Woodstock W1831 User Manual

MODEL W1831

®

SHOP FOX

OSCILLATING SPINDLE SANDER

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 3/12)

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © MARCH, 2012 BY WOODSTOCK INTERNATIONAL. REVISED APRIL, 2013 (TR)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

#ST14859 Printed in China

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Contents

INTRODUCTION .....................................2

Woodstock Technical Support .................. 2

SAFETY ............................................... 6

Standard Machinery Safety Instructions ...... 6

Additional Safety for Sanders .................. 8

ELECTRICAL .........................................9

Circuit Requirements ............................9

Polarized Plug ................................... 10

Extension Cords ................................ 10

SETUP .............................................. 11

Unpacking ....................................... 11

Inventory ........................................ 11

Machine Placement ............................ 12

Cleaning Machine ............................... 12

Bench Mounting................................. 13

Assembly ......................................... 14

Dust Collection ................................. 14

Test Run .......................................... 15

OPERATIONS....................................... 16

General .......................................... 16

Disabling Switch ................................ 16

Sanding Drum/Sleeve Installation ........... 17

Sanding .......................................... 17

ACCESSORIES ...................................... 18

Sander Accessories ............................. 18

MAINTENANCE .................................... 19

Schedule ......................................... 19

Cleaning ......................................... 19

SERVICE ............................................ 20

General .......................................... 20

Changing Motor Brushes ....................... 20

Troubleshooting ................................. 22

Wiring Diagram ................................. 23

PARTS .............................................. 24

Main Breakdown ................................ 24

Main Parts List .................................. 25

Label Placement ............................... 26

WARRANTY ........................................ 29

SAFETYINTRODUCTION

SET UPELECTRICAL MAINTENANCE

OPERATIONS

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

SERVICE PARTS

Model W1831 (For Machines Mfg. Since 2/12)

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

This machine has been specially designed to provide many years of trouble-free service. Close attention

to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, setup, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

-2-

Model W1831 (For Machines Mfg. Since 2/12)

MODEL W1831

SHOP FOX® OSCILLATING SPINDLE SANDER

Product Dimensions

Weight............................................................................................. Not Available lbs.

Width (side-to-side) x Depth (front-to-back) x Height............................ 15-9/16 x 14-1/8 x 17 in.

Footprint (Length x Width)......................................................................... 15-1/2 x 14 in.

Shipping Dimensions

Type.................................................................................................... Cardboard Box

Content........................................................................................................ Machine

Weight........................................................................................................... 34 lbs.

Length x Width x Height........................................................................... 19 x 16 x 21 in.

Must Ship Upright................................................................................................. N/A

INTRODUCTION

Electrical

Power Requirement.................................................................... 120V, Single-Phase, 60 Hz

Prewired Voltage................................................................................................. 120V

Full-Load Current Rating........................................................................................ 3.5A

Minimum Circuit Size............................................................................................. 15A

Connection Type......................................................................................... Cord & Plug

Power Cord Included.............................................................................................. Yes

Power Cord Length............................................................................................... 6 ft.

Power Cord Gauge............................................................................................ 18 AWG

Plug Included....................................................................................................... Yes

Included Plug Type............................................................................................... 1-15

Switch Type............................................................ Paddle Safety Switch w/Removable Key

Motors

Main

Type................................................................................ Permanent Magnet Motor

Horsepower.............................................................................................. 1/2 HP

Phase.............................................................................................. Single-Phase

Amps......................................................................................................... 3.5A

Power Transfer ................................................................................... V-Belt Drive

Bearings................................................................. Sealed & Permanently Lubricated

-3-

INTRODUCTION

Model W1831 (For Machines Mfg. Since 2/12)

Spindle Sander Info

Sanding Drum Diameters...................................................... 1/2, 3/4, 1, 1-1/2, 2, 3 in.

Sanding Drum Length................................................................................ 4-1/2 in.

Spindle Speed........................................................................................ 2000 RPM

Spindle Oscillation...................................................................................... 58 SPM

Stroke Length........................................................................................... 5/8 in.

Table Length.............................................................................................. 15 in.

Table Width.......................................................................................... 11-1/2 in.

Table Thickness..................................................................................... 1-5/16 in.

Table-to-Floor Height................................................................................... 13 in.

