Woodstock D4041 User Manual

Model D4041

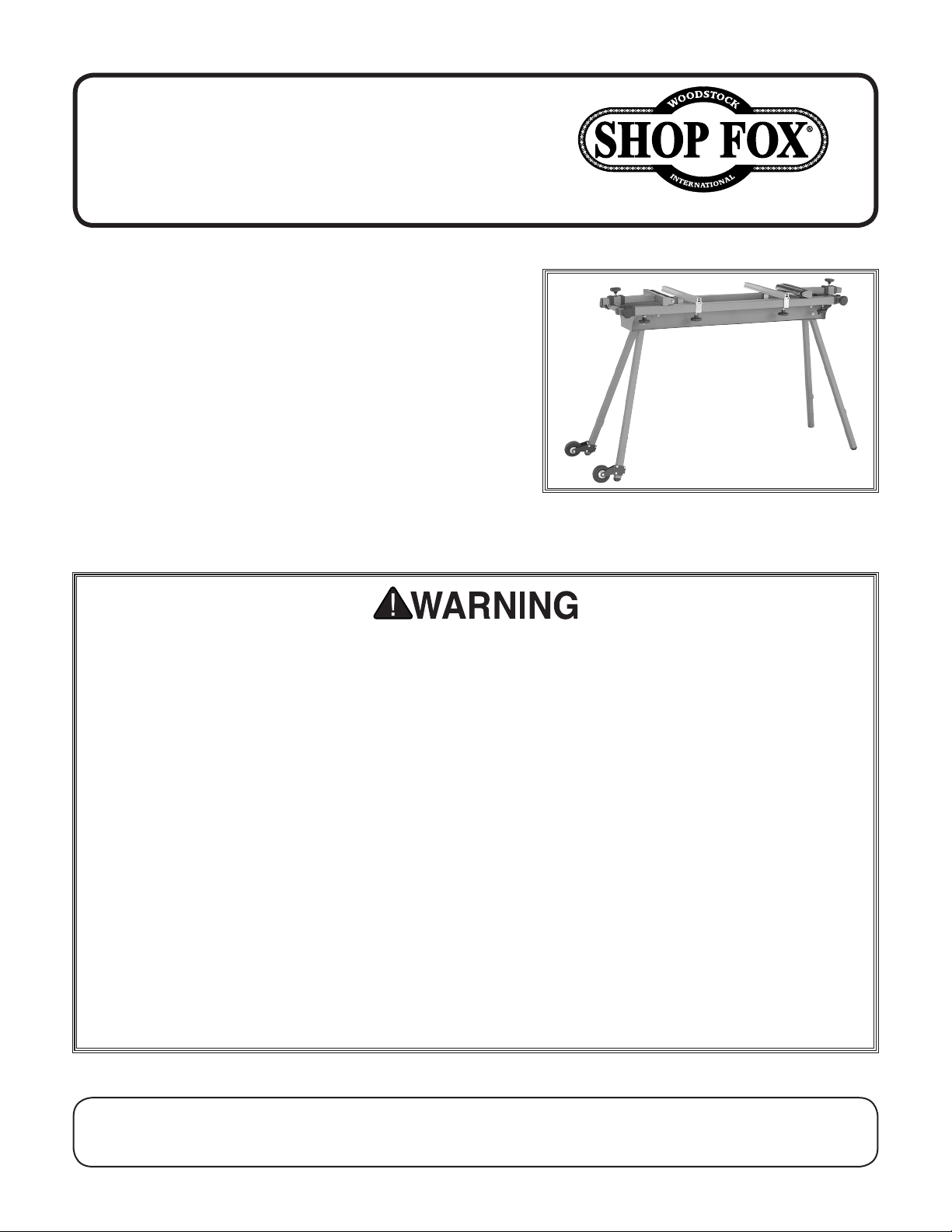

Miter Saw Stand

Instruction Sheet

Phone #: (360) 734-3482 • Online Tech Support: tech-support@shopfox.biz • Web: www.shopfox.biz

Introduction

The Model D4041 Miter Saw Work Stand (Figure 1)

features a universal, adjustable T-track mounting system

for securing miter saws without modification. Laterally

and vertically adjustable ball bearing rollers on each

end of the stand support long workpieces. Roller mounts

rotate incrementally for fine height adjustment. Folding

legs and rubber wheels make this work stand portable.

