Mobile Base Models

D2057A, D2058A, D2260A

Instruction Sheet

Phone #: (360) 734-3482 • Online Tech Support: tech-support@shopfox.biz • Web: www.shopfox.biz

Introduction

Your new Mobile Base is designed to give you a stable

and mobile platform upon which to mount machinery and

equipment. Be sure to select the model that matches

your machine specifications.

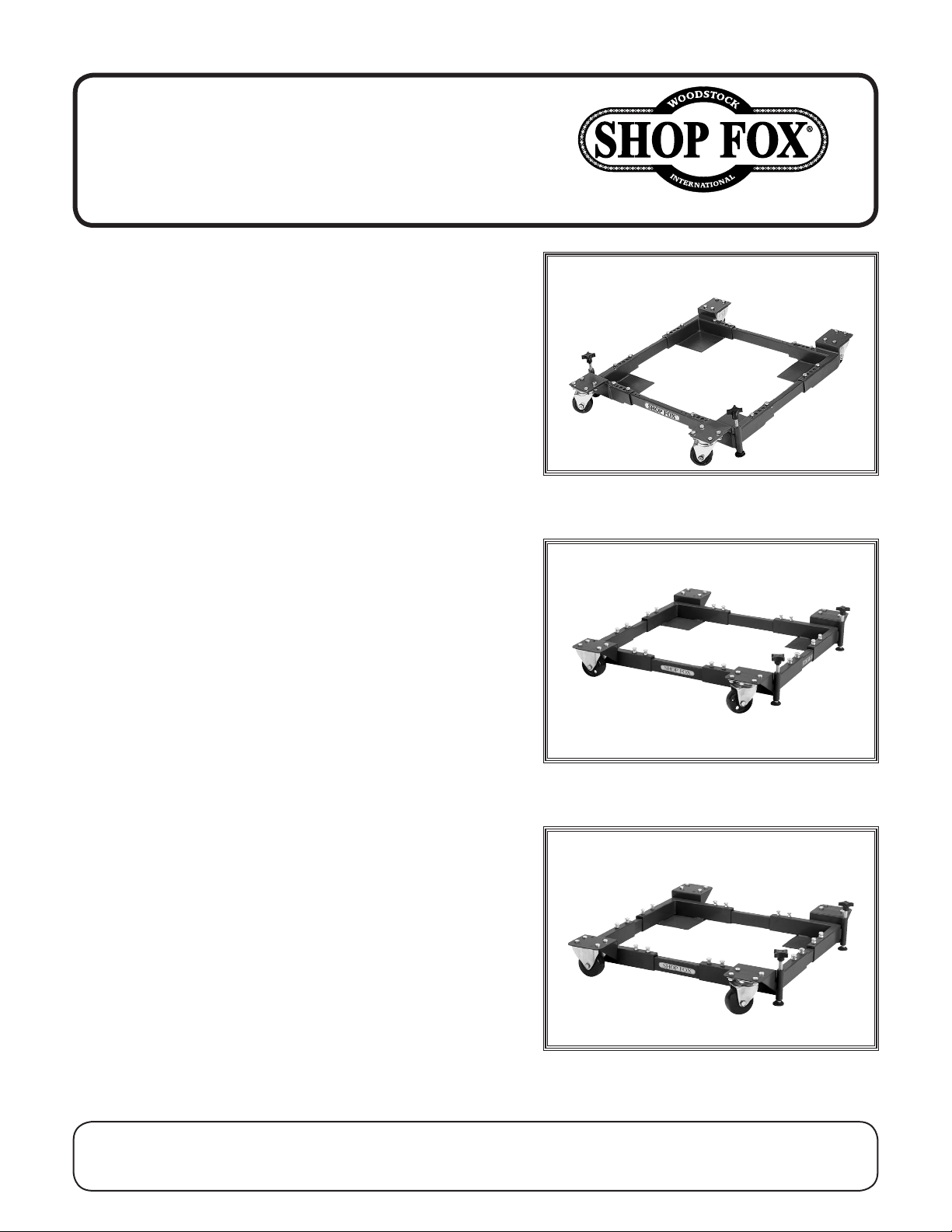

D2057A Specifications (see Figure 1)

• Minimum Inside Dimensions .................... 20" x 20"

• Maximum Inside Dimensions ............. 29

• Maximum Weight Capacity ....................... 700 lbs

D2058A Specifications (see Figure 2)

• Minimum Inside Dimensions .............. 18

• Maximum Inside Dimensions ............. 28

• Maximum Weight Capacity ...................... 1300 lbs

1

⁄2" x 291⁄2"

1

⁄2" x 241⁄2"

1

⁄2" x 331⁄2"

Figure 1. Model D2057A.

