Woodstock W1668 User Manual

INSTRUCTION MANUAL

MODEL W1668

131⁄4" Oscillating Drill Press

Phone: 1-800-840-8420 • On-Line Technical Support: tech-support@woodstockint.com

COPYRIGHT © 2000 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China

-1-

Table Of Contents

PAGE

1. INTRODUCTION

ABOUT YOUR NEW DRILL PRESS ......................................................2

WOODSTOCK SERVICE AND SUPPORT ................................................2

WARRANTY AND RETURNS..............................................................3

MACHINE SPECIFICATIONS ..............................................................3

2. SAFETY..........................................................................................4

STANDARD SAFETY INSTRUCTIONS ................................................4-5

DRILL PRESS SAFETY ....................................................................5

ELECTRICAL REQUIREMENTS ..........................................................6

AVOIDING POTENTIAL INJURIES ......................................................7

3. ASSEMBLY INSTRUCTIONS ..................................................................8

BOX CONTENTS ..........................................................................8

BASE AND COLUMN ......................................................................9

DUST PORT ................................................................................9

TABLE SUPPORT ....................................................................10-11

MOUNTING TABLE ......................................................................11

HEADSTOCK ..............................................................................12

DRILL CHUCK ............................................................................13

HANDLES..................................................................................13

4. ADJUSTMENTS ..............................................................................14

SPEED CHANGE......................................................................14-15

SPINDLE ADJUSTMENTS ..............................................................15

OSCILLATING FEATURE ................................................................16

TABLE ADJUSTMENTS ..................................................................17

5. OPERATIONS..................................................................................18

TEST RUN ................................................................................18

DRILL CHANGES ........................................................................19

6. MAINTENANCE................................................................................20

GENERAL..................................................................................20

TABLE AND BASE........................................................................20

LUBRICATION ............................................................................20

7. CLOSURE ......................................................................................21

PARTS BREAKDOWN AND PARTS LISTS ........................................22-23

YOUR NOTES ............................................................................24

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

-2-

INTRODUCTION

ABOUT YOUR NEW DRILL PRESS

This new Shop Fox®Oscillating Drill Press has been specially designed by Woodstock

International, Inc. to provide many years of trouble free service. Close attention to detail,

ruggedly built parts and a rigid quality control program assure safe and reliable operation.

The

Shop Fox

®

Model W1668 is a drill press and oscillating sander in one compact machine. It is

capable of a wide variety of drilling and sanding operations. A sanding spindle is included for

use with drums ranging in size from 1" to 2" diameter and 4

1

⁄4" long. Purchasing drums and

sleeves will allow you to sand small or finely detailed pieces and with the oscillating feature,

your abrasives will last longer and provide a smoother finish. Included are table inserts to give

maximum support for the workpiece and a dust port to connect to your dust collection system.

The W1668 is packaged with a drill chuck, chuck key, motor and paddle switch with removable

safety key.

Woodstock International, Inc. is committed to customer satisfaction in providing this manual. It

is our intent to make sure all the information necessary for safety, ease of assembly, practical

use and durability of this product be included.

If you should have any comments regarding this manual, please feel free to contact us at:

Woodstock International, Inc.

P.O. Box 2309

Bellingham, WA 98227

WOODSTOCK SERVICE AND SUPPORT

We stand behind our machines! In the event that a defect is found, parts are missing or questions arise

about your machine, please contact Woodstock Service and Support at:

1-360-734-3482

or

tech-support@woodstockint.com.

Our knowledgeable staff will help you troubleshoot problems, send out parts or arrange warranty

returns.

-3-

WARRANTY AND RETURNS

Woodstock International, Inc. warrants all SHOP FOX®machinery to be free of defects from workmanship and materials for a period of 2 years from the date of original purchase by the original owner. This

warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

lack of maintenance, or to repair or alterations made or specifically authorized by anyone other than

Woodstock International, Inc.