Unpacking

This item was carefully packaged for safe transportation.

If you notice that it was damaged during shipping, please

contact your Shop Fox dealer immediately.

Figure 1. Model D4041.

TO REDUCE THE RISK OF SERIOUS PERSONAL INJURY WHEN USING THIS ITEM:

1. MITER SAW SAFETY. Follow all safety instructions in the miter saw manual.

2. MITER SAW WORK STAND SET UP. Make sure

the leg locking pins are fully snapped into

place before mounting the miter saw.

3. MITER SAW WORK STAND PLACEMENT. Only

operate the miter saw work stand on a hard,

flat, and level surface. DO NOT set up the

miter saw work stand on a soft surface, such

as sand or mud.

4. MITER SAW WORK STAND USAGE. Only use

the miter saw work stand to support a miter

saw. This stand is NOT intended for use as a

ladder or scaffolding.

5. WORKPIECE BALANCE. Use extra support

tables, or get assistance, when working with

large workpieces to prevent the stand from

tipping over.

6. ATTACH MITER SAW SECURELY. DO NOT

operate the miter saw unless it is securely

attached to the miter saw work stand.

7. LOCK WORK SUPPORTS. Tighten lock knobs

to secure the work supports before using the

miter saw work stand.

8. EXPERIENCING DIFFICULTIES. If at any time

you are experiencing difficulties performing

the intended operation, stop using this stand!

Contact Tech Support at (360) 734-3482 for

help.

COPYRIGHT © JULY, 2010 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China#13127TR

Inventory

In the event that any nonproprietary parts are missing

(e.g. a nut or a washer), we would be glad to replace

them, or for the sake of expediency, replacements can be

obtained at your local hardware store.

Box Contents: (Figure 2) Qty

A. Stand (not shown) .........................................1

B. Roller Assembly ............................................2

C. Roller Crossbar .............................................2

D. Wheel Brackets ............................................4

E. Wheels ......................................................2

Hardware: Qty

—Support Braces ...........................................2

—Hex Bolts M8-1.25 x 45 .................................2

—Hex Bolts M6-1 x 45 ................................... 12

—Flat Washers 6mm ..................................... 12

—Hex Nuts M6-1 .......................................... 12

—Lock Nuts M8-1.25 .......................................2

—Knobs M8-1.25 x 50 ......................................4

—Knobs M8-1.25 x 20 ......................................2

—Hex Bolts M8-1.25 x 50 .................................4

—Hex Nuts M8-1.25 ........................................8

—Flat Washers 8mm .......................................6

D4041 Miter Saw Stand Instructions

B

D E

Figure 2. Model D4041 inventory.

C

Assembly

1. Lay the work stand upside down and unfold the top

set of legs (inset in Figure 3). Make sure the locking

pins snap into place.

2. Place a wheel bracket on both sides of the wheel

and thread (1) M8-1.25 x 45 hex bolt through the

assembly (see Figure 3), then secure it with (1)

8mm flat washer and (1) M8-1.25 lock nut.

3. Place each wheel bracket assembly over the stand

leg, thread (4) M6-1 x 45 hex bolts through each

wheel bracket (see Figure 3), and secure them with

flat washers and hex nuts.

4. Unfold the remaining legs; install the support braces

between the legs with the remaining M6-1 x 45 hex

bolts, flat washers, and hex nuts.

5. Place the work stand upright, move the bottom of

the wheels approximately an

tighten the hex nuts.

1

⁄8" above the floor and

Figure 3. Wheel assembly.

Roller

Crossbar

M8-1.25 x 50 Knob

6. Place the roller crossbar between the extension arms

and secure them with the M8-1.25 x 50 knobs, as

shown in Figure 4.

-2-

Roller

M8-1.25 x 20 Knob

Figure 4. Support roller assembly.

Assembly

Loading...

Loading...