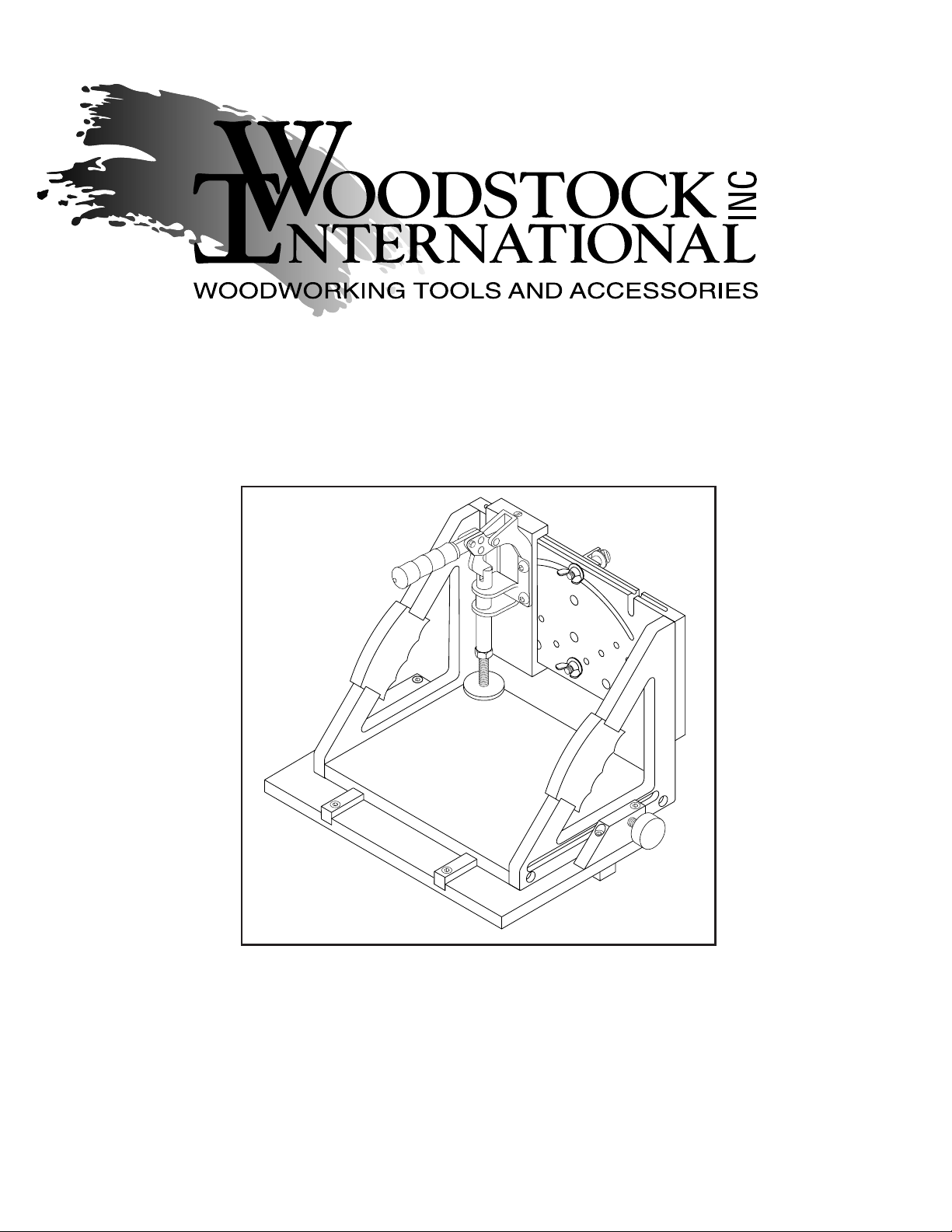

Woodstock W1500 User Manual

The Shop Fox®

ITEM W1500

P.O. Box 2309

Bellingham, WA 98227

COPYRIGHT © 1995 BY WOODSTOCK INTERNATIONAL, INC. REG.# VA 742-641

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

REVISED APRIL 1998, PRINTED IN TAIWAN

TABLE OF CONTENTS

I. Introduction ..........................................................................................................................................2

A. Safety Instructions for all Tools .............................................................................................

B. Additional Safety Rules for The Shop Fox

C. Commentary ............................................................................................................................

D. Piece Inventory .......................................................................................................................

II. Assembly ..............................................................................................................................................

A. Lock Knobs .............................................................................................................................

B. Clamping Mechanism .............................................................................................................