Spindle Shaft Diameter................................................................................ 1/2 in.

Number of Table Inserts...................................................................................... 6

Construction Materials

Base....................................................................................................... Plastic

Table................................................................................................... Cast Iron

Other Related Info

Number of Dust Ports......................................................................................... 1

Dust Port Size......................................................................................... 1-1/2 in.

Features

Space-saving benchtop style.

Locking power switch with removable key.

Sanding drums store neatly in the base for easy, organized access.

Includes 3 spindle washers: 5/8, 7/8, 1-3/4 in.

Includes 6 table inserts: 1/2, 3/4, 1, 1-1/2, 2, 3 in.

Includes 6 sanding sleeves: 1/2, 3/4, 1, 1-1/2, 2, 3 in.

Includes 5 rubber sanding spindles: 3/4, 1, 1-1/2, 2, 3 in.

-4-

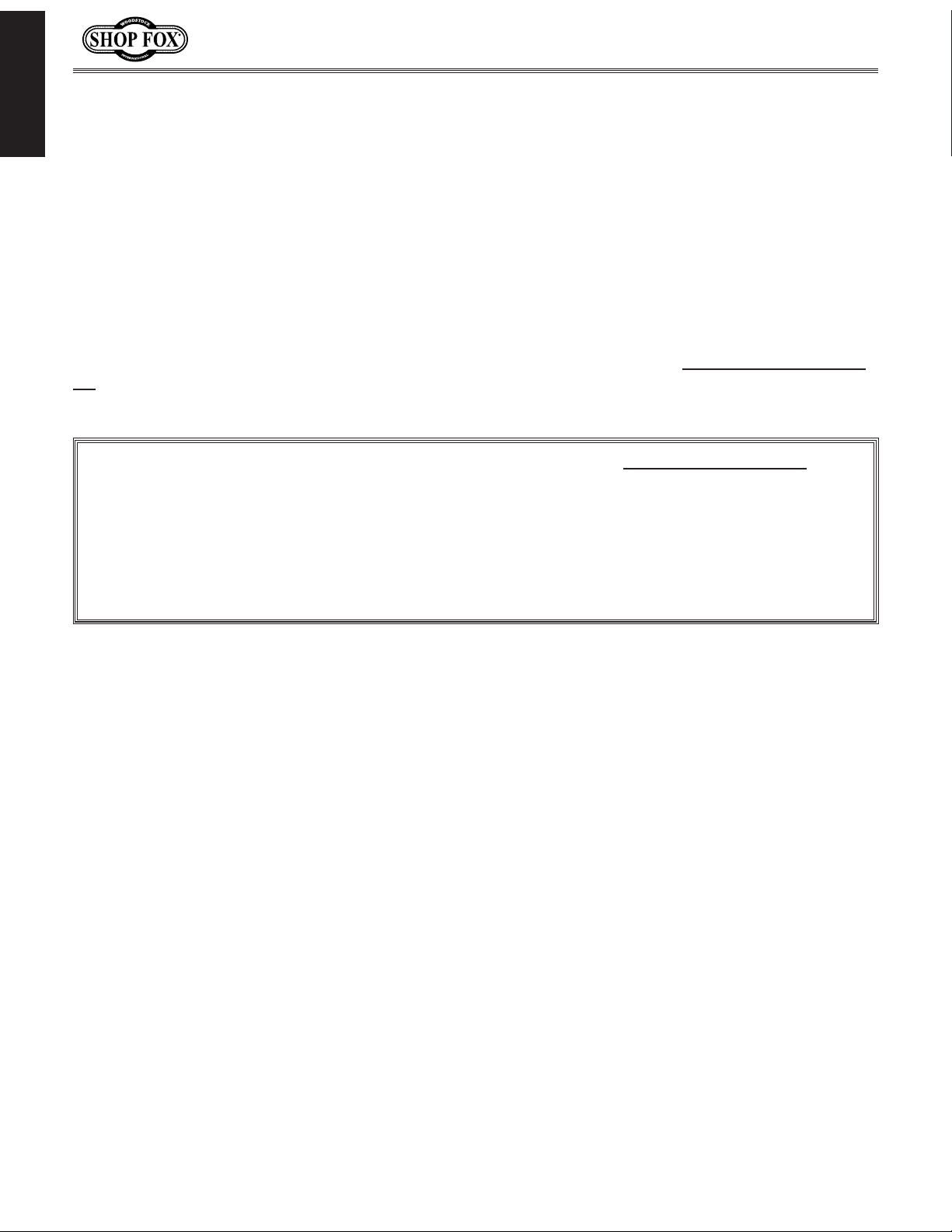

Model W1831 (For Machines Mfg. Since 2/12)

