Page 1

59757 Sub-Frame Mounting Kit

Woods Backhoe Model

mounting to

BH6500

Ford/New Holland

Tractor Models

TC18, TC21

Compatible with:

New Holland Loader

7106

or

Woods Loader

1006

MANUAL

PART NUMBER

59756

PN-59756 (Rev. 4/9/01)

Page 2

TO THE DEALER:

Assembly and proper i nstallation of thi s product is the responsibil ity of the WOODS dealer. Read manual instructi ons

and safety rules. Make su re all item s on the Dealer ’s Pre- Delivery and Delivery Check L ists in the O perator ’s Ma nual

are completed before releasing equipment to the owner.

The dealer must co mplete the Warranty Regi stratio n inc luded in this manu al. Bo th deal er and custome r mus t sign th e

registration which cer tifies that all Dealer Check List items have been completed. The de aler is to return the prepaid

postage portion to WOODS , give one c op y to the c us tom er, and retain one copy. Note: Wa rranty credit is subject to

this form being completed and returned.

TO THE OWNER:

Read this manual before operating your WOODS equipment. The information presented will prepare you to do a better

and safer job. Keep thi s manual handy for ready referenc e. Require all operators to read this m anual carefully and

become acquainted with all the adjustment and operating procedures before attempting to operate. Replacement

manuals can be obtained from your dealer or, in the United States and Canada, by calling 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized WOODS dealer has trained mechanics, genuine WOODS service parts, and the

necessary tools and equipment to handle all your needs.

Use only genuine WOODS serv ice parts. Substitute parts will void the warranty and may not m eet s tandards r equi red

for safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

Model: #59757 Sub-Frame Mounting Kit Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The terms CAUTION, WARNING and DANGER are used in conjunctio n with the Safety-Aler t Symbol, (a

triangle with an exclamation mark), to indicate the degree of hazard for items of personal safety.

This Safety-Alert Symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and includes hazards that are

exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury .

Indicates that failure to observe can cause damage to equipment.

NOTE

Indicates helpful information.

ii

Introduction (2/9/01)

Page 3

TABLE OF CONTENTS

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PUMP KIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

#59757 SUB-FRAME MOUNTING KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

#59757 SUB-FRAME MOUNTING KIT PARTS LISTS . . . . . . . . . . . . . . . . 17

BOL T TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

BOL T SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 19

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . INSIDE BACK COVER

PN-59756 (Rev. 4/9/01)

Table of Contents 1

Page 4

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern,

judgement, and proper training of personnel

involved in the operation, transport, maintenance

and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be that

kind of operator.

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

INSTALLATION

n This Sub-Frame Mounting Kit is to be used only

for the backhoes and tractors specified in the SubFrame Mount Installation section of this manual.

Any other use or modification of this mounting kit

may result in serious injury or death.

n Hydraulics must be connected as instructed in

this manual. Do not substitute parts, modify, or

connect in any other way.

n After connecting hoses, check that all control

lever positions func tion a s in s truct ed in th e O per ator’s Manual. Do not put into service until control

lever and equipment movements are correct.

TRAINING

n Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals are available from dealer or, in the

United States and Canada, call 1-8 00-319-6637.)

Failure to follow instructions or safety rules can

result in serious injury or death.

n If you do not understand any part of this manual

and need assistance, see your dealer.

n Know your controls and how to stop engine and

attachment quickly in an emergency.

n Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

n Make sure that all operating and service personnel know that if hyd raulic flui d penetrates s kin, it

must be surgically removed as soon as possible by

2 SAFETY

SAFETY RULES

a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

n Never allow children or untrained persons to

operate equipment.

PREPARATION

n Check that all hardware is properly installed.

Always tighten to torque chart specif ications

unless instructed otherwise in this manual.

n Air in hydraulic systems ca n cause erratic operation and allows loads or equipment components

to drop unexpectedly. When connecting equipment

or hoses or performing any hydraulic maintenance,

purge any air in hydraulic system by operating all

hydraulic functions several times. Do this before

putting into service or allowing anyone to

approach the equipment.

n After connecting hoses, check that all control

lever positions func tio n as instructed in the Oper ator’s Manual. Do not put into service until control

lever and equipment movements are correct.

n Protective hose slee ves must cover all hydraulic hoses and be secured onto metal hose fittings.

Replace hoses or sleeves if damaged or if protective sleeve cannot be properly positioned or

secured.

n Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking bef ore

starting power unit or using equipment. Check and

route hoses carefully to prevent d amage. Hoses

must not be twisted, bent sharply, kinked, frayed,

pinched, or come into c ontact with any moving

parts . Operate moveable components through full

operational range to check clearances. Replace

any damaged hoses immediately.

n Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, roug h-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

n Make sure attachment is properly secured,

adjusted, and in good operating condition.