C. Angle Bracket .........................................................................................................................

III. Adjustments .........................................................................................................................................

A. Sliding Table ...........................................................................................................................

B. Hold-Down Bracket ................................................................................................................

C. Face Plate ................................................................................................................................

D. Miter Bar .................................................................................................................................

E. Parallelism ..............................................................................................................................

IV. Set-Up ..............................................................................................................................................

®

..........................................................................3

2

4

4

5

5

5

6

7

7

7

8

8

9

10

A. Planning ................................................................................................................................

B. Clamping your Work ............................................................................................................

C. Horizontal Clamping ............................................................................................................

D. Vertical Clamping .................................................................................................................

E. Other Clamping Methods .....................................................................................................

F. Clearance ..............................................................................................................................

V. Operations ..........................................................................................................................................

A. General Procedures ...............................................................................................................

B. Horizontal Work ...................................................................................................................

C. Vertical Work .......................................................................................................................

D. Angled Work ........................................................................................................................

VI. Closure ..............................................................................................................................................

VII. Specifications .....................................................................................................................................

VIII. Part Diagram ......................................................................................................................................

IX. Part List ..............................................................................................................................................

10

10

10

11

11

12

13

13

14

15

15

16

17

18

19

X. Warranty ............................................................................................................................................

Shop Fox

®

20

-1-

SECTION I: INTRODUCTION

WARNING: For Your Own Safety,

Read Instructions Before Using The Shop Fox

®

• Always wear eye protection

• Always feed against the rotation of the cutter

• Use overhead guard when fence is not in place

• Keep fingers away from rotating cutters

• Do not use awkward hand positions

A. Safety Instructions For All Tools

These safety rules cannot cover every situation in a workshop. Consider your individual workshop conditions

when setting up or operating any machine.

1. KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applica

tions and limitations, as well as its particular

hazards.

2. KEEP ALL GUARDS IN PLACE and in work

ing order.

7. KEEP CHILDREN AND VISITORS AWAY.

-

-

All children and visitors should be kept a safe

distance away from your work area.

8. MAKE WORKSHOP CHILD-PROOF with pad

locks, master switches, or by removing starter

keys.

-

3. GROUND ALL TOOLS. If an adapter is used to

accommodate a two-prong receptacle, the adapt

er plug must be attached to a known ground.

Never remove the grounding prong.

4. REMOVE ADJUSTING KEYS AND

WRENCHES. Make it a habit to check that keys

and adjusting wrenches are removed from the

machine before turning it on.

5. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents.

6. AVOID DANGEROUS ENVIRONMENTS. Do

not use power tools in damp or wet locations or

expose them to rain. Keep your work area well

lighted.

-2- Shop Fox

9. DO NOT FORCE TOOL. Tools work better and

-

more safely when they are allowed to work at

their own speed.

10. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, or jewelry that might

get caught in moving parts. Non-slip footwear

should be worn. Wear a hat or other protective

head wear if your hair is long.

11. NEVER STAND OR LEAN ON TOOL.

12. USE SAFETY GLASSES AND EAR PROTEC

TION. Also use a DUST MASK if the cutting

operation is dusty.

-

®

13. DO NOT OVERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS IN TOP CONDITION.

Keep tools sharp and clean for best and safest per

formance. Follow instructions for lubricating and

changing accessories.

15. DISCONNECT TOOLS FROM POWER before

servicing and when changing accessories, such as

blades, bits, and cutters.

16. AVOID ACCIDENTAL STARTING. Make sure

the switch is in the “

OFF” position before plug-

ging in the cord.

17. CHECK DAMAGED PARTS. Do not operate the

machine until you are certain it is in perfect run

ning condition.

18. NEVER LEAVE THE TOOL RUNNING UNATTENDED - TURN POWER OFF. Do not leave the

tool until it comes to a full stop.

19. DO NOT OPERATE THE TOOL IF USING

DRUGS, ALCOHOL, OR MEDICATION.

20. DO NOT WORK IN HASTE or operate machine

if you are mentally or physically fatigued.

21. IF THERE IS SOMETHING YOU DO NOT

KNOW OR UNDERSTAND, DO NOT OPER

ATE MACHINE! Ask for help first. Confusion is

dangerous.

22. BAD HABITS ARE DANGEROUS. Review all

safety procedures often.

-

-

B. Additional Safety Rules For The Shop Fox

1. Feed against the rotation of the cutter, saw blade,

or sanding tool. Caution: Be aware when you

reverse the rotation on a machine like a shaper.