Woodstock International, Inc. will repair or replace, at its expense and at its option, the SHOP FOX

®

machine or machine part which in normal use has proven to be defective, provided that the original

owner returns the product prepaid to the SHOP FOX

®

factory service center or authorized repair facility

designated by our Bellingham, WA office, with proof of their purchase of the product within 2 years, and

provides Woodstock International, Inc. reasonable opportunity to verify the alleged defect through

inspection. If it is determined there is no defect, or that the defect resulted from causes not within the

scope of Woodstock International Inc.'s warranty, then the original owner must bear the cost of storing

and returning the product.

This is Woodstock International, Inc.'s sole written warranty and any and all warranties that may be

implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited

to the duration of this written warranty. We do not warrant that SHOP FOX

®

machinery complies with

the provisions of any law or acts. In no event shall Woodstock International, Inc.'s liability under this warranty exceed the purchase price paid for the product, and any legal actions brought against Woodstock

International, Inc. shall be tried in the State of Washington, County of Whatcom. We shall in no event

be liable for death, injuries to persons or property or for incidental, contingent, special or consequential damages arising from the use of our products.

Every effort has been made to ensure that all SHOP FOX

®

machinery meets high quality and durability

standards. We reserve the right to change specifications at any time because of our commitment to continuously improve the quality of our products.

Machine Specifications

Capacities:

Oscillating Stoke Length............................................................................................

3

⁄4"

Spindle Travel ......................................................................................................3

1

⁄4''

Max. Distance, Spindle to Base....................................................................................24''

Max. Distance, Spindle to Table................................................................................17

1

⁄4''

Spindle Taper ......................................................................................................B-16

Swing................................................................................................................13

1

⁄

4''

Chuck Size ........................................................................................

5

⁄8'' (13mm), keyed

Speeds..............................................................................................12, Belt Controlled

Range of Speeds ......................

250, 330, 380, 500, 590, 640, 980, 1530, 1600, 1870, 2580, 3050 RPM

Drilling Capacity ..............................................................................3⁄4'' Diameter in Steel

Motor:

Type ................................................................................TEFC Capacitor Start Induction

Horsepower........................................................................................................

3

⁄4 HP

Phase ⁄ Cycle ..................................................................................Single Phase ⁄ 60 Hz

Voltage ..............................................................................................................110V

Amps......................................................................................................................9

RPM ..................................................................................................................1720

Power Transfer .......................................................................................... V-Belt Drive

Bearings ......................................................................Shielded & Lubricated Ball Bearings

Switch................................................................Toggle ON/OFF Switch, w/ Safety Lock Tab

-4-

READ MANUAL BEFORE OPERATING MACHINE

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY

SAFETY FIRST!

1. Thoroughly read the instruction manual before operating your machine. Learn the applications,

limitations and potential hazards of this machine. Keep manual in a safe, convenient place for future

reference.

2. Keep work area clean and well lighted. Clutter and inadequate lighting invite potential hazards.

3. Ground all tools. If a machine is equipped with a three-prong plug, it must be plugged into a three-

hole electrical outlet or grounded extension cord. If using an adapter to aid in accommodating a twohole receptacle, ground using a screw to a known ground.

4. Wear eye protection at all times. Use safety glasses with side shields or safety goggles, meeting the

national safety standards, while operating this machine.

5. Avoid dangerous environment. Do not operate this machine in wet or open flame environments.

Airborne dust particles could cause an explosion and severe fire hazard.

6. Ensure all guards are securely in place and in working condition.

7. Make sure switch is in the “OFF” position before connecting power to machine.

8. Keep work area clean; free of clutter, grease, etc.

9. Keep children and visitors away. All visitors should be kept a safe distance away while operating

unit.

10. Childproof workshop with padlocks, master switches or by removing starter keys.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This symbol is used to alert the user to useful information about proper

operation of the equipment.

NOTICE

1. Always operate your drill press at speeds that are appropriate for the drill bit size and the mate-

rial that you are drilling.

2. Feed the drill bit evenly into the workpiece. Back the bit out of deep holes and clear the chips

with a brush after you have turned the machine off.

3. Make sure the drill bit you are using is tightened properly. Use only round, hex or triangular shank

drill bits.

4. Never do maintenance or change speeds with this machine plugged in.

5. Never use tools that are in poor condition. Cutting tools that are dull or damaged are difficult to

control and may cause serious injury.

