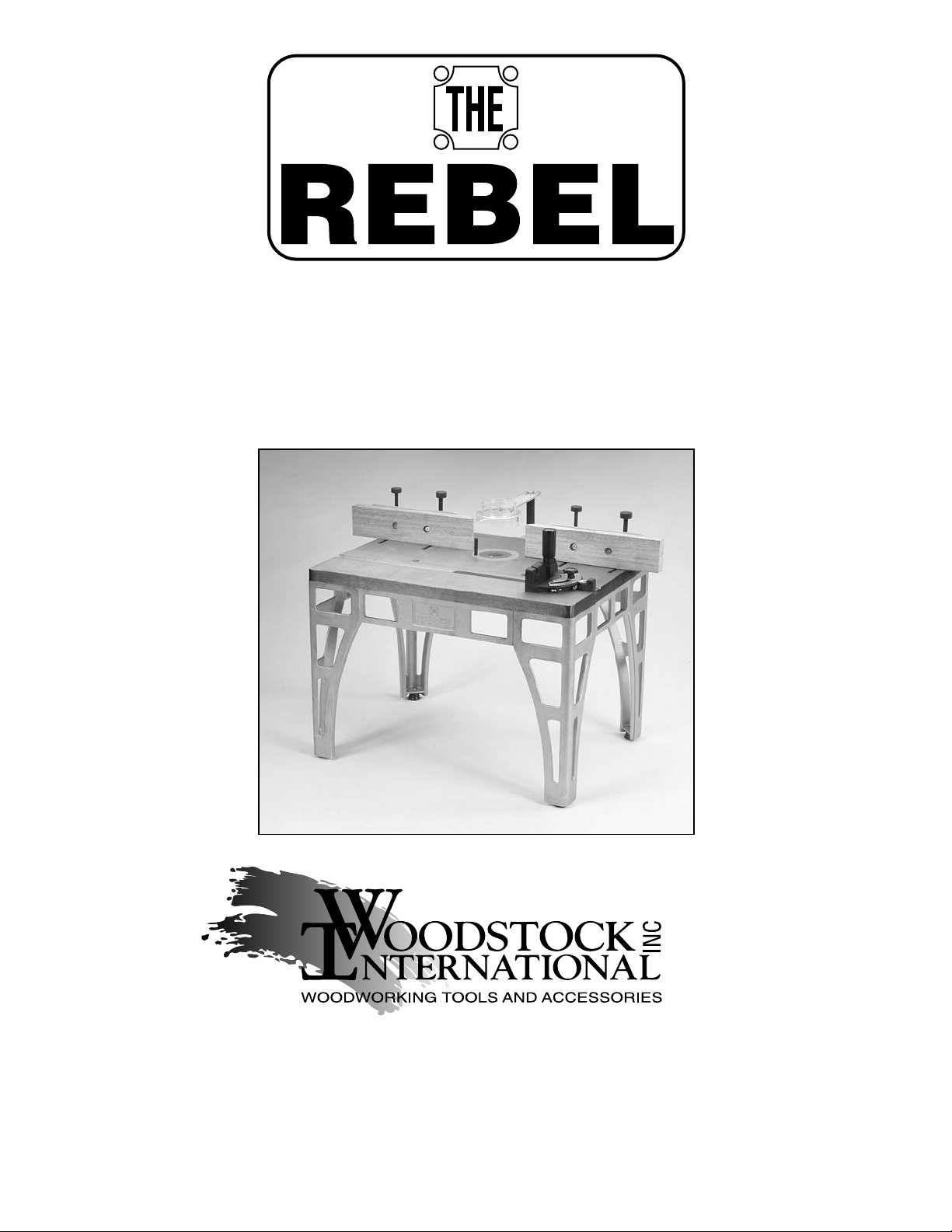

Woodstock International, Inc. is proud to offer the

W2000 Rebel

®

Router Table. The Rebel®, named

because of its radical design and construction features,

is substantially different to what is currently available

in the market place. You won’t find any tin, plastic or

wood construction that looks as if it’s been hammered

out in someone’s garage. Instead you will find an inherent ruggedness which denotes strength and durability.

The Rebel

®

represents countless hours of research,

development and hands-on testing by skilled woodworkers. The effort that went into the development of

this router table will be appreciated every time you use

it.

The Rebel

®

, in conjunction with your router is truly a

versatile woodworking tool. This combination will

allow you to utilize the full potential of your router. The

Rebel

®

will allow you to joint, rabbet, slot, flute cove,

bead, miter, mold, tenon and perform many other tasks

that are necessary for fine quality woodworking. Best

of all, The Rebel

®

can be used by anyone at any level of

woodworking. The beginner as well as the master

craftsman will appreciate its versatility and will come to

depend upon its quality construction, ruggedness and

durability.

Woodstock is committed to offering top quality

products and supporting them through customer service

and technical documentation. The manual you now

have represents our latest effort to produce the best documentation possible. If you have any criticisms or comments you feel we should pay attention to in our next

printing, please write us at the address below.

Manager, Technical Documentation

Woodstock International, Inc.

P.O. Box 2309

Bellingham, WA 98227

FAX 1-800-647-8801

Phone 360-734-3482

If you have any parts problems or requests, please contact your Woodstock distributor or call Woodstock

International at 1-800-840-8420 between 8am and 5pm

Pacific Standard Time, Monday through Friday.

The specifications, drawings, and photographs illustrated in this manual represent the Model W2000 as

supplied when the manual was prepared. But owing to

Woodstock’s policy of continuous improvement,

changes to the Model W2000 may occur at any time

with no obligation on the part of Woodstock. Should

you receive a manual update, please insert it into the

manual and keep it for reference.