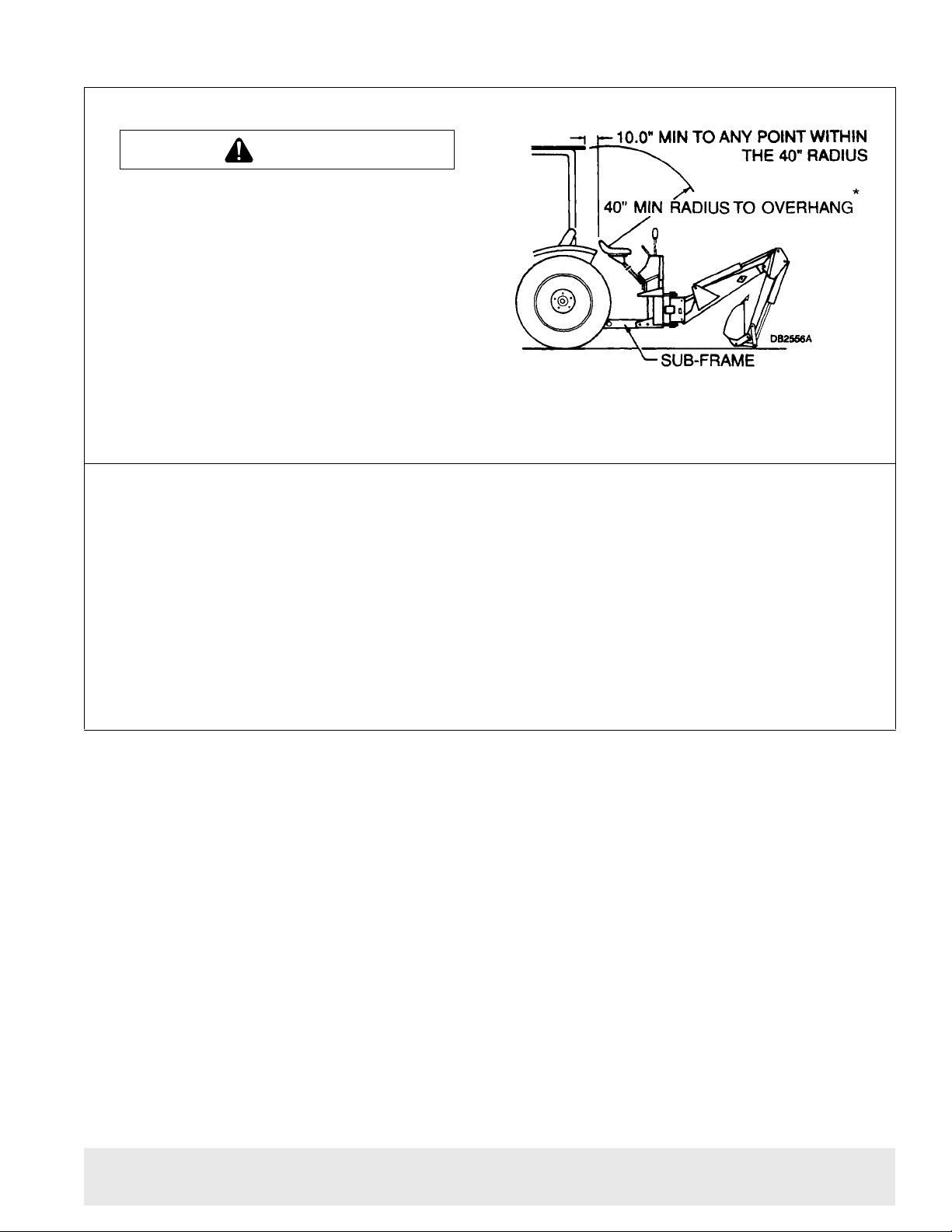

n The sub-frame mount is designed to provide

secure mounting and adequate operator clearance

when properly installed. Check clearance dimensions shown in figure 1 to be sure you have

installed sub-frame correctly. Follow all mounting

instructions in this manual. Do not operat e backhoe unless there is adequate clearance. Failure to

BH6500/7500 SFMK 11/1/00

Page 5

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

check and comply with these instructions may

result in serious injury or death.

n Remove seat and upper support assembly

before installing or removing backhoe from tractor.

Failure to comply may resu lt in equip ment fail ure

and/or personal injury.

n If tractor is equipped with draft sensing control,

set control to “HEAVY” (minimum sensitivity) position.

n On tractors equipped with optional “Draft Con-

trol Hitch,” you must install the “Draft Lockout”

(provided in sub-frame kit) into position as shown.

Failure to install the “Draft Lockout” will allow

upper hitch to move during backhoe operation and

could result in operator injury.

n Make sure all safety decals are installed.

Replace if damaged. (See S af ety D ecal s se ct ion for

location.)

n A minimum 25% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader, front wheel w eights, ballast in tires, or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

hoe and use extreme care

• Always stand between re ar tire and backhoe

stabilizer arms or along side of tractor to avoid

being trapped should the boom swing control

be accidentally activated.

n Never leave equipment unattended with engine

running or with bucket in raised posi tion. Always

engage swing and boom transport locks, relieve

system pressure by operating controls, and

remove ignition key before leaving equipment.

MAINTENANCE

n Refer to backhoe manual and follow all maintenance safety rules and instructions.

n Do not modify or alter or permit anyone else to

modify or alter the equipment or any of i ts components in any way.

n Your dealer can supply original equipment

hydraulic accessories and repair parts. Substitute

parts may not meet orig inal equipment specifications and may be dangerous.

n Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, roug h-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

OPERATION

n Do not allow bystanders in the area when o perating, attaching, removing, assembling, or servicing equipment.

n Before operating, make sure stabilizer pads are

lowered firmly to the ground. Stabilizer arms provide support for the backhoe and support for the

backhoe mounting brackets.

n Do not operate equipment while under the influence of alcohol or drugs.

n Always comply with all state and local lighting

and marking requirements.

n Do not allow riders. Do not lift or carry anybody

on the power unit or attachments.

n The only time the backhoe may be operated

from a position other than the operator seat is during backhoe attach ment and removal. Operator

must

• Read Sub-Frame Mounting Kit Manual

instructions on attaching and removing back-

n Do not allow bystanders in the area wh en operating, attaching, removing, assembling, or servicing equipment.

n Make sure attachment is properly secured,

adjusted, and in good operating condition.

n Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

n

Before working on backhoe, extend boom and

dippersti ck and pl ace buc ket on grou nd. Make sur e

that all system pressure has been relieved by operating con trols be fore per formi ng maint enance or

service or before disconnecting any hydraulic lines.

n Tighten all bolts, nuts and screws to torque

chart specifications. Check that all cotter pins ar e

installed secu rely to ensu re eq uipme nt is i n a sa fe

condition before putting unit into service.

v

BH6500/7500 SFMK 11/1/00

SAFETY 3

Page 6

BACKHOE SUB-FRAME INSTALLATION

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern,

judgement, and proper training of personnel

involved in t he operation, transport, maintenanc e

and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be that

kind of operator.

