Woodstock d4327, d4328 User Manual

Model D4327/D4328

Quick Release Wood Vise

Instruction Sheet

Phone #: (360) 734-3482 • Online Tech Support: tech-support@shopfox.biz • Web: www.shopfox.biz

Introduction

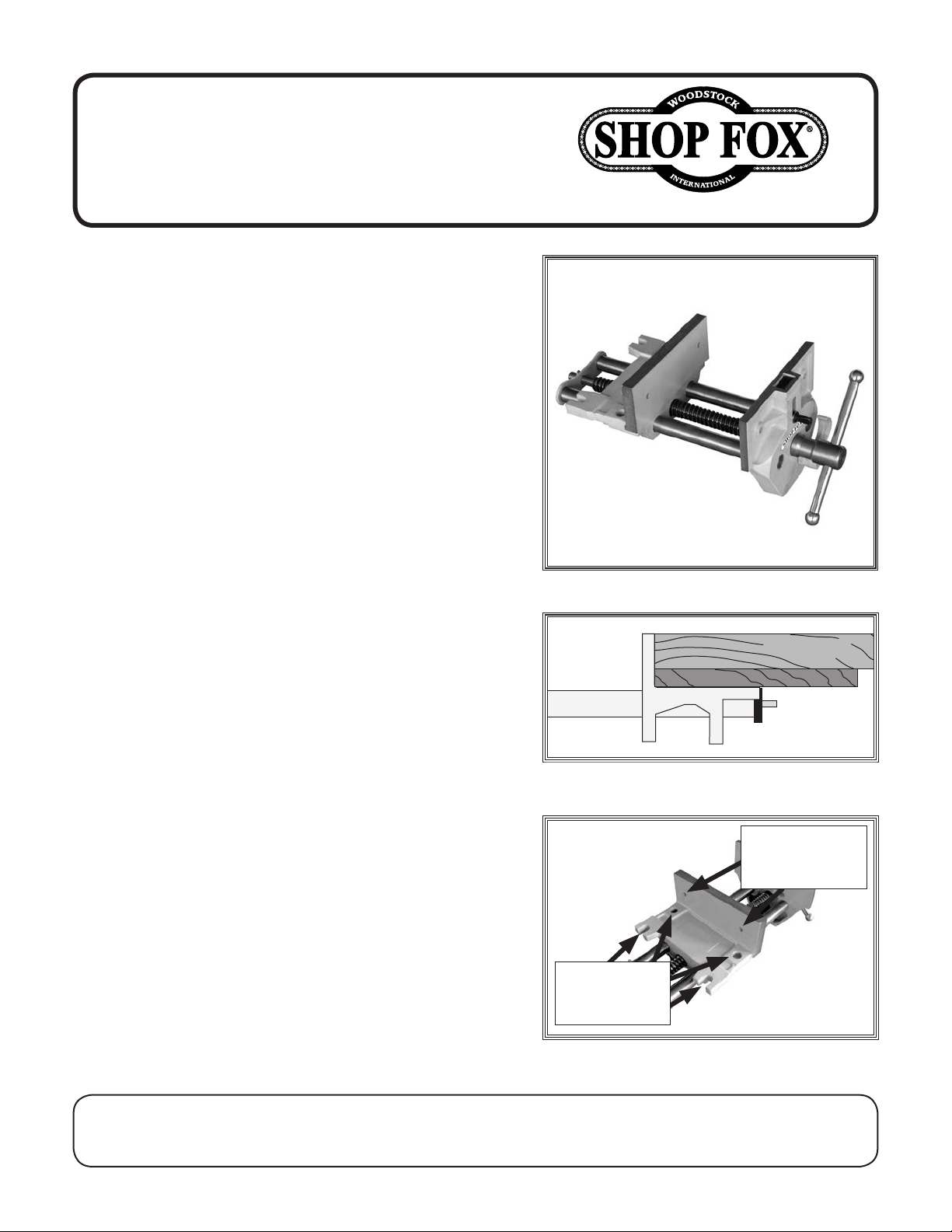

Your new Model D4327/D4328 Quick Release Wood Vise

(Figure 1) is designed to fit on workbenches 2

thicker, but can be adapted to workbenches down to 1

thick by using a shim. Holes are pre-drilled in the jaw

faces to attach aftermarket or shop-built wood clamping

vise jaw pads.