We have included some important safety measures

which we believe to be essential to this tool’s

operation. While most safety measures are generally

universal, Woodstock reminds you that each work

environment is different and safety rules should be

considered

as they apply to your situation.

We also believe additional information sources are

very important to better realize the full potential of this

tool. Trade journals, woodworking magazines, and

your local library are good places to start.

The Model W2000 was designed for shaping. It must

never be modified and/or used for any other purpose.

Modifications or improper use of this tool will void

all warranties. If you are confused about any aspect of

the Rebel

®

, DO NOT use it until you have resolved

any questions you might have.

C. Commentary

To operate this, or any tool, safely and efficiently, it is essential to become as familiar with its

characteristics as possible. Take as much time as

necessary to become acquainted with the W2000

Rebel

®

Router Table. The time you invest before

you begin to use it will be time well spent. Also,

read all of the safety procedures. If you do not

understand them, DO NOT use your Router

Table. Serious personal injury may occur.

Page 6

W2000 Rebel

®

– 5

The Rebel®is designed for heavy-duty use, yet it

weighs only 35 pounds and is completely portable.

However, when lifting, we must caution against

improper lifting techniques. Always keep your back

straight and lift with your legs. If you are limited by the

amount of weight you can lift and carry, please refrain

from moving The Rebel

®

until you get the necessary

assistance.

At this time, slide the solid foam packing out. The parts

are arranged in two layers of packing. Remove the

parts in an orderly fashion. This will simplify identification and make inventory and assembly that much

easier. When removing the parts, please take care not

to destroy the foam and cardboard carton. It is a good

idea to save the carton for future storage or shipment if

necessary. After you have completed your inventory,

inspect all the parts (especially the contact areas) for

burrs and other irregularities which might hinder the

assembly process. If you find any burrs or flash left

over from the machining or casting process, simply

sand or file them flat. Please note that while this is not

a common occurrence, it is possible that one or more of

the parts could have been missed during the machining

and deburring process.

Carefully remove the items packed in the carton. It

may be a good idea to save the carton and packing

material in case it might be needed in the future. Upon

removal of all items from the package, you should

have:

In the event that any non-propriety parts are missing

(e.g. a bolt or nut etc..) we would be glad to replace it.

For expediency, replacements can be obtained from

your local hardware store.

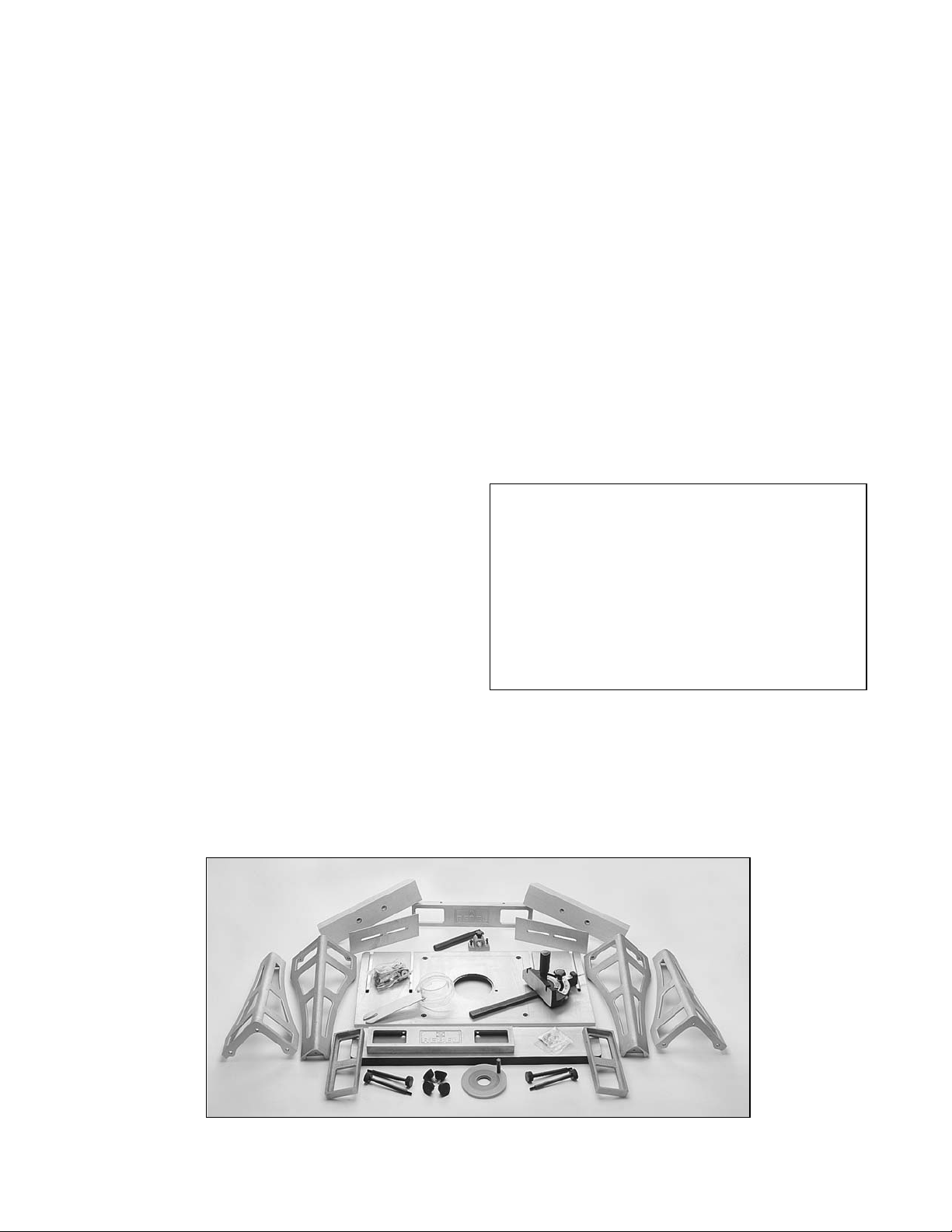

Figure 1. Rebel®parts ready for assembly.

