®

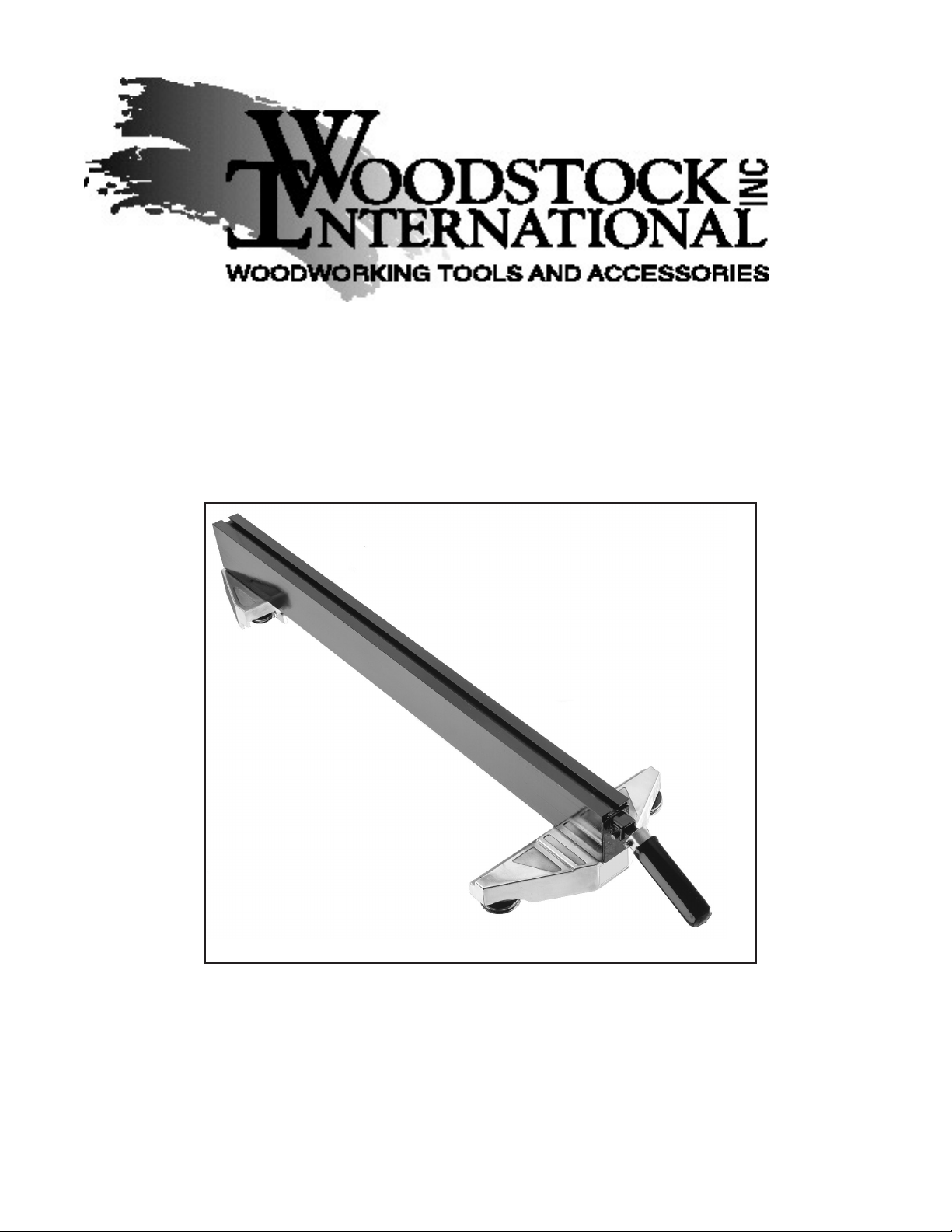

Shop Fox Fence

ITEM W1410

OPERATING MANUAL

P.O. Box 2309

Bellingham, WA 98227

COPYRIGHT © 1996 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

REVISED MAY, 1997 PRINTED IN USA

TABLE OF CONTENTS

I. INTRODUCTION ...................................................................................................................... 2

A. SAFETY RULES FOR ALL TOOLS ........................................................................................

B. UNPACKING .............................................................................................................................

C. PIECE INVENTORY .................................................................................................................

D. CLEAN UP .................................................................................................................................