6. Never drill sheet metal unless it is clamped securely to the table.

7. Work should be positioned in such a way as to avoid drilling into the table.

8. A face guard used with safety glasses is recommended.

9. Always clamp workpiece securely to table before drilling. Never hold a workpiece by hand while

drilling.

10. Always remove handles before using oscillating feature.

11. Habits – good and bad – are hard to break. Develop good habits in your shop and safety will become

second-nature to you.

Additional Safety Instructions For Drill Presses

11. Disconnect machine when cleaning, adjusting or servicing.

12. Do not force tool. The machine will do a safer and better job at the rate for which it was designed.

13. Use correct tool. Do not force machine or attachment to do a job for which it was not designed.

14. Wear proper apparel. Do not wear loose clothing, neck ties, gloves, jewelry, etc.

15. Remove adjusting keys and wrenches. Before turning the machine on, make it a habit to check that

all adjusting keys and wrenches have been removed.

16. Use proper extension cord. When using an extension cord, make sure it is in good condition. When

extension cord is 100’ and less in length, use those that are rated Hard Service (grade S) or better,

and that have a conductor size of 16 A.W.G. A drop in line voltage, loss of power and overheating

can result when using an undersized cord. The extension cord should have a ground wire and ground

plug pin, as well.

17. Keep proper footing and balance at all times.

18. Do not leave machine unattended. Wait until it comes to a complete stop before leaving the area.

19. Perform machine maintenance and care. Follow lubrication and accessory attachment instructions

in the manual.

20. Keep machine away from open flame. Operating machines near pilot lights and/or open flames cre-

ates a high risk if dust is dispersed in the area. Dust particles and an ignition source may cause an

explosion. Do not operate the machine in high risk areas, including but not limited to, those mentioned above.

-

5-

-6-

110V Operation

ELECTRICAL REQUIREMENTS

When it is necessary to use an extension cord,

use the following guidelines:

