Woodstock W1683 User Manual

INSTRUCTION MANUAL

MODEL W1683

20" PLANER

Phone: 1-360-734-3482 • On-Line Technical Support: tech-support@woodstockint.com

COPYRIGHT © April, 2002 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in Taiwan

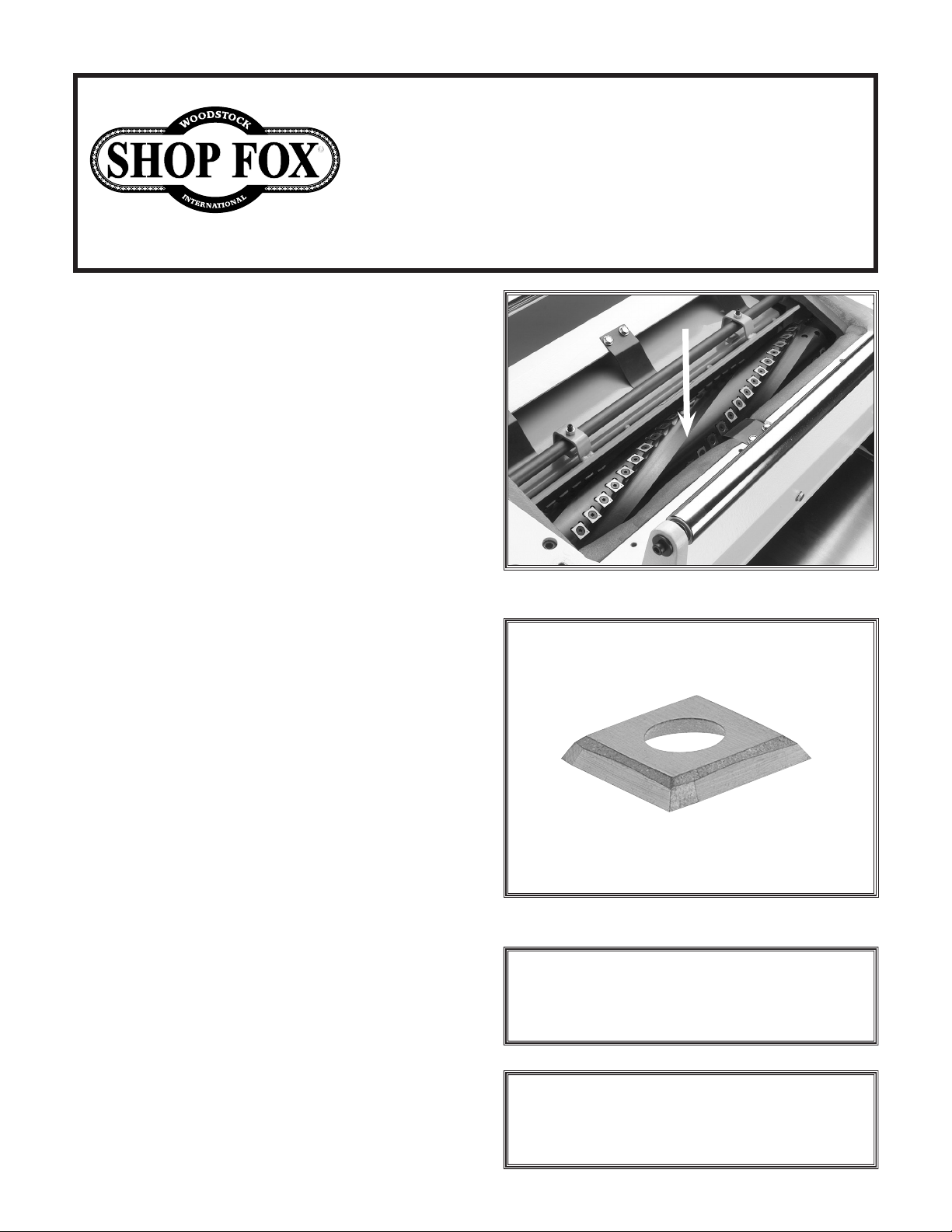

Spiral Cutterhead Planer

INTRODUCTION

The Model W1718 is the same planer as the

Model W1683 with the upgrade of the spiral

cutterhead.

The spiral cutterhead consists of 96 indexable

carbide inserts. Each insert has four cutting

edges, which can be easily rotated if the current

cutting edge becomes dull or damaged.

In addition, a reference dot is in one corner of

each insert face to indicate when that insert

has been rotated. After all four edges have

been used, the dot will be back to its original

position and replacement of the insert will then

be necessary. Note—To avoid confusion about

which edges are sharp, always rotate inserts

clockwise.

INSTRUCTION SHEET

Model W1718

Figure 1. Spiral cutterhead.

INVENTORY

For the Model W1718, use the inventory list from

the Model W1683, but exchange the parts below

for the knife setting jig:

Torx T-Handle Wrench .............................

Flat-Head Torx Screws ...........................

Torx Bits T20 ......................................

Indexable Carbide Inserts .........................

REPLACING or ROTATING INSERTS

To replace or rotate the inserts, do these

steps:

1. UNPLUG THE PLANER, and open the top

cover to access the spiral cutterhead.

2. Clean out the heads of the indexable insert

Torx screws that you wish to replace or

rotate.

3. Remove the Torx screw, replace or rotate

the cutter, lubricate the threads of the Torx

screw with a light machine oil, and torque

the screw down to 50 in/lb (inch pounds).