D2260A Specifications (see Figure 3)

• Minimum Inside Dimensions .............. 10

• Maximum Inside Dimensions ............. 21

• Maximum Weight Capacity ....................... 600 lbs

COPYRIGHT © JUNE, 2009 BY WOODSTOCK INTERNATIONAL, INC. REVISED JUNE, 2013 (DM)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

1

⁄2" x 141⁄2"

1

⁄2" x 171⁄2"

Figure 2. Model D2058A.

Figure 3. Model D2260A.

Printed in China#11846BL

D2057A, D2058A, D2260A Mobile Base Instructions

Available Accessories

Base modification accessories are available for machines

with an extension table or machine bases larger than the

maximum inside dimensions of Model D2058A.

D2259A—Mobile Base Extension Kit

Model D2259A (see Figure 4) is designed to install onto

the Model D2260A or D2057A mobile base to provide a

stable support platform for a machine and an extension

table unit.

Specifications

1

• Minimum Extension Length ........................ 28

• Maximum Extension Length ........................ 45

• Maximum Leg Span ..................................... 32"

D2246A—36" Extension Bar Kit

The 36" extension bars replace the longer or shorter

length rails on the Model D2058A Super Heavy-Duty Mobile

Base. The extension bars are suitable for heavy and long

machines such as jointers, bandsaws, wide belt and drum

sanders, lathes (see Figure 5), or heavy workbenches.

⁄2"

3

⁄4"

Figure 4. Mobile base extension support

platform assembled.

Specifications

• Minimum Inside Dimensions .................... 18" x 34"

• Maximum Inside Dimensions ................... 28" x 44"

• Maximum Weight Capacity ...................... 1200 lbs

Figure 5. D2246A extension bar kit in use

with Model D2058A mobile base.