Contents of the bolt bag.

1 Working Table

4 Legs

4 Rubber Feet

2 Short Side Panels

2 Long Side Panels

2 Aluminum Fences

2 Wood Facings

4 Fence Lock Handles

4 T-Nuts (Bagged)

1 Plastic Insert Assembly

1 Starting Pin

1 Safety Guard

1 Safety Guard Bracket

1 Safety Guard Rod

2 Cap screws

1

/4 - 28 x 1''

1 Miter Gauge

1 Miter Gauge Handle

1 Bolt Bag

Description:

Cap Screws:

Setscrews:

Hex Nuts:

Flat Washers:

Flat Head Screws:

Hex Bolt:

Size:

1

/4'' - 28 x 5/8''

1

/4'' - 28 x 3/4''

10 - 32 x

3

/4''

10 - 32

1

/4'' - 20

1

/4''

5

/16''

1

/4'' - 20 x 11/4''

5

/16'' - 18 x 3/4''

Qty:

20

2

4

4

2

10

1

4

1

E. Piece InventoryD. Unpacking

Page 7

6– W2000 Rebel

®

Assembly of The Rebel® is extremely straight forward

and can be accomplished with just a few simple hand

tools. In fact, the only tools you will need are a regular

screwdriver, Phillips

®

screwdriver, adjustable wrench,

3

⁄16" Allen®wrench and a good quality straight edge.

The design of The Rebel

®

is such that most of the parts

are joined together with socket head cap screws. We

recommend that you assemble The Rebel

®

in the order

presented here. Use the exploded parts diagram for

visual reference during assembly. We suggest that you

use a table or work bench that has sufficient surface

area to hold all of your tools and the finished Rebel

®

safely and securely. It is also best to have a well lighted area to reduce eye strain during assembly.

The stand is made up of four legs, two side pieces and

a front piece and back piece. All similar parts are interchangeable with one another.

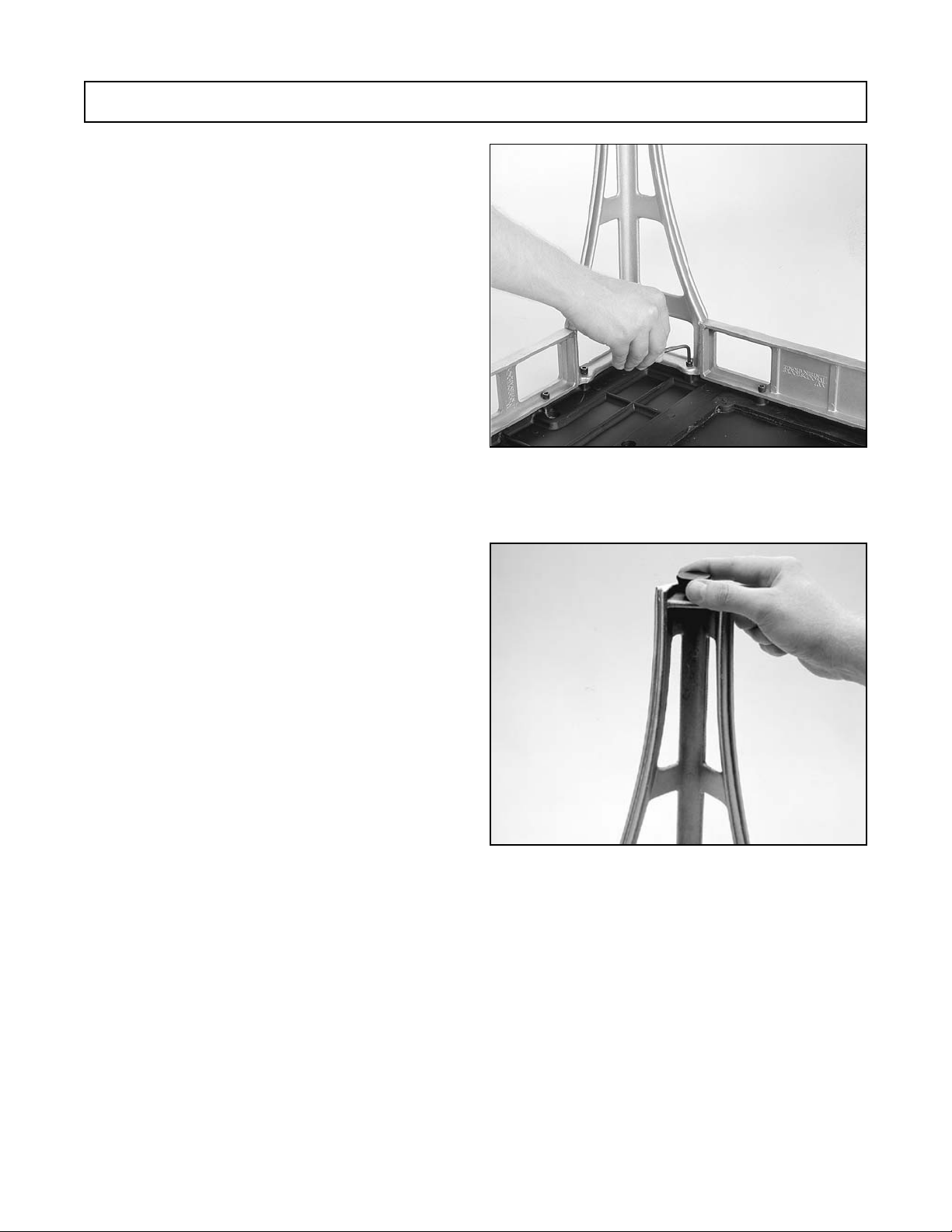

Step 1 - Turn the working table up side down and

loosely bolt on all four legs using the

1

⁄4"-28 x

5

⁄8" socket head cap screws provided.

