Woodstock D3978 User Manual

ACCU-SHARP® GRINDING JIG

To reduce the risk of serious injury when using

this grinding jig, take the following precautions:

1. GRINDER OWNER'S MANUAL. Read

and understand the owner's manual for your

grinder and always follow all of the safety

precautions and instructions for your grinder.

2. EYE/FACE PROTECTION. Always wear

safety glasses or a face shield to protect yourself from flying material.

3. HAND PLACEMENT. Always keep your

hands and fingers away from the spinning

grinding wheel, and protect yourself from the

sharp edges of the tool.

4. SECURE CLAMPING. Make sure the tool is

securely clamped in the jig and that the table is

firmly locked in the proper position.

Introduction

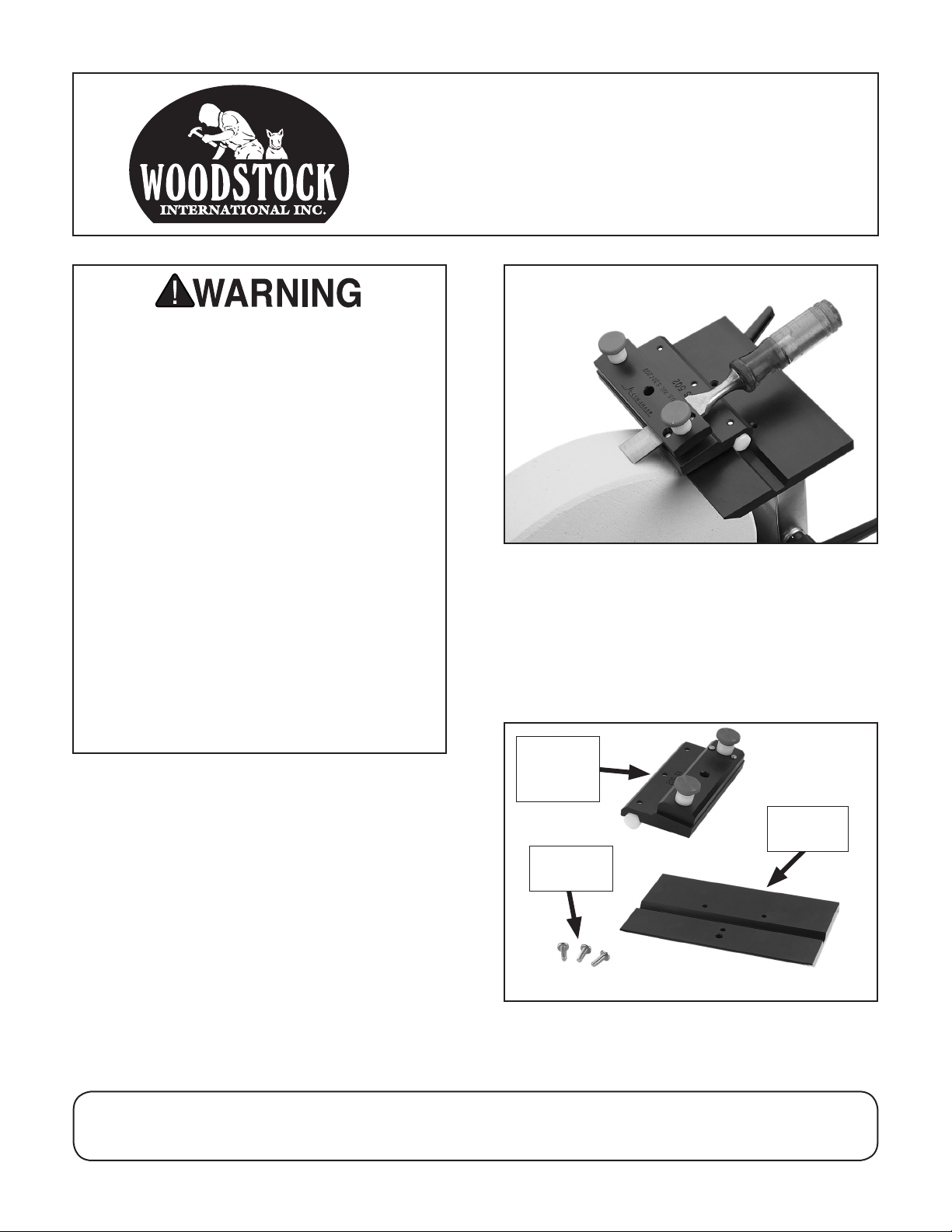

The Model D3978 Accu-Sharp® Grinding Jig works

with the tool rest table of your grinder to properly position chisels and plane irons up to 2

in Figure 1. The tool clamping jig uses a special

plastic rod and pads to slide the tool from side-to-side

across the auxiliary table and the grinding wheel.

3

⁄4" wide, as shown

MODEL D3978

INSTRUCTIONS

Figure 1. Using the Accu-Sharp Jig to grind the bevel

of a flat chisel.