DANGER

n The sub-frame mount is designed to provide

secure mounting and adequate operator clearance

when properly installed. Check clearance dimensions shown in figure 1 to be sure yo u have

installed sub-frame correctly. Follow all mounting

instructions in this manual. Do not operate backhoe unless there is adequate clearance. Failure to

check and comply with these instructions may

result in serious injury or death.

n The only time the backhoe may be operated

from a position other than the operator seat is during backhoe attachment and removal. Operator

must

• Read Sub-Frame Mounting Kit Manual

instructions on attaching and removing backhoe and use extreme care

• Always stand between r ear tire and backhoe

stabilizer arms or along side of tractor to avoid

being trapped should the boom swing control

be accidentally activated.

4 Installation

WARNING

■ Only use #59757 Sub-Frame Mounting Kit for

mounting Woods BH6500 backhoe on Ford/New

Holland TC18, TC21 tractor models. Sub-Frame

must be installed with either a Woods 1006 loader

or New Holland 7106 loader. Any other use or modification of this mounting kit may result in serious

injury or death.

n Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals are available from dealer or, in the

United States and Canada, call 1 -800-319-6637.)

Failure to follow instructions or safety rule s can

result in serious injury or death.

n

A minimum 25% of tractor and equipment

weight must be on the tractor front wheels when

attachments are i n transp or t positi on. Witho ut thi s

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader, front wheel weights, ballast in tires, or front

tractor weights. Weigh the tractor a nd equipment.

Do not estimate.

n Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

n

Before working on backhoe, extend boom and

dipperstick and place bucket on ground. Make sure

that all system pressure has been relieved by operating controls before performing maintenance or

service or before disconnecting any hydraulic

lines.

n Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking bef ore

starting power unit or using equipment. Check and

route hoses carefully to prevent d amage. Hoses

must not be twisted, bent sharply, kinked, frayed,

pinched, or come into c ontact with any moving

parts . Operate moveable components through full

operational range to check clearances. Replace

any damaged hoses immediately.

PN-59756 (Rev. 4/9/01)

Page 7

SUB-FRAME INSTALLATION Cont’d

CAUTION

n If you do not understand any part of this man-

ual and need assistance, see your dealer.

n Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes , hair, hands, hearing, and

head.

TRACTOR PREPARATION

1. Refer to the WOODS 6500/7500 Backhoe Opera-

tor’s Manual for backhoe assembly instructions.

NOTE: For installing this sub-frame, reference to

right, left, forward and rea rward directions are determined from the operator’s position in the tractor seat.

* Operator ’s seat must be located in the lowes t and

most forward position to obtain 40” minimum radius.

Figure 1 Sub-Frame Clearance

3. Disconnect and remov e the f ront e nd loa der fro m

the tractor using instructions in loader manual. Do not

remove loader mounting brackets.

NOTE: Leave all hardware loose until sub-frame

weldment has been fit up.

2. Remove the tractor top link, 3-point lower lift

arms, and lower hi tch pi ns. Store these parts for reinstallation when backhoe and sub-frame are r emoved

and when 3-point hitch is required.

PN-59756 (Rev. 4/9/01)

Installation 5

Page 8

SUB-FRAME INSTALLATION Co nt’d

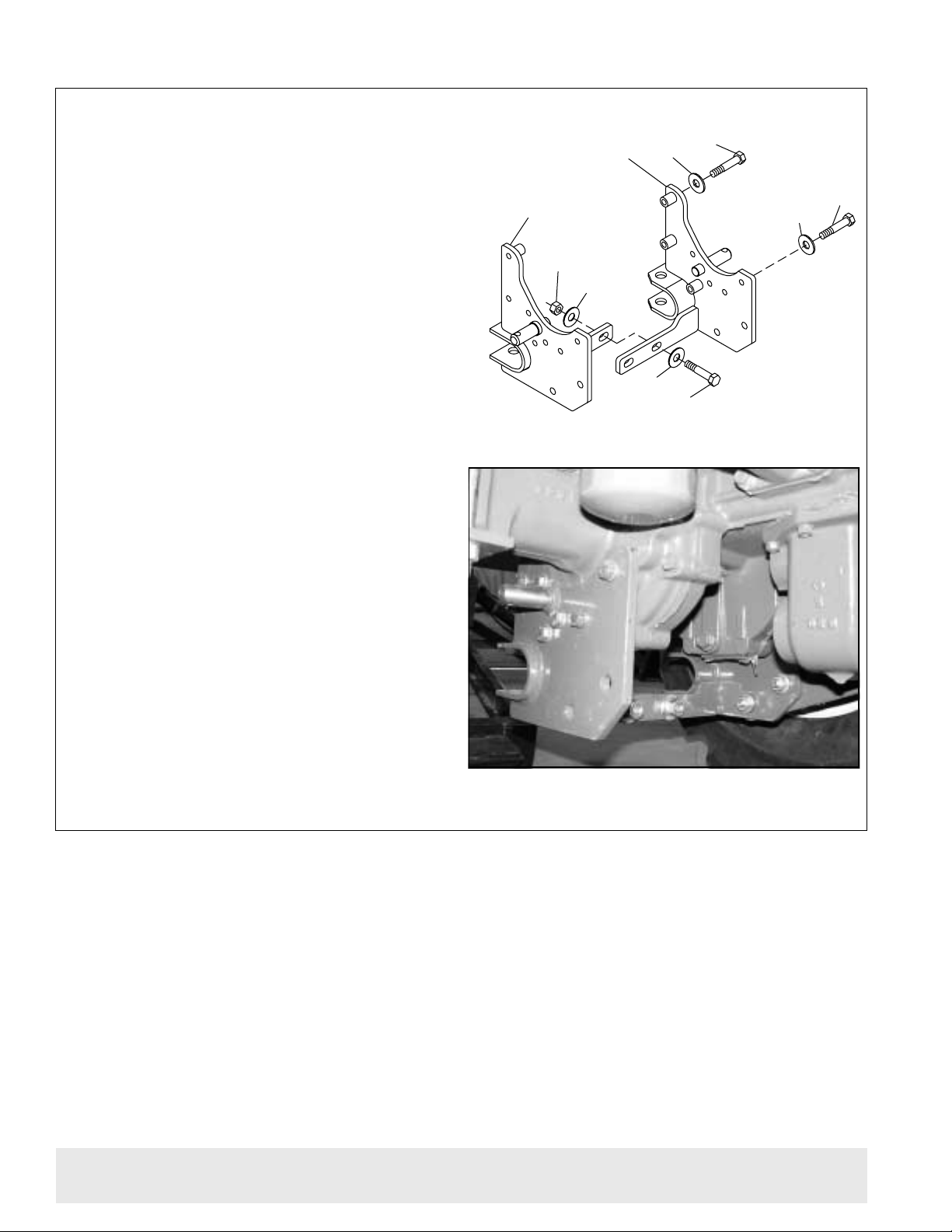

Install Rear Hanger Brackets

1. Install new right and lef t rear hanger br ackets (1,

2), using eight 10mm bolts (20) and hardened flat

washers (22).