-2-

D2057A, D2058A, D2260A Mobile Base Instructions

Tools Needed for Assembly

Tape Measure ....................................................1

Wrenches or Sockets 13mm ...................................2

Light Machine Oil (Optional) ...................... As Needed

Crowbar (Optional) .............................................1

Rubber Mallet (Optional) ......................................1

6" 2x4's (Optional) ..............................................2

6" 2x6 (Optional) ................................................1

12" 4x4 (Optional) ..............................................1

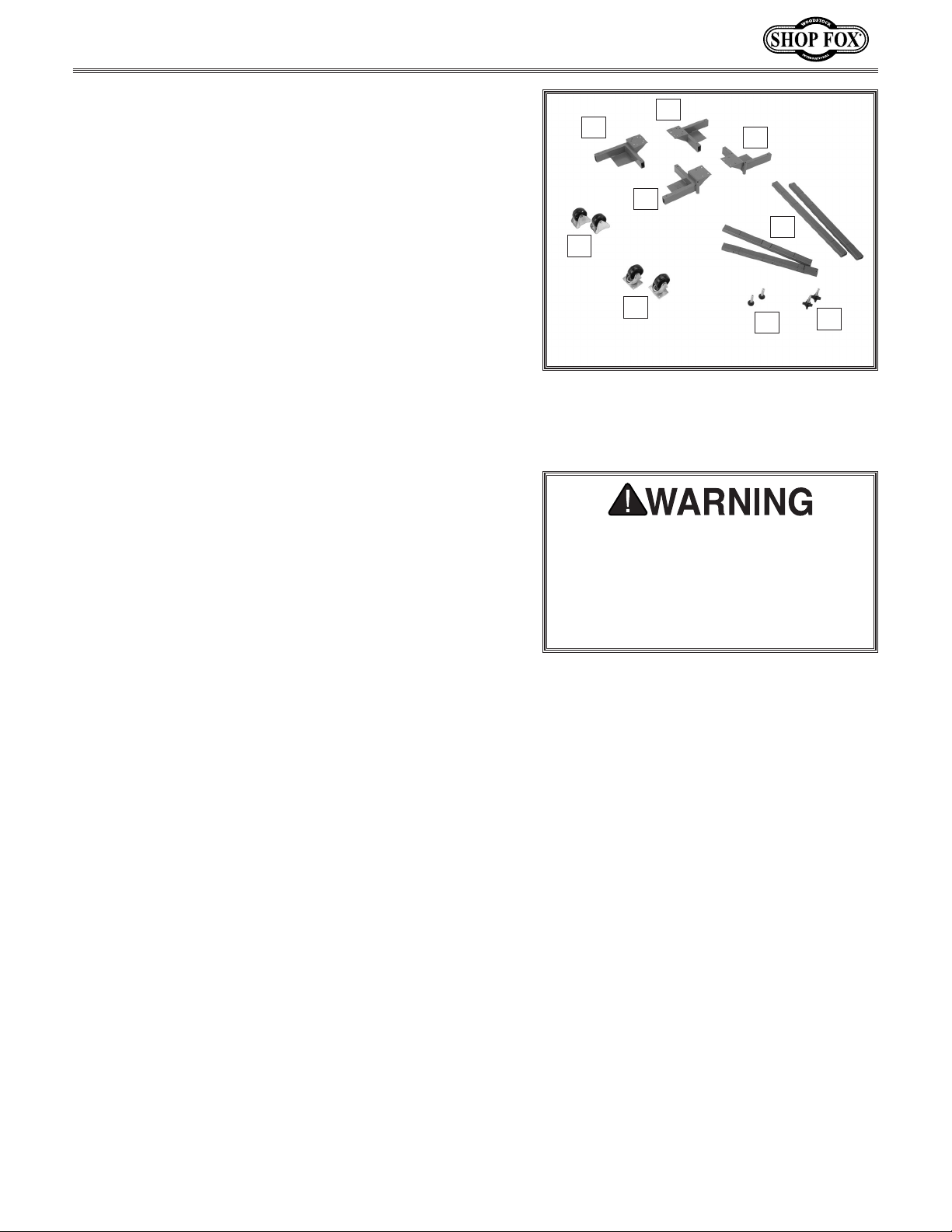

Inventory (see Figure 6) Qty

A. Swivel Casters ..............................................2

B. Fixed Casters ...............................................2

C. Left Corner Bracket .......................................1

D. Right Corner Bracket ......................................1

E. Right Corner Bracket w/Foot Post ......................1

F. Left Corner Bracket w/Foot Post .......................1

G. Side Rails ...................................................4

H. Knobs M12-1.75 ............................................2

I. Feet ..........................................................2

J. Hardware Bag (not shown)

—Hex Bolts M8-1.25 x 16 (Casters) ................... 16

—Hex Bolts M8-1.25 x 25 (Brackets) .................. 16

— Lock Nuts M8-1.25 (Brackets) ....................... 16

— Lock Washers 8mm (Casters) ........................ 16

— Flat Washers 8mm (Casters) ......................... 16

— Hex Nuts M8-1.25 (Casters) .......................... 16

D

C

F

B

A

Figure 6. Inventory.

Do not use the mobile base until

you have read and understood this

instruction sheet and completed the

entire assembly procedure. Serious

personal injury may occur if you ignore

this warning.

E

G

I

H

-3-

D2057A, D2058A, D2260A Mobile Base Instructions

Preparation for Assembly

There is more than one way to assemble the mobile

base. Each method has advantages and disadvantages,

depending on the size and weight of the machine that

you plan to put on the mobile base. The purpose of this

section is to help you decide which method will work best

for your situation.

If the machine can be lifted, the easiest method is to

assemble the mobile base according to the dimensions of

your machine, and then lift and place the machine on the

corner bracket pads of the mobile base (see Page 5).

If the machine is top heavy or has a narrow base (such as

a drill press), there is an increased risk when moving it

around on a mobile base. To reduce the risk, a mounting

base plate should be used between the mobile base and

machine (see Page 12).

If the machine is too heavy to lift into position on the

mobile base, then the base can be built around the

machine. For instructions on how to build the base around

the machine, refer to Page 8.