1

20

10

5

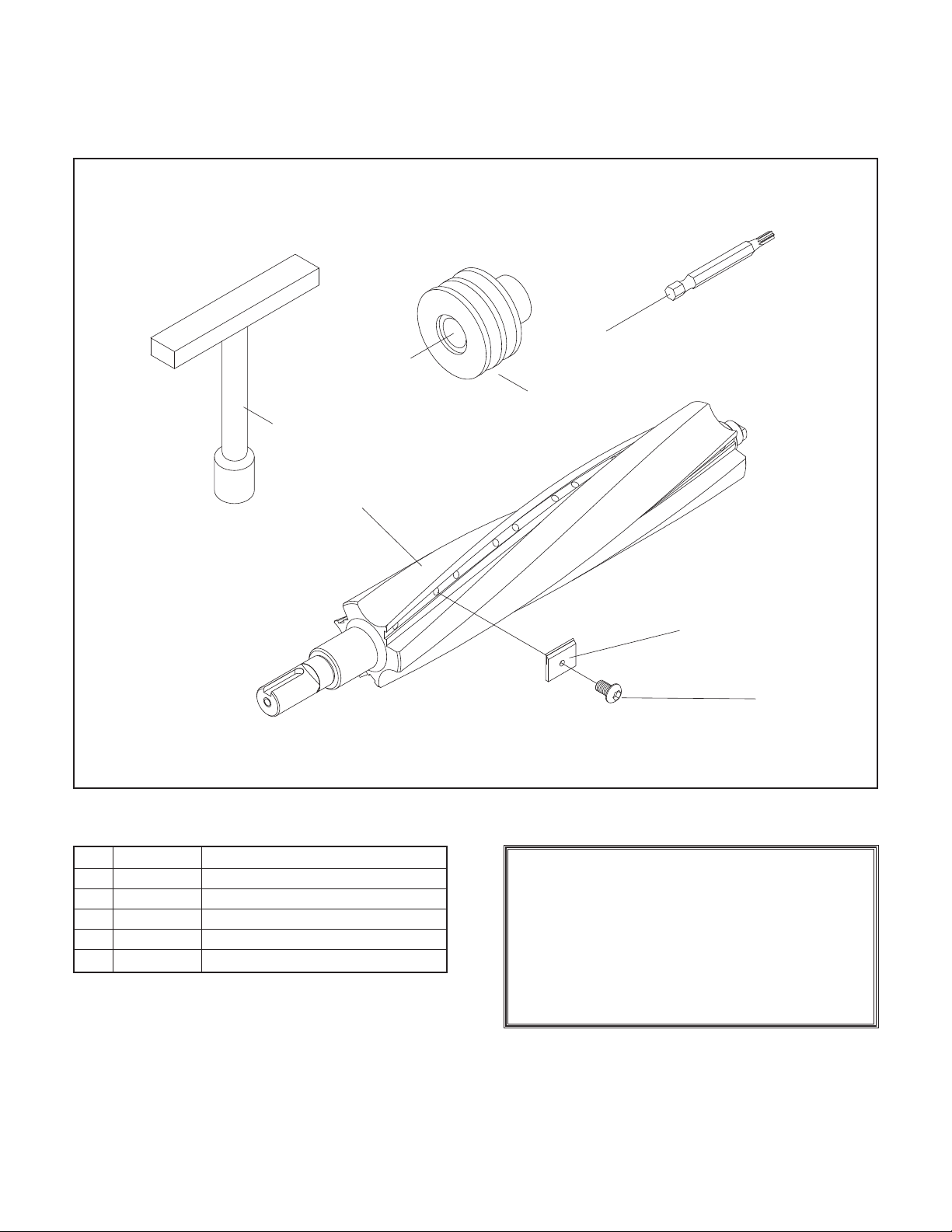

Figure 2. Indexable carbide insert.

NOTICE

Make sure there is no wood dust or debris

under insert when replacing it.

NOTICE

Over-tightening Torx screws may cause damage

to the cutterhead!

W1718 Replacement Parts

REF PART # DESCRIPTION

3 X1718003 SPIRAL CUTTERHEAD

17 X1718017 MOTOR PULLEY

110 X1718110 INDEXABLE CARBIDE INSERT

111 XPFH15M FLAT HD TRX T20 M6-1 X 16

115 X1718115 TORX BIT T20

116 X1718116 TORX T-HANDLE WRENCH

COPYRIGHT, AUGUST 2003 © BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS DOCUMENT MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

#5483TR REVISED SEPTEMBER 2004. PRINTED IN TAIWAN.

NOTICE

All parts for the Model W1718, except those

shown above, are the same as the Model

W1683. Therefore, please use the included

Model W1683 manual when ordering new

parts for your machine, unless those parts

are shown above.

WARNING

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and

other masonry products.

• Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic

particles.