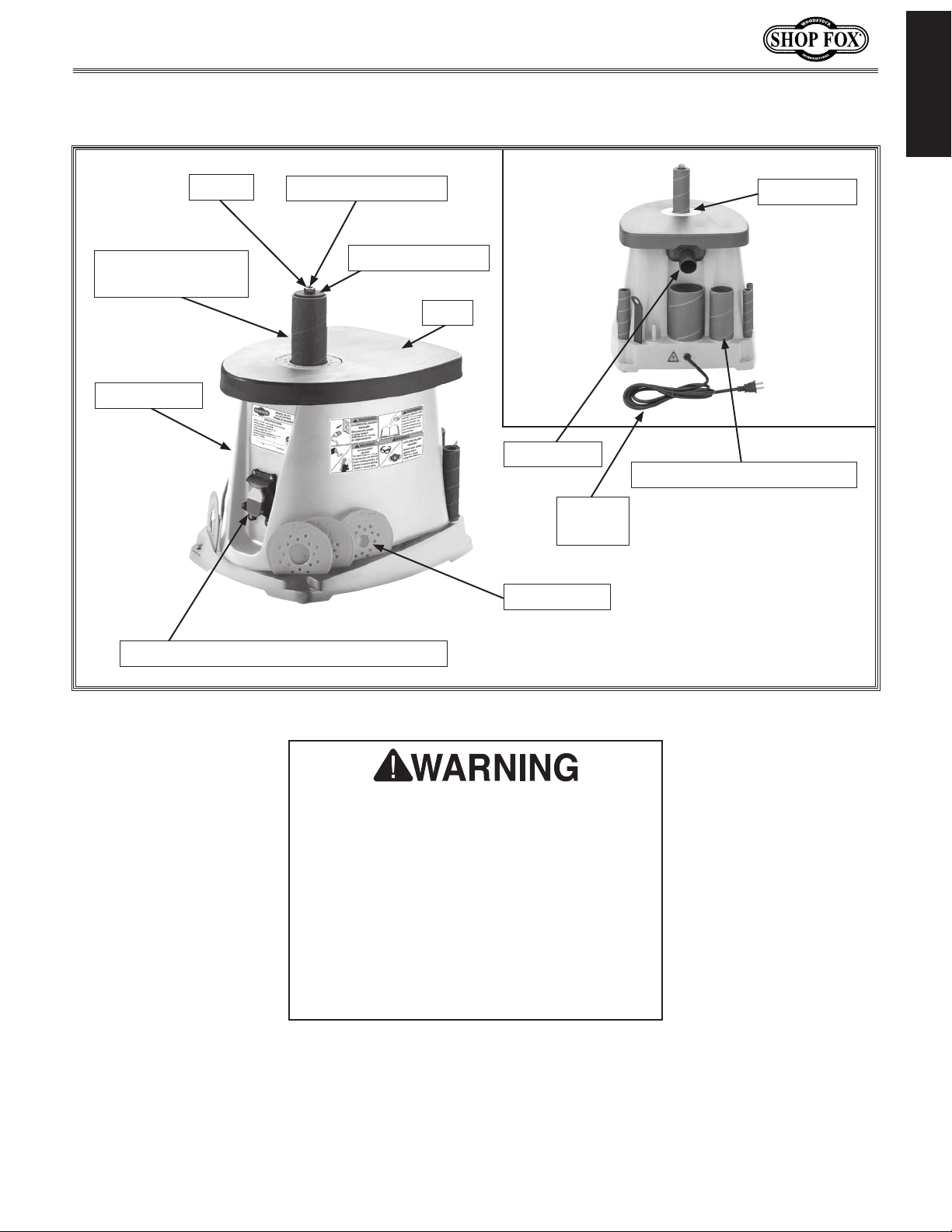

Do not wear gloves, necktie, or loose

Controls and Features

INTRODUCTION

Spindle

Drum and Sanding

Sleeve

Sander Body

Spindle Hex Nut

Spindle Washer

Table Insert

Table

Dust Port

Drums and Sanding Sleeves

Power

Cord

Table Inserts

ON/OFF Paddle Switch w/Disabling Key

Figure 1. Machine identification.

