Woodstock M1099 User Manual

MODEL M1113

18" WOOD/METAL BANDSAW

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 2/08)

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © OCTOBER, 2007 BY WOODSTOCK INTERNATIONAL, INC., REVISED JANUARY, 2010 (TS)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

#9997TR

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in Taiwan

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Contents

INTRODUCTION .....................................2

Woodstock Technical Support .................. 2

SAFETY ...............................................6

Standard Safety Instructions ................... 6

Additional Safety for Bandsaws ................ 8

ELECTRICAL .........................................9

220V Operation ................................... 9

Extension Cords .................................. 9

Electrical Specifications ........................ 9

SETUP .............................................. 10

Inventory ........................................ 10

Machine Placement ............................ 11

Cleaning Machine ............................... 11

Lifting & Moving ................................ 12

Mounting to Shop Floor ........................ 13

Assembly ......................................... 14

Dust Collection ................................. 16

Blade Tracking .................................. 17

Test Run .......................................... 18

Blade Tensioning ................................ 19

Support Bearing Adjustment.................. 20

Blade Guide Adjustment ...................... 21

Table Stop Adjustment ........................ 22

Table Tilt Scale Calibration ................... 22

Table Alignment ................................ 23

Fence Alignment................................ 23

ACCESSORIES ...................................... 36

MAINTENANCE .................................... 37

Schedule ......................................... 37

Cleaning ......................................... 37

Table & Base .................................... 37

Redressing Rubber Tires ....................... 37

SERVICE ............................................ 38

General .......................................... 38

Servicing V-Belts ................................ 38

Shimming Table ................................. 40

Blade Lead ...................................... 40

Wheel Alignment ............................... 42

Electrical Component Wiring ................. 44

Wiring Diagram ................................. 45

Troubleshooting ................................. 46

PARTS .............................................. 48

Bandsaw Body Breakdown .................... 48

Bandsaw Body Parts List ...................... 49

Table & Guides Breakdown ................... 50

Table & Guides Parts List ..................... 51

Fence Breakdown .............................. 52

Label Placement ............................... 53

SAFETYINTRODUCTION

SET UPELECTRICAL MAINTENANCE

OPERATIONS

OPERATIONS....................................... 24

General .......................................... 24

Basic Controls ................................... 24

Workpiece Inspection (Wood) ................ 25

Workpiece Inspection (Metal) ................ 26

Cutting Overview ............................... 27

Table Tilt ........................................ 27

Guide Post ....................................... 28

Rip Cutting ...................................... 28

Crosscutting ..................................... 29

Resawing ......................................... 29

Cutting Curves .................................. 30

Stacked Cuts .................................... 30

Blade Characteristics (Wood Cutting) ....... 31

Blade Selection (Metal Cutting) ............. 33

Blade Changes .................................. 34

Fence Scale Calibration ....................... 35

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

SERVICE PARTS

Model M1113 (Mfg. Since 2/08)

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

This machine has been specially designed to provide many years of trouble-free service. Close attention

to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, setup, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

-2-

Model M1113 (Mfg. Since 2/08)

SHOP FOX® WOOD/METAL BANDSAW

Product Dimensions

Weight.......................................................................................................... 314 lbs.

Width (side-to-side) x Depth (front-to-back) x Height........................................ 40 x 31 x 76 in.

Footprint (Length x Width)......................................................................... 26-1/2 x 20 in.

Shipping Dimensions

Type.................................................................................................. Wood Slat Crate

Content........................................................................................................ Machine

Weight.......................................................................................................... 327 lbs.

Length x Width x Height........................................................................... 19 x 33 x 79 in.

Must Ship Upright................................................................................................. N/A

INTRODUCTION

MODEL M1113

Electrical

Power Requirement.................................................................... 220V, Single-Phase, 60 Hz

Prewired Voltage................................................................................................. 220V

Full-Load Current Rating........................................................................................... 5A

Minimum Circuit Size............................................................................................. 15A

Connection Type......................................................................................... Cord & Plug

Power Cord Included.............................................................................................. Yes

Power Cord Length............................................................................................... 6 ft.

Power Cord Gauge............................................................................................ 16 AWG

Plug Included........................................................................................................ No

Recommended Plug Type........................................................................................ 6-15

Switch Type............................................ ON/OFF Push Button Switch w/Large Shut-Off Paddle

Inverter Type.............................................................................. Rhymebus RM5G-200V 1

Inverter Size....................................................................................................... 1 HP

Motors

Main

Type............................................................................................ TEFC Induction

Horsepower.............................................................................................. 1.5 HP

Phase.................................................................................................... 3-Phase

Amps........................................................................................................... 5A

Speed.................................................................................................. 1725 RPM

Power Transfer ................................................................................... V-Belt Drive

Bearings............................................................... Shielded & Permanently Lubricated

Main Specifications

Operation Info

Blade Speeds.................................................................... 150 — 3000 (Variable) FPM

Std. Blade Length....................................................................................... 133 in.

-3-

INTRODUCTION

Model M1113 (Mfg. Since 2/08)

Cutting Capacities

Cutting Height............................................................................................ 12 in.

Cutting Capacity Left of Blade.................................................................... 17-1/2 in.

Construction

Table............................................................................. Precision-Ground Cast Iron

Upper Wheel...................................................................... Fully Balanced Aluminum

Lower Wheel...................................................................... Fully Balanced Aluminum

Tire....................................................................................................... Rubber

Body......................................................................................................... Steel

Base......................................................................................................... Steel

Wheel Cover............................................................................................... Steel

Paint............................................................................................ Powder Coated

Other

Wheel Size................................................................................................ 18 in.

Table Info

Table Tilt - Left/Right................................................................ 45 Right, 5 Left deg.

Table Size Length........................................................................................ 24 in.

Table Size Width......................................................................................... 18 in.

Table Size Thickness................................................................................. 1-3/4 in.

Floor To Cutting Area Height..................................................................... 37-1/4 in.

Other

Country Of Origin ............................................................................................. Taiwan

Warranty ....................................................................................................... 2 Years

Approximate Assembly & Setup Time ...................................................................... 1 Hour

Serial Number Location ............................................ ID Label on Center of Upper Wheel Cover

Sound Rating .................................................................................................... 74 dB

ISO 9001 Factory ................................................................................................... No

CSA Certified ....................................................................................................... No

Features

Precision-ground cast iron table

Variable frequency drive speed control

Left and right table tilting control

Upper and lower blade guides

Rack and pinion adjustment on upper blade guide support

Fully balanced cast iron wheels w/rubber tires

Quick release blade tension

Steel guide blocks

Two dust ports

Wheel brush on lower wheel

Blade tension scale with magnified cursor

Twin drive belts

Includes rip fence and miter gauge

Rip fence comes with right and left reading indicators, T-slots, dead lift quick release

-4-

Model M1113 (Mfg. Since 2/08)