Step 2 - Mount the short and long side panels between

the legs using the

1

⁄4"-28 x 5⁄8" socket head cap

screws provided. Figure 2.

Step 3 - Use a

3

⁄16" Allen®wrench to assist in starting

and tighten all cap screws down.

Step 4 - Attach the feet to the legs. Figure 3.

Step 5 - Turn the stand assembly over and move on to

the next section.

A. Stand

Figure 2. Mounting legs and side panels to the work-

ing table.

Figure 3. Attaching the feet to the legs.

II. Assembly

Page 8

W2000 Rebel

®

– 7

Figure 4. Attaching the fence.

The Rebel®has a two-part, split fence designed for

either straight-line or offset shaping. Assembling the

fence is quite simple and straightforward.

Step 1 - Choose one of the fence halves. Select two

fence lock handles and insert the threaded

ends into the

1

/4'' flat washers and two holes

on the bottom of the fence. Select two T-nuts

and loosely thread onto the ends of the lock

knobs. Line up the T-nuts with the slots in the

router table and slide the fence onto the router

table. Figure 4. Roughly lock the fence in

position. Repeat this process for the other

fence half.

B. Fence

Step 2 - Attach the wood facings to the fence using the

flat head screws, flat washers and hex nuts

provided. Figure 5. Tighten for now; howev-

er, you will notice that there are slots in the

back of the fence for side to side adjustment.

Side to side adjustment of the wood facings is

dependent upon the overall diameter of the

router bit. For maximum safety and support,

adjust the wood facings as close to the router

bit as possible. Check clearance before starting the router.

Figure 5. Attaching the wood facing.

Page 9

8– W2000 Rebel

®

The safety guard system consists of a clear plastic

guard and arm which have been assembled at the factory. There is also a height adjustment bar, mounting

bracket with lock knob and bolt and washer. The clear

plastic guard has been designed to fit over the router bit

during operation and can be connected to a 3" flexhose for dust collection purposes.

Step 1 - Mount the safety guard mounting bracket to

the back of The Rebel

®

table with the two 1⁄4"-

28 x 1" socket head cap screws provided.

Figure 6.

C. Safety Guard

Figure 6. Mounting safety guard bracket.

The miter gauge has been pre-assembled at the factory,

except for the handle. The handle greatly aids in miter

gauge control. To assemble the handle:

Thread the handle into the hole located on top of the

miter gauge body and tighten down. Figure 8.

D. Miter Gauge

Figure 8. Attaching the miter gauge handle.

Figure 7. Safety guard installed.

Step 2 - Insert the height adjustment bar into the

mounting bracket so the threaded hole is facing up. Tighten the lock knob to secure the

height adjustment bar.

Step 3 - Slide the

5

⁄

16"-18 x

3

⁄

4" hex head bolt through

the

5

⁄16" flat washer and loosely thread into the

hole on top of the height adjustment bar.

Step 4 - Slide the slotted end of the safety guard arm

under the washer and tighten the hex head

bolt. Figure 7.

Page 10

W2000 Rebel

®

– 9

Although the power switch on your router can be

turned on and off each time you use The Rebel

®

, the

optional switch (Item Number W2001) offers greater

convenience and safety. The optional switch is available through your retailer.

The switch assembly consists of a guarded rocker type

switch with removable key, three prong 110 volt

female cord and three prong 110 volt male power cord.

Step 1 - Mount the electrical switch in the right front

leg opening. To mount the switch, feed the

male and female cords through the leg opening and snap the switch plate into place.

Figure 9.

E. Electrical Switch (optional)

Figure 9. Installing the switch.

Figure 10. Attaching the grounding ring terminals.

Step 2 - The two grounding terminals must be

attached to the Rebel

®

frame. Remove any

convenient socket head cap screw attaching

the leg to the tabletop. Overlap the two ring

terminals connected to the end of the two

grounding (green) wires. Insert the socket

head cap screw through the ring terminals and

re-fasten to the tabletop. Figure 10.

Grounding

Ring

Terminals

The Rebel®must be electrically grounded when

using the optional switch. Failure to attach the

grounding terminal to the Rebel

®

frame may

result in serious personal injury.

F. Mounting the Router

Figure 11. Removing sub-base from router.

Attaching your router to The Rebel®is very easy.

When using your router in The Rebel

®

you must

follow all safety recommendations by the router manufacturer.

Step 1 - Remove the existing router sub-base that is

attached to your router base. Figure 11.

Page 11

10 – W2000 Rebel

®

If using the optional safety switch, make sure it is in

the off position. You can now plug your router into the

cord connected to the back of the switch. Turn the

router switch on. Refer to the router instruction manual. If everything is secure, including router collet and

all loose tools and bits are put away, you can now test

the optional switch. Plug the 110V plug from The

Rebel

®

switch into the wall outlet. Turn the safety lock

switch on and the router should start up.