For Your Own Safety Read This Manual

Before Operating Spindle Sander

a) Wear eye protection.

b) Support workpiece on worktable.

c) Minimize pinch hazards. Use the smallest

table insert possible with sanding drum.

d) Avoid kickback. Feed workpiece against

rotation of drum.

e) Avoid entanglement with spinning drum.

clothing. Tie back long hair.

-5-

Model W1831 (For Machines Mfg. Since 2/12)

SAFETY

OWNER’S MANUAL.

TRAINED OPERATORS ONLY.

DANGEROUS ENVIRONMENTS.

MENTAL ALERTNESS REQUIRED.

electrical components or improperly grounded

manual uses a series of symbols and signal words intended to convey the level of importance of the

safety messages. The progression of symbols is described below. Remember that safety messages by

SAFETY

For Your Own Safety,

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This

SAFETY

themselves do not eliminate danger and are not a substitute for proper accident prevention measures—this responsibility is ultimately up to the operator!

NOTICE

Standard Machinery Safety Instructions

Standard Machinery Safety Instructions

Read and understand this

owner’s manual BEFORE using machine.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

This symbol is used to alert the user to useful information about

proper operation of the equipment or a situation that may cause

damage to the machinery.

ELECTRICAL EQUIPMENT INJURY RISKS. You can

be shocked, burned, or killed by touching live

have a higher risk of being hurt or killed. Only

allow trained/supervised people to use this

machine. When machine is not being used,

disconnect power, remove switch keys, or

lock-out machine to prevent unauthorized

use—especially around children. Make

workshop kid proof!

machinery in areas that are wet, cluttered,

or have poor lighting. Operating machinery

in these areas greatly increases the risk of

accidents and injury.

alertness is required for safe operation of

machinery. Never operate under the influence

of drugs or alcohol, when tired, or when

distracted.

Untrained operators

Do not use

Full mental

machinery. To reduce this risk, only allow an

electrician or qualified service personnel to

do electrical installation or repair work, and

always disconnect power before accessing or

exposing electrical equipment.

DISCONNECT POWER FIRST. Always disconnect

machine from power supply BEFORE making

adjustments, changing tooling, or servicing

machine. This eliminates the risk of injury

from unintended startup or contact with live

electrical components.

EYE PROTECTION. Always wear ANSI-approved

safety glasses or a face shield when operating

or observing machinery to reduce the risk of

eye injury or blindness from flying particles.

Everyday eyeglasses are not approved safety

glasses.

-6-

Model W1831 (For Machines Mfg. Since 2/12)

WEARING PROPER APPAREL. Do not wear

HAZARDOUS

HEARING PROTECTION.

REMOVE ADJUSTING TOOLS.

INTENDED USAGE.

AWKWARD POSITIONS.

CHILDREN & BYSTANDERS.

GUARDS & COVERS.

FORCING MACHINERY. Do not force machine. It

will do the job safer and better at the rate for

loss of control. Before starting, verify machine

malfunction, leading to serious personal injury

from heated surfaces, high traffic areas, harsh

clothing, apparel, or jewelry that can become

entangled in moving parts. Always tie back

or cover long hair. Wear non-slip footwear to

avoid accidental slips, which could cause loss

of workpiece control.

DUST. Dust created while using

machinery may cause cancer, birth defects,

or long-term respiratory damage. Be aware of

dust hazards associated with each workpiece

material, and always wear a NIOSH-approved

respirator to reduce your risk.

Always wear hearing

protection when operating or observing

loud machinery. Extended exposure to this

noise without hearing protection can cause

permanent hearing loss.

machinery can become dangerous projectiles

upon startup. Never leave chuck keys,

wrenches, or any other tools on machine.

Always verify removal before starting!

its intended purpose and never make

modifications not approved by Woodstock.

Modifying machine or using it differently

than intended may result in malfunction or

mechanical failure that can lead to serious

personal injury or death!

balance at all times when operating machine.