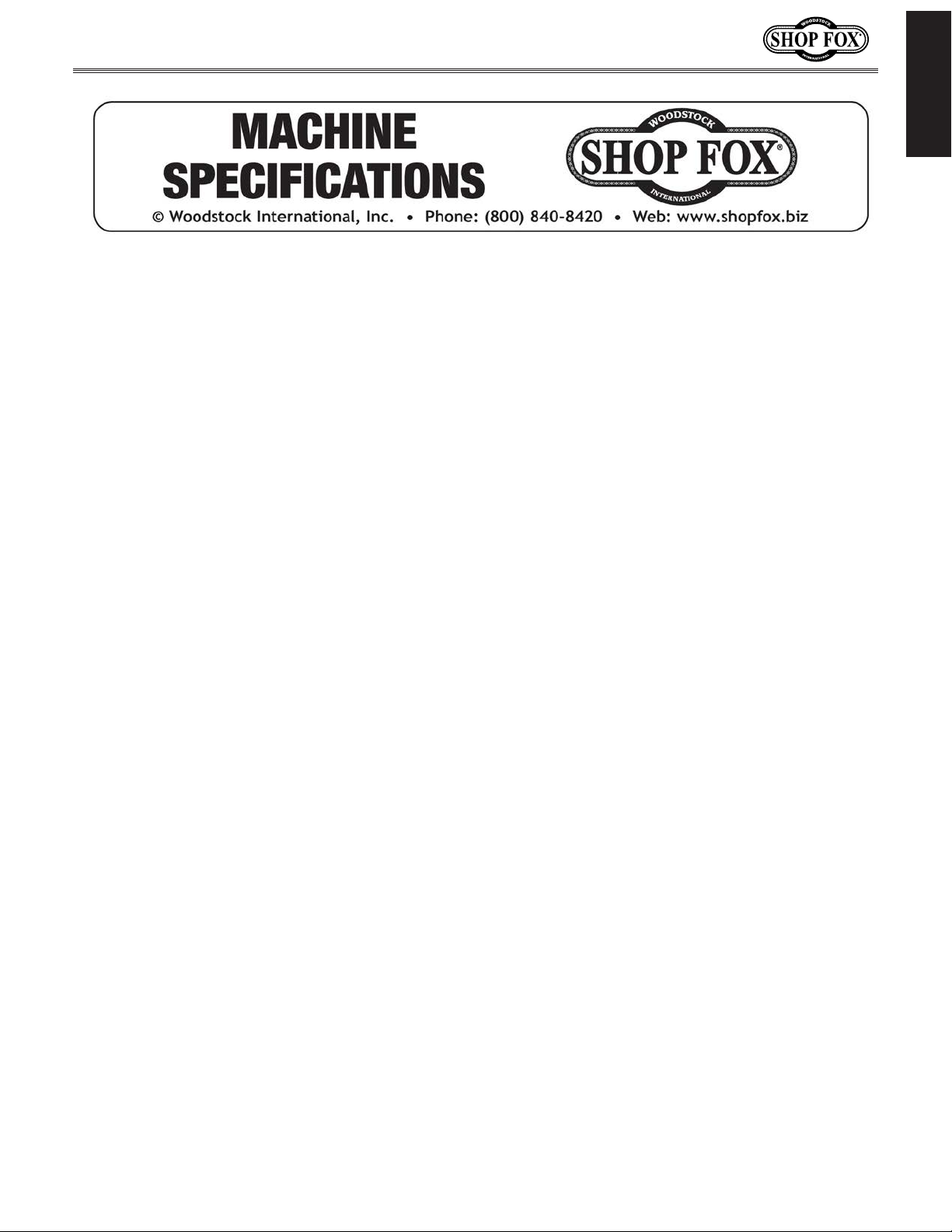

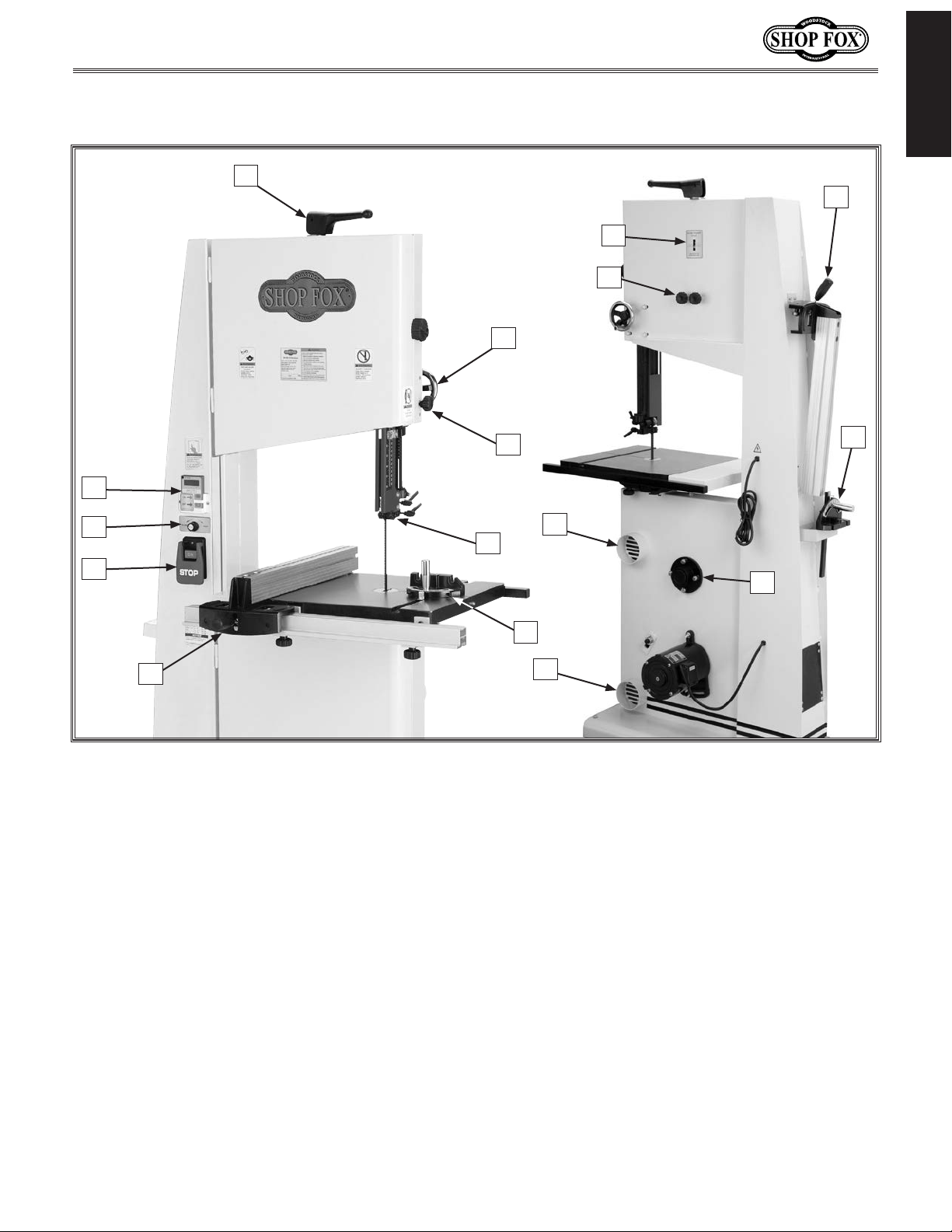

Controls and Features

A

INTRODUCTION

N

J

K

B

D

E

F

H

A. Blade Tension Lever

B. Blade Guide Elevation Handwheel

C. Blade Guide Elevation Lock Knob

D. Motor Switch

E. Speed Dial

F. Power Switch

G. Upper Blade Guide Assembly

H. Fence

C

L

G

I

M

I. Miter Gauge

J. Blade Tension Scale

K. Blade Tracking Knobs

L. Upper 4" Dust Port

M. Lower 4" Dust Port

N. Fence Holder

O. Miter Gauge Holder

P. Lower Wheel Adjustment Hub

O

P

-5-

Model M1113 (Mfg. Since 2/08)

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

SAFETY

NOTICE

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

1. READ THROUGH THE ENTIRE MANUAL BEFORE STARTING MACHINERY. Machinery presents serious

injury hazards to untrained users.

