Woods Equipment 1012606 User Manual

1012606

3-POINT MOUNTING KIT

For Woods BH90-X Backhoe

SAVE THIS

MANUAL!

Include it with

your Backhoe Manual.

It contains safety,

operation, and repair

part information not

found in other

manuals.

MAN0549

(6/30/2006)

Tested. Proven. Unbeatable.

TO THE DEALER:

CAUTION

IMPORTANT

WARNING

DANGER

NOTE

®

Assembly and proper installation of this product is the responsibility of the Woods

and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual

are completed before releasing equipment to the owner.

The dealer must complete the Product Registration included with this manual. The customer must sign the registration

which certifies that all Dealer Check List items have been completed. The dealer is to return the prepaid postage

portion to Woods, give one copy to the customer, and retain one copy. Failure to complete and return this card does

not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Woods equipment. The information presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized Woods dealer has trained mechanics, genuine Woods service parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

dealer. Read manual instructions

Model: _______________________________ Date of Purchase: _____________________

Serial Number: (see Parts section for location) __________________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-Alert Symbol (a

triangle with an exclamation mark) to indicate the degree of hazard for items of personal safety.

This Safety-Alert Symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

NOTE

2 Introduction

Indicates helpful information.

SFMK (Rev. 6/6/2005)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

!

LEA EL INSTRUCTIVO!

Si no lee Ingles, pida ayuda a

alguien que si lo lea para que le

traduzca las medidas de seguridad.

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of

personnel involved in the operation, transport,

maintenance, and storage of equipment.

It has been said, “The best safety device is an

informed, careful operator.” We ask you to be

that kind of operator.

INSTALLATION

This Mounting Kit is to be used only for the

backhoes and tractors specified in the Installation

section of this manual. Any other use or modification of this mounting kit may result in serious

injury or death.

Hydraulics must be connected as instructed in

this manual. Do not substitute parts, modify, or

connect in any other way.

After connecting hoses, check that all control

lever positions function as instructed in the Operator's Manual. Do not put into service until control

lever and equipment movements are correct.

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service personnel know that if hydraulic fluid penetrates skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Never allow children or untrained persons to

operate equipment.

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Air in hydraulic systems can cause erratic operation and allows loads or equipment components

to drop unexpectedly. When connecting equipment

or hoses or performing any hydraulic maintenance,

purge any air in hydraulic system by operating all

hydraulic functions several times. Do this before

putting into service or allowing anyone to

approach the equipment.

Protective hose sleeves must cover all hydraulic hoses within 20 inches of the operator and be

secured onto metal hose fittings. Replace hoses or

sleeves if damaged or if protective sleeve cannot

be properly positioned or secured.

Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking before

starting power unit or using equipment. Check and

route hoses carefully to prevent damage. Hoses

must not be twisted, bent sharply, kinked, frayed,

pinched, or come into contact with any moving

parts. Operate moveable components through full

operational range to check clearances. Replace

any damaged hoses immediately.