2. Install six 10mm x 1.5P x 80mm (21) and washers

(22) to secure rear hangers.

3. Install cap screws (25), washers (29), and nuts

(28) through crossmembers welded to rear hanger

brackets.

4. Torque 10mm cap screws to 29 lbs-ft.

5. Torque 12mm cap screws to 50 lbs-ft.

1. 1000578 Right rear hanger bracket

2. 1000579 Left rear hanger bracket

20. 307301 M10–1.5P x 30mm Cap screw

21. 58514 M10–1.5P x 80mm Cap screw

22. 44546 3/8 Ex tr a thick fla t washer

25. 58515 M12–1.75P x 45mm Cap screw

28. 307813 M12 x 1.75 Hex nut

29. 57811 1/2 Extra thick flat washer

21

22

2

1

28

29

29

25

Figure 2 Rear Hanger Bracket Assembly

22

20

6 Installation

Figure 3 Rear Hanger Brackets Installed

PN-59756 (Rev. 4/9/01)

Page 9

SUB-FRAME INSTALLATION Cont’d

Install Mid-mount Bracket

1. Install mid-mount bracket (3) to underside of

transmission housing, using cap screws (23) and

washers (29) as shown in Figure 4.

NOTE: B racket has a small notch, to b e positioned

on the left side the the tractor.

NOTE: Leave hardware loose.

2. The mounting kit will limit access for two grease

fittings on the clutch and brake pedals. Replace 6mm

straight grease fitting w ith a 90-degree grease fittin g

(not supplied in reinforcement kit).

3. 1000590 Mid-mount bracket

23. 62584 M12–1.75P x 35mm Cap screw

29. 57811 1/2 Extra thick flat washer

GREASE FITTINGS

2923

Figure 4 Mid-mount Bracket Installed

Modify Loader Mounts

For tractors equipped with New Holland 7106

Loader

1. Position right and left reinfor cement brackets (5,

6) on tractor.

2. Hand tighten appropriate hard ware (refer to Fig-

ure 6) to hold brackets in place.

3. An additional hole will need to be drilled into each

side of the New Holl and loader rear mount (refer to

Figure 5):

a. Using the left re inforcemen t bracket a s a tem-

plate, match up exis ting two holes on the load er

rear mount and mark location for new hole.

b. Remove the reinforcement bracket.

c. Drill a 17/32” diameter hole as shown. This

can be done with the loader mo unt installed if a

right angle drill is used.

d. Repeat for right mount.

17/32” HOLE

PN-59756 (Rev. 4/9/01)

Figure 5 Additional Hole Drilled for 7106 Loader

(Left side shown)

Installation 7

Page 10

SUB-FRAME INSTALLATION Cont’d

Modify Loader Mounts

For tractors equipped with Woods 1006 Loader

Loader mounts manufactured p rior to April 2001 will

need to be modified before reinforcement brackets

can be installed. Contact Woods Technical Service for

assistance.

Install Right & Left Reinforcement

Brackets

NOTE: If rear mount has five slots on ea ch side, pro-

ceed to next section, Install Right & Left Reinforcement Brackets.

For tractors equipped with either

New Holland 7106 or Woods 1006 Loader

1. After holes have been dri lled, install right an d left

reinforcement brackets (5, 6). Use cap screws (25),

washers (29), and nuts (28) in new drilled holes.

NOTE: Cap screws that attach the reinforcement to

the tractor clutch housing are different lengths on right

and left side of tractor. Refer to Figure 6 for correct

hardware.

2. Secure reinforcement brackets to mid-mount

bracket with cap screws (27), flat washers (29), and

hex nuts (28).

3. Secure to rear brackets wi th cap scr ews (25), fla t

washers (29), and hex nuts (28).

29

24

29

28

6

29

5

26

29

Figure 6 Reinforcement bracket assembly

25

4. 1000581 Crossmember bracket

5. 1000594 Right reinforcement bracket

6. 1000595 Left reinforcement bracket

24. 307301 M12–1.75P x 40mm Cap screw

25. 58515 M12–1.75P x 45mm Cap screw

26. 58516 M12–1.75P x 50mm Cap screw

27. 307302 M12–1.75P x 90mm Cap screw

28. 307813 M12 x 1.75 Hex nut

29. 57811 1/2 Extra thick flat washer

Figure 7 Reinforcement bracket assembly to mid-mount bracket & rear bracket

8 Installation

28

29

25

29

6

29

27

PN-59756 (Rev. 4/9/01)

28

Page 11

SUB-FRAME INSTALLATION Cont’d

Install Crossmember

1. Attach crossmember br acket (4) to right and left

reinforcement brackets, using cap screws (24) and

washers (29) as shown in Figure 9.

4. 1000581 Crossmember bracket

24. 307301 M12–1.75P x 40mm Cap screw

29. 57811 1/2 Hardened flat washer, extra

thick

24

29

4

Figure 9 Crossmember Bracket Installation

PN-59756 (Rev. 4/9/01)

Installation 9

Page 12

SUB-FRAME INSTALLATION Cont’d

Sub-Frame Fit-Up

1. Insert sub-frame (1) into rear mounting bracket

cradle (2 & 3).

2. Secure with clevis pins (17) and safety pins (19).

3. Pivot sub-frame up and secure to front mo unt (6)

with bent pin (7) and Klik pin (18).