2. ALWAYS USE ANSI APPROVED SAFETY GLASSES WHEN OPERATING MACHINERY. Everyday eyeglasses only have impact resistant lenses—they are NOT safety glasses.

3. ALWAYS WEAR AN NIOSH APPROVED RESPIRATOR WHEN OPERATING MACHINERY THAT PRODUCES

DUST. Wood dust is a carcinogen and can cause cancer and severe respiratory illnesses.

4. ALWAYS USE HEARING PROTECTION WHEN OPERATING MACHINERY. Machinery noise can cause

permanent hearing damage.

5. WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, or jewelry which may

get caught in moving parts. Wear protective hair covering to contain long hair and wear non-slip

footwear.

6. NEVER OPERATE MACHINERY WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL.

Be mentally alert at all times when running machinery.

7. ONLY ALLOW TRAINED AND PROPERLY SUPERVISED PERSONNEL TO OPERATE MACHINERY. Make

sure operation instructions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS AWAY. Keep all children and visitors a safe distance from the work

area.

9. MAKE WORKSHOP CHILD PROOF. Use padlocks, master switches, and remove start switch keys.

-6-

Model M1113 (Mfg. Since 2/08)

10. NEVER LEAVE WHEN MACHINE IS RUNNING. Turn power off and allow all moving parts to come to

a complete stop before leaving machine unattended.

11. DO NOT USE IN DANGEROUS ENVIRONMENTS. DO NOT use machinery in damp, wet locations, or

where any flammable or noxious fumes may exist.

12. KEEP WORK AREA CLEAN AND WELL LIT. Clutter and dark shadows may cause accidents.

13. USE A GROUNDED EXTENSION CORD RATED FOR THE MACHINE AMPERAGE. Undersized cords over-

heat and lose power. Replace extension cords if they become damaged. DO NOT use extension cords

for 220V machinery.

14. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING MACHINERY. Make sure switch is

in OFF position before reconnecting.

15. MAINTAIN MACHINERY WITH CARE. Keep blades sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

16. MAKE SURE GUARDS ARE IN PLACE AND WORK CORRECTLY BEFORE USING MACHINERY.

SAFETY

17. REMOVE ADJUSTING KEYS AND WRENCHES. Make a habit of checking for keys and adjusting

wrenches before turning machinery ON.

18. CHECK FOR DAMAGED PARTS BEFORE USING MACHINERY. Check for binding and alignment of

parts, broken parts, part mounting, loose bolts, and any other conditions that may affect machine

operation. Repair or replace damaged parts.

19. USE RECOMMENDED ACCESSORIES. Refer to the instruction manual for recommended accessories.

The use of improper accessories may cause risk of injury.

20. DO NOT FORCE MACHINERY. Work at the speed for which the machine or accessory was designed.

21. SECURE WORKPIECE. Use clamps or a vise to hold the workpiece when practical. A secured

workpiece protects your hands and frees both hands to operate the machine.

22. DO NOT OVERREACH. Keep proper footing and balance at all times.

23. MANY MACHINES WILL EJECT THE WORKPIECE TOWARD THE OPERATOR. Know and avoid condi-

tions that cause the workpiece to "kickback."

24. ALWAYS LOCK MOBILE BASES (IF USED) BEFORE OPERATING MACHINERY.

25. BE AWARE THAT CERTAIN DUST MAY BE HAZARDOUS to the respiratory systems of people and

animals, especially fine dust. Make sure you know the hazards associated with the type of dust you

will be exposed to and always wear a respirator approved for that type of dust.

-7-

Model M1113 (Mfg. Since 2/08)

Additional Safety for Bandsaws

READ and understand this

entire instruction manual

before using this machine.

SAFETY

1. BLADE CONDITION. Do not operate with a dull, cracked, or badly worn blade. Dull blades require

more effort to use and are difficult to control. Inspect blades for cracks and missing teeth before

each use, and replace if necessary.

2. HAND PLACEMENT. Never position fingers or thumbs in line with the cut. Serious personal injury

could occur.

3. GUARDS. Do not operate this bandsaw without the blade guard in place.

4. BLADE REPLACEMENT. When replacing blades, make sure the teeth face down, toward the front

of the saw and the blade is properly tensioned before operating.

Serious personal injury

may occur if safety and

operational information is

not understood and followed. DO NOT risk your

safety by not reading!

USE this and other machinery with caution

and respect. Always consider safety first,

as it applies to your individual working

conditions. No list of safety guidelines can

be complete—every shop environment is

different. Failure to follow guidelines could

result in serious personal injury, damage

to equipment or poor work results.

5. WORKPIECE HANDLING. Never hold small workpieces with your fingers when cutting. Always sup-

port/feed the workpiece with a push stick, table support, vise, or some type of clamping fixture.

6. CUTTING TECHNIQUES. Plan your cuts carefully. DO NOT back the workpiece away from the blade

while the saw is running. If you need to back the work out, turn the bandsaw OFF and wait for

the blade to come to a complete stop. DO NOT twist or put excessive stress on the blade while

backing work away.

7. BLADE SPEED. Allow blade to reach full speed before cutting.

8. LEAVING WORK AREA. Never leave a machine running while unattended. Allow the bandsaw to

come to a complete stop before leaving unattended.

9. FEED RATE. Always feed stock evenly and smoothly. DO NOT force or twist blade while cutting,

especially when sawing tight curves.

10. MAINTENANCE/SERVICE. Do all inspections, adjustments, and maintenance with the machine

turned OFF and disconnected from the power source.

11. BLADE CONTROL. Do not attempt to stop or slow the blade with your hand or a workpiece. Allow

the blade to stop on its own.

12. EXPERIENCING DIFFICULTIES. If you experience difficulties performing the intended operation,

stop using the machine and contact our Technical Support Department at (570) 546-9663.

-8-

Model M1113 (Mfg. Since 2/08)