II. INSTALLATION .......................................................................................................................

A. ORDER OF INSTALLATION ..................................................................................................

B. TOOLS REQUIRED ..................................................................................................................

C. MOUNTING THE RAILS ......................................................................................................

D. OPTIONAL EXTENSION RAILS ............................................................................................

E. MOUNTING THE FENCE ........................................................................................................

F. BLADE GUARDS .....................................................................................................................

III. ADJUSTMENTS ......................................................................................................................

A. TABLE CLEARANCE ............................................................................................................

B. TRACKING .............................................................................................................................

C. LOCK HANDLE ......................................................................................................................

D. FENCE CLAMPING PRESSURE ......................................................................................

12-13

3

4

4

4

5

5

5

5-7

8

8

9

10

10

10

11

E. PARALLELISM TO BLADE .............................................................................................

F. 90˚ TO TABLE TOP ...........................................................................................................

G. SCALE/INDICATOR .........................................................................................................

H. FENCE STOP ...........................................................................................................................

IV. OPERATIONS .........................................................................................................................

A. FINE POSITIONING ...............................................................................................................

B. BOARD BUDDIES

C. WOOD FACING ......................................................................................................................

V. TROUBLESHOOTING ...........................................................................................................

A. RAILS TOO CLOSE TOGETHER .........................................................................................

B. RAILS TOO FAR APART .................................................................................................

C. FRONT CLAMP WILL NOT ADJUST ..................................................................................

D. REAR CLAMP WILL NOT ADJUST ....................................................................................

E. FENCE DOES NOT MOVE SMOOTHLY .......................................................................

F. FENCE WILL NOT ADJUST PARALLEL TO BLADE .......................................................

VI. PART DOCUMENTATION ...............................................................................................

®

................................................................................................................ 18

14-15

15-16

16-17

20-21

22-23

24-26

17

18

18

19

20

20

21

22

23

VII. SPECIFICATIONS ..................................................................................................................

XIII. WARRANTY ..........................................................................................................................

Shop Fox® Fence

27

28

-1-

SECTION I: INTRODUCTION

Thank you for purchasing Woodstock

International’s Shop Fox® Fence. The Item W1410

Shop Fox® Fence was designed by Woodstock’s

engineering staff to provide the woodworker

with a precision alternative to standard table saw

fences. The Shop Fox® Fence fits most contractor

and cabinet-style table saws with tables measuring

27" from front to back.

The key to the Shop Fox® Fence’s accuracy is its

unique roller tracking system, which allows the

fence to hold precise alignment with the blade,

even when the locking system is disengaged. This

consistency allows the woodworker to make even

the most minute adjustments with complete confidence.

The Shop Fox® Fence features polished and blackanodized aluminum construction with built-in

micro adjustment knobs on either side of the positive locking lever. A T-slot on top of the fence

is designed to accept Woodstock’s Board Buddies®

hold down rollers. Optional extension rails are

also available for the Shop Fox® Fence for use

with wider materials such as plywood and wood

composites.

Woodstock is pleased to provide this manual to

assist in the installation and operation of the Shop

Fox® Fence. It represents our effort to offer the

finest documentation available. If you feel there

are areas where this manual could be improved,

we encourage you to write us with your comments

at the following address:

Technical Documentation

Woodstock International, Inc.

P.O. Box 2309

Bellingham, WA 98227

(360) 734-3482

Fax (360) 671-3053

-2- Shop Fox® Fence

A. SAFETY RULES FOR TABLE SAWS

1. KNOW YOUR TABLE SAW. Read the

owner’s manual carefully. Learn the tool’s

applications and limitations, as well as its

particular hazards.

2. DO NOT REMOVE GUARDS. Maintain

guards in working order.

3. ENSURE THAT YOUR TABLE SAW IS

ELECTRICALLY GROUNDED. Never

remove the grounding prong.

4. KEEP WORK AREA CLEAN. Cluttered

areas invite accidents.

5. AVOID DANGEROUS ENVIRONMENTS.

Do not use power tools in damp or wet locations or expose them to rain. Keep your work

area well lighted.

6. MAKE WORKSHOP CHILD-PROOF with

padlocks, master switches, or by removing

starter keys.

7. DO NOT FORCE WORK THROUGH

TABLE SAW. Tools work better and more

safely when they are allowed to work at their

own speed.

8. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, or jewelry

that might get caught in moving parts. Nonslip footwear should be worn. Wear a hat

or other protective head wear if your hair is

long.

13. DO NOT REACH BEHIND TABLE SAW

TO GRAB CUTOFF PIECE. If wood binds

against saw blade it will kick back faster than

you can let go.

14. DO NOT LET THE END OF THE WORKPIECE CONTACT THE FENCE WHILE

CROSSCUTTING WOOD WITH THE

MITER GAUGE. There is a potential for

kick-back. Move the fence away.

15. DISCONNECT TABLE SAW FROM

POWER before servicing and when changing

accessories, such as blades, bits, and cutters.

16. AVOID ACCIDENTAL STARTING. Make

sure the switch is in the “OFF” position

before plugging in the cord.

17. CHECK DAMAGED PARTS. Do not operate the table saw until you are certain it is in

perfect running condition.

18. NEVER LEAVE THE TABLE SAW RUNNING UNATTENDED - TURN POWER

OFF. Do not leave the saw until it comes to a

full stop.

19. DO NOT OPERATE EQUIPMENT IF

USING DRUGS, ALCOHOL, OR MEDICATION.

20. DO NOT WORK IN HASTE or operate

equipment if you are mentally or physically

fatigued.

9. NEVER STAND OR LEAN ON TOOL.

10. ALWAYS USE SAFETY GLASSES, EAR

PROTECTION AND RESPIRATORY PROTECTION.

11. DO NOT OVERREACH. Keep proper footing and balance at all times.

12. USE A PUSH STICK WHEN CUTTING

NARROW PIECES.

Shop Fox® Fence -3-

21. IF THERE IS SOMETHING YOU DO NOT

KNOW OR UNDERSTAND, DO NOT

OPERATE MACHINE! Ask for help first.

22. BAD HABITS ARE DANGEROUS. Review

all safety procedures often.

These safety rules cannot cover every situation in

a woodshop. Consider your conditions when setting up and using your Shop Fox® Fence.

B. UNPACKING

Piece count for the W1410 Shop Fox

®

Fence.

The Item W1410 Shop Fox® Fence is shipped

from our factory in a carefully packed carton. If

you discover the product is damaged, please contact your local Woodstock dealer immediately for

advice. Be sure to save the packing containers for

possible inspection.

The Shop Fox® Fence weighs only 35 pounds.

However, when lifting, we must caution against

improper lifting techniques. Always keep your

back straight and lift with your legs. If you are

limited by the amount of weight you can lift and

carry, please refrain from moving The Shop Fox®

Fence until you get the necessary assistance.

C. PIECE INVENTORY

The parts are arranged in two layers of packing.

Remove the parts in an orderly fashion. This will

simplify identification and make inventory and

assembly that much easier. When removing the

parts, please take care not to destroy the foam and

cardboard carton. It is a good idea to save the car

ton for future storage or shipment if necessary.

In the event that any parts or hardware are miss

ing, please contact Woodstock at the phone number or address found on page 2 and we will send

replacements right away.

Qty Description

®

1 Shop Fox

Fence

1 Front rail

1 Back Rail

1 Manual

1 Scale

1 Bag of Mounting Hardware

1 Universal Blade Guard Bracket (optional)

Mounting Hardware Consists of:

4 3⁄8" - 16 x 1" Hex Bolts

9

1

1

3

⁄8" Flat Washers

5

⁄16" Drill Bit

3

⁄8" - 16 Tap

1 Rubber Bumper w/ Mounting Hardware

1 Cross Brace w/ Mounting Hardware

D. CLEAN UP

Remove the plastic protective covering and wipe

the fence off with a clean rag. Inspect all the parts

(especially the contact areas) for burrs and other

-

irregularities that might hinder assembly. If you

find any burrs or “flash” from the machining or

casting process, simply sand or file them flat.

Although this is not a common occurrence, it is

possible that one or more of the parts could have

been missed during the machining and deburring

process.