4. Remove sub-frame from tractor.

5. Tighten 12mm hardware to 50 lbs.-ft.

IMPORTANT

■ DO NOT install the 3-point hitch top link on

this subframe mounting kit. No top link

bracket should be used on this backhoe.

CD4891

17

19

17

19

2

3

Figure 10 Sub-frame Fit-up (typical)

6

18

7

1

1. Sub-frame

2. Right rear mount bracket

3. Left rear mount bracket

6. Front mount

7. Bent pin, .75 x 11

17. Clevis pin, .75 x 2.76

18. 1/4 x 1-3/4 Klik pin

19. 1/8 Safety pin

10 Installation

PN-59756 (Rev. 4/9/01)

Page 13

SUB-FRAME INSTALLATION Cont’d

Attaching Sub-Frame to Backhoe

1. With sub-frame removed from tractor, attach to

the backhoe using four cap screws (13), six lock

washers (14), and six nuts (15).

2. Align step (12) and insert two cap screws (7)

through sub-frame holes. Secure with lock washers

(6) and nuts (5).

5. 7/8 NC Hex nut

6. 7/8 NC Hex lock nut

7. 7/8 NC x 2-1/2 Cap screw

12. Step

13. 3/4 NC x 2 Cap screw

14. 3/4” Lock washer

15. 3/4 NC Hex nut

15

14

5

6

13

Figure 11 Sub-frame attached to backhoe

12

7

CD4771A

PN-59756 (Rev. 4/9/01)

Installation 11

Page 14

SUB-FRAME INSTALLATION Cont’d

Mount Bracket to Pump Kit

NOTE: For complete information on pum p kit ins talla-

tion, consult the Woods BH65 00/7500 backhoe o perators manual #37541.

The pump mounting bracket is designed to slip over

the tractor drawbar and prevent the pump from rotating.

1. Trim the bracket flush with the bo ttom of th e trac-

tor drawbar if necessary.

2. Attach pump mounting bracket #59760 (2) to

pump assembly as shown in Figure 12.

3. Secure with cap screw (5) and lock nut (3) as

shown.

4. Torque cap screw to 85 lbs.-ft.

1. Pump

2. Pump mounting bracket

3. 1/2 NC Lock nut

4. Tractor drawbar

5. 1/2 NC x 1-1/2” Cap screw

6. Tractor PTO shaft

Figure 12 Pump Bracket Assembly

(Typical)

12 Installation

PN-59756 (Rev. 4/9/01)

Page 15

SUB-FRAME & BACKHOE TO TRACTOR

Mount Sub-Frame & Backhoe to Tractor

DANGER

n The sub-frame mount is designed to provide

secure mounting and adequate operator clearance when properly installed. Check clearance

dimensions shown in figure 1 to be sure you have

installed sub-frame correctly. Follow all mounting

instructions in this manual. Do not operate backhoe unless there is adeq uat e clearance. Failure to

check and comply with these instructions may

result in serious injury or death.

n The only time the backhoe may be operated

from a position other than t he operator seat i s

during backhoe attachment and removal. Operator must

• Read Sub-Frame Mounting Kit Manual

instructions on attaching and removing backhoe and use extreme care

• Always stand between rear tire and backhoe stabilizer arms or along side of tractor to

avoid being trapped should the boom swing

control be accidentally activated.

WARNING

WARNING

n Remove seat and upper support assembly

before installing or removing backhoe from tractor. F ailure to comply may result in equipment failure and/or personal injury.

Remove the backhoe seat assembly.

1.

2. Place sub-frame flat on a hard level surface.

3. Back tractor over the sub-frame and center

between the tractor rear tires. Position tr actor so that

the hydraulic system can be connected. Shut off tractor, set brake, remove key.

4. Install pump (see Conn ect Hy dr aul ic S y ste m sec -

tion, next page).

5. Start tractor.

NOTE: You will use the backhoe hydraulics to maneu-

ver the sub-frame into position. Use ca re in this procedure to avoid being trapped between tractor and

backhoe or between backhoe parts.

6. Raise rear of sub-frame up by lowering stabilizers

and boom section until even with channels of rear

mount.

7. Drive tractor back so that crosstube slides into

channel. Shut off tractor, set brake, remove key.

8. Fasten sub-frame in place by placing cl evis pins

into channel holes and secure with safety pins.

9. With the tractor engine off, reliev e p re ssur e in th e

backhoe boom and s tabilizers to raise s ub-fram e into

front hanger.

10. Install bent pin and klik pin in front hanger mount.

11. Reinstall seat.

12. Start tractor and put backhoe i nto transpor t posi-

tion (see backhoe operator’s manual).

NOTE: Install swing lock before transporting.

PN-59756 (Rev. 4/9/01)

Installation 13

Page 16

SUB-FRAME & BACKHOE TO TRACTOR Cont’d

Couple the backhoe h ydra uli c p ump to th e tr actor

Connect Hydraulic System

WARNING

1.

PTO.

2. Insert the pump brack et over the tractor draw bar

to prevent pump rotation. Engage the pump PTO coupler pin firmly in the tractor PTO spline groove.

n Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for le aks. Wear safety goggles. Hydraulic fluid under pressure can easily

penetrate skin and will cause serious injury or

death.

n Make sure that all operating and service per-

sonnel know that if hydra ulic fluid penetrates

skin, it must be surgically removed as soon as

possible by a doctor familiar with this form of

injury or gangrene, serious injur y, or death will

result. CONTACT A PHYSICIAN IMMEDIATELY IF

FLUID ENTERS SKIN OR EYES. DO NOT DELAY.

n Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking

before starting power unit or u sing equipm ent.

Check and route hoses carefully to prevent damage. Hoses must not be twisted, bent sharply,

kinked, frayed, pinched, or come into contact with

any moving parts. Operate moveable components

through full operational range to check clearances. Replace any damaged hoses immediately.

3. Check all hydraulic fittings and lines to be sure

they are tight and free of kinks or twists.