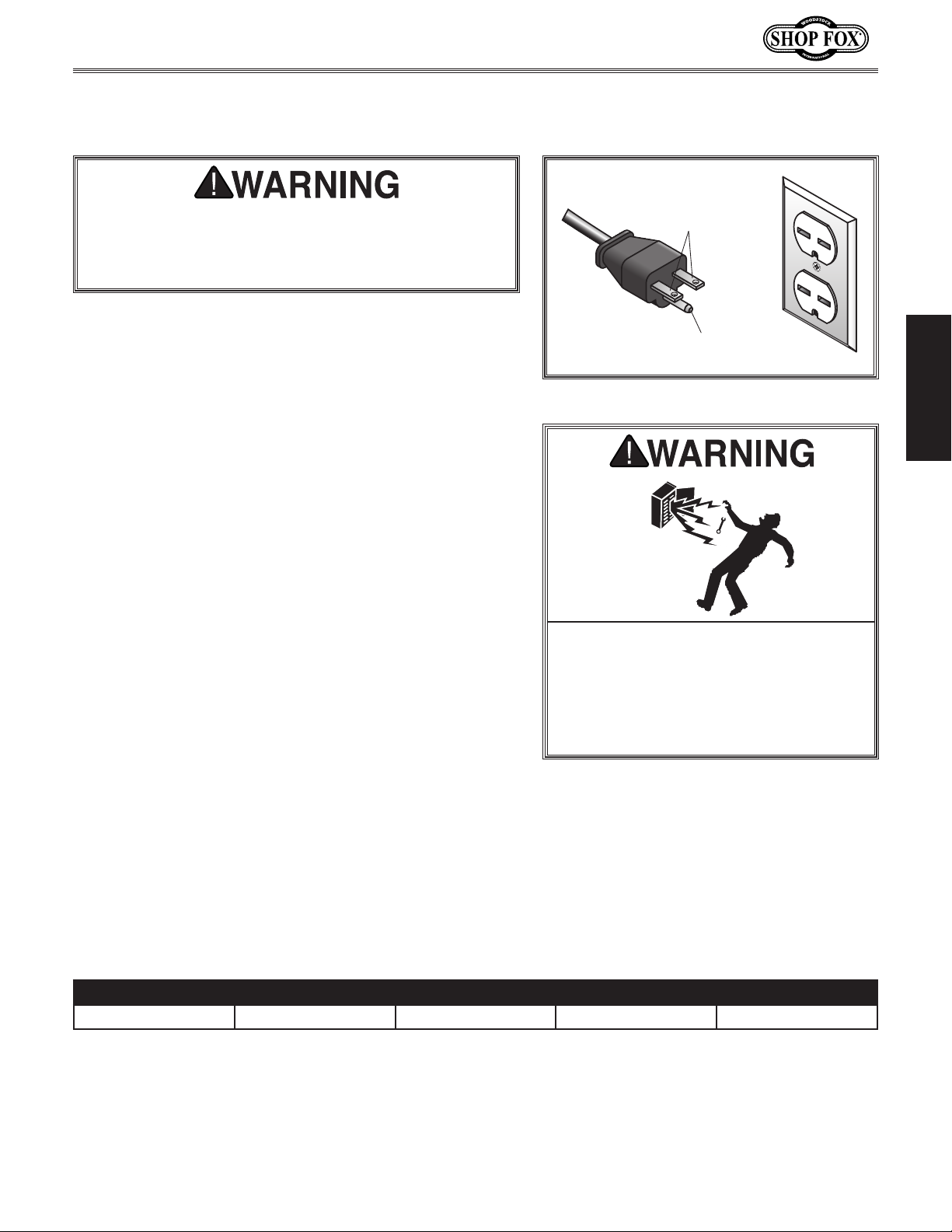

ELECTRICAL

The machine must be properly set up before it is

safe to operate. DO NOT connect this machine to the

power source until instructed to do so in the "Test

Run" portion of this manual.

220V Operation

The Model M1113 operates on 220V single-phase power.

We recommend connecting this machine to a dedicated

circuit with a verified ground, using the circuit size given

below. Never replace a circuit breaker with one of higher

amperage without consulting a qualified electrician to

ensure compliance with wiring codes. This machine must

be connected to a grounded circuit!

A plug is not supplied with this machine. See below for

the recommended plug type for this machine.

If you are unsure about the wiring codes in your area

or you plan to connect your machine to a shared circuit, you may create a fire or circuit overload hazard—

consult a qualified electrician to reduce this risk.

Extension Cords

We do not recommend using an extension cord; however,

if you have no alternative, use the following guidelines:

220V

Current Carrying Prongs

6-15 PLUG

Figure 1. 6-15 plug and receptacle.

DO NOT work on your electrical system

if you are unsure about electrical

codes and wiring! Seek assistance from

a qualified electrician. Ignoring this

warning can cause electrocution, fire,

or machine damage.

GROUNDED

6-15 RECEPTACLE

Grounding Prong

ELECTRICAL

• Use a cord rated for Standard Service (S).

• Do not use an extension cord longer than 50 feet.

• Ensure that the cord has a ground wire and pin.

• Use the gauge size listed below as a minimum.

Electrical Specifications

Operating Voltage Amp Draw Min. Circuit Size Recommended Plug Extension Cord

220V Single-Phase 5 Amps 15A NEMA 6-15 (not incl.) 14 Gauge

-9-

SETUP

Inventory

This machine has been carefully packaged for safe transportation. If you notice the machine has been damaged

during shipping, please contact your authorized Shop Fox

dealer immediately. The following is a description of the

main components shipped with the Model M1113.

Note: If you can't find an item on this list, check the

mounting location on the machine or examine the packaging materials carefully. Occasionally we pre-install certain components for safer shipping.