-4- Shop Fox® Fence

SECTION II: INSTALLATION

A. ORDER OF INSTALLATION

Installation of the Shop Fox® Fence is quick and

easy. Installation involves mounting the front and

back rails to your table saw and then attaching

the fence to the rails. On some saws, the mounting holes for the rails will match the existing rail

mounting holes. On other saws where the mounting holes do not line up, it will be necessary to

drill and tap new mounting holes in your table top

edge. We’ve supplied you with a drill and tap for

this purpose. If you are uncomfortable with the

tapping process, through-bolting may be used as

an alternative. If through-bolting, make sure you

have access to the backside of the hole and that the

table webbing will not interfere with the nut and

bolt before attempting this method.

Before beginning installation, measure your table

saw top from front to back. The Shop Fox® Fence

comes preset to fit on tables measuring between

265⁄8'' and 271⁄4''. If your table top is not within

this range, refer to the Troubleshooting Guide for

further instruction.

C. MOUNTING THE RAILS

Step 1.

Locate the back fence rail (the rail with the oval

cut-outs) and set it against the rear edge of the

table saw. Position the back rail so that its top

edge is 1⁄16" below the table top and the oval cutouts are in line with the miter slots. Figure 1. If the

back rail mounting holes line up with the existing

holes in the table top, attach the rail using the

original mounting hardware as shown in Figure

3. If the holes do not line up, use the mounting

method covered in Steps 3-6.

B. TOOLS REQUIRED

Only a few common tools are required to assemble

your Shop Fox

14mm open end wrench

5mm Allen wrench

3mm Allen wrench

Needle nose pliers

7

Optional Tools:

3

5

1

Center punch

Hammer

Tap handle

Shop Fox® Fence -5-

®

Fence. Specifically, these are:

Regular screwdriver

6" adjustable wrench

⁄16'' socket and ratchet

⁄8''-16 tap

⁄16'' drill bit

⁄8'' drill bit

3

⁄8'' or 1⁄2'' Electric drill

Figure 1. Attaching the back rail.