Table Of Contents

PAGE

1. INTRODUCTION ........................................................................................................2

ABOUT YOUR NEW PLANER ....................................................................................2

WOODSTOCK SERVICE AND SUPPORT ........................................................................2

WARRANTY AND RETURNS ......................................................................................3

PLANER MACHINE SPECIFICATIONS............................................................................3

2. SAFETY FIRST! ..........................................................................................................4

SAFETY INSTRUCTIONS........................................................................................4-5

ADDITIONAL SAFETY INSTRUCTIONS FOR PLANERS........................................................6

ELECTRICAL REQUIREMENTS....................................................................................7

220V OPERATION ................................................................................................7

EXTENSION CORDS................................................................................................7

GROUNDING ........................................................................................................7

3. ASSEMBLY................................................................................................................8

BOX CONTENTS....................................................................................................8

OVERVIEW ..........................................................................................................8

SHOP PREPARATION..............................................................................................9

CLEANING MACHINE ..............................................................................................9

EXTENSION ROLLERS ..........................................................................................10

HANDWHEEL ....................................................................................................11

DUST HOOD ......................................................................................................11

SWITCH............................................................................................................12

KNIFE SETTING JIG..............................................................................................12

4. ADJUSTMENTS ........................................................................................................13

LOCATION OF CONTROLS......................................................................................13

MOVING BED ROLLERS..........................................................................................14

TABLE ........................................................................................................14-16

CHECKING KNIVES ..............................................................................................17

KNIFE ADJUSTMENT ........................................................................................18-19

FEED ROLLERS, CHIPBREAKER & PRESSURE BAR ....................................................20-21

CHIP DEFLECTOR ................................................................................................22

ANTI-KICKBACK PAWLS ........................................................................................22

CHAIN TENSIONER ..............................................................................................23

SPRING TENSION ................................................................................................23

TABLE ROLLERS ................................................................................................24

5. OPERATIONS ..........................................................................................................25

TEST RUN ........................................................................................................25

FEED RATE........................................................................................................25

OPERATIONAL TIPS ............................................................................................26

TROUBLESHOOTING PLANING RESULTS ....................................................................27

AFTERMARKET SETUP ACCESSORIES ........................................................................28

6. MAINTENANCE ........................................................................................................29

GENERAL ..........................................................................................................29

CLEANING ........................................................................................................29

TABLE AND BASE ................................................................................................29

LUBRICATION ....................................................................................................30

BELT TENSION ..................................................................................................31

PULLEY ALIGNMENT ............................................................................................31

WIRING DIAGRAM ....................................................................................................32

TROUBLESHOOTING ..................................................................................................33

7. CLOSURE ..............................................................................................................34

DIAGRAMS AND PARTS LISTS..............................................................................35-42

WARRANTY AND REPLACEMENT..............................................................................43

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

2

INTRODUCTION

ABOUT YOUR NEW PLANER

This new Shop Fox®20" Planer has been specially designed to provide many years of trouble free service.

Close attention to detail, ruggedly built parts and a rigid quality control program assure safe and reliable

operation.

Woodstock International, Inc. is committed to customer satisfaction in providing this manual. It is our

intent to make sure all the information necessary for safety, ease of assembly, practical use and

durability of this product be included.

If you should have any comments regarding this manual, please contact us at:

Woodstock International, Inc.

P.O. Box 2309

Bellingham, WA 98227

WOODSTOCK SERVICE AND SUPPORT

We stand behind our machines! In the event that a defect is found, parts are missing or questions arise

about your machine, please contact Woodstock International Service and Support at 1-360-734-3482 or

tech-support@woodstockint.com

. Our knowledgeable staff will help you troubleshoot problems, send out

parts or arrange warranty repair or returns.

3

WARRANTY AND RETURNS

Planer Machine Specifications

Motor ..................................................................5 H.P., 220V, Single-Phase

Amps ................................................................................................28

Cutting Width ....................................................................................20"

Cutting Height ....................................................................................8"

Minimum Stock Thickness ......................................................................

1

⁄4"

Minimum Stock Length ............................................................................7"

Maximum Depth of Cut ..........................................................................

1

⁄8"

Cutterhead Diameter ..........................................................................3

3

⁄16"

Cutterhead Speed ....................................................................5500 R.P.M.

Table Size ..............................................................................25

3

⁄4" x 20"

Knives ........................................................................................4 H.S.S.

Feed Rates ..........................................................................18 & 23 F.P.M.

Woodstock International, Inc. warrants all SHOP FOX®machinery to be free of defects from workmanship

and materials for a period of 2 years from the date of original purchase by the original owner. This

warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

lack of maintenance, or to repair or alterations made or specifically authorized by anyone other than

Woodstock International, Inc.

Woodstock International, Inc. will repair or replace, at its expense and at its option, the SHOP FOX

®

machine or machine part which in normal use has proven to be defective, provided that the original

owner returns the product prepaid to the SHOP FOX

®

factory service center or authorized repair facility

designated by our Bellingham, WA office, with proof of their purchase of the product within 2 years, and

provides Woodstock International, Inc. reasonable opportunity to verify the alleged defect through

inspection. If it is determined there is no defect, or that the defect resulted from causes not within the

scope of Woodstock International Inc.'s warranty, then the original owner must bear the cost of storing

and returning the product.

This is Woodstock International, Inc.'s sole written warranty and any and all warranties that may be

implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited

to the duration of this written warranty. We do not warrant that SHOP FOX

®

machinery complies with

the provisions of any law or acts. In no event shall Woodstock International, Inc.'s liability under this

warranty exceed the purchase price paid for the product, and any legal actions brought against

Woodstock International, Inc. shall be tried in the State of Washington, County of Whatcom. We shall in

no event be liable for death, injuries to persons or property or for incidental, contingent, special or

consequential damages arising from the use of our products.

Every effort has been made to ensure that all SHOP FOX

®

machinery meets high quality and durability

standards. We reserve the right to change specifications at any time because of our commitment to

continuously improve the quality of our products.

4

READ MANUAL BEFORE OPERATING MACHINE

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY

SAFETY FIRST!