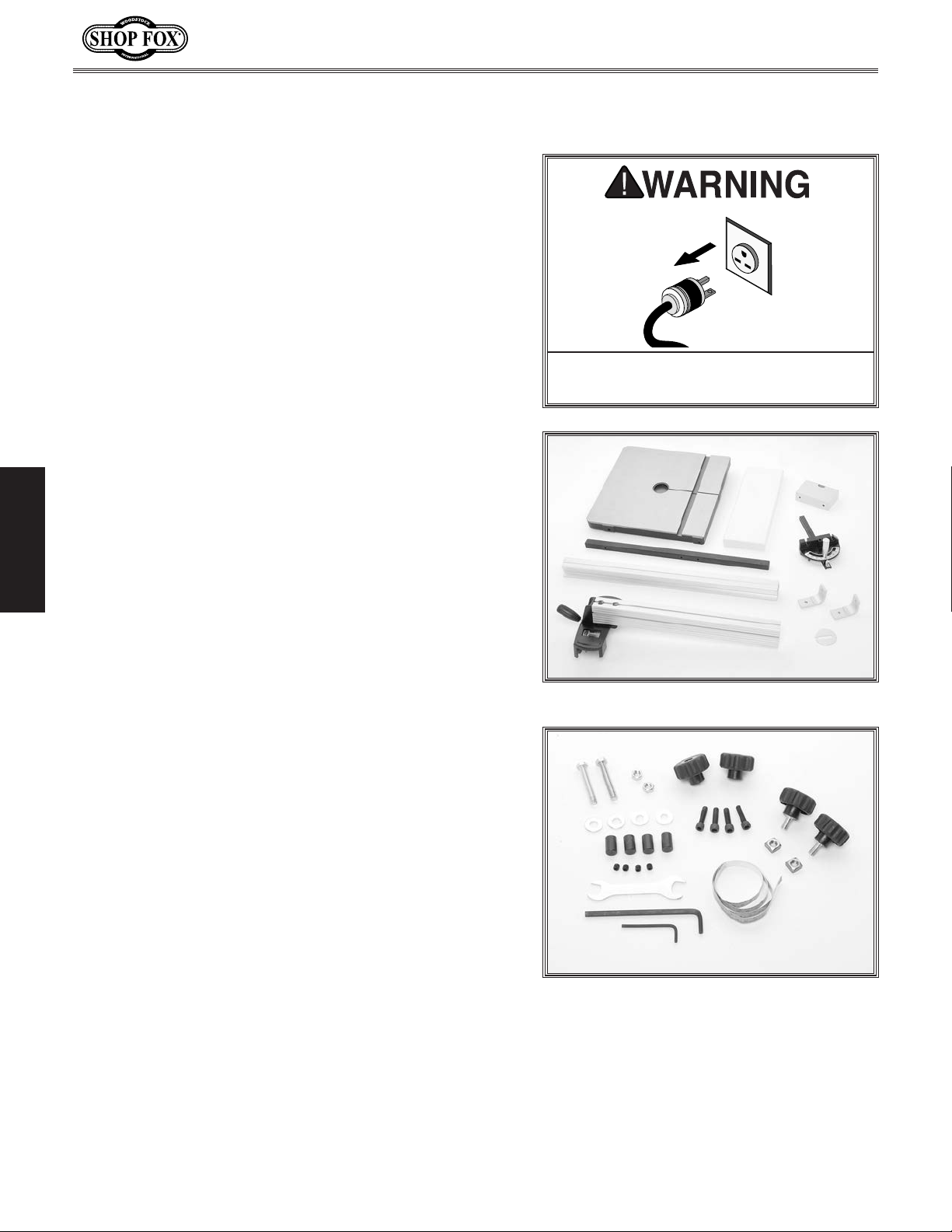

Main Components: (Figure 2) Qty

A. Table .........................................................1

B. Table Extension ............................................1

C. Table Insert .................................................1

D. Rear Rail ....................................................1

E. L-Brackets ..................................................2

F. Front Rail ...................................................1

SETUP

G. Fence Assembly ............................................1

H. Miter Gauge Holder .......................................1

I. Miter Gauge ................................................1

Model M1113 (Mfg. Since 2/08)

Keep machine disconnected from

power until instructed otherwise.

Fasteners, Tools, & Miscellaneous: (Figure 3) Qty

• Hex Bolts

• Hex Nuts

• Flat Washers

• Knobs

• Cap Screws M6-1 x 16 (Rear Rail to Table) ............2

• Cap Screws M6-1 x 16 (L-Brackets to Table) ..........2

• Knobs

• T-Slot Nuts

• Scale (Front Rail) ..........................................1

• Guide Blocks (Blade Guides) .............................6

• Thumb Screws

• Hex Wrenches 3 and 5mm ........................1 each

• Flat Wrench 12/14mm ....................................1

5

⁄16"-18 x 2" (Table Extension) ...............2

5

⁄16"-18 (Table Extension) .....................2

5

3

⁄8"-16 (Table Trunnion) ...........................2

5

⁄16"-18 x 5⁄8" (L-Bracket to Front Rail) ........2

⁄16" (Table Extension) ....................4

5

⁄16" (L-Bracket to Front Rail) .............2

1

⁄4"-20 x 1⁄2" (Blade Guides) ...........6

Figure 2. Main component inventory.

Figure 3. Fasteners, tools, &

miscellaneous item inventory.

-10-

Model M1113 (Mfg. Since 2/08)

30-3/4"

40"

Machine Placement

• Floor Load: This machine distributes a

heavy load in a small footprint. Some

residential floors may require additional

bracing to support both machine, operator,

and material to be processed.

• Working Clearances: Consider existing and

anticipated needs, size of material to be

processed through the machine, and space

for auxiliary stands, work tables or other

machinery when establishing a location for

your bandsaw. Refer to Figure 4.

• Lighting: Lighting should be bright enough

to eliminate shadow and prevent eye strain.

• Electrical: Place the machine near a

power source to avoid long runs of power

cords strung across your shop. Refer to the

Electrical section on Page 9 for information

on minimum circuit requirements.

Cleaning Machine

The table and other unpainted parts of your

machine type are coated with a waxy grease

that protects them from corrosion during shipment. Clean this grease off with a solvent cleaner or citrus-based degreaser. DO NOT use chlorine-based solvents such as brake parts cleaner

or acetone—if you happen to splash some onto a

painted surface, you will ruin the finish.

NEVER clean with gasoline

or other petroleumbased solvents. Most have

low flash points, which

make them extremely

flammable. A risk of

explosion and burning

exists if these products

are used. Serious personal

injury may occur if this

warning is ignored!

SETUP

Figure 4. Model M1113 working clearances.

-11-

Model M1113 (Mfg. Since 2/08)

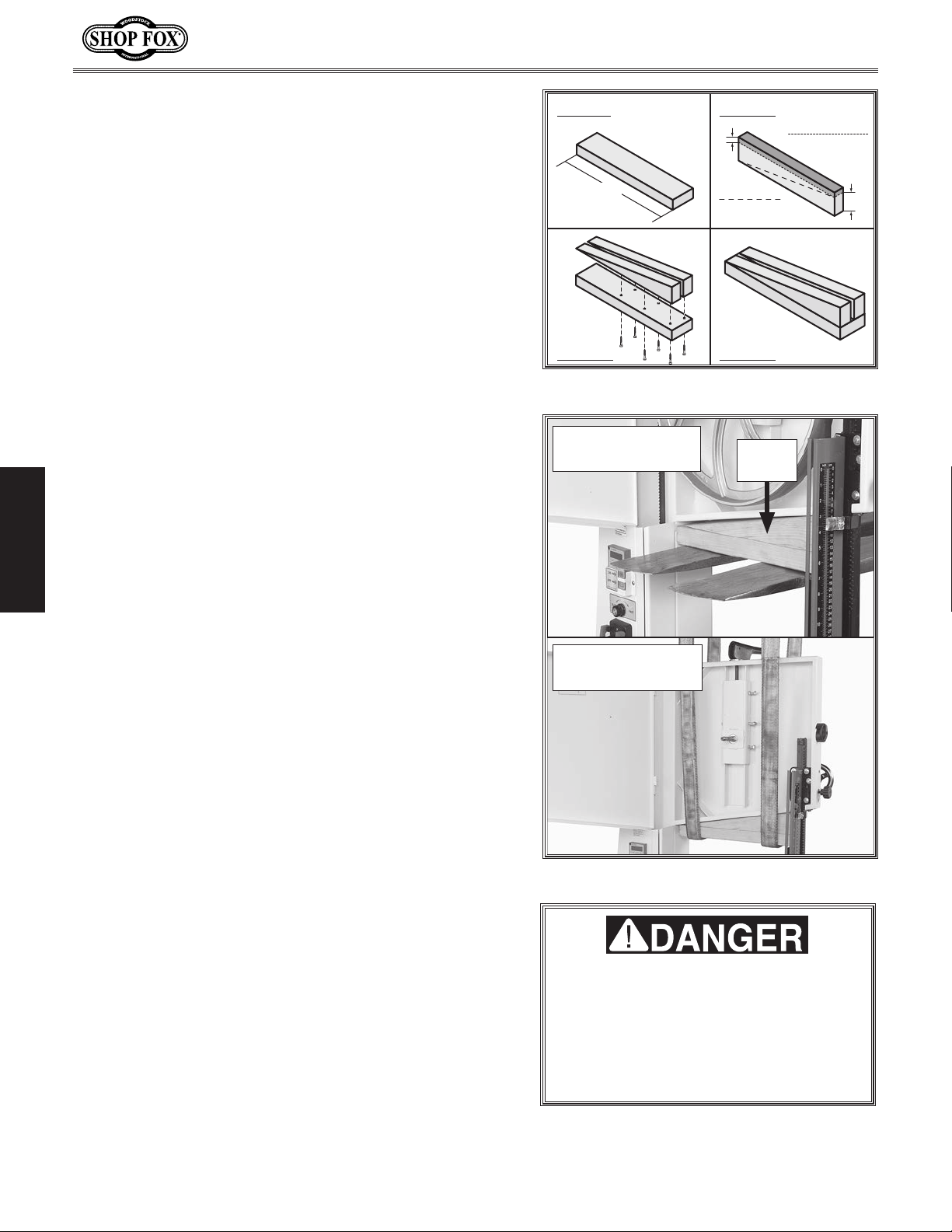

Lifting & Moving

Lifting and moving this bandsaw is most safely done using

a forklift. The upper frame is angled at the lifting area, so

we recommend making a lifting block, as shown in Figure

5, to balance the machine when lifting.