Do not overreach! Avoid awkward hand

positions that make workpiece control difficult

or increase the risk of accidental injury.

bystanders at a safe distance from the work

area. Stop using machine if they become a

distraction.

accidental contact with moving parts or flying

debris—make sure they are properly installed,

undamaged, and working correctly.

Only use machine for

Guards and covers reduce

Tools left on

Keep proper footing and

Keep children and

which it was designed.

NEVER STAND ON MACHINE. Serious injury may

occur if machine is tipped or if the cutting

tool is unintentionally contacted.

STABLE MACHINE. Unexpected movement during

operation greatly increases risk of injury or

is stable and mobile base (if used) is locked.

USE RECOMMENDED ACCESSORIES. Consult

this owner’s manual or the manufacturer for

recommended accessories. Using improper

accessories will increase risk of serious injury.

UNATTENDED OPERATION. To reduce the risk

of accidental injury, turn machine OFF and

ensure all moving parts completely stop

before walking away. Never leave machine

running while unattended.

MAINTAIN WITH CARE. Follow all maintenance

instructions and lubrication schedules to

keep machine in good working condition. A

machine that is improperly maintained could

or death.

CHECK DAMAGED PARTS. Regularly inspect

machine for any condition that may affect

safe operation. Immediately repair or replace

damaged or mis-adjusted parts before

operating machine.

MAINTAIN POWER CORDS. When disconnecting

cord-connected machines from power, grab

and pull the plug—NOT the cord. Pulling the

cord may damage the wires inside, resulting

in a short. Do not handle cord/plug with wet

hands. Avoid cord damage by keeping it away

chemicals, and wet/damp locations.

EXPERIENCING DIFFICULTIES. If at any time

you experience difficulties performing the

intended operation, stop using the machine!

Contact Technical Support at (360) 734-3482.

SAFETY

-7-

Model W1831 (For Machines Mfg. Since 2/12)

Additional Safety for Sanders

FEED RATE. Never jam a workpiece against the

sanding surface. This can cause the workpiece

to kick back or damage the machine. Firmly

hold the workpiece and ease it against the

spindle using light pressure.

SAFETY

AVOIDING ENTANGLEMENT. Keep loose clothing

articles such as sleeves, belts or jewelry items

away from the spindle. These items could get

entangled in the spindle, resulting in serious

personal injury. Never wear gloves when

operating the spindle sander.

HAND PLACEMENT. Do not place hands near, or in

contact with, sanding surfaces during operation

to avoid personal injury.

WORKPIECE HANDLING. Hold the workpiece

with both hands to maintain control while

sanding (or use an appropriate holding jig)

to reduce the likelihood of losing control of

the workpiece and having it thrown from the

machine.

SANDING SLEEVES. Worn or damaged sanding

sleeves can tear apart and become entangled

in the spindle or be thrown from the machine,

resulting in personal injury or property

damage. Replace sanding sleeves as required.

DUST COLLECTION. Never operate the sander

without an adequate dust collection system

in place and running. Proper dust collection

reduces dust in the work area, which decreases

the risk of long-term respiratory damage.

DIRECTION. Never sand tapered or pointed stock

with the point facing the feed direction to

avoid the workpiece being thrown from the

machine.

POWER DISCONNECT. Disconnect the machine

from the power source before changing the

sanding sleeve to avoid injuries in the event of

an accidental startup.

RESPIRATOR USE. Always use a respirator that

is approved for wood dust when using this

machine to reduce the risk of short and long

term respiratory illness. A dust collector is not

an adequate substitute.

TABLE INSERTS. Always use the table insert that

fits closest to the diameter of the installed

sanding drum. A pinch hazard exists from the

gap between the table and the oscillating

drum. Keeping this gap as small as possible

reduces the risk of this hazard.

FOREIGN MATERIAL. Always inspect stock for

nails, staples, knots, and other imperfections

that could be dislodged and thrown from the

machine during sanding operations.

READ and understand this

entire manual before using

this machine. Serious personal injury may occur

if safety and operational

information is not understood and followed. DO

NOT risk your safety by

not reading!

USE this and other machinery with caution

and respect. Always consider safety first,

as it applies to your individual working

conditions. No list of safety guidelines can

be complete—every shop environment is

different. Failure to follow guidelines could

result in serious personal injury, damage

to equipment or poor work results.

-8-

Loading...

Loading...