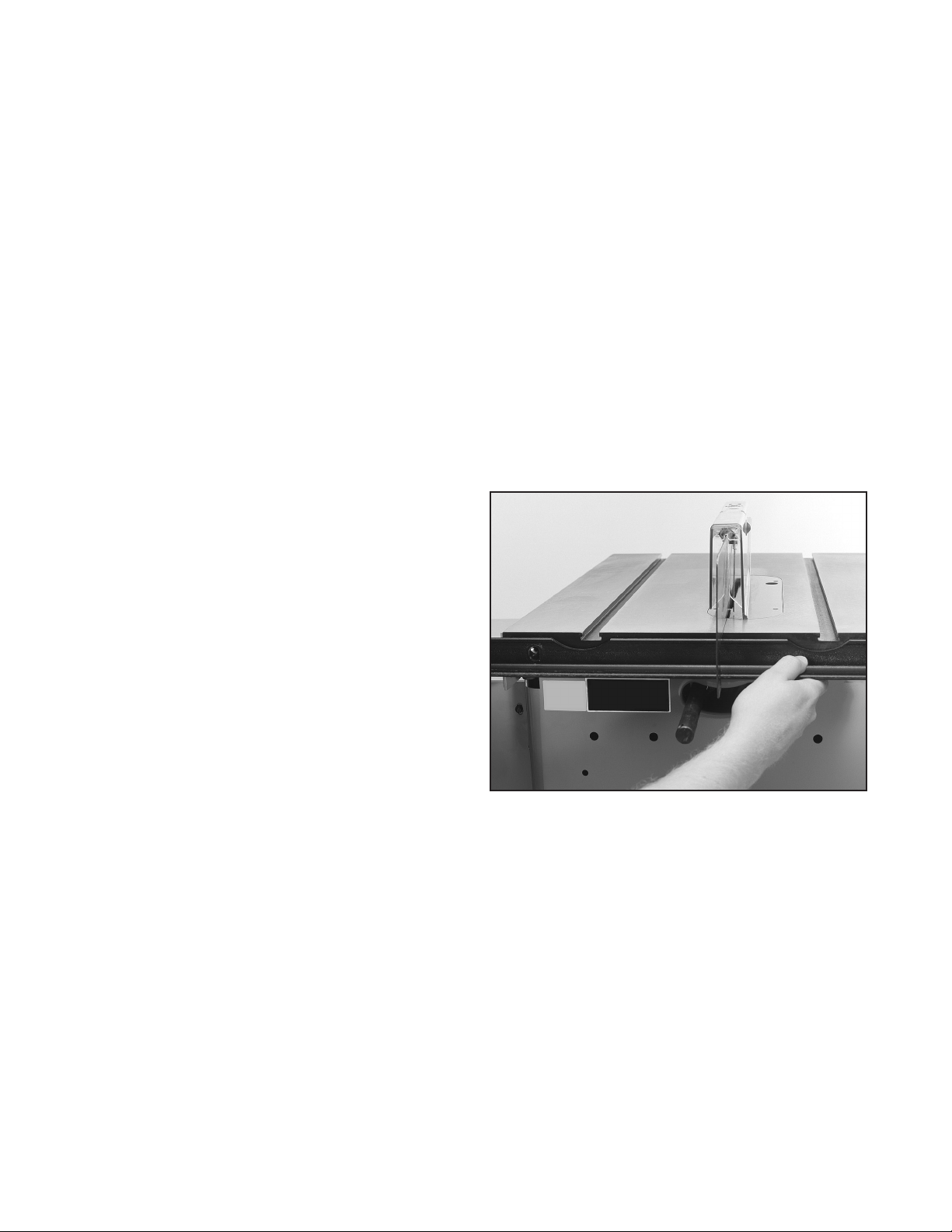

Step 2.

Line up the ends of the front rail even with the

back. Set the top edge

1

⁄16" below the bottom of

the miter slots. Figure 2. If the front rail mounting

holes line up with the existing holes in the table

top, attach the rail using the original mounting

hardware as shown in Figure 3. If the holes do

not line up, use the mounting method covered in

Steps 3-6. If both rails are mounted at this point,

skip to Step 7.

Note: Delay installation of the adhesive scale

(#56) until Section III Part G.

Figure 2. Attaching the front rail.

Step 3.

If the front and back mounting holes do not line

up with the existing holes in the table top, you

will need to drill and tap new mounting holes in

the table top.

drill chuck. Loosen the chuck, detach the tap and

continue turning the tap into the hole with an

adjustable wrench. Advance the tap half a turn,

back it out half a turn, advance another half turn,

etc. until the tip of the tap extends 1⁄2" beyond the

hole. Back the tap out and proceed to the next

hole. It is not necessary to use cutting oil when

tapping cast iron.