2. Cut end grain before putting an edge all the way

around any stock such as a table top, raised panel,

or rail end.

3. Guard against grain tear out by placing a scrap

piece behind the work so the cutter exits through it

as the workpiece clears the bit.

4. Use quality material. Wood that is cupped, warped,

bent, or split will not machine properly and is

dangerous. Do not shape loose material such as

knots.

5. Wear the appropriate ANSI approved safety equip

ment for eyes, face, ears, and lungs.

®

8. Plan your work. Figure your steps out before you

start machining.

9. Do not shape material that is too small to be

clamped securely, even for the Shop Fox

10. Make sure that all fasteners such as the cap screws

are not loose. Tighten them if necessary.

11. Make sure all clamps, jigs, and fixtures associated

®

with the Shop Fox

and other tools are clear of

the cutting tool. It is imperative that all clamp

ing methods be done correctly and inspected for

proper clearance.

12. Make sure your workpiece is solidly supported and

all clamps are secure. Unstable work may kick-out

-

during the cutting process if not properly secured

®

to the Shop Fox

.

®

.

-

6. Check all devices that hold cutting tools in place,

i.e. router collets, shaper spindles, moulding head

gibs and arbor nuts.

7. Always use sharp cutting tools.

Shop Fox

®

®

When adjusting the Shop Fox

or stationary machine,

always turn the machine off, make sure it has come

to a complete stop and pull the plug from the outlet

or interrupt power at the disconnect switch BEFORE

performing such duties.

-3-

C. Commentary

D. Piece Inventory

The Shop Fox® is a multi-functional accessory fixture

which can be used in conjunction with a router table,

horizontal borer, shaper, bandsaw, table saw, sander,

and various other woodworking machines. Its purpose

is to help cut, shape and sand wood, wood composites,

and plastics. The Shop Fox

®

combines conventional

clamping methods with unique positioning features

to assist in cutting tenons, mortises, rail ends, finger

joints, glue joints, and other joints used in woodwork

ing as well as making edge mouldings and raised

panels.

Woodstock International is committed to offering top

quality products and supporting its products through

customer service and technical documentation. This

manual represents our latest effort to produce the best

documentation possible. If you have any criticisms

or comments you feel we should consider in our next

printing, please write or fax to:

Technical Documentation

Woodstock International, Inc.

P.O. Box 2309

Bellingham, WA 98227

FAX 1-800-647-8801

Phone 360-734-3482

If you have any parts problems or requests, please con

tact your Woodstock distributor. They will be happy to

assist you.

Remove the Shop Fox® from the package. You may

want to save the carton in case of return or future

storage.

You will notice that most of the Shop Fox

preassembled at the factory and little assembly is

required on your part. Compare the Shop Fox

parts list in the back of this manual to ensure that you

-

have all the pieces.

Upon removal of all items from the package, you

should have:

®

1. Shop Fox

2. Shop Fox

Upper Unit

®

Lower Unit

3. Lock Knobs (2)

4. Clamping Assembly

5. Angle Stop

6. Clamping Stud W/ Rubber Foot

7. Thumb Screws (2)

8. Aluminum Spacers (2)

9. 1/4'' Flat Washer (2)

10. Wing Nuts (2)

®

11. Allen

Wrenches (2)

After you have completed your inventory, inspect all

the parts (especially the contact areas) for burrs and

-

other irregularities which might hinder the assem

bly process. If you find any burrs left over from the

machining process, simply sand or file them flat.

Please note that while burrs are not a common occur

rence, it is possible that one or more of the parts could

have been missed during the manufacturing process.