If using The Rebel

®

without the optional switch,

observe all safety procedures, plug your router power

cord into an outlet and switch the router on. Some

routers have a simple toggle switch while others have

a trigger switch with locking device for hands-free

operation. If your router has a spring loaded locking

devise, depress the trigger, depress the locking devise

and then release the trigger. To turn the router off, simply depress the router switch to release the locking

device. Please refer to the instruction manual supplied

with your router for more information regarding your

particular switch.

G. Wiring the Router

Figure 12. Marking insert for drilling.

Figure 13. Drill and counter sink insert.

Step 3 - Drill and counter sink the screw holes in the

table insert. Fasten the router base to the

router table insert using the screws from the

router sub-base. Figure 13.

Your existing sub-base mounting screws may be

too short to safely secure your router to the table

insert. Ensure that your mounting screws are

sufficiently long enough to safely hold your

router in an inverted position. If necessary, purchase longer mounting screws of the same thread

size to secure your router to the table insert.

Step 4 - Make sure all router mounting screws are fas-

tened securely and slip the router with the

router table insert into The Rebel

®

table.

Always wear safety glasses and follow all safety

procedures. If using an extension cord, it must be

rated “Hard Service Grade S” — or better.

Conductor size must be 12 AWG, or larger, and the

cord must contain a grounding wire and plug pin.

Repair or replace the extension cord if damaged.

Step 2 - Center the sub-base on the table insert and

mark the screw mounting locations on the

table insert. Figure 12. To find the center of

the table insert, position the sub-base on the

table insert so the distance from edge to edge

on the right and left side are the same and the

distance from edge to edge on the top and

bottom are the same.

Page 12

W2000 Rebel

®

– 11

A. Router Table Insert

Located in the four corners of the insert ledge on the

table are four holes. These holes are threaded to accept

the 10-32 x

3

⁄4" setscrews provided. Figure 14. The

setscrews are turned in or out from underneath to

adjust router table insert flush with the table.

III. Adjustments

To adjust the router table insert:

Step 1 - Use a good quality straightedge and place it

on the table surface so it rests above one corner of the router table insert. Figure 15.

Step 2 - Loosen the jam nut and turn the leveling

setscrew in or out so that the router table

insert just touches the straightedge.

Step 3 - Repeat this procedure for the other three

corners.

Step 4 - Re-check each corner and make fine adjust-

ments if necessary. Once the insert is level,

tighten down all four jam nuts.

Figure 14. Leveling setscrew and jam nut.

Figure 15. Checking insert for flushness.

Page 13

12 – W2000 Rebel

®

For applications where the entire edge of the workpiece is being shaped, the outfeed fence must be offset

by the same amount of material that you are removing.

Use a sample piece at least 12" long as a test piece.

Read and follow all safety procedures covered in this

manual before cutting a sample.

B. Fence Adjustment

The Rebel®uses a two-piece fence adjusting system.

Each fence can be independently controlled. This system has the advantage of allowing the two fences to be

offset from one another. In certain applications, such

as edge jointing, this offset is necessary to safely and

precisely machine your workpiece. In other instances

where the outfeed bearing surface is the same as the

infeed bearing surface, the two fences must be perfectly aligned in the same plane. The split fence arrangement gives you the flexibility to do both.

To move the fence, simply loosen the two fence lock

handles and slide the fence either forward or backward

and lock in position.

Depending on the size of the router bit and the amount

of material to be removed, adjust the infeed fence. The

infeed fence is the right hand fence as you are facing

the front of The Rebel

®

. Slide the infeed fence to the

back or to the front depending upon the desired depth

of cut. Use a good quality rule to measure the distance

between the miter gauge slot and the maximum arc of

the router bit. Transfer this measurement, less the

desired depth of cut, to both ends of the infeed fence.

You can also gauge the infeed fence by placing a sample piece of wood against the fence and sliding it up to

the router bit. Figure 16.

Figure 16. Gauge position of infeed fence with a

sample piece of wood.

Figure 17. Gap indicates amount fence should be

adjusted.

Gap

Both fences must also be perfectly parallel with each

other. Check each fence with a precision rule against

the miter slot. Add the offset amount, if any and measure the outfeed fence at both ends. If each end of the

infeed and outfeed measurements are the same, then

the two fences are parallel.

Do not make fence adjustments while the router

is running.

Adjust your infeed fence accordingly. Feed the sample

far enough so that the end of the workpiece extends

well beyond the cutter and overlaps with the outfeed

fence. Figure 17. With the uncut end still supported by

the infeed fence, adjust the outfeed fence so that it supports the other end of the workpiece. After the outfeed

fence contacts the workpiece and is securely locked in

position, begin again with your test piece and make a

full length sample cut. If your workpiece catches on

the edge of the outfeed fence, then the fence must be

set back slightly for the workpiece to clear. On the

other hand, if everything clears but your are getting

snipe on the end of your workpiece, then the edge of

the outfeed fence needs to be brought forward.

Page 14

W2000 Rebel

®

– 13

Figure 18. Fence alignment.

Figure 19. Safety guard adjusted properly.

For applications where an adequate bearing surface

remains after edge shaping, the fences must be in a

straight line in relation to one another. One of the easiest ways to do this is to remove the existing wood facings and put on a one piece unit. Make sure the piece

you use is rigid enough so it does not flex as you push

your workpiece along. We recommend using

3

⁄4" hardwood plywood for stability and strength. Of course,

most species of solid hardwoods are just as suitable

(birch, maple, etc.). For some applications it may be

necessary to notch the bottom of the auxiliary wood

fence so it will clear the router bit.

If you would rather use the fence as is, then you must

adjust the outfeed fence so it lies in the same plane as

the infeed fence. To adjust the two fences, simply take

a good quality machined straightedge and place it

against the infeed fence. Adjust the outfeed fence up to

the straightedge and lock in position. Figure 18.