D4327 Specifications

• Jaw Width .................................................7"

• Mounting Height (Workbench Thickness) ..........2

• Maximum Jaw Opening ..................................8"

• Weight ................................................21 lbs.

1

⁄4" and

1

⁄2"

1

⁄4"

D4328 Specifications

• Jaw Width .................................................9"

• Mounting Height (Workbench Thickness) ..........2

• Maximum Jaw Opening ................................ 10"

• Weight ................................................25 lbs.

1

⁄4"

Installation

1. Have another person hold the vise up against the

workbench in the desired mounting location. If the

workbench has holes for bench dogs, make sure the

bench dog on the vise is aligned with those holes.

1

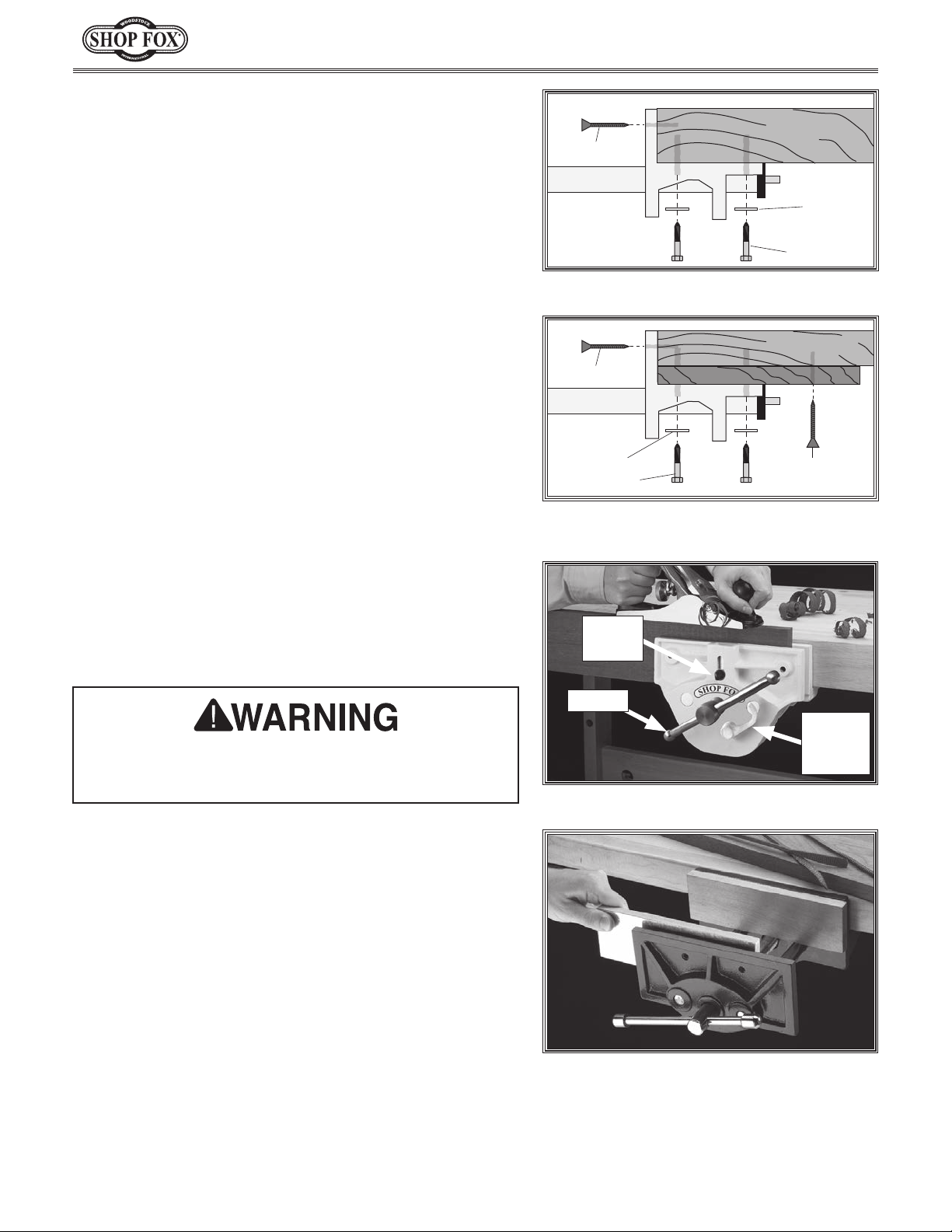

Note: If the workbench is less than 2

piece of scrap wood (Figure 2) between the vise and

workbench as a shim. Cut the shim to the necessary

thickness so the vise does not protrude above the

workbench after mounting.

2. Pencil mark the workbench through the mounting

holes to establish locations to drill pilot holes.

1

3. Use a

1

⁄8" drill bit to drill pilot holes approximately

1

⁄2" deep in the face of the workbench, where the

wood screws will be used (see Figure 3).

⁄4" thick, use a

Figure 1. Quick release wood vise.

Workbench

Shim

Vise

Figure 2. Shim placed between workbench

1

and vise for workbenches under 2

⁄4".

Mounting Holes

for Wood

Screws

Mounting

Holes for Lag

Screws

Figure 3. Mounting hole locations.

COPYRIGHT © MARCH, 2012 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China#14922ST

D4327/D4328 - For Models Manufactured Since 3/12

4. Use a 1⁄4" drill bit to drill pilot holes approximately

1" deep in the underside of the workbench, where

the lag screws will be used.

Workbench

Wood Screw