1. Thoroughly read the instruction manual before operating your machine. Learn the applications,

limitations and potential hazards of this machine. Keep manual in a safe, convenient place for future

reference.

2. Keep work area clean and well lighted. Clutter and inadequate lighting invite potential hazards.

3. Ground all tools. If a machine is equipped with a three-prong plug, it must be plugged into a three-

hole electrical outlet or grounded extension cord. If using an adapter to aid in accommodating a twohole receptacle, ground using a screw to a known ground.

4. Wear eye protection at all times. Use safety glasses with side shields or safety goggles (that meet

the national safety standards) while operating this machine.

5. Avoid dangerous environments. Do not operate this machine in wet or open flame environments.

Airborne dust particles could cause an explosion and severe fire hazard.

6. Ensure all guards are securely in place and in working condition.

7. Make sure switch is in the “OFF” position before connecting power to machine.

8. Keep work area clean and free of clutter, grease, etc.

9. Keep children and visitors away. All visitors should be kept a safe distance away while operating

unit.

10. Childproof workshop with padlocks, master switches or by removing switch keys.

11. Disconnect machine when cleaning, adjusting or servicing.

12. Do not force tool. The machine will do a safer and better job at the rate for which it was designed.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This symbol is used to alert the user to useful information about proper

operation of the equipment.

NOTICE

5

13. Use correct tool. Do not force machine or attachment to do a job for which it was not designed.

14. Wear proper apparel. Do not wear loose clothing, neck ties, gloves, jewelry, etc.

15. Remove adjusting keys and wrenches before turning the machine on. Make this a habit!

16. Use proper extension cord. When using an extension cord, make sure it is in good condition. Use

extension cords 100' or less in length that are rated Hard Service (grade S) or better, and that have

a conductor size of 16 A.W.G. A drop in line voltage, loss of power and overheating can result when

using an undersized cord. The extension cord must have a ground wire and ground plug pin, as well.

17. Keep proper footing and balance at all times.

18. Do not leave machine unattended—wait until it comes to a complete stop before leaving the area.

19. Perform machine maintenance and care. Follow lubrication and accessory attachment instructions

in the manual.

20. Keep machine away from open flame. Operating machines near pilot lights and/or open flames

creates a high risk if dust is dispersed in the area. Dust particles and an ignition source may cause

an explosion. Do not operate the machine in high risk areas, including but not limited to, those

mentioned above.

21. Do not use machine under the influence of drugs or alcohol or if you are excessively tired.

22. Do not let untrained people use the machine if they are not supervised by an experienced

operator.

23. If at any time you are experiencing difficulties performing the intended operation, stop using the

machine! Then contact our service department or ask a qualified expert how the operation should

be performed.

24. Mag switches can be accidentally turned on when they are bumped. Always be aware of the mag

switch location when moving items around the shop.

Operating this equipment has the potential

for flying debris to cause eye injury. Always

wear safety glasses or goggles when

operating equipment. Everyday glasses or

reading glasses only have impact resistant

lenses, they are not safety glasses. Be

certain the safety glasses you wear meet

the appropriate standards of the American

National Standards Institute (ANSI).

ADDITIONAL SAFETY INSTRUCTIONS FOR PLANERS

1. Always make sure the planer is on firm ground and is stable before operating. Immediately fix or

shim the planer if it rocks or wobbles.

2. Always inspect the workpiece before running it through the planer. Stock with loose knots, nails,

staples, dirt or other foreign objects should be rejected from use or corrected by eliminating the

condition that makes it questionable.

3. Always make sure that all components of the planer are adjusted to their proper specifications

before planing stock.

4. Always use the help of another person or some type of support fixture when planing long stock.

5. Never stand behind the workpiece when you are feeding it into the planer; the workpiece could

possibly kick back and be thrown in the direction from which it came.

6. Never operate the planer if knives are dull or damaged. Sharp knives are safer and produce better

final results.

7. Never process any material through the planer other than wood. This planer is designed for wood

only!

8. Always take multiple light cuts rather than excessively deep cuts.

9. Never attempt to free a stalled workpiece while the planer is powered on and plugged in.

10. Absolutely never reach inside the planer or open the top cover while the planer is powered on

and/or plugged in.

11. Never plane wood that is less than 7" long or less than

1

⁄4" thick.

12. Always wear hearing protection when operating the planer.

No list of safety guidelines can be

complete. Every shop environment is

different. Always consider safety first, as it

applies to your individual working

conditions. Use this and other machinery

with caution and respect. Failure to do so

could result in serious personal injury,

damage to equipment or poor work results.

6

Read the manual

completely before

assembly and operation.

Become familiar with the

machine and its operation

before beginning any

work. Serious personal

injury may result if safety

or operational information

is not understood or

followed.

7

ELECTRICAL REQUIREMENTS

220V Operation

We do not recommend using an extension cord

for 220V equipment. Instead, arrange the

placement of your machinery and installed

wiring to eliminate the need for extension

cords. If you must use an extension cord, make

sure it is rated Hard Service (grade S) and

capable of handling a 28 amp load. The

extension cord must always contain a ground

wire and plug pin. Be sure to ask an expert

about the correct gauge to use with your

desired cord length. Always repair or replace

extension cords when they become worn or

damaged.