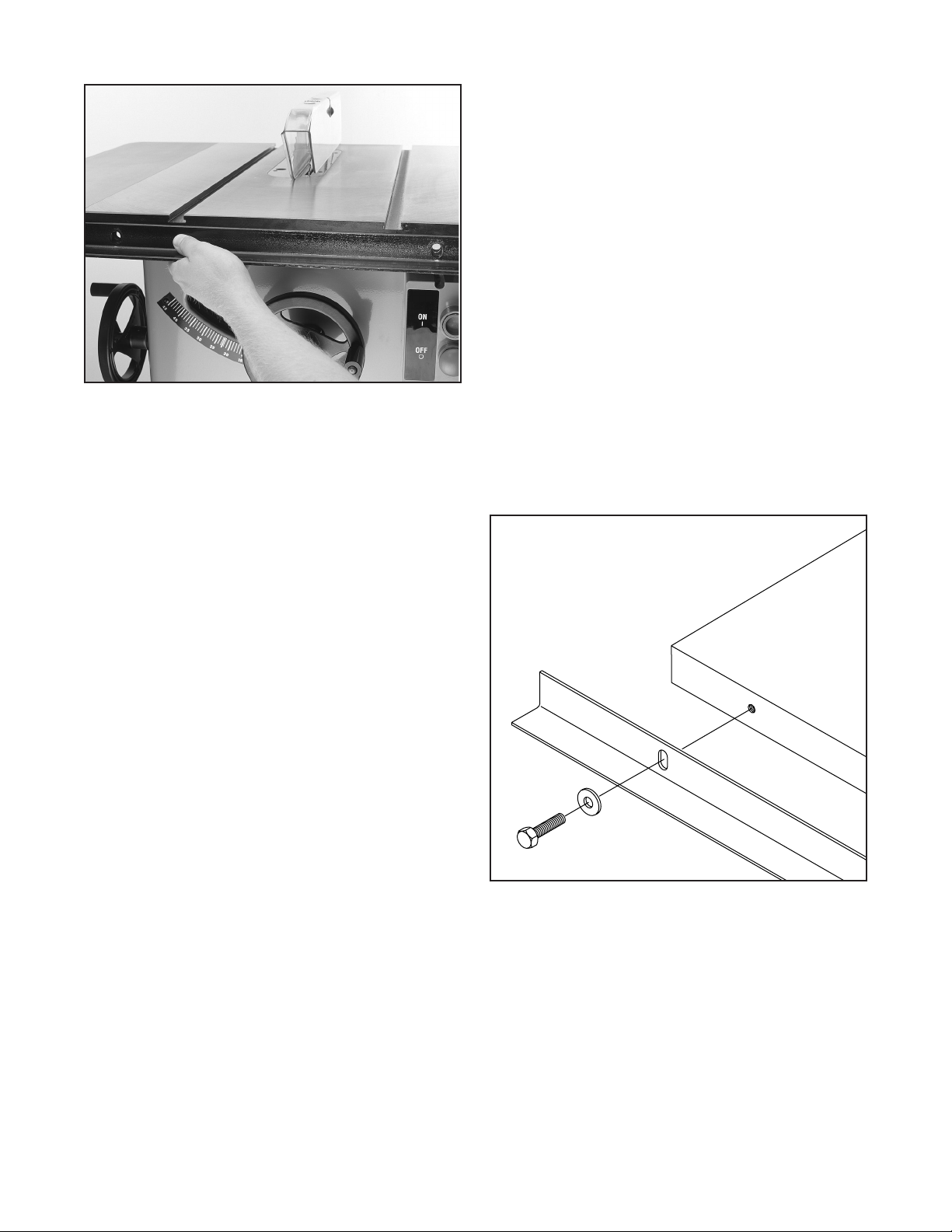

Step 6.

Mount the front rail with the 3⁄8''-16 x 1'' Hex Bolts

and Flat Washers provided. Figure 3. It is imperative that the front rail mounts flat against the

front edge of the table. If there is a gap between

the front rail and the extension wing, it is a good

idea to loosen the wing and move it over until it

touches the rail. This will add extra support to the

front rail.

Position the back rail according to the instructions

in Step 1. Clamp the rail to the table saw using Cclamps or bar clamps. The use of wood clamping

blocks will ensure a secure, non slip set-up. Mark

the oval mounting holes on the edge of the table.

Remove the rail and centerpunch the middle of the

outlined slots on the table edge. Refer to Step 2 for

positioning the front rail and repeat this process

for the front rail.

Step 4.

1

At each centerpunch location, drill a

⁄8" diameter

starter hole, then drill a 5⁄16" hole using the bit supplied with the Shop Fox® Fence. It is not necessary

to use cutting oil when drilling cast iron.

Step 5.

Tap each hole with the 3⁄8" - 16 tap supplied. Hold

the tap in a tap wrench if one is available. If a tap

wrench is not available use a 3⁄8 " or 1⁄2" electric

drill that is set on slow speed. Treat it as though it

were a drill bit. After the first few rotations however, the tap will invariably start slipping in the