If using a forklift is not an option, then the machine can

be moved with a heavy-duty dolly and at least three

strong people. Heavy-duty dollies can be easily purchased

at your local hardware store or rented.

To lift and move the bandsaw with a forklift, do these

steps:

1. Make the lifting block shown in Figure xx to ensure

that the machine remains balanced when lifted and

does not swing.

2. Place the lifting block under the upper frame, as

shown in Figure 6.

3. Either place the forks directly against the lifting

SETUP

block, or place straps under the lifting block and

around the upper frame.

STEP 1 STEP 2

Qty = 2

2x4

161⁄2"

STEP 3 STEP 4

Figure 5. Making a lifting block.

Lifting with Forklift

Forks

1"

2nd Cut

Lifting

Block

SCRAP

1st Cut

21⁄2"

Note: If you are using lifting straps, you must

remove the blade and upper wheel to avoid damaging the machine. The upper wheel is easily removed

by removing the hex nut from the center and sliding

the wheel off.

To lift and move the bandsaw with three strong people

and a dolly, do these steps:

1. Carefully "walk" (pivot the bandsaw in alternating

steps) off of the shipping pallet and onto the shop

floor.

2. Place the dolly under the machine and move it into

place, having two extra people steady the machine

the entire time so that it does not tip over.

Lifting with Forklift

and Straps

Figure 6. Lifting machine with a forklift.

This is a heavy machine that cannot

be safely moved alone. Tipping this

machine onto yourself or another person will cause serious personal injury.

Use extreme caution when moving this

machine without a forklift and only

get help from strong, capable people.

-12-

Model M1113 (Mfg. Since 2/08)

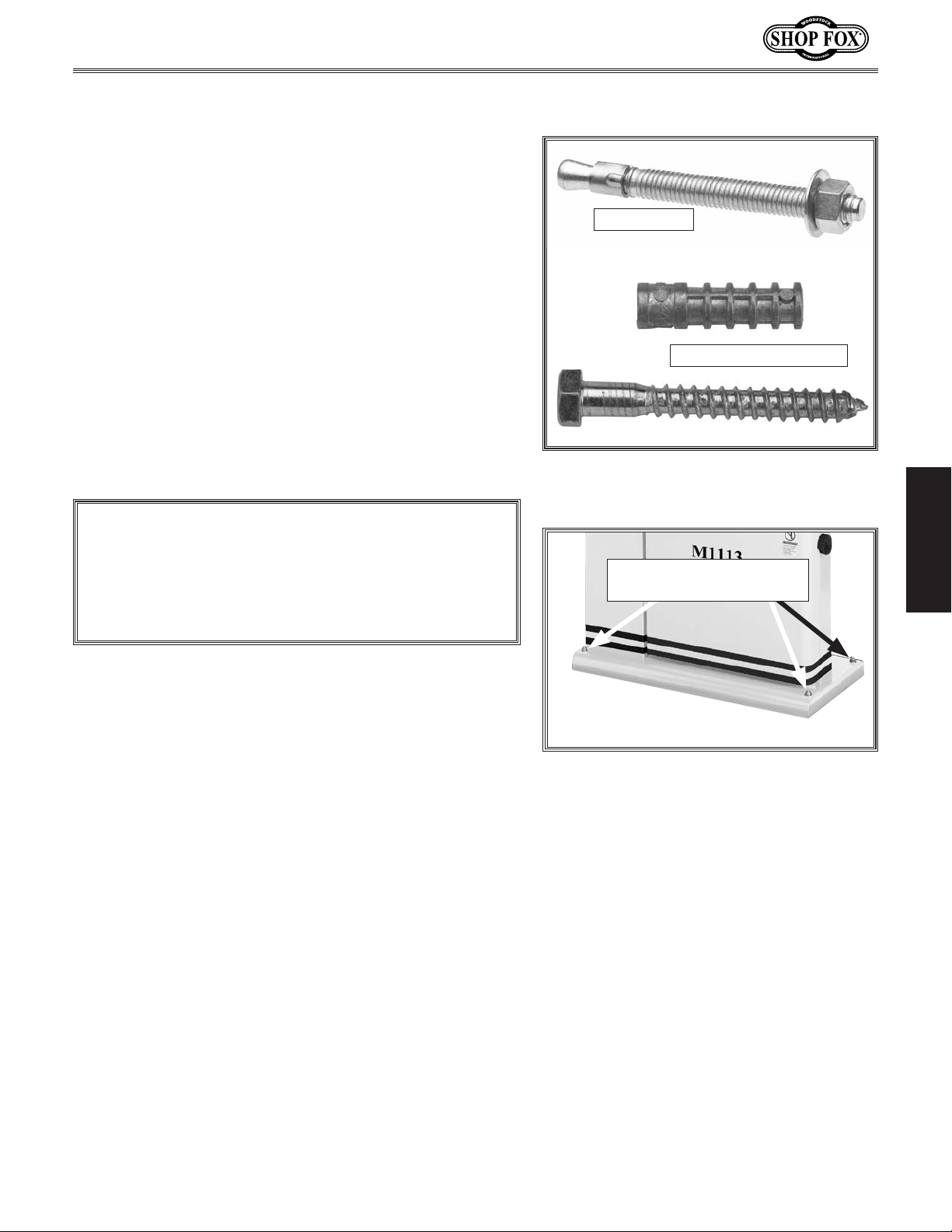

Mounting to Shop Floor

Although not required, we recommend that you mount

your new machine to the floor. Because this is an

optional step and floor materials may vary, floor mounting hardware is not included. Generally, you can either

bolt your machine to the floor or mount it on machine

mounts. Both options are described below. Whichever

option you choose, it will be necessary to use a precison

level to level your machine.

Bolting to Concrete Floors

Lag shield anchors with lag bolts and anchor studs

(Figure 7) are two popular methods for anchoring an

object to a concrete floor. We suggest you research the

many options and methods for mounting your machine

and choose the best that fits your specific application.

Figure 8 shows the mounting locations for this machine.

Anchor Stud

Lag Screw and Anchor

Figure 7. Typical fasteners for mounting

to concrete floors.

SETUP

NOTICE

Anchor studs are stronger and more permanent alternatives to lag shield anchors; however, they will stick

out of the floor, which may cause a tripping hazard if

you decide to move your machine at a later point.

Base Mounting Locations

(3 of 4 shown)

Figure 8. Location of machine base

mounting locations.