The safety guard’s primary purpose is to keep your fingers away from the router bit. The secondary function

is to serve as a dust pickup. Always use the safety

guard! Adjust the safety guard as follows:

Step 1 - Loosen the

5

⁄16" hex bolt. Center the safety

guard over the router collet and re-tighten the

hex bolt.

Step 2 - Loosen the lock knob and lower the safety

guard as close to the workpiece as possible

without restricting stock movement. Figure

19. After the guard has been positioned,

securely tighten the lock knob on the back of

The Rebel

®

table.

Step 3 - A dust collector or shop type vacuum can be

connected to the top of the safety guard. Use

a 3" flex hose and secure with a hose clamp.

Figure 19. When connecting a dust collection

unit, make sure that the hose and other dust

pickup devices do not hamper your movement or stock feeding. Please note that the

safety guard is not intended to be used as a

hold down. All hold downs and other safety

devices must be used correctly so they will

work as intended.

C. Safety Guard

Please take the time to adjust your fence correctly. You

will avoid frustration and the chance of ruining your

workpiece. Remember to always use a sample and

make a test cut before using a finish piece. Always

double check yourself and make sure that the lock

knobs are securely tightened so the fence will not move

during the routing process.

Page 15

14 – W2000 Rebel

®

Figure 20. Miter gauge.

Step 6 - Adjust the 90° miter gauge stop bolt so it rests

against the pin. Re-tighten the jam nut. Be

careful not to alter the position of the stop

bolt.

Step 7 - Re-check the squareness of the miter gauge to

the miter slot using your square. If it is not

square, repeat steps 1-6.

Repeat steps 1-7 for the two 45° miter gauge stop bolts.

In order to make straight, predictable miter cuts, the

miter gauge must be properly adjusted. There are 3

adjustable stops built into the miter gauge (two at 45°

and one at 90°) that are engaged by pushing in the stop

pin. These stops make it easier to make changes in the

miter gauge angle.

To adjust the miter gauge stops:

Step 1 - Insert the miter gauge into its slot and adjust

the blade angle to 90°. Pull out the miter

gauge stop pin.

Step 2 - Place an accurate square against the miter

gauge bar and the face of the miter gauge.

.

Step 3 - If there is a gap between the miter gauge bar

and the square, loosen the miter gauge lock

knob and move the face of the miter gauge

into the square until the gap is eliminated. Re-

tighten the lock knob.

Step 4 - Push in the miter gauge stop pin.

Step 5 - Loosen the jam nut on the stop bolt.

Stop pin

lock knob

Jam nut

Stop bolt

D. Miter Gauge

Page 16

W2000 Rebel

®

– 15

A. Site Planning B. Working Height

Although The Rebel®is completely portable and can

be set up and used just about anywhere, we would like

to discuss some basic considerations. When choosing a

location for The Rebel

®

, ensure that there is adequate

room for maneuverability and safety. Give yourself

enough room for the longest piece that you anticipate

shaping. Keep the area clean and open so that you can

access The Rebel

®

from all four sides. This not only

gives you plenty of elbow room, but it makes adjusting

and using The Rebel

®

that much safer and easier. If

you plan to process long stock, we suggest that you

pick up a couple of roller stands to support the infeed

and outfeed end of the workpiece during machining.

Finally, when choosing a location, make sure that you

have adequate lighting so that you can clearly see what

you are doing.

When transporting The Rebel

®

to the job site, take

measures to protect it from damage. Do not stack other

equipment or lumber on top of the table. Secure The

Rebel

®

so it will not bounce around and cause nicks,

dents and/or casting cracks. Once at the job site,

observe the same considerations as you would for stationary use. Always give yourself plenty of room.

IV. Operations

The Rebel®was designed to be used with a fabricated

stand to raise the height to a comfortable distance

above the floor.

The recommended working table height above the

floor ranges between 32" and 36", depending on your

personal preference. The Rebel

®

is 17" tall, so the

stand should be between 15" and 19" tall.

Minimum stand width and depth are 26" and 20"

respectively. The width and depth can, of course, be

increased to suit your needs.

The stand should be strong enough and have the stability to support the anticipated weight of material and

the hold-down pressure of the operator. Please follow

all safety procedures when constructing a new or

adapting an existing stand or bench top. We also caution against temporary support surfaces such as a thin

piece of plywood on top of a couple of saw horses.

While this is certainly quick, we do recommend that if

you use plywood and saw horses, make sure that the

top is strong and stable enough and will not flex or

shift under load.

Adjust the foot pads to compensate for any irregular

stand surface. It is very important that The Rebel

®

is

stable and supported by all four legs. If machining long

or unstable stock, we recommend removing the feet

and securing The Rebel

®

directly to the table surface.

It may be necessary to shim under the legs to compensate for an irregular stand surface before permanently

securing The Rebel

®

. Mount The Rebel®to the work

surface with screws, lag bolts or clamps - whichever is

easier.

Do not operate The Rebel®in a position that will

compromise comfort and safety. Serious personal injury may occur.

Page 17

16 – W2000 Rebel

®

D. General Operations

The general operating procedures are just that: “general in nature”. They are not the final word on performing any one of the many functions that are possible

with The Rebel

®

. If you are a beginning woodworker,

gather as much information as you can and understand

all safety procedures about woodworking relating to

your particular operation. There are plenty of information sources available, from public TV, books and

video’s to the high school shop instructor or woodworking club in your area. Do not jump right in and

attempt to perform something beyond your capabilities. Instead, start by making simple projects to gain

the experience necessary to do more complex tasks. No

matter what your skill level, always practice good safety procedures and follow the recommendations listed

in this manual.