4. Make sure backhoe PTO driven hydraulic system

is full (approximate ly 5- 7 US g all on s). Check the tractor hydraulic reservoir and service if necessary.

5. Be sure the backhoe con trols are cente red in the

neutral position and the backhoe hydraulic pump is

securely mounted to the tractor.

6. With the tractor PTO and transmi ssion in neutr al,

start the engine and run at low idle.

7. Smoothly engage the PTO pump to provide back-

hoe hydraulics.

NOTE: Very little engine power is required to operat e

the hydraulic sy stem in this m ode. Shoul d the en gine

pull down excessively, check the plumbing hook-up

for reversed lines or a control lever stuck in an operating position.

14 Installation

PN-59756 (Rev. 4/9/01)

Page 17

SUB-FRAME & BACKHOE to TRACTOR Cont’d

Remove Backhoe With Sub-Frame

DANGER

n The only time the backhoe may be operated

from a position other than t he operator seat i s

during backhoe attachment and removal. Operator must

• Read Sub-Frame Mounting Kit Manual

instructions on attaching and removing backhoe and use extreme care

• Always stand between rear tire and backhoe stabilizer arms or along side of tractor to

avoid being trapped should the boom swing

control be accidentally activated.

On a hard level surface, center the backhoe

1.

boom.

2. Remove the seat assembly.

3. Remove retaining pins from front sub-frame

bracket and clevis pins fr om rear hanger bracket OR

from sub-frame hooks.

4. Start the tractor. Engage PTO pump at slow idle

speed. Curl the bucket all the way towards the operator.

WARNING

WARNING

n Remove seat and upper support assembly

before installing or removing backhoe from tractor. F ailure to comply may result in equipment failure and/or personal injury.

NOTE: For re moval, the front of the sub-frame must

be low enough to clear the lowe st point of the tractor.

Maintain clearance throughout this procedure.

9. Move the tractor fa r enough to release the sub-

frame from the brackets.

10. Place blocks under backhoe mainframe and raise

stabilizers to lower backhoe onto the blocks.

11. Disengage PTO, turn o ff engine, set b rakes, and

remove key before leaving tractor seat.

5. Remove transport lock.

6. Extend boom and dippersti ck so that dipperstick

is vertical.

7. Rest bucket on the ground and lower stabilizers

to take backhoe weight off tractor. Extend boom and

stabilizers to release subframe.

8. Keeping the bucket and stabilizer s in contact with

the ground, raise the re ar of the backh oe to pivot th e

front of the sub-frame down.

Store Hydraulic Pump

1. Disconnect pump from tractor PTO.

2. Store pump on backside of backhoe to prevent

dirt and debris from accumulating in pump adapter.

12. Remove the backhoe hydraulic pump from the

PTO shaft (see Store Hydraulic Pump section).

13. Reinstall seat assembly.

14. Make sure backhoe and sub-frame clear the trac-

tor chassis. Start tractor and drive the tractor away.

NOTE: For instructions on extended storage, see

backhoe operator’s manual

PN-59756 (Rev. 4/9/01)

Installation 15

Page 18

33

1

32

#59757 SUB-FRAME MOUNTING KIT

30

21

22

15

20

2

22

25

29

29

6

29

28

24

29

3

28

29

29

23

27

29

24

29

25

4

28

29

29

5

25

28

29

29

26

10

36

35

8

34

9

Serial Number Plate

Located inside sub-frame side rail, rear of cross tube

31

7

16

CD5888

MODELNO. SERIALNO. MASS (KG)

ID NO.

OREGON, IL U.S.A.

16 Parts

YR OF MFG.

PN-59756 (Rev. 4/9/01)

Page 19

#59757 SUB-FRAME MOUNTING KIT PARTS LIST

REF PART QTY DESCRIPTION

1 1000578 1 BRACKET-REAR HANGER RT

2 1000579 1 BRACKET-REAR HANGER LT

3 1000590 1 BRACKET-MID MOUNT

4 1000581 1 BRACKET-CROSS MEMBER

5 1000594 1 BRACKET-REINFORCEMENT RT

6 1000595 1 BRACKET-REINFORCEMENT LT

7 37463 1 WA 7500 SUBFRAME-67.2

8 62944 2 BACKHOE MOUNTING STEP

9 65540 1 3/4 X 11 LOCK PIN

10 59760 1 PUMP BRKT .25 X 6.75 X 7.00

15 2688 2 5/32 HAIR PIN COTTER

16 62043 1 1/4 X 1-3/4 KLIK PIN

20 307201 8 HHCS M10-1.50P X 30MM

21 58514 6 HHCS M 10-1 .50P X 80MM

22 44546 14 WSHR 3/8 FLAT EXTRA THK HRDN

REF PART QTY DESCRIPTION

23 62584 4 HHCS M12-1.75P X 35MM

24 307301 6 HHCS M12-1.75P X 40MM

25 58515 8 HHCS M12-1.75P X 45MM CL10.9ZP

26 58516 2 HHCS M12-1.75P X 50MM CL10.9ZP

27 307302 4 HHCS M12-1.75P X 90MM

28 307813 12 NUT HEX M12 X 1.75

29 57811 36 WSHR 1/2 FLAT EXTRA THK HRDN

30 62540 2 PIN CL V .75 X 2.76

31 735 4 HHCS 3/4 NC X 2 GR5

32 2522 6 WSHR 3/4 LOCK ZP

33 1450 6 NUT HEX 3/4 NC PLTD

34 62541 4 HHCS 7/8 NC X 2-1/2 GR5

35 30008 4 WSHR 7/8 LOCK

36 4261 4 NUT HEX 7/8 NC

PN-59756 (Rev. 4/9/01

Parts 17

Page 20

BOLT TORQUE CHART

Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific

application.

Fasteners must always be replaced with the same grade as specified in the manual parts list.

Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for metric hardware.

Make sure fastener threads are clean and you start thread engagement properly.

All torque values are given to specifications used on hardware defined by SAE J1701 & J1701M JUL96.