®

has been

®

to the

-

-

-4- Shop Fox

®

SECTION II: ASSEMBLY

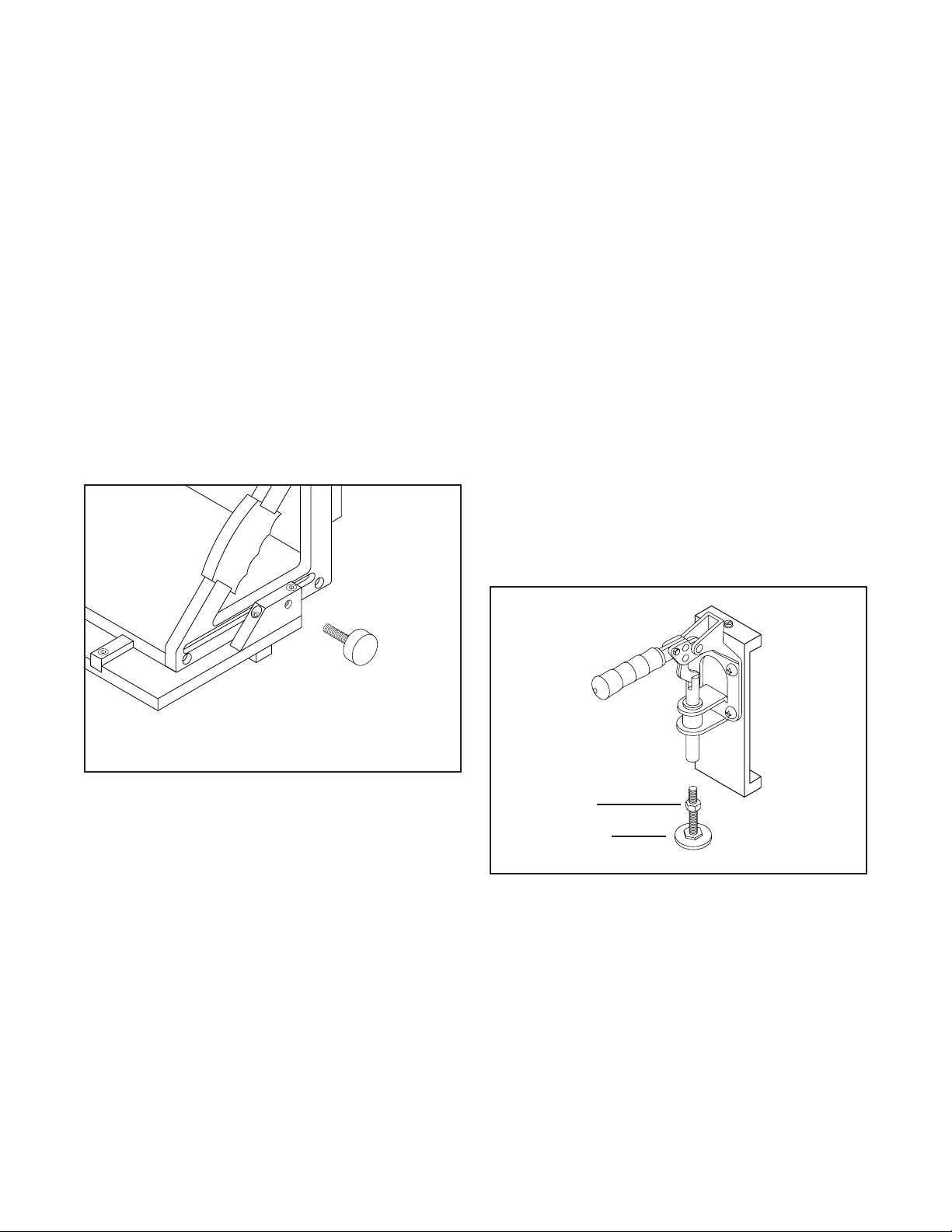

A. Lock Knobs

To secure the Shop Fox® assembly to the base plate:

1. Thread each of two (2) lock knobs into the

lock knob brackets mounted on the base plate.

Figure 1.

2. Tighten sufficiently to hold the Shop Fox

base plate.

®

to the

B. Clamping Mechanism

To attach the horizontal clamping mechanism to the

Shop Fox

1. Press the rubber clamping pad onto the head of

2. Thread the carriage bolt into the toggle clamp.

3. Tighten the lock nut against the toggle clamp

®

:

the 2" carriage bolt.

Figure 2.

shoulder. Adjustment is made by loosening the

lock nut and turning the carriage bolt in or out of

the toggle clamp and then re-tightening the lock

nut.

Shop Fox

Figure 1. Lock knob installation.

®

Lock Nut

Rubber Pad

Figure 2. Threading the clamping pad into the

toggle clamp.