C. Safety

Figure 21. Pressure rollers.

Figure 22. Feather board.

Before you use your Rebel®, Please review the general

safety rules for all power tools listed in the beginning

of this manual.

There are many after-market hold-down devises available that increase the safety factor when processing

material. These hold-down devises include springloaded pressure wheels and feather boards. Figure 21

and 22.

When adjusting the fence, replacing router bits

or performing any maintenance or inspection,

always turn the router off, make sure it has come

to a complete stop and pull the plug from the outlet BEFORE performing such duties.Serious personal injury may occur.

Please observe all safety rules specified in your

router owners manual. Make sure you fully understand your capabilities and that you have a complete

understanding of your router and the inherent hazards associated with it. You must follow all safety

procedures and perform each operation in the safest

way possible. Failure to do so may result in serious

personal injury.

Page 18

W2000 Rebel

®

– 17

E. Straight Edge Shaping

Straight edge shaping requires the use of the fence

assembly. Although many edge shaping router bits

have a guide bearing, the fence should still be used to

provide maximum support and safety during the routing operation. Please review the Fence Adjustment

Section on Page 13. Remember use a sample piece of

wood and make a test cut. For straight edge shaping,

proceed as follows:

Step 1 - Select the appropriate router bit and mount it

securely into the router collet. Follow the

router manufacturer’s recommended procedure.

Step 2 - Adjust the router and router bit height in rela-

tion to your workpiece. Lock the router

height adjustment mechanism into position.

Again follow the manufacturer’s recommended procedure.

Step 3 - Position the infeed fence for the correct depth

of cut. Please refer to the Fence Adjustment

Section.

Step 4 - Select a sample piece of wood for testing.

Make sure the sample you choose is at least

12'' long. As with your finish piece, the test

piece must be processed using all safety measures and safety devices. After you have completed your test cut, re-adjust the router bit

height, the fences, the hold downs or other

safety devises if necessary. Please refer to the

appropriate sections in this manual.

If removing a lot of material, it is best to run your

stock through in multiple passes, each time setting

the router to cut deeper until reaching the desired

depth.

F. Miter Gauge Work

Step 1 - Position the miter gauge in the miter slot.

Always feed against the direction of router bit

rotation. Adjust the miter gauge angle if necessary. See Miter Gauge Adjustment on

Page 15.

Step 2 - Since the miter gauge supports the work

through the entire cut, slide the outfeed fence

out of the way. Failure to do so may cause a

dangerous kick-back situation. The infeed

fence in conjunction with a wood block may

be used as a workpiece positioning guide

when using the miter gauge.

Step 3 - Determine the depth of cut and position the

workpiece against the miter gauge. Firmly

hold the workpiece against the miter gauge

body and slide the miter gauge and workpiece

past the router bit. Figure 23.

When shaping end grain, the router bit will tend to

tear-out the wood as the bit clears the workpiece. To

prevent tear-out, use a back-up piece of wood positioned between the workpiece and the miter gauge.

You may also fasten a wood face piece against the

miter gauge body with screws through the two slots.

Ensure that the face piece is long enough to support the

end of the workpiece but not so long that it won’t slide

past the router bit.

Figure 23. Using the miter gauge.

The miter gauge is used to control narrow workpieces

when shaping or routing end grain such as door rails,

tenons and profiling edges. To use the miter gauge:

Page 19

18 – W2000 Rebel

®

G. Freehand Work

The Rebel®is ideally suited to performing freehand

work. Freehand shaping enables you to profile the edge

of curved or irregular shaped wood. In order to freehand shape on The Rebel

®

: The fence must be

removed, a starting pin or starting block and a router

bit with a guide bearing must be used.

In many cases it is advantageous to use a jig or fixture

during freehand shaping. When properly designed, a

jig or fixture will: Keep the workpiece firmly in position, speed production runs, provide a guide for pattern

work and provide greater safety for the operator. When

freehand shaping, we recommend the use of a jig or

fixture whenever possible.

When making a jig or fixture, use a material that is

dimensionally stable and is easy to fasten such as a

good quality plywood or MDF. If the fixture will

incorporate a pattern, use a material that will smoothly

follow the guide bearing. Figure 24.

Do not use rough wood composites such as oriented

strand board or a plywood with inner voids for a pattern edge. The jig or fixture should also be stable, comfortable to use and designed with safety in mind.

Secure your workpiece with blocks, screws or wedges.

If using screws, make sure they don’t protrude through

the finish face of your workpiece.

The workpiece should rest flat on the surface of the

table and must not chatter inside the jig. There are a

number of shaper handbooks available that describe

many types of jigs, fixtures, hold-downs and patterns

that are used in the cabinetmaking industry. These

same books apply to router shaping as well. When

using any fixture, always test it to ensure that it functions as it was intended before turning your router on.

To freehand shape, proceed as follows:

Step 1 - Remove the two part fence assembly from

The Rebel

®

.

Step 2 - Place the starting pin in the router insert or

clamp a starting block to the table surface.

Figures 25 and 26.

Figure 24. Inverted Fixture with workpiece.

Figure 25. Using the starting pin. Note: safety guard

has been raised to demonstrate pin positioning.

Page 20

W2000 Rebel

®

– 19

Step 6 - Once the workpiece or fixture is contacting

the guide bearing on the router bit, move the

workpiece or fixture away from the starting

pin or starting block and continue feeding

against the guide bearing. Figure 27. It is

important that you feed the work smoothly

and evenly in order to reduce tear-out and

burning. In some cases it may be desirable to

start and end the cut in waste portions of the

workpiece in order to avoid these types of

problems.