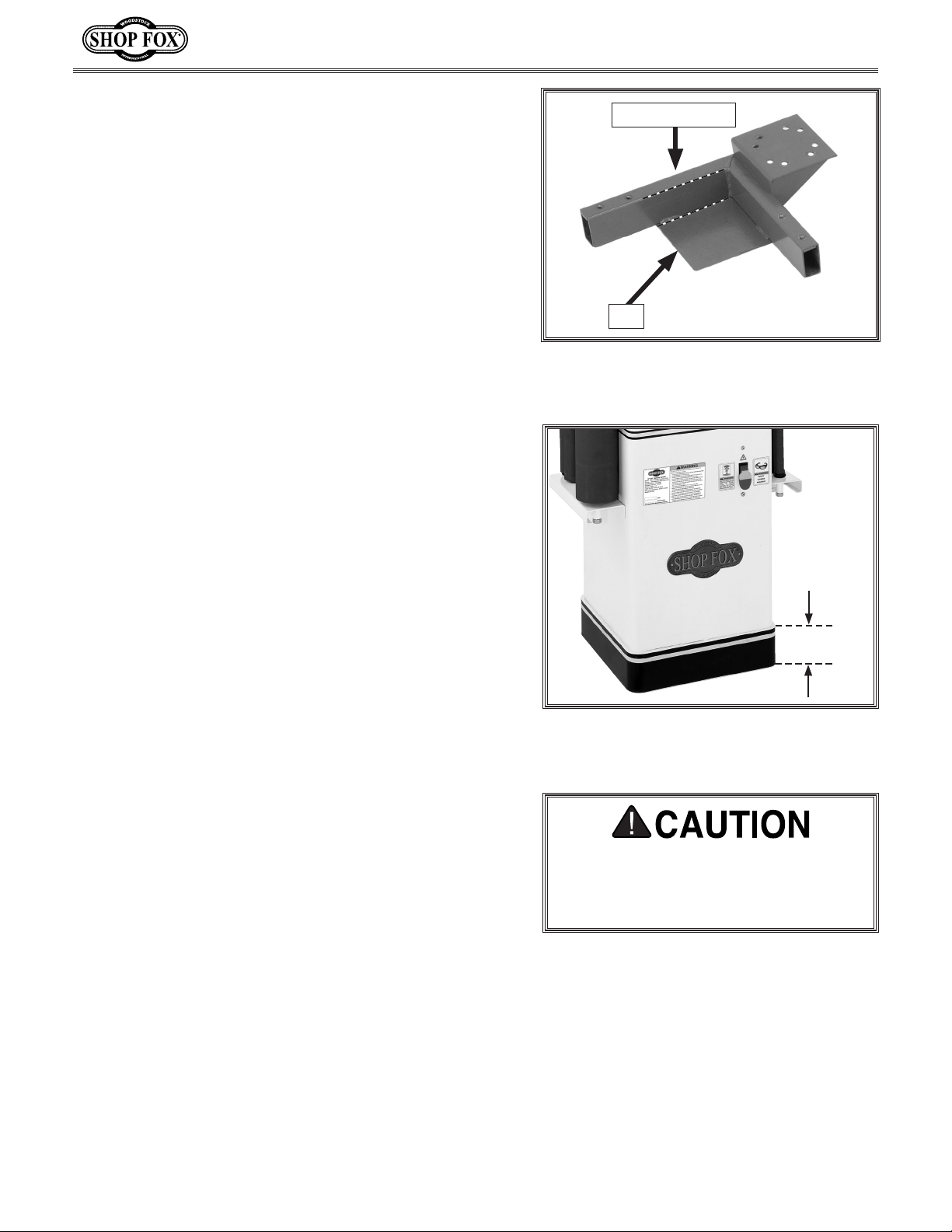

Corner Bracket

Pad

Figure 7. One of four corner bracket pads

machine will sit on.

Note: Anything extending or opening outward within a 3"

high band (see Figure 8) around the base of the machine

may interfere with the installation of the machine on the

base, so be sure to account for that prior to assembly.

3"

Figure 8. Example of 3" high band on

machine base.

Lift heavy machinery carefully and with

the proper equipment. Get assistance

if needed to reduce the risk of lifting

injuries.