-5-

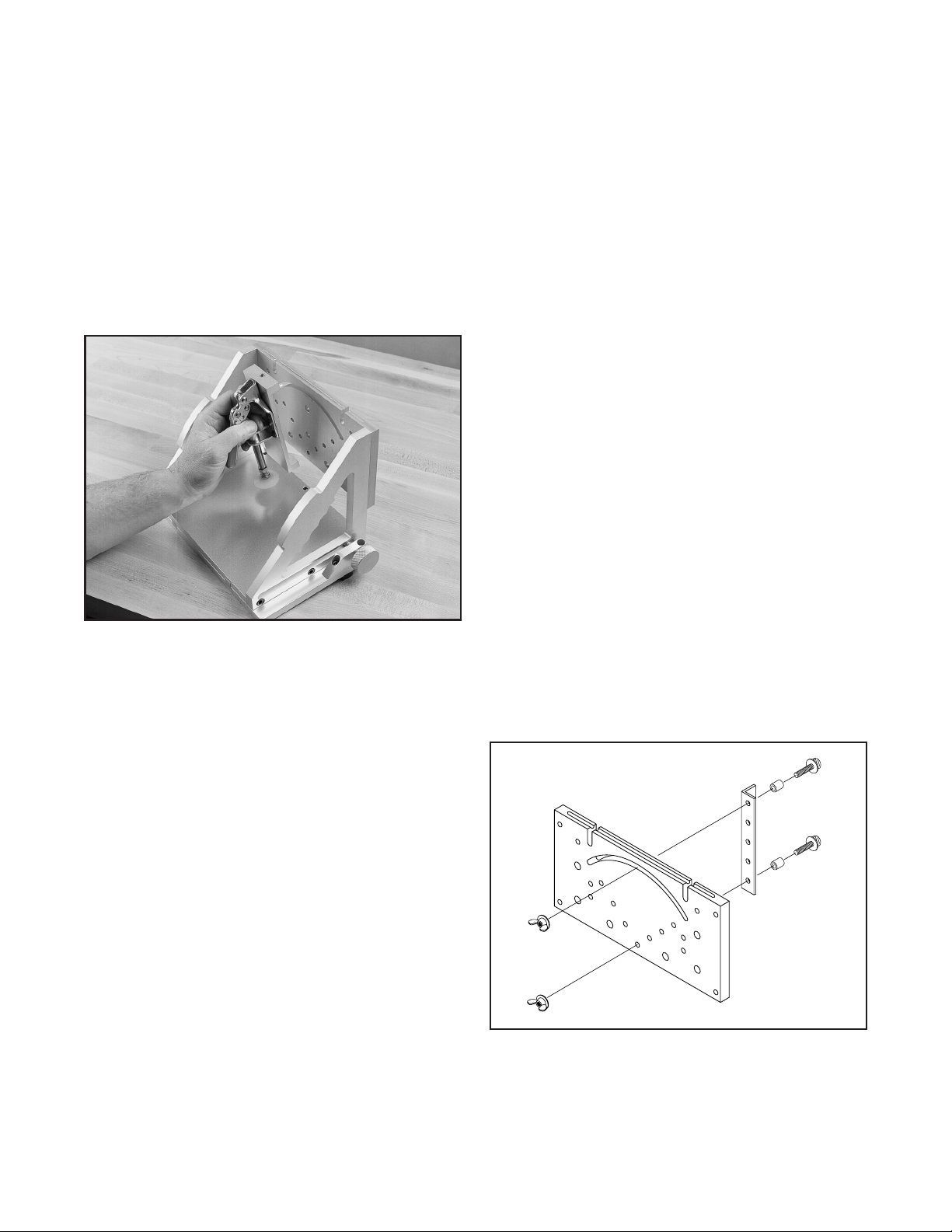

Clamping Mechanism Continued

C. Angle Bracket

4. Snap the toggle clamp bracket onto the inside

®

vertical plate of the Shop Fox

. Figure 3.

5. See page 7 for ball-plunger adjustment.

The Shop Fox® Face Plate features a variety of predrilled holes for mounting the angle bracket. The Angle

Bracket is adjustable and supports your workpiece at a

variety of angles. To mount the Angle Bracket:

1. Slide the aluminum bushing onto the thumb

screw and insert the thumb screw through one of

the end holes in the angle bracket. Figure 4.

2. Slide the thumb screw with angle bracket into

the bottom hole located in the middle of the face

plate. Slide on a washer and thread on the wing

nut.

3. Repeat this process on the other end of the angle

bracket so the thumb screw passes through the arc

cut-out.

4. If making angled cuts between -45° and +45°,

transfer the angle with a bevel gauge to the angle

bracket and tighten the thumbscrews and wing

nuts.

Figure 3. Mounting the clamping bracket to the

®

Shop Fox

.

5. If making either -45°, 90° or +45° cuts, mount the

angle bracket into any of the fixed position holes

with both sets of thumbscrews, bushings, washers

and wing nuts.

Figure 4. Mounting the Angle Bracket to the

®

Shop Fox

.

-6- Shop Fox

®

Loading...

Loading...