Extension Cords

Grounding

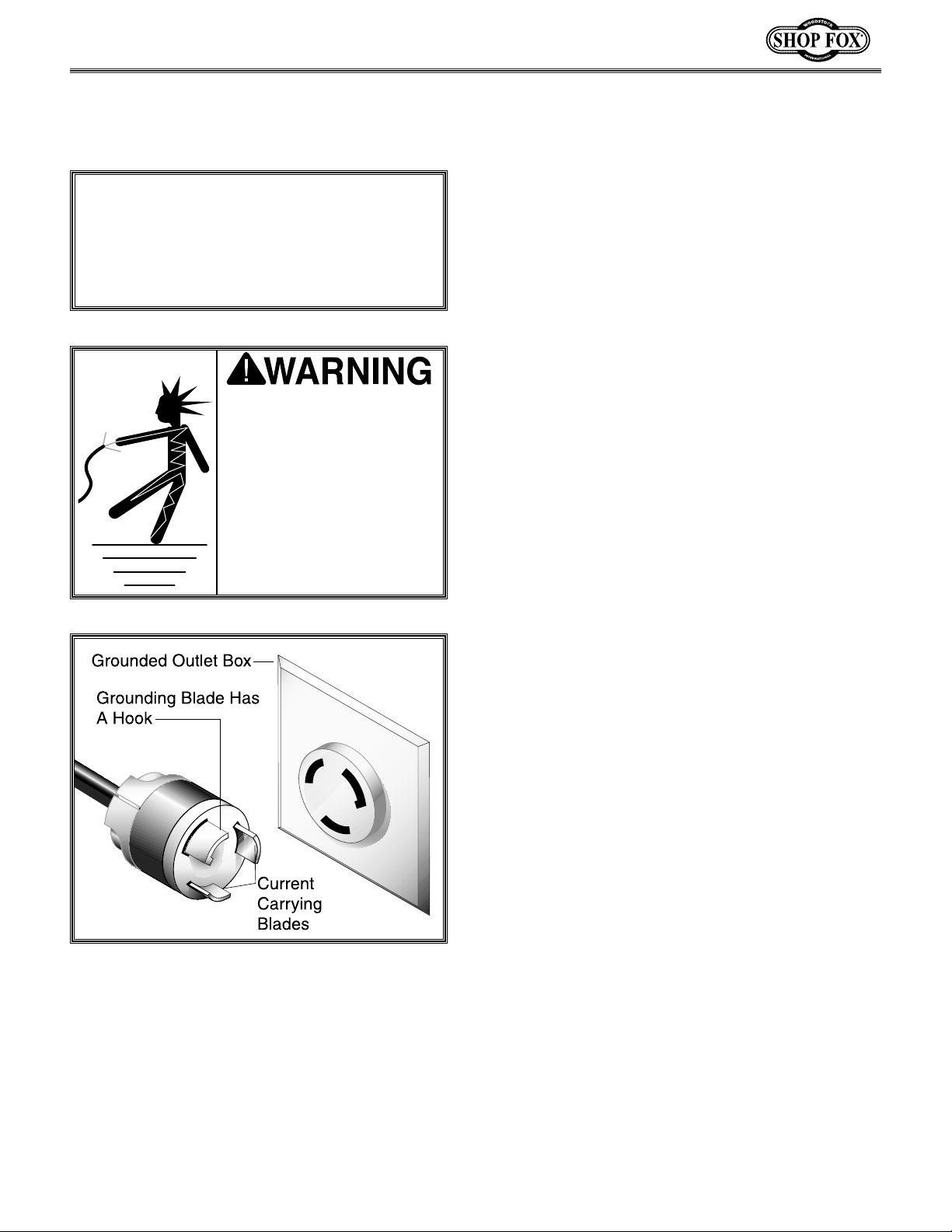

This machine must be grounded! See Figure 1.

The electrical cord supplied with the Model

W1683 does not come with a 220 volt plug. Use

a plug with a ground pin. If your outlet does not

accommodate a ground pin, have it replaced by

a qualified electrician or have an appropriate

adapter installed and grounded properly. An

adapter with a grounding wire does not

guarantee the machine will be grounded. A

ground source must be verified.

The motor supplied with your new planer is

rated at 5 H.P. and will draw approximately 28

amps during 220 volt operation. When choosing

an outlet for this machine, we recommend

using a NEMA L6-30A with a 30 amp circuit

breaker or fuse. Keep in mind that a circuit

being used by other machines or tools at the

same time will add to the total load being

applied to the circuit. Add up the load ratings

of all machines on the circuit. If this number

exceeds the rating of the circuit breaker, fuse

or wires, use a different circuit.

Figure 1. Typical 220V 3-prong plug and outlet.

NOTICE

NEVER replace the circuit breaker with one

rated at a higher amperage or damage to the

circuit may occur.

This equipment must be

grounded. Verify that any

existing electrical outlet and

circuit you intend to plug

into is actually grounded.

Under no circumstances

should the grounding pin

from any three-pronged plug

be removed. Serious injury

may occur.