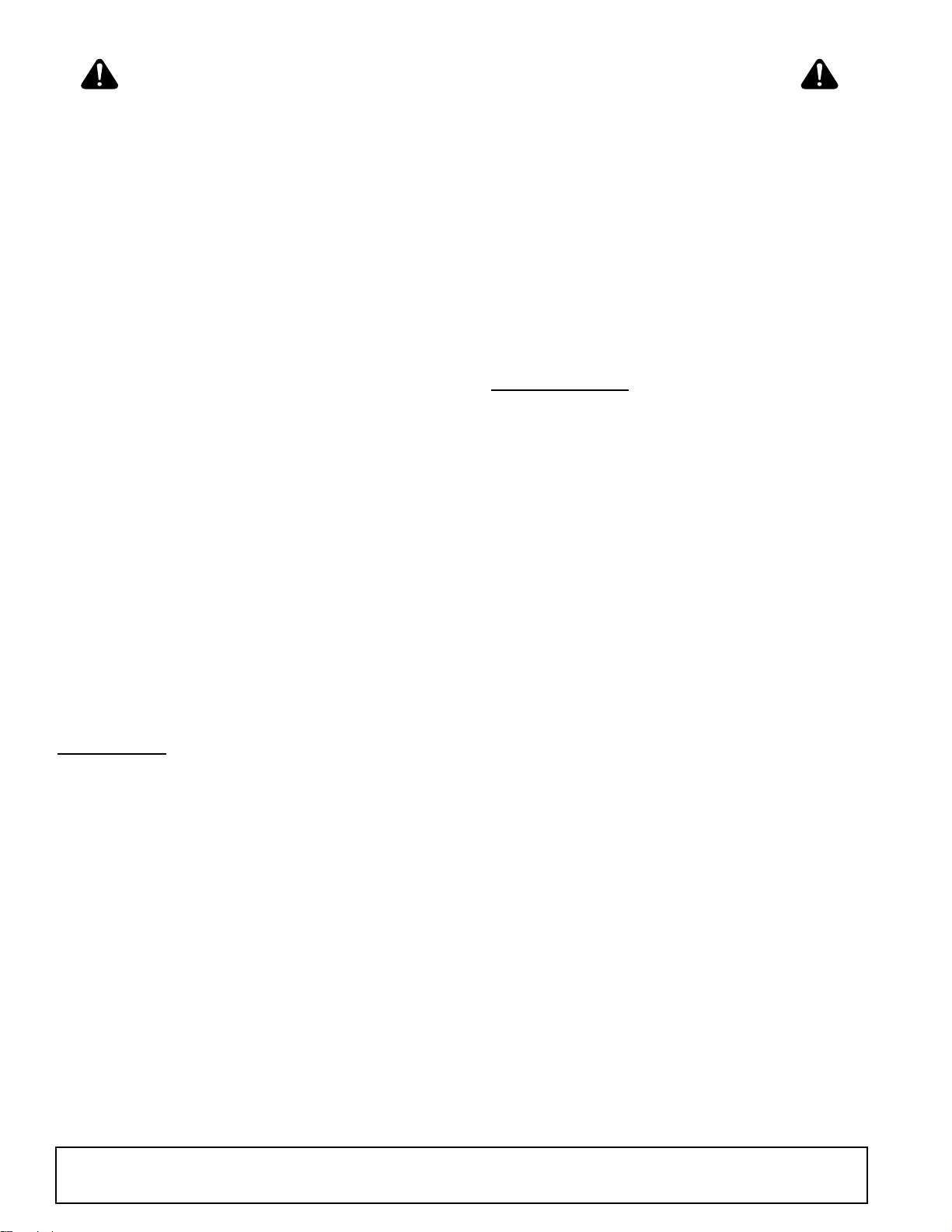

This mounting kit is designed to provide secure

mounting and adequate operator clearance when

properly installed. Check clearance dimensions

shown in Figure 1 to be sure you have installed

mounting kit correctly. Follow all mounting instructions in this manual. Do not operate backhoe

unless there is adequate clearance. Failure to

check and comply with these instructions may

result in serious injury or death.

(Safety Rules continued on next page)

BH 3-Pt Mount (Rev. 2/25/2005)

Safety 3

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

(Safety Rules continued from previous page)

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Remove seat and upper support assembly

before installing or removing backhoe from tractor.

Failure to comply may result in equipment failure

and/or personal injury.

Always use original equipment high-strength

tractor top link pin when attaching mount to tractor.

If tractor is equipped with draft sensing control,

set control to “HEAVY” (minimum sensitivity) position.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader, front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

• Read Mounting Kit Manual instructions on

attaching and removing backhoe and use

extreme care.

• Always stand between rear tire and backhoe

stabilizer arms or along side of tractor to avoid

being trapped should the boom swing control

be accidentally activated.

Never leave equipment unattended with engine

running or with bucket in raised position. Always

engage swing and boom transport locks, relieve

system pressure by operating controls, and

remove ignition key before leaving equipment.

MAINTENANCE

Refer to backhoe manual and follow all maintenance safety rules and instructions.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

Your dealer can supply original equipment

hydraulic accessories and repair parts. Substitute

parts may not meet original equipment specifications and may be dangerous.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

OPERATION

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Before operating, make sure stabilizer pads are

lowered firmly to the ground. Stabilizer arms provide support for the backhoe and support for the

backhoe mounting brackets.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Always comply with all state and local lighting

and marking requirements.

Do not allow riders. Do not lift or carry anybody

on the power unit or attachments.

The only time the backhoe may be operated

from a position other than the operator seat is during backhoe attachment and removal. Operator

must:

4 Safety

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Before working on backhoe, extend boom and

dipperstick and place bucket on ground. Make sure

that all system pressure has been relieved by operating controls before performing maintenance or

service or before disconnecting any hydraulic lines.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before putting unit into service.

BH 3-Pt Mount (Rev. 2/25/2005)

BACKHOE 3-POINT MOUNT INSTALLATION

TRACTOR PREPARATION

NOTE: For installing this 3-point mounting kit, refer-

ence to right, left, forward and rearward directions are

determined from the operator’s position in the backhoe seat.

NOTE: Leave all hardware loose until mounting kit

has been fit up.