-13-

Model M1113 (Mfg. Since 2/08)

Assembly

To assemble the bandsaw, do these steps:

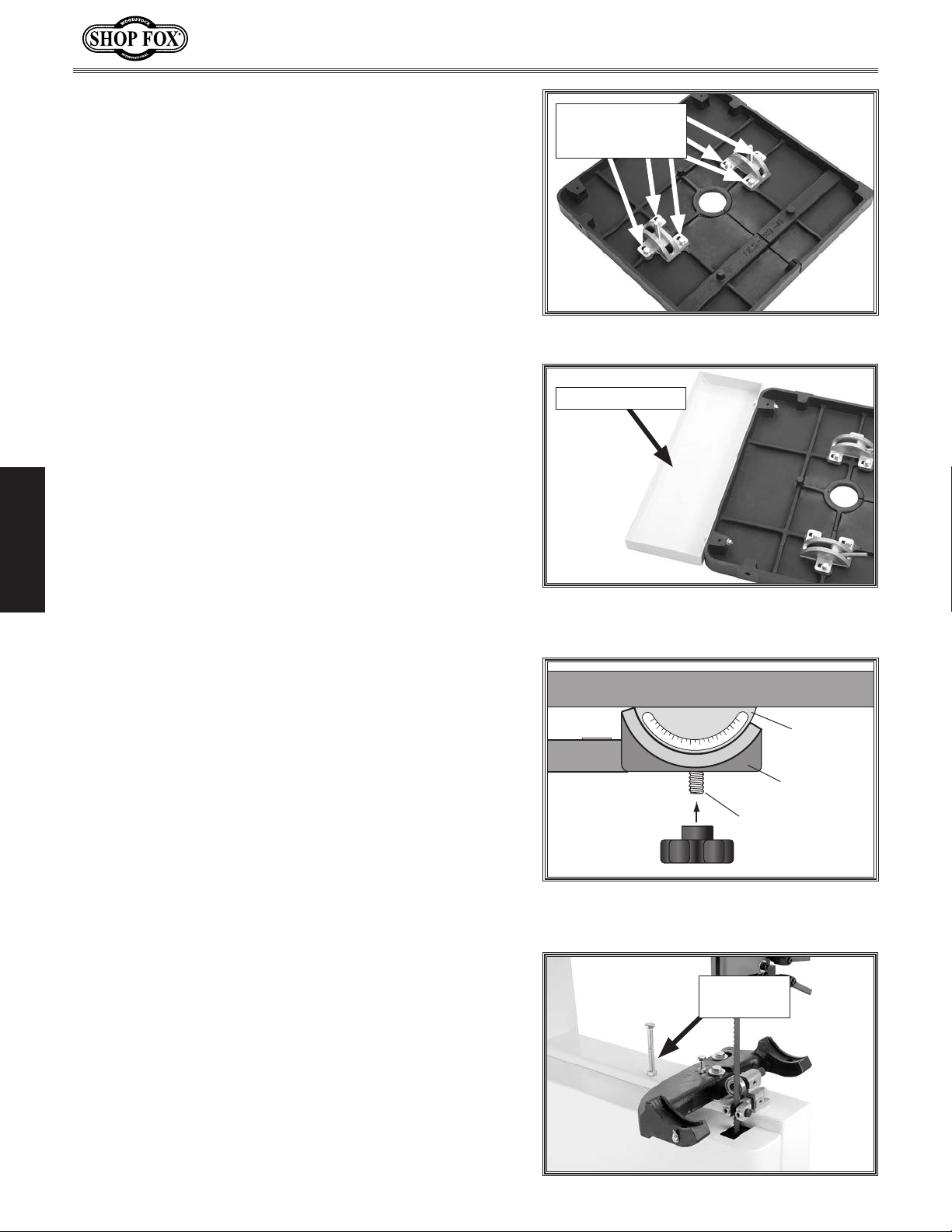

1. Place the bandsaw table upside down on a flat sur-

face (preferably a workbench) and make sure the

table trunnion mounting bolts (Figure 9) are tight.

2. Attach the table extension to the table with the two

5

⁄16-18 x 2" hex bolts, two 5⁄16-18 hex nuts, and four

5

⁄16" flat washers, as shown in Figure 10. Make sure

that the table and table extension are firmly pressed

against the flat surface and tighten the bolts/nuts.

3. Remove the table pin from the table slot, fit the

table around the blade, and rest the table trunnions

on the trunnion base, making sure the trunnion bolts

extend through the bottom of the trunnion base.

SETUP

Table Trunnion

Mounting Bolts

Figure 9. Table trunnion mounting bolts.

Table Extension

4. Thread the two table trunnion knobs onto the trunnion bolts, as illustrated in Figure 11.

5. Adjust the table stop bolt (Figure 12) so the table is

approximately perpendicular to the blade. (Precise

adjustment of the table stop bolt will be covered

later.)

Figure 10. Table extension attached to

table on flat surface.

Table

Table

Trunnion

Trunnion

Base

Trunnion Bolt

Trunnion Knob

Figure 11. Installing the table on trunnion

base.

Table Stop

Bolt

6. Place the table insert in the center of the table, so

it sits flush with the table top surface.

7. Insert the table pin into the end of the table slot.

-14-

Figure 12. Table stop bolt.

Model M1113 (Mfg. Since 2/08)

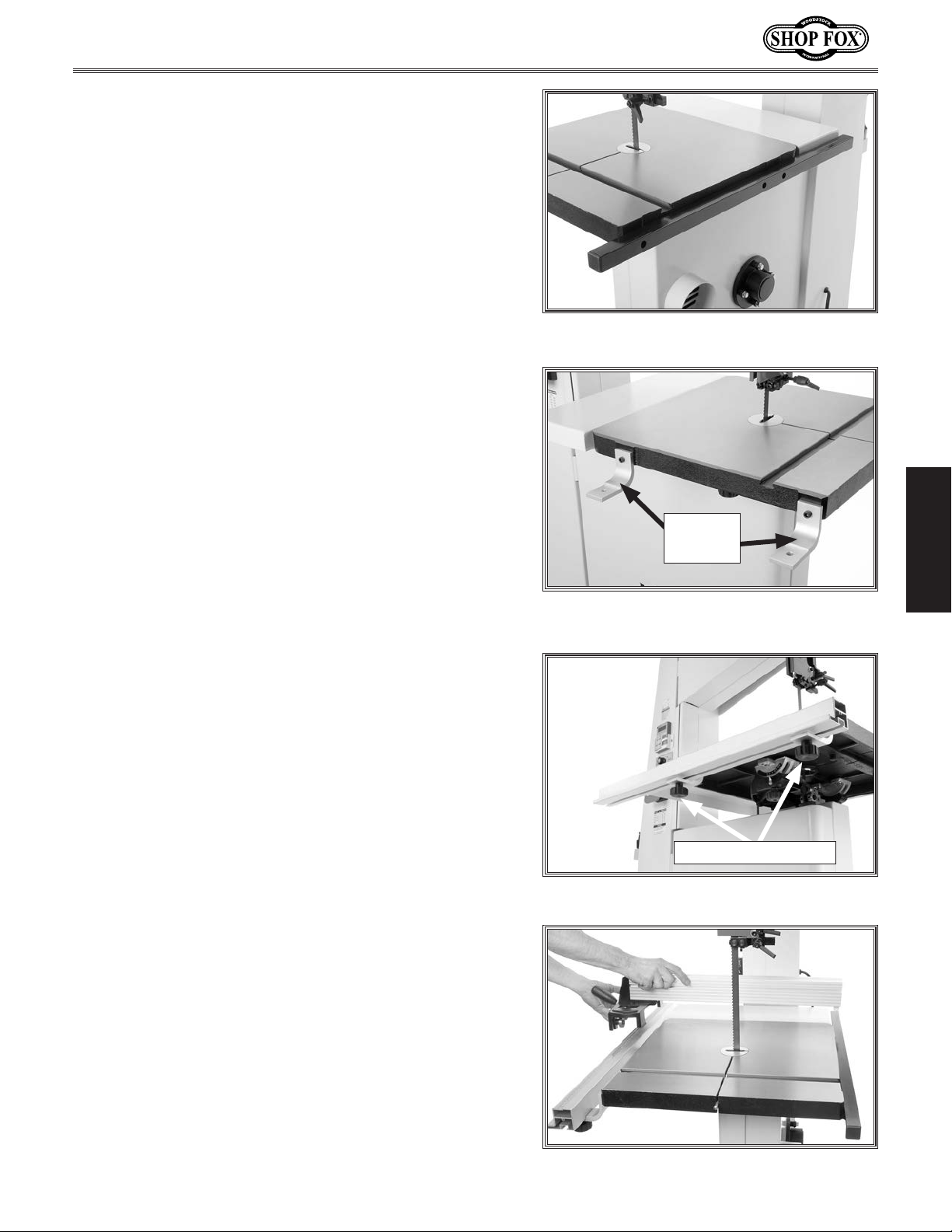

8. Attach the rear fence rail to the backside of the

bandsaw table with two M6-1 x 6 cap screws, as

shown in Figure 13.