8

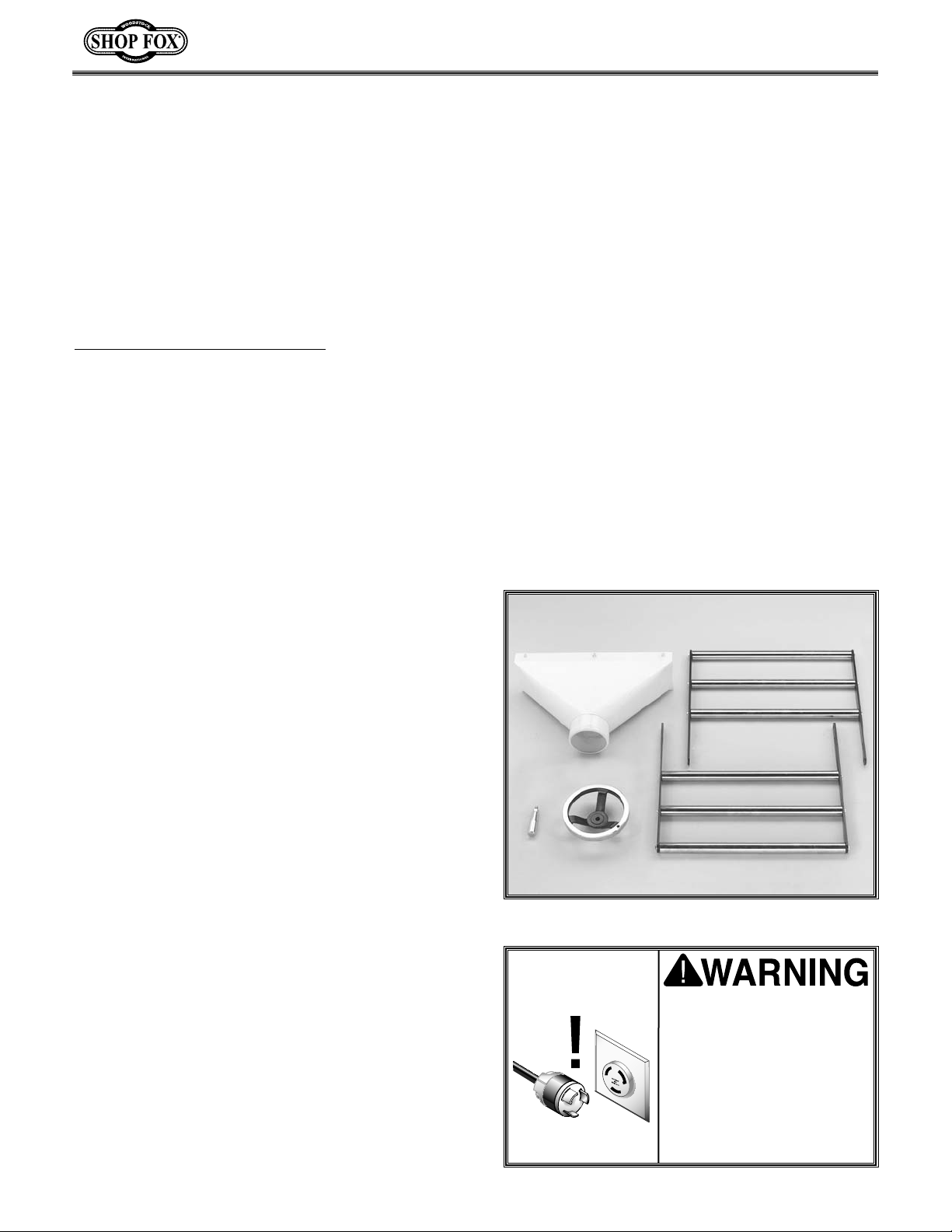

The following is a description of the components

shipped with the Shop Fox

®

W1683 20" Planer.

Should any parts be missing, examine the

packaging carefully to be sure parts are not

among the packing materials. If any key parts

are missing, contact Woodstock International,

Inc. at 360-734-3482 or by e-mail at:

tech-support@woodstockint.com

.

Box Contents

1. Planer Unit

2. Dust Hood

3. Starter Switch

4. Rollers (2)

5. Handwheel

6. Hardware Bag:

(6) M6-1.0 x 12 Hex Bolts

(6) 6mm Flat Washers

(8)