-4-

D2057A, D2058A, D2260A Mobile Base Instructions

Assembling Base & Mounting Machine

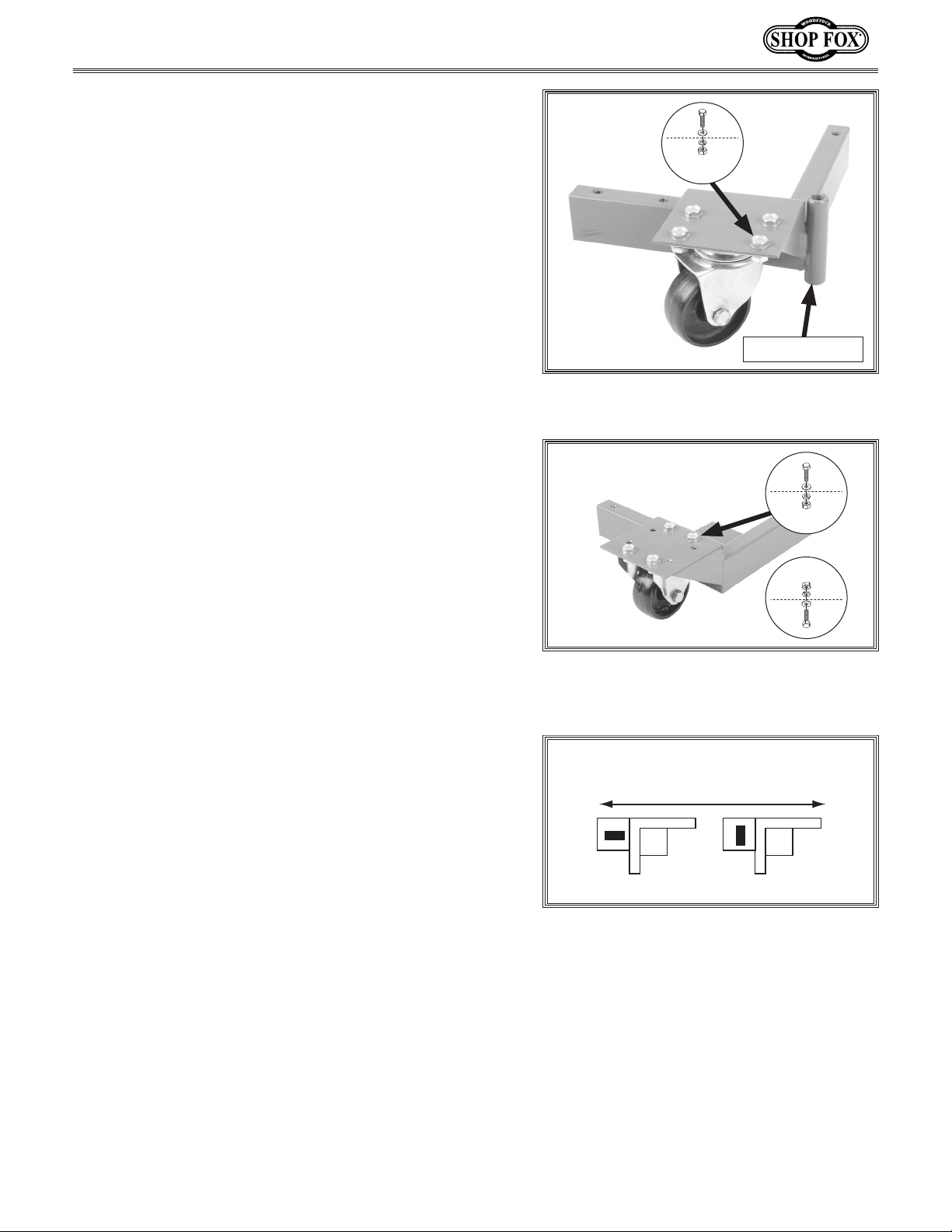

1. Mount the two swivel casters to the corner brackets

with threaded posts (see Figure 9), using (4)

M8-1.25 x 16 hex bolts, 8mm flat washers, 8mm lock

washers, and M8-1.25 hex nuts on each.

2. Mount the two fixed casters to the remaining

brackets (see Figure 10), using (4) M8-1.25 x 16

hex bolts, 8mm flat washers, 8mm lock washers and

M8-1.25 hex nuts on each.

x 4

Threaded Post

Figure 9. Swivel caster mounted to corner

bracket with threaded post.

x 4

Or

x 4

3. Orient the fixed casters so they point in the same

direction that your machine will typically be moved

(see Figure 11). Mounting the fixed casters in the

wrong direction will make it difficult to move your

mobile base.

Figure 10. Fixed caster mounted to corner

bracket.

(TOP VIEW OF CASTER)

Typical Direction of Movement

CORRECT INCORRECT

Figure 11. Mounting casters based upon

typical direction of movement.

-5-

Loading...

Loading...