9. Attach the rail brackets to the front of the table

with the two M6-1 x 16 cap screws, as shown in

Figure 14.

Figure 13. Rear fence rail attached to

table.

10. Insert the rail bracket knobs through the front fence

rail brackets, then thread the T-nuts onto the ends

of the knobs a couple of turns.

11. Slide the front fence rail T-slot over the T-nuts, as

shown in Figure 15, then position the front fence

rail brackets even with the rear fence rail, and

tighten the knobs.

12. Pull the fence handle up and place the fence on the

front fence rail, as shown in Figure 16.

SETUP

Rail

Brackets

Figure 14. Rail brackets attached to table.

Rail Bracket Knobs

Figure 15. Front fence rail attached.

13. Slide the fence against the blade.

Figure 16. Installing fence onto rails.

-15-

14. Use a sharp pencil to mark the fence rail where the

fence scale indicator on the right-hand side is pointing (there is a gap just behind the indicator plate

where you can mark the rail). This mark will indicate

where to align the 0" mark when you install the scale

in Step 16.

15. Remove the fence from the front rail.

16. Carefully install the adhesive-backed scale on the

front fence rail, as shown in Figure 17, so the 0"

mark on the scale lines up with the pencil mark

made in Step 14.

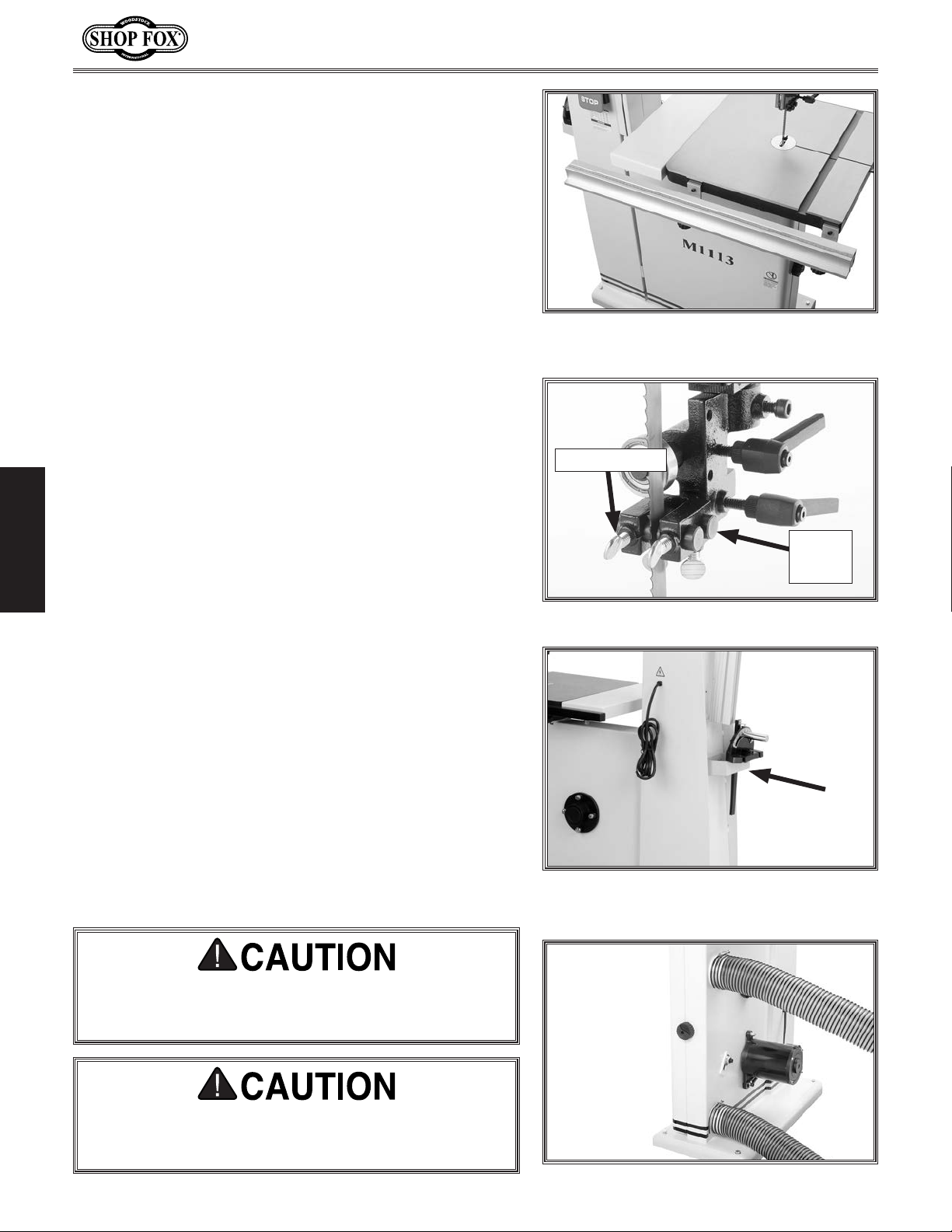

17. Insert the guide blocks into the upper and lower

blade guide assemblies, making sure they are at

least a

secure them with the six

as shown in Figure 18.

1

⁄8" away from the blade (for now), then

1

⁄4"-20 x 1⁄2" thumb screws,

Model M1113 (Mfg. Since 2/08)

Figure 17. Scale installed on front fence

rail.

Thumb Screw

18. Attach the miter gauge holder to the spine of the

SETUP

bandsaw, as shown in Figure 19, using the cap

screws already installed in the bandsaw spine.

19. Insert the miter gauge in the holder holder, as

shown in Figure 19.

Dust Collection

Recommended CFM at each Dust Port: ......... 400 CFM

Connect this machine to a shop vacuum rather than a

dust collector. Most dust collectors are not designed to

capture metal shavings and doing so may lead to a fire.

If you are in doubt about the capabilities of your shop

vacuum or dust collector, refer the owner's manual before

connecting it to this machine.

This saw creates substantial amounts of fine dust

while operating. Failure to use a vacuum system can

result in respiratory illness.

Guide

Block

Figure 18. Blade guide installation.

Figure 19. Miter gauge holder attached

with miter gauge inserted.

ONLY connect this machine to a shop vacuum. A

wood dust collector is not designed for metal chips,

which may spark and cause a fire.

-16-

Figure 20. Dust port connected to dust

collection system.

Loading...

Loading...