SAE SERIES

A

A

Diameter

(Inches)

1/4” 7/16” 6 8 10 13 14 18

5/16” 1/2” 12 17 19 26 27 37

3/8” 9/16” 23 31 35 47 49 67

7/16” 5/8” 36 48 55 75 78 106

1/2” 3/4” 55 75 85 115 120 163

9/16” 13/16” 78 106 121 164 171 232

5/8” 15/16” 110 149 170 230 240 325

3/4” 1-1/8” 192 261 297 403 420 569

7/8” 1-15/16” 306 416 474 642 669 907

1” 1-1/2” 467 634 722 979 1020 1383

TORQUE

CHART

Wrench

Size

SAE Grade 2

(No Dashes)

SAE 2 SAE 5 SAE 8

Lbs.-Ft. N-m Lbs.-Ft. N-m Lbs.-Ft. N-m

METRIC SERIES

A

TORQUE

CHART

A

Diameter &

Thread Pitch

(Millimeters)

6 x 1.0 10 mm 8 6 11 8 8 6 11 8 6 x 1.0

8 x 1.25 13 mm 20 15 27 20 21 16 29 22 8 x 1.0

10 x 1.5 16 mm 39 29 54 40 41 30 57 42 10 x 1.25

12 x 1.75 18 mm 68 50 94 70 75 55 103 76 12 x 1.25

14 x 2.0 21 mm 109 80 151 111 118 87 163 120 14 x 1.5

16 x 2.0 24 mm 169 125 234 173 181 133 250 184 16 x 1.5

18 x 2.5 27 mm 234 172 323 239 263 194 363 268 18 x 1.5

20 x 2.5 30 mm 330 244 457 337 367 270 507 374 20 x 1.5

22 x 2.5 34 mm 451 332 623 460 495 365 684 505 22 x 1.5

24 x 3.0 36 mm 571 421 790 583 623 459 861 635 24 x 2.0

30 x 3.0 46 mm 1175 867 1626 1199 1258 928 1740 1283 30 x 2.0

Wrench

Size

N-m Lbs.-Ft. N-m Lbs.-Ft. N-m Lbs.-Ft. N-m Lbs.-Ft.

COARSE THREAD FINE THREAD

MARKING ON HEAD MARKING ON HEAD

Metric 8.8 Metric 10.9 Metric 8.8 Metric 10.9

SAE Bolt Head

Identification

8.8

Metric

Grade 8.8

SAE Grade 5

(3 Radial Dashes)

MARKING ON HEAD

Metric Bolt Head

Identification

SAE Grade 8

(6 Radial Dashes)

10.9

Metric

Grade 10.9

A

Diameter &

Thread Pitch

(Millimeters)

Typical Washer Installations

Lockwasher

Bolt

18 Appendix

Nut

Flat Washer

8/9/00

Bolt Torque & Size Charts (Rev. 9/5/00)

Page 21

BOLT SIZE CHAR T

NOTE: Chart shows bolt thread sizes and corresponding head (wrench) sizes for standard SAE and metric bolts.

SAE Bolt Thread Sizes

5/16 3/8 1/2 5/8 3/4 7/8

IN 1 2 3 4 5 6 7

MM 25 50 75 100 125 150 175

Metric Bolt Thread Sizes

8MM 18MM14MM12MM10MM 16MM

ABBREVIATIONS

AG............................................................. Agriculture

ATF ..............................Automatic Transmission Fluid

BSPP...........................British Standard Pipe Parallel

BSPTM ..............British Standard Pipe Tapered Male

CV...................................................Constant Velocity

CCW............................................ Counter-Clockwise

CW............................................................. Clockwise

F .....................................................................Female

GA ...................................................................Gauge

GR (5, etc.)......................................... Grade (5, etc.)

HHCS ...................................... Hex Head Cap Screw

HT..........................................................Heat Treated

JIC ...............Joint Industry Council 37°

LH...............................................................Left Hand

LT..........................................................................Left

m....................................................................... Meter

mm.............................................................. Millimeter

M.........................................................................Male

MPa .......................................................Mega Pascal

N.................................................................... Newton

Degree Flare

NC ..................... ....... ...... ..................National Coarse

NF......................................................... National Fine

NPSM ...................National Pipe Straight Mechanical

NPT ........................................ National Pipe Tapered

NPT SWF........National Pipe Tapered Swivel Female

ORBM......................................... O-Ring Boss - Male

P .........................................................................Pitch

PBY .....................................................Power Beyond

psi........................................Pounds per Square Inch

PTO ................................................... Power Take Off

QD ..................................................Quick Disconnect

RH ............................................................Right Hand

ROPS.......................... Roll Over Protective Structure

RPM.......................................Revolutions Per Minute

RT...................................................................... Right

SAE ........................Society of Automotive Engineers

UNC............................................. .......Un ifi ed Coar se

UNF ........................................................ Unified Fine

UNS....................................................Unified Special

Bolt Torque & Size Charts (Rev. 9/5/00)

Appendix 19

Page 22

WARRANTY

(Replacement Parts For All Models Except Mow’n Machines)

WEC Company, d/b/a Wood s Equipment Company (“WOODS”), warrants this product to be free from

defect in material and workmans hip for a period of ninety (90) days from the date of delivery of the product to the original purchaser.

Under no circumstances will this Warranty apply in the event that the product, in the good faith opinion of

WOODS, has been subjected to improper op eration, improper maintenance, misuse, or an accident. This

Warranty does not cover normal wear or tear, or normal maintenance items.

This Warranty is extended solely to the original purchaser of the product. S hould the original purchaser

sell or otherwise transfer this product to a third party, this Warranty does not transfer to the third party purchaser in any way. There are no third party beneficiaries of this Warranty.

WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replacement, free

of charge, of the product if WOODS, in its sole discretion, deems it to be defective or in noncompliance

with this Warran ty. The product must be returned to WOODS with proof of purchase within thirty

(30) days after such defect or noncompliance is discovered or should have been discovered, routed

through the dealer and distributor from whom the purchase was made, transportation charges prepaid. WOODS shall complete such repair or replacement within a reasonable time after WOODS receives

the product. THERE ARE NO OTHER REMEDIES UNDER THIS WARRANTY. THE REMEDY OF

REPAIR OR REPLACEMENT IS THE SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

OF THIS WARRANTY. WOODS MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND

WOODS SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OF MERCHANTABILITY

AND/OR ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

WOODS shall not be liable for any incid ental or con sequential lo sses, dama ges or expen ses, arising

directly or indirectly from the product, whether such claim is based upon breach of contract, br ea ch

of warranty, negligence, strict liability in tort or any other legal theory. Without limiting the generality

of the foregoing, Woods specifically disclaims any damages relating to (i) lost profits, business, revenues

or goodwill; (ii) loss of crops; (iii) loss because of delay in harvesting; (iv) any expense or loss incurred for

labor, supplies, substitute machinery or rental; or (v) any other type of damage to property or economic

loss.

This Warranty is subject to any existing conditions of supply which may directly affect WOODS’ ability to

obtain materials or manufacture replacement parts .

No agent, representative, dealer, distributor, service person, salesperson, or employee of any company,

including without limitation, WOODS, its authorized dealers, distributors, and service centers, is authorized to alter, modify, or enlarge this Warranty.

Answers to any questions regarding warranty service and locations may be obtained by contacting:

Woods Equipment

Company

2606 Illinois Route 2 South

Post Office Bo x 1000

Oregon, Illinois 61061

815-732-2141 tel

815-732-7580 fax

F-8494 Effective 3/1/2000 (Rev. 2/14/01)

Page 23

WARRANTY

(All Models Except Mow’n Machines)

Please Enter Information Below and Save For Future Reference.

Date Purchased: __________________________ From (Dealer): _____________________________

Model Number: __________________________ Serial Number: ______________ _____________ __

WEC Company, d/b/a Woods Equipment Company (“WOODS”), warrants this product to be free from defect in material

and workmansh i p. Exc e pt as otherwise se t forth below, t he du r a tio n of this Warranty shall be for TWELVE (12) MONT HS

COMMENCING ON THE DATE OF DELIVERY OF THE PRODUCT TO THE ORIGINAL PURCHASER.

The warranty period for certain gearboxes are listed below:

Model No. Part Warranted Duration

1160, 1190, BB600, BB720, BB840, BB6000,

BB7200, BB8400 Gearbox components 5 year s f rom the date of delivery.

1130, 3180, 3240, BB48, BB60, BB7 2, BB84 Gearbox components 3 years from the date of delivery.

90 days from the date of de livery if used

XT148, XT160, XT172 , XT 184 Rotary cutter gearbox

Under no circumstances will this Warranty apply in the event that the product, in the good faith opin ion of WOODS, h as been

subjected to improper operation, improper maintenance, misuse, or an accident. This Warranty does not apply in the event that

the product has been ma terially m odif ied o r repaire d by som eone o ther tha n WO ODS, a W OOD S autho rized dea ler or distrib utor, and/or a WOODS authorized service center. Thi s Warranty does not cover normal wear or tear, or normal maintenance

items. This W a rranty also doe s not co v e r repairs made with pa rts other than those obtainable throu gh W O ODS.

This W arranty is e xtended solely to the original purc haser of the prod uct. Should the original purchaser sell or otherwise transfer this product to a third party, this Warranty does not transfer to the third party purchaser in any way . There are no third party

beneficiaries of this Warranty.

WOODS makes no wa rranty, express or implied, with respe ct to en gine s, b atterie s, tire s o r othe r pa rts or a cces sor ies not m anufactured by WOODS. Warranties for these items, if any, are provided separately by their respecti v e manufacturers.

WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replacement, free of charge, of the

product if WOODS, in its sole discretion, deems it to be defective or in noncompliance with this Warranty. The product must

be returned to WOODS with proof of purchase within thirty (30) days after such defect or noncompliance is discovered or should have been discovered, routed through the dealer a nd distri butor from whom t he purchase was made,

transportation charges pr epa id. W OODS shall complete such repair or replacement within a reasonable time after WOODS

receives the product. THERE ARE NO OTHER REMEDIES UNDER THIS WARRANTY. THE REMEDY OF REPAIR OR

REPLACEMENT IS THE SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE OF THIS WARRANTY. WOODS MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND WOODS SPECIFICALLY DISCLAIMS ANY IMPLIED W ARRANTY OF MERCHANTABILITY AND/OR ANY IMPLIED WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE.

WOODS shall not be liable for any incidental or consequential losses, damage s or expenses, arising directly or indirectly from the product, whether such claim is based upon breach of contract, breach of warranty, negligence, strict

liability in tort or any other legal theory. Without limiting the generality of the foregoing, Woods specifically disclaims any

damages relating to (i) lost profits, bus iness, revenues or goodwill; (ii) loss of crops; (iii) loss because of delay in harvesting;

(iv) any expense or lo ss incurred for labor, supplies, substitute machinery or rental; or (v) any other type of damage to property

or economic loss.

This Wa rranty is subject to any e xisting conditio ns of supply which may directly af fect WOODS’ ability to obtain materials or

manufacture re pl ac em ent parts.

No agent, representative, dealer, distributor, serviceperson, salesperson, or employee of any company, including without limitation, WOODS, its authorize d dealers, distributors, and service centers, is autho rized to alter, modify, or enlarge this Warranty.

This Warranty is effecti ve only if the warranty registration card is returned within ten ( 10) days.

Answers to any que stion s regarding warranty service and locations ma y be obta i ne d by c on t actin g:

in rental or commercial a pplications.

Woods Equipment

Company

2606 Illinois Route 2 South

Post Office Box 100 0

Oregon, Illinois 61061

815-732-2141 tel

815-732-7580 fax

F-3079 Effective 3/2/2000 (Revised 3/1/01)

.

Page 24

PART NO.

59756

Woods Equipment

Company

2606 Illinois Route 2 South

Post Office Box 1000

Oregon, Illinois 61061

815-732-2141 tel

815-732-7580 fax

©1999 Woods Equip men t Comp a ny. All rights reserved.

Loading...

Loading...