5. Attach the vise to the workbench with two #10 x 2"

wood screws through the face of the vise jaw, as

shown in Figure 4.

6. Secure the vise to the underside of the workbench

with four

ers as shown in Figure 4.

Note: If you're using a shim, make sure the lag

screws pass completely through the shim and secure

at least halfway into the workbench thickness, as

shown in Figure 5.

5

⁄16" x 13⁄4" lag screws and 5⁄16" flat wash-

Operation

Rotating the handle (Figure 6) clockwise moves the slid-

ing jaw toward the fixed jaw; rotating handle counterclockwise moves the sliding jaw away from the fixed jaw.

Moving the quick release lever (Figure 6) towards the vise

handle disengages the leadscrew so the sliding jaw can be

freely moved by pushing or pulling it.

Tightening/loosening the finger bolt (Figure 6) allows for

adjustment the height of the bench dog.

Vise

Flat

Washer

Lag Screw

Figure 4. Attaching vise to workbench.

Workbench

Wood Screw

Vise

Flat

Washer

Lag Screw

Figure 5. Attaching vise to workbench

with shim between vise and workbench.

Finger

Bolt

Shim

Wood

Screw

This vise is not a toy. DO NOT use as a crushing tool.

Never clamp containers with compressed or explosive

contents. Using incorrectly may cause serious injury.

Accessories

Ask your Shop Fox dealer for the wood-faced magnetic

jaw pads shown in Figure 7.

Maintenance

The painted parts of the vise can be cleaned with a damp

rag. If wood pitch has built up on the components, clean

this with a pitch dissolver or blade and bit cleaner.

Lubricate the leadscrew with dry lubrication, such as silicone or graphite, that will not cause sawdust to stick to

the threads.

If material becomes built up on the threads, clean thoroughly with a pitch dissolver.

Handle

Quick

Release

Lever

Figure 6. Operation controls of vise.

Figure 7. Shop Fox wood-faced magnetic

jaw pads (Models D3127-D3133).

-2-

Loading...

Loading...