1. Refer to the WOODS BH90-X Backhoe Operator’s Manual for backhoe assembly instructions.

2. Remove the tractor top link and top link storage

bracket, if equipped.

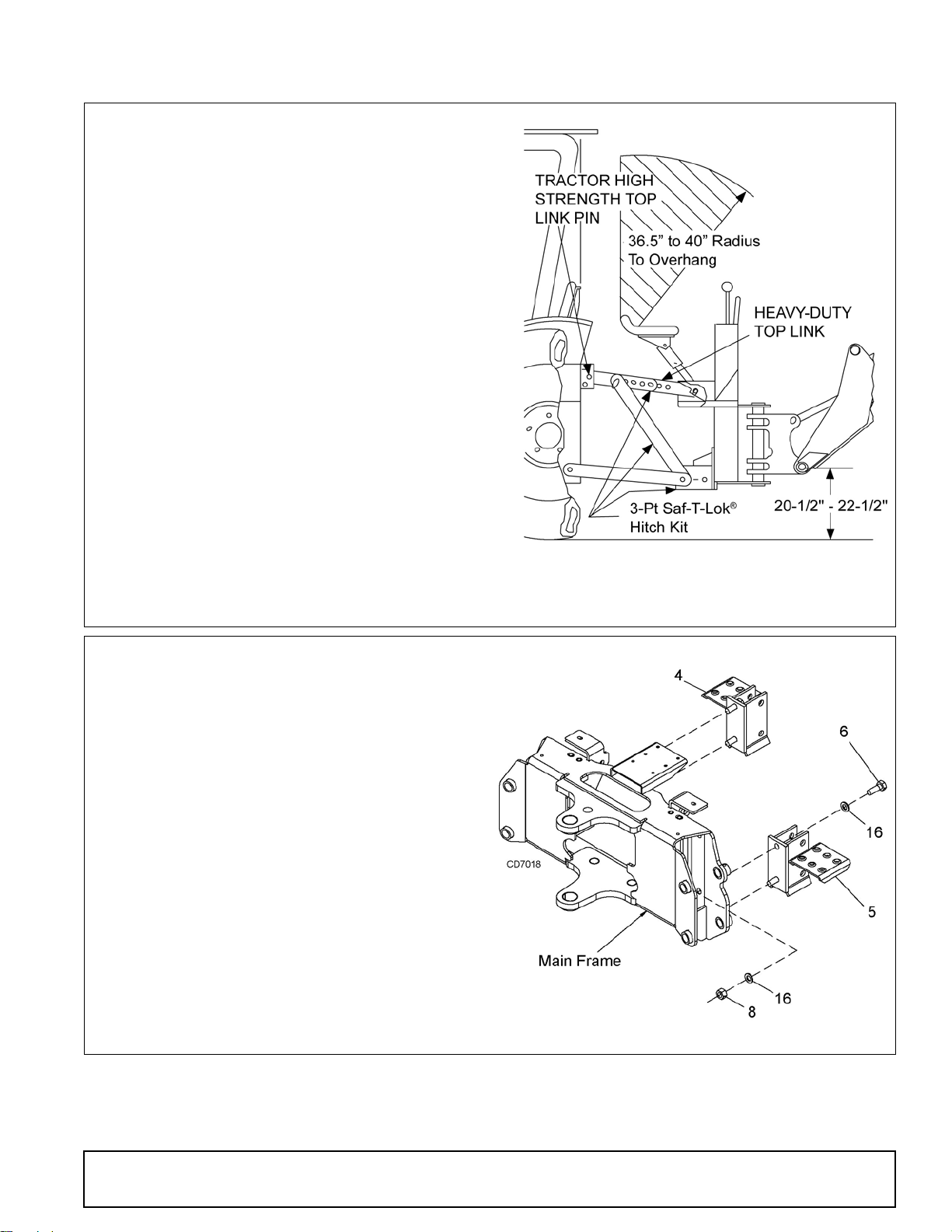

Attach Rear Brackets to Backhoe

1. Attach rear brackets (4 & 5) to main frame using

bolts (6), hardened flat washers (16), and hex

nuts (8) as shown in Figure 2.

2. Torque hardware to 297 lbs-ft.

4. 37682 Right mount bracket

5. 37683 Left mount bracket

6. 13759 3/4 NC x 2-1/4 HHCS GR5

8. 1450 3/4 NC Hex nut

16. 57798 3/4 Hardened flat washer

* Operator’s seat must be located in the lowest and

most forward position to obtain 40" minimum radius.

Figure 1. Seat Clearance

MAN0549 (6/30/2006)

Figure 2. Rear Bracket Installation

Installation 5

Loading...

Loading...