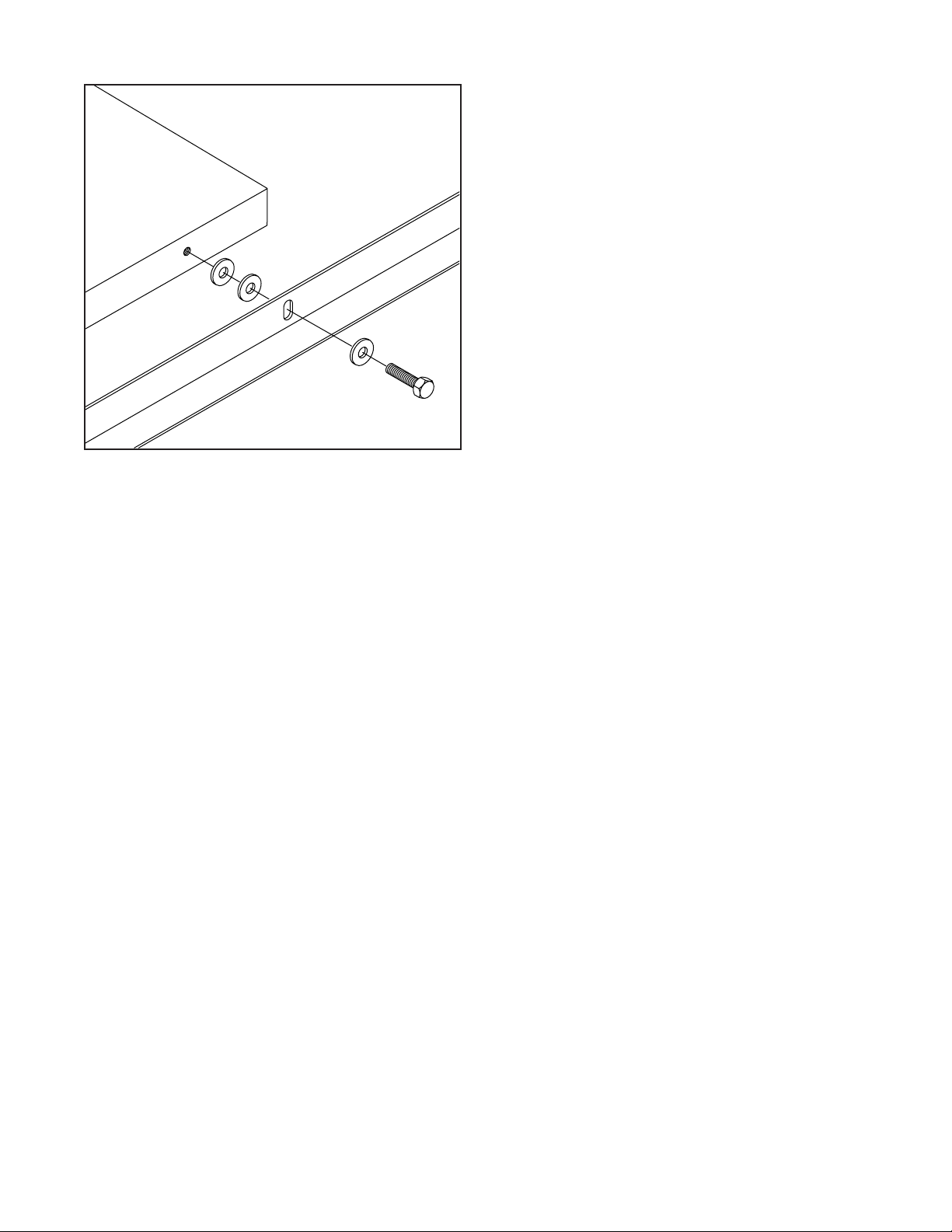

Figure 3. Mounting the front rail.

Step 7.

3

Mount the rear rail with the

⁄8''-16 x 1'' Hex Bolts

and Flat Washers provided. There should be 2 flat

washers between the rear rail and the table top.

Figure 4.

-6- Shop Fox® Fence

Figure 4. Mounting the rear rail.

Step 9.

Measure the distance between both ends of the

rails to determine if they are parallel. The differ

ence between the two ends of the rails should be

no more than ±1⁄8".

Note: relative parallelism between the ends of the

rails is not critical to the accuracy of the fence, but

will prevent the unlocked fence from moving by

itself in the direction of the taper. Extra washers

may be added or removed from between the table

and back rail to achieve parallelism.

Step 10.

Mount the cross brace to the end of the rails using

the 3⁄8-16 x 1'' Hex Bolts and Flat Washers provided. Leave the bolt in the middle of the brace loose

until the bolts at the ends of the brace are tight.

-

Step 8.

The distance between the front and back rail

1

should be 27'' ±

⁄4''. Add or remove washers to

achieve this measurement. If your measurement

does not fall within this range, refer to Section V

on page 20 for further instruction.