•Use cords rated for Hard Service

•Never exceed a length of 100 feet

•Use cords with 14 ga. wire or bigger

•Insure cord has a ground wire and pin

•Do not use cords in need of repair

Extension Cords

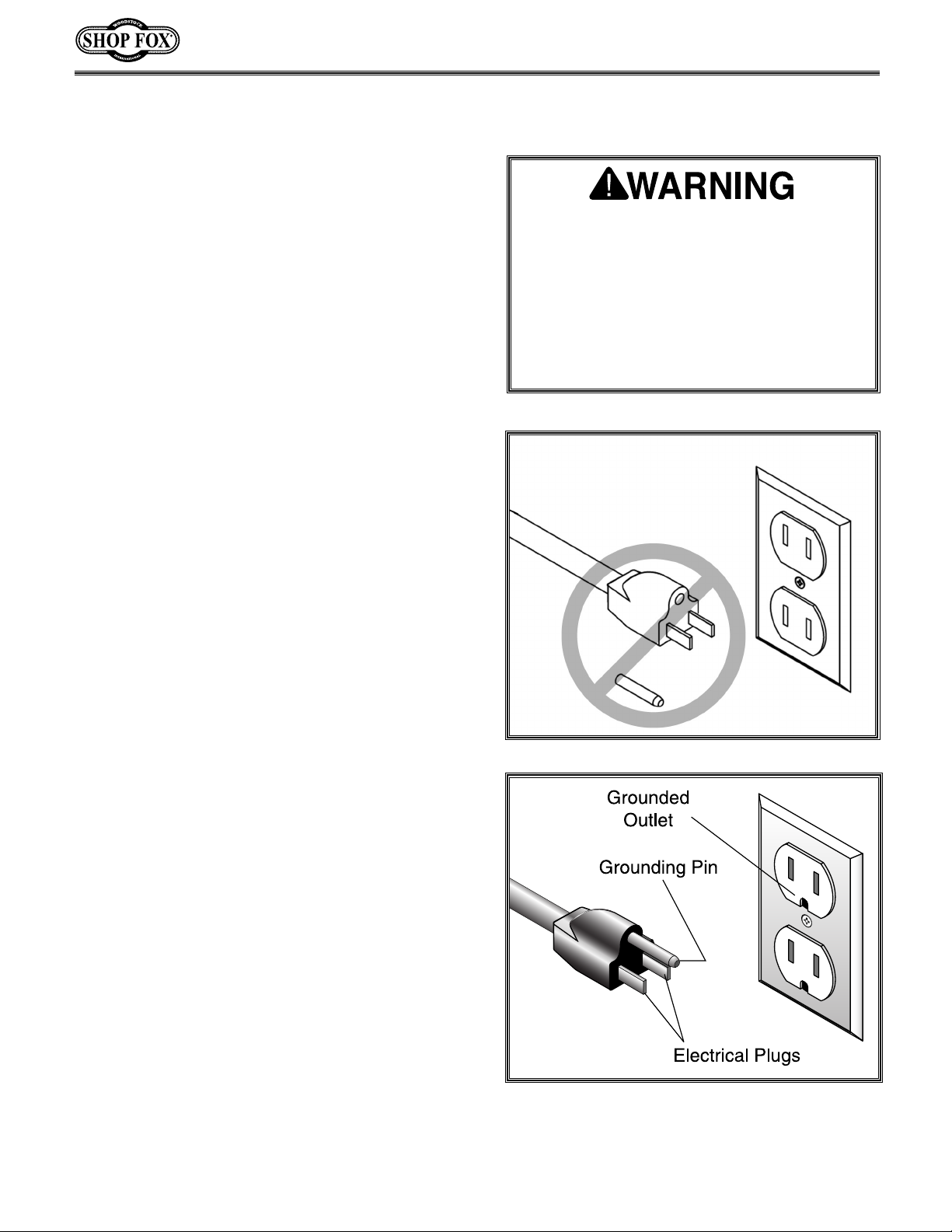

Grounding

This equipment must be grounded. Verify

that any existing electrical outlet and circuit

you intend to plug into is actually grounded.

If it is not, it will be necessary to run a separate 12 A.W.G. copper grounding wire from

the outlet to a known ground. Under no circumstances should the grounding pin from

any three-pronged plug be removed. Serious

injury may occur.

This machine must be grounded! See Figure 1.

The electrical cord supplied with the Shop Fox

®

W1668 comes with a grounding pin. Do not

remove it. If your outlet does not accommodate

a ground pin, have it replaced by a qualified

electrician or have an appropriate adapter

installed with a proven ground source. An

adapter does not ensure a grounded system if

the adapter is not grounded.

The Shop Fox

®

W1668 131⁄4" Oscillating Drill

Press can only be operated at 110 volts. The

motor supplied with your new drill press is rated

at

3

⁄4 horse power and will draw approximately

9 amps. When choosing an outlet for this

machine, consider using one with a 15 amp circuit breaker or fuse. Keep in mind that a circuit

being used by other machines or tools at the

same time will add to the electrical load being

applied by the drill press. Add up the load ratings of all machines on the circuit. If this number exceeds the rating of the circuit breaker or

fuse, use a different outlet.

Figure 1. Typical 110V 3-prong plug and outlet.