Step 7 - As you approach the end of a squared off cut,

control the workpiece or fixture so that the

corner of the workpiece or fixture does not

ride around the guide bearing. Slide the workpiece smoothly past the guide bearing.

Step 3 - Insert a desired router bit with support bear-

ing into your router and securely tighten the

router collet. See your router owner’s manual

for correct procedure.

Step 4 - Set the depth of cut by raising or lowering the

router in its mounting base. Refer to your

router owner’s manual.

Step 5 - Follow all safety procedures and turn the

router on. Firmly support the workpiece

against the starting pin or starting block AND

THEN gently swing the work into the router

bit.

Figure 27. Work is supported by the guide bearing.

Figure 26. Using a starting block.

It may be necessary to lift the router insert with

router out of The Rebel

®

to safely and efficiently

install or remove router bits.

There is a tremendous cutting force on the workpiece. Fixtures must be stable, solid and designed

for safety. Please follow all recommended safety

procedures.

Page 21

20 – W2000 Rebel

®

Figure 28. Stop block in position.

H. Using Stop Blocks

If a particular application requires that you precisely

and consistently start and/or stop multiple workpieces

at the same place, it may be beneficial to use stop

blocks. Stop blocks are positioned so that when the end

of the workpiece contacts the stop block, travel is

restricted. Figure 28. For example, if cutting mortises

with a router, they must be precise in length so that the

tenons will fit properly. In some instances, it may be

desirable to precisely start and/or stop while doing

edge work such as chamfering. Stop blocks can be simple scraps of wood that clamp to the fence or table or

they can be adjustable, after-market stop blocks that

attach to the top of the fence. To use stop blocks, determine their position and secure to the fence or table.

The amount of offset between the stop block and router

bit is dependent upon the distance between the end of

the cut and the end of the workpiece. Test your setup

with a scrap piece of wood and adjust if necessary.

Once the stop blocks are properly adjusted, it is a simple matter to produce consistent, multiple cuts.

Page 22

W2000 Rebel

®

– 21

Because there are no moving parts, maintenance is virtually eliminated. However, we do make the following

recommendations:

• Give the table a shot of some type of protec-

tive coating. Many types of machine table

coatings are available on the market today.

These will keep the table surface in prime

condition and reduces friction when feeding

material.

• Periodically check all bolts and fasteners to

make sure that they are tight.

• Periodically check the router insert and

ensure that it is flush to The Rebel

®

table.

Ensure that the router is firmly mounted to

the router insert.

• Inspect the router, especially the collet.

Ensure that the collet tightens securely

around the router bit.

V. Maintenance

Any maintenance performed on The Rebel®should

be only done after the router has been turned off and

the cutter has come to a complete stop and the plug

pulled from the outlet. Failure to do so may result in

serious personal injury.

Page 23

22 – W2000 Rebel

®

VI. Parts Breakdown

Page 24

W2000 Rebel

®

– 23

VII. Parts List

1 TABLE TOP

2 LEG

3 PANEL

4 SIDE PANEL

5 CAP SCREW

1

/4"-28 X 5/8''

7 SETSCREW 10-32 X

5

/8''

8 FOOT

9 FENCE

10 FENCE LOCK

11 FLAT WASHER

1

/4''

12 HEX NUT

1

/4"-20

13 FLAT HEAD SCREW

1

/4"-20 X 11/4''

14 T-NUT

16 GUARD

17 ARM

18 POST

19 BRACKET

20 LOCK KNOB

21 PHILLIPS

®

HD SCREW 6-32 X 1/2''

22 HEX NUT 6-32

23 HEX BOLT

5

/16"-18 X 3/4''

24 FLAT WASHER

5

/16''

25 MITER BODY

26 HEX NUT 10-24

27 PHILLIPS

®

HD SCREW 10-24 X 3/4''

28 PUSH HANDLE

31 LOCK KNOB

32 FLAT WASHER

1

/4''

33 FIBER WASHER

1

/4''

34 STUD

35 PHILLIPS

®

HD SCREW 10-24 X 1/4''

36 FLAT WASHER #10

37 SCALE

38 GUIDE STUD

39 STOP PIN

40 STOP BLOCK

41 FLAT HEAD SCREW 10-20 X

3

/8''

42 MITER BAR

43 HEX NUT 10-32

44 FLAT HEAD SCREW

1

/4"-28 X 3/4''

45 SMALL INSERT

46 LARGE INSERT

47 STARTING PIN

48 ALUMINUM INSERT

49 CAP SCREW

1

/4"-28 X 1''

Ref. # Description

Ref. # Description

Page 25

24 – W2000 Rebel

®

Woodstock International, Inc. (Woodstock) warrants

this product against defects in workmanship and materials under normal use and service for a period of one

year. This warranty extends to the original purchaser

from the date of purchase. This warranty does not

apply to defects due directly or indirectly to misuse,

abuse, negligence, accidents, repairs or alterations or

lack of maintenance.

This is Woodstock’s sole written warranty and any and

all warranties that may be implied by law, including

any merchantability or fitness, for any particular

purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent that the

merchandise complies with the provisions of any law

or acts. In no event shall Woodstock’s liability under

this warranty exceed the purchase price paid for the

product and any legal actions brought against

Woodstock shall be tried in the State of Washington,

County of Whatcom.

VIII. Warranty and Returns

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special

or consequential damages arising from the use of our

products.

To take advantage of this warranty, the product or part

must be returned to the original place of purchase.

Proof of purchase must accompany the merchandise.

Woodstock reserves the right to change specifications

at any time since we constantly strive to achieve better

quality equipment.

We make every effort to ensure that our products meet

high quality and durability standards and we hope you

never need to use this warranty.

Loading...

Loading...