Shop Fox® Fence -7-

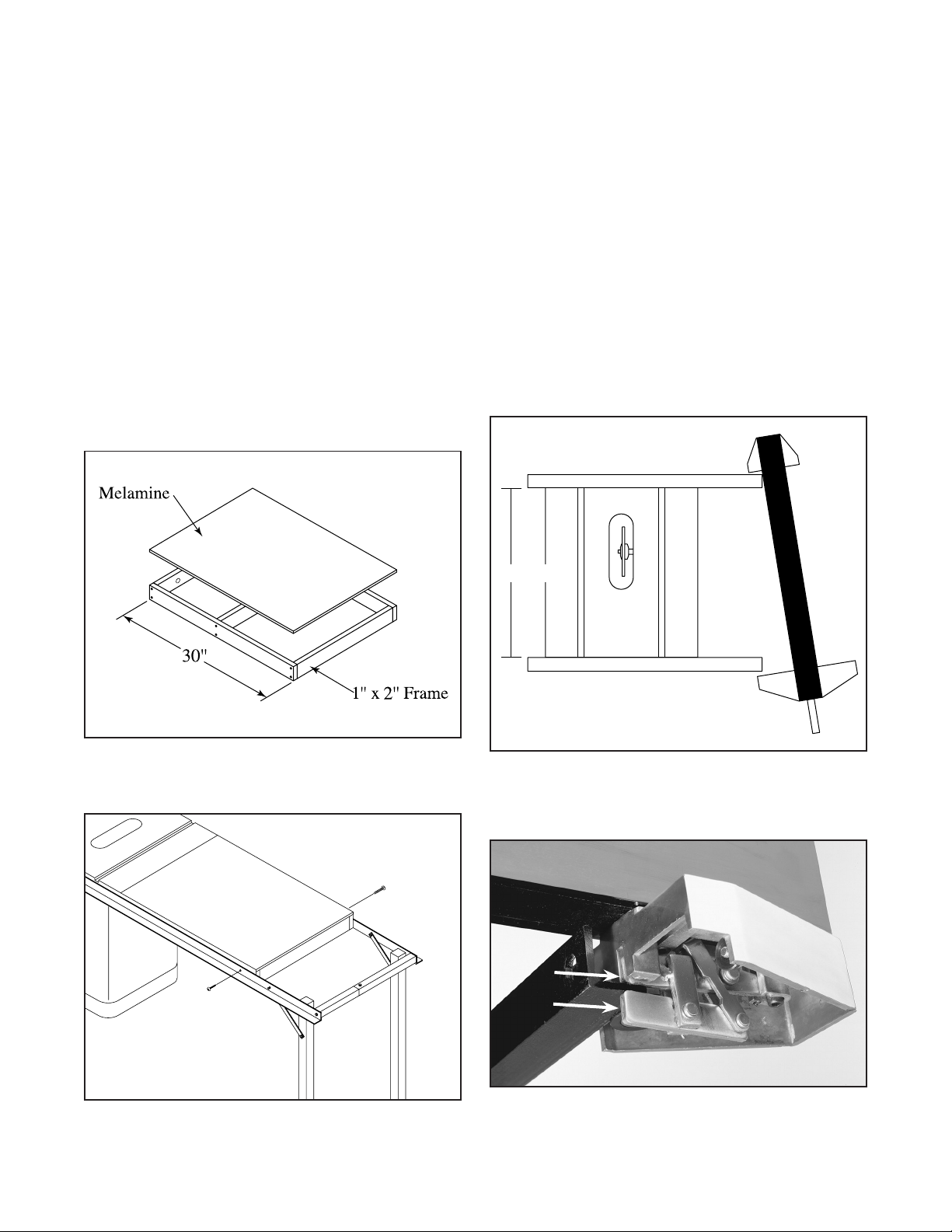

D. OPTIONAL EXT. RAILS

E. MOUNTING THE FENCE

An extended rail set is available for the Shop Fox

Fence increasing the rip capacity to the right of the

blade to 49''. They are mounted in the same manner as the standard rails.

An extension table (Figure 5.) must be mounted

between the fence extension rails to properly support the rails as well as the workpiece. The extension table must fit in the gap between the rails perfectly or the rails will be bowed. Remove the right

side table saw wing and bolt the extension table in

place using the existing holes for the wing. Extra

holes will need to be drilled in the rails to secure

the extension table at the right end.

®

With the lock handle in the ''UP'' (unlocked) position, attach the fence to the rails by skewing the

fence so the groove in the rear spring loaded roller

engages the back rail first. Figure 7. Then, holding the rear of the fence stationary, roll the first

front roller onto the front rail. Align the rear jaws

so the back rail will pass between them. Figure 8.

You may need to gently separate the jaws with a

screwdriver to allow them to clear the rail. Feed

the front jaws onto the front rail and slide the

fence the rest of the way on, making sure the second front roller engages securely.

27"±1⁄4"

Figure 5. Extension table.

Figure 7. Fence installation.

Figure 6. Extension table and extension rails

assembled.

-8- Shop Fox® Fence

Figure 8. Jaw position.