Inventory

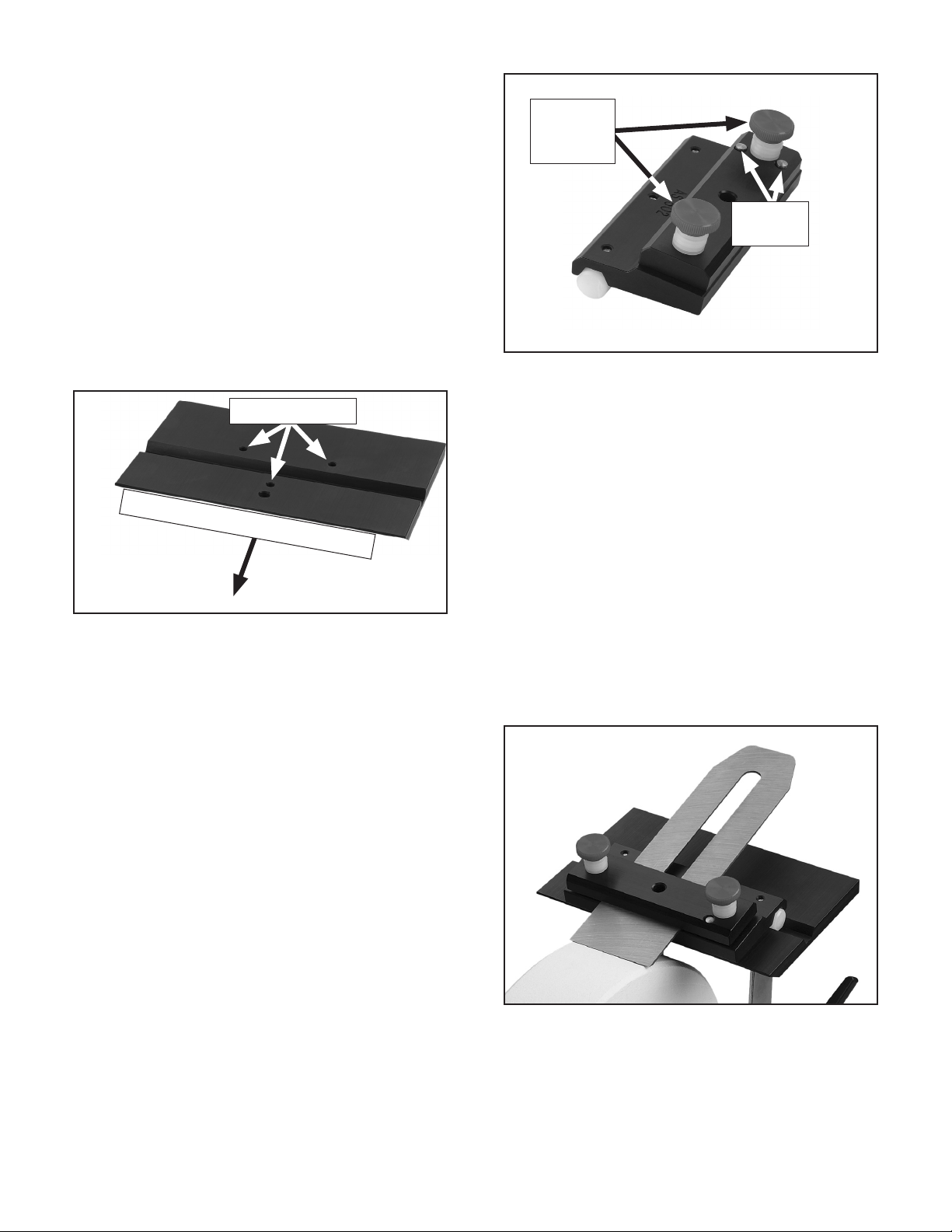

After removing the contents of the shipping package,

lay them out and refer to Figure 2 to inventory the

components.

Tool

Clamping

Jig

Auxiliary

Table

Mounting

Screws

If you need help with your new grinding jig, call

Woodstock Tech Support at: (360) 734-3482.

COPYRIGHT © NOVEMBER, 2008 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Figure 2. Model D3978 inventory.

Printed in China#11386TS

Installing Auxiliary Table

1. DISCONNECT GRINDER FROM POWER!

2. Remove the tool rest table from your grinder.

3. Center the jig auxiliary table over the grinder

table, then use a scratch awl through the three

mounting holes of the auxiliary table to mark the

grinder table (see Figure 3).

Note: Make sure that you position the tables so

that when the jig is mounted on the grinder, the

auxiliary table edge shown in Figure 3 is facing

the grinding wheel.

Clamping

Screws &

Washers

90° Stop

Pins

Figure 4. Clamping screws, washers, and stop pins.

Mounting Holes

Auxilary Table Edge Faces Grinder

Figure 3. The mounting holes of the jig auxiliary

table.

4. Use a center punch to indent these marks on the

grinder table, then drill

7

⁄32" holes completely

through the table.

5. Insert the three included mounting screws from

underneath the grinder table, then loosely thread

them into the auxiliary table.

6. Square the auxiliary table with the grinding wheel

surface, then fully tighten the mounting screws.

The plastic washers of the clamping screws can be

arranged to accommodate various tool thicknesses

and to provide good thread bearing for the screws.

However, be sure the bottom of the screws do not

1

protrude beyond the bottom of the jig more than

⁄8" to

avoid scratching the auxiliary table.

1

If your tool width is 1

⁄8" or less, remove the right-hand

clamping screw and washers and thread it into the

middle hole to provide secure clamping.

Place the tool and jig on the auxiliary table, align

and lock the table in place, then slide the tool across

the rotating grinding wheel with light pressure (see

Figure 5).

Operation

Loosen the clamping screws shown in Figure 4, slide

the tool under the top bar and align its left side up

against the 90° stop pins to make it square with the

grinding wheel, then re-tighten the screws.

Figure 5. Plane iron clamped in the jig.

Loading...

Loading...