1

⁄2" Flat Washers

(8) M10-1.5 x 25 Hex Bolts

(1) Knife Setting Rod

(2) Knife Setting Gauge

(4) 9mm E-Clip Ring

(1) Handle

(1) 3mm Allen Wrench

(1) 4mm Allen Wrench

(1) 5mm Allen Wrench

(1) 6mm Allen Wrench

(1) 8mm & 10mm Combo Wrench

(1) 12mm & 14mm Combo Wrench

(1) 17mm & 19mm Combo Wrench

ASSEMBLY

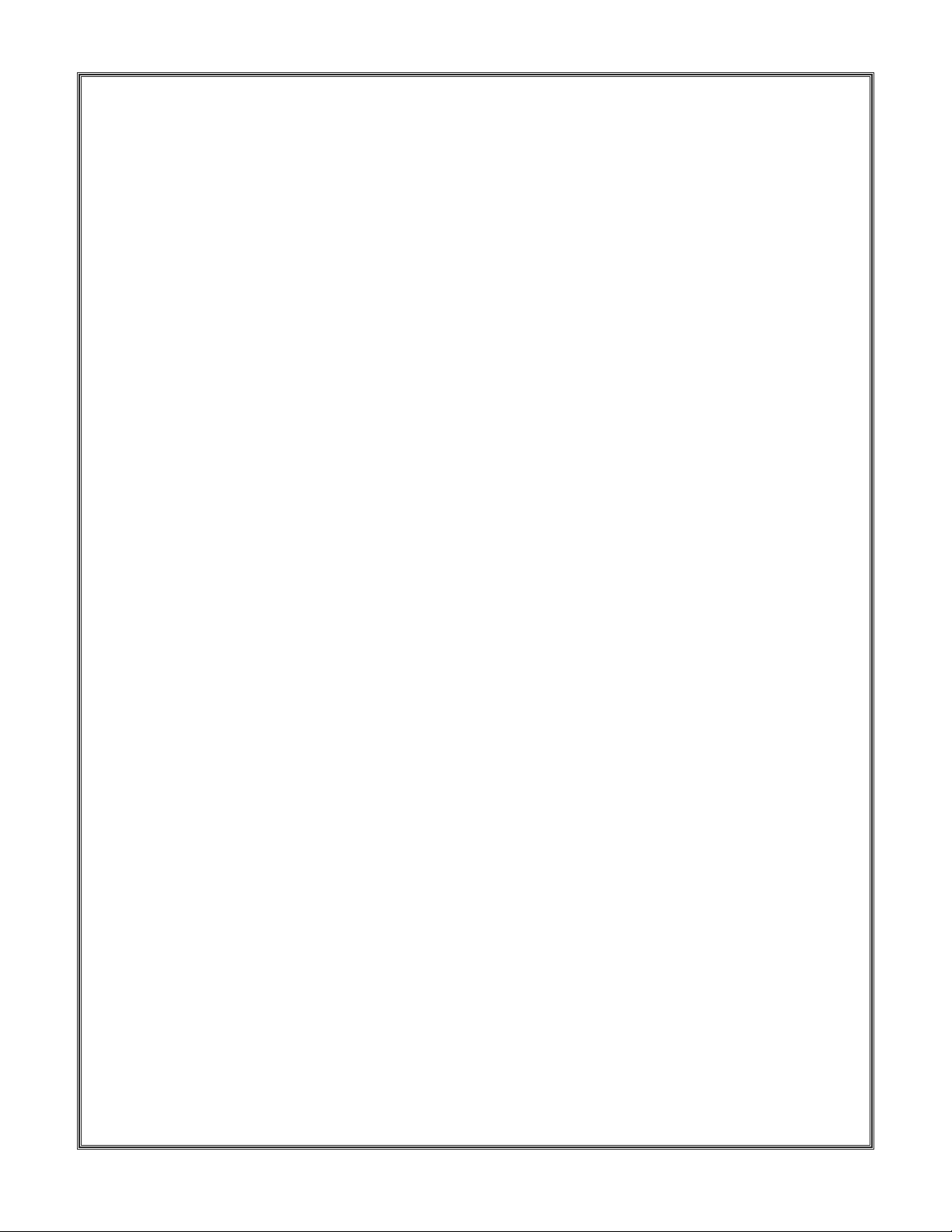

Figure 2. Parts that need to be assembled.

Overview

Do not connect the

machine to power at this

time. The machine must

remain unplugged

throughout the entire

assembly process. Failure

to do this may result in

serious personal injury.

We have assembled most of your new planer for

you at the factory; however, the parts shown in

Figure 2 still need to be assembled after

delivery. Please take your time and try to be as

accurate as possible when following each step.

This care will provide you with better results

when you are finished.

Additional Tools Required: Besides the tools

that were included with the planer, you will also

need a Phillips

®

screwdriver, a flat-head

screwdriver and a good straightedge. A set of

feeler gauges and a dial indicator will also be

necessary for the Adjustments section.

9

The Model W1683 is a

heavy machine, 840 lbs.

shipping weight. Use

power equipment.

Serious personal injury

may occur if safe moving

methods are not

followed.

Shop Preparation

• Floor Load: Your Model W1683 represents a

large weight load in a small footprint. Most

commercial floors are suitable for the

planer. Some residential floors may require

additional bracing to support both machine

and operator.

• Working Clearances: Consider existing and

anticipated needs, size of material to be

processed through each machine, and space

for auxiliary stands, work tables or other

machinery when establishing a location for

your planer.

• Lighting and Outlets: Lighting should be

bright enough to eliminate shadow and

prevent eye strain. Electrical circuits should

be dedicated or large enough to handle

amperage requirements. Outlets should be

located near each machine so power or

extension cords are clear of high-traffic

areas. Observe local electrical codes for

proper installation of new lighting, outlets,

or circuits.

Make your shop “child

safe.” Ensure that your

workplace is inaccessible

to youngsters by closing

and locking all entrances

when you are away. Never

allow visitors in your shop

when assembling,

adjusting or operating

equipment.

Cleaning Machine

The table and other unpainted parts of the

Model W1683 are coated with a waxy grease that

protects them from corrosion during shipment.

Clean this grease off with a solvent cleaner or

citrus-based degreaser. Do not use chlorinebased solvents—if you happen to splash some

onto a painted surface, you will ruin the finish.

Do not use gasoline or

other petroleum-based

solvents. They have low

flash points which make

them extremely

flammable. A risk of

explosion and burning

exists if these products

are used. Serious personal

injury may occur if this

warning is ignored.

Many of the solvents

commonly used to clean

machinery can be toxic

when inhaled or

ingested. Always work in

well-ventilated areas far

from potential ignition

sources when dealing

with solvents. Use care

when disposing of waste

rags and towels to be

sure they do not create

fire or environmental

hazards.

Do not smoke while using

solvents. A risk of

explosion or fire exists and

may result in serious

personal injury.

10

Figure 3. Checking roller extension with a

straightedge.

Extension Rollers

The extension roller assemblies are identical for

both the infeed and the outfeed ends of the

table. To mount these assemblies:

1. Attach an extension bar to the end of each

roller. Secure these in place with the 12mm

snap rings provided in the hardware bag.