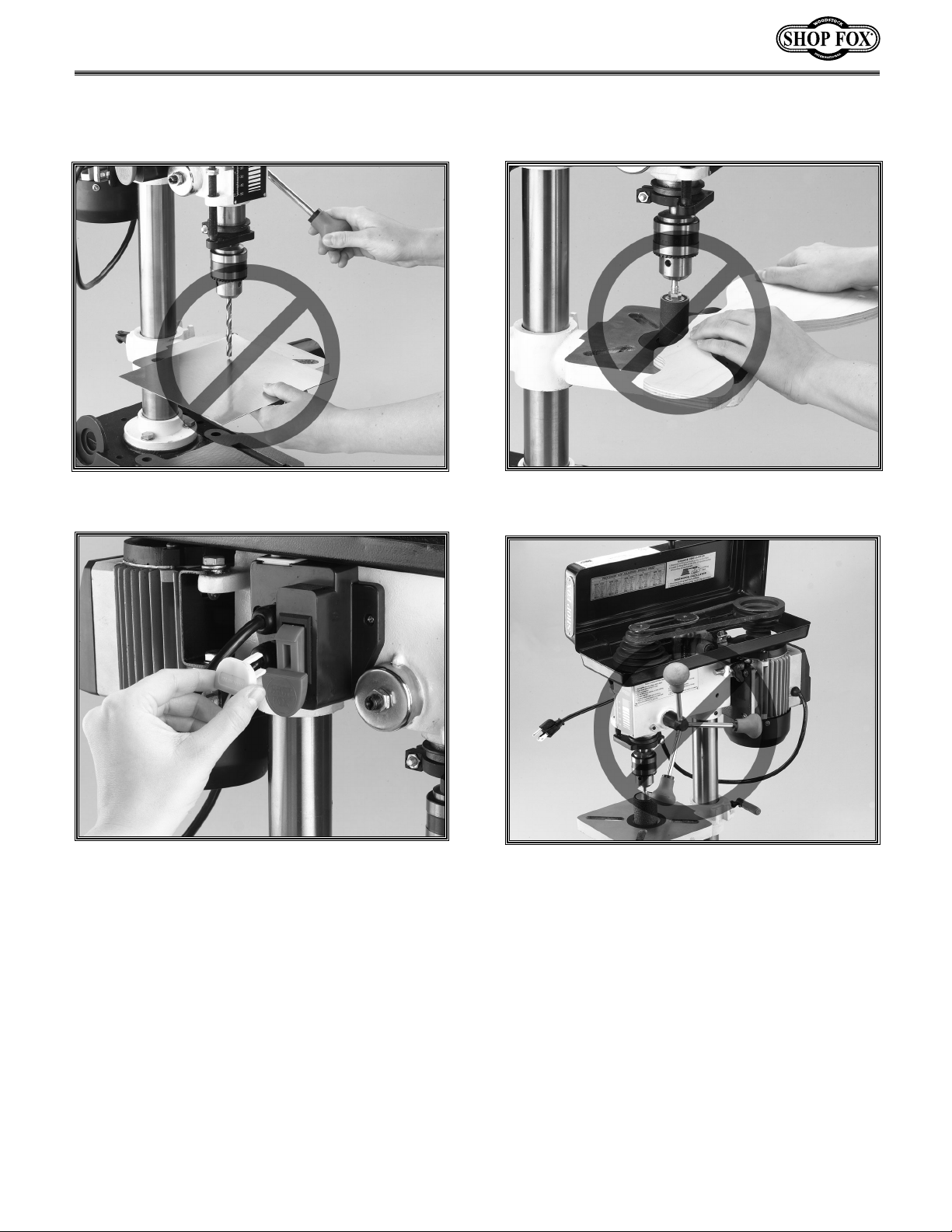

AVOIDING POTENTIAL INJURIES

-7-

Figure 2. Never drill, holding workpiece by hand.

Figure 3. Keep fingers away from spinning tool.

Fig. 4. Remove Switch Safety Key when not in use.

Figure 5. Remove handles when using oscillating

mode.

-8-

Figure 6. Components laid out for identification.

The following is a description of the components shipped with the Shop Fox

®

W1668 Oscillating Drill

Press. It is recommended that the components be laid out in a similar fashion to those in Figure 6. This

will help in identification before beginning assembly. Should any part be missing, examine the packaging carefully and check under the belt guard. If any key parts are missing call Woodstock International

at 360-734-3482 or at tech-support@woodstockint.com.

1. Headstock Assembly

2. Base

3. Column

4. Table

5. Table Bracket

6. Pinion Gear

7. Clamp Shoe

8. Hand Crank

9. Dust Port

10. Drill Chuck and Key

11. Table Inserts (4)

12. Spindle Handles (3)

13. Belt Tension Lock Knob

14. Sanding Mandrel

15. Hex Head Bolts (4)

16. Phillips

®

Head Screws (4)

17. Cap Screw

18. Mandrel Washers (4)

19. Allen

®

Wrenches (3)

20. Open End Wrench

21. Lock Handles (2)

22. Rack

23. Rack Ring

24. Belt Cover Knob

25. Machine Screw w/ Washer

26. Sanding Sleeves

27. Sanding Drums

28. Mandrel Nut

ASSEMBLY INSTRUCTIONS

Loading...

Loading...