2. Match the tapped holes on the side of the

table to the extension bars. Lightly secure in

place with the M10-1.5 x 25 hex bolts and

washers from the hardware bag.

3. The end (outside) roller is fixed in place.

Place a straightedge flat across the table

and across the rollers as shown in Figure 3.

Adjust the end roller so it is flush with the

table, and tighten the M10-1.5 x 25 hex

bolts to secure the extension bars in place.

4. The two inside rollers are mounted in

slotted holes so they can be adjusted flush

with the table and the end roller. Make

these adjustments and tighten the bolts to

secure the inside rollers in place.

The top of the rollers should now be completely

even with the top of the table. Double-check to

make sure that the rollers did not move during

the tightening process.

11

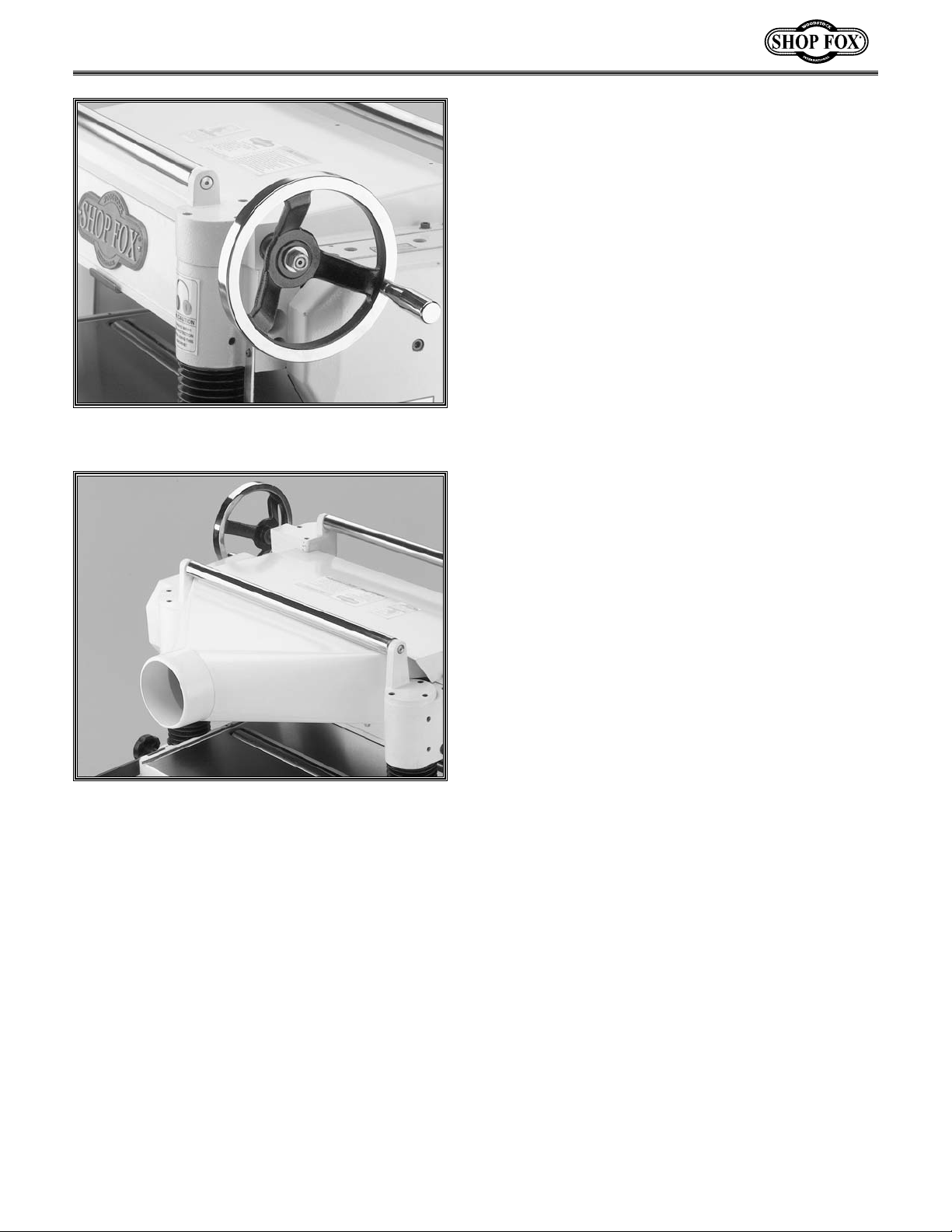

Handwheel

The handwheel operates the chain driven system

that raises/lowers the table to control the

cutting depth.

To mount the handwheel:

1. Secure the handwheel to the worm gear

shaft (as shown in Figure 4) with the hex

nut and washer that is already on the

threads.

2. Thread the handle into the handwheel and

tighten the hex nut to keep it locked in

place.

Dust Hood

The dust hood included should only be installed

if you plan on hooking your planer up to a dust

collection system.

To install the dust hood:

1. Match the holes in the dust hood to the

tapped holes in the planer casting on the

outfeed end.

2. Secure the dust hood with the (6) M6-1.0 x

12 hex bolts from the hardware bag, as

shown in Figure 5.

3. Attach a 5" dust hose to the dust port.

Figure 4.

Handwheel attached correctly.

Figure 5.

Dust hood attached to planer